DSMAC PYG SERIES HYDRAULIC CONE CRUSHERfrom small portable plants, PY cone crushers provide...

Transcript of DSMAC PYG SERIES HYDRAULIC CONE CRUSHERfrom small portable plants, PY cone crushers provide...

Capacities exceeding 600 tph

High-production, low-maintenance, with the latest in cone crusher technology

Aggregates production and mines

Secondary, tertiary and fine crushing stages

Hard rocks, ores and minerals.

DSM

AC PYG SERIES H

YDRAU

LIC CON

E CRUSH

ER

PRODUCT BRIEF INTRODUCTION

2

The hydraulically adjusted PYG cone

crushers are characterized by robust design

and high performance. A combination of

Constant Liner Performance crushing

chambers and high motor power give these

crushers very high capacity. the PYG Series

Hydraulic Cone Crusher combines the

highest crushing efficiency and end product

quality with the lowest per ton production

costs.

PYGD-0909 Hydraulic Cone Crusher in Nigeria.

PYGB-1415×2 Hydraulic Cone

PYGD-0909 Hyd rau l i c Cone

3

MAIN CUSTOMOF THE PYG SE

ER BENEFITS RIES CONES

DSMAC PY Series -fulfilling all your

crushing needs

From limestone to taconite, from ballast

production to manufactured sand, and

from small portable plants, PY cone

c r u s h e r s p r o v i d e u n b e a t a b l e

performance in secondary, tertiary, and

quaternary applications.

High performance - low operating

costs

The choke feed arrangement is set by

simply choosing the correct stroke for the

PYG cone crusher – the most efficient

crushing action is easily achieved. use of

high quality components with optimized

wear parts keep operating costs down.

The DSMAC PYG cone crusher is the

right machine to maximize your

profitability.

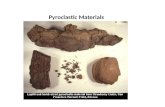

Forging process of Mantle and Concave

DSMAC PY Series - fulfilling all your crushing needs

4

Easy adjustment for production requirements

Several standard crushing chambers are

available for each model. The crushers can easily

be matched to changes in production by the

selection of crushing chamber and eccentric

throw. The chambers available are:

EF = Extra fine

F = Fine

MF = Medium fine

M = Medium

C = Coarse

EC = Extra coarse

Total control of crusher and process

The automation unit guarantees constant choke

feeding. It also improves the liner utilization rate

and thus the end product quality by promoting

inter-particle crushing. The automation system

keeps crushing at maximum operational limits and

within safety margins.

Little dust and low noise levels

Equipped with dust-cleaning apparatus water

tank, in order to reduce the noise, damping layer is

filled in the interlayer between the upper body and

the lower body. All this combines to create a safer

and cleaner working environment.

Life cycle services -adding customer value

E a s y a d j u s t m e n t f o r production requirements

Dynamic AdjustTM system,

allows adjustments under

load and remote control.

Head skirt protects

counterweights and seals.

Internal counterweights

enable the crusher to

be balanced at all times.

Maintenance-free overload

relief manifold

and valve.

Optional hydraulic anti-spin

system reduces manganese

liner wear, requires no resetting or maintenance.

External locking

cylinders are accessible

for maintenance.

Large crusher feed opening

yields high performance.

Long inner and outer bronze

sleeves allow radial crushing

forces to be distributed over a wide area.

Countershaft assembly

uses tapered bearings

to reduce end play and

extend gear life.

Easily replaceable frame

liner, frame-arm liner and

countershaft box liners offer

decades of protection.

Eccentric and thrust roller

bearings create cam and

lever crushing action.

Labyrinth seal and piston

ring provide a dual sealing

system, keeping oil clean

and reducing wear.

CRUSHER FEATURES & BENEFITS

5

CRUSHING COMPONENTSMechanical Sealing The internals of the Rockstar are fully protected by an advanced sealing arrangement, comprising upper and lower piston rings and twin banks of upper and lower replaceable labyrinth seals.

EccentricThe eccentric is steel casting machined on special fixtures to achieve the optimised throw to maximise production and product shape. The unit is jig drilled to accommodate the rotary seal ring and gear.

All Roller Bearing ConstructionThe Rockstar is equipped with a proven combination of Taper and radial roller bearings. These provide long trouble free service, and minimise friction losses. Utilising these generously proportioned heavy duty bearings also eliminates the need for a large oil tank and ensures consistently accurate alignment of gears, sealing rings and the crushing members themselves.

Cone headThe cast steel cone head in machined internally to accept a large capacity taper roller bearing, and a top radial roller bearing. Externally the lower section is machined to accept the mantle and shaped to allow plastic metal backing to be poured behind the mantle during re-metals.

Concave Support BowlThe cast steel concave support bowl is accurately machined to support the concave ring and is shaped to receive a plastic metal backing for the crushing member. Is lower face is provided with a machined tapered face to form a locked engagement with the upper frame.

Mantle and ConcaveBoth mantle and concave are cast from high grade manganese steel. The both parts are machined to ensure accurate location in their mating parts.

MainshaftThe mainshaft is an alloy-steel forging, fully heat treated for strength. The lower section of the shaft is shrunk into the central boss of the mainframe whilst the upper section is machined and ground to carry the roller bearings.

Gear and PinionThe machine cut bevel gear and pinion are manufactured form alloy steel forgings, the teeth of both c o m p o n e n t s a r e i n d u c t i o n hardened to ensure long life. The pinion is located on the counter shaft by a special locking ring, and the gear is keyed and capscrewed to the eccentric.

Induction hardening of gear teeth provides both enhanced resistance to wear and greatly improves fatigue resistance.

6

PYG SERIES CONE CRUSHER SPECIFICATIONS

7

Type Model

Ф900

PYGB-0913

PYGB-0916 Standard medium type 18-38 132 145-250

PYGB-0921 Standard coarse type 22-38 178 155-250

PYGD-0907 Short coarse type 80-220

PYGD-0909 Short head medium type 10-25 90-220

PYGD-0912 Short head coarse type 12-25 100 120-220

PYGB-1114 Standard fine type 16-45 115 180-445

PYGB-1121 Standard medium type 20-45 180 200-445

PYGB-1124 Standard coarse type 26-45 200 230-445

PYGD-1107 Short coarse type 120-220

PYGD-1110 Short head medium type 12-25

PYGD-1112 Short head coarse type 14-25 105 120-220

120-220

PYGB-1415 Standard fine type 16-50 130 225-620

PYGB-1420 Standard medium type 22-50 170 270-620

PYGB-1433 Standard coarse type 26-50 280 300-620

PYGD-1408 Short coarse type 115-370

PYGD-1411 Short head medium type 10-25 140-370

PYGD-1414 Short head coarse type 12-25 115 180-370

PYGB-1518 Standard fine type 19-50 152 320-725

60

76

60

82

68

90

Ф1500

Ф1400

Ф1100

Weight (kg)

Dimension (L×W×H)(mm)

220 18500 2520×2620×2400

315 29700 3106×3170×2945

400 38800 3405×3480×3196

Chamber Type

Diameter of Large End

of Crushing Cone (mm)

Adjustable Range of

Discharge Opening

(mm)

Max FeedSize

MotorPower(kw)

Standard fine type

950

14-38 110 130-250

160 17000 2007×2225×1950 8-25

Capacity(t/h)

8-25 1100

8-25

1400

1500

Questionnaire

To enable us to quote for equipment relative to your particular requirements, it will

greatly assist us if all essential information is supplied with the initial enquiry. For

your guidance we tabulate the information required :

Material ..................................................................

Material hardness, or chemical content? ............................................

Feed size ? (mm) ................................................

Your required output size? (mm) ....................

Capacity required in tonnes / hour ...........................

For more requirement, you can send to me now, or later, to our expert mail

scanning the code above and then entering the website

ZHENGZHOU DINGSHENG ENGINEERING TECHNOLOGY CO.,LTD

ADDRESS:National HI-TECH Industry Unit B Torch Building, Zhengzhou,China.

TEL:0086-371-67897103 0086-371-53738757

FAX:0086-371-60535395 0086-371-65948723

SKYPE:dscrusher

Email:[email protected]

WEBSITE:www.dscrusher.com