DSP Biomedical® - Dental Implant System

-

Upload

dsp-biomedical -

Category

Documents

-

view

279 -

download

3

description

Transcript of DSP Biomedical® - Dental Implant System

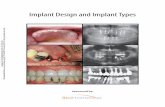

D E N T A LI M P L A N TS Y S T E M S

PRODUCTS CATALOG

2

3

Table of ContentsTHE COMPANY .................................................................

THE INDUSTRY............................................................

QUALITY / SURFACE TREATMENT..............................

SOCIAL ACTION / ENVIRONMENT.............................

PACKAGE....................................................................

CATALOGUE PRODUCTS............................................

EXTERNAL HEXAGON.................................................

INTERNAL MORSE HEXAGON.....................................

INDEXED MORSE TAPER..........................................

HEXAGONAL MORSE TAPER.......................................

FRICTIONAL MORSE TAPER........................................

FLEXCONE..................................................................

MINIFLEXCONE...........................................................

SURGICAL...................................................................

PROSTHETIC ABUTMENTS.........................................

NOMENCLATURES......................................................

03

06

08

12

16

18

18

40

46

60

72

80

88

92

108

110

4

Experience in Smile Making.

5

For DSP BIOMEDICAL, the satisfaction of the patients is the most important. That´s why the company has the constant commitment of surching new technologies, for manufacturing odontologic products of high quality at an affordable price, establishing an optimal relation cost-benefit in the market.

Trust, that´s the main raw as well as the main result of our Work.

14 AnOS DEEvolução

The DSP Biomedical® linked the practice of themost qualified dentists with a precision and technicof the engineers, to create the bests and inovatedproducts at dental areas, oral and maxillo-facialsurgery and implantodonty. The results can beviewed at patients smiles and in the life quality bythem conquered.

EvOLvIngSINCE 2000

6

Precision and Innovation generate quantity with quality.

The Industry

7

DSP BIOMEDICAL® owns the most complete line of products for implantology procedures in the national market. It´s more than 1.500 items manufactured with milimesimal precision equipments, measure projectures and optical microscopes of measurement, in way to assure the maximum quality and the better finishing of the product.

The combination between biological reliability and intelligent systems, results in products with precision on implant and abutments manufacturing. That work practice is registered in the Health Ministery, by national Sanitary Surveillance Agency (AnvISA). Wich certifies the quality and competence of DSP BIOMEDICAL®.

Commitment of producing the best product in a accurate way.

8

QualityThe recognition of your work, starts with our respect in the market.

9

Certifi cate of qualityManagement

ISO 9001:2000.

Certifi cate of healthproducts, regulatory

requirements for export.

(NBR ISO 13.485:2004).

MADEIN BRAZILMADEIN BRAZIL

EX

PORT GUARANTEEDEX

PORT GUARANTEED

EXPORT GUARANTEED EXPORT GUARANTEED

93/42CCE

PCT Patent Cooperation

Treaty - Russia

DSP Biomedical® was recognized and registered by the biggest quality institutes, and it´s fit to manufacture commercialize and export products on the Odontology, Bucomaxilofacial Surgery and Implantology.

Threads of the implant totally inert, trough the MEv that promotes a nanotopographic surface, with peaks and valleys more similar, and a highly hydrophilic surface. Excellent for a good biologic tissue fixation.

Surface treatment

SlA Zircon® TreatmentSandblasted Large grift Acid etching. Comes from the Sandblasting process of big particules, that creates microrugosities on the titanium surface, followed by an acid treatment process neutralization, that overcome the microrugosities. Ideal topography for cells adding.

Certifi cate of Good practice, the national agency for health monitoring.

(ANVISA) RDC 59/200

10

odontologic Health with agility and cost-benefit.

+55 41 3291-2200www.dspbiomedical.com.br

11

DSP BIOMEDICAL® attends all national market and exports implants and prosthetic abutments for several countries.So, independently of the map place wherever you are,you can always count on the best Odontology, Bucomaxilofacial and Implantology solutions.The biological reliability of the DSP BIOMEDICAL® products,and the delivery agility, assure you the best benefit for you.

12

It’s the future generations that will make the world a better and happier place.That’s why DSP BIOMEDICAL®, invests constantly in social projects that offer new opportunities for children. A commitment that becomes today and will make difference in the future.

Smile is a right of all.

13

Aldeia São Jose Association -

Campo largo - PR

DSP BIOMEDICAL® selects and separates 100% of his fabric residues, and sends for specialized companies on recycling.The company seizes the natural illumination on his facilities and also avoids the waste of water on his activities.This responsible measures, assure an internally healthier environment, and cooperate on the building for a better future for the planet.

Be sustainable is to think on today and tomorrow.

14

Developed specifically to be used when the bone high is limited. It´s the shortest implants available on the market with variations of prosthetic conectivities.Making the therapy with implants available for patients with few bone high, eliminating the need of bone augmentation.This way achieving easier and quicker surgeries.

These implants are being widely used dued to the biomechanical success, when we have a thin bone resulting from the fisiological reabsorbable bone or in a general way for lower incisive and upper lateral rehabilitation. We have a wide range of implants, with prosthetic options resulting on an excellent aesthetic.

SHoRTIMPLAnTS

DSP Biomedical® presents

HEIGHT 5,5 HEIGHT 5,5 HEIGHT 5,5 HEIGHT 5,0 3.3 3.3 2.8 2.5 2.5

SlIMIMPLAnTS

15

+55 41 3291-2200www.dspbiomedical.com.br

Know our regular implants range.

EXTERNAl HEXAGoN

MoRSE INTERNAl HEXAGoN

MoRSETAPER

HEXAGoNAl MoRSE TAPER

FRICTIoNAl MoRSE TAPER

FlEX CoNE MINI FlEX CoNE

3.3 3.3 2.8 2.5 2.5

16

Making life easier for those who purchase DSP BIOMEDICAL®, is our main concern.

We combine an attractive visual and layout combined with the company concepts and the

quality of our products.

Main changes:• specific colour code

• reference number• window on the package,

(now you can see the product you are

purchasing)

Packages and labels of DSP Biomedical®Much more practical, comfortable, safety and technology for you and your patients.

The package Iv is much more intelligent and versatile.Projected to avoid any mechanical internal contact, preserving the implant surface. It has intelligent opening mecanism, with rectractable lid. Once more DSP BIOMEDICAL thinks in your comfort, practically and safetyness.

SMART vERSATILE

Product NameReference CodeLotManufacture DateExpiration Date

Product NameDiameterReference Code

Color identifi cationProduct Line

17

Implants with assembler mount HE, FC, FCM and CM.

Removal of the implant with handler

Fixation on the titanium implant plier and removal of

the handler

Fixation on the titanium implant plier and removal of

the handler

Removal of the implant with handler

Removal of implant with handler

Removal of the handler

Fitting on ratchet driver or torquimeter

Fitting of the internal connection driver

Fitting of the internal connection driver

Implants with capture by implant plier HETI, HIM, CMH and CMF.

Implants with capture by driver HETI and CMI.

Avaiable on the version with or without assembler mount.

No cover screw included

PROSTHETIC SOLUTIONS: Indicated for multiple or unitary

clinical applications, for cemented, screw or overdenture,

producing excellent aesthetic.

MATERIAL: Titanium level IV.

SURFACE: Sandblasted Large grift Acid etching .

ROTATION DRILLING: 800 to 1200 rpm.

ROTATION INSERTION: 20 to 30 rpm.

INSERTION TORQUE: 35 to 55 Ncm.

EXTERNAL HEXAGONCILINDRICAL

TECHNIQUE SPECIFICATION

SW

H

P

A

D

L

M

SW

H

P

A

D

L

M

SW

H

P

A

D

L

M

The HE implants were designed with external hexagon platform and has interchangeability with multiple systems. His body shape is cylindrical, it has triangular threads, which compact the bone tissue, and an ultra polished collar of 1mm high on the base of the platform. Its installation is done through themount giving greater strength when compared to the implant external hexagon internal torque.

ØP SW H M 3.3 2.4 1.0 1.8 4.1 2.7 0.7 2.0

CylindricalØD ØA L3.3 2.4 4.03.75 2.7 4.04.0 3.0 4.05.0 4.0 4.0

19

ENCODING UP with an M of MOUNT after the code. Example: 17.3308 without mount and 17.3308M with mount.SEE next page the procedure for use of the implant mounted.

EXTERNALHEXAGON

EXTERNALHEXAGON

EXTERNALHEXAGON

EXTERNALHEXAGON

MODELS AND LENGTHSMODELS AND LENGTHS

Platform 4.1SLIMPlatform 3.3

7.0

8.5

10

11.5

13

15

17

8.5

10

11.5

13

15

17

17.3308

17.3310

17.3311

17.3313

17.3315

17.3317

17.3707

17.3708

17.3710

17.3711

17.3713

17.3715

17.3717

17.4007

17.4008

17.4010

17.4011

17.4013

17.4015

17.4017

17.5007

17.5008

17.5010

17.5011

17.5013

17.5015

Ø 3.75 Ø 4.0 Ø 5.0 Ø 3.3

1 - With the Badock take the implant to the grip2 - Takeoff the badock3 - Fix the mount.

EXTERNALHEXAGON_____________ technical

specifications

IMPLANTS MOUNTED CAPTURE AND TRANSPORT OF IMPLANT NOT MOUNTED

01 0302

3.3mm

Spea

r / S

pira

l 2

Drill

2.5

Drill

2.8

Pilo

t 2.0

/ 3.

0

Drill

3.0

Drill

3.1

5

Pilo

t 2.0

/3.8

Drill

3.3

Drill

3.5

Drill

3.8

Drill

4.3

Coun

ters

ink

5.0

3.75mm

4.0mm

5.0mm

SEQUENCEOF DRILLS

Indicated OptionalApical Drilling

20

Prepare the surgical, as indicated drills sequence.

Remove from the blister and put the sterile package over surgical bench. Attach the traceability label on patient records.

• Cut the mount assembler as required occlusal height; it´s possible with height of 4 or 6 mm. Both use a capsule of 4 or 6 mm.

• Using provisional mount assembler.

4mm

01

1

02

2a

03

2b

21

TECHNICAL INSTRUCTIONS

• Sequence of the pillar transference, using cemented pillar for provisory or definitive.

• Sequence use of capsule with the correct preparation and cementation.

01

01

04

02

02

05

03

03

Implants with mount assembler

Installed with hexagonal internal driver without using assembler

mount, reducing surgical procedure.

PROSTHETIC SOLUTIONS: : Indicated for clinical multiple and

unitary applications, either on cemented, screw or overdenture,

producing excellent aesthetic.

MATERIAL: Titanium grade IV.

SURFACE: Sandblasted Large grift Acid etching .

PRESENTATION: only available for connection driver with internal torque

(ConnectHex). Cover screw not included.

SPEED DRILLING: 800 to 1200 rpm.

ROTATION INSERT: 20 to 30 rpm.

TORQUE INSERTION: 35 to 55 Ncm.

EXTERNAL HEXAGONCILINDRICAL WITH INTERNAL TORQ

TECHNICAL SPECIFICATIONS

SW

H

P

A

D

L

M

SW

H

P

A

D

L

M

SW

H

P

A

D

L

M

The HE internal torq implants, were designed with external hexagon platform and interchangeability with multiple systems. It has a internal hexagon, used for connection with the connecthex driver for insertion of the implant, which increases the mechanical resistance when applied higher torqs, preserving the integrity of the external hexagon and making easier his placement with minimum trauma.

ØP SW H M 4.1 2.7 0.7 2.0

CilyndricalØD ØA L3.3 2.4 4.03.75 2.7 4.04.0 3.0 4.05.0 4.0 4.0

23

This implant is connected with an internal hexagon connection driver (ConnectHex). Its has fi t with contra-angle or Torque Wrench (ratchet).

EXTERNAL

HEXAGONEXTERNALHEXAGON

MODELS AND LENGTHS

cylindrical internal torque Plataform 4.1

5.5

7.0

8.5

10

11.5

13

15

17

19.3707

19.3708

19.3710

19.3711

19.3713

19.3715

19.3717

16.3308

16.3310

16.3311

16.3313

16.3315

19.4005

19.4007

19.4008

19.4010

19.4011

19.4013

19.4015

19.4017

19.5005

19.5007

19.5008

19.5010

19.5011

19.5013

19.5015

Ø 3.3 Ø 3.75 Ø 4.0 Ø 5.0

1 - With the Badock take the implant to the grip2 - Takeoff the Badock3 - Fix the internal connection driver (ConnectHex).

EXTERNAL HEXAGON_____________technical

specifications

DRIVERS CAPTURE AND TRANSPORT OF IMPLANT

01 0302

3.3mm

Spea

r / s

crew

2

Drill

2.5

Drill

2.8

Pilo

t 2.0

/ 3.

0

Drill

3.0

Drill

3.1

5

Pilo

t 2.0

/ 3.

8

Drill

3.3

Drill

3.5

Drill

3.8

Drill

4.3

Coun

ters

ink

5.0

3.75mm

4.0mm

5.0mm

28.202028.5020 28.3020

SEQUENCE OF DRILLS

Indicated OptionalApical Drilling

EXTERNALHEXAGON

Only available in not mounted version.

Cover screw not included.

PROSTHETIC SOLUTIONS: is indicated for clinical applicationssingle

or multiple, for cemented prostheses, screw-retained prostheses and

overdenture, resulting in great esthetics.

Biofit implant was designed with external hexagon platform, with interchangeability to multiple systems. It has a cylindrical body shape, with triangular threads, presenting a groove retention profile. Idealized for having primary stability in lower, medium and high bone density. With sharpest chanfers and small diameter apex. It has two cutting chambers on the middle of body implant, which provides an optimal secondary stability. It has reduced drilling protocol, and his insertion driver is the hexagonal type (connecthex), that avoids the galling between driver and implant.

MATERIAL: Titanium grade IV.

SURFACE: Sandblasted Large grift Acid etching .SPEED DRILLING: 800 to 1200 rpm.ROTATION INSERT: 20 to 30 rpm.TORQUE INSERTION: 35 to 55 Ncm.

TECHNICAL SPECIFICATIONS

SWH

P

A

D

M

L

SWH

P

A

D

M

L

SWH

P

A

D

M

L

ØP SW H M 4.1 2.7 0.7 2.0

CilyndricalØD ØA L3.5 1.8 3.03.75 2.0 3.04.0 2.3 3.04.5 2.8 3.05.0 3.3 3.0

25

TAIL SHARK

GROOVE RETENTIVE NARROW EDGE

19.3508B

19.3510B

19.3511B

19.3513B

19.3515B

19.3517B

19.4005B

19.4007B

19.4008B

19.4010B

19.4011B

19.4013B

19.4015B

19.4017B

19.3705B

19.3707B

19.3708B

19.3710B

19.3711B

19.3713B

19.3715B

19.3717B

19.4505B

19.4507B

19.4508B

19.4510B

19.4511B

19.4513B

19.5005B

19.5007B

19.5008B

19.5010B

19.5011B

EXTERNALHEXAGONBIOFIT

5.5

7

8.5

10

11.5

13

15

17

Ø 3.5 Ø 3.75 Ø 4.0 Ø 4.5 Ø 5.0EXTERNALHEXAGON

1 - With the Badock take the implant to the grip2 - Takeoff the badock3 - Fix an internal connection driver (ConnectStar).

DRIVERS CAPTURE AND TRANSPORT OF IMPLANT

01 0302

01 02

03

FULL TREATMENT

04

EXTERNAL HEXAGON_____________technical

specifications

3.5mm

Spea

r / 2

.0

Drill

2.5

Drill

2.8

Pilo

t 2.0

/ 3.

0

Drill

3.0

Drill

3.1

5

Pilo

t 2.0

/ 3.

8

Drill

3.3

Drill

3.5

Drill

3.8

Drill

4.3

Coun

ters

ink

5.0

3.75mm

4.0mm

4.5mm

5.0mm

Indicated OptionalApical Drilling

SEQUENCE OF DRILLS

This implant is placed with an internal connection driver (connecthex). Installing possibilities with counter-angle, or torq wrench (ratchet).

28.202028.5020 28.3020

Only available in not mounted version. Cover screw not included.

PROSTHETIC SOLUTIONS: is indicated for clinical applications

single or multiple, for cemented prostheses, screw-retained prostheses and

overdenture producing a great esthetics.

Cilindrical body implant, designed with external hexagon platform and interchangeability with multiple systems.Double thread design, that provides a faster placement with less trauma. It has a small diameter apex, providing easier bone compactation.

MATERIAL: Titanium grade IV.

SURFACE: Sandblasted Large grift Acid etching .SPEED DRILLING: 800 to 1200 rpm.ROTATION INSERT: 20 to 30 rpm.TORQUE INSERTION: 35 to 55 Ncm.

TECHNICAL SPECIFICATIONS

SW

H

P

A

D

M

L

SW

H

P

A

D

M

L

SW

H

P

A

D

M

L

EXTERNALHEXAGON

ØP SW H M 4.1 2.7 0.7 2.0

CilyndricalØD ØA L

3.5 2.15 3.03.75 2.4 3.04.0 2.65 3.05.0 3.65 3.0

27

This implant is connected with an internal hexagon connection driver (ConnectHex). Its has fi t with contra-angle or Torque Wrench (ratchet).

1 - With the Badock take the implant to the grip2 - Takeoff the badock3 - Fix an internal connection driver (ConnectStar).

DRIVERS CAPTURE AND TRANSPORT OF IMPLANT

01 0302

EXTERNAL HEXAGON_____________technical

specifications

19.3508S

19.3510S

19.3511S

19.3513S

19.3515S

19.3517S

19.3707S

19.3708S

19.3710S

19.3711S

19.3713S

19.3715S

19.3717S

19.4005S

19.4007S

19.4008S

19.4010S

19.4011S

19.4013S

19.4015S

19.4017S

19.5005S

19.5007S

19.5008S

19.5010S

19.5011S

19.5013S

19.5015S

EXTERNALHEXAGONSOULFIT

5.5

7

8.5

10

11.5

13

15

17

Ø 3.5 Ø 3.75 Ø 4.0 Ø 5.0EXTERNALHEXAGON

MODELS AND LENGTHS

3.5mm

Spea

r / 2

.0

Drill

2.5

Drill

2.8

Pilo

t 2.0

/ 3.

0

Drill

3.0

Drill

3.1

5

Pilo

t 3.0

/ 3.

8

Drill

3.3

Drill

3.5

Drill

3.8

Drill

4.3

Coun

ters

ink

5.0

3.75mm

4.0mm

5.0mm

SEQUENCE OF DRILLS

28.202028.5020 28.3020

Indicated OptionalApical Drilling

EXTERNALHEXAGON

TECHNICAL SPECIFICATIONS

SW

H

P

A

D

M

SW

H

P

A

D

M

øP SW H M4.1 2.7 0.7 2.0

CilyndricaløD øA3.8 2.54.3 2.85.0 3.5

SW

H

P

A

D

M

MATERIAL: Titanium grade IV.

SURFACE: Sandblasted Large grift Acid etching .SPEED DRILLING: 400 to 800 rpm.ROTATION INSERT: 20 to 30 rpm.TORQUE INSERTION: 35 to 55 Ncm.

Available with internal hexagon connection driver (ConnectHex).

Doesn’t follow cover screw.

INSTALLATION: with internal hexagon driver without using

assembler, reducing surgical time.

PROSTHETIC SOLUTIONS: are recommended for multiple clinical

applying or unique being cemented, screw-retained or over

denture giving an excellent esthetic.

The HE Propfit conical implant, was designed with external hexagon platform, and it has interchangeability to multiple systems. His conical body shape mimetizes the natural rooth tooth, simplifying the surgery. It has 1mm collar on platform and trapezoidal threads. Indicated for immediate post-extraction loading.

29

This implant is connected with an internal hexagon connection driver (ConnectHex). Its has fi t with contra-angle or Torque Wrench (ratchet).

1 - With the Badock take the implant to the grip2 - Takeoff the badock3 - Fix an internal connection driver (ConnectStar).

EXTERNAL HEXAGON_____________technical

specifications

DRIVERS CAPTURE AND TRANSPORT OF IMPLANT

01 0302

EXTERNALHEXAGON

MODELS AND LENGTHS

PROPFIT

8.5

10

11.5

13

15

41.3808P

41.3810P

41.3811P

41.3813P

41.3815P

41.4308P

41.4310P

41.4311P

41.4313P

41.4315P

41.5008P

41.5010P

41.5011P

41.5013P

41.5015P

Ø 3.8 Ø 4.3 Ø 5.0 EXTERNALHEXAGON

Spea

r

Coni

cal D

rill 3

.8

Coni

cal D

rill 4

.3

Coni

cal D

rill 5

.0

3.8mm

4.3mm

5.0mm

SEQUENCEOF DRILLS

REGULAR 8.5 - 10.0 - 11.5

13.0 - 15.0

HEIGHTDRILL

Indicated

28.5020 28.2020 28.3020

Available on internal hexagon connection driver (ConnectHex).

Doesn’t follow cover screw.

PROSTHETIC SOLUTIONS: are recommended for multiple clinic application or

unique being cemented, screw-retained or overdenture resulting in a better esthetic.

Wayfit implant was designed with external hexagon platform, and it has interchangeability for multiple systems. His body shape is conical with double conical threads. Used for bone typem IV and post-extraction loading.

MATERIAL: Titanium grade IV.

SURFACE: Sandblasted Large grift Acid etching .SPEED DRILLING: 400 to 800 rpm.ROTATION INSERT: 20 to 30 rpm.TORQUE INSERTION: 35 to 55 Ncm.

TECHNICAL SPECIFICATIONS

SW

H

P

A

D

M

L

SW

H

P

A

D

M

L

SW

H

P

A

D

M

L

EXTERNALHEXAGON

ØP SW H M 4.1 2.7 0.7 2.0

CilyndricalØD ØA L

3.8 3.0 5.754.3 3.5 5.755.0 4.2 5.75

31

3.8mm

Spea

r / 2

.0

Coni

cal D

rill 3

.8

Coni

cal D

rill 4

.3

Coni

cal D

rill 5

.0

4.3mm

5.0mm

SEQUENCEOF DRILLS

This implant is connected with an internal hexagon connection driver (ConnectHex). Its has fi t with contra-angle or Torque Wrench (ratchet).

1 - With the Badock take the implant to the grip2 - Takeoff the badock3 - Fix an internal connection driver (ConnectStar).

DRIVERS CAPTURE AND TRANSPORT OF IMPLANT

01 0302

EXTERNAL HEXAGON_____________technical

specifications

EXTERNALHEXAGON

MODELS AND LENGTHS

WAYFIT

8.5

10

11.5

13

15

40.3808W

40.3810W

40.3811W

40.3813W

40.3815W

40.4308W

40.4310W

40.4311W

40.4313W

40.4315W

40.5008W

40.5010W

40.5011W

40.5013W

40.5015W

Ø 3.8 Ø 4.3 Ø 5.0 EXTERNALHEXAGON

Indicated

28.202028.5020 28.3020

REGULAR 8.5 - 10.0 - 11.5

13.0 - 15.0

HEIGHTDRILL

32

Code

1.3301

2

3

4

5

6

2

3

4

5

6

3.3

3.3

3.3

3.3

3.3

4.0

4.0

4.0

4.0

4.0

9.3332

9.3333

9.3334

9.3335

9.3336

9.3342

9.3343

9.3344

9.3345

9.3346

Height Profile Code

Height Profile Code

Cover Screw

Straight healing cap

Anatomical healing cap

EXTERNAL HEXAGONCILINDRICAL

3.31 5.3312

Height Profile Code

Straight abutment

1

2

3

4

4

4

4.3301L

4.3302L

4.3303L

Height Profile Code

Anatomical abutment

O’ring abutment

Code

1.3300

Analog

0.910 Ncm

1.330 Ncm

1.220 Ncm

1.220 Ncm

Code

9.3301

Open tray impression transfer

1.210 Ncm

Code

9.3300

Closed tray impression transfer

1.210 Ncm

Lab prosthetic screw

Code

3.3350

Screw

Code

3.3310

3.3300

1.330 Ncm

1

2

3

4

5

2.3341

2.3342

2.3343

2.3344

2.3345

Height Code

1.2

2.430 Ncm

EXTERNALHEXAGON_____________

PROSTHETIC LINE

PROSTHETIC LINEPLATFORM 3.3 - SLIM

PROSTHETIC SOLUTIONSOVER IMPLANT

PROSTHETIC SOLUTIONSOVERDENTURE

PROSTHETIC SOLUTIONSCEMENTED

33

1

2

3

1

2

3

15

15

15

25

25

25

2.1531N

2.1532N

2.1533N

2.2531N

2.2532N

2.2533N

Height Profile Code Height Profile Code

Angled abutment 15º Angled abutment 25º Plastic cylinderImpression Transfer SLIM Analog

Titanium UCLA

CoCr PillarPlastic UCLA CoCr plastic UCLA

Code

2.4001Code

2.4094

Closed keeperPositioner o’ring kit Code

2.4091 Soft

2.4092 Medium

2.4093 Hard

Rubber ring

1.330 Ncm

1.330 Ncm

1.330 Ncm

1.330 Ncm

Code

3.3301

3.3302

Code

5.3501

5.3502

Code

5.3310

5.3410

Code

5.3501T

1.330 Ncm

1.330 Ncm

4.3321S

4.3321L

4.3490i

4.3390i

4.3410i

4.3410M

4.3310i

4.3310M

4

6

4

6

4

4

6

6

Height CodeHeight Code Height Code

EXTERNALHEXAGON

34

Healing Cap

Code

7.33807.3301

7.3302

7.3303

1

2

3

Height Code

Conical Pillar

Conical Mini Pillar

Height Code

1

2

3

6.3401

6.3402

6.3403

Code

6.4080

Healing Cap

Open tray impression transfer

Closed tray impression transfer

Code

6.4091

Code

6.4090

Open tray impression transfer

Closed tray impression transfer

Code

7.3393

Code

7.3392

1.210 Ncm

1.210 Ncm

1.210 Ncm

2.030 Ncm

1.210 Ncm

1.210 Ncm

1.210 Ncm

2.030 Ncm

EXTERNALHEXAGON_____________

INTERMEDIATE COMPONENTS

PROSTHETIC LINEPLATFORM 3.3 - SLIM

PROSTHETIC SOLUTIONSCONICAL MINI-PILLAR

PROSTHETIC SOLUTIONSCONICAL PILLAR

EXTERNAL HEXAGONCILINDRICAL

35

Analog

Plastic

Titanium

Code

6.4022

Code

6.4031

Code

6.4062

CoCr plastic UCLA

Code

7.3411

Titanium Pillar (UCLA)

Plastic UCLA

Code

7.3511

Code

7.3311

Lab prosthetic screw

Screw

Code

6.4055

Code

6.4050

Analog

Code

6.4021

Titanium Pillar(UCLA)

Code

6.4212

Plastic UCLA

Code

6.4012

CoCr plastic UCLA

Code

6.4112

Analog

Code

7.3321

Lab prosthetic screw

Screw

Code

7.4055

Code

7.4050

1.210 Ncm

1.210 Ncm

1.210 Ncm

1.210 Ncm

1.2

1.2

1.210 Ncm

1.210 Ncm

1.210 Ncm

1.210 Ncm

1.210 Ncm

1.2

1.2

EXTERNALHEXAGON

PROSTHETIC SOLUTIONSCONICAL PILLAR

IMEDIATEPASSIVE SEATING

36

4

4

4

4.4001L

4.4002L

4.4003L

Height Profile Code

Anatomical abutment

Straight abutment

3.3 5.4012

Height Profile Code

1

1

2

3

1

2

3

4

5

2.4041

2.4042

2.4043

2.4044

2.4045

Height Code

O’ring abutment

Code

1.4001

Cover Screw

2

3

4

5

6

4.0

4.0

4.0

4.0

4.0

9.4042

9.4043

9.4044

9.4045

9.4046

Height Profile Code

Straight healing cap

2

3

4

5

6

5.0

5.0

5.0

5.0

5.0

9.4052

9.4053

9.4054

9.4055

9.4056

Height Profile Code

Anatomical healing cap

3.75

4.0

5.0

STANDARD WITH INTERNAL TORQUE

3.5

3.75

4.0

5.0

SOULFIT

3.8

4.3

5.0

PROPFIT

3.5

3.75

4.0

4.5

5.0

MODEL BIOFIT

Code

1.4000

Analog

Code

9.4001

Open tray impression transfer

Code

9.4000

Closed tray impression transfer

Screw

Code

3.4010

3.4000

Lab prosthetic screwCode

3.4050

0.910 Ncm

1.220 Ncm

1.220 Ncm

2.430 Ncm

1.210 Ncm

1.210 Ncm

1.330 Ncm

1.330 Ncm

EXTERNALHEXAGON_____________

PROSTHETICLINE

PROSTHETIC LINEPLATFORM 4.1

PROSTHETIC SOLUTIONSOVERDENTURE

PROSTHETIC SOLUTIONSOVER IMPLANT

3.8

4.3

5.0

WAYFIT

PROSTHETIC SOLUTIONSCEMENTED

37

1

2

3

25

25

25

2.2541N

2.2542N

2.2543N

Height Angle Code

Angled abutment 25º

1

2

3

15

15

15

2.1541N

2.1542N

2.1543N

Height Angle Code

Angled abutment 15º

Code

2.4001

Closed keeperCode

2.4091 Soft

2.4092 Medium

2.4093 Hard

Rubber ring

Code

2.4094

Positioner o’ring kit

Code

5.4010

5.4110

Titanium Pillar (UCLA)

1.330 Ncm

Code

3.4001

3.4002

Plastic UCLA

1.330 Ncm

CoCr plasticUCLA

Code

5.4201

5.4202

1.330 Ncm

Code

5.4202T

CoCr Pillar

1.330 Ncm

6.0

6.0

6.0

5.4310

5.4320

5.4330

Height Profile Code

Anatomical abutmentLONG

1

2

3

1.330 Ncm

1.330 Ncm

1.330 Ncm

Plastic cylinderTransfer Analog

4.4021S

4.4021L

4

6

Height CodeCode

4.4490i

4.4090i

Code

4.4410i

4.4410M

4.4010i

4.4010M

Height

4

6

Height

4

4

6

6

38

Mini-Pilar Angulado

6.1541

6.1542

6.1543

6.2541

6.2542

1

2

3

15

15

15

1

2

25

25

Height Angle Code

Height Angle Code

Code

6.4080

Healing Cap

Conical Pillar

7.4001

7.4002

7.4003

1

2

3

Height Code

Pilar Ângulado

7.1541

7.1542

7.1543

7.2541

7.2542

1

2

3

15

15

15

1

2

25

25

Height Angle Code

Height Angle Code

Healing Cap

Code

7.4080

Conical Mini Pillar

6.4101

6.4102

6.4103

6.4104

6.4105

1

2

3

4

5

Height Code

2.030 Ncm

1.215 Ncm

1.210 Ncm

1.210 Ncm

1.215 Ncm

2.030 Ncm

EXTERNALHEXAGON_____________

INTERMEDIATE COMPONENTS

PROSTHETIC LINEPLATFORM 4.1

PROSTHETIC SOLUTIONSCONICAL MINI-PILLAR

PROSTHETIC SOLUTIONSCONICAL PILLAR

3.75

4.0

5.0

STANDARD WITH INTERNAL TORQUE

3.5

3.75

4.0

5.0

SOULFIT

3.8

4.3

5.0

PROPFIT

3.5

3.75

4.0

4.5

5.0

MODEL BIOFIT

3.8

4.3

5.0

WAYFIT

39

Analog

Code

7.4021

CoCr plasticUCLACode

7.4111

Lab prosthetic screw

Screw

Code

7.4055

Code

7.4050

Open tray impressiontransfer

Closed tray impressiontransfer

Code

6.4091

Code

6.4090

Analog

Code

6.4021

Titanium Pillar (UCLA)

Plastic UCLA

CoCr plasticUCLA

Code

6.4212

Code

6.4012

Code

6.4112

Analog

Plastic

Titanium

Code

6.4022

Code

6.4031

Code

6.4062

Lab prosthetic screw

Screw

Code

6.4055

Code

6.4050

Open tray impressiontransfer

Code

7.4093

7.4091

Closed tray impressiontransfer

Code

7.4092

7.4090

Titanium Pillar (UCLA)

Plastic UCLA

Code

7.4211

Code

7.4011

1.2

1.210 Ncm

1.210 Ncm

1.210 Ncm

1.210 Ncm

1.2

1.210 Ncm

1.210 Ncm

1.210 Ncm

1.210 Ncm

1.210 Ncm

1.210 Ncm

1.210 Ncm

1.2

1.2

PROSTHETIC SOLUTIONSCONICAL MINI-PILLAR

PROSTHETIC SOLUTIONSCONICAL PILLAR

IMEDIATEPASSIVE SEATING

1.210 Ncm

1.210 Ncm

HIM IMPLANTSHEXAGONAL INTERNAL MORSE

Only available in not mounted version.

Cover screw not included.

PROSTHETIC SOLUTIONS: accept a large variety prosthetic

components options. Belong to the line the esthetic

components and all FlexCone® and mini FlexCone® line.

Were designed with the concept of the internal Hexagon associated to the morse taper benefits. His body shape is cylindrical, and has trapezoidal self-cutting threads. On the third cervical implant area, those threads become in to microthreads, with double entry, providing better primary stability and increasing the osteointegration area. His advantages are prosthetic reduced platform, a single prosthetic line for all implant sizes and platforms, and compatibility with international line.

MATERIAL: Titanium grade IV.

SURFACE: Sandblasted Large grift Acid etching .SPEED DRILLING: 800 to 1200 rpm.ROTATION INSERT: 20 to 30 rpm.TORQUE INSERTION: 35 to 55 Ncm.

TECHNICAL SPECIFICATIONS

ø 2,8

ø 3,3

ØA

ØD

L

ø 2,8

ø 3,3

ØA

ØD

L

ØD ØA L 3.5 2.4 4.03.75 2.65 4.04.0 3.0 4.04.5 3.4 4.05.0 3.9 4.0

41

HEXAGONAL INTERNAL

MORSE _____________Technical

Specifications

3.5mm

Spea

r / s

crew

2

Drill

2.8

Drill

2.5

Pilo

t 2.0

/ 3.

0

Drill

3.0

Drill

3.1

5

Pilo

t 3.0

/ 3.

8

Drill

3.3

Drill

3.5

Drill

3.8

Drill

4.3

Coun

ters

ink

5.0

3.75mm

4.0mm

4.5mm

5.0mm

Note:1 - The last drill isn’t necessary perfurate the total height, being a less measure.2 - For corticalizado bone type I and II drilling with drill 3mm that only the region corresponding to the micro-threads. This drill will act as the region’s micro thread height 3.5

INTERNALMORSEHEXAGON

MODELS AND LENGTHS

CYLINDRICALMICRO-THREADS

7.0

8.5

10

11.5

13

15

50.3507R

50.3508R

50.3510R

50.3511R

50.3513R

50.3515R

50.4007R

50.4008R

50.4010R

50.4011R

50.4013R

50.4015R

50.3707R

50.3708R

50.3710R

50.3711R

50.3713R

50.3715R

50.4507R

50.4508R

50.4510R

50.4511R

50.4513R

50.4515R

50.5007R

50.5008R

50.5010R

50.5011R

50.5013R

50.5015R

Ø 3.5 Ø 3.75 Ø 4.0 Ø 4.5 Ø 5.0

HEXAGONAL INTERNAL MORSE

SEQUENCEOF DRILLS

This implant is connected with a connection driver double hexagon.Its has fit with contra-angle or Torque Wrench (ratchet).

28.5020R 26.5060R 26.5061R

1 - With the Badock take the implant to the grip2 - Takeoff the badock3 - Fix the double hexagon connection driver.

DRIVERS CAPTURE AND TRANSPORT OF IMPLANT

01 0302

Optional Apical DrillingIndicated

See item 2

42

Code

59.4001SH

59.4001SN

Open tray impression transferSHORT

Code

59.4001LH

59.4001LN

Open tray impression transferLONG

Code

59.4000SH

Code

59.4000LH

Closed tray impression transferSHORT

Closed tray impression transferLONG3.5

3.75

4.0

4.5

5.0

HIM CYLINDRICAL

Code

51.4000R

Analog

Code

51.4001R

Cover Screw

1

2

2

1

2

4

1

2

2

2

2

2

3

4

6

1

2

2

4

2

4

6

5.5

5.5

5.5

2 3.3

4

6

6.5

6.5

2

2

4

6

8

10

4

6

8

4.0

4.0

4.0

4.0

4.0

4.0

4.0

4.0

4.0

2

4

6

6

4.5

4.5

4.5

4.5

59.5512R

59.5524R

59.5526R

59.3312R

59.6524R

59.6526R

59.4012R

59.4022R

59.4024R

59.4026R

59.4028R

59.4029R

59.4034R

59.4046R

59.4068R

59.4512R

59.4524R

59.4526R

59.4546R

A L Ø Code

A L Ø Code

A L Ø Code

A L Ø Code

A L Ø Code

Healing

PROSTHETIC SOLUTIONS OVER IMPLANT

PROSTHETIC SOLUTIONS OVERDENTURE

1 3.5 55.3512R

Height Profile Code

Straight abutment

0

1

2

3

4

5

6

52.4040R

52.4041R

52.4042R

52.4043R

52.4044R

52.4045R

52.4046R

Height Code

O’ring abutment

1.210 Ncm

1.210 Ncm

1.230 Ncm

2.430 Ncm

1.220 Ncm

1.210 Ncm

1.210 Ncm

1.2

1.2

1.210 Ncm

ScrewCode

53.4000R

Lab prosthetic screwCode

53.4000L

1

2

3

4.0

4.0

4.0

55.4011R

55.4012R

55.4013R

Height Profile Code

Anatomical abutment

1.230 Ncm

A

L

Ø

HEXAGONAL INTERNAL MORSE _____________

PROSTHETIC LINE

PROSTHETIC LINEHEXAGONAL INTERNAL MORSE

PROSTHETIC SOLUTIONS CEMENTED

43

Code

55.4201H

55.4202N

CoCr plastic UCLA

Angled abutment estético

1

1

1

1

4.5

4.5

5.5

5.5

15

25

15

25

55.4515RA

55.4525RA

55.5515RA

55.5525RA

Height Profile Angle Code

Transfer

Profile Height Code

4

6

4

4

4.3490i

4.3390i

Transfer

Profile Height Code

4

6

5

5

4.4490i

4.4090i

Analog

Ø Height Code

4

6

4

4

4.3321S

4.3321L

Analog

Ø Height Code

4

6

5

5

4.4021S

4.4021L

Esthetic abutment

1.5

3

1.5

3

1.5

3

4.5

4.5

5.5

5.5

6.5

6.5

55.4515R

55.4530R

55.5515R

55.5530R

55.6515R

55.6530R

Height Profile Code

Code

2.4001

Code

2.4094

Closed keeper Positioner o’ring kitCode

2.4091 Soft

2.4092 Medium

2.4093 Hard

Rubber ring

Plastic cylinder

Plastic cylinder

Height Profile Code

Height Profile Code

4

4

4

4

5

5

5

5

4

4

6

6

4

4

6

6

4.3410i

4.3410M

4.3310i

4.3310M

4.4410i

4.4410M

4.4010i

4.4010M

1.230 Ncm

1.230 Ncm

1.230 Ncm

1

2

1

2

1

2

1

2

4

4

4

4

5

5

5

5

15

15

25

25

15

15

25

25

55.1551RA

55.1552RA

55.2551RA

55.2552RA

55.1561RA

55.1562RA

55.2561RA

55.2562RA

Height Profile Angle Code

Height Profile Angle Code

Angled abutment anatômico

1.230 Ncm

1

2

3

5.0

5.0

5.0

55.5011R

55.5012R

55.5013R

Height Profile Code

Anatomical abutment

1.230 Ncm

HEXAGONAL INTERNAL MORSE

44

HEXÁGONOINTERNO MORSE_____________

PROSTHETIC LINE

PROSTHETIC SOLUTIONSMINI-FLEXCONE®

Open tray impressiontransfer

Code

77.3093

77.3091

3.5

3.75

4.0

4.5

5.0

HIM Cilyndrical

Mini-FlexCone® Pillar

58.4001R

58.4002R

58.4003R

58.4004R

1

2

3

4

Height Code

2.230 Ncm

Code

77.3080

Healing Cap

1.210 Ncm

1.210 Ncm

Closed tray impressiontransfer

Code

77.3092

77.3090

1.210 Ncm

Healing Cap

Code

77.3380

1.210 Ncm

1.210 Ncm

1.210 Ncm

Open tray impressiontransfer

Code

77.3393

77.3391

Closed tray impression

transfer

Code

77.3392

77.3390

Multiple FlexCone® Pillar

FlexCone® Pillar Angled FlexCone®Pillar

57.4001M

57.4002M

57.4003M

57.4004M

57.4006M

1

2

3

4

6

Height Code

57.4001R

57.4002R

57.4003R

57.4004R

57.4006R

57.4008R

1

2

3

4

6

8

Height Code

2.730 Ncm

1.220 Ncm2.7

30 Ncm

57.2041

57.2042

57.2043

57.3041

57.3042

1.5

2.5

3.5

20

20

20

1.5

2.5

30

30

Height Angle Code

Height Angle Code

HEXAGONAL INTERNAL MORSE _____________

PROSTHETIC LINE

PROSTHETIC LINEHEXAGONAL INTERNAL MORSE

PROSTHETIC SOLUTIONSFLEXCONE®

Code

6.4080

Healing Cap

Conical Mini Pillar

56.4101M

56.4102M

56.4103M

1

2

3

Height Code

2.030 Ncm

1.210 Ncm

PROSTHETIC SOLUTIONSCONICAL MINI-PILLAR

45

Analog

Code

77.3021

Analog

Code

77.3321

Micro O’ring Pillar and

Closed Keeper

* Closed Keeper sale apart:

Closed keeper code: 2.4001

Code

72.3004

O’ring Pillar andClosed keeper

Code

72.3704

Cemented metalcylinderSHORT

Code

72.3009

72.3006

Cemented plasticcylinderSHORT

Code

72.3008

72.3005

Cemented metalcylinder

LONG

Code

72.3011

72.3012

Cemented plasticcylinder

LONG

Code

72.3010

72.3007

Cemented metalcylinderSHORT

Code

72.3709

Cemented metalcylinder

LONGCode

72.3711

Cemented plasticcylinderSHORTCode

72.3708

Cemented plastic cylinderLONG

Code

72.3710

Titanium UCLACode

77.3511

77.3512

Lab prostheticscrew

Screw

Code

7.7055

Code

7.7050

Titanium Pillar (UCLA)Code

77.3211

77.3212

Plastic UCLACode

77.3011

77.3012

CoCr plastic UCLACode

77.3111

77.3112 Screw

Code

7.3050

Lab prosthetic screw

Code

7.3055

1.220 Ncm

1.220 Ncm

1.210 Ncm

1.210 Ncm

1.210 Ncm

1.210 Ncm

1.210 Ncm

1.220 Ncm

1.210 Ncm

CoCr plastic UCLACode

77.3411

77.3412

1.210 Ncm

Plastic UCLACode

77.3311

77.3312

1.210 Ncm

1.210 Ncm

1.210 Ncm

1.210 Ncm

1.210 Ncm

1.210 Ncm

SCREW-RETAINED

SCREW-RETAINED

CEMENTED

CEMENTED

OVERDENTURE

OVERDENTURE

* Closed keeper sale apart:Closed keeper code: 2.4101

Open tray impressiontransfer

Closed tray impressiontransfer

Code

6.4091

Code

6.4090

Analog

Code

6.4021

Titanium Pillar (UCLA)

Plastic UCLA

Pilar base CrCo

Code

6.4212

Code

6.4012

Code

6.4112

Lab prosthetic screw

Screw

Code

6.4055

Code

6.4050

1.2

1.210 Ncm

1.210 Ncm

1.210 Ncm 1.2

1.210 Ncm

1.210 Ncm

PROSTHETIC SOLUTIONSCONICAL MINI-PILLAR

IMEDIATEPASSIVE SEATING

AnalogCode

6.4022

Titanium

1.210 Ncm

1.210 Ncm

PlasticCode

6.4031

1.210 Ncm

CMI BIOFIT Indexed Morse Taper

This implant presents a platform switching, with main caractheristic, the prosthetic locking with cold pressure welding thread. With this sealing the peri-implant tissue remain healthier by the decreasing of inflammatory infiltration. It has a unique prosthetic interface and high mechanical resistance.

Now with capture system and insertion through an hexagonal driver.

New prosthetic line with indexed abutments, providing easier procedure on unitary abutment, or when it demands precision on placement. It has a cylindrical body shape, with triangular threads, showing retention profile grooves. Idealized for primary stability in low, medium, and high density bones. With sharper chambers and lower diameter apex. It has a reduced drilling protocole.

MATERIAL: Titanium grade IV.

SURFACE: Sandblasted Large grift Acid etching .SPEED DRILLING: 800 to 1200 rpm.ROTATION INSERT: 20 to 30 rpm.TORQUE INSERTION: 35 to 55 Ncm.

TECHNICAL SPECIFICATIONS

ØC

SW

A

D

M

L

ØC

SW

A

D

M

L

ØC

SW

A

D

M

L

ØC SW M 2.5 2.0 1.8

CilyndricalØD ØA L3.5 1.8 2.73.75 2.05 2.74.0 2.3 2.74.5 2.8 2.75.0 3.3 2.7

47

INDEXED MORSE TAPER

MORSE

MODELS AND LENGTHS

TAPERBIOFIT

7.0

8.5

10

11.5

13

15

70.3507B

70.3508B

70.3510B

70.3511B

70.3513B

70.3515B

70.3707B

70.3708B

70.3710B

70.3711B

70.3713B

70.3715B

70.4507B

70.4508B

70.4510B

70.4511B

70.4513B

70.4515B

70.4007B

70.4008B

70.4010B

70.4011B

70.4013B

70.4015B

70.5007B

70.5008B

70.5010B

70.5011B

70.5013B

70.5015B

Ø 3.5 Ø 3.75 Ø 4.0 Ø 4.5 Ø 5.0

The implant comes in mounted version and should have took with: square contra-angle driver, torque wrench (reatchet) or right with torque wrench (reatchet).

CAPTURE AND TRANSPORT OF IMPLANTDRIVERS

0303 0202 0101

INDEXED MORSE TAPER ____________

technical specifications

3.5mm

Spea

r / H

elic

oida

l 2

Drill

2.5

Drill

2.8

Pilo

t 2.0

/ 3.

0

Drill

3.0

Drill

3.1

5

Pilo

t 2.0

/ 3.

8

Drill

3.3

Drill

3.5

Drill

3.8

Drill

4.3

Coun

ters

ink

5.0

3.75mm

4.0mm

4.5mm

5.0mm

Indicated

28.5020i 28.2020i 28.3020i

OptionalApical Drilling

SEQUENCE OF DRILLS

Note: For implant removal with immediate capture, see page 8.

Removed with clamp:

1 - With the Badock take the implant to the surgical place

2 - Takeoff the badock

3 - Attach the driver for contra-angle, surgical

torque or ratchet wrench with torque.Removal of

implant with

handler

Removal of the

handlerFitting of

the internal connection

driver

MATERIAL: Titanium grade IV.

SURFACE: Sandblasted Large grift Acid etching .SPEED DRILLING: 800 to 1200 rpm.ROTATION INSERT: 20 to 30 rpm.TORQUE INSERTION: 35 to 55 Ncm.

TECHNICAL SPECIFICATIONS

ØC

SW

A

D

M

L

ØC

SW

A

D

M

L

ØC

SW

A

D

M

L

CMI

This implant presents a platform switching with main caractheristics, the prosthetic locking with cold pressure welding thread. With this sealing the peri-implant tissues, remain healthier by the decreasing of the inflammatory infiltration. It has a unique prosthetic interface and high mechanical resistance.

Now with capture system and insertion trough an hexagonal driver.

With a design of double thread, that’s provides a faster and less trauma placement. Beeing his apex of a small diameter, which makes easier the bone compactation.

ØC SW M 2.5 2.0 1.8

CilyndricalØD ØA L3.8 2.5 3.04.3 2.76 3.05.0 3.5 3.0

INDEXED MORSE TAPER

49

INDEXED MORSE TAPER _____________

technical specifications

INDEXED MORSE TAPER

MORSETAPER

MODELS AND LENGTHS

SOULFIT

7.0

8.5

10

11.5

13

15

70.3507S

70.3508S

70.3510S

70.3511S

70.3513S

70.3515S

70.3707S

70.3708S

70.3710S

70.3711S

70.3713S

70.3715S

70.4007S

70.4008S

70.4010S

70.4011S

70.4013S

70.4015S

70.5007S

70.5008S

70.5010S

70.5011S

70.5013S

70.5015S

Ø 3.5 Ø 3.75 Ø 4.0 Ø 5.0

3.5mm

Spea

r / 2

.0

Drill

2.5

Drill

2.8

Pilo

t 2.0

/ 3.

0

Drill

3.0

Drill

3.1

5

Pilo

t 3.0

/ 3.

8

Drill

3.3

Drill

3.5

Drill

3.8

Drill

4.3

Coun

ters

ink

5.0

3.75mm

4.0mm

5.0mm

Indicated OptionalApical Drilling

SEQUENCE OF DRILLS

The implant comes in mounted version and should have took with: square contra-angle driver, torque wrench (reatchet) or right with torque wrench (reatchet).

CAPTURE AND TRANSPORT OF IMPLANTDRIVERS

0303 0202 0101

28.5020i 28.2020i 28.3020i

Note: For implant removal with immediate capture, see page 8.

Removed with clamp:

1 - With the Badock take the implant to the

surgical place

2 - Takeoff the badock

3 - Attach the driver for contra-angle, surgical

Removal of

implant with

handler

Removal of the

handlerFitting of

the internal connection

driver

MATERIAL: Titanium grade IV.

SURFACE: Sandblasted Large grift Acid etching.SPEED DRILLING: 400 to 800 rpm.ROTATION INSERT: 10 to 30 rpm.TORQUE INSERTION: 35 to 55 Ncm.

TECHNICAL SPECIFICATIONS

ØC

SW

A

D

M

ØC

SW

A

D

M

ØC

SW

A

D

M

CMI

This implant presents a platform switching, with main caractheristic the prosthetic locking with cold pressure welding thread. With this sealing the peri-implant tissues, remain healthier by decreasing the inflammatory infiltration. It has a unique prosthetic interface and high mechanical resistance. Now with capture system and insertion trough an hexagonal driver.

New prosthetic line with indexed abutments, providing easier procedure on unitary abutment, or when it demands precision on placement.

This conical body implant shape mimetizes the natural rooth tooth shape, simplifying the surgery. It has 1mm polished collar high on the platform. Indicated on post-extraction loading.

ØC SW M 2.5 2.0 1.8

CilyndricalØD ØA 3.8 2.5 4.3 2.85.0 3.5

INDEXED MORSE TAPER

51

INDEXED MORSE TAPER_____________

technical specification

SEQUENCE OF DRILLS

3.8mm

Spea

r / D

rill 2

.5

Coni

cal D

rill 3

.8

Coni

cal D

rill 4

.3

Coni

cal D

rill 5

.0

4.3mm

5.0mm

DRILL HEIGHT

REGULAR 8.5, 10.0, 11.5, 13 e 15

INDEXED MORSE TAPER

CONEMORSE

MODELS AND LENGTHS

PROPFIT

8.5

10

11.5

13

15

70.3808P

70.3810P

70.3811P

70.3813P

70.3815P

70.4308P

70.4310P

70.4311P

70.4313P

70.4315P

70.5008P

70.5010P

70.5011P

70.5013P

70.5015P

Ø 3.8 Ø 4.3 Ø 5.0

The implant comes in mounted version and should have took with: square contra-angle driver, torque wrench (reatchet) or right with torque wrench (reatchet).

CAPTURE AND TRANSPORT OF IMPLANTDRIVERS

0303 0202 0101

28.5020i 28.2020i 28.3020i

Note: For implant removal with immediate capture, see page 8.

Removed with clamp:

1 - With the Badock take the implant to

the surgical place

2 - Takeoff the badock

3 - Attach the driver for contra-angle, surgical

Removal of

implant with

handler

Removal of the

handlerFitting of

the internal connection

driver

MATERIAL: Titanium grade IV.

SURFACE: Sandblasted Large grift Acid etching .SPEED DRILLING: 400 to 800 rpm.ROTATION INSERT: 20 to 30 rpm.TORQUE INSERTION: 35 to 55 Ncm.

TECHNICAL SPECIFICATIONS

ØC

SW

A

D

M

ØC

SW

A

D

M

ØC

SW

A

D

M

CMI

INDEXED MORSE TAPER

This implant presents a platform switching, with main caractheristic the prosthetic locking with cold pressure welding thread.

With this sealing the peri-implant tissues remain healthier by decreasing the inflammatory infiltration. It has a unique prosthetic interface and high mechanical resistance.Now with capture system and insertion trough an hexagonal driver.

New prosthetic line with indexed abutments, providing easier procedure on unitary abutment, or when it demands precision on placement. It has a conical body shape with double conical threads. It has a blade apex, with a scalling platform, providing compactating cutting chambers, inverted over the threads. Used for bone type IV, on post-extraction loading.

ØC SW M 2.5 2.0 1.8

CilyndricalØD ØA 3.8 3.04.3 3.55.0 4.2

53

INDEXED MORSE TAPER____________

technical specification

SEQUENCE OF DRILLS

3.8mm

Spea

r / D

rill 2

.5

Coni

cal D

rill 3

.8

Coni

cal D

rill 4

.3

Coni

cal D

rill 5

.0

4.3mm

5.0mm

DRILL HEIGHT

REGULAR 8.5, 10.0, 11.513.0 e 15.0

INDEXED MORSE TAPER

MORSETAPER

MODELS AND LENGTHS

WAYFIT

8.5

10

11.5

13

15

70.3808W

70.3810W

70.3811W

70.3813W

70.3815W

70.4308W

70.4310W

70.4311W

70.4313W

70.4315W

70.5008W

70.5010W

70.5011W

70.5013W

70.5015W

Ø 3.8 Ø 4.3 Ø 5.0

The implant comes in mounted version and should have took with: square contra-angle driver, torque wrench (reatchet) or right with torque wrench (reatchet).

CAPTURE AND TRANSPORT OF IMPLANTDRIVERS

0303 0202 0101

28.5020i 28.2020i 28.3020i

Note: For implant removal with immediate capture, see page 8.

Removed with clamp:

1 - With the Badock take the implant to

the surgical place

2 - Takeoff the badock

3 - Attach the driver for contra-angle, surgical

Removal of

implant with

handler

Removal of the

handlerFitting of

the internal connection

driver

54

INDEXED MORSE TAPER_____________

PROSTHETIC LINE

Code

71.4000

79.4049

79.4049i

79.4050i

without index

Indexed

Indexed

Code

Code

Analog

Open tray impression transfer

Closed tray impression transfer

1.5

2.5

3.5

1.5

2.5

3.5

79.4021

79.4022

79.4023

79.4041

79.4042

79.4043

Straight healing cap

Anatomical healing cap

Height

Cinta

3.5

4.5

5.5

5.5

6.5

7.5

1.5

2.5

3.5

1.5

2.5

3.5

4.0

4.0

4.0

4.0

4.0

4.0

79.3321

79.3322

79.3323

79.3341

79.3342

79.3343

Cinta Height Profile Code

3.5

4.5

5.5

5.5

6.5

7.5

4.8

4.8

4.8

4.8

4.8

4.8

Cinta Height Profile Code

79.4050 without index

Code

Closed tray impression transfer

Code

71.4001

Cover Screw

1.210 Ncm

1.210 Ncm

1.210 Ncm

1.210 Ncm

1.220 Ncm

1.220 Ncm

1.210 Ncm

PROSTHETIC LINEINDEXED MORSE TAPER

3.5

3.75

4.0

4.5

5.0

CMI BIOFIT

3.5

3.75

4.0

5.0

CMI SOULFIT

3.8

4.3

5.0

CMI PROPFIT

3.8

4.3

5.0

CMI WAYFIT

Code

71.4001L

Cover ScrewLONG

CoCr base screw-retainedabutment

75.4103

75.4107

75.4111

75.4112

75.4113

0.35

0.70

1.50

2.50

3.50

4.8

4.8

4.8

4.8

4.8

Height Profile Code

20 Ncm

INDEXED MORSE TAPER

PROSTHETIC SOLUTIONSOVER IMPLANT

O’ring abutment

72.4041

72.4042

72.4043

72.4044

4.0

4.0

4.0

4.0

Height Profile Code

1.5

2.5

3.5

4.5

2.430 Ncm

Code

2.4094

Positioner o’ring kitClosed Keeper

Code

2.4001

Code

2.4091 Soft

2.4092 Medium

2.4093 Hard

Rubber ring

PROSTHETIC SOLUTIONSOVERDENTURE

CoCr base screw-retainedabutment indexed

75.4103i

75.4107i

75.4111i

75.4112i

75.4113i

0.35

0.70

1.50

2.50

3.50

4.8

4.8

4.8

4.8

4.8

Height Profile Code

20 Ncm

Height Code

1.5

2.5

3.5

74.3301Ei

74.3302Ei

74.3303Ei

Esthetic abutment SLIM

20 Ncm

Height Code

1.5

2.5

3.5

74.4001Ei

74.4002Ei

74.4003Ei

Esthetic abutment

20 Ncm

0.35

0.70

1.50

2.50

3.50

Titanium UCLA

75.4003

75.4007

75.4011

75.4012

75.4013

4.8

4.8

4.8

4.8

4.8

Height Perfil Code

20 Ncm

Titanium UCLA Indexed

75.4003i

75.4007i

75.4011i

75.4012i

75.4013i

4.8

4.8

4.8

4.8

4.8

Height Profile Code

0.35

0.70

1.50

2.50

3.50

20 Ncm

56

CONE MORSE_____________

LINHA PROTéTICA

INDEXED MORSE TAPER_____________

PROSTHETIC LINE

3.5

3.75

4.0

4.5

5.0

CMI BIOFIT

3.5

3.75

4.0

5.0

CMI SOULFIT

3.8

4.3

5.0

CMI PROPFIT

3.8

4.3

5.0

CMI WAYFIT

PROSTHETIC LINEINDEXED MORSE TAPER

PROSTHETIC SOLUTIONSCEMENTED ANATOMICAL

HE

IGH

T 4

MM

Pla

tafo

rm 4

.8P

lata

form

4.0

Pla

tafo

rm M

ini 3

.3P

lata

form

Min

i 3.3

HE

IGH

T 6

mm

Pla

tafo

rm 4

.0P

lata

form

4.8

Abutment Indexed Slim

1.230 Ncm

Anatomical abutment indexed

1.230 Ncm

Abutment Indexed Mini

1.230 Ncm

74.2800i74.2801i74.2802i74.2803i

0.751.502.503.50

4444

Anatomical abutment

1.330 Ncm

1.330 Ncm

Anatomical abutment Slim

1.330 Ncm

Anatomical abutment

Slim Abutment

1.330 Ncm

Abutment Mini

1.330 Ncm

74.2700L74.2701L74.2702L74.2703L74.2704L74.2705L

0.751.502.503.504.505.50

444444

1.330 Ncm

Abutment Mini

74.2710L

74.2711L

74.2712L

74.2713L

74.2714L

74.2715L

1.230 Ncm

Anatomical abutment Slim

1.230 Ncm

Anatomical abutment indexed

1.230 Ncm

Anatomical abutment indexed

74.2810i

74.2811i

74.2812i

74.2813i

Height Code Height Code

Height CodeHeight Code

Height CodeHeight Code

Height CodeHeight Code

Height CodeHeight Code

Height Code Height Code

INDEXED MORSE TAPER

4.2810i

4.2610M

4.2890I4.2721S

HE

IGH

T 4

MM

Pla

tafo

rm 4

.8P

lata

form

4.0

Pla

tafo

rm M

ini 3

.3P

lata

form

Min

i 3.3

HE

IGH

T 6

mm

Pla

tafo

rm 4

.0P

lata

form

4.8

4.2710I4.2710M

4.2790I4.2721L

1.230 Ncm

74.1521i

74.1522i

74.1523i

1.230 Ncm

74.1521

74.1522

74.1523

74.2521

74.2522

74.2523

74.2521i

74.2522i

74.2523i

1.230 Ncm

1.230 Ncm

1.230 Ncm

1.230 Ncm

Plastic cylinder

Plastic cylinder

Plastic cylinder

Plastic cylinder

Anatomical Abutment angled

Anatomical Abutment angled

Anatomical Abutment angled

Angl

edAn

gled

Angl

ed

Anatomical Abutment angled indexed

Anatomical Abutment angled indexed

Anatomical Abutment angled indexed

Plastic cylinder

Plastic cylinder

Analog

Analog

Analog

Analog

Analog

Analog

Indexed

Multiple

Indexed

Multiple

Indexed

Multiple

IndexedMultiple

IndexedMultiple

IndexedMultiple

Indexed

Indexed

Indexed

Indexed

Indexed

Indexed

Indexed

Indexed

Indexed

Indexed

IndexedIndexed

Type Code

Type Code

Type Code

Type Code

height Angle Codeheight Angle Code

height Angle Code

height Angle Code

height Angle Code

height Angle Code

height Angle Code

height Angle Code

height Angle Code

height Angle Code

height Angle Code

height Angle Code

Type Code

Type Code

Type Code

Type Code

Type Code

Type Code

Type Code

Type Code

Type Code

Type Code

Type Code

Type Code

Type CodeType Code

58

Code

77.3080

Healing Cap

78.4000

78.4001

78.4002

78.4003

78.4004

78.4005

0.75

1.50

2.50

3.50

4.50

5.50

Height Code

Mini-FlexCone® Pillar

76.4100

76.4000

76.4001

76.4002

76.4003

76.4004

76.4005

76.4006

0.30

0.75

1.50

2.50

3.50

4.50

5.50

6.50

Height Code Height Angle Code

Height Angle Code

Conical Mini PillarAngled Conical Mini Pillar

Healing Cap

Code

6.4080

77.4100

77.4000

77.4001

77.4002

77.4003

77.4004

77.4005

0.30

0.75

1.50

2.50

3.50

4.50

5.50

Height Code

77.4100M

77.4000M

77.4001M

77.4002M

77.4003M

77.4004M

77.4005M

0.30

0.75

1.50

2.50

3.50

4.50

5.50

Height Code

FlexCone® Pillar Multiple FlexCone® Pillar

Open tray impression

transferCode

77.3093

77.3091

Closed tray impression

transferCode

77.3092

77.3390

Open tray impression transfer*

Code

77.3393

77.3391

Closed tray impression transfer

Code

77.3392

77.3390

Healing Cap

Healing cap for angled pillar

Code

77.3380

Code

77.3380A

2.230 Ncm

2.730 Ncm

2.730 Ncm

1.210 Ncm

1.210 Ncm

1.210 Ncm

1.220 Ncm

2.030 Ncm

1.210 Ncm

1.210 Ncm

1.210 Ncm

1.210 Ncm

1.210 Ncm

Open tray impression transfer

Code

6.4091

Closed tray impression transfer

Code

6.4090

INDEXED MORSE TAPER_____________

PROSTHETIC LINE

PROSTHETIC LINEINDEXED MORSE TAPER

PROSTHETIC SOLUTIONSMINI-FLEXCONE

PROSTHETIC SOLUTIONSFLEXCONE

PROSTHETIC SOLUTIONSMINI CONICAL PILLAR

3.5

3.75

4.0

4.5

5.0

CMI BIOFIT

3.5

3.75

4.0

5.0

CMI SOULFIT

3.8

4.3

5.0

CMI PROPFIT

3.8

4.3

5.0

CMI WAYFIT

77.2041

77.2042

77.2043

77.3041

77.3042

1.5

2.5

3.5

17

17

17

1.5

2.5

30

30

Height Angle Code

Height Angle Code

Angled FlexCone® Pillar

2.720 Ncm

77.2041i

77.2042i

77.2043i

77.3041i

77.3042i

1.5

2.5

3.5

17

17

17

1.5

2.5

30

30

Height Angle Code

Height Angle Code

Angled FlexCone® PillarIndexed

2.720 Ncm

* When used for FlexCone® Angled Pillar, take off the screw that follow and use the FlexCone® Angled Pillar.

1.210 Ncm

1.210 Ncm

Analog

Code

6.4021

O’ring Pillar

*Closed keeper sale apart:Closed keeper code: 2.4001

Code

72.3004

Cemented metalcylinder SHORT

Cemented metalcylinder SHORT

Code

72.3009

72.3006

Code

72.3709

Cemented metalcylinder SHORT

Cemented metalcylinder SHORT

Code

72.3008

72.3005

Code

72.3708

Cemented metalcylinder LONG

Cemented metalcylinder LONG

Code

72.3011

72.3012

Code

72.3711

Cemented metalcylinder LONG

Cemented metalcylinder LONG

Code

72.3010

72.3007

Code

72.3710

Titanium Pillar (UCLA)

Plastic UCLA

Plastic UCLA

CoCr plastic UCLA

Code

77.3511

77.3512

Code

77.3011

77.3012

Code

77.3311

77.3312

Code

77.3411

77.3412

Lab prosthetic screw

Code

7.3055

Screw

Code

7.3050

Lab prostheticscrew

Code

6.4055

Screw

Code

6.4050

AnalogCode

77.3021

CoCr plastic UCLA

Code

77.3111

77.3112

Analog

Code

77.3321

Analog forangled pillar

Code

77.3321A

Lab prosthetic screwCode

7.7055

ScrewCode

7.7050

7.7060

O’ring Pillar

Titanium Pillar (UCLA)

Code

77.3211

77.3212

1.220 Ncm

1.220 Ncm

1.220 Ncm

1.220 Ncm

CoCr plastic UCLACode

6.4112

1.210 Ncm

Plastic UCLACode

6.4012

1.210 Ncm

Titanium Pillar (UCLA)

Code

6.4212

1.210 Ncm 10 Ncm

10 Ncm

1.220 Ncm

1.2

1.210 Ncm

1.210 Ncm

1.210 Ncm

10 Ncm

1.210 Ncm

1.2

1.220 Ncm

1.2

1.2

1.210 Ncm

1.210 Ncm

1.210 Ncm

1.210 Ncm

1.210 Ncm

Analog

Plastic

Titanium

Code

6.4022

Code

6.4031

Code

6.4062

1.210 Ncm

1.210 Ncm

1.210 Ncm

IMEDIATEPASSIVE SEATING

SCREW-RETAINED

SCREW-RETAINED OVERDENTURECEMENTED

INDEXED MORSE TAPER

SCREW-RETAINED CEMENTED OVERDENTURE

*Closed keeper sale apart:Closed keeper code: 2.4001

Code

72.3704

øD øA øC SW M3.3 2.4 3.3 2.4 1.8

3.75 2.7 3.5 2.5 2.04.0 3.0 3.5 2.5 2.05.0 4.0 3.5 2.5 2.0

Only available in not mounted version. Cover screw not included.

PROSTHETIC SOLUTIONS: A wide variety of pillars produce excellent

esthetics and prosthetic solutions for each situation, single or multiple,

cemented or screw-retained prostheses.

MATERIAL: Titanium grade IV.

SURFACE: Sandblasted Large grift Acid etching .SPEED DRILLING: 800 to 1200 rpm.ROTATION INSERT: 20 to 30 rpm.TORQUE INSERTION: 35 to 55 Ncm.

TECHNICAL SPECIFICATIONS

CMH Implant combines internal hexagon connection, the same cone of 40º of the minipilar (multi-unit).For example it allows the connection of a prosthesis protocol directly on implants, without need of using intermediate angled prosthetic abutments. This implant follows the same surgical and prosthetic protocols of the external hexagon. It has trapezoidal conical threads on his internal profile, and cilindrical on the external profile. However it´s used cylindrical drills on the surgery. It has an ultra polished collar of 1 mm high on the incisal region, which allows lightly upper bone level loading.

SWØ C M

A

D

L

SWØ C M

A

D

L

SWØ C M

A

D

CMH HEXAGONAL MORSE TAPER

L = 4.0

61

SEQUENCE OF DRILLS

3.3mm

Note: 1 - It is suggested that the last drill is not used to drill overall height of the implant, but a depth of about 3mm.

Spea

r / s

crew

2

Drill

2.5

Drill

2.8

Pilo

t 2.0

/ 3.

0

Drill

3.0

Drill

3.1

5

Pilo

t 3.0

/ 3.

8

Drill

3.3

Drill

3.5

Drill

3.8

Drill

4.3

Coun

ters

ink

5.0

3.75mm

4.0mm

5.0mm

CMH - HEXAGONAL MORSE TAPER

CMH - HEXAGONAL MORSE TAPER

MORSE TAPER

MORSE TAPER

MODELS AND LENGTHS MODELS AND LENGTHS

HEXAGONALSLIM

HEXAGONAL

7.0

8.5

10

11.5

13

15

17

7.0

8.5

10

11.5

13

15

17

60.3308

60.3310

60.3311

60.3313

60.3315

60.3317

60.3708

60.3710

60.3711

60.3713

60.3715

60.3717

60.4007

60.4008

60.4010

60.4011

60.4013

60.4015

60.4017

60.5007

60.5008

60.5010

60.5011

60.5013

60.5015

03.3 Ø 3.75 Ø 4.0 Ø 5.0

SLIM

For 3.3 Other

This implant is connected with a connection driver internal hexagon.Its has fi t with contra-angle or Torque Wrench (ratchet).

26.5050 26.505126.5057 26.506026.5058 26.50611 - With the Badock take the implant to the grip

2 - Takeoff the badock

3 - Fix an internal hexagon connection driver

CAPTURE AND TRANSPORT OF IMPLANTDRIVERS

030201

HEXAGONAL MORSE TAPER_____________

technical specifications

Indicated OptionalApical Drilling

SW 2.5Ø 3.5

M 2.0

A

D

L

SW 2.5Ø 3.5

M 2.0

A

D

L

CMHCRESTAL LEVEL

TECHNICAL SPECIFICATIONS

SW 2.5Ø 3.5

M 2.0

A

D

L

Only available in not mounted version. Cover screw not included.

PROSTHETIC SOLUTIONS: A wide variety of pillars procuce

a great esthetic and prosthetic solutions for each case,

being single or multiple, cemented or screwed.

MATERIAL: Titanium grade IV.

SURFACE: Sandblasted Large grift Acid etching.SPEED DRILLING: 800 to 1200 rpm.ROTATION INSERT: 20 to 30 rpm.TORQUE INSERTION: 35 to 55 Ncm.

Versatile implant for migration from the external hexagon to the morse taper. The morse taper crestal level implants, combine the internal hexagon connection with the 40º angulation, that is the same angulation of the minipilar (multi-unit), when the prosthesis is screw. It allows the connection of a protocol prosthesis directly on the implant, having the same prosthetic and surgical procedures of the external hexagon.It has trapezoidal threads on the internal profile, and cylindrical threads on the external profile, and double micro-threads on the third incisal region, allowing to be supported on cortical bone.Loading for bone level or submerged bone.

øD øA L3.75 2.7 4.04.0 3.0 4.04.3 3.3 4.05.0 4.0 4.0

63

SEQUENCE OF DRILLS

3.8mm

Spea

r / s

crew

2

Pilo

t 2.0

/ 3.

0

Drill

2.8

Drill

3.0

Drill

3.1

5

Pilo

t 3.0

/ 3.

8

Drill

3.3

Drill

3.5

Drill

3.8

Drill

4.3

Coun

ters

ink

5.0

4.0mm

4.3mm

5.0mm

CRESTALLEVEL

MODELS AND LENGTHS

CRESTALLEVEL

7.0

8.5

10

11.5

13

15

60.3807C

60.3808C

60.3810C

60.3811C

60.3813C

60.3815C

60.4007C

60.4008C

60.4010C

60.4011C

60.4013C

60.4015C

60.4307C

60.4308C

60.4310C

60.4311C

60.5007C

60.5008C

60.5010C

60.5011C

Ø 3.8 Ø 4.0 Ø 4.3 Ø 5.0

Note 1: The last drill doesn’t need to punch the entire height, use one before the last measure. Note 2: for cortical bones type I and II, may use the selected drill with 3mm depth to avoid the implant lock because micro threads.

This implant is connected with a connection driver internal hexagon.Its has fi t with contra-angle or Torque Wrench (ratchet).

1 - With the Badock take the implant to the grip

2 - Takeoff the badock

3 - Fix an internal hexagon connection driver

CAPTURE AND TRANSPORT OF IMPLANTDRIVERS

030201

HEXAGONAL MORSE TAPER_____________

technical specifications

Optional

See item 2

Indicated

Apical Drilling

26.5051 26.5060 26.5061

64

Code

61.3301

Code

61.3300

Code

69.3301

Code

69.3300

2

3

4

6

2

3

4

8

3.3

3.3

3.3

3.3

4.0

4.0

4.0

4.0

69.3332

69.3333

69.3334

69.3336

69.3342

69.3343

69.3344

69.3348

Height Profile Code

Height Profile Code

Cover Screw

Analog

Open tray impression transfer

Closed tray impression transfer

Straight healing cap

Anatomical healing cap

O’ring abutment

3.3

CMH 3.3 - SLIM

1

2

3

1

2

3

4

5

62.3341

62.3342

62.3343

62.3344

62.3345

Height Code

Straight abutment

4

4

4

64.3301N

64.3302N

64.3303N

Height Profile Code

Anatomical abutment

1.210 Ncm

1.330 Ncm

1.330 Ncm

2.430 Ncm

1.2

1.210 Ncm

1.210 Ncm

1.220 Ncm

1.220 Ncm

Code

3.3350

Lab prosthetic screw

3.3310

3.3300

Code

Lab prosthetic screw

1 3.3 65.3312

Height Profile Code

PROSTHETIC LINEHEXAGONAL MORSE TAPER - SLIM

PROSTHETIC SOLUTIONSOVER IMPLANT