Dry Gas Seals Type 28

description

Transcript of Dry Gas Seals Type 28

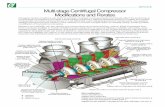

■ Temperature: -140°C to 315°C/-220°F to 600°F■ Pressure: Up to 450 BARG/6,500 PSIG across

single stage■ Speed: Up to 200 m/s / 660 fps■ Shaft: Up to 330 mm/13 in.

Performance Capabi l i t ies

Design Features■ Shrouded mating ring prevents secondary damage in

the event of a mating ring fracture.■ Low-level leakage can be vented to a safe area, used as

fuel to drive equipment, or returned to process via alow-pressure ejector.

28AT/

28X

P/2

8EX

P

Product Descript ionType 28 compressor dry-running gas seals have been theindustry standard since early 1970 for gas-handling turbomachinery. Utilizing John Crane's patented spiralgroove pattern, these seals are non-contacting in operation.■ During dynamic operation, the mating ring/seat and

primary ring/face maintain a sealing gap of approximately0.0002 in./5 microns, thereby eliminating wear.

■ These seals eliminate seal oil contamination and reducemaintenance costs and downtime.

■ Single, double opposed, and tandem cartridge seals arecapable of handling a wide variety of gas sealingapplications in the gas collection/transmission, refining,chemical and petrochemical processing industries.

TYPE 28 Compressor SealsDry-Running, Non-Contacting Gas Seals

Optional Bidirectional Groove DesignStandard Unidirectional Groove Design

*Contact [email protected] for more information about exact application requirements.

Type

28A

T Ta

ndem

Arr

ange

men

t

Inle

t for

Filt

ered

Proc

ess

Gas

Outle

t for

1st

STA

GELe

akag

e an

dSe

para

tion

Gas

Outle

t for

2nd

STA

GELe

akag

e an

dBa

rrie

r Gas

Barr

ier G

asSu

pply

1st S

TAGE

2nd

STAG

E

MAT

ING

RING

MAT

ING

RING

PRIM

ARY

RING

PRIM

ARY

RING

BEAR

ING

CAVI

TYPR

OCES

SGA

S

Inle

t for

Sep

arat

ion

Gas

(Opt

iona

l)

O-Ri

ng S

econ

dary

Sea

l

*Typ

ical

App

licat

ion

pres

sure

s up

to 1

,800

PSI

G/12

5 BA

RG

Proc

ess

Gas

Laby

rinth

Inte

rsta

ge L

abyr

inth

Type

82

Barr

ier S

eal

28AT/28XP/28EXPTY

PE

28

AT

Com

pres

sor

Sea

lsD

ry-R

unnin

g,

Non-C

onta

cting G

as S

eals

1st S

TAGE

2nd

STAG

E

MAT

ING

RING

MAT

ING

RING

PRIM

ARY

RING

PRIM

ARY

RING

BEAR

ING

CAVI

TY

Inle

t for

Filt

ered

Proc

ess

Gas

Outle

t for

1st

STA

GELe

akag

e an

dSe

para

tion

Gas

Outle

t for

2nd

STA

GELe

akag

e an

dBa

rrie

r Gas

Barr

ier G

asSu

pply

Inle

t for

Sep

arat

ion

Gas

(Opt

iona

l)

PROC

ESS

GAS

Proc

ess

Gas

Laby

rinth

Inte

rsta

ge L

abyr

inth

Poly

mer

Sec

onda

ry S

eal

*Typ

ical

App

licat

ion

pres

sure

s up

to 3

,000

PSI

G/20

0 BA

RG

Type

82

Barr

ier S

eal

Type

28X

P Ta

ndem

Arr

ange

men

t

28AT/28XP/28EXPTY

PE

28

XP C

ompr

esso

r Sea

lsD

ry-R

unnin

g,

Non-C

onta

cting G

as S

eals

Type

28E

XP T

ande

m A

rran

gem

ent

BEAR

ING

CAVI

TYPR

OCES

SGA

S

1st S

TAGE

2nd

STAG

E

MAT

ING

RING

MAT

ING

RING

PRIM

ARY

RING

PRIM

ARY

RING

Inle

t for

Filt

ered

Proc

ess

Gas

Outle

t for

1st

STA

GELe

akag

e an

dSe

para

tion

Gas

Outle

t for

2nd

STA

GELe

akag

e an

dBa

rrie

r Gas

Barr

ier G

asSu

pply

Inle

t for

Sep

arat

ion

Gas

(Opt

iona

l)

Proc

ess

Gas

Laby

rinth

Inte

rsta

ge L

abyr

inth

Adva

nced

Pol

ymer

Sec

onda

ry S

eal

Type

82

Barr

ier S

eal

*Typ

ical

App

licat

ion

pres

sure

s up

to 6

,500

PSI

G/45

0 BA

RG

28AT/28XP/28EXPTY

PE

28

EXP C

ompr

esso

r Sea

lsD

ry-R

unnin

g,

Non-C

onta

cting G

as S

eals

5

4

3

2

1

0

Pow

er (K

W)

6.0

5.0

4.0

3.0

2.0

1.0

02.187 3.187 4.187 5.187 6.125 7.125 8.125 9.125 10.125

50 100 150 200 250

Seal Size

Pow

er (H

P)

(inches)

(mm)

Conditions: Air, 140°F/60°C

10,000 rpm; 69 BARG/1,000 PSIG

10,000 rpm; 7 BARG/100 PSIG

5,000 rpm; 7 BARG/100 PSIG

5

4

3

2

1

0

Leak

age

(SCF

M)

125

100

75

50

25

02.187 3.187 4.187 5.187 6.125 7.125 8.125 9.125 10.125

50 100 150 200 250

Seal Size

Leak

age

(sl/m

in)

(inches)

(mm)

Conditions: Air, 83 BARG/1,200 PSIG

5,000 rpm

10,000 rpm15,000 rpm

5

4

3

2

1

0

Leak

age

(SCF

M)

125

100

75

50

25

0

0 200 400 600 800 1,000 1,200

80

Pressure

Leak

age

(sl/m

in)

(PSIG)

(BARG)

Conditions: 6.187-inch Diameter Seal, 14,000 rpm

0 20 40 60

Hydrogen, 38°C/100°FMethane, 38°C/100°FAir, 38°C/100°FAir, 150°C/300°F

TYPE 28 Compressor SealsDry-Running, Non-Contacting Gas Seals

Size and Speed E f fect on Leakage

Pressure, Temperature and Gas E f fect on Leakage

Gas Seal Power Consumpt ion

*This information should not be used for specification purposes. Contact [email protected] for more information about exact application requirements.

TYPE 28 Compressor SealsDry-Running, Non-Contacting Gas Seals

Typica l S ing le Seal Arrangement and Seal Support System

Typica l Double Opposed Seal Arrangement and Seal Support System

Typica l Tandem Seal Arrangement and Seal Support System

*Single Seal Arrangement for applications not requiring a safety back-up seal.

*Tandem Seal Arrangement for applications requiring a safety back-up seal.

For your nearest John Crane facility, please contact one of the locations above.

If the products featured will be used in a potentially dangerous and/or hazardous process, your John Crane representative should be consulted prior to their selection and use. In the interest of continuous development, John Crane Companies reserve the right to alter designs and specifications without prior notice. It is dangerous to smoke while handling products made from PTFE. Old and new PTFE products must not be incinerated.

©2002 John Crane Inc. Print 2/02 www.johncrane.com ISO-Certified QS 9000 S-28AT/28XP/28EXP

*For more information contact [email protected]

EuropeSlough, UK

Tel: 44-1753-224000Fax: 44-1753-224224

North AmericaMorton Grove, Illinois USA

1-800-SEALINGTel: 1-847-967-2400Fax: 1-847-967-3915

Latin AmericaSão Paulo, Brazil

Tel: 55-11-3371-2500Fax: 55-11-3371-2599

Middle East, Africa, AsiaDubai, United Arab Emirates

Tel: 971-4-3438940Fax: 971-4-3438970

VENTVENT

JOHN CRANE GAS SEALS

VENTVENT

JOHN CRANE GAS SEALS

EXTERNAL SUPPLY

APPROVED VENTVENT

JOHN CRANE GAS SEALS

APPROVED VENT VENT

*Double Seal Arrangement where hazardous gas is not permissible to leak into atmosphere.