DOOSAN PLASTIC MOLD STEEL DP10 drill working time is short. Tools wear is small. DP10 product has a...

Transcript of DOOSAN PLASTIC MOLD STEEL DP10 drill working time is short. Tools wear is small. DP10 product has a...

DOOSAN PLASTIC MOLD STEEL

DP10Doosan Heavy Industries & Construction

GLOBAL LEADER IN POWER & WATERWe are helping to drive economic development around the world by supplying the basic materials and building the facilitiesneeded by industry. Our product portfolio includes castings and forgings, nuclear power plants, thermal power plants, waterdesalination plants, environmental plants, and material handling systems.

Superior mirror polishability and high rust resistivityDP10 has a superior cleanliness by using the special technology for refining and electroslag remelting, which is required in plastic mold steel.It also has outstanding properties such as resistance to rust, corrosion, erosion and goodweldability. Especially, it offers superior mirror polishability.DP10 is supplied in free hardened condition.

DP10 product characteristics marks and applications■ Although high hardness, DP10 has the excellent machinability, especially in

gun drill work.

* DOOSAN Precipitation free harden mold steels 2010** Steam Injection Method*** Gas Injection Method

DP10

HP70

Grade

38~42

37~42

Hardness(HRc) Machinability

◦

Rust-resistivity

◦

Mirror-polishability

◦

Gun Drill workability

△

Repair-weldability

■ Characteristic•Applied to superior mirror polishability from #8,000 to #14,000 of lapping grade with

excellent cleanness•Excellent Gun Drill workability (flatness and straightness)•Suitable for precision mold steel•Long fatigue life•Minimization in the increase of hardness during the machining and welding process

■ Application : Plastic Injection mold steels for superior mirror polishability•TV part : LCD/LED TV front panel and stand•Premier home appliances : advanced audio, front cover of air conditioner and refrigerator•High class automobiles : Lamp, Head Light, Audio Frame etc.

Excellent >◦ >△ > x Poor

Adv.DP10

DP10*

Rust

resi

tivity

,Cle

anlin

ess,

Wel

dability

Mirror polishability, Hardness

Transfer Injection MoldingTransparent exterior product :

HRc 32~36(VTR, lighting equipments)

SIM**, GIM*** of double-shotInjection Molding

Transparent exterior product :HRc 40±2

(LCD, LED, PDP, etc.)

High funtional materialTransparent exterior

TrTrT ansfer Infer Inf jection MoldingTrTrT ansparent exterior product :t

T f If j ti M ldi

HP4A(D1)HP4MA(D2)

HP4MA(D2) HHHP70

DOOSAN HEAVY INDUSTRIES & CONSTRUCTION

Mechanical Properties

>1092

Yield Strength(MPa)

at RT

>1200

Tensile Strength(MPa)

17

Elongation(%)

40±2

Hardness(HRc)

12.7

Impact Absorbed Energy(J/cm2), 2mm-U notch

DP10 TS

DP10 YS

DP10

20 --

15 --

10 --

5 --

0 --Comm. mat'l

CUN

Ener

gy,J

/cm

2

0 50 100 150 200

CenterSurface

Temperature, ℃

60 --

50 --

40 --

30 --

-- 1300

-- 1250

-- 1200

-- 1150

1100

Har

dnes

s,H

Rc

UTS

,MPa

Stre

ngth

,MPa

1400

1200

1000

800

6000 100 200 300 400 500

DP10 RA

DP10 EL

100 200 300 400 500

Temperature, ℃

100 --

80 --

60 --

40 --

20 --

0 --

EL&

RA,%

TSHRc

■ Uniform hardness distribution and excellent mechanical properties

■ Excellent corrosion resistance

Rust Resistivity

DP10 Typical material of precipitation hardening steel

Dipped in water

for 82hrs

Sprayed 1㎛ -polished(3') Sprayed 1㎛ -polished(3')

Sprayed in 5%

Nacl for 65hrs

* Tess-over photography after sprayed salt water and dipped in water (x1.1)

■Outstanding cleanliness properties, it can be applied to maximum #14,000 of lapping grade

Index of Cleanliness / Mirror Polishability

0.15

0.10

0.05

0.00

-0.05DP10 Comm. mat'I

Surf

ace

Roug

hnes

s,㎛

■ Gun drill working time is short. Tools wear is small. DP10 product has a flatness and straightness (with in 1m/m/1,000m/m, surface roughness more than 2.5S)

Gun Drill Workability

■ Specific Gravity 7.82 ■ Young’s Modulus 217GPa

■ Thermal Conductivity ■ Thermal Expansion Coefficient

Physical and Thermal Properties

•Gun Drill size : Ø6.0mm•Intermittent : 1,170mmL•Continuous : 1,000mmL x 5회=5,000mmL

as -Ø6.0

DP10

200 --

150 --

100 --

50 --

0 --Comm. mat'l

Mac

hini

ngTi

me,

min

.

60

40

20

0

-20

Ther

mal

Cond

uctiv

ity,W

/m.K

0 100 200 300 Temperature, ℃

0 100 200 300 400 500

20

15

10

5

0

Ther

mal

Expa

nsio

nCo

effic

ient

,10

-6/℃

Temperature, ℃

Intermittent

Continuous

■Minimized hardness variation depending on location(WM*/HAZ**/BM***) after repair welded■ No appearance of yellowing phenomenon, gas bubble and weld line after re-lapped with

GTAW/Laser weld

Weldability Characteristics

■ GTAW (Pre Heat), (Inter-pass Heat) : 250 ~ 330±30℃■ GTAW (Post Heating) : 300 ~ 350℃

■ GTAW PWHT

■ Laser Weld : Not apply to heat

GTAW / Laser Weld Cycle

< Lapping(#14,000) after repair welded >

BM

GTAW, Pre-heat

GTAW, NO-heat

BM ▶◀◀ ▶

WMHAZ HAZ

* Required hardness of user

GTAW_P

GTAW_N

Method

TGS-5CM

AdaptionWeld Rod

NO

NO

Weld lineafter 1㎛polish

1.69

1.04

HAZ Width(mm)

Welded

A.C

300~350℃

30(min)/inch

RT

A.C

450~590℃*

1~2hrs

0

10

20

30

40

50

60

70

Distance

Har

dnes

s,H

Rc

* Weld Metal ** Heat Affect Zone*** Base Metal

Doosan Heavy Industries & Construction www.doosanheavy.com

SEOUL OFFICE HEAD OFFICE AND CHANGWON PLANTMail Code 137-920 Mail Code 642-792 22 DoosanVolvo-ro, 465 Gangnam-daero, Seocho-Gu, Seoul Korea Seongsan-Gu, Changwon, Gyeongnam KoreaTel. 82-2-513-6114 Fax. 82-2-513-6200 Tel. 82-55-278-6114, 7114 Fax. 82-55-264-5551~2

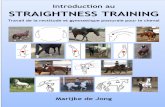

| DP10 Product Applications |

premier automobile

LCD/LED TV standair conditioner

refrigerator

smart phone LCD/LED TV front panel

water purifierwater softener

DP10