DYEING: DEFINITIONS DYEING UNIFORM COLOURATION OF TEXTILE MATERIAL IN FIBRE, YARN OR FABRIC FORM....

-

Upload

tyrone-ferguson -

Category

Documents

-

view

228 -

download

3

Transcript of DYEING: DEFINITIONS DYEING UNIFORM COLOURATION OF TEXTILE MATERIAL IN FIBRE, YARN OR FABRIC FORM....

DYEING: DEFINITIONS

DYEING

• UNIFORM COLOURATION OF TEXTILE MATERIAL IN FIBRE, YARN OR FABRIC FORM.

• THE COLOUR PRODUCED SHOULD WITHSTAND EXTERNAL AGENCIES SUCH AS WASHING, LIGHT, RUBBING etc TO WHICH TEXTILE MATERIAL IS SUBJECTED DURING USE.

• THE COLOURATION SHOULD NOT RESTRICT ONLY TO THE FIBRE SURFACE BUT SHOULD PENETRATE THE FIBRE CROSS SECTION.

• THE SURFACE COLOURATION IS KNOWN AS RING DYEING.

DYEING: DEFINITIONSPAINTING

• APPLICATION OF COLOUR TO ANY SURFACE WITH THE HELP OF SUITABLE ADHESIVE. IT IS BASICALLY SURFACE COLOURATION. HAS FASTNESS PROPERTY TO SOME EXTERNAL AGENCIES DEPENDING ADHESIVE FORCES BETWEEN (FIBRE) SURFACE AND COLOURING COMPOUND.TINTING

• SURFACE COLURATION. NO FASTNESS PROPERTY TO EXTERNAL AGENCIES. THE PROCESS IS USED FOR FIBRE IDENTIFICATION OF DIFFERENT VARIETIES DURING SPINNINGPRINTING

• LOCALIZED COLOURATION IN THE FORM OF DESIGN. DYE PENETRATION IN THE FIBRE CROSS SECTION

DYES AND PIGMENTS

DYES• COLOUR COMPOUND• SOLUBLE IN WATER OR CAN BE MADE SOLUBLE IN

WATER• POSSESSES AFFINITY TO FIBRE TO BE DYED• PENETRATION OF DYE IN FIBRE CROSS-SECTION

UNDER DYEING CONDITIONS• INTERACT WITH FIBRE WITH SUITBLE DYE-FIBRE

INTERACTIVE FORCES DEPENDING ON THE NATURE OF FIBRE AND NATURE OF DYE

• NATURE OF DYE-FIBRE INTERACTION DETERMINES THE FASTNESS PROPERTY OF DYE TO EXTERNAL AGENCIES. THERE SOME EXCEPTIONS TO THIS RULE.

DYES AND PIGMENTS

TINTING COLOURS• DYES HAVING NO AFFINITY TO FIBRE.

• EASILY REMOVED DURING WASHING

PIGMENTS• COLOURING COMPOUND

• INSOLUBLE IN WATER

• NO AFFINITY TO FIBRE

• NO INTERACTION WITH FIBRE

AFFINITY OR SUBSTANTIVITY

• ATTRACTION BETWEEN DYE AND FIBRE UNDER GIVEN DYEING CONDITIONS.

• ABILITY OF DYE TO MOVE FROM SOLUTION PHASE TO FIBRE PHASE DURING THE DYEING OPERATION

• THIS MEANS REDUCTION IN DYE CONCENTRATION

IN SOLUTION PHASE AND CORRESPONDING

INCREASE OF DYE CONCENTRATION IN FIBRE

PHASE WITH DYEING TIME.

• DYES HAVE AFFINITY TO FIBRE

• PIGMENT AND TINTING COLOURS HAVE NO

AFFINITY TOWARDS FIBRE.

CLASSIFICATION OF FIBRES

NATURALVEGETABLE ANIMAL

COTTON WOOL

JUTE SILK

RAMIE

LINEN

REGENERATED

VISCOSE

CELLULOSE ACETATE

SYNTHETIC

POLYESTER, NYLON, ACRYLIC

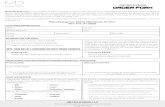

CLASSIFICATION OF DYESWATER SOLUBLE SUITABILITY TO FIBRE

• DIRECT COTTON, WOOL, SILK, NYLON• ACID WOOL, SILK, NYLON• BASIC OR CATIONIC MAINLY ACRYLIC, LIMITED

WOOL, SILK• REACTIVE MAINLY COTTON, LIMITED WOOL,

SILK• SOLUBILIZED VAT COTTON

WATER INSOLUBLE

• VAT COTTON• SULPHUR COTTON• DISPERSE MAINLY POLYESTER, LIMITED

NYLON, ACRYLIC

IN-SITU COLOUR FORMATION • AZOIC COTTON• OXIDATION COLOURS COTTON

PIGMENT COLOURS ALL FIBRES DEPENDING ON BINDER

THEORETICAL CONCEPT

DYEING PROCESS• FIBRE DYE BATH: DYE, WATER, DYEING

AUXILIARY• INTRODUCTION OF FIBRE IN DYE BATH• DYEING UNDER SUITABLE CONDITIONS FOR

SUITABLE LENGTH OF TIME• ZERO TIME ALL DYE IN DYE BATH• WITH PASSAGE OF TIME INCREASE IN DYE

CONCENTRATION ON FIBRE• CORRESPONDING DECREASE IN DYE

CONCENTRTION IN DYE BATH• THIS PHENOMENON IS KNOWN AS DYE

EXHAUSTION AND OCCURS DUE TO AFFINITY OF DYE FOR FIBRE

DYEING MECHANISM• DIVISION OF DYE SYSTEM IN THREE PHASES

• DYE IN SOLUTION

• FIBRE SURFACE

• INTERIOR OF FIBRE

• DURING DYEING THREE TYPES OF EQUILIBRIA EXIST

• DYE IN SOLUTION DYE ON FIBRE SURFACE DYE IN THE INTERIOR OF FIBRE

• FIRST EQUILIBRIA TRANSFER OF DYE FROM SOLUTION TO FIBRE SURFACE

• SECOND EQUILIBRIA PENETRATION OF DYE FROM FIBRE SURFACE TO FIBRE INTERIOR

• DISTURBANCE IN FIRST EQUILIBRIA

• PROCESS CONTINUE TILL THREE PHASES ARE IN EQUILIBRIUM

DYE FIBRE INTERACTION

CLASSIFICATION OF ATTRACTIVE FORCES

ATTRACTIVE FORCES BETWEEN DYE AND FIBRE1. VAN DER WAAL’S FORCES OR DISPERSION FORCES

2. HYDROGEN BONDS

3. ELECTROSTATIC ATTRACTION

4. CO-VALENT BOND

DYE-FIBRE INTERCTION

FORCES OF ATTRACTIONDYE CLASS FORCE OF ATTRACTION

CELLULOSIC (COTTON, JUTE, VISCOSE)DIRECT, VAT, SULPHUR VANDER WAAL, H-BONDSOLUBILIZED VATREACTIVE CO-VALENT BOND

WOOL, SILK, NYLONDIRECT, ACID, METAL IONIC OR ELECTROSTATICCOMPLEXREACTIVE IONIC/COVALENT

POLYESTERDISPERSE VANDER WAAL, H-BOND

ACRYLICCATIONIC INONIC OR ELECTROSTTIC

FORCE OF ATTRACTION AND WASH FASTNESS

• DYED FIBRE MUST MEET CERTAIN FASTNESS REQUIREMENT TO VARIOUS AGENCIES LIKE WASHING, LIGHT, RUBBING

• FASTNESS PROPERTY DEPENDS ON SEVERAL FACTORS

• WASH FASTNESS DEPENDS ON

• FORCE OF ATTRACTION BETWEEN DYE AND FIBRE

• PHYSICAL STATE OF DYE INSIDE THE FIBRE

• PHYSICAL STRUCTURE OF FIBRE

• BOND ENERGY• COVALENT BOND > ELECTROSTATIC BOND > H-BOND >

VANDER WAAL FORCE

• WASH FASTNESS• REACTIVE DYE > ACID, METAL COMPLEX, CATIONIC >

DIRECT, VAT, SULPHUR, DISPERSE

EXCEPTIONS

• VAT DYES ON COTTON• EXCELLENT WASH FASTNESS PROPERTY

REASONS• DYE INSIDE FIBRE WATER INSOLUBLE FORM

• STATE OF DYE INSIDE FIBRE AGGREGATED (VERY HIGH MOLECULAR WEIGHT)

• BOTH THESE FACTORS LEAD TO VERY HIGH WASH FASTNESS ON COTTON THOUGH WEAK FORCES OF DYE-FIBRE INTERACTION

DISPERSE DYES ON POLYESTER• DYE INSIDE FIBRE WATER INSOLUBLE FORM• VERY COMPACT PHYSICAL STRUCTURE OF FIBRE

• DYE UNABLE TO DIFFUSE OUT UNDER WASHING CONDITIONS

BRIEF HISTORY OF DYEING

• PRACTICED AS EARLY AS • 3000 B C IN CHINA• 2500 B C IN INDIA• DYED GARMENTS FOUND IN EGYPTIAN TOMBS• KNOWLEDGE OF DYEING WENT TO EGYPT THROUGH INDIA• DYES USED WERE OF NATURAL ORIGIN, • EXTRACTION FROM PLANTS OR INSECTS

PLANT DYES• INDIGO, MADDER

INSECT DYES• LAC, COCHENEAL, KERMES• MAJORITY OF NATURAL DYES ARE FIXED ONTO FIBRE WITH

THE HELP OF METAL SALTS KNOWN AS MORDANTS IMPORTANT MORDANTS

• ALUM, FeSO4, CuSO4, SnCl2, K2CR2O7

SYNTHETIC DYES• 1856 FIRST SYNTHETIC DYE. WILLIAM PERKIN, ENGLAND• CHANCE DISCOVERY• AT THE AGE OF 14, ASSOCIATED WITH FAMOUS GERMAN

CHEMIST HOFFMAN• FASCINATED BY EXPERIMENTS IN ORGANIC CHEMISTRY• SET UP HIS OWN LABORATORY AT RESIDENCE• EXPLORED EXPERIMENTS IN CHEMISTRY IN HIS

LABORATORY AFTER OFFICE HOURS AND ON HOLIDAYS • IN THE COURSE OF EXPERIMENTS OXIDIZED ANILINE WITH

K2Cr2O7, OBTAINED BLACK PRECIPITATE• BLACK PRECIPITATE EXTRACTED WIT ETHYL ALCOHOL

GAVE BRILL. PURPLE SOLUTION WHICH COLULD USED FOR COLORATION OF SILK

• FIRST SYNTHETIC DYE MAUVE• AT THE AGE OF 18 PERKIN SET UP HIS OWN FACTORY FOR

MANUFACTURE OF DYES ON INDUSTRIAL SCALE• MANY CHEMIST IN EUROPE STARTED WORKING ON DYE

SYNTHESIS

100 YEARS OF CHRONOLOGICAL DEVELOPMENTS OF SYNTHEIC DYES

• 1856 FIRST SYNTHETIC DYE (PURPLE ), PERKIN• 1858 DISCOVERY OF THE PROCESS OF DIAZOTIZATION

AND COUPLING, PETER GREISS• 1859 MAGENTA DYE, FRENCH CHEMIST VERGUIN• 1862 FIRST SULPHONATED DYE• 1863 ANILINE BLACK, NICHOLSON• 1880 IN SITU AZOIC COLOUR FORMATION, READ

HOLLIDAY• 1884 FIRST DIRECT DYE, CONGO RED, BOTTIGER• 1893 FIRST SULPHUR DYE• 1897 SYNTHETIC INDIGO• 1890 METAL COMPLEX DYE• 1901 VAT DYE• 1922 DISPERSE DYE• 1956 REACTIVE DYE

NATURAL DYES BEFORE 1856 ABOUT 100SYNTHETIC DYES TODAY 2000-3000

NOMENCLATURE OF DYES• SYNTHETIC DYES KNOWN BY THEIR TRADE NAMES

• USUALLY INDICATE THE TRADE NAME OF COMPANY, SHADE OBTAINED, HUE OR TONE OF THE SHADE e.g.

CHLORAZOL BROWN R (DIRECT DYE)

INDANTHRENE BLUE 2R (VAT DYE)

• CHLORAZOL TRADE NAME OF ICI

• BROWN SHADE

• R REDDISH HUE OF BROWN

• FOR HUE LETTERS LIKE B, R, Y, OR BB, RR OR 2B, 3R, 4R ETC ARE USED

• SOMETIMES OTHER LETTERS INDICATES SUB CLASS WITHIN THE MAIN CLASS e.g.

• PROCION RED M5B (COLD BRAND REACTIVE DYE)

• PROCION RED H5B (HOT BRAND REACTIVE DYE)

• COLOUR INDEX DOCUMENTATION OF ALL DYES

JOINT PUBLICATION OF SOCIETY OF DYERS AND COLOURISTS (SDC), ENGLAND AND AMERICAN ASSOCIATION OF TEXTILE CHEMISTS AND COLOURISTS (AATCC) , USA

• INFORMATION ON TRADE NAMES, CHEMICAL STRUCTIRE, PROPERTDIES etc.

• EACH DYE IS IDENTIFIED BY CI NUMBER (COLOIUR INDEX NUMBER)

FIBRE FORM

• FIBRE • YARN • FABRIC

FABRIC FORM• WOVEN• KNITTED• NON-WOVEN

DYEING METHODS

BATCHWISE OR EXHAUST DYEING• FIBRE• YARN • FABRIC

SEMI-CONTINUOUS DYEING• FABRIC

CONTINUOUS DYEING• FABRIC• YARN IN WARP SHEET FORM (INDIGO DYEING FOR DENIM)

EXHAUST DYEING

MATERIAL TO LIQUOR RATIO (M:L RATIO)• VOLUME OF WATER TAKEN IN RELATION TO WEIGHT OF

MATERIAL (FIBRE, YARN OR FABRIC)e.g. M:L :: 1:10 MEANS FOR 1 kg OF TEXTILE MATERIAL 10 LITRES OF WATER TAKEN FOR DYEING

% DYEBATH EXHAUSTION• AMOUNT OF DYE GONE FROM SOLUTION PHASE TO FIBRE

PHASE AT THE END OF DYEING PERIOD EXPRESSED IN TERMS OF %. IT IS A MEASURE OF DYE SUBSTANTIVITY. THE TERM IS MAINLY APPLICABLE TO BATCHWISE DYEING.

• % FIXATION: AMOUNT OF DYE FIXED (INTERACTED) WITH FIBRE AFTER WASHING/SOAPING.

% SHADE• AMOUNT OF DYE TAKEN FOR DYEING ON THE BASIS OF

WEIGHT OF MATERIAL• e.g. 2% SHADE MEANS 2 gm DYE TAKEN FOR DYEING 100 gm

MATERIAL i.e TEXTILE FIBRE, YARN OR FABRIC.

BATCHWISE DYEING• DYEING IN SMALL BATCHES, 100-300 kg FABRIC

FABRIC DYEING EQUIPMENTSDESIGNED ON THREE PRINCIPLES

FABRIC MOVING, DYE LIQUOR STATIONARY• JIGGER (FABRIC IN OPEN WIDTH FORM) • WINCH (FABRIC IN ROPE FORM)

FABRIC STATIONARY, DYE LIQUOR MOVING• BEAM DYEING MACHINE FOR DYEING POLYESTER OR

POLYESTER/COTTON BLENDS (FABRIC IN OPEN WIDTH)

BOTH FABRIC AND DYE LIQUOR MOVINGJET DYEING MACHINE (FABRIC IN ROPE FORM)

CONTINUOUS DYEING

PADDING• SATURATION OF FABRIC BY DYE SOLUTION AND SQUEEZING

THE EXCESS LIQUOR BY PRESSING BETWEEN SQUEEZ ROLLERS

• MACHINE: PADDING MANGLE• TERMS COMMON FOR CONTINUOUS DYEING OF FABRIC.

EXPRESSION• %INCREASE IN WEIGHT OF DRY FABRIC AFTER PADDING e.g.• DRY FABRIC WEIGHT 1kg• FABRIC WEIGHT AFTER PADDING 1.8 kg• INCREASE IN DRY FABRIC WEIGHT 0.8 kg• % INCREASE IN WEIGHT 80%• EXPRESSION 80%• HIGHER THE VALUE OF % EXPRESSION LESS IS LIQUOR

SQUEEZING BY PADDING MANGLE AND VICE VERSA