Driving GPC/SEC ForwardPSS supplies certified standards that meet the requirements of DIN 55672 and...

Transcript of Driving GPC/SEC ForwardPSS supplies certified standards that meet the requirements of DIN 55672 and...

Driving GPC/SEC Forward

Reference Materials & LC Columns

Driving GPC/SEC Forward

PSS GmbH was founded in 1985 by 2 PhD students at the Physical Chemistry Department, University of Mainz, Germany,

producing polymer standards at the University facilities. The following years PSS expanded staff and products includ-

ing tailor-made polymers, organic and aqueous GPC/SEC columns, GPC/SEC software and moved 2001 to own facilities

located in Mainz, Germany. PSS-USA opened its office in Houston, Texas in 1994, moved to Silver Spring, Maryland, in

1995 and since 2003 operates from Warwick, Rhode Island. To date, PSS has successfully gained leadership in the over-

all GPC/SEC market, making innovative contributions not only in Germany and the USA, but around the world.

PSS is fully dedicated to the advancement of macromolecular liquid chromatography, by means of materials design,

synthesis, manufacturing, consulting, service, and innovative research, applying the highest standard of expertise and

reliability. Our close relationship with our costumers has helped us to continuously improve the quality of our products

and services. Our high caliber staff, mostly chemists, is experienced, creative and trained in problem solving. Corpora-

tions, universities, and organizations in more than 60 countries use our products and profit from our outstanding

service and know-how.

Certified DIN ISO EN 9001

PSS is certified (DIN ISO EN 9001:2008) to produce high quality reference polymers, GPC/SEC columns and

software for the characterization of polymers by their molecular weight and their structural character-

istics. PSS employs the latest findings in polymer science for the synthesis and characterization of

polymers, block copolymers and biopolymers. PSS operates manufacturing facility equipped with a

complete state-of-the-art characterization laboratory at the headquarters in Mainz, Germany, fully

supporting customers working under stringent requirements i.e., GLP, DIN, ISO certifications.

About PSS

About this catalog

This catalog contains the most frequently ordered consumables.

Please refer to the website for a comprehensive listing of our products.

Contact us to inquire about custom materials or services.

ContactPSS Polymer Standards Service GmbH

In der Dalheimer Wiese 5

D-55120 Mainz, Germany

Phone: +49 6131 96239-0

Fax: +49 6131 96239-11

www.polymer.de

PSS-Polymer Standards Service – USA Inc

43 Jefferson Blvd. Suite 3

Warwick, RI 02888 USA

Phone: (401) 780 8884

Fax: (401) 780 8824

www.pssgpcshop.com

Contents

1| Molecular Weight Reference Polymers 4

1.1. Polydispersity 4

1.2. Methodology for Characterization Levels 4

1.3. Polymer Part Numbers Deviation 5

1.4. Permanent and Temporary Standards Stock 6

1.5. Specialty Polymers 6

1.6. Polymer Standards Handling 6

1.7. Warranty 7

2| Polymer Standards Temporary Stock and Specialty Polymers 8

2.1. Specialty Polymer 8

3| Polymer Standards Permanent Stock 9

3.1. Organic Standards 9

3.2. Aqueous Standards 12

4| Assembled Kits of Molecular Weight Standards 14

4.1. GPC/SEC Calibration Kits 14

4.2. Organic Standards 14

4.3. Aqueous Standards 16

4.4. ReadyCal Kits 18

4.5. DIN Kits 19

4.6. MALDI Validation Kits 20

4.7. Light Scattering/Viscometry Validation Kit 20

5| Standards for Membrane Characterization 21

6| GPC/SEC System Suitability Test with PSS EasyValid Validation Kit 22

7| Successful GPC/SEC Separation 23

8| GPC/SEC Columns Powerful solutions for size separation 24

8.1. Column Selection 24

8.2. Advantages of PSS Column Technology 26

8.3. Column Order Deliverables 26

8.4. Column Handling 27

8.5. Warranty 28

9| Columns for Organic Solvents 29

9.1. SDV Columns 29

9.2. GRAM Columns 32

9.3. PFG Columns 33

9.4. POLEFIN Columns 34

10| Columns for Aqueous Columns 35

10.1. SUPREMA Columns 35

10.2. NOVEMA Columns 37

10.3. MCX Columns 38

10.4. PROTEEMA Columns 39

11| GPC/SEC Application Guide 40

12| Summary of PSS Columns Specifications 42

4 Reference Materials & LC Columns4

PSS is one of the world‘s largest manufacturers of ref-

erence polymers copolymers, and customer-designed

polymers. A great selection of polymer types in a wide

range of molar masses is produced regularly.

The PSS reference materials are characterized extensively

by modern analytical methods. They are available in vari-

ous characterization levels: GPC, DIN Certified Standards,

MALDI validation standards, Light Scattering, Viscometry

and Certified Reference Materials. Their suitability for a

given application depends on the polydispersity, or the

level of characterization. Reference polymers come as

individual standards or assembled into kits. The kit com-

ponents are carefully selected to cover given molecular

weight ranges to establish calibration curves.

1| Molecular Weight Reference PolymersFor broad standards the Mp value is a function of the col-

umn resolution and therefore not defined.

Broad standards are characterized by Mw and Mn.

Modern GPC/SEC software packages allow the construc-

tion of a calibration curve by the use of Mw, Mn or the

intrinsic viscosity [η] of broad standards.

Up to 8 different broad standards can be used and

only one of the Mn, Mw, or [η] values is nescessary.

Broad standards are used:

• to validate a chromatographic system

• to determine physical constants such as the Mark-

Houwink constants K and a.

• to construct a calibration curve

• to proof a column missmatch.

1.1.1. Methodology for Characterization Levels

PSS uses GPC/SEC to obtain molecular weight values,

which are subsequently confirmed by alternative meth-

ods; e.g., Laser Light Scattering, Viscometry, MALDI-ToF,

VPO and NMR. Each product comes with a Quality

Certificate, which provides the characterization informa-

tion. The signed Quality Certificates include the testing

parameters, the molecular weight values (Mn, Mw, Mp,

PDI) and usually the chromatogram with the parameters

(conditions) at which the data was obtained.

GPC

/SE

C St

anda

rds

PSS Polymer standards in the stock are analyzed via GPC/SEC, yielding Mn, Mw, Mp and the polydispersity (PDI = Mw /Mn ).

DIN

cer

tifi

ed S

tand

ards

PSS supplies certified standards that meet the requirements of DIN 55672 and ISO/EN 13885. Also the PSS Quality Certificates fulfill all DIN and ASTM requirements.

PSS documents the molecular weight using GPC and additonal methods such as Light Scattering, MALDI-Tof, NMR, Viscometry or VPO.

1.2. Methodology for Characterization Levels

PSS uses GPC/SEC to obtain molecular weight values,

which are subsequently confirmed by alternative

methods; e.g., Laser Light Scattering, Viscometry, MALDI-

ToF, VPO and NMR. Each product comes with a Quality

Certificate, which provides the characterization informa-

tion. The signed Quality Certificates include the testing

parameters, the molecular weight values (Mn, Mw, Mp,

PDI) and usually the chromatogram with the parameters

(conditions) at which the data was obtained.

1.1. Polydispersity

In principle the distinction of broad and narrow standards

is based on the PolyDispersityIndex, PDI = Mw/Mn.

Narrow Standards

Narrow polymer standards are made by living ionic

polymerization techniques or by fractionation of very

broad standards. All narrow standards have small poly-

dispersities with sharp and slim chromatogram profile.

The Mp value is well defined and independent of the col-

umn resolution.

TIP: Mp (molar mass at the peak maximum) is the only

well defined point in the chromatogram and so far dedi-

cated in order to construct a calibration curve.

Narrow standards are defined by average molar mass

values such as Mn (Number average molar mass) and Mw

(Weight average molar mass).

Mn and Mw are well established values to define the

molar mass distribution of a polymer.

The construction of the calibration curve in GPC is based

on the Mp values of the polymers in a calibration kit,

e.g., an ensemble of polymers of the same type but dif-

ferent molar masses.

Broad Standards

Broad reference materials are made by radical polymeri-

zation, polycondensation or coordinative polymerization

(polyolefins). The PDI of broad standards is usually >1.5.

5

MA

LDI

Stan

dard

s

PSS MALDI standards are suitable for the validation and comparison of MALDI instruments. PSS provides MALDI spectra including Mw, Mn and Mp values of selected narrow polymers, which differ in molar mass and polymer type (polarity). Furthermore the quality certificate comes with GPC data (Mw, Mn and Mp) and molar mass information of one more absolute method such as NMR, Light Scattering, Viscometry, VPO (depending on polymer type and molar mass).

The Quality Certificate includes the GPC parameters as well as condi-tions and values of MALDI-ToF measurements.

Polymer Standards Service GmbH Polymer Standards Service USA, IncIn der Dalheimer Wiese 5 D-55120 Mainz 43 Jefferson Blvd. Suite 3 Warwick, RI 02888 USATel.: +49 (0) 6131-96239-0 Fax: +49 (0) 6131-96239-11 Phone: +1 401-780-8884 Fax: +1 401-780-8824Email: [email protected] www.polymer.de Email: [email protected] www.pssgpcshop.com

Certificate of Analysis

Manufacture and control according to PSS method of analysis

Dr. T. Hofeproduction director

Storage: Store the tightly recapped polymer standard in a dry, dark, cool area;e.g. a refrigerator (4 °C).Expiration date: 5 years after purchase date provided standard is stored asdescribed above.Purchase date:

Note:Mw = Weight average molecular weightMn = Number average molecular weightMp = Molar mass at the peak maximumPDI= Polydispersity Index

Polymer type: Poly(styrene)Part No: PSS-mps1.5kLot No: ps24040ma

Molar Mass Distribution

0.5

1.0

1.5

2.0

2.5

3.0

3.5

Molar mass [Da]

1*10 2 1*10 3 1*10 4

W(lo

g M

)

PSS

Win

GP

C U

nity

, Bui

ld 6

727,

LA

B_P

RO

D3,

Inst

anz

#1

GPC/SEC - Conditions

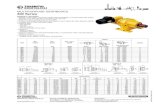

Sample concentration 1,00 g/lSolvent THFPrecolumn [8 x 50 mm] PSS SDV 5µmColumns [analytical, each 8 x 300 mm] PSS SDV 5µm 10e3Å / 10e5Å / 10e6ÅData Acquisition Software PSS WinGPC

Inject volume 20 µlFlow rate 1,00 ml/minTemperature 23 °C

Operator S. Fugmann

GPC/SEC - Results

Detector Mw [Da] Mn [Da] Mp [Da] PDI [Mw/Mn]

MALDI-ToF - Results

1 550Mw [Da] Mn [Da]

1 480Calculated Mw, MALDI = Mn MALDI x (Mw/Mn) GPC

Shodex RI 71 1380 1320 1 370 1,05

Ligh

t Sc

atte

ring

/Vi

scom

etry

Sta

ndar

ds

PSS Light Scattering/ Viscometry Standards are suitable for the easy, fast and exact valida-tion and data comparison of Light Scattering and Viscometry instru-ments. PSS provides GPC, Light Scattering and Viscometry data for various narrow and broad distributed polymers.

The Quality Certificate includes the molar mass averages of different methods the GPC parameters as well as conditions of Light Scattering (LS) and/or Viscometry (Visco) measurements.

Custom Request Polymerizations, Specialty Polymers

and Polymer Networks

PSS masters a wide variety of different polymerization

techniques, thus we can synthesize almost all kinds of

homopolymers, functionalized homopolymers, copoly-

mers and polymer networks.

Polymerization bases include but are not limited to:

• Acrylate, Methacrylate

• Styrene

• Diene

• Vinyl

• Isobutylene

• Ethlyleneoxide

Synthesis techniques include but are not limited to:

• Ionic polymerization (anionic, cationic)

• Radical polymerization

• Suspension polymerization

1.3. Polymer Part Numbers Deviation

Polymer Part Numbers reflect the nominal

“Weight Average Molecular Weight” of the polymer.

Unless otherwise specified, the actual molecular weight

of a polymer shipped may vary from the nominal

mostly within a range of ±10% Molecular Weight

deviation of the listed value;

e.g. part number PSS-ps700 will have an actual Mw that

is somewhere within the range of 630 - 770 Da.

Exact values appear in the label of the vial and Quality

Certificate.

1 Characterization of Polymer Reference materials

Classification of Polymer Standards

Characterization MethodsAvailable as

Individual

Standard Kit

GPC organic and aqueous

GPC 4 4

DIN certified GPC + absolute method* 4 4

CRMGPC + Light Scattering

+ Viscosity and physical onstants (round robin test)

4

LS/Visco ValidationGPC + Light Scattering +

Viscosity 4

MALDI ValidationGPC + MALDI + Absolute

method* 4

ReadyCal GPC 4

Specialty polymers: Deuterated Highly tactic, etc.

GPC 4

Polymer Standards Service GmbH Polymer Standards Service USA, IncIn der Dalheimer Wiese 5 D-55120 Mainz 43 Jefferson Blvd. Suite 3 Warwick, RI 02888 USATel.: +49 (0) 6131-96239-0 Fax: +49 (0) 6131-96239-11 Phone: +1 401-780-8884 Fax: +1 401-780-8824Email: [email protected] www.polymer.de Email: [email protected] www.pssgpcshop.com

Certificate of Analysis

Polymer type: Poly(styrene)Part No: PSS-mps1.5kLot No: ps24040ma

MALDI-ToF - Conditions

MALDI-ToF - Plot

Page 2 of 2

Instrument: Hewlett-Packard G2030AShots: 250Matrix: DithranolMonomer repeat units: 104 DaPolymer endgoups: C2H5-(CH)-CH3- / HSide products: none

Comment:Please note, that for some reasons (reslution, detection, matrix, counterion) the weight average molecular weight and the number average molecular weight-values for synthetic polymers, measured by MALDI-ToF, do not represent the true molecular weight distribution of the polymer.

Cert

ifie

d Re

fere

nce

M

ater

ials

CRM

Certified Reference Materials (CRM) are highly characterized polymers certified by German Federal Institute for Material Research and Testing (BAM). Their reported molar mass result from round robin experiments at certified laboratories. The CRM’s quality certificates are full reports with the results of the different characterization methods: GPC, Light Scattering and Viscometry. Further, the certificate includes additional non-certified data, (MALDI-ToF; NMR; DSC and in some instances Rheology data) to provide the most sophisticated set of documentation for a particular polymer available worldwide.

Polymer Standards Service GmbH Polymer Standards Service USA, IncIn der Dalheimer Wiese 5 D-55120 Mainz 43 Jefferson Blvd. Suite 3 Warwick, RI 02888 USATel.: +49 (0) 6131-96239-0 Fax: +49 (0) 6131-96239-11 Phone: +1 401-780-8884 Fax: +1 401-780-8824Email: [email protected] www.polymer.de Email: [email protected] www.pssgpcshop.com

Only one page available; The complete documentation will be delivered with the product.

Certified Reference Material

BAM-P001

Poly(styrene)(PS)

Batch No.: ps2088

CH3

CH3

CH3

C CH2 CH H

n

6 Reference Materials & LC Columns

Samples Preparation for GPC Analysis

1. Prepare fresh standard solutions to assure accurate

concentrations. Precise concentration values are

required when using Light Scattering, Viscometry or

Triple Detection systems.

2. Select the appropriate clean dissolution container

(autosampler vial, bottle, flask, etc.).

3. Add an appropriate quantity of sample using an

analytical balance.

Start with the concentrations provided in table 2 as

guideline.

Select your working concentration based on detection

type and number of columns in use.

The moisture content should be determined before

starting any measurements

Dry the polymer if necessary.

Its variability depends on several parameters

(e.g. surface, molecular weight, sample preparation,

storage conditions, etc.).

4. Adjust the desired sample concentration by an exact

weight. Add the solvent volume accurately.

5. Note: If you use an internal standard for flow rate

monitoring, mix it with a fraction of mobile phase in

a separate container. Use the marked solvent to pre-

pare your standards. Do not add it into the general

solvent bottle.

TIP: The internal standard should be monodisperse, and

elute after the separation limit.

6

1.4. Permanent and Temporary Standards Stock

PSS offers permanent and temporary stock of reference

materials. The stock of permanent materials is renewed

when a particular lot sells out whereas the temporary

part numbers will be only avalable while supplies last.

Production of temporary part numbers will be discontin-

ued.

Temporary Standards are listed in chapter 2, Permanent

Standards are listed in chapter 3 (starting from page 9)

and in chapter 4 (Kits starting from page 13).

Look up the Temporary Standards comprehensive list

at www.polymer.de. The listing is updated regularly.

1.5. Specialty Polymers

Specialty Polymers are polymers, which are not poly-

merized as “classical reference materials” regarding to

molar mass variation. The term “Specialty Polymers”

includes all different kinds of copolymers and functional-

ized or deuterated polymers. They are also offered on a

temporary basis. Please visit our website

www.polymer.de for an updated list.

TIP: PSS will tailor Specialty Polymers exhibiting new

topologies or novel properties, in close co-operation with

our customers. Call us for a consultation and a personal

quotation.

Copolymers

PSS offers a multitude of different copolymers. The offer

contains various topologies, compositions, architectures

as well as deuterated and partly deuterated products.

For an extensive list of our actually available copolymers

please visit our website www.polymer.de. The list is

constantly extended by new products.

1.6. Polymer Standards Handling

Storage of Polymer Standards

Store the standards in a dry, dark, cool area; e.g. a

refrigerator (4oC), and tightly recapped. This keeps

excessive moisture away and increases the standard

shelf life.

WARNING: Do not store standards exposed to direct sun-

light (windowsill or shelf near windows), to prevent

sample degradation over time. This condition is critical to

Poly(isoprene), Poly(butadiene) and other temperature

and/or light sensitive polymers.

TIP: Use only freshly prepared solutions and use them up

within two days. Solutions may be stored in the refriger-

ator temporarily.

WARNING:

Do not freeze standards in solution; freezing can destroy

the sample.

7

6. Close or seal the dissolution container and let sit at

room temperature for 24 hours or overnight for com-

plete dissolution.

TIP: Let polymers of Mw < 200 000 Da, sit for 3-4 hours.

Ultra High Molecular weight standards and samples

>2 000 000 Da may take from 1-3 days to dissolve

completely.

7. Gently swirl the vials for a homogeneous solution.

WARNING: Do not use stir bars, ultrasonic baths, micro-

wave heating or harsh shaking as this can cause sample

degradation.

8. Standard Mixes: It is possible to dissolve up to four

standards of the same type in a given dissolution

container. If you make your mixture, the individual

standards molecular weight must be separated by

orders of magnitude to prevent coelution; e.g.

Poly(styrene): 5 000 Da, 50 000 Da, 500 000 Da.

PSS offers pre-made mixtures or kits that prevent

coelution (see ReadyCal-Kits). Note: separation will

depend on the column(s) you use.

TIP: When using a viscometer or Light Scattering detec-

tor, your standard mixture peaks must reach the baseline

between each standard injected in order for the standard

to be used in a calibration curve.

9. Inject each solution separately.

Start with the guideline below (Table 3) to develop

your optimum injection volume.

10. Ultra High Molecular Weight Samples

(Mw > 1 000 000 Da) elute best in low concentra-

tions, through columns of large particle (10µm,

20µm) and pore sizes.

Work at reduced flow rates (0.5 – 0.3 ml/min) and if

necessary increased injection volume. This reduces

the probability of sample degradation. Example:

3 Recommended Injection VolumeNumber of columns

(length 30 cm)Guideline injection volume

[µl]

4 - 5 and more 200 to 250

3 100

2 50

1 20

2 Recommended Sample ConcentrationMolecular Weight Range [Da] Concentration [g/l] or [mg/ml]

100 - 10 000 1 to 2

10 000 - 100 000 1 to 2

100 000 - 500 000 1 to 2

500 000 - 1 000 000 1 to 2

1 000 000 and above 0,5 or less

broad standards usally 4.0 - 5.0 mg/ml

Inject 100 µl of a solution of 0.1 g/l instead of 20 µl

of a solution of 0.5 g/l.

11. Use the measured Mp values of the standards to

construct a calibration curve.

1.7. Warranty

PSS Polymer Standards

Service offers the warranty for the standards according to

specifications given in the Quality Certificate under the

following circumstances:

1. Polymers shall be stored in a cool, dry and dark

environment.

2. Do not expose the standards to UV radiation.

3. Prevent undue stress including, but not limited to,

shaking, high-pressure filtration, ultrasound, and or

microwaves, during sample dissolution and/or actual

testing.

PSS will replace any sealed standard, which was stored

according to conditions mentioned above, within one

month of its purchase date. Consumable materials are

excluded from return and exchange when seal is broken.

8 Reference Materials & LC Columns8

2| Polymer Standards Temporary Stock and Specialty Polymers

2.1. Specialty Polymer

10 CopolymersExcerpt of the available copolymers:

Poly(styrene-b-methyl methycrylate)

Poly(styrene-b-n-butyl methacrylate)

Poly(styrene-b-vinylpyridine)

Poly(styrene-b-butadiene)

Poly(styrene-b-isoprene)

Poly(styrene-b-dimethyl siloxane)

Poly(styrene-b-alpha-methylstyrene)

Poly(styrene-b-acrylic acid)

Poly(styrene-b-ethylene oxide)

Poly(methyl methacrylate-b-n-butyl methacrylate)

Poly(methyl methacrylate-b-t-butyl methacrylate)

Poly(butadien-b-methacrylic acid)

Poly(isoprene-b-butadiene)

6 Deuterated PolymersPolymer Molar mass range [Da]

min. max.

Poly(butadiene-1.4-d6) 23 000 190 000

Poly(carbonate-d4) broad 50 000

Poly(dimethyl siloxane-d6) 5 000 25 000

Poly(methyl-methacrylate-d8) 4 000 580 000

Poly(para-methylstyrene-d10) 100 000

Poly(styrene-d3) 2 500 160 000

Poly(styrene-d8) 900 830 000

Poly(styrene sulfonate-d8) lithium salt 80 000 90 000

7 Polymers with Functional End groupPolymer Molar mass range [Da]

min. max.

Poly(butadiene-1.4) OH-end group 10 000

Poly(ethylene glycol) dimethylether 90 2 000

Poly(styrene) brominated 40 000 230 000

Poly(styrene) fluorescein labeled 600 5 000 000

Poly(styrene) sulfonated labeled 5 000 18 000

Poly(styrene) with deuterium end group 2 000 70 000

Poly(styrene) without initiator end group 2 000 60 000

Poly(styrene sulfonate-d8) lithium salt 80 000 90 000

9 Star PolymersPolymer Molar mass range [Da]

min. max.

Poly(isoprene-1,4) 3-star 30 000 150 000

Poly(styrene) 3-star 45 000 300 000

Poly(styrene) 8-star 120 000 230 000

4 Temporary Stock of Organic StandardsPolymer Molar mass range [Da]

min. max.

Nylon 6 broad 15 000 40 000

Nylon 6.6 broad 32 000 110 000

Poly(carbonate) broad 4 000 60 000

Poly(ethylene) broad 50 000 100 000

Poly(isoprene-3.4) 1 000 75 000

Poly(isopropyl methacrylate) 14 000 100 000

Poly(n-propyl methacrylate) 15 000 60 000

Poly(ortho-chlorostyrene) 100 000 300 000

Poly(para-methylstyrene) 3 000 800 000

Poly(propylene) 700 3 500

Poly(propylene) broad 6 000 350 000

Poly(vinyl acetate) broad 17 000 300 000

Poly(vinyl chloride) 42 000 300 000

Poly(vinyl pyrrolidone) broad 14 000 1 000 000

5 Temporary Stock of Aqueous StandardsPolymer Molar mass range [Da]

min. max.

Hydroxypropyl cellulose 12 000 60 000

Hydroxypropyl cellulose broad 30 000 900 000

Poly(2-vinylpyridinium bromide) 3 000 3 300 000

Poly(acrylamide) broad 3 500 9 000 000

Poly(DADMAC) 45 000 450 000

Poly(styrene sulfonate) sodium salt broad 100 000 500 000

Poly(styrene) without initiator end group 2 000 60 000

Poly(styrene sulfonate-d8) lithium salt 80 000 90 000

8 Highly Tactic PolymersPolymer Molar mass range [Da]

min. max.

Poly(methyl methacrylate) isotactic 5 000 60 000

Poly(methyl methacrylate) syndiotactic 8 000 400 000

9

3| Polymer Standards Permanent Stock

3.1. Organic Standards

11 Oligo(ethylene) monodispersePart Number Molar Mass [Da]* PDI Weight [mg]

PSS-oe72 72 1.00 1000

PSS-oe114 114 1.00 1000

PSS-oe200 200 1.00 1000

PSS-oe254 254 1.00 1000

PSS-oe340 340 1.00 1000

PSS-oe450 450 1.00 1000

PSS-oe500 500 1.00 1000

This catalog represents items available on a regular

basis and therefore, deliverable immediately.

12 Poly(2-vinylpyridine)Part Number Molar Mass [Da]* PDI Weight [mg]

PSS-pvp1k 1 000 <1.50 1000

PSS-pvp2.1k 2 100 <1.50 1000

PSS-pvp4.7k 4 700 <1.15 1000

PSS-pvp10k 10 000 <1.15 1000

PSS-pvp21k 21 000 <1.15 1000

PSS-pvp45k 45 000 <1.15 1000

PSS-pvp110k 110 000 <1.15 1000

PSS-pvp265k 265 000 <1.15 1000

13 Poly(alpha-methylstyrene)Part Number Molar Mass [Da]* PDI Weight [mg]

PSS-ams1.5k 1 500 <1.50 1000

PSS-ams4k 4 000 <1.15 1000

PSS-ams8k 8 000 <1.15 1000

PSS-ams16k 16 000 <1.15 1000

PSS-ams29k 29 000 <1.15 1000

PSS-ams60k 60 000 <1.15 1000

PSS-ams110k 110 000 <1.15 1000

PSS-ams230k 230 000 <1.15 1000

PSS-ams430k 430 000 <1.15 1000

PSS-ams850k 850 000 <1.15 1000

14 Poly(butadiene-1.2) Part Number Molar Mass [Da]* PDI Weight [mg]

PSS-bdt1k 1 000 <1.50 1000

PSS-bdt1.8k 1 800 <1.50 1000

PSS-bdt3.2k 3 200 <1.15 1000

PSS-bdt5.6k 5 600 <1.15 1000

PSS-bdt12k 12 000 <1.15 1000

PSS-bdt20k 20 000 <1.15 1000

15 Poly(butadiene-1.4)Part Number Molar Mass [Da]* PDI Weight [mg]

PSS-bdf2.1k 2 100 <1.15 1000

PSS-bdf4.7k 4 700 <1.15 1000

PSS-bdf10k 10 000 <1.15 1000

PSS-oe500 500 1.00 1000

PSS-bdf21k 21 000 <1.15 1000

PSS-bdf47k 47 000 <1.15 1000

PSS-bdf100k 100 000 <1.15 1000

PSS-bdf210k 210 000 <1.15 1000

PSS-bdf470k 470 000 <1.15 1000

PSS-bdf1m 1 000 000 <1.50 1000

16 Poly(dimethyl siloxane)Part Number Molar Mass [Da]* PDI Weight [mg]

PSS-pdm162 162 1.00 500

PSS-pdm237 237 1.00 500

PSS-pdm311 311 1.00 500

PSS-pdm1.5k 1 500 <1.50 500

PSS-pdm3.5k 3 500 <1.25 500

PSS-pdm10k 10 000 <1.15 500

PSS-pdm30k 30 000 <1.15 500

PSS-pdm100k 100 000 <1.15 500

17 Poly(ethylene)Part Number Molar Mass [Da]* PDI Weight [mg]

PSS-pe1.2k 1 200 <2.00 250

PSS-pe2k 2 000 <2.00 250

PSS-pe17k 17 000 <2.00 250

PSS-pe21k 21 000 <2.00 250

PSS-pe37k 37 000 <2.00 250

PSS-pe60k 60 000 <2.00 250

PSS-pe77k 77 000 <2.00 250

PSS-pe85k 85 000 <2.00 250

PSS-pe92k 92 000 <2.00 250

PSS-pe110k 110 000 <2.00 250

PSS-pe150k 150 000 <2.00 250

PSS-pe170k 170 000 <2.00 250

PSS-pe180k 180 000 <2.00 250

18 Poly(ethylene terephthalate)Part Number Molar Mass [Da]* PDI Weight [mg]

PSS-pet3.5k 3 500 <2.10 250

PSS-pet10k 10 000 <2.10 250

PSS-pet18k 18 000 <2.10 250

PSS-pet25k 25 000 <2.10 250

PSS-pet35k 35 000 <2.10 250

PSS-pet40k 40 000 <2.10 250

PSS-pet50k 50 000 <2.10 250

PSS-pet75k 75 000 <2.10 250

PSS-pet120k 120 000 <2.10 250

15 Poly(butadiene-1.4)Part Number Molar Mass [Da]* PDI Weight [mg]

PSS-bdf110 110 1.00 1000

PSS-bdf470 470 <1.50 1000

PSS-bdf1k 1 000 <1.50 1000

10 Reference Materials & LC Columns

19 Poly(ethyl methacrylate)Part Number Molar Mass [Da]* PDI Weight [mg]

PSS-em1.8k 1 800 <1.50 1000

PSS-em5k 5 000 <1.15 1000

PSS-em8k 8 000 <1.15 1000

PSS-em45k 45 000 <1.15 1000

PSS-em145k 145 000 <1.15 1000

PSS-em165k 165 000 <1.15 1000

PSS-em280k 280 000 <1.15 1000

PSS-em300k 300 000 <1.15 1000

PSS-em350k 350 000 <1.15 1000

PSS-em500k 500 000 <1.15 1000

20 Poly(isobutylene)Part Number Molar Mass [Da]* PDI Weight [mg]

PSS-pib112 112 1.00 250

PSS-pib390 390 <1.30 250

PSS-pib1k 1 000 <1.30 250

PSS-pib2.1k 2 100 <1.30 250

PSS-pib4.7k 4 700 <1.30 250

PSS-pib10k 10 000 <1.30 250

PSS-pib21k 21 000 <1.30 250

PSS-pib47k 47 000 <1.30 250

PSS-pib100k 100 000 <1.30 250

PSS-pib210k 210 000 <1.30 250

PSS-pib470k 470 000 <1.30 250

PSS-pib700k 700 000 <1.30 250

21 Poly(isoprene-1.4)Part Number Molar Mass [Da]* PDI Weight [mg]

PSS-pio800 800 <1.50 1000

PSS-pio1k 1 000 <1.50 1000

PSS-pio2.1k 2 100 <1.15 1000

PSS-pio4.7k 4 700 <1.15 1000

PSS-pio10k 10 000 <1.15 1000

PSS-pio21k 21 000 <1.15 1000

PSS-pio47k 47 000 <1.15 1000

PSS-pio100k 100 000 <1.15 1000

PSS-pio210k 210 000 <1.15 1000

PSS-pio470k 470 000 <1.15 1000

PSS-pio1m 1 000 000 <1.50 1000

22 Poly(methyl methacrylate)Part Number Molar Mass [Da]* PDI Weight [mg]

PSS-mm470k 470 000 <1.15 1000

PSS-mm1m 1 000 000 <1.50 1000

PSS-mm2m 2 000 000 <1.50 1000

PSS-mm3m 3 000 000 <1.50 1000

22 Poly(methyl methacrylate)Part Number Molar Mass [Da]* PDI Weight [mg]

PSS-mm102 102 1.00 1000

PSS-mm202 202 1.00 1000

PSS-mm600 600 <1.50 1000

PSS-mm1k 1 000 <1.50 1000

PSS-mm2.1k 2 100 <1.15 1000

PSS-mm4.7k 4 700 <1.15 1000

PSS-mm10k 10 000 <1.15 1000

PSS-mm21k 21 000 <1.15 1000

PSS-mm47k 47 000 <1.15 1000

PSS-mm100k 100 000 <1.15 1000

PSS-mm210k 210 000 <1.15 1000

23 Poly(methyl methacrylate) broad)Part Number Molar Mass [Da]* PDI Weight [mg]

PSS-mmb20k 20 000 >1.50 1000

PSS-mmb60k 60 000 >1.50 1000

PSS-mmb100k 100 000 >1.50 1000

PSS-mmb2.2m 2 200 000 >1.50 1000

24 DIN-Poly(methyl methacrylate)Part Number Molar Mass [Da]* PDI Weight [mg]

PSS-dmm450 450 <1.30 1000

PSS-dmm3.5k 3 500 <1.10 1000

PSS-dmm5k 5 000 <1.10 1000

PSS-dmm14k 14 000 <1.05 1000

PSS-dmm23k 23 000 <1.05 1000

PSS-dmm45k 45 000 <1.05 1000

PSS-dmm65k 65 000 <1.05 1000

PSS-dmm90k 90 000 <1.05 1000

PSS-dmm170k 170 000 <1.05 1000

PSS-dmm350k 350 000 <1.05 1000

PSS-dmm600k 600 000 <1.05 1000

PSS-dmm850k 850 000 <1.10 1000

25 CRM-Poly(methyl methacrylate)Part Number Molar Mass [Da]* PDI Weight [mg]

PSS-cmm350k 365 900 1.25 1000

26 CRM-Poly(methyl methacrylate)broadPart Number Molar Mass [Da]* PDI Weight [mg]

PSS-cmmb100k 101 100 2.15 1000

PSS-cmmb350k 366 400 2.23 1000

27 CRM-Poly(lactide)Part Number Molar Mass [Da]* PDI Weight [mg]

PSS-cpla90k 92 400 1.68 1000

PSS-cpla230k 249 400 1.98 1000

28 Poly(n-butyl methacrylate)Part Number Molar Mass [Da]* PDI Weight [mg]

PSS-nb1k 1 000 <1.50 1000

PSS-nb2.8k 2 800 <1.15 1000

PSS-nb5.5k 5 500 <1.15 1000

PSS-nb12k 12 000 <1.15 1000

PSS-nb20k 20 000 <1.15 1000

PSS-nb47k 47 000 <1.15 1000

PSS-nb100k 100 000 <1.15 1000

PSS-nb210k 210 000 <1.15 1000

PSS-nb470k 470 000 <1.15 1000

PSS-nb700k 700 000 <1.15 1000

11

29 Poly(propylene glycol)Part Number Molar Mass [Da]* PDI Weight [mg]

PSS-ppg76 76 1.00 1000

PSS-ppg192 192 1.00 1000

PSS-ppg450 450 <1.25 1000

PSS-ppg790 790 <1.25 1000

PSS-ppg1k 1 000 <1.25 1000

PSS-ppg3k 3 000 <1.25 1000

PSS-ppg5k 5 000 <1.25 1000

30 Poly(styrene)Part Number Molar Mass [Da]* PDI Weight [mg]

PSS-ps162 162 1.00 1000

PSS-ps266 266 1.00 1000

PSS-ps370 370 1.00 1000

PSS-ps560 560 <1.50 1000

PSS-ps1k 1 000 <1.50 1000

PSS-ps1.8k 1 800 <1.50 1000

PSS-ps3.2k 3 200 <1.15 1000

PSS-ps5.6k 5 600 <1.15 1000

PSS-ps10k 10 000 <1.15 1000

PSS-ps18k 18 000 <1.15 1000

PSS-ps33k 33 000 <1.15 1000

PSS-ps56k 56 000 <1.15 1000

PSS-ps100k 100 000 <1.15 1000

PSS-ps180k 180 000 <1.15 1000

PSS-ps320k 320 000 <1.15 1000

PSS-ps560k 560 000 <1.15 1000

PSS-ps1m 1 000 000 <1.50 1000

PSS-ps1.8 1 800 000 <1.50 1000

PSS-ps3.2m 3 200 000 <1.50 1000

PSS-ps5m 5 000 000 <1.50 1000

PSS-ps10m 10 000 000 <1.50 1000

PSS-ps20m 20 000 000 <1.50 1000

31 Poly(styrene) broad Part Number Molar Mass [Da]* PDI Weight [mg]

PSS-psb45k 45 000 >1.50 1000

PSS-psb100k 100 000 >1.50 1000

PSS-psb250k 250 000 >1.50 1000

PSS-psb450k 450 000 >1.50 1000

33 CRM-Poly(styrene)Part Number Molar Mass [Da]* PDI Weight [mg]

PSS-cps80k 79 600 1.08 1000

34 CRM-Poly(styrene) broadPart Number Molar Mass [Da]* PDI Weight [mg]

PSS-cpsb180k 181 200 2.26 1000

PSS-cpsb330k 311 800 2.25 1000

35 Poly(t-butyl acrylate)Part Number Molar Mass [Da]* PDI Weight [mg]

PSS-tba27k 27 000 <1.25 1000

PSS-tba47k 47 000 <1.25 1000

PSS-tba100k 100 000 <1.25 1000

PSS-tba210k 210 000 <1.25 1000

PSS-tba470k 470 000 <1.25 1000

PSS-tba1m 1 000 000 <1.50 1000

36 Poly(t-butyl methacrylate)Part Number Molar Mass [Da]* PDI Weight [mg]

PSS-tbma1.5k 1 500 <1.50 1000

PSS-tbma2.1k 2 100 <1.15 1000

PSS-tbma4.7k 4 700 <1.15 1000

PSS-tbma10k 10 000 <1.15 1000

PSS-tbma21k 21 000 <1.15 1000

PSS-tbma47k 47 000 <1.15 1000

PSS-tbma100k 100 000 <1.15 1000

PSS-tbma210k 210 000 <1.15 1000

PSS-tbma470k 470 000 <1.15 1000

PSS-tbma1m 1 000 000 <1.50 1000

32 DIN-Poly(styrene)Part Number Molar Mass [Da]* PDI Weight [mg]

PSS-dps162 162 1.00 1000

PSS-dps700 700 <1.20 1000

PSS-dps1.4k 1 400 <1.20 1000

PSS-dps3.2k 3 200 <1.05 1000

PSS-dps9k 9 000 <1.05 1000

PSS-dps18k 18 000 <1.05 1000

PSS-dps32k 32 000 <1.05 1000

PSS-dps100k 100 000 <1.05 1000

PSS-dps250k 280 000 <1.05 1000

PSS-dps560k 560 000 <1.05 1000

PSS-dps800k 800 000 <1.05 1000

PSS-dps1.8m 1 800 000 <1.20 1000

*) For most part numbers with a PDI ≠ 1 the molar mass produced will be within ±10% of the listed nominal molar mass (15-20% for some excep-tions). e.g. part number PSS-ps700 will have an actual molar mass that is somewhere within the range of 630 - 770 Da. Exact values appear in the label of the vial and Quality Certificate.

12 Reference Materials & LC Columns

3.2. Aqueous Standards

38 DextranPart Number Molar Mass [Da]* PDI Weight [mg]

PSS-dxt180 180 1.00 1000

PSS-dxt342 342 1.00 1000

PSS-dxt504 504 1.00 1000

PSS-dxt1.3k 1 300 <1.50 1000

PSS-dxt5k 5 000 <2.00 1000

PSS-dxt12k 12 000 <1.50 1000

PSS-dxt25k 25 000 <1.50 1000

PSS-dxt50k 50 000 <1.50 1000

PSS-dxt80k 80 000 <1.50 1000

PSS-dxt150k 150 000 <1.50 1000

PSS-dxt270k 270 000 <2.00 1000

PSS-dxt410k 410 000 <2.00 1000

PSS-dxt670k 670 000 <2.50 1000

39 Dextran broad/branchedPart Number Molar Mass [Da]* PDI Weight [mg]

PSS-dxtb4k 4 000 >1.50 1000

PSS-dxtb10k 10 000 >1.50 1000

PSS-dxtb40k 40 000 >1.50 1000

PSS-dxtb70k 70 000 >1.50 1000

PSS-dxtb500k 500 000** >1.70 1000

PSS-dxtb1.5m 1 500 000** >1.70 1000

PSS-dxtb3m 3 000 000** >1.70 1000

PSS-dxtb17m 17 000 000** >1.70 1000

40 DIN-Dextran Part Number Molar Mass [Da]* PDI Weight [mg]

PSS-ddxt180 180 1.00 1000

PSS-ddxt342 342 1.00 1000

PSS-ddxt1.3k 1 300 <1.50 1000

PSS-ddxt5k 5 000 <2.00 1000

PSS-ddxt12k 12 000 <1.50 1000

37 Hydroxyethyl starchPart Number Molar Mass [Da]* PDI Weight [mg]

PSS-hes24k 24 000 <2.50 250

PSS-hes50k 50 000 <2.50 250

PSS-hes140k 140 000 <2.50 250

PSS-hes350k 350 000 <2.50 250

PSS-hes800k 800 000 <2.50 250

PSS-hes1.4m 1 400 000 <2.50 250

PSS-hes2m 2 000 000 <2.50 250

41 Poly(acrylic acid) sodium salt Part Number Molar Mass [Da]* PDI Weight [mg]

PSS-paa2k 2 000 <2.00 250

PSS-paa4k 4 000 <2.00 250

PSS-paa8k 8 000 <2.00 250

PSS-paa18k 18 000 <2.00 250

PSS-paa35k 35 000 <2.00 250

PSS-paa130k 130 000 <2.00 250

PSS-paa245k 245 000 <2.00 250

PSS-paa585k 585 000 <2.00 250

PSS-paa1m 1 000 000 <2.00 250

PSS-paa1.3m 1 300 000 <2.00 250

42 Poly(ethylene glycol) Part Number Molar Mass [Da]* PDI Weight [mg]

PSS-peg106 106 1.00 1000

PSS-peg194 194 1.00 1000

PSS-peg232 232 1.00 1000

PSS-peg330 330 <1.25 1000

PSS-peg400 400 <1.25 1000

PSS-peg600 600 <1.25 1000

PSS-peg1k 1 000 <1.25 1000

PSS-peg1.5k 1 500 <1.25 1000

PSS-peg2k 2 000 <1.25 1000

PSS-peg3k 3 000 <1.25 1000

PSS-peg4k 4 000 <1.25 1000

PSS-peg6k 6 000 <1.25 1000

PSS-peg10k 10 000 <1.25 1000

PSS-peg12k 12 000 <1.25 1000

PSS-peg18k 18 000 <1.25 1000

PSS-peg26k 26 000 <1.25 1000

PSS-peg42k 42 000 <1.30 1000

40 DIN-Dextran Part Number Molar Mass [Da]* PDI Weight [mg]

PSS-ddxt25k 25 000 <1.50 1000

PSS-ddxt50k 50 000 <1.50 1000

PSS-ddxt80k 80 000 <1.50 1000

PSS-ddxt150k 150 000 <1.50 1000

PSS-ddxt270k 270 000 <2.00 1000

PSS-ddxt410k 410 000 <2.00 1000

PSS-ddxt3m 3 000 000 >1.70 1000

13

*) For most part numbers with a PDI ≠ 1 the molar mass produced will be within ±10% of the listed nominal molar mass (15-20% for some excep-tions). e.g. part number PSS-ps700 will have an actual molar mass that is somewhere within the range of 630 - 770 Da. Exact values appear in the label of the vial and Quality Certificate.

**) Mw based on light scattering

43 DIN-Poly(ethylene glycol) Part Number Molar Mass [Da]* PDI Weight [mg]

PSS-dpeg106 106 1.00 1000

PSS-dpeg194 194 1.00 1000

PSS-dpeg400 400 <1.25 1000

PSS-dpeg1k 1 000 <1.25 1000

PSS-dpeg2k 2 000 <1.25 1000

PSS-dpeg3k 3 000 <1.25 1000

PSS-dpeg6k 6 000 <1.25 1000

PSS-dpeg12k 12 000 <1.25 1000

PSS-dpeg26k 26 000 <1.25 1000

PSS-dpeg42k 42 000 <1.30 1000

44 Poly(ethylene oxide) Part Number Molar Mass [Da]* PDI Weight [mg]

PSS-peo42k 42 000 <1.30 1000

PSS-peo110k 110 000 <1.35 1000

PSS-peo220k 220 000 <1.35 1000

PSS-peo500k 500 000 <1.50 1000

PSS-peo1m 1 000 000 <1.35 1000

45 CRM-Poly(ethylene oxide) Part Number Molar Mass [Da]* PDI Weight [mg]

PSS-cpeo6k 6 200 1.06 1000

PSS-cpeo11k 11 350 1.11 1000

46 Poly(methacrylic acid) sodium salt Part Number Molar Mass [Da]* PDI Weight [mg]

PSS-pma1.2k 1 200 <1.20 500

PSS-pma3.5k 3 500 <1.20 500

PSS-pma7.6k 7 600 <1.20 500

PSS-pma18k 18 000 <1.20 500

PSS-pma36k 36 000 <1.20 500

PSS-pma76k 76 000 <1.20 500

PSS-pma160k 160 000 <1.20 500

PSS-pma340k 340 000 <1.20 500

PSS-pma500k 500 000 <1.20 500

47 Poly(styrene sulfonate) sodium salt Part Number Molar Mass [Da]* PDI Weight [mg]

PSS-pss1k 1 000 <1.20 500

PSS-pss3.4k 3 400 <1.20 500

PSS-pss6k 6 000 <1.20 500

PSS-pss15k 15 000 <1.20 500

PSS-pss30k 30 000 <1.20 500

PSS-pss67k 67 000 <1.20 500

PSS-pss140k 140 000 <1.20 500

PSS-pss280k 280 000 <1.20 500

PSS-pss600k 600 000 <1.20 500

PSS-pss1m 1 000 000 <1.20 500

PSS-pss2m 2 000 000 <1.20 500

48 Poly(vinyl alcohol) broad Part Number Molar Mass [Da]* PDI Weight [mg]

PSS-pvo5k 5 000 <2.50 1000

PSS-pvo12k 12 000 <3.50 1000

PSS-pvo30k 30 000 <2.50 1000

PSS-pvo40k 40 000 <2.50 1000

PSS-pvo75k 75 000 <2.50 1000

PSS-pvo100k 100 000 <2.50 1000

PSS-pvo120k 120 000 <2.50 1000

PSS-pvo160k 160 000 <2.50 1000

49 DIN-Pullulan Part Number Molar Mass [Da]* PDI Weight [mg]

PSS-dpul342 342 1.00 100

PSS-dpul1.3k 1 300 <1.30 100

PSS-dpul6k 6 000 <1.20 100

PSS-dpul12k 12 000 <1.20 100

PSS-dpul22k 22 000 <1.20 100

PSS-dpul50k 50 000 <1.20 100

PSS-dpul110k 110 000 <1.20 100

PSS-dpul200k 200 000 <1.20 100

PSS-dpul400k 400 000 <1.20 100

PSS-dpul800k 800 000 <1.20 100

PSS-dpul1.6m 1600 000 <1.20 100

PSS-dpul2.5m 2 500 000 <1.50 100

Reference Materials & LC Columns14

4| Assembled Kits of Molecular Weight Standards

4.2. Organic Standards

50 Kit Oligo(ethylene) monodisperse

PSS-oekit 8 x 500 mgMw Part [Da]* PDI

72 1.00

86 1.00

114 1.00

170 1.00

225 1.00

280 1.00

390 1.00

500 1.00

51 Kit Poly(2-vinylpyridine)

PSS-pvpkit 8 x 1000 mg Mw Part [Da]* PDI

1 000 < 1.50

2 100 < 1.50

4 700 < 1.15

10 000 < 1.15

21 000 < 1.15

45 000 < 1.15

110 000 < 1.15

265 000 < 1.15

52 Kit Poly(alpha-methylstyrene)

PSS-amskit 10 x 1000 mg Mw Part [Da]* PDI

60 000 < 1.15

110 000 < 1.15

230 000 < 1.15

430 000 < 1.15

850 000 < 1.15

53 Kit Poly(butadiene-1.4)

PSS-bdfkit 10 x 1000 mg Mw Part [Da]* PDI

1 000 < 1.50

2 100 < 1.50

4 700 < 1.15

10 000 < 1.15

18 000 < 1.15

35 000 < 1.15

100 000 < 1.15

170 000 < 1.15

500 000 < 1.15

1 000 000 < 1.50

52 Kit Poly(alpha-methylstyrene)

PSS-amskit 10 x 1000 mg Mw Part [Da]* PDI

1 500 < 1.50

4 000 < 1.15

8 000 < 1.15

16 000 < 1.15

29 000 < 1.15

4.1. GPC/SEC Calibration Kits

A calibration kit consists of 8 to 12 well-characterized

standards of one polymer type. The kits include a calibra-

tion report using the individual standards, as well as the

analytical conditions to create the calibration curve.

A Quality Certificate accompanies each standard with all

pertinent analytical parameters and molar mass distribu-

tion via GPC.

The composition of a kit may change.

Please visit www.polymer.de for an updated list.

15

56 Kit Poly(isobutylene)

PSS-pibkit 10 x 250 mg Mw Part [Da]* PDI

350 < 1.30

1 000 < 1.30

2 100 < 1.30

4 700 < 1.30

10 000 < 1.30

29 000 < 1.30

47 000 < 1.30

150 000 < 1.30

300 000 < 1.30

700 000 < 1.30

57 Kit Poly(isoprene-1.4)

PSS-piokit 10 x 1000 mg Mw Part [Da]* PDI

1 000 < 1.50

2 100 < 1.15

4 700 < 1.15

10 000 < 1.15

21 000 < 1.15

47 000 < 1.15

100 000 < 1.15

210 000 < 1.15

470 000 < 1.15

1 000 000 < 1.15

58 Kit Poly(L-lactide) low

PSS-plakit 8 x 200 mg Mw Part [Da]* PDI

150 1.00

700 < 1.15

1 500 < 1.15

2 500 < 1.15

10 000 < 1.15

20 000 < 1.15

28 000 < 1.20

40 000 < 1,40

59 Kit Poly(L-lactide) high

PSS-plakith 8 x 200 mg + 1 (broad) x 500 mg

Mw Part [Da]* PDI

150 1.00

700 < 1.15

1 500 < 1.15

2 500 < 1.15

10 000 < 1.15

20 000 < 1.15

28 000 < 1.20

40 000 < 1,40

200 000 > 1.50

60 Kit Poly(methyl methacrylate) high

PSS-mmkith 12 x 500 mg Mw Part [Da]* PDI

102 1.00

800 < 1.50

2 500 < 1.15

6 500 < 1.15

12 500 < 1.15

23 000 < 1.15

40 000 < 1.15

85 000 < 1.15

210 000 < 1.15

380 000 < 1.15

615 000 < 1.15

1 000 000 < 1.50

54 Kit Poly(dimethyl siloxane)

PSS-pdmkit 8 x 500 mg Mw Part [Da]* PDI

311 1.00

2 000 < 1.50

6 000 < 1.25

15 000 < 1.15

30 000 < 1.15

60 000 < 1.15

150 000 < 1.15

200 000 < 1.15

55 Kit Poly(ethylene)

PSS-pekit 10 x 250 mg Mw Part [Da]* PDI

340 1.00

500 1.00

1 200 < 2.00

2 000 < 2.00

17 000 < 2.00

37 000 < 2.00

60 000 < 2.00

85 000 < 2.00

110 000 < 2.00

180 000 < 2.00

61 Kit Poly(methyl methacrylate) low

PSS-mmkitl 8 x 500 mg Mw Part [Da]* PDI

102 1.00

800 < 1.50

2 100 < 1.15

3 000 < 1.15

4 700 < 1.15

6 500 < 1.15

8 000 < 1.15

17 000 < 1.15

16 Reference Materials & LC Columns

64 Kit Poly(styrene) high

PSS-pskith 12 x 1000 mg Mw Part [Da]* PDI

560 < 1.50

1 200 < 1.50

3 200 < 1.15

8 000 < 1.15

18 000 < 1.15

33 000 < 1.15

62 000 < 1.15

120 000 < 1.15

280 000 < 1.15

560 000 < 1.15

1 200 000 < 1.15

2 500 000 < 1.50

66 Kit Poly(t-butyl methacrylate)

PSS-tbmakit 10 x 1000 mg Mw Part [Da]* PDI

1 500 < 1.50

2 100 < 1.15

4 700 < 1.15

10 000 < 1.15

16 000 < 1.15

40 000 < 1.15

100 000 < 1.15

300 000 < 1.15

600 000 < 1.15

1 000 000 < 1.50

65 Kit Poly(styrene) low

PSS-pskitl 8 x 1000 mg Mw Part [Da]* PDI

162 1.00

560 < 1.50

1 200 < 1.50

2 500 < 1.15

3 200 < 1.15

4 500 < 1.15

8 000 < 1.15

18 000 < 1.15

4.3. Aqueous Standards

67 Kit Dextran

PSS-dxtkit 10 x 500 mg Mw Part [Da]* PDI

180 1.00

342 1.00

1 300 < 2.00

5 000 < 2.00

12 000 < 1.50

25 000 < 1.50

50 000 < 1.50

150 000 < 1.50

270 000 < 2.00

410 000 < 2.00

68 Kit Hydroxyethyl starch

PSS-heskit 7 x 250 mg Mw Part [Da]* PDI

24 000 < 2.50

50 000 < 2.50

140 000 < 2.50

350 000 < 2.50

800 000 < 2.50

1 400 000 < 2.50

2 000 000 < 2.50

62 Kit Poly(n-butyl methacrylate)

PSS-nbkit 9 x 1000 mg Mw Part [Da]* PDI

1 500 < 1.50

3 500 < 1.15

7 500 < 1.15

20 000 < 1.15

47 000 < 1.15

100 000 < 1.15

210 000 < 1.15

470 000 < 1.15

700 000 < 1.15

63 Kit Poly(propylene glycol)

PSS-ppgkit 7 x 1000 mg Mw Part [Da]* PDI

76 1.00

192 1.00

450 < 1.25

790 < 1.25

1 000 < 1.25

3 000 < 1.25

5 000 < 1.25

17

70 Kit Poly(ethylene glycol)

PSS-pegkit 10 x 500 mg Mw Part [Da]* PDI

106 1.00

194 1.00

400 < 1.25

1 000 < 1.25

2 000 < 1.25

3 000 < 1.25

6 000 < 1.25

12 000 < 1.25

26 000 < 1.25

42 000 < 1.30

71 Kit Poly(ethylene oxide)

PSS-peokit 8 x 500 mg Mw Part [Da]* PDI

25 000 < 1.35

42 000 < 1.35

60 000 < 1.35

110 000 < 1.35

180 000 < 1.35

270 000 < 1.35

500 000 < 1.50

1 000 000 < 1.50

72 Kit Poly(methacrylic acid) sodium salt

PSS-pmakit 8 x 500 mg Mw Part [Da]* PDI

1 200 < 1.20

3 500 < 1.20

7 600 < 1.20

36 000 < 1.20

76 000 < 1.20

160 000 < 1.20

340 000 < 1.20

500 000 < 1.20

73 Kit Poly(styrene sulfonate) sodium salt

PSS-psskit 10 x 500 mg Mw Part [Da]* PDI

1 000 < 1.20

3 400 < 1.20

6 000 < 1.20

15 000 < 1.20

30 000 < 1.20

67 000 < 1.20

140 000 < 1.20

280 000 < 1.20

600 000 < 1.20

1 000 000 < 1.20

74 Kit Pullulan

PSS-pulkit 10 x 100 mg Mw Part [Da]* PDI

342 1.00

1 300 < 1.30

6 000 < 1.20

10 000 < 1.20

22 000 < 1.20

50 000 < 1.20

110 000 < 1.20

200 000 < 1.20

400 000 < 1.20

800 000 < 1.30

*) For all parts with a PDI ≠ 1 the molar mass produced will be within ±10% of the listed nominal molar mass (15-20% for broad standards). e.g. part number PSS-ps700 will have an actual molar mass that is somewhere within the range of 630 - 770 Da. Exact values appear in the label of the vial and Quality Certificate.

69 Kit Poly(acrylic acid) sodium salt

PSS-paakit 10 x 250 mg Mw Part [Da]* PDI

2 000 < 2.00

4 000 < 2.00

8 000 < 2.00

18 000 < 2.00

35 000 < 2.00

130 000 < 2.00

245 000 < 2.00

585 000 < 2.00

1 000 000 < 2.00

1 300 000 < 2.00

18 Reference Materials & LC Columns

4.4. ReadyCal Kits

75 ReadyCal-Kit Poly(methyl methacrylate)

PSS-mmkitr4 3 x 10 Vials-4.0mlPSS-mmkitr1 3 x 10 Vials-1.5ml

Mw Part [Da]* PDI

800 < 1.50

2 500 < 1.15

6 500 < 1.15

12 500 < 1.15

23 000 < 1.15

40 000 < 1.15

85 000 < 1.15

210 000 < 1.15

380 000 < 1.15

615 000 < 1.15

1 000 000 < 1.15

1 500 000 < 1.50

PSS ReadyCal Standards are polymer cocktails pre

weighted into auto-sampler vials. Each vial has three or

four polymers of the same type with different molar

masses. Carefully selected molar masses are placed into

each vial so that the polymer traces are baseline separat-

ed (if a proper column combination is used)

A ReadyCal Kit allows you to prepare fast and repro-

ducible a 8 - 12 point calibration curve without the mess

of weighing samples. Just add solvent directly into the

auto sampler vial, let it stand for two hours, shake

gently and load into your auto sampler for analysis.

Each kit contains 30 autosampler vials (for at least 10

calibration curves) that are color coded for your

convenience.

Available in 1.5ml and 4.0ml vials.

76 ReadyCal-Kit Poly(styrene) high

PSS-pskitr4h 3 x 10 Vials-4.0mlPSS-pskitr1h 3 x 10 Vials-1.5ml

Mw Part [Da]* PDI

1 500 < 1.50

3 200 < 1.15

8 000 < 1.15

18 000 < 1.15

33 000 < 1.15

62 000 < 1.15

120 000 < 1.15

238 000 < 1.15

560 000 < 1.15

1 200 000 < 1.50

2 500 000 < 1.50

6 500 000 < 1.50

77 ReadyCal-Kit Poly(styrene) low

PSS-pskitr4l 3 x 10 Vials-4.0mlPSS-pskitr1l 3 x 10 Vials-1.5ml

Mw Part [Da]* PDI

266 1.00

560 < 1.50

1 200 < 1.50

2 500 < 1.50

3 200 < 1.15

4 500 < 1.15

8 000 < 1.15

18 000 < 1.15

33 000 < 1.15

62 000 < 1.15

78 ReadyCal-Kit Poly(styrene)

PSS-pskitr4 3 x 10 Vials-4.0mlPSS-pskitr1 3 x 10 Vials-1.5ml

Mw Part [Da]* PDI

560 < 1.50

1 200 < 1.50

3 200 < 1.15

8 000 < 1.15

18 000 < 1.15

33 000 < 1.15

62 000 < 1.15

120 000 < 1.15

280 000 < 1.15

560 000 < 1.15

1 200 000 < 1.50

2 500 000 < 1.50

19

79 ReadyCal-Kit PEO/PEG

PSS-peokitr4 3 x 10 Vials-4.0mlPSS-peokitr1 3 x 10 Vials-1.5ml

Mw Part [Da]* PDI

232 1.00

600 < 1.25

2 000 < 1.25

6 000 < 1.25

18 000 < 1.25

42 000 < 1.30

110 000 < 1.35

270 000 < 1.35

500 000 < 1.50

1 000 000 < 1.50

80 ReadyCal-Kit Poly(ethylene glycol)

PSS-pegkitr1 3 x 10 Vials-1.5mlMw Part [Da]* PDI

232 1.00

330 < 1.25

600 < 1.25

1 000 < 1.25

1 500 < 1.25

3 000 < 1.25

4 000 < 1.25

6 000 < 1.25

12 000 < 1.25

18 000 < 1.25

26 000 < 1.25

42 000 < 1.30

4.5. DIN Kits

81 DIN-Kit Poly(methyl methacrylate)

PSS-mmkitd 12 x 500 mg Mw Part [Da]* PDI

450 < 1.30

3 500 < 1.10

5 000 < 1.10

14 000 < 1.05

23 000 < 1.05

45 000 < 1.05

65 000 < 1.05

90 000 < 1.05

170 000 < 1.05

350 000 < 1.05

600 000 < 1.05

850 000 < 1.10

82 DIN-Kit Poly(styrene)

PSS-pskitd 12 x 1000 mg Mw Part [Da]* PDI

162 1.00

700 < 1.20

1 400 < 1.20

3 200 < 1.05

9 000 < 1.05

18 000 < 1.20

32 000 < 1.05

100 000 < 1.05

250 000 < 1.05

560 000 < 1.05

800 000 < 1.05

1 800 000 < 1.20

83 DIN-Kit Dextran

PSS-dxtkitd 10 x 500 mg Mw Part [Da]* PDI

180 1.00

342 1.00

1 300 < 1.50

5 000 < 2.00

12 000 < 1.50

25 000 < 1.50

50 000 < 1.50

150 000 < 1.50

270 000 < 2.00

410 000 < 2.00

84 DIN-Kit Poly(ethylene glycol)

PSS-pegkitd 10 x 500 mgMw Part [Da]* PDI

106 1.00

194 1.00

400 < 1.25

1 000 < 1.25

2 000 < 1.25

3 000 < 1.25

6 000 < 1.25

12 000 < 1.25

26 000 < 1.25

42 000 < 1.30

20 Reference Materials & LC Columns

4.6. MALDI Validation Kits

PSS provides Polymer Standard Kits that will help you to

check, calibrate and validate a Matrix-Assisted-Laser-

Desorption-Ionization-Time-of-Flight measurement (MALDI-

ToF) instrument. Standards with different molecular

weight ranges and different polarities are included. The

different molecular weights allow you to determine the

resolution of the instrument as a function of the molecular

weight, whereas different polymer polarities help you

determine the compatibility of your Matrix and polymer.

4.7. Light Scattering/ViscometryValidation Kit

The kit is useful to check the instrument calibration and

the delay volume between the concentration detector

and the molar mass detector.

This kit includes a mixture of well defined Light

Scattering (LS) and/or Viscometry (Visco) reference

materials (narrow and broad distributed) with the

relevant Light Scattering and/or Viscometry data. The

validation of your Light Scattering or Viscometry instru-

ment is simple, fast and reliable.

85 MALDI-Kit Poly(methyl methacrylate)

PSS-mmkitm 6 x 500 mgMw Part [Da]* PDI

450 < 1.50

2 500 < 1.15

5 000 < 1.15

10 000 < 1.15

23 000 < 1.15

60 000 < 1.15

*) For all parts with a PDI ≠ 1 the molar mass produced will be within ±10% of the listed nominal molar mass (15-20% for broad standards). e.g. part number PSS-ps700 will have an actual molar mass that is somewhere within the range of 630 - 770 Da. Exact values appear in the label of the vial and Quality Certificate.

86 MALDI-Kit Poly(styrene)

PSS-pskitm 6 x 500 mgMw Part [Da]* PDI

700 < 1.50

1 200 < 1.50

5 000 < 1.15

9 000 < 1.15

34 000 < 1.15

65 000 < 1.15

87 MALDI-Kit Poly(ethylene glycol)

PSS-pegkitm 6 x 500 mgMw Part [Da]* PDI

400 < 1.25

1 000 < 1.25

3 000 < 1.25

6 000 < 1.25

12 000 < 1.25

26 000 < 1.25

88 MALDI mixed-Kit PS, PMMA, PDMS, PEG, PSS

PSS-mixkitm 5 x 500 mgMw Part [Da]* PDI

Poly(dimethyl siloxane) 4 500 < 1.25

Poly(ethylene glycol) 6 000 < 1.25

Poly(methyl methacrylate) 5 000 < 1.15

Poly(styrene) 5 000 < 1.15

Poly(styrene sulfonate) sodium salt 5 000 < 1.20

89 LS-Visco-Kit Poly(methyl methacrylate)

PSS-mmkitv 4 x 500 mgMw Part [Da]* PDI

8 000 < 1.15

100 000 > 1.50

160 000 < 1.05

850 000 < 1.15

91 LS-Visco-Kit Dextran

PSS-dxtkitv 4 x 500 mgMw Part [Da]* PDI

12 000 < 1.50

50 000 < 1.50

70 000 > 1.50

410 000 < 2.00

90 LS-Visco-Kit Poly(styrene)

PSS-pskitv 4 x 500 mgMw Part [Da]* PDI

9 000 < 1.05

120 000 < 1.05

250 000 > 2.50

560 000 < 1.05

21

GPC/SEC is a fast, robust and significant method for the

characterization of membranes, especially in their native

environment (swelled state). PSS offers the ability to

perform an automated, fast and simple membrane

characterization including cut-off and pore size distribu-

tion determination.

The GPC/SEC membrane characterization is accomplished

by filtering the sample through the membrane.

Depending on the membrane type and quality some

smaller molecules can pass the pores of the membrane

while others will be retained. The filtered and the

un filtered stock solution are then measured on a GPC/

SEC system. The average pore size distribution and the

cut-off the membrane is determined automatically by

comparing the elution profiles of the unfiltered sample

to the filtered fraction.

5| Standards for Membrane Characterization

Mem

bran

e St

anda

rds

Following membrane standards are available:

• Linear Polysaccharide (Pullulan):

Part Nummber: PSS-mepulb300k (Mw: 300 000 Da)

• Branched Polysaccharide (Dextran):

P/N PSS-medxtb70k (Mw: 70 000 Da)

P/N PSS-medxtb2m (Mw: 2 000 000 Da)

• Polystyrene:

P/N PSS-mepsb200k (Mw: 200 000 Da)

Packing sizes: 50 g,100 g, 250 g, 500 g.

These new PSS membrane standards are featured by:

• a broad molar mass distribution

• the molar mass average Mw and Mn

• the integral molar mass information Mmin, Mmax

• the corresponding radii of gyration Rgmin

and Rgmax.

22 Reference Materials & LC Columns

PSS has developed a dedicated GPC/SEC system

suitability test that evaluates the integral system:

equipment, electronics, and analytical operations, using

the PSS EasyValid Validation Kit. This ensures that the

system will yield validated GPC/SEC results.

The PSS EasyValid Validation Kit is designed for the

validation of GPC/SEC instrumentation with concentration

detectors independently of brand.

It consists of:

• a validation column

• calibration standards

• certified reference materials

• WinGPC Unity report layouts

• WinGPC Unity import files

• a comprehensive user documentation.

6| GPC/SEC System Suitability Test with PSS EasyValid Validation Kit

Valid

atio

n Re

port

The Validation Kit EasyValid is ideal:

• for checking the system performance

after installation

• as part of the OQ/PV (Operational

Qualification/Performance Verification)

• for performance review after maintenance

• for inter laboratory consistence checks

• for identifying systematic errors

• for training new employees

For additional validation of molar mass sensitive

detectors use Light Scattering / Viscometry Valdiation

Kits (see page 20)

EasyValid for organic systems

P/N PSS-pskitval

EasyValid for aqueous systems

P/N PSS-dxtkitval

23

Gel Permeation Chromatography (GPC),

Size Exclusion Chromatography (SEC),

or Gel Filtration Chromatography (GFC)

are names used interchangeably for a liquid chromatog-

raphy technique to obtain separation according to mole-

cular dimensions.

Contrary to LAC- (Liquid Adsorption Chromatography)

methods like HPLC, that rely on interactions between

sample and stationary phase (column material),

GPC/SEC must operate free of interactions.

Only then is a separation according the size of the mole-

cules ensured. Ideally, only entropic effects should influ-

ence this type of separation.

The following information should help you to successfully

install GPC/SEC in your lab.

1. Select an appropriate stationary phase (column

material) that fits your samples and ensures interac-

tion free separation.

2. Make sure to select and use a mobile phase (eluent)

that is compatible with the stationary phase (column

material, gel).

3. To improve the resolution and/or expand the molec-

ular weight separation range, PSS recommends to

use multiple columns in series.

7| Successful GPC/SEC Separation

4. Select the proper particle size and the appropriate

pore size distribution.

5. Maintain a flow rate and a temperature that agrees

with the column diameter and viscosity of the sol-

vent to prevent sample shearing and high backpres-

sure.

6. Use precolumns to increase the overall column life

time.

7. Filter your samples through a 0.45 µm filter for 5 µm

particle size or 1 µm filter for 10/20 µm particle size

to prevent solids from entering the column.

8. Determine the plate count, asymmetry and resolu-

tion of your column(s) regularly to check their per-

formance.

9. Determine the molecular weight range of the sepa-

ration with a calibration curve.

10. Use appropriate concentration and injection volume

balance to prevent column overload.

11. The higher the molecular weight of your sample the

lower the sample concentration. Refer to chapter

“Standards Handling” for guidelines.

24 Reference Materials & LC Columns

Fig. 2: PSS Magic Triangle for GPC/SEC applications

PMMA

PS

THF

Toluene

DMF

HFIP

GRAM PFG SUPREMA

WATER

Dextran

PAA

SDV

Sam

ple

Pola

rity Solvent Polarity

Sorbent Polarity

GPC/SEC

Fig. 3: PSS Magic Triangle for aqueous GPC/SEC applications

Neutral Polymers

Polycations

NOVEMA SUPREMA

12

11

10

9

7

8

23

45

6Weak

Polyanions

Strong Polyanions

MCX

Poly

mer

Ioni

c Ch

arac

ter

pH Value

Stationary Phase Polarity

Aqueous GPC/SEC

Our high performance columns are the result of compre-

hensive research focusing on the development of more

efficient and robust gel materials and an improved pack-

ing technology. We manufacture stationary phase gels for

the chromatography able to separate synthetic and natu-

ral macromolecules by their hydrodynamic volume. PSS

offers the widest range of column materials optimized

for aqueous or organic solvents alike:

TIP: See summary of specifications on last page

8.1. Column Selection

A GPC/SEC column can be selected by different criteria

depending on your analytical goal (highest resolution,

product screening, etc.). This chapter will present the

most important and essential criteria.

8| GPC/SEC Columns Powerful solutions for size separation

SDV

SDV Lux

GRAM

PFG

POLEFIN

ORGANIC SOLVENTS

SuPREMA

SuPREMA Lux

NOVEMA

MCX

PROTEEMA

AquEOuS SOLVENTS

Fig. 1: Overview of gel materials

1. Step: Optimum Stationary Phase

The PSS column concept is to minimize interactions

between polymer and stationary phases. In general, the

sample is the determinant factor: the polarity of the

sample defines the polarity of the solvent and therefore

also that of the stationary phase. To ensure interaction

free chromatography the stationary phase needs to be

selected carefully.

PSS allows the selection of stationary phases of different

polarities. The PSS Magic Triangle provides a quick visual

aid for the selection of columns, where the three sides

represent sample, mobile phase, and stationary phase

(see Fig. 2).

25

Handling of the PSS Magic Triangle

Construct an isosceles triangle by locating the polarity of

sample and mobile phase; the peak of the Magic

Triangle guides you to the proper stationary phase.

This concept is also applicable for aqueous GPC/SEC. The

magic triangle for aqueous systems takes the pH value

instead of the stationary phase into account (see Fig. 3).

TIP: Solvent Compatibility

It is imperative that a sample passing through a column

be soluble in the mobile phase. When using a solvent

different from the mobile phase to dissolve and inject a

sample, both solvents must be completely miscible and

compatible with the stationary phase. PSS recommends

to use the mobile phase also for sample preparation.

2. Step: Column Dimensions and Field of Application

Our stationary phases are packed in stainless steel (V4A)

columns of standard dimensions that fit any HPLC or

GPC/SEC instrument

** I.D.: internal diameter ** Any other column dimension on request

TIP:

For additional column dimensions please call us or your

closest representative.

101 Column dimension and field of application

Column I.D.* x length Field of

Type [mm]** application

Precolumn 8 x 50

4.6 x 30 20 x 50

Protection

Analytical8 x 300 8 x 600

Conventional analysis

Micro 4.6 x 250Solvent saving, small

sample amounts

Preparative 20 x 300 20 x 600 40 x 250

Preparative sample fractionation, sample

collection

HighSpeed 20 x 50 Ultra fast analysis

Lux 8 x 300 GPC Light Scattering

Hig

hSpe

ed C

olum

ns

Fig. 4: A HighSpeed column (red line) reduces the run time

for a sample (broad Poly(styrene)) by a factor of 6 - 8 compared to

a conventional column (black line).

Lux

Colu

mns

Fig. 5: Lux columns reach the steady state mode > 25 times faster

than conventional columns, and their overall noise reduction is more

than 25 times better.

Elution Volume [ml]

Elution Volume [ml]

Det

ecto

r Si

gnal

[V]

Det

ecto

r Si

gnal

[V]

26 Reference Materials & LC Columns

102 Application of different column typesSelect Recommended application

HighSpeed columns Very fast results needed in process

control and high throughput screening

Analysis time: 2 - 4 min per sample

Linear or mixed

bed columns

Product screening at constant peak

resolution Analysis time: ~ 12 min

per sample

Combination of single

porosity columns

Highest resolution and maximum

information Analysis time: > 12 min

per sample

8.3. Column Order Deliverables

Installation Tips

1. Purge the system with mobile phase first. Pump sol-

vent through the system to remove air and to prevent

that air is entering the colums. Dont’ forget to flush

the injection loop.

2. Use the column connections supplied from PSS to

connect columns in series.

PSS carefully tests every column according resolution, asymmetry and plate count number. The quality certificate contains the testing results and the corresponding test chro-matograms.

qua

lity

Cert

ific

ate

Polymer Standards Service GmbH Polymer Standards Service USA, IncIn der Dalheimer Wiese 5 D-55120 Mainz 43 Jefferson Blvd. Suite 3 Warwick, RI 02888 USATel.: +49 (0) 6131-96239-0 Fax: +49 (0) 6131-96239-11 Phone: +1 401-780-8884 Fax: +1 401-780-8824Email: [email protected] www.polymer.de Email: [email protected] www.pssgpcshop.com

Quality Certificate

Column: PSS SUPREMA analytical 100ÅSerial No: 9120753Dimension: 8 x 300 mmParticle size: 5 µmShipped in: Water, Sodium azide 0.05%

0.00

0.02

0.04

0.06

0.08

0.10

0.12

0.14

0.16

Elution Volume [-]

6 7 8 9 10 11 12 13 14 15

50%, dV=0.19 ml

10%

Det

ecto

r Res

pons

e [-]

PSS

Win

GPC

Uni

ty, B

uild

921

5, L

AB_P

RO

D5,

Inst

anz

#1

GPC Column test according to:DIN 55672, ISO 13885

Testsample EGTheoretical plates / m 50 000Asymmetry 1,0

Polymer mixturePullulan mix low

GPC/SEC - Conditions

Solvent Water, Sodium azide 0.05%Flow rate 1,00 ml/minTemperature 23 °CColumn pressure 20 BarDetector RI-DetectorInject volume 20 µlOperator M. NaumannData acquisition software PSS WinGPC

Dr. G. Reinholdproduction director

Manufacture and control according to PSS method of analysis

0.000

0.005

0.010

0.015

0.020

0.025

0.030

Elution Volume [-]

6.5 7.0 7.5 8.0 8.5 9.0 9.5 10.0 10.5

Det

ecto

r Res

pons

e [-]

PS

S W

inG

PC

Uni

ty, B

uild

921

5, L

AB_

PR

OD

5, In

stan

z #1

Component 1: Mp = 112000 [Da]Component 2: Mp = 11800 [Da]Component 3: Mp = 991 [Da]Component 4: Mp = 180 [Da]

8.2. Advantages of PSS ColumnTechnology

• Excellent separation efficiency obtained with narrowly

classified gels and optimized frit technology.

• Excellent stability under a wide range of physical,

chemical and biological environments.

• High solvent compatibility with organic or aqueous

mobile phases alike.

• Column production under DIN EN ISO 9001 quality

standards.

• Controlled Quality: each column is tested according

to DIN 55672 and ISO/EN 13885

• Delivery with a detailed user documentation and

a quality certificate.

• PSS engineered fittings and their integrated diffusers

provide excellent sample injection.

• Easy to service: easy to change end frits.

• Refill Service: PSS will refurbish cost saving old

columns with new gel-material.

• Dedicated support in questions, problems and

applicational demands from a team of commited

and experienced scientists.

3. Step: Particle Sizes and Porosities

PSS GPC/SEC column materials are available in several

particle sizes from 3 µm up to 20 µm particles.

The optimum particle size depends on

• the solvent viscosity (higher viscosity requires

higher particle size)

• the sample molar mass (higher molar masses

require higher particle sizes).

Porosities

The pore size distribution of the column material

determines the separation range.

• To separate low molecular weight products use

small porosities.

• The higher the molecular weight the higher is the

required porosity.

• Single porosity columns show a high resolution in

a narrow molecular weight range.

• A wide molecular weight range at constant high

resolution is covered if columns with single

porosities are coupled in series.

• Linear or mixed bed columns provide a very wide

porosity range therefore offering a broad separation

range with a smaller resolution.

For any desired application PSS offers the optimum col-

umn or column combination (single porosity or linear).

4. Step: Laboratory workflow requirements/Tasks

Once you know the stationary phase, particle size and

porosity, there are different options to optimize the poly-

mer separation, depending on laboratory workflow

requirements:

TIP: The combination of single porosity columns has the

inherent risk of column mismatch. Use the column com-

binations recommended by PSS to avoid column mis-

match.

27

Fig. 6: Maximum distance between ferrule and capillary end.

8.4. Column Handling

Installation Tips

1. Purge the system with mobile phase first. Pump sol-

vent through the system to remove air and to prevent

that air is entering the colums. Dont’ forget to flush

the injection loop.

2. Use the column connections supplied from PSS to

connect columns in series.

WARNING: Make sure that the fitting tubing protrudes a

maximum of 1 mm inside the column head (see Fig. 6)

Solvent of Choice

PSS delivers the columns in the eluent of the customer

choice, except solvents with a high freezing point like

DMSO and TCB.

The solvent within the columns is marked with colour-

coded screw stops.

Column Connector

PSS ships connection fittings with the column.

Test mixture

PSS ships a polymer mixture for testing with the column

if possible.

User documentation

Each column is delivered with detailed user documen-

tation.

Refill Services

PSS will refill your old columns at a considerable cost

saving upon request. They will be tested individually and

delivered with a new quality certificate.

103 Recommended flow ratesFlow I.D. 8 mm I.D. 4.6 mm I.D. 20 mm

Operating 1 ml/min 0.33 ml/min 6.25 ml/min

Reduced 0.25 ml/min 0.1 ml/min 1.5 ml/min

Idle 0.1 ml/min 0.03 ml/min 0.6 ml/min

3. Be aware of column flow direction. Operating the flow

rate in the reverse direction is only part of trouble-shoot-

ing or operating after a long storage time.

4. Thread the column fittings finger tight into the system.

Do not over tighten the fitting. Overtightening may

damage the column and the column head.

5. Flush the column with 10 times of the column

volume at 1/5 of the recommended flow rate.

6. Eluent should come out after 2-3 minutes at 0.2 ml/

min flow rate. If not, see “Recovering partially dry col-

umns”.

7. When the solvent exchange is completed, connect to

the detector(s).

8. Slowly increase the flow rate to the typical operating

flow rate which depends on the column dimensions

(see table 103).

9. Check the column pressure.

WARNING: Maximum pressure should never exceed twice

the pressure specified in the column certificate.

10. Give the columns time to equilibrate.

11. Check the plate count of the whole chromato-graphic

system incl. columns (see column user documenta-

tion). If this test fails, first check each column sepa-

rately when using a column combination, then con-

tact PSS or a PSS representative.

TIP: For Multiple Columns use

• Install the middle porosity first and use the largest

porosity connected into the detector.

• Use only column combinations recommended by PSS.

• Do not combine linear and single porosity columns.

• Do not combine different particle sizes.

Cleaning

When columns loose efficiency (Rsp, Asymmetry) or you

suspect the presence of foreign material adsorbed on the

column, PSS recommends the following procedures:

• Remove the column from the detector.

• Install the column in reverse direction for clean-up.

• Flush the column at 0.1 ml/min flow rate with a sol-

vent that dissolves the suspect impurities and is fully

compatible with your system, until the impurities are

removed.

28 Reference Materials & LC Columns

TIP: To clean aqueous columns, use variation of pH, buff-

er concentration, or mixtures of organic and aqueous

eluents. Organic columns are cleaned best by variation of

eluent polarity. Use mixtures of appropriate solvents (e.g.

THF in toluene resp. chloroform) or solvent additives

(TFAc in THF).

Storage

PSS recommends to store the columns in the solvent

used during shipment; f.e. columns shipped in DMAc or

DMF must be stored in DMAc or DMF.

1. Remove salt solutions with pure solvent, disconnect

the column from the GPC/SEC system and tightly plug

with the original end plugs.

2. It is a good practice to store columns with volatile

mobile phases in a refrigerator (4°C) to prevent solvent

evaporation.

WARNING: Never let the column temperature fall below

the freezing point of the storage solvent. This will

destroy the stationary phase.

Recovering partially dry columns

Occasionally solvent is lost during long-term storage or

due to high storage temperatures. When after (re-)

installing the column no solvent overflows or the expect-

ed system pressure does not build up, this can be an

indication for a partially dry column.

To re-wet a partially dry column:

• Install the column in the reverse direction.

• Fill the column with solvent, using a flow rate of

0.1 ml/min, until no more bubbles appear at the

column outlet.

• Change the column to the correct flow direction

and use 0.1 ml/min for 2h.

• Increase the flow rate slowly to the operating flow

rate with an increment of 0.2 ml/min per 5 minutes.

8.5. Warranty

PSS Polymer Standards Service offers the warranty for

the columns accorduing to specifications given in the

Quality Certificate.

29

9.1. SDV Columns

104 GPC/SEC of Polymers in unpolar and Medium Polar Organic Solvents

Field of Application

ApplicabilityPoly(styrene), Poly(vinyl chloride), Poly(carbonate), Elastomers, Resins and others