Double Cut LP Jr

-

Upload

rxillusionist -

Category

Documents

-

view

261 -

download

3

description

Transcript of Double Cut LP Jr

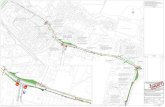

144 x 34”ver. 1.50 Double Cut Junior - design study

This all on one main page can be imported into many cad and drawing programs.For those that need it: https://www.dropbox.com/s/39lajijp5k080dw/DCLPJr.dxf...reduced to 4.5 mb. You may need to rejoin line segments into closed paths.

Download for better viewing. If found re-uploaded online, check for revisions here:https://www.dropbox.com/s/gxzbb6524doqtn0/Double Cut LP Jr.pdfor this thread:http://www.mylespaul.com/forums/luthiers-corner/212273-les-paul-junior-pdf.html

Blue type denotes a clickable link: Spreadsheet - fractions tab.Measurements tagged with an * are not exact fractions.Measurements given in full (excessive) decimal form due to an odd personailty defect.

Value:http://www.mylespaul.com... subscriptions.htmlhttp://www.tdpri.com/forum/misc.php?do=donatethey make the sharing possible.

Copies of the following pages can be printed as needed.Borders are drawn in 1 x 0.25” blocks for checking accuracy.

Gator Payne covers the perils of printing pretty well here:http://www.mylespaul.com/forums/luthiers-corner/131930-fret-slotting-templates-2.htmlthe kyocera (xerox process) printer I test printed this 44 x 34 main page on was 1/8th offon the short side and near a 1/4 off on the long side. Two weeks later, the second try wasa little worse... same printer. The 7” measurement on the headstock was closer to 7 - 1/16th.

Take a good ruler and a calculator to find the percentages it’s off (in both directions as theywon’t necessarilly be the same). Most services will be able to tweak and reprint it. Dependingon your need for print accuracy, it may be worth tracking down a service that can use a pen plotterand premium (again, depending on your needs) stable paper (i.e. vellum - plasticized paper).

Posted freely, but all rights reserved, etc... blah blah blah.

exposed heel

varies,but...

0.625

2.338* 2.328*

2.25

0.3125 R

2.8125

1.4375

0.3125 0.25 D plastic pearloid fret markers - 0.9375 D side dots

18.078125

0.1875

0.18752.15625

0.50

27.530*

1.6875

the exposed flat sawn maple channel filler stripis sanded flush and covered by the nut and paint.

No headstock veneer on juniors.Filing a nut slot removes residualfret board glue and cleans up thenut edge of the headstock

filed nut slot

x 20.890*

0.203

x-ray truss access detail - pages 3 & 46.8125

2.560*

17°0.120 0.56259” R

0.980*

“leftie” side dots shown for reference

profile straight between marks

1.3762*

cut angle drawn as 2.37°tapered fretboard adds 0.12+°for an effective neck angle of 2.5°

join line in red = 1.3751.375

2.37°0.6251.493*

2.81253.8125

0.84375

14.074*

13.00

16.138*

1” D50°

0.40625 D

3.00

2.375

59guard

very close

2.81254.875

1.30*

9.625 8.4375

0.25

0.15625

centeredvertically

1.75to

1.78125

flat sawnmahogany

0.1875 R

1.1875 D

2.531253.71875

Control Cavity

1.46875 D

2.81254.28125

Cover Ledge

The cover ledge is sized to givea 64th gap around the cover

2.81254.25

1.4375 D

0.15625

Back Cover0.09* thick

0.1875 R 0.078 thickbwb

0.3751.00

1.3125

2.40625

2.06250.040* thick

#2 round head screws(pick-up cover screws)

jack plate, back coverand pick guardare countersunk for:#3 oval head screwsthreaded 0.375”

“original” brand coversdrawn to the right.

aftermarket P90 dogear coversmay be a mm or so shorter.

level route“c” will need to be 0.625 or a little over.

to have the p’up sitting on the wood,you want to get the pickup and cover

first and then measure.

ab

c

angled route(2° here)

link

0.329*0.553*

0.28*0.585*

1.375

0.625 varies - it seems to mirror how far the heel extends.

0.375 0.4375

1.625

3.40625

3.8125

4.6875

0.625

soapbar cover in black1/64th gap on sides

1/32nd gap top & bottom

1.375

3.390625 0.116* 3.453125

1.40625

main pickup routemeasured

3.455 x 1.405

0.5 D bit

0.375 D bit

3.359375

0.0625

2 passes

The Rist Option

0.4375

0.53125

0.4375

0.9375

0.03125

1.03125

1.9375/ 5

0.3875

0.3125 R0.28125 R

vol - 500k split shaft audio taper pottone - 250k split shaft audio taper pot

0.022 uf/mfd non-polar capmono jack

.022uf

braided pickup wire

unused tab normally clipped off2 tabs bent up and soldered to casing (ground)

sleevetip

bridge ground

Back View

DC Jr P90s seem to be mostcommonly around 8.2 to 8.3k.

Soapbar P90s have been usedunder the dogear cover...

4 digit dc specials used 8.3k inthe neck position and beefed upthe bridge to 8.9 - 9.1k. Some ofthese may have found their wayinto single p’up double cuts... aswell as a high 7k here and there.

SC Jr P90s - high 7s

2.75

2.3125 2.307*

0.25 D 2.252.25

2.336*

If, for whatever reason, you want or need to use a 0.25” corner radius,then you’ll want to shorten the tenon and pocket by a sixteenth to keepthe corner of the pocket covered by the pick guard.

bridge holes for illustration onlysee page 8

1.6875 1.717*

1.375 1.375

3.005*

2.15625

1.75

6.498*

7.00

1.50

1.75

1.75

neck and headstock angled up to show full size

6.81250.1875

0.25 D

2.75

2.328*2.3125 2.306*individual neck

sanded to fitgeneric pocket

manufacturer’s pinched neck pocket

tapered sides aren’t in linewith the taper of the neck.

2.25

2.8125

0.3125 R

2.338*

2.8125

2.328*pocket template

form fitted toindividual neck

blocked neck (as drawn to the left)

0.3125 R

2.25

early 58 - large guard

59

noteglue lines

and3/16 R roundovers

...meet Matt King

0.625 0.593750.614* 0.602*

0.073 = problemsee pg. 3

0.250 0.5625

0.240* thick

0.240* thick

0.250 thick

0.200* thick

0.217* thick

0.250 thick

2.25 1.6875

12” Radius over 18.078125 board length

A tapered thickness creates an even looking edge.The side profile above is drawn with the fretboard

tapering from 0.240 to 0.200 (as measured).

other thicknesses / tapers can be accomodatedwhen carving the neck profile... see right.

CAD perfect for a board of these dimensionswould be from 0.240 to 0.217

Rosewood fretboard

0.625

0.4375

3/16ths D truss rod

cut to length

threaded 10 -32

0.10

0.34375

0.375 D rod

0.5625

store bought options includestewmac kit

(half moon “D” washer)not included

0.75

0.3125

0.171875

x-ray of the 59 showed the anchor cut about 1/2” long,perhaps even a kerf width shy of 1/2 for 2 per inch of rod

fret scale is drawn here as 24.75 - rule of 18other scales (24.5625 or 24.625 - rule of 17.817)

can be substituted with minimal change to the profile.

frets measured as 0.10 wide x 0.043 high

the threaded end of the polesare 1/8th in diameter.

the headstock thickness / taper varies...some may even be even along the length.the posts on the tuners are 63/64ths long,

you’ll want about 3/8ths or more of that above the face.

pinchedblocked

1” D

1.3125

1.00

0.375

5.272*

1.196*

this headstock view distortedby headstock angle

overall rod length will be somewhere between 18 and 18.5”

spreadsheet - Neck angle tab

backcut

angle cut

2.2°

2.9°2.3°

3.0°2.4°

3.1°2.5°

3.2°2.6°

3.3°2.7°

3.4°

2.8°

3.5°

1.484*

1.489*

1.494*

1.496*

1.504*

1.509*

1.514*

1.519*

1.524*

1.530*

1.535*

1.540*

1.545*

1.550*

1.376*

1.377*1.376*

1.377*

1.377*1.376*

1.377*1.376*

1.377*1.377*

1.377*

1.377*

1.378*

join line in red = 1.375

join line changes with angle1.3750 at 0.0°1.3760 at 2.2°1.3775 at 3.5°

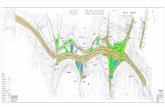

Neck2

34 x 22”

1.375

exposed heel can be sanded parallel to back after glueing

with a fretboard that tapers in thickness,a distinction needs to be made betweenneck angle and cut angle.

a 2.37° cut angle with a fretboard that tapersfrom 0.240 to 0.20 over the 18.078125 lengthcreates an effective neck angle of 2.5°

a

b

a

c

c

b

shim flat to body

shim flat to template

ramped template

1.376*

2.818*

2.817*

2.817*

2.817*

2.817*

2.816*

2.816*

2.816*

2.816*

2.815*

2.815*

2.815*

2.815*

2.815*

2.37°

cut thick then sand to finalthickness while neck fitting

cut thick then sand to finalthickness while neck fitting

join lines in red = 1.375

flat created by a cutterpresumedly following atemplate... then belt sanded.it’s probably a good idea toshy away from the sidesuntil after it’s set and gluedto avoid the potential for gaps.

Original is as above...but below is a viable option.

A piece of flat sawn maple is glued into the truss channel as a filler strip... it’ll need to be planed / sanded flush.Mahogany ears are glued to the sides of the headstock, they’ll need to be planed / sanded flush front and back.Before the fretboard is glued on, about a third of a turn of tension should be put on the truss / compression rod andthe glue face of the neck planed perfectly flat yet again. In other words, cut wide of the profile lines...you’ll have plenty of opportunities to get closer and closer to the final dimensions.

2.328*

2.25

0.3125 R

2.8125

1.4375

0.3125 0.25 D plastic pearloid fret markers - 0.9375 D side dots

18.078125

0.1875

0.18752.15625

0.50

27.530*

1.6875

the exposed flat sawn maple channel filler stripis sanded flush and covered by the nut and paint.

exposed heel

varies,but...

0.625

No headstock veneer on juniors.Filing a nut slot removes residualfret board glue and cleans up thenut edge of the headstock

filed nut slot

x 20.890*

0.203

x-ray truss access detail - pages 3 & 46.8125

2.560*

17°0.120 0.56259” R

0.980*

1.3762*

cut angle drawn as 2.37°tapered fretboard adds 0.12+°for an effective neck angle of 2.5°

1.375

2.37°0.6251.493*

3.8125

0.84375“leftie” side dots shown for reference

profile straight between marksjoin line in red = 1.375

2.8125

2.338* this headstock view distortedby headstock angle

a couple more vids from prs(Jack Higgenbotham 5:15 mark, and Herman Efland)

http://youtu.be/UjHpVGMaleMhttp://youtu.be/loV2_sDuEo8

to stress the importance of removing wood in stagesand letting the neck relax before going further.

0.3125

0.625

0.375 D

x-ray of the 59had the anchorabout 1/2” long...perhaps even akerf width shy fortwo per inch of rod.

0.4375

Truss (compression) Rod Access Options3

22 x 17”

3/16ths D truss rodcut to length

threaded 10 -32 0.75

0.34375

0.10

store bought options include a stewmac kit . . . . . half moon “D” washernot included

0.5625

vintage style - 3° down from horizontalthen squared up so the washer sits flat

0.75 D forstner drill bitsee right of page forstart (in blue) and stop points.

if you read build threads, you may noticesome of the guys letting thin superglue

soak into the end grain of the accessto reinforce the wood. It can’t hurt.

#8 washer = sameas driver in green

0.125

0.109375

0.09375

0.078125

bottom of channelshimmed

0.03125

stewmacD

1/2 Dthick

washers

3/4, 21/32 & 1/2shown

clearance = 0.03125

0.0625

0.109375

0.125

0.140625

0.15625

set screw for 3/16 D rod as pilot

set screw for 1/8 D rod as pilot

0.4375 Dthin wall

nut driver

1/2 D1/8 P

21/32 D3/16 P

11/16 D3/16 P

23/32 D3/16 P

3/4 D3/16 P

21/32 to 3/4 D - 3/16 pilot shankexcess rod used as pilot

1/2 D - 1/8 pilot shanksmaller diameter means less wood taken outof a vulnerable area, but not as convenient asthe larger diameters with spare 3/16 rod as pilot....foil tape? ...brass tubing from a hobby shop?...that or a metal lathe or creative shimming.

counterbore / spotfacer

http://www.mylespaul.com/forums/luthiers-corner/162252-video-cutting-truss-rod-nut-recess.html

clearance givendetermines the

starting point,not the diameter

of the bit used.

0.125 0.506*

0.250 rosewood0.640* mahogany

0.25 even

0.4375

2.216*2.005*

0.523*0.125

0.531252.070*2.281*

0.234* rosewood0.656* mahogany

0.234375 even15/64ths

0.540*0.125

0.59375

2.436*2.131*

0.219* rosewood0.671* mahogany

0.240* to 0.217*

0.557*0.125

0.6252.189*2.413*

0.56250.120*

0.203* rosewood0.687* mahogany

0.240* to 0.200*same taper as aboveadjusted to 0.125

x-ray

2.435*2.206*

0.203* rosewood0.687* mahogany

0.240* to 0.200*as drawn on previous pages

0.625

Below are examples of truss (compression) rod channeldepths optimized for other board thicknesses / tapers.

Each shows the bottom of the channel angled up from the samepoint (5/8ths down at the butt end of the neck) to where it’s

1/8th from the back of the neck at the first fret (0.890).

#10

0.50o.d.

0.203125i.d.

#8

0.4375o.d.

0.1875i.d.

0.06to

0.09

0.08to

0.011

mcmaster.com

withoutshim

overall rod length will be somewhere between 18 and 18.5”

.....tip as drawn, but...wings need leveled,neck needs contoured / shaped,and the back of headstock needsto be level for the tuner plates.did I mention they varied?

1.75

1.751.50

5.0625

1.375 1.375

2.747158* 1.75

0.59375

0.53125

1.750018*

1.750166*

2.747187*

2.747418*

0.614*2.747187*

0.602*1.752742*

0.59375

0.53125

0.578125

0.5625

0.546875

2.747158* 1.75

1.754019*0.590*0.609*

2.747223*

1.752.747158*

0.604*2.747273*

0.579*1.755234*

1.752.747158*

1.752.747158*

1.757477*0.555*

1.75

2.747418*0.593*

2.747158*

0.598*2.747338* 1.756387*

0.567*

0.1875 6.8125

1.717*

3.3125

2.4375

3.50

7.00

2.15625

6.498*1.259*

2.672*

1.6875

3.005*

0.593750.602*0.614*0.625

symmetrical

closer to realitysymmetrical in gray

422 x 17” Headstock

above: drilled from top - below: drilled from bottomwith set 3 on a plate spacing, does it matter ?this was drawn to find out... now it’s page filler.

thickness at tip: one 59 was 0.583one 61 was 0.539

the headstock thickness / taper varies...some might even be even along the length.the posts on the tuners are 63/64ths long,

at least 3/8ths of that should be above the face.

* see below

0.240* 0.200*

12” Radius

Scale Comparison

24.5625rule of 17.817

24.625rule of 17.817

24.75rule of 18

24.57rule of 17.817

522 x 17”

24.75rule of 18

18.078125then ends sanded

2.25 1.6875

Scale

http://www.mylespaul.com/forums/luthiers-corner/190617-1st-lp-burst-build-bartlett-plan-4.html#post3848540

http://www.tdpri.com/forum/tele-home-depot/194271-1959-les-paul-build-9.html#post2277092

thickness tapering a fretboard

622 x 17”

24.5625rule of 17.817

24.625rule of 17.817

2.25 1.6875

A pre-slotted board from stewmac comes with slots for 24 frets... the 23rd will likely be short of the 18.078125 board length

2.25 1.6875

18.078125then ends sanded

23rd fret slot width

Scale

24.562512th root of 2a.k.a. rule of 17.817

24.62512th root of 2a.k.a. rule of 17.817

1.125

0.8125

60s thin - 1/8th inside glue line - head lowered about a 64th.the template starts pushing the neck away after the 15th fret.

later 58 & 59 - the cutter edge isa 32nd past the glue line - changingthe shape of the shoulders slightly.starts to flatten out after the 17th to blend into the exposed heel.remember that mean looking cutter in the pic linked above?

12th 7th 5th 3rd 1st

shaper redsanding blue

DC JrProfiles

722 x 17”

Jr fretboard thickness

LP fretboard thickness

2.25 1.6875

12” Radius over 18.078125 board length

17thshaper cutter speculationcustom ground 1/4 ellipse:

early 58 (top) - full half ellipse.exposed heel has a roundedshape created by the cutter

58

59

60s thinneeds curved

truss rod

comparison

pic

rub collar

exposed heels

neck shaping basics - more can be found onlinehttp://www.liutaiomottola.com/construction/NeckCarve.htm

Preeb marking and carving0.240

0.215

0.200

0.190

if I’m right about the shape of the cutter,it may have been designed specifically for the

double cut and it’s extended neck access.

The speculation below turned out to be way off the mark for the 1950s...Read how it was done by clicking here.

How they do it today is shown in this vid @ the 9:50 mark.

822 x 17” segmented outline over scan

922 x 17” Drawn vs. the body measured - loose jig / tray slop - for whatever reason

neck center line0.686°

to body centerline

if you look at a dozen double cuts,you’ll see worse... in both directions.

on a single cut junior, the treble sideof the neck pocket tells the story.

on the double cut, it’s the fit ofthe bottom of the pick guard.The flat of the guard is flushto the butt end of the neck.

The pick-up route is cutwith the neck pocket, so

the guard will be fairlyconsistent in relation

to the p’up cover.

it’s pretty ingenious, really.

quiz time... go full screenand guess the direction ofthe neck center line here:

http://youtu.be/IKBVRO_6T4s

pickup routesquare to neck

vol. & toneholes 1.475°

to body centerline

bushings set by jig placed on neck(do not trust these marks for a build)

(seriously... just don’t)

channel: as a separate operation, oneor both of the 1/32nd soapbar ledgesin the lower left corner often (partially

or fully) dissapeared in production

control cavity routessame tray - around 1°

to body centerline

although it’s close to being exaclty 50°it was probably drawn as 51.05°...

in line with how the body outline was drawn

Body Template - original pinched neck pocket10

22 x 17”

the outline is symmetrical from the center of the hips backwhich would make it easy to double up and have both thecontrol cavity and control plate ledge on one template.

Roundover: early 58 was 3/16ths R straight into pocket. In late 58, it got visibly rounder - see link:http://www.mylespaul.com/forums/luthiers-corner/123788-mlp-bartlett-build-4.html#post2404892

holes for the vol. and tone pots can beeasily positioned with pencil.

1.1875 D1 - 3/16

forstner bit

14.074* 12.031* 9.625 8.4375 4.875 2.8125 2.8125

1.46875 D1 - 15/32

forstner bit

4.28125

3.001.40625

2.3125

blocked

pinched

0.625

2.25 0.3125 R 2.25

2.306* at widest

0.3125 R

pinched pocket blocked pocket

0.109 D

0.1875 D2.375

3.00

3.71875

5.272*

1.00 D (drill after roundover)

2.328*2.338*

50°

0.40625 D

3.453125

0.3125 R

pinched pocket blocked pocket

2.252.25 0.25 D0.25 D

2.75 2.75

2.336* 2.328*

If using a 0.25” corner radius, see note on page 1.

2.3125 2.307*

13/32 drill bit

using a stoptakes some of the

excitement out of it

11letter 58

12letter 59

13letter Misc plastics

for something stiffer than pickguard material,have a look at Garolite (XX)

http://www.mcmaster.com/#garolite/=iot2sr

1.1875 D

2.531253.71875

Control Cavity

1.46875 D

2.81254.28125

Cover Ledge

2.81254.25

1.4375 D

0.15625

Back Cover0.09* thick

0.1875 R 0.078 thickbwb

0.3751.00

1.3125

2.40625

2.06250.040* thick

#2 round head screws(pick-up cover screws)

jack plate, back coverand pick guardare countersunk for:#3 oval head screwsthreaded 0.375”

1.3125

1.00

1.196*

14letter

Volume - 500k split shaft audio taper potTone - 250k split shaft audio taper pot

0.022 uf/mfd non-polar capmono jack

.022ufbraided pickup wire

sleeve

tip

bridge ground

Wiring - View From Back

TV

unused tab normally clipped off2 tabs bent up and soldered to casing

(ground)

http://youtu.be/hgUg9Sa1SZs

Bridge Placement - stop bar / stop tail / wrap tail ...so many names

7.5°50s vintage

6.5°historic reissue

5.1°modern

if you value the vintage lookover intonation

then this is the angle for you!

Strings change... (pardon the pun)and as they improved over the years,

people found they were backingaway from the treble post about

a 16th more than they did the fromthe bass post... so the reissues

have the treble post a 16th back.

for an uncompensated stop tail,these modern stud positions will

give you the best overall intonation.

obviously, it was designed as an idealreplacement bridge, but there’s no

reason it can’t be used on a new build IF you use the vintage placement

7.5°6.5°5.1°

postcomparison

7.5°6.5°5.1°

But... now you can have both thevintage look and perfect intonationwith a bridge specifically designed

to compensate for vintage placementMojoaxe.com the mojoaxe bridge intonates in

about the same position as thebest fit for an uncompensatedbridge, so this is a better angle

than vintage for using it.

the method for finding them comesfrom an authorized gibson repair tech

via ltdave32 on the MLP forums.

so... if planning to use a plain stop tail,then use this method... if planning onthe compensated bridge mentioned,

use one of the previous angles...the compensated bridge on this anglewill not be ideal. (more on this later)

pg 15letter

step 1:“Measure from the face of the nut to the center point of the 12th fret. Transfer thatmeasurement to the lower bout, marking a straight line with a pencil across the body.”

ltdave32 described a method for locating the bushings in the MyLesPaul forums...words in quotation marks are his own.

pg 16letter

1/2 scale to fit on letter size page

ltdave32 described a method for locating the bushings in the MyLesPaul forums...words in quotation marks are his own.

step 2:“Lay a ruler against each side of the neck, down the body, and mark two lines thatare perpendicular to the first line you drew.”

pg 17letter

step 3:from the treble side intersection, measure 1/16” toward the neck (sharp).from the bass side intersection, measure 5/32” away from the neck (flat).draw a line through these two points.

“This is your bridge line.”(click link)

5/32”

1/16”

pg 18letter

step 4:measure and mark the center of your bridge line.

pg 19letter

step 5:Wraptail Only: because of the 5.1° angle, the strings will exit the bridge and maketheir bend lower than they would if the bridge was square to the body center line.To compensate for this, move the center of the bridge 1/16” to the bass side.

“This will result in the strings beingperfectly aligned over the pole pieces.”

pg 20letter

step 5:Wraptail Only: because of the 5.1° angle, the strings will exit the bridge and maketheir bend lower than they would if the bridge was square to the body center line.To compensate for this, move the center of the bridge 1/16” to the bass side.

step 6:Measure your bridge from the centers of the ear hooks and divide by 2.Measure and mark your bridge line from center mark (for tune o matic types)or compensated center mark for wrap tail bridge (as shown here).

w

w

w

w

pg 21letter

step 7:Measure the diameter of the stud at the point where the bridge makes contact.Divide the diameter by 2 for the radius and measure that distance toward the neckfrom your previous marks. “This is where the drill point goes.”

r

r

pg 22letter

clear?pg 23letter

donepg 24letter

1.0372

0.9797

andshiftsbridge

0.0293”towardtreble

1.0109

1.0122

0.0575difference

towardbass

0.0013essentially

even

string tensiondominant

angle tensioncomes moreinto play...

not to make it complicated, but rather to explain small differences that might add up...

having perfect intonation with the back of the bridge hooks flushto the posts is not a realistic (or even desirable) goal... betterto have the posts set forward of where the bridge will intonate toavoid a noticeable shift in string alignment when adjusting.

in this regard, the positions shown previously are fine; the bridgewill need to be backed out slightly and it will brace against thebass side of the hook. Adjusting about a 32nd back is enough.

right... so after the shift, the centers of the back of the throughholes are equidistant from the neck (and pickup) center line.

but... with an angled bridge, strings will not start straight lines totheir respective nut slots from the center of the string hole exit.they’ll pull down with the angle toward the treble post.

how much strings are allowed to pull down depends on the individualbridge design... not all stop / wrap tail bridges are the same.

the downhill string shift may be minimal and not be worth worryingabout, or it may be enough (depending on how picky you are aboutstring alignment over the poles and up the neck) that you’ll want toshift the bridge more toward the bass to compensate for it.(step 5 of the previous method).

it may also be that your choice of stud diameter offsets the amountof pull, or it may be that it adds to the misalignment.

see next page

link to pic posted by danelectro

greenfromhole

center

redshift

1/32nddownas a

reference

so it may be worth pulling a string taught with thethe bridge at your angle to check the amount of pull from center.

spread drawn 2.025 E to E.

pg 25letter

0.245 Dtonepros locking

0.300 Dschroeder locking *

0.0361713string shiftto treble

1/32nd = 0.03125

0.0112239string shiftto treble

1/64th = 0.015625

stud diameter - to finish this finicky train of thought before moving on.

smaller radiusshifts the bridge more toward treble

potential need to compensate more toward bassthe difference here from the standard 0.260 D

is only a 0.0075 difference in radius whichtranslates to a marginal 0.00683

on the bridge angle line

* the stewmac page says schroeder studs won’t work with a pigtail wraparound bridge... they mean the adjustablesaddle wraparound they sell. It has thinner ears and the schroeders won’t clamp down far enough to secure them.The vintage type stop tail bridges available today have thicker ears and can be clamped by these.

0.260 D was drawn on previous pages... adjustments here are relative to that

larger radiusshifts the bridge less toward treble

potential need to compensate less toward bassthe difference here from the standard 0.260 D

is a 0.020 difference in radius whichtranslates to 0.0182

on the bridge angle line(a little over a 64th)

again, the differences are small, but can add to, or partially offset, the string pull on the bridge.

pg 26letter

Danelectro’smeasurementsof a 55 sc Jr.

50s vintage gibson stud placement...for bridges specifically designed to compensate for such placement...or, for those that just prefer the look and flatter lower end of old juniors, etc. Many do.

1.508

1.715

12.516

12.092

neck center line

http://www.mojoaxe.com

... can be found / verified asshown in step 4 previously

pg 27letter

With only 0.002” difference in the distance of the treble posts from the nut, the real difference here is in angles.A bridge designed to compensate for a 50s vintage’s wider angle will be a bit off on the steeper 5.1° angle.

55 sc Jr in blue - previous method in red (same nut to 12th fret measurement -12.31”)

vintage angle = 7.494°method angle = 5.10°

50s vintage bass post is:0.1371” flat of what the method gave us0.0336” more toward bass

50s vintage treble post is:0.0019” flat of what the method gave us0.0478” more toward bass

50s vintage bridge shifted nearly an additional 3/64thstoward the bass due to increased bridge angle’s

effect on string alignment *

50s vintage gibson stud placement...for bridges specifically designed to compensate for such placement...or, for those that just prefer the look and flatter lower end of old juniors, etc. Many do.

pg 1 - you could increase the method’s angle from 5.1° by backing thebass side away from the post, but the strings shift down by about

a 32nd by the time you reach 6.5°. A 32nd doesn’t sound likemuch, but it will be noticeable over the poles and up the neck.

the flatter bass side can come in handy with heavier low end strings and higher action.

pg 28letter

55 sc Jr in blue - previous method in red (same nut to 12th fret measurement -12.31”)

we could also recreate the vintage positions using ltdave32’s methodby substituting 0.0528548” for the treble and 0.2703106” for the bassto draw the bridge line (page 3) and changing the shift to the bass in step 6 from 1/16th to 0.1018566”. It seems a bit redundant, though.

Historic Reissue wraptail guitars have the treble post about 1/16th flat of 50s vintage.The step 3 treble mark at the intersection leaves the treble post flat by 0.0565That’s a 16th less of adjusting the treble away from the post.

0 - 9/32 lineangle = 6.528°

bass post0.0020” flat0.0052” less toward bassthan 50’s vintage wraptail

0treble post0.0565” flat - 0.006 shy of 1/16th0.0111” less toward bassthan 50’s vintage wraptail

9/32

3/32

1.625 R3.25”bridge

pg 29letter

it’s not necessarily ideal to use 50s vintage, historic reissue or even the method’s 5.1°angled stud positions when planning on using an adjustable saddle wrap around - click link.· strings riding the extreme treble edge of the saddles· G and low E saddles all the way back· treble side backed way out from post

wrap-around adjustable saddle bridge... (for lack of a consistent name)

so... http://www.stewmac.com/freeinfo/Fretting/i-fretcalc.html

after entering the number of frets and the scale, you get recommendations at the bottom of the page for the bridgesthey carry. example: @ 24.625 scale with pigtail (the one that doesn’t work with the schroeder studs)

quote:24.685" (±0.030") from nut to center of mounting studs.Note: Some bridge/tailpieces may require you to mountthe bass-side stud an additional 1/16"-1/8" further from the nut.

pg 30letter

1/8th back gives a 2.2° angle1/16th back gives a 1.1° angle

1/8

1/16on neck

center line

straight is a no brainer... once you find the neck center line.bass 1/8th back might make it a little better for thicker strings and / or higher action.

pgs 10 & 11 - to compensate (if you think it needs it)shift the center of the radius straight toward the bass

pg 31letter

like so...pg 32letter

clearly, the saddles reach further forward.

comparison... for fun ‘n’ such

vintage 7.5method 5.1

pg 33letter

lightning bars - rough representations below

for wound G string for plain G string

lightening bars appeared in the early 60s... first on SGs, I think. The angle of the studs is about 2°. They’re mainlysold as replacement bridges for such guitars, but there’s no reason they couldn’t be used on a new build.

The ones for a plain G are much more difficult to find, but mojoaxe.com carries them. They may have additionaladvice on stud placement... maybe even know where the studs were placed on original guitars that sported these.

stewmac carries a wound G one... and gives the same stud placement advice for them as for the adjustable saddlebridge just covered. Again, when the bass stud is placed an 8th behind, the angle is 2.2 degrees.

misc links:posts 29 & 32 by Danelectroposts 4 & 7 by Danelectroand : http://www.lespaulforum.com/forum/showthread.php?t=178930and for tune o matics: http://youtu.be/CUpLDgygD2g

pg 33letter