DRAFT Point Hope Wind-Diesel Hybrid Feasibility Study

Transcript of DRAFT Point Hope Wind-Diesel Hybrid Feasibility Study

DRAFT Point Hope Wind-Diesel Hybrid

Feasibility Study

December 22, 2011

Douglas Vaught, P.E. V3 Energy, LLC

Eagle River, Alaska

Point Hope Wind-Diesel Hybrid Feasibility Study P a g e | i

This report was prepared by V3 Energy, LLC under contract to WHPacific for a North Slope Borough project to assess the technical and economic feasibility of installing wind turbines in a wind-diesel hybrid power system design for the villages of Point Hope, Point Lay, and Wainwright, Alaska. This report addresses Point Hope.

Contents Executive Summary ....................................................................................................................................... 1

1 Introduction .......................................................................................................................................... 3

1.1 Scope of Work ............................................................................................................................... 3

1.2 Village of Point Hope..................................................................................................................... 3

1.3 Climate .......................................................................................................................................... 4

1.4 Geology ......................................................................................................................................... 5

1.5 Permitting ..................................................................................................................................... 5

2 Wind Resource Assessment .................................................................................................................. 6

2.1 Met tower data synopsis .............................................................................................................. 6

2.2 Data Recovery ............................................................................................................................... 6

2.3 Wind Speed ................................................................................................................................... 6

2.4 Wind Rose ..................................................................................................................................... 7

2.5 Turbulence Intensity ..................................................................................................................... 8

2.6 Extreme Winds .............................................................................................................................. 8

3 Wind Project Sites ................................................................................................................................. 9

3.1 Site A ............................................................................................................................................. 9

3.2 Site B ........................................................................................................................................... 10

3.3 Other Site Options ...................................................................................................................... 12

4 Wind-Diesel System Design and Equipment ....................................................................................... 13

4.1 Wind-diesel Integration Controls ................................................................................................ 14

4.2 Energy Storage Options ............................................................................................................... 14

4.2.1 Batteries .............................................................................................................................. 14

4.2.2 PowerStore Flywheel .......................................................................................................... 15

5 Wind Turbines and HOMER Modeling .................................................................................................... 16

5.1 Diesel Power Plant ...................................................................................................................... 16

5.2 Wind Turbines ............................................................................................................................. 17

Point Hope Wind-Diesel Hybrid Feasibility Study P a g e | ii

5.2.1 Northern Power Systems Northwind 100 ........................................................................... 17

5.2.2 Aeronautica AW29-225 ....................................................................................................... 18

5.2.3 Wind Turbine Performance Comparison ............................................................................ 19

5.3 Modeling ..................................................................................................................................... 19

5.3.1 Electric Load ........................................................................................................................ 19

5.3.2 Thermal Load ...................................................................................................................... 20

5.4 Diesel Generators........................................................................................................................ 20

6 Economic Analysis ............................................................................................................................... 22

6.1 Wind Turbine Costs ..................................................................................................................... 22

6.2 Fuel Cost ...................................................................................................................................... 22

6.3 HOMER Modeling Assumptions .................................................................................................. 23

6.4 Wind Power Scenario Cost Assumptions .................................................................................... 24

6.5 Site A Project Economics ............................................................................................................. 25

6.5.1 Medium Fuel Price Projection, 82% Turbine Availability .................................................... 25

6.5.2 High Fuel Price Projection, 82% Turbine Availability .......................................................... 26

6.5.3 Low Fuel Price Projection, 82% Turbine Availability ........................................................... 27

6.5.4 Medium Fuel Price Projection, 100% Turbine Availability .................................................. 28

6.6 Site B Project Economics ............................................................................................................. 29

6.6.1 Medium Fuel Price Projection, 82% Turbine Availability .................................................... 29

6.6.2 High Fuel Price Projection, 82% Turbine Availability .......................................................... 30

6.6.3 Low Fuel Price Projection, 82% Turbine Availability ........................................................... 31

6.6.4 Medium Fuel Price Projection, 100% Turbine Availability .................................................. 32

7 Conclusion and Recommendations..................................................................................................... 33

Appendix A: Determination of No Hazard, Site A ...................................................................................... 34

Appendix B: Notice of Presumed Hazard, Site B ........................................................................................ 35

Appendix C: Northwind 100 Wind Turbine ................................................................................................ 36

Appendix D: Aeronautica AW29-225 Wind Turbine .................................................................................. 37

Point Hope Wind-Diesel Hybrid Feasibility Study P a g e | 1

Executive Summary

The measured high Class 5 to Class 6 wind resource in Point Hope, based on a wind classification system with a range of 1 (poor) to 7 (superb) in terms of wind energy potential, is outstanding with an average annual wind velocity of 7.12 m/s (15.9 mph) at 30 meters elevation. Additionally, the test location experiences low turbulence and relatively low probability of extreme wind events, making Point Hope a superior candidate for a wind energy project.

Two potential wind turbine sites were investigated for this study: Site A, located approximately 2-1/2 miles due east of the village; and site B, located near the airport immediately west of an old fuel tank farm. Given the similarity of terrain between the sites, each was considered to have equivalent wind resource potential. Site B has an FAA-imposed height restriction which would require shorter turbine tower heights, whereas Site A has no height restrictions. Site B requires minimal construction of an access road and is very close to existing three-phase power distribution. Site A is adjacent to good road access but requires construction of 2-1/2 miles of new power distribution line for connection to the power grid. A power line to serve site A could have other potential uses however.

With an outstanding wind resource and considering NSB’s goal to offset as much as possible the usage of expensive fossil fuel to generate electricity, medium or high penetration wind-diesel power configurations are the most suitable choice for Point Hope. There have been significant challenges to date though with implementing high penetration wind-diesel systems in rural Alaska due to complexity, high capital cost and operational problems. With an understanding that NSB must provide very high power system reliability, only the medium penetration configuration was modeled in this study as it represents a robust middle ground between insufficient fuel savings of the low penetration approach and the expense and considerable complexity of high penetration wind. A medium penetration approach would employ wind turbine capacity capable to approximately match peak load on windy days. In Point Hope, this would offset 20 to 50 percent of annual diesel energy production. To maintain reliability, “spinning reserve” (an on-line diesel generator operating between 10% and 100% rated output) would be maintained at all times to supplement the electrical load in anticipation of fluctuating wind conditions. During higher winds and lower electrical load, surplus wind-generated electricity would be shunted to an electric boiler to supplement thermal heat loads.

Based on the average and peak electrical loads in Point Hope, only new wind turbines between 100 and 350 kW rated power were considered in this study. Market availability for turbines in this size range is very limited worldwide and more limited yet in the United States, so only the fully arctic-rated 100 kW Northern Power Systems Northwind 100 and the 225 kW Aeronautica AW29-225, both manufactured in the United States, were identified as turbines suitable for use in Point Hope. The 330 kW German Enercon E33 would be a very good alternate choice, but this turbine is not available in the American market. The NW100 and the AW29-225 both have a history of successful use in utility power systems and have established support in Alaska.

Point Hope Wind-Diesel Hybrid Feasibility Study P a g e | 2

HOMER software was used to predict the performance of wind turbines if added to the existing Point Hope diesel power system with reference to load profile and operating costs reported to Alaska Energy Authority for the power cost equalization (PCE) program. Based on these simulations, economic analyses was performed to determine benefit/cost (B/C) ratios based on initial capital cost of wind turbines and related distribution and control system upgrades, O&M cost of the diesel plant and wind turbines, fuel cost and related avoided fuel usage. The economic analyses were tabulated using medium, high, and low fuel cost projections (as predicted by UAA’s Institute for Social and Economic Research) for Sites A and B with a number of different turbine configurations at each site. Even with conservative estimates of capital costs and O&M expenses over the life of the project, the medium and high fuel cost projections yield positive benefit-to-cost ratios for either turbine at both sites. Only the low cost projection fails to predict positive project benefit-to-cost ratios.

Point Hope Wind-Diesel Hybrid Feasibility Study P a g e | 3

1 Introduction The North Slope Borough (NSB) contracted with WHPacific to prepare wind power feasibility studies for the villages of Wainwright, Point Lay, and Point Hope. WHPacific contracted with V3 Energy, LLC to assist with the project. This report documents the feasibility study of Point Hope; the Point Lay and Wainwright studies are contained under separate cover.

Although NSB is home to vast fields of recoverable oil and natural gas, the huge size of the borough and the relative geographic concentration of these fossil fuel resources means that a number of NSB villages, including the coastal village of Point Hope, cannot tap these resources in any practical manner and instead must rely on the importation of diesel fuel for electricity generation and thermal heating. NSB desires to reduce Point Hope’s dependency on diesel fuel by developing renewable energy sources to augment the diesel generator and fuel oil boilers. Previous studies have determined that wind power has the most potential of the borough’s renewable energy resources to be economically viable and hence this study focuses only on the wind resource and wind turbines to exploit that resource.

1.1 Scope of Work This study, which was paid for with Alaska Energy Authority funds made available through the Alaska Renewable Energy Fund Program and with matching funds from the North Slope Borough, investigates and evaluates wind turbine power options in Point Hope, Point Lay, and Wainwright. The scope of work of this study includes:

• Select two wind turbine locations per village • Perform geotechnical investigation at each site • Identify land and/or regulatory issues for each site • Conduct wind technology workshop with NSB • Prepare conceptual design and feasibility reports

An environmental study, which is essential in determining site feasibility, will be conducted under a separate contract and is not included in this report.

1.2 Village of Point Hope Point Hope (Tikeraq) peninsula is one of the oldest continuously occupied Inupiat Eskimo areas in

Alaska. Several settlements have existed on the peninsula over the past 2,500 years, including Old and New Tigara, Ipiutak, Jabbertown, and present Point Hope. The peninsula offers good access to marine mammals and ice conditions allow easy boat launchings into open leads early in the spring whaling season. The people were traditionally aggressive and exercised dominance over an extensive area, from the Utukok to Kivalina Rivers and far inland. By 1848 commercial whaling activities brought an influx of Westerners, many of whom employed Point Hope

Point Hope Wind-Diesel Hybrid Feasibility Study P a g e | 4

villagers. By the late 1880s, the whalers established shore-based whaling stations such as Jabbertown. These disappeared in the early 1900’s with the demise of whaling. The Point Hope city government was incorporated in 1966. In the early 1970s, the village moved to a new site just east of the old village because of erosion and periodic storm-surge flooding. Most of the housing was moved on runners to the new site. New houses were constructed by the borough and individuals.

A federally-recognized tribe is located in the community -- the Native Village of Point Hope. Point Hope residents (Tikeraqmuit Inupiat Eskimos) are dependent upon marine subsistence. This highly favorable site, with its abundant resources, has enabled the Tikeraqmuit to retain strong cultural traditions after more than a century of outside influences. The sale, importation, and possession of alcohol are banned in the village.

According to Census 2010 there are 221 housing units in Point Hope and 186 of them are occupied. The Point Hope population of 674 people is approximately 89 percent Alaska Native, five percent Caucasian, four percent multi-racial, and two percent Hispanic, black or other.

The North Slope Borough provides all utilities in Point Hope. Water is derived from a lake six miles to the east and is treated and stored in a tank. A number of homes have water tanks with delivery, which provides running water for kitchens; others haul water. Electricity is provided by North Slope Borough. There is one school located in the community which has 222 students. Emergency Services have coastal and air access. Emergency service is provided by 911 Telephone Service volunteers and a health aide based at the Point Hope Clinic. Auxiliary health care is provided by the Point Hope Volunteer Fire Dept.

Most full-time positions in Point Hope are with the city and borough governments. Residents manufacture whalebone masks, baleen baskets, ivory carvings, and Eskimo clothing. Seals, bowhead whales, beluga whales, caribou, polar bears, birds, fish, and berries are utilized.

The 2005-2009 American Community Survey (ACS) estimated that 304 Point Hope residents are employed. The public sector employs 64.5% of all workers. The local unemployment rate is 23.6%. The percentage of workers not in labor force is 32.4%. The ACS surveys established that average median household income (in 2009 inflation-adjusted dollars) is $73,438 (MOE +/-$8,581). The per capita income (in 2009 inflation-adjusted dollars) is $18,825 (MOE +/-$2,549). About eight percent of all residents had incomes below the poverty level.

Note that information regarding Point Hope is drawn from the Alaska Community Database Community Information Summaries (CIS) which can be found at http://www.dced.state.ak.us/dca/commdb/CIS.cfm. Regarding the American Community Survey information, MOE refers to margin of error.

1.3 Climate Point Hope is located near the tip of Point Hope peninsula in the Chukchi Sea, a large gravel spit that forms the western-most extension of the northwest Alaska. The climate is arctic with temperatures ranging from -49° F in winter to 78 °F in summer. Precipitation is light, averaging only ten inches of water equivalent annually, including 36 inches of snowfall. The Chukchi Sea at Point Hope is ice-free from late June until mid-September.

Point Hope Wind-Diesel Hybrid Feasibility Study P a g e | 5

1.4 Geology Geotechnical study was accomplished at Sites A and B by Golder and Associates of Anchorage. Their report of findings may be found under separate cover.

1.5 Permitting The permits that are typically required to erect wind turbines and construct supporting access roads and power distribution lines are:

• Federal Aviation Administration (FAA) obstruction notification • State of Alaska land use, if constructing on State land • Local land use, if constructing on Borough land • Alaska Fish and Game fish habitat, if access road crosses stream(s) • U.S. Army Corps of Engineers (USACE) wetlands, if constructing on identified wetlands; may

require concurrence with: o National Historic Preservation Act o Endangered Species Act, if endangered species potentially impacted o Consideration of essential fish habitat, if access road crosses stream(s) o Migratory Bird Act, U.S. Fish and Wildlife Service

Point Hope Wind-Diesel Hybrid Feasibility Study P a g e | 6

2 Wind Resource Assessment The wind resource measured in Point Hope is superior, with measured high wind power class 6 (outstanding). In addition to high annual mean wind speed and wind power density, Point Hope experiences highly directional prevailing winds, low turbulence and calculations indicate low extreme wind speed probability.

A 34 meter met tower, erected to 30 meters, was installed in June 2009 at the northeast corner of Point Hope between the village water storage tank and a large snow fence to the north. This site was chosen as it is near the power plant and other existing electrical power infrastructure and did not present obstruction problems for airport operations. The met tower was removed in July 2010.

2.1 Met tower data synopsis Data dates June 16, 2009 to July 15, 2010 (13 months) Wind power class 6 (outstanding) Power density mean, 30 m 515 W/m2 Wind speed mean, 30 m 7.12 m/s Max. 10-min wind speed average 27.9 m/s Maximum wind gust 32.2 m/s (Dec. 2009) Weibull distribution parameters k = 1.82, c = 7.92 m/s Wind shear power law exponent 0.110 (low) Roughness class 0.27 (rough sea) IEC 61400-1, 3rd ed. classification Class III-c (lowest defined and most common) Turbulence intensity, mean 0.073 (at 15 m/s) Calm wind frequency 20% (<3.5 m/s)

2.2 Data Recovery Met tower data recovery in Point Hope was outstanding, with nearly 100 percent functionality of the anemometers, wind vane and temperature sensor. This is remarkable anywhere in Alaska, but even more so on the Chukchi Sea coast of the North Slope with its intensely cold winter temperatures.

2.3 Wind Speed Wind data collected from the met tower, from the perspective of both mean wind speed and mean power density, indicates an outstanding wind resource. The minor discrepancy in mean wind speed between the 30 m A and the 30 m B anemometer is due to the placement of the of the 30 m A anemometer at 178° T. With frequent northerly winds, the 30m A anemometer experienced some minor tower shadowing effects. The cold arctic temperatures of Point Hope contributed to the high wind power density, a key consideration of wind turbine performance.

Point Hope Wind-Diesel Hybrid Feasibility Study P a g e | 7

Wind speed profile

2.4 Wind Rose Wind frequency rose data indicates highly directional winds from the north and southeast. Power density rose data (representing the power in the wind) indicates power winds are strongly directional, from 345°T to 025°T and to a lesser extent from 130°T. Calm frequency (percent of time that winds at the 30 meter level are less than 3.5 m/s) was 20 percent during the met tower test period.

Wind frequency rose Wind energy rose

Point Hope Wind-Diesel Hybrid Feasibility Study P a g e | 8

2.5 Turbulence Intensity Turbulence intensity at the Point Hope test site is well within acceptable standards with an IEC 61400-1, 3rd edition (2005) classification of turbulence category C, which is the lowest defined. Mean turbulence intensity at 15 m/s is 0.073.

Turbulence graph

2.6 Extreme Winds Although thirteen months of data is minimal for calculation of extreme wind probability, use of a modified Gumbel distribution analysis, based on monthly maximum winds vice annual maximum winds, yields reasonably good results. Extreme wind analysis indicates a highly desirable situation in Point Hope: moderately high mean wind speeds combined with low extreme wind speed probabilities. This may be explained by particular climactic aspects of Point Hope which include prominent coastal exposure, offshore wind conditions, and due to the extreme northerly latitude, lack of exposure to Gulf of Alaska storm winds.

Industry standard reference of extreme wind is the 50 year, 10-minute average probable wind speed, referred to as Vref. For Point Hope, this calculates to 32.1 m/s, below the threshold of International Electrotechnical Commission (IEC) 61400-1, 3rd edition criteria (of 37.5 m/s) for a Class III site. Note that Class III extreme wind classification is the lowest defined and all wind turbines are designed for this wind regime.

Point Hope Wind-Diesel Hybrid Feasibility Study P a g e | 9

3 Wind Project Sites NSB requested that two wind turbine sites be identified in Point Hope. On July 7 and 8, 2011, Ross Klooster of WHPacific, Doug Vaught of V3 Energy, LLC, and Max Ahgeak of NSB Public Works Dept. traveled to Pint Hope and met with Village of Point Hope and Tikigaq Corporation representatives to discuss the wind power project and to identify the two sites. This was accomplished by reviewing maps and ownership records and then driving and walking to a number of locations near the village to assess suitability for construction and operation of wind turbines.

Identifying suitable wind turbine sites in Point Hope was somewhat difficult because of complicated land ownership with many native allotments near the village, airport interference considerations, and cultural and traditional land use considerations that are incompatable with wind turbine construction and operation. Two sites on Tikigaq Corporation land were eventually chosen, identified as Site A and Site B in the Google Earth image below.

Point Hope site options, Google Earth image

3.1 Site A Site A, at 4 km (2.5 miles) is further from the village than ideal considering the cost of construction of new power distribution, but it is the nearest distance available as intervening land on the spit is completely defined by traditional use areas and Native allotments. The Site A parcel is land owned by Tikigaq Corporation, is large enough to accommodate several wind turbines and appears to be permafrost-free. A key advantage of Site A is that turbine height is essentially unrestricted from an FAA airport operations perspective (refer to Appendix A)

Point Hope Wind-Diesel Hybrid Feasibility Study P a g e | 10

Point Hope Site A

3.2 Site B Site B is much closer to Point Hope and very near existing 3-phase power distribution lines, but its proximity to the airport presents height restrictions. As with Site A, The Site B parcel is land owned by Tikigaq Corporation, is large enough to accommodate several wind turbines and is permafrost-free. FAA’s notice of presumed hazard for Site B (refer to Appendix B) limits turbine construction to 158 ft. above ground level. With respect to the turbines options considered in this report (refer to Section 5.2), only the Aeronautica AW 29-225 on a 30 meter tower has a sufficiently low elevation tip height to meet FAA’s height restrictions for this site. A possible alternative is the Northern Power Northwind 100B/21 on a 30 meter tower instead of the normal 37 meter tower (refer to Section 5.2). This possibility must be discussed with Northern Power Systems, however, as a 30 meter tower option may not be available for the B model NW100 as it had once been for their A model Northwind 100.

Point Hope Wind-Diesel Hybrid Feasibility Study P a g e | 11

Point Hope Site B

Point Hope wind turbine site options table Wind Turbine Site Advantages Disadvantages

A Tikigaq Corp. land 4.0 km (2.5 miles) of new distribution line required

Site large enough to accommodate several wind turbines and should have sufficient room for future expansion

Future expansion beyond Tikigaq property boundaries likely be possible due to Native Allotments to the east and west

Dry site; likely good geotech conditions for turbine foundations

Short new access road; minimal cost

FAA Determination of No Hazard to Air Navigation for turbines up to 195 ft AGL (possibly higher)

B Tikigaq Corp. land Close to the airport; FAA determination of Notice of Presumed Hazard (NPH) for turbines exceeding 158 ft AGL

Very short (~1000 ft) new distribution line required to connnect to existing three phase powerline to the airport

Point Hope Wind-Diesel Hybrid Feasibility Study P a g e | 12

Short new access road; minimal cost

Site large enough to accommodate several wind turbines and should have sufficient room for future expansion

Dry site; likely good geotech conditions for turbine foundations

3.3 Other Site Options Other than locating turbines at the met tower site, which was rejected by Village of Point Hope and Tikigaq Corporation representatives during the site visit in July as too close to the village, Sites A and B, represent the only realistic wind turbine site options for Point Hope. Terrain further east of Site A might be possible, but one would have to go a considerable distance to avoid Native Allotments for no benefit and considerable financial penalty with a longer distance distribution line. Terrain between Site B and the village is another possibility, but it is mostly Native Allotment(s) and hence difficult to obtain construction approval. In addition, locating turbines closer to the village, whether to the east or west, increases the possibility of aesthetic and noise objections.

Point Hope Wind-Diesel Hybrid Feasibility Study P a g e | 13

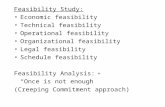

4 Wind-Diesel System Design and Equipment Wind-diesel power systems are categorized based on their average penetration levels, or the overall proportion of wind-generated electricity compared to the total amount of electrical energy generated. Commonly used categories of wind-diesel penetration levels are low penetration, medium penetration, and high penetration, as summarized below. The wind penetration level is roughly equivalent to the amount of diesel fuel displaced by wind power. Note however that the higher the level of wind penetration, the more complex and expensive a control system and demand-management strategy is required.

Categories of wind-diesel penetration levels Penetration

Penetration Level Operating characteristics and system requirements Instantaneous Average

Low 0% to 50% Less than 20%

Diesel generator(s) run full time at greater than minimum loading level. Requires minimal changes to existing diesel control system. All wind energy generated supplies the village electric load; wind turbines function as “negative load” with respect to diesel generator governor response.

Medium 0% to 100+% 20% to 50%

Diesel generator(s) run full time at greater than minimum loading level. Requires control system capable of automatic generator start, stop and paralleling. To control system frequency during periods of high wind power input, system requires fast acting secondary load controller matched to a secondary load such as an electric boiler augmenting a generator heat recovery loop. At high wind power levels, secondary (thermal) loads are dispatched to absorb energy not used by the primary (electric) load. Without secondary loads, wind turbines must be curtailed to control frequency.

High (Diesels-off Capable)

0% to 150+% Greater than 50%

Diesel generator(s) can be turned off during periods of high wind power levels. Requires sophisticated new control system, significant wind turbine capacity, secondary (thermal) load, energy storage such as batteries or a flywheel, and possibly additional components such as demand-managed devices.

Choosing the ideal wind penetration for Point Hope depends on a number of factors, including load profile of the community, wind resource, construction cost and challenges, fuel price and also technical capability and experience of the utility with wind power and energy storage systems. There is no one “right” answer and the most optimal wind-diesel system for Point Hope may not be the one that displaces the most fuel, nor even one that has the highest estimated benefit-to-cost ratio. It is presumed for the purposes of this feasibility study that North Slope Borough’s interest will be with a medium penetration option as that provides significant enough fuel savings to justify the high construction costs of a wind turbine project yet avoids the significant design complexity and operational challenges of high penetration.

Point Hope Wind-Diesel Hybrid Feasibility Study P a g e | 14

4.1 Wind-diesel Integration Controls Medium to high-penetration wind-diesel systems require fast-acting real and reactive power management to compensate for rapid variation in village load and wind turbine power output. A wind- diesel system master controller, typically referred to as a supervisory control and data acquisition (SCADA) system, is installed to select the optimum system component configuration based on village load demand and available wind power. Regardless of the supplier, a SCADA system is capable of controlling individual components and allowing those components to communicate status to the system. A typical SCADA will consist of the following:

• Station Controller: schedules and dispatches diesel generators, wind turbines and other components units, performs remote control functions, and stores collected component and system data

• Generation Controller: monitors and controls individual diesel generators • Wind Turbine Controller: monitors and controls individual wind turbine and dispatches wind

turbines • Feeder Monitor: monitors vital statistics of an individual distribution feeder, including

ground fault information • Demand Controller: monitors, controls, and schedules demand-managed devices

4.2 Energy Storage Options Although high penetration wind power is not proposed in this feasibility study, as reference for future development, electrical energy storage provides a means of storing wind generated power during periods of high winds and releasing that power to the electrical distribution system as winds subside.

4.2.1 Batteries Batteries are most appropriate for providing medium-term energy storage to allow a transition, or bridge, between the variable output of wind turbines, and diesel generation. This bridging period is typically between five and fifteen minutes. Storage for several hours or days is also possible with batteries, but requires more capacity and higher cost. In general, the disadvantages of batteries for energy storage, even for a small utility system, are high capital and maintenance costs and limited lifetime. Of particular concern to rural Alaska communities is that batteries are heavy and expensive to transport to the site, and many contain toxic material that requires disposal as hazardous waste at the end of a battery’s useful life.

Because batteries operate on direct current (DC), a converter is required when connected to an alternating current (AC) system. A typical battery storage system includes a bank of batteries and a power conversion device. Recent advances in power electronics have made solid state converter (inverter/rectifier) systems cost effective and hence the preferred power conversion device.

Despite some drawbacks, electric power storage with batteries is a proven technology, but it has seen limited use in rural Alaska wind-diesel projects to date. Wales is equipped with a high penetration wind system with battery storage that is functional, but its operational history has been very disappointing and given the design age, it is not considered a reproducible system. Kokhanok has a recently-installed

Point Hope Wind-Diesel Hybrid Feasibility Study P a g e | 15

high-penetration wind-diesel system with lead-acid type battery storage, designed and constructed by Marsh Creek LLC of Anchorage, although it is not yet operational. Of interest is a 250 kW flow battery that Kotzebue Electric Association plans to install in 2012 in Kotzebue to support their planned installation of two 900 kW EWT wind turbines.

4.2.2 PowerStore Flywheel Built by Powercorp Pty of Darwin, Australia, the PowerStore is a very fast-acting energy source and sink system based on a modern flywheel and bi-directional converter. During normal operation, energy is supplied to the PowerStore as a steady 12 kW load to maintain rotational energy. When necessary to control power system frequency, energy is delivered to or drawn from the flywheel. The PowerStore can absorb or deliver 300 or 1000 kW (depending on the inverter) of power in 5 milliseconds. The PowerStore has been used in rural wind-diesel and mining applications in a number of locations worldwide, including Antarctica and remote regions of Australia.

Point Hope Wind-Diesel Hybrid Feasibility Study P a g e | 16

5 Wind Turbines and HOMER Modeling Considering NSB’s goal of displacing as much diesel fuel for electrical generation as possible and yet recognizing the present limitations of high penetration wind power in Alaska and NSB’s desire to operate a highly stable and reliable electrical utility in Point Hope, only the medium penetration wind-diesel configuration scenario was modeled with HOMER software. Note that low penetration wind was not modeled as this would involve use of smaller farm-scale turbines that are not designed for severe cold climates, and low penetration would not meet NSB’s goal of significantly displacing fuel usage in Point Hope.

As previously noted, a medium penetration wind-diesel configuration is a compromise between the simplicity of a low penetration wind power and the significant complexity and sophistication of the high penetration wind. With medium penetration, instantaneous wind input is sufficiently high (at 100 plus percent of the village electrical load) to require a secondary or diversion load to absorb excess wind power, or alternatively, to require curtailment of wind turbine output during periods of high wind/low electric loads. For Point Hope, appropriate wind turbines for medium wind penetration are generally in the 100 to 300 kW range with more numbers of turbines required for lower output machines compared to larger output models.

There are a number of comparative medium penetration village wind-diesel power systems presently in operation in Alaska. These include the AVEC villages of Toksook Bay, Chevak, Savoonga, Kasigluk, Hooper Bay, among others. All are characterized by wind turbines directly connected to the AC distribution system. AC bus frequency control during periods of high wind penetration, when diesel governor control would be insufficient, is managed by the sub-cycle, high resolution, and fast-switching capability of the secondary load controller (SLC). Ideally, the SLC is connected to an electric boiler serving a thermal load as this will enhance overall system efficiency by augmenting the operation of the fuel oil boiler(s) serving the thermal load.

5.1 Diesel Power Plant Electric power (comprised of the diesel power plant and the electric power distribution system) in Point Hope is provided by North Slope Borough Public Works Department, the utility for all communities on the North Slope, with the exception of Deadhorse and Barrow. The existing power plant in Point Hope consists of two older Caterpillar 3406B diesel generators rated at 320 kW output and three Caterpillar 3512 diesel generators, two rated at 665 kW and one rated at 950 kW output.

Point Hope powerplant diesel generators and bays Generator/Bay Electrical Capacity Diesel Engine Model Status

1 320 kW Caterpillar 3406B Standby unit 2 320 kW Caterpillar 3406B Standby unit 3 open open open 4 open open open 5 open open open 6 665 kW Caterpillar 3512 Prime unit 7 665 kW Caterpillar 3512 Prime unit 8 950 kW Caterpillar 3512 Prime unit

Point Hope Wind-Diesel Hybrid Feasibility Study P a g e | 17

Generator sets in the Point Hope power plant are controlled by Woodward 2301A load sharing and speed control governors with protection and alarms initiated by discreet protective relays for each unit. A user-programmable PLC controller with SCADA interface automatically parallels and dispatches the diesel generators, based on system load and operator-programmable preferences, via a unit-based auto synchronizer

5.2 Wind Turbines For this study, the wind turbines considered are restricted to rated outputs of 100 to 350 kW as this size range well matches Point Hope’s electric load. This eliminates the battery-charging turbines and small grid-connect home and farm-scale turbines that are insufficient for village power needs and the very large utility-scale turbines that would overwhelm the Point Hope power system. Unfortunately though, the world wind turbine market offers very few turbines in this mid or village-scale size range. Of new turbines, two American-made options are the 100 kW Northwind 100 and the 225 kW Aeronautica 29-225. The 330 kW German-made Enercon E33 would be an excellent option, but it remains unavailable to the U.S. market due to a past patent dispute between Enercon and General Electric. Remanufactured wind turbines are a possible option for NSB to consider, with the 225 kW Danish-made Vestas V27 available through Halus Power Systems of San Leandro, California.

Whether new or remanufactured, the primary criteria for wind turbines suitable for Point Hope are:

• Alternating current (AC) generator; synchronous or asynchronous are acceptable • Cold-climate capable (rated to -40° C) with appropriate use of materials, lubricants and heaters • IEC Class II rated • A “known” turbine with an existing track record of installed operation • Suitable for marine environments • Established North American support capability, preferably with an Alaska presence

5.2.1 Northern Power Systems Northwind 100 The Northwind 100 (the NW100B/21 model) wind turbine is manufactured by Northern Power Systems in Barre, Vermont. The NW100 turbine is stall-regulated, has a direct-drive permanent magnet synchronous generator, active yaw control, a 21 meter diameter rotor, is rated at 100 kW power output, and is available only on a 37 meter tubular steel tower. The NW100B/21 is fully arctic-climate certified to -40° C and is the most represented village-scale wind turbine in Alaska at present with a significant number of installations in the Yukon-Kuskokwim Delta and on St. Lawrence Island. More information can be found at: http://www.northernpower.com/ and in Appendix C of this report.

Point Hope Wind-Diesel Hybrid Feasibility Study P a g e | 18

NW100 wind turbine NW100B/21 power curve

5.2.2 Aeronautica AW29-225 The Aeronautica AW29-225 wind turbine is manufactured new by Aeronautica in Durham, New Hampshire. This turbine was originally designed by the Danish-manufacturer Norwin in the 1980’s and had a long and successful history in the wind industry before being replaced by larger capacity turbines for utility-scale grid-connect installations. The AW29-225 turbine is stall-regulated, has a synchronous (induction) generator, active yaw control, a 29 meter diameter rotor, is rated at 225 kW power output, and is available with 30, 40, or 50 meter tubular steel towers. The AW29-225 is fully arctic-climate certified to -40° C and is new to the Alaska market with no in-state installations at present. More information can be found at http://aeronauticawind.com/aw/index.html and in Appendix D of this report.

Aeronautica AW29-225 AW29-225 power curve

Point Hope Wind-Diesel Hybrid Feasibility Study P a g e | 19

5.2.3 Wind Turbine Performance Comparison In the table below is an analysis of turbine output and capacity factor performance of the turbines profiled above, with comparisons of manufacturer rated output power at 100%, 90% and 80% turbine availability (percent of time that the turbine is on-line and available for energy production). Both the NW100B/21 and the AW29-225 perform very well in the Point Hope wind regime with excellent capacity factors and annual energy production.

Turbine capacity factor comparison

100% availability 90% availability 80% availability

Turbine Model

Rated Output

(kW)

Hub Height

(m)

Tip Height (m)*

Tip Height (ft.)*

Annual Energy (MWh)

Capacity Factor

(%)

Annual Energy (MWh)

Capacity Factor

(%)

Annual Energy (MWh)

Capacity Factor

(%) NW100B/21 100 37 47.5 156 313.9 34.8 282.5 31.3 251.1 27.8 AW29-225 225 30 44.5 146 628.3 31.9 565.5 28.7 502.6 25.5

225 40 54.5 179 662.9 33.6 596.6 30.2 530.3 26.9

*Note: assumes base of turbine tower at ground level

5.3 Modeling Wind turbine and system performance modeling of wind-diesel configurations in Point Hope was accomplished with HOMER software. This software enables static modeling of a power system to demonstrate energy balances and fuel displacement with introduction of wind power. A limitation of the software is that it is not suitable for dynamic modeling. In other words, it cannot model voltage and frequency perturbations and power system dynamics, although it will provide a warning for systems that are potentially unstable.

5.3.1 Electric Load The Point Hope electric load was synthesized with the Alaska Electric Load Calculator Excel program written in 2006 by Mia Devine of the Alaska Energy Authority. This spreadsheet allows one to create a “virtual” village load in one hour increments, suitable for import into HOMER software. For this feasibility study, 2010 PCE data of reported gross kWh generated, average power, fuel usage, and powerplant efficiency was used with the Alaska Load Calculator to synthesize a 728 kW average load with a 1,189 kW peak load and approximately 400 kW minimum load. Graphical representations of the electric load are shown below.

Point Hope Wind-Diesel Hybrid Feasibility Study P a g e | 20

5.3.2 Thermal Load The thermal load available to the diesel generator heat recovery system was estimated based on better-documented thermal loads in other villages, the size of Point Hope’s electrical load, and village meter log information. Typically very difficult to quantify as accurately as the electric load, the thermal load serves as an energy “dump” in medium and high penetration wind-diesel configurations, or, more precisely, as the secondary load available to absorb excess electrical energy generated by wind turbines during periods of relatively high wind turbine output and low electric load demand.

5.4 Diesel Generators The HOMER model was constructed three of Point Hope’s five operational diesel generators, all Caterpillar 3512 models, two with 665 kW output generators and one rated at 950 kW. They are listed as numbers 6, 7 and 8 to denote their bay positions in the Port Hope powerplant. The remaining two operational diesel generators are Caterpillar 3406B models, but these are old machines and reportedly only used in standby capacity. For cost modeling purposes, AEA assumes a generator O&M cost of $0.020/kWh. This was converted to $14.56/operating hour for each diesel generator for use in the HOMER software model (based on Point Hope’s modeled average electrical load of 728 kW).

Manufacturer fuel curves for the diesel generators, provided by David Lockard of AEA in an Excel file entitled Cat C9M C18M 3508 3512 3456 Mar 20081, were used in the HOMER models. In addition, the

Point Hope Wind-Diesel Hybrid Feasibility Study P a g e | 21

diesel engines in the modeling runs were set to “optimize”, which HOMER interprets as use of the most efficient diesel generator whenever possible.

Diesel generator HOMER modeling information Diesel generator Caterpillar

3512 Caterpillar

3512 Caterpillar

3512 HOMER model identification

Cat 3512 (6) (Bay 6)

Cat 3512 (7) (Bay 7)

Cat 3512 (8) (Bay 8)

Power output (kW) 665 665 950 Intercept coeff. (L/hr/kW rated)

0.01937 0.01937 0.01937

Slope (L/hr/kW output)

0.2325 0.2325 0.2325

Minimum electric load (%)

10 10 10

Heat recovery ratio (% of waste heat that can serve the thermal load)

18 18 18

Intercept coefficient – the no-load fuel consumption of the generator divided by its capacity Slope – the marginal fuel consumption of the generator

Caterpillar 3512 fuel efficiency curve

Point Hope Wind-Diesel Hybrid Feasibility Study P a g e | 22

6 Economic Analysis Selected wind turbines in medium penetration mode are modeled in this report to demonstrate the economic viability of various configurations and fuel price points.

6.1 Wind Turbine Costs Capital and installation costs of wind turbines are somewhat difficult to estimate without detailed consideration of shipping fees, foundation design, cost efficiencies with installation of multiple turbines, identification of constructor, mobilization fees, etc. Although the cost assumptions detailed below should be considered tentative, they are generally in-line with other rural Alaska wind projects of the past few years. Note that for modeling purposes, an AW29-225 on a 30 meter tower is assumed to cost 1.5 percent less than noted below.

Wind turbine cost assumptions

Single Turbine

450-500 kW installed turbine capacity

NW100B (100 kW)

AW29-225 (225 kW)

NW100B (100 kW)

AW29-225 (225 kW)

Total turbine output (kW) 100 225 500 450 No. of turbines 1 1 5 2 Price/turbine $348,000 $580,000 $348,000 $580,000 Engineering, VAR support n/a $35,000 n/a $35,000 Capacitors cost/turb, VAR support n/a $40,000 n/a $80,000 Turbine cost $348,000 $655,000 $1,740,000 $1,355,000 Turbine capital cost/kW $3,480 $2,756 $3,480 $2,933 Construction cost (estimated) $696,000 $1,160,000 $2,923,200 $2,088,000 Total installed cost $1,047,480 $1,817,756 $4,666,680 $3,445,933 Total installed cost/kW $10,475 $8,079 $9,333 $7,658 Note: AW29-225 price with 40 meter tower

6.2 Fuel Cost A fuel price of $5.77/gallon ($1.53/Liter) was chosen for the initial HOMER analysis by reference to Alaska Fuel Price Projections 2011-2035, prepared for Alaska Energy Authority by the Institute for Social and Economic Research (ISER), dated July 7, 2011. The $5.77/gallon price reflects the average value of all fuel prices between the 2013 (assumed project start year) fuel price of $4.74/gallon and the 2032 (20 year project end year) fuel price of $6.54/gallon using the medium price projection three-year moving average (MA3) analysis.

Additional analyses with ISER’s low price projection MA3 and high price projection MA3 are included in the economic analysis of this report. For the high price projection, the median 2013 to 2032 three-year moving average price is $8.91/gallon ($2.35/Liter). For the low price projection, the average 2013 to 2032 three-year moving average price is $2.95/gallon ($0.78/Liter). Note also that heating fuel in HOMER is priced the same as diesel fuel.

Point Hope Wind-Diesel Hybrid Feasibility Study P a g e | 23

Fuel cost table Cost

Scenario 2013 (/gal) 2032 (/gal) Average (/gallon)

Average (/Liter)

Medium $4.74 $6.54 $5.77 $1.53 High $5.87 $10.42 $8.91 $2.35 Low $3.81 $2.70 $2.95 $0.78

ISER, MA3 cost projections

6.3 HOMER Modeling Assumptions In the HOMER modeling simulations, the annual average wind speed was reduced to 6.40 m/s (from a measured 7.12 m/s) to yield an approximate turbine availability of 82 percent. This is in-line with AEA assumptions of turbine availability in their economic models. HOMER modeling assumptions are listed in the table below.

Basic modeling assumptions Economic Assumptions Project life 20 years Discount rate 3% System fixed O&M cost $649,000/year (2010 PCE Report) Operating Reserves Load in current time step 10% Wind power output 50% Fuel Properties (both types) Heating value 42.5 MJ/kg Density 820 kg/m3

Diesel Generators Generator capital cost $0 (already exist) O&M cost $14.56/hour ($0.02/kWh) Time between overhauls 20,000 hours Overhaul cost (Cat 3512) $100,000 Minimum load ratio 10%; based on AVEC’s operational

experience of 50 kW minimum diesel loading with their wind-diesel systems

Schedule Optimized Wind Turbines Availability 82% Scaled annual average wind speed

6.30 m/s (7.12 m/s non-scaled, from met tower data)

O&M cost $0.0469/kWh (translated to $/year based on 26% turbine CF)

• NW100B/21 • $10,700/yr/turbine • AW 29-225 • $24,000/yr/turbine

Point Hope Wind-Diesel Hybrid Feasibility Study P a g e | 24

6.4 Wind Power Scenario Cost Assumptions The base or comparison scenario, which does not include wind turbines, is the existing Point Hope powerplant with its present configuration of diesel generators.

Wind turbines in a medium penetration system configuration may be constructed at Site A or Site B. Development costs between the sites will be different because of varying distances of access roads and new power distribution lines. For both sites, $150,000 is assumed both for SCADA improvements to accommodate the inclusion of wind power into the existing diesel power plant operating system and a secondary load controller and electric boiler to allow excess wind turbine power to serve the thermal load. Additionally for both sites, $50,000 is assumed for basic permitting and project management. As noted in the table below, these fixed costs plus the varying road access and power distribution extension development costs for each site result in total development costs of $1,250,000 for Site A and $330,000 for Site B. Typically, geotechnical studies are also included as part of the site development process to support the design of turbine foundations, but these efforts have already been accomplished.

Wind project cost assumptions

Base Site A Site B SCADA upgrade, SLC, boiler $150,000 $150,000 3Φ distribution line extension $1,000,000 $80,000 Road extension $50,000 $50,000 Permitting $50,000 $50,000

$0 $1,250,000 $330,000

Distribution distance (miles)

2.5 0.2 Road distance (miles)

0.1 0.1

Notes: Distribution line, $400K/mi Road, $500K/mi

Point Hope Wind-Diesel Hybrid Feasibility Study P a g e | 25

6.5 Site A Project Economics

6.5.1 Medium Fuel Price Projection, 82% Turbine Availability

NW100 AW29 Initial capital

Operating cost ($/yr) Total NPC

COE ($/kWh)

Renewable fraction

Heating oil arctic

(L) Diesel

arctic (L)

Total fuel use

(gal)

Fuel use avoided

(gal) Project

B/C ratio

4 $7,952,287 2,881,946 $50,828,356 0.469 0.24 123,719 1,163,730 340,145 120,644 1.025

5 $9,580,464 2,787,949 $51,058,100 0.471 0.29 113,400 1,097,356 319,883 140,906 1.020

3 $6,324,110 3,009,744 $51,101,492 0.471 0.18 125,368 1,260,435 366,130 94,659 1.019

8

$8,631,080 2,878,476 $51,455,536 0.475 0.23 129,619 1,162,986 341,507 119,282 1.012 10

$10,440,680 2,767,978 $51,621,200 0.477 0.28 123,558 1,083,430 318,887 141,902 1.009

6 $11,208,641 2,718,108 $51,647,216 0.477 0.32 103,826 1,046,862 304,013 156,776 1.009

6

$6,821,480 3,015,546 $51,685,180 0.478 0.17 125,850 1,269,277 368,594 92,195 1.008

2 $4,695,933 3,162,852 $51,751,180 0.478 0.11 114,849 1,385,228 396,322 64,467 1.007

5

$5,916,680 3,091,386 $51,908,692 0.480 0.14 120,135 1,330,745 383,324 77,465 1.003 Base system $0 3,501,209 $52,089,140 0.482 0.00 88,741 1,655,345 460,789 0 1.000 12

$12,250,280 2,682,236 $52,155,172 0.483 0.33 114,209 1,023,547 300,596 160,193 0.999

4

$5,011,880 3,169,464 $52,165,492 0.483 0.11 113,605 1,394,391 398,414 62,375 0.999 3

$4,107,080 3,250,090 $52,460,200 0.486 0.08 106,951 1,459,074 413,745 47,044 0.993

1 $3,067,756 3,327,770 $52,576,568 0.487 0.05 101,180 1,519,193 428,104 32,685 0.991

2

$3,202,280 3,332,213 $52,777,192 0.489 0.05 100,561 1,524,148 429,249 31,539 0.987 1

$2,297,480 3,416,174 $53,121,520 0.493 0.01 94,433 1,589,691 444,947 15,842 0.981

Note: AW29-225 at 40 m hub height Note: NW100B/21 at 37 meter hub height

Point Hope Wind-Diesel Hybrid Feasibility Study P a g e | 26

6.5.2 High Fuel Price Projection, 82% Turbine Availability

NW100 AW29 Initial capital

Operating cost ($/yr) Total NPC

COE ($/kWh)

Renewable fraction

Heating oil arctic

(L) Diesel

arctic (L)

Total fuel use

(gal)

Fuel use avoided

(gal) Project

B/C ratio

6 $11,208,641 3,671,305 $65,828,388 0.590 0.32 103,825 1,046,860 304,012 156,776 1.118

5 $9,580,464 3,790,845 $65,978,668 0.592 0.29 113,400 1,097,353 319,882 140,906 1.116

12

$12,250,280 3,624,903 $66,179,676 0.594 0.33 114,209 1,023,545 300,596 160,193 1.112 10

$10,440,680 3,767,930 $66,497,964 0.597 0.28 123,558 1,083,428 318,887 141,901 1.107

4 $7,952,287 3,948,286 $66,692,800 0.599 0.24 123,719 1,163,727 340,144 120,644 1.104

8

$8,631,080 3,949,182 $67,384,928 0.607 0.23 129,619 1,162,983 341,506 119,282 1.092

3 $6,324,110 4,157,438 $68,176,280 0.615 0.18 125,368 1,260,432 366,129 94,659 1.080

6

$6,821,480 4,171,044 $68,876,072 0.622 0.17 125,850 1,269,274 368,593 92,195 1.069 5

$5,916,680 4,292,915 $69,784,408 0.632 0.14 120,135 1,330,742 383,323 77,465 1.055

2 $4,695,933 4,404,981 $70,230,928 0.637 0.11 114,849 1,385,225 396,321 64,467 1.048

4

$5,011,880 4,418,165 $70,743,008 0.642 0.11 113,605 1,394,388 398,413 62,375 1.040 3

$4,107,080 4,546,801 $71,751,992 0.653 0.08 106,951 1,459,073 413,745 47,043 1.026

1 $3,067,756 4,669,341 $72,535,752 0.661 0.05 101,180 1,519,192 428,104 32,685 1.015

2

$3,202,280 4,677,348 $72,789,400 0.664 0.05 100,560 1,524,145 429,248 31,540 1.011 Base system $0 4,947,056 $73,599,696 0.662 0.00 88,741 1,655,342 460,788 0 1.000 1

$2,297,480 4,810,271 $73,862,168 0.675 0.01 94,433 1,589,689 444,946 15,842 0.996

Note: AW29-225 at 40 m hub height Note: NW100B/21 at 37 meter hub height

Point Hope Wind-Diesel Hybrid Feasibility Study P a g e | 27

6.5.3 Low Fuel Price Projection, 82% Turbine Availability

NW100 AW29 Initial capital

Operating cost ($/yr) Total NPC

COE ($/kWh)

Renewable fraction

Heating oil arctic

(L) Diesel

arctic (L)

Total fuel use

(gal)

Fuel use avoided

(gal) Project

B/C ratio Base system $0 2,200,121 $32,732,236 0.311 0.00 88,741 1,655,342 460,788 0 1.000 1

$2,297,480 2,157,779 $34,399,776 0.328 0.01 94,433 1,589,689 444,946 15,842 0.952

1 $3,067,756 2,117,255 $34,567,156 0.330 0.05 101,180 1,519,192 428,104 32,685 0.947

2

$3,202,280 2,118,436 $34,719,260 0.332 0.05 100,560 1,524,145 429,248 31,540 0.943 3

$4,107,080 2,080,314 $35,056,892 0.335 0.08 106,951 1,459,073 413,745 47,043 0.934

2 $4,695,933 2,042,365 $35,081,164 0.335 0.11 114,849 1,385,225 396,321 64,467 0.933

4

$5,011,880 2,043,075 $35,407,676 0.339 0.11 113,605 1,394,388 398,413 62,375 0.924

3 $6,324,110 1,974,802 $35,704,168 0.342 0.18 125,368 1,260,432 366,129 94,659 0.917

5

$5,916,680 2,007,783 $35,787,420 0.343 0.14 120,135 1,330,742 383,323 77,465 0.915 6

$6,821,480 1,973,724 $36,185,504 0.347 0.17 125,850 1,269,274 368,593 92,195 0.905

4 $7,952,287 1,920,558 $36,525,336 0.351 0.24 123,719 1,163,727 340,144 120,644 0.896

8

$8,631,080 1,913,335 $37,096,672 0.357 0.23 129,619 1,162,983 341,506 119,282 0.882

5 $9,580,464 1,883,910 $37,608,284 0.362 0.29 113,400 1,097,353 319,882 140,906 0.870

10

$10,440,680 1,866,927 $38,215,832 0.369 0.28 123,558 1,083,428 318,887 141,901 0.857

6 $11,208,641 1,858,975 $38,865,496 0.375 0.32 103,825 1,046,860 304,012 156,776 0.842

12

$12,250,280 1,832,940 $39,519,800 0.382 0.33 114,209 1,023,545 300,596 160,193 0.828 Note: AW29-225 at 40 m hub height Note: NW100B/21 at 37 meter hub height

Point Hope Wind-Diesel Hybrid Feasibility Study P a g e | 28

6.5.4 Medium Fuel Price Projection, 100% Turbine Availability

NW100 AW29 Initial capital

Operating cost ($/yr) Total NPC

COE ($/kWh)

Renewable fraction

Heating oil arctic

(L) Diesel

arctic (L)

Total fuel use

(gal)

Fuel use avoided

(gal) Project

B/C ratio

4 $7,952,287 2,746,172 $48,808,380 0.447 0.29 126,634 1,073,421 317,055 143,733 1.057

5 $9,580,464 2,639,207 $48,845,204 0.448 0.34 111,112 1,004,042 294,625 166,164 1.056

6 $11,208,641 2,561,332 $49,314,792 0.453 0.39 99,037 951,460 277,542 183,246 1.046

3 $6,324,110 2,895,350 $49,399,596 0.454 0.22 131,860 1,181,053 346,873 113,915 1.045

10

$10,440,680 2,629,957 $49,567,792 0.455 0.34 123,518 994,571 295,400 165,388 1.041 8

$8,631,080 2,754,477 $49,610,740 0.456 0.28 134,289 1,078,632 320,455 140,333 1.040

12

$12,250,280 2,536,126 $49,981,428 0.460 0.39 110,209 933,578 275,769 185,019 1.032 6

$6,821,480 2,914,208 $50,177,532 0.462 0.21 132,444 1,198,152 351,545 109,244 1.028

2 $4,695,933 3,081,745 $50,544,508 0.466 0.14 120,529 1,328,577 382,855 77,933 1.021

5

$5,916,680 3,004,603 $50,617,580 0.466 0.17 126,253 1,269,756 368,827 91,961 1.019 4

$5,011,880 3,098,525 $51,110,104 0.472 0.13 118,522 1,345,095 386,689 74,099 1.010

3

$4,107,080 3,195,327 $51,645,472 0.477 0.10 110,556 1,421,790 404,847 55,941 0.999

1 $3,067,756 3,285,120 $51,942,036 0.480 0.06 103,792 1,490,591 421,237 39,551 0.993

Base system $0 3,501,209 $51,601,224 0.482 0.00 88,741 1,655,342 460,788 0 1.000 2

$3,202,280 3,294,789 $52,220,416 0.483 0.06 102,843 1,499,257 423,276 37,512 0.988

1

$2,297,480 3,396,023 $52,821,728 0.490 0.02 95,516 1,577,209 441,935 18,853 0.977 Note: AW29-225 at 40 m hub height

Note: NW100B/21 at 37 meter hub height

Point Hope Wind-Diesel Hybrid Feasibility Study P a g e | 29

6.6 Site B Project Economics

6.6.1 Medium Fuel Price Projection, 82% Turbine Availability

NW100 AW29 Initial capital

Operating cost ($/yr) Total NPC

COE ($/kWh)

Renewable fraction

Heating oil arctic

(L) Diesel

arctic (L)

Total fuel use

(gal)

Fuel use avoided

(gal) Project

B/C ratio

4 $6,968,264 2,920,731 $50,421,360 0.464 0.22 122,570 1,190,471 346,906 113,882 1.033

3 $5,356,369 3,041,432 $50,605,200 0.466 0.17 123,417 1,283,432 371,691 89,097 1.029

5 $8,580,160 2,830,045 $50,684,080 0.467 0.27 113,782 1,124,913 327,264 133,524 1.028

8

$7,714,080 2,904,223 $50,921,580 0.470 0.22 128,531 1,181,246 346,044 114,744 1.023 6

$5,904,480 3,036,001 $51,072,500 0.471 0.17 124,393 1,284,506 372,232 88,556 1.020

2 $3,744,474 3,184,458 $51,121,164 0.472 0.11 113,221 1,401,456 400,179 60,609 1.019

10

$9,523,680 2,797,076 $51,137,100 0.472 0.27 123,341 1,102,948 323,987 136,802 1.019 5

$4,999,680 3,108,249 $51,242,572 0.473 0.14 118,850 1,343,643 386,392 74,396 1.017

6 $10,192,055 2,763,718 $51,309,204 0.474 0.31 105,009 1,075,488 311,888 148,900 1.015

4

$4,094,880 3,182,834 $51,447,412 0.475 0.11 112,552 1,404,864 400,903 59,886 1.012 3

$3,190,080 3,259,804 $51,687,728 0.478 0.08 106,190 1,466,956 415,626 45,162 1.008

12

$11,333,280 2,713,372 $51,701,396 0.478 0.32 114,835 1,043,394 306,005 154,783 1.007

1 $2,132,579 3,337,626 $51,788,020 0.479 0.05 100,442 1,527,265 430,041 30,747 1.006

2

$2,285,280 3,337,972 $51,945,876 0.480 0.04 100,086 1,529,385 430,508 30,281 1.003 Base system $0 3,501,209 $52,089,140 0.482 0.00 88,741 1,655,342 460,788 0 1.000 1

$1,380,480 3,417,728 $52,227,632 0.483 0.01 94,219 1,592,246 445,565 15,223 0.997

Note: AW29-225 at 30 m hub height Note: NW100B/21 at 30 meter hub height if available; if not available, then the NW100B/21 is not an option for Site B

Point Hope Wind-Diesel Hybrid Feasibility Study P a g e | 30

6.6.2 High Fuel Price Projection, 82% Turbine Availability

NW100 AW29 Initial capital

Operating cost ($/yr) Total NPC

COE ($/kWh)

Renewable fraction

Heating oil arctic

(L) Diesel

arctic (L)

Total fuel use

(gal)

Fuel use avoided

(gal) Project

B/C ratio

6 $10,192,055 3,742,350 $65,868,776 0.591 0.31 105,009 1,075,488 311,888 148,900 1.117

5 $8,580,160 3,856,924 $65,961,440 0.592 0.27 113,782 1,124,913 327,264 133,524 1.116

12

$11,333,280 3,673,543 $65,986,312 0.592 0.32 114,835 1,043,394 306,005 154,783 1.115 10

$9,523,680 3,813,669 $66,261,444 0.595 0.27 123,341 1,102,948 323,987 136,802 1.111

4 $6,968,264 4,009,242 $66,615,660 0.598 0.22 122,570 1,190,471 346,906 113,882 1.105

8

$7,714,080 3,990,029 $67,075,628 0.603 0.22 128,531 1,181,246 346,044 114,744 1.097

3 $5,356,369 4,207,711 $67,956,472 0.613 0.17 123,417 1,283,432 371,691 89,097 1.083

6

$5,904,480 4,203,978 $68,449,056 0.618 0.17 124,393 1,284,506 372,232 88,556 1.075 5

$4,999,680 4,320,656 $69,280,128 0.627 0.14 118,850 1,343,643 386,392 74,396 1.062

2 $3,744,474 4,440,125 $69,802,320 0.632 0.11 113,221 1,401,456 400,179 60,609 1.054

4

$4,094,880 4,440,772 $70,162,352 0.636 0.11 112,552 1,404,864 400,903 59,886 1.049 3

$3,190,080 4,563,942 $71,090,008 0.646 0.08 106,190 1,466,956 415,626 45,162 1.035

1 $2,132,579 4,686,995 $71,863,232 0.654 0.05 100,442 1,527,265 430,041 30,747 1.024

2

$2,285,280 4,688,804 $72,042,832 0.656 0.04 100,086 1,529,385 430,508 30,281 1.022 1

$1,380,480 4,815,808 $73,027,536 0.666 0.01 94,219 1,592,246 445,565 15,223 1.008

Base system $0 4,947,056 $73,599,696 0.672 0.00 88,741 1,655,342 460,788 0 1.000 Note: AW29-225 at 30 m hub height

Note: NW100B/21 at 30 meter hub height if available; if not available, then the NW100B/21 is not an option for Site B

Point Hope Wind-Diesel Hybrid Feasibility Study P a g e | 31

6.6.3 Low Fuel Price Projection, 82% Turbine Availability

NW100 AW29 Initial capital

Operating cost ($/yr) Total NPC

COE ($/kWh)

Renewable fraction

Heating oil arctic

(L) Diesel

arctic (L)

Total fuel use

(gal)

Fuel use avoided

(gal) Project

B/C ratio Base system $0 2,200,121 $32,732,236 0.311 0.00 88,741 1,655,342 460,788 0 1.000 1

$1,380,480 2,159,624 $33,510,234 0.319 0.01 94,219 1,592,246 445,565 15,223 0.977

1 $2,132,579 2,123,356 $33,722,756 0.321 0.05 100,442 1,527,265 430,041 30,747 0.971

2

$2,285,280 2,122,388 $33,861,044 0.323 0.04 100,086 1,529,385 430,508 30,281 0.967 3

$3,190,080 2,086,238 $34,228,024 0.326 0.08 106,190 1,466,956 415,626 45,162 0.956

2 $3,744,474 2,054,509 $34,310,376 0.327 0.11 113,221 1,401,456 400,179 60,609 0.954

4

$4,094,880 2,050,842 $34,606,228 0.330 0.11 112,552 1,404,864 400,903 59,886 0.946

3 $5,356,369 1,991,923 $34,991,148 0.335 0.17 123,417 1,283,432 371,691 89,097 0.935

5

$4,999,680 2,017,229 $35,010,952 0.335 0.14 118,850 1,343,643 386,392 74,396 0.935 6

$5,904,480 1,984,962 $35,435,708 0.339 0.17 124,393 1,284,506 372,232 88,556 0.924

4 $6,968,264 1,941,202 $35,848,448 0.344 0.22 122,570 1,190,471 346,906 113,882 0.913

8

$7,714,080 1,927,129 $36,384,892 0.349 0.22 128,531 1,181,246 346,044 114,744 0.900

5 $8,580,160 1,905,979 $36,936,304 0.355 0.27 113,782 1,124,913 327,264 133,524 0.886

10

$9,523,680 1,882,264 $37,527,020 0.361 0.27 123,341 1,102,948 323,987 136,802 0.872

6 $10,192,055 1,883,068 $38,207,352 0.368 0.31 105,009 1,075,488 311,888 148,900 0.857

12

$11,333,280 1,849,333 $38,846,688 0.375 0.32 114,835 1,043,394 306,005 154,783 0.843 Note: AW29-225 at 30 m hub height

Note: NW100B/21 at 30 meter hub height if available; if not available, then the NW100B/21 is not an option for Site B

Point Hope Wind-Diesel Hybrid Feasibility Study P a g e | 32

6.6.4 Medium Fuel Price Projection, 100% Turbine Availability

NW100 AW29 Initial capital

Operating cost ($/yr) Total NPC

COE ($/kWh)

Renewable fraction

Heating oil arctic

(L) Diesel

arctic (L)

Total fuel use

(gal)

Fuel use avoided

(gal) Project

B/C ratio

4 $6,968,264 2,786,170 $48,419,440 0.443 0.27 125,918 1,100,017 323,893 136,895 1.076

5 $8,580,160 2,682,778 $48,493,116 0.444 0.33 111,968 1,031,351 302,066 158,722 1.074

3 $5,356,369 2,929,121 $48,934,288 0.449 0.21 129,976 1,204,643 352,607 108,181 1.064

6 $10,192,055 2,606,866 $48,975,632 0.449 0.37 100,574 979,210 285,280 175,508 1.064

10

$9,523,680 2,659,814 $49,094,988 0.450 0.33 123,668 1,013,729 300,501 160,287 1.061 8

$7,714,080 2,781,613 $49,097,456 0.450 0.27 133,299 1,097,081 325,067 135,721 1.061

12

$11,333,280 2,567,004 $49,523,808 0.455 0.37 111,238 952,586 281,063 179,725 1.052 6

$5,904,480 2,936,189 $49,587,548 0.456 0.20 131,003 1,213,757 355,287 105,501 1.050

2 $3,744,474 3,105,547 $49,947,168 0.459 0.13 118,819 1,345,522 386,880 73,908 1.043

5

$4,999,680 3,023,368 $49,979,752 0.460 0.17 124,904 1,283,156 372,011 88,778 1.042 4

$4,094,880 3,113,904 $50,421,900 0.464 0.13 117,421 1,355,999 389,279 71,509 1.033

3

$3,190,080 3,206,758 $50,898,532 0.469 0.09 109,767 1,429,907 406,783 54,005 1.023

1 $2,132,579 3,297,131 $51,185,556 0.472 0.06 103,028 1,499,036 423,267 37,522 1.018

2

$2,285,280 3,302,557 $51,418,980 0.475 0.06 102,337 1,504,699 424,580 36,208 1.013 1

$1,380,480 3,399,948 $51,963,120 0.481 0.02 95,271 1,579,932 442,590 18,198 1.002

Base system $0 3,501,209 $52,089,140 0.482 0.00 88,741 1,655,342 460,788 0 1.000 Note: AW29-225 at 30 m hub height

Note: NW100B/21 at 30 meter hub height if available; if not available, then the NW100B/21 is not an option for Site B

Point Hope Wind-Diesel Hybrid Feasibility Study P a g e | 33

7 Conclusion and Recommendations The prospect of wind power in Point Hope is excellent due to the relatively high average wind speed, high wind power density, highly directional winds, and lack of extreme wind events. In anticipation of medium to high fuel price projections over a 20-year project period and even with the conservative nature of the cost and performance assumptions, the economic analyses contained in this report show positive benefit-to-cost ratios for incorporation of wind power into the Point Hope power system.

It is highly recommended and strongly urged that NSB pursue a conceptual design for a wind-diesel power system for Point Hope. Although the prospects of a high penetration wind-diesel system, based on present experience in Alaska with current technology, do not seem favorable at this time, upgrade to high penetration will be a strong consideration in the near future and is the natural evolution of the recommended medium penetration configuration option modeled in this study.

Point Hope Wind-Diesel Hybrid Feasibility Study P a g e | 34

Appendix A: Determination of No Hazard, Site A

Mail Processing CenterFederal Aviation AdministrationSouthwest Regional OfficeObstruction Evaluation Group2601 Meacham Boulevard

Aeronautical Study No.2011-WTW-9173-OE

Fort Worth, TX 76137

Page 1 of 4

Issued Date: 09/23/2011

Kent GrinageNorth Slope BoroughP.O. Box 69Barrow, AK 99723

** DETERMINATION OF NO HAZARD TO AIR NAVIGATION **

The Federal Aviation Administration has conducted an aeronautical study under the provisions of 49 U.S.C.,Section 44718 and if applicable Title 14 of the Code of Federal Regulations, part 77, concerning:

Structure: Wind Turbine PHO Wind Turbine Site ALocation: Point Hope, AKLatitude: 68-20-23.80N NAD 83Longitude: 166-37-32.30WHeights: 195 feet above ground level (AGL)

204 feet above mean sea level (AMSL)

This aeronautical study revealed that the structure does not exceed obstruction standards and would not be ahazard to air navigation provided the following condition(s), if any, is(are) met:

As a condition to this Determination, the structure is marked/lighted in accordance with FAA Advisory circular70/7460-1 K Change 2, Obstruction Marking and Lighting, white paint/synchronized red lights - Chapters4,12&13(Turbines).

It is required that FAA Form 7460-2, Notice of Actual Construction or Alteration, be completed and returned tothis office any time the project is abandoned or:

_____ At least 10 days prior to start of construction (7460-2, Part I)__X__ Within 5 days after the construction reaches its greatest height (7460-2, Part II)

This determination expires on 03/23/2013 unless:

(a) extended, revised or terminated by the issuing office.(b) the construction is subject to the licensing authority of the Federal Communications Commission

(FCC) and an application for a construction permit has been filed, as required by the FCC, within6 months of the date of this determination. In such case, the determination expires on the dateprescribed by the FCC for completion of construction, or the date the FCC denies the application.

NOTE: REQUEST FOR EXTENSION OF THE EFFECTIVE PERIOD OF THIS DETERMINATION MUSTBE E-FILED AT LEAST 15 DAYS PRIOR TO THE EXPIRATION DATE. AFTER RE-EVALUATIONOF CURRENT OPERATIONS IN THE AREA OF THE STRUCTURE TO DETERMINE THAT NO

Page 2 of 4

SIGNIFICANT AERONAUTICAL CHANGES HAVE OCCURRED, YOUR DETERMINATION MAY BEELIGIBLE FOR ONE EXTENSION OF THE EFFECTIVE PERIOD.

Additional wind turbines or met towers proposed in the future may cause a cumulative effect on the nationalairspace system. This determination is based, in part, on the foregoing description which includes specificcoordinates and heights . Any changes in coordinates will void this determination. Any future construction oralteration requires separate notice to the FAA.

This determination does include temporary construction equipment such as cranes, derricks, etc., which may beused during actual construction of the structure. However, this equipment shall not exceed the overall heights asindicated above. Equipment which has a height greater than the studied structure requires separate notice to theFAA.

This determination concerns the effect of this structure on the safe and efficient use of navigable airspaceby aircraft and does not relieve the sponsor of compliance responsibilities relating to any law, ordinance, orregulation of any Federal, State, or local government body.

Any failure or malfunction that lasts more than thirty (30) minutes and affects a top light or flashing obstructionlight, regardless of its position, should be reported immediately to (800) 478-3576 so a Notice to Airmen(NOTAM) can be issued. As soon as the normal operation is restored, notify the same number.

If we can be of further assistance, please contact our office at (907) 271-5863. On any future correspondenceconcerning this matter, please refer to Aeronautical Study Number 2011-WTW-9173-OE.

Signature Control No: 147441520-150028067 ( DNE -WT )Robert van HaastertSpecialist

Attachment(s)Map(s)

Page 3 of 4

TOPO Map for ASN 2011-WTW-9173-OE

Page 4 of 4

Sectional Map for ASN 2011-WTW-9173-OE

Point Hope Wind-Diesel Hybrid Feasibility Study P a g e | 35

Appendix B: Notice of Presumed Hazard, Site B

Mail Processing CenterFederal Aviation AdministrationSouthwest Regional OfficeObstruction Evaluation Group2601 Meacham Boulevard

Aeronautical Study No.2011-WTW-9174-OE

Fort Worth, TX 76137

Page 1 of 5

Issued Date: 09/29/2011

Kent GrinageNorth Slope BoroughP.O. Box 69Barrow, AK 99723

** NOTICE OF PRESUMED HAZARD **

The Federal Aviation Administration has conducted an aeronautical study under the provisions of 49 U.S.C.,Section 44718 and if applicable Title 14 of the Code of Federal Regulations, part 77, concerning:

Structure: Wind Turbine PHO Wind Turbine Site BLocation: Point Hope, AKLatitude: 68-20-58.90N NAD 83Longitude: 166-46-22.90WHeights: 195 feet above ground level (AGL)

199 feet above mean sea level (AMSL)

Initial findings of this study indicate that the structure as described exceeds obstruction standards and/or wouldhave an adverse physical or electromagnetic interference effect upon navigable airspace or air navigationfacilities. Pending resolution of the issues described below, the structure is presumed to be a hazard to airnavigation.

If the structure were reduced in height so as not to exceed 158 feet above ground level (162 feet above mean sealevel), it would not exceed obstruction standards and a favorable determination could subsequently be issued.

To pursue a favorable determination at the originally submitted height, further study would be necessary.Further study entails distribution to the public for comment, and may extend the study period up to 120 days.The outcome cannot be predicted prior to public circularization.

If you would like the FAA to conduct further study, you must make the request within 60 days from the date ofissuance of this letter.

See Attachment for Additional information.

NOTE: PENDING RESOLUTION OF THE ISSUE(S) DESCRIBED ABOVE, THE STRUCTURE ISPRESUMED TO BE A HAZARD TO AIR NAVIGATION. THIS LETTER DOES NOT AUTHORIZECONSTRUCTION OF THE STRUCTURE EVEN AT A REDUCED HEIGHT. ANY RESOLUTION OF THEISSUE(S) DESCRIBED ABOVE MUST BE COMMUNICATED TO THE FAA SO THAT A FAVORABLEDETERMINATION CAN SUBSEQUENTLY BE ISSUED.

Page 2 of 5

IF MORE THAN 60 DAYS FROM THE DATE OF THIS LETTER HAS ELAPSED WITHOUTATTEMPTED RESOLUTION, IT WILL BE NECESSARY FOR YOU TO REACTIVATE THE STUDY BYFILING A NEW FAA FORM 7460-1, NOTICE OF PROPOSED CONSTRUCTION OR ALTERATION.

If we can be of further assistance, please contact our office at (907) 271-5863. On any future correspondenceconcerning this matter, please refer to Aeronautical Study Number 2011-WTW-9174-OE.

Signature Control No: 147441522-150336903 ( NPH -WT )Robert van HaastertSpecialist

Attachment(s)Additional InformationMap(s)

Page 3 of 5

Additional information for ASN 2011-WTW-9174-OE