Experiment Safety Plan (ESP) - New Mexico State · Web viewUpon approval of the written plan,...

Transcript of Experiment Safety Plan (ESP) - New Mexico State · Web viewUpon approval of the written plan,...

Department of Chemical & Materials Engineering ESP# Editor: Gabby Kral

Experiment Safety Plan Rev

An Experiment Safety Plan (ESP) is required for every experiment conducted within the Department, including those experiments performed by Department Employees/Students at a location away from Jett Hall. The purpose of the ESP is to assure the safety of all by identifying the safest possible methods to conduct an experiment. By signing below the individual(s) conducting the experiment, Chemical Hygiene Officer (CHO), and the faculty advisor acknowledge responsibility for the following requirements.

1) Appropriate Personal Protective Equipment (PPE) must always be worn while in the lab (as described in the ESP). The minimum required PPE to enter a research/teaching lab in Jett Hall is (1) long pants, (2) closed toe shoes, (3) lab coat or long sleeve shirt, and (4) safety glasses with side shields.

2) For safety reasons, no researcher is permitted to work alone in the lab at any time. Because the labs are open 24/7, there may be occasions (such as a late night or over weekends) when there are no other people working in the lab. If you plan to work during a time when the lab might be expected to be empty, please plan ahead and coordinate your work schedule with another lab member.

3) Training must be completed prior to working the experiment in the lab. The minimum required training to enter the lab can be completed through EH&S and includes the following courses: (1) Employee & HAZCOM Safety, (2) Lab Standard, (3) Hazardous Waste Management and (4) the SACHE certification "Basics of Laboratory Safety." Researchers must attend the annual lab refresher seminar. Other training may be required by the CHO or EH&S personnel based on the ESP review.

4) ESP approval occurs in two phases. Phase I is the preparation of a written safety plan. Upon approval of the written plan, researcher(s) may order equipment and necessary supplies, and begin to assemble experiment. Phase I also includes an evaluation by CHO (and if appropriate by EH&S) to establish controls of hazardous operations, avoid the purchase of inappropriate supplies, and establish expected waste(s) streams. Phase II approval requires evaluation of the assembled experiment, and a “dry run” of the experimental procedure or Emergency Shutdown Procedure. High Hazard work may be subject to approval by official university boards, including any work with radioactive materials or radiation producing machines, certain biological materials, animals and/or human subjects.

Date

ESP Phase I approval:Department Head

ESP Phase II approvalChemical Hygiene Officer

5) By signing below, both faculty advisor and researchers(s) understand that the CHO can approve/disapprove any part of the ESP. The CHO can further assemble a committee of individuals with appropriate technical or EH&S background to assist in reviewing the ESP. It is the goal of the CHO to help the researcher(s) find the safest method(s) of conducting an experiment. The CHO, or any faculty member, may stop lab activity of individuals not following good lab practices.

Name Signature Date

Faculty Advisor

Researcher

Researcher

COE Safety Juanita Miller

EH&S (at request of CHO)

NMSU CHME ESP (rev. 11/07/2016) 1

NMSU Chemical Engineering Experiment Safety Plan (ESP)This document must be typed.

Name/Title of Experiment: Electrodeposition of tin on TiO2, Gold, and ITO substrates

Building and Room Number: Genesis B Room 108A

Location within Room: [Right side of the lab, near the fume hood]

Emergency Contacts: EMERGENCY 911

Department Engineer Meng Zhou (575) 646-1214

Faculty Advisor Abbas Ghassemi

Reza Foudazi

(575) 646-2357

(575) 646-3691

Department Head David Rockstraw (575) 635-9539

Responsible Researcher Navid Attarzadeh (915) 588-4337

Required attachments to the ESP:

Attachment 1: Experiment Scope

Attachment 2: Drawing of the laboratory or pilot area

Attachment 3: Normal Operations, Startup and Shutdown Procedures

Attachment 4: Emergency Shutdown Procedure and medical emergency instructions.

Attachment 5: Waste Management Procedure

Attachment 6: Hazard Identification and Mitigation

Attachment 7: Material Safety Data Sheets

NMSU CHME ESP (rev. 11/07/2016) 2

Attachment 1 – Experiment Scope

Provide a concise description of the laboratory experiment to be undertaken.

1. Explain why the work is being performed, the goal(s) of the experimental program

a. If this is an update/revision of previous ESP describe all changes

2. Provide the stoichiometry of any chemical reactions and their heats of reaction

3. Demonstrate the inherent thermal safety of your experiment through calculation or through the use of accelerating rate calorimetry data.(http://chme.nmsu.edu/admin/ehs/experimental-safety-plan-esp/esp-energetics-calculation/ )

4. Include a complete list of all chemicals (reactants and products) involved in the work.

5. Include a complete list of all equipment (e.g. autoclave, centrifuge, pump, heat bath etc.) involved in this work

This is an edited version of a previously written ESP. Any major changes, besides grammar or layout changes, will be indicated with red brackets.

[New methods of collecting clean energy are needed in order to help protect our nonrenewable resources that have previously been used to power our world. One solution to this problem is to use solar cells to produce electricity. The goal of this experiment is to produce a perovskite solar cell capable of maximizing power efficiency by upwards of 20 percent.] Tin and lead will be electrodeposited on top of several substrates and the optoelectronic behavior of the formed layers will be studied.

Tin electrodeposited films are used in food and electronics industries when non-toxic materials are needed. There are two types of electrolytes used in electrodeposition: Alkaline stannate based electrolytes and acidic stannous based electrolytes [1]. The electrodeposition will be carried out at ambient temperature and the pH will be maintained at approximately 3 on the pH scale. Tin will be electrodeposited on the cathode surface. The temperature will remain steady during tin electrodeposition [2].

The main reaction is: Sn2++2eSn which will be done on the cathode surface.The evolution of hydrogen is negligible. ΔHcathodic reaction=0, Sn2+ is non-exothermic [3]

[1] T. Djenizian, I. Hanzu, Y.D. Premchand, F. Vacandio, P. Knauth, Electrochemical fabrication of Sn nanowires on titania nanotube guide layers., Nanotechnology. 19 (2008) 205601. doi:10.1088/0957-4484/19/20/205601.

[2] I. Hanzu, T. Djenizian, G.F. Ortiz, P. Knauth, Mechanistic Study of Sn Electrodeposition on TiO2 Nanotube Layers: Thermodynamics, Kinetics, Nucleation, and Growth Modes, J. Phys. Chem. C. 113 (2009) 20568–20575. doi:10.1021/jp906070v.

[3] N.M. Martyak, R. Seefeldt, Additive-effects during plating in acid tin methanesulfonate electrolytes, Electrochim. Acta. 49 (2004) 4303–4311. doi:10.1016/j.electacta.2004.03.039.

NMSU CHME ESP (rev. 11/07/2016) 3

Chemicals involved (Table 1): [Updated Table for Chemicals] Chemicals used for rinsing/cleaning glass slides (A)

Chemicals used in spin coating step (B)

Chemicals used in surface treatment (C)

Chemicals used in electrodeposition (D)

Chemicals used in doping (E)

Alconox detergent

Titanium Isopropoxide

Ethyl acetate Stannous sulfate PbI2

Methanol Hydrochloride Acid

Diethylene glycol Sulfuric acid Methylamine solution: 33 wt. % absolute ethanol

Ethanol Ethanol Diethylene glycoldimethyl ether

Triton-X-100 Hydroiodic acid

Isopropanol Diethyl ether Polyethylene glycol

PbCl2

1,2-dimethyloxyethane

Thiourea SnI2

Dimethyl-formamide

Lead Sulfate SnCl2

Dimethyl sulfoxide

DMSO

Hexamethyl phosphoramide

Methyl t-butyl ether

γ-butyrol acetone

N-methyl-2-pyrrolidinone

Tetra hydrofuran

Toluene

2-propanol

TiCl4

Methyl ammonium bromide CAS#6876-37-5

Methyl ammonium iodide CAS#14965-49-2

Formamidinium bromide CAS# 879643-71-7

Formamidinium iodide CAS# 879643-71-7

Equipment involved (Table 2): [Made a table for equipment needed]

Equipment used for rinsing (A)

Equipment used in spin coating (B)

Equipment used in surface treatment (C)

Equipment used in Electrodeposition

Equipment used in Doping

Ultrasonic Bath

Spin Coater Hot Plate Metrohm series 300

Drying vacuum oven

OML Glasscutter

Fume hood/Glove box

Glove box Ice bath

Centrifuge Spin Coater Rotary evaporator

Vacuum pump Weighing scale

hot plate

Nitrogen cylinder

Weighing scale

Weighing Scale

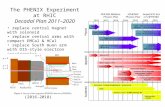

Attachment 2 - Drawing of the laboratory or pilot area

Provide a detailed drawing of the laboratory or pilot area in which the work will be performed. Include locations of the experimental equipment, safety equipment (including eyewash stations and safety showers, fire extinguishers, first aid kids, noting the date(s) of last inspection of these safety devices), Safety Data Sheet (MSDS) compilation, chemical storage, and evacuation route.[Updated image floor plan]

NMSU CHME ESP (rev. 11/07/2016) 7

Lab Floor Plan Genesis B 108A

Attachment 3 – Normal Operations, Startup and Shutdown Procedures

Provide a step-wise procedure that describes in detail how the work will be performed. The procedure should begin and end with the equipment in the normal idle (inoperative) state. Include a statement of the required PPE at the beginning of the procedure, and at every location in the procedure where the PPE requirements change.Indicate where hazardous feedstock chemicals will be stored, how they will be transported to the location of the experimental work, how they will be transferred from storage vial into the experimental apparatus, and how they will be returned to storage.Take into account those items for which you indicate “yes” on the NMSU Lab Hazard Assessment Checklist (link found on the department website “Safety” page).The detailed safety procedures in accordance with the sequence of the experiments are as follows:Personal protective equipment, which includes nitrile gloves, goggles, a lab coat, [closed toed shoes and long pants,] will be worn at all times in the lab. [Hands will not be submerged in any liquid, so the gloves only need to protect against splashed chemicals. Acidic chemicals are kept in a corrosive cabinet with secondary containment. Organic chemicals are kept either in an explosive proof refrigerator or a flammables cabinet. All chemical storage is located in the lab as pictured in the diagram above. All chemicals will be placed back where they belong after they are used.] The work steps are as follows:

A) Substrate preparation1. ITO glass will be cut in 3 by 1 inch pieces using a OML glasscutter2. Glass sheets will be washed with deionized water in an ultrasonic bath for 30 minutes3. Glass sheets will be washed with Alconox detergent in an ultrasonic bath for 30

minutes. {Alconox is a biodegradable detergent that can be stored with other dish washing detergents. It can be disposed of like any other dish washing detergent: down the drain)

4. Glass sheets will be washed with ethanol in an ultrasonic bath for 30 minutes. [(Ethanol is stored in the flammable cabinet in the lab. Used ethanol will be disposed of in the flammable waste container located under the fume hood.)]

5. Glass sheets will be washed with acetone in an ultrasonic bath for 30 minutes. [(Acetone is stored in the flammable cabinet in the lab. Used Acetone will be disposed of in the flammable waste container located under the fume hood.)]

Additional Safety notes: [This portion was re-worded to flow better with section]

[Any procedure that uses an organic solvent in an unsealed container through ultra- sonication has to be done in the fume hood. Each glass slide needs to be washed with deionized water, Alconox detergent (a biodegradable, interfering-residue free detergent), ethanol, and acetone subsequently. Samples must be dried completely in an oven overnight.When using ultrasonic bath, there needs to be more than 50 mm of water (measured from the bottom) in the tank. The water must not be filled over the maximum mark located on the device. The ultrasonic bath must be kept a safe distance from the sink or water outlets to avoid electrical breakdown. Avoid sonicating materials that are sensitive to temperature or that can spontaneously ignite because the temperature of the fluid will increase under normal operating conditions. Keep hands and body away from the water when the ultrasonic bath is on. The device cannot be left unattended when on. The maximum temperature for the ultrasonic bath is 60 degrees C. This temperature setting should not be bypassed.]

B) TiO2 Compact layer preparation [This section was reworded to flow better]

NMSU CHME ESP (rev. 11/07/2016) 8

1. When operating spin coater, make sure work is done in either the hood or a glove box.

2. Place a ITO glass substrate on the spin coater.3. Deposit a mild solution of titanium isopropoxide in ethanol on the indium tin oxide

(ITO) substrate. 0.3 M titanium isopropoxide solution in ethanol is prepared by adding 350 microliters titanium isopropoxide into 5ml ethanol. The pH will then be adjusted by adding 0.013 M HCl solution dropwise until the desired pH is reached. This HCl solution should contain 3.52 g from 37% HCl solution diluted with deionized water up to 100ml. The measured acid will be added slowly to the rest of the deionized water to reach the solution volume to 100 ml.

4. Spin coat the substrate at 2000 rpm for 30 seconds. The spin coater will automatically turn off after the time is up. The spin coater is connected to a vacuum pump and a nitrogen cylinder. The cylinder should be maintained in its upright position with a cylinder holder securely fastened around it. The vacuum pump must be turned on during spin coating, and turned off after spin coating is complete.

5. The samples will then be annealed using a hot plate at 500 degrees C for 30 minutes. The hot plate will be turned on prior to annealing so that it can heat up. It will be turned off using the dial on the front of the device and unplugged from the outlet after the annealing process is complete. It shall be monitored at all times when in use.

Additional safety notes:

In case of electricity outage during spin coating: The fume hood’s sash will be positioned at a standby position. Latex gloves must be worn during isoproxide solution preparation, for they are preferred when working with this material. Chemicals can be found in their designate supply cabinets found within the lab. Used chemicals will be disposed of in their proper waste containers found under the fume hood. Transporting:Secondary containment is critical to prevent major spills or accidents when transporting acids.

Preparing solution for spin coating: i. Always add acid to water, do not add water to concentrated acids. The acid

may splatter and generate acidic steam.ii. The preparation should always be done in borosilicate (e.g., Pyrex®)

glassware.iii. Stir to mix the solution.

Personal protection:i. Nitrile rubber gloves are acid-resistant and are the best choice for this

procedure. Plastic or vinyl gloves will provide some protection against the occasional splash or small spill, but nitrile works the best.

ii. Chemical splash goggles must be worn during procedure.

C) Surface Treatment [Grammar was fixed and some layout changes were made]In order to change the surface condition during electrodeposition, it is necessary to treat the surface with some organic solvents. These solvents have been indicated in Table 1. Treating the surface with organic solvents leads to a higher deposition rate and nucleation and allows growth to be refined. The purpose of using an organic solvent is to change the wettability of the surface during the deposition; subsequently,

a refined growth of tin grain can be achieved. With the use of syringes resistant to organic solution, the surface of titanium oxide will be treated with four droplets of the organic solutions and the spin coater will distribute the solution over the surface uniformly. At this time the organic moieties will change the surface condition to interphase phase and the rate of solution evaporation will change the tin crystal grain size.

1. This part of the experiment will be done inside the glove box. All organic solvents for this portion of the experiment will be stored inside the glove box, as well. When treating the surface, 3 to 4 drops of solvent will be dropped on the tin surface placed inside the spin coater, then the surface will be treated uniformly with a high turning rate from the spin coater.

2. Hazardous feedstock will be stored inside the glove box, because the volume of these non-halogenated solvents are in the range of 100 ml. Storage inside the glove box will be adequate under these conditions.

3. All other safety points mentioned for organic solvents in the first procedure will be considered in this experimental step.

4. Because this process is done inside the glove box, the need for using specific gloves for skin protection is no longer valid.

Additional safety notes:

The surface treatment will be done with non-halogenated solvents inside the glove box. Therefore, the most important safety issues include moving the liquids to the glove box and some related safety issues regarding the glove box. The following chemicals must be stored in the glovebox: diethylene glycol, Hexamethyl phosphoramide, diethyl ether, Methyl t-butylether, diethylene glycoldimethyl ether, y-butyroactone, 1,2-dimethyoxyethane, N-methyl-2-pyrrolidinone, Dimethyl-formamide, Tetra hydrofuran, dimethyl-formamide, Tetra-hydrofuran, dimethyl sulfoxide, toluene, 2-propanol. In case of a power outage, the fume hood fan will turn off, so the sash must be closed.

D) Electrodepositing Tin on top of TiO2 layer [This section was re-written to stay consistent with the rest of the paper]

Electrochemically deposit the Tin layer on glass substrates in a three-electrode compartment cell where the TiO2, Au plate, and ITO substrates are used as a working electrode. Use a large platinum grid as a counter electrode. Use a Saturated calomel electrode (SCE) for all electrochemical experiments as a reference electrode.

1. To prepare solution, add 0.3 g SnSO4 and 2 ml H2SO4

to 200 ml deionized water. Mix together while stirring

2. Place the electrodes in a beaker in a solution bath3. Allow the stannous salt to dissolve completely

The additives that need to be used during plating are as follows:(1) Triton X-100 (C8H17C6H4(OCH2CH2)nOH, n=9-10 with average molar mass 625 g/mol, (2) Polyethylene glycol, H(CH2CH2O)nOH, n=8000 with average molar mass of 8000 g/mol, and (3) Thiourea, CH4N2S, with a molar mass ~76 g/mol.

Additional safety notes [Section in brackets was moved from section B to section D. Any other edits were made to fix flow of paragraph and to stay consistent with the rest of the paper.]

[Electrolyte will be prepared with the materials mentioned above and disposed in container for acid disposal. The electrolyte bath is prepared in total volume of 200 ml and retained for several electrodeposition processes, finally it will be disposed in acidic waste container. After electrodeposition samples will be rinsed with deionized water. The liquid waste produced will be disposed in acid waste container.] The amount of surfactants that must be added to the solution is lower than 2 milligrams. Electrodeposition will be performed with the Metrohm series 300. The solution for electroplating is mildly acidic. The solution should be handled using nitrile gloves (as previously mentioned) and should be done carefully. It is important to maintain the amperage below 650 mA/cm2 during electroplating due to the increased risk of electrocution due to the combination of water, electricity and damp corrosive conditions. When working with an acidic solution, hydrochloric acid should be added carefully by dropping the acid into the solution gently while wearing all designated personal protection equipment. Electrodeposition should be performed at ambient temperature.

E) Doping the tin layerIn order to get higher refractivity from the deposited tin layer, some inorganic materials can be used to change the band gap and the refractivity of the layer. 1. Dissolve the doping materials (PbI2, PbCl2,SnI2, or SnCl2 depending on sample) in

DMSO and deposit during electrodeposition. 2. Synthesize MAI by reacting 24 mL of methylamine (33 wt. % in absolute ethanol,

Sigma-Aldrich) and 10 mL of hydroiodic acid (57 wt% in water, Sigma-Aldrich) in a 250 mL round-bottom flask at 0 °C for 2 h with stirring. The precipitate will be recovered by putting the solution on a rotary evaporator and carefully removing the solvents at 50 °C. The yellowish raw product CH3NH3I will be re-dissolved in 80 mL absolute ethanol and precipitate with the addition of 300 mL diethyl ether. The solid will be collected and dried at 60 degrees Celsius in a vacuum oven for 24 hours.

3. Distribute Methylamine iodide (MAI) powder on the Tin layer uniformly using the doctor blading method and then diffuse by annealing at 100 degrees C for varying times.

4. The precipitation rate shall be expedited by use of an ice bath. This allows for more control of the reaction temperature and an increase in safety.

The following depicts the enthalpy of reaction:

C H3 N H 2+HI → C H3 N H 3 IΔ HC H 3 N H 2=−23 KJ

mol

Δ H HI=26 KJmol

Δ HC H 3 N H 3 I=−112 KJmol

Δ H r ×n=−115 KJmol

∆ T=Δ H r × n

X A

nA ×C p(mix )

=115× 1× 10001× 1020

≈ 100

P2=P1( T 2

T 1)=1 × 373

298=1.25 atm

Additional safety notes:Personal protective equipment (PPE) including safety glasses or face shield and laboratory coat must be worn to protect against the hazards of vacuum procedures. The rotation speed and application of vacuum should be done gradually when using a rotary evaporator. Do not hold onto sample whilst it is revolving: failure of the flask could result in serious lacerations to the hands. Only heavy-walled, vacuum grade rubber tubing shall be used for the application of vacuum. Thin-walled rubber tubing and plastic tubing is not suitable because they collapse leaving a partially closed system. The length of the vacuum tubes should be as short as practicable and should not have to be secured with cable ties. Quality silicone tubing shall be used for the cooling water which must be secured to the screw fittings with cable ties. All tubing shall be checked regularly and replaced when brittle. Large volumes of organic solvent vapor can be generated through rotary evaporation. When in use, the condenser should always be cooled. Clean the apparatus after use. Do not mix halogenated and non-halogenated solvents in the receiver.

Attachment 4 -. Emergency Shutdown Procedure

Provide a step-wise procedure that describes how the equipment will be brought to a safe state in the event of an emergency. The description should include a detailed explanation of how to attend to potential medical emergencies that may result.

A) [In case of emergency, turn ultrasonic bath off by turning nozzle on the front of the device to zero]B) General precautions when using spin coater [Moved from another section of document]

Medical emergency:

a. The best first aid for any chemical exposure to body tissue or eyes is immediate dilution with water.

b. If an acid is splashed in the eyes, use eyewash to irrigate the eyes for at least 15–20 minutes.

c. If an acid is splashed onto bare skin, rinse with water for at least 15–20 minutes.

[In case of emergency, turn off vacuum pump, close nitrogen gas cylinder, and power down spin coater.]

C) In result of chemical splash or exposure to skin Medical emergency:

1) Any splash or exposure of the skin should be immediately, thoroughly flushed for 5 - 15 minutes. I should not allow contaminated clothing to remain in contact with the skin. 2) If skin irritation or dermatitis develops, the affected individual must be examined at a Medical Facility. 3) In the event of eye contact, I should use flushing for 15 minutes of flushing with water.

D) General precautions when using a Rotovapor [Moved from another section of document]

In case of chemical contact: If inhaledIf breathed in, move person into fresh air. If not breathing, give artificial respiration. Consult a physician. Call 911 if emergency. In case of skin contactTake off contaminated clothing and shoes immediately. Wash off with soap and plenty of water. Take victim immediately to hospital. Consult a physician. Call 911 if emergency. In case of eye contactRinse thoroughly with plenty of water for at least 15 minutes and consult a physician. Continue rinsing eyes during transport to hospital. Call 911 if emergency. If swallowedDo NOT induce vomiting. Never give anything by mouth to an unconscious person. Rinse mouth with water. Consult a physician. Call 911 if emergency.In case of fire:

Unplug hot plate (if in use). Pull the fire alarm. Use fire extinguisher. Don’t breathe the fumes.

If fire is large, exit the building and call 911.

In case of liquid spill:

Use spill kit. Absorb liquid with vermiculite. Place vermiculite in appropriate solid waste and label it.

NMSU CHME ESP (rev. 11/07/2016) 13

In case of solid spill:

Dispose in solid waste.

E) [When using hot plate:Medical emergency:In case of burn, the wound must be cleaned in the bathroom, as long as no chemical contact has occurred. If chemical exposure has occurred, first aid procedure will be followed from the SDS for the chemical that is affecting the burned area. The experimenter should wash the affected area in the eyewash station or under the chemical shower, depending on the severity. In case of emergency:The hot plate can be turned off by switching the dial on the front panel to the off position. The fume hood area will be evacuated until the experiment has returned to a safe temperature. ]

F) [When using oven

In case of burn, the wound must be cleaned in the bathroom, as long as no chemical contact has occurred. If chemical exposure has occurred, first aid procedure will be followed from the SDS for the chemical that is affecting the burned area. The experimenter should wash the affected area in the eyewash station or under the chemical shower, depending on the severity.

In case of emergency, switch the oven power off. In case of fire, use fire extinguisher if appropriate with use of given chemicals. If fire becomes too big to handle, alert all people in the room and building. Call 911 and follow building evacuation plan.]

G) Managing chemical spills:

Small spills (less than 100 ml)

Small spills generally consisting of only a few ml may be wiped up using paper towels or other absorbent pads. This should be done as quickly as possible, while minimizing any exposure to vapors. After absorbing any excess liquid, clean-up materials should be placed in the fume-hood and allowed to evaporate

Large spills (100ml-500 ml)

Eliminate sources of ignition. Alert others working in laboratory. Keep people out of the immediate area. Establish barriers if the spill has occurred in public passageways. Transfer the material containing the spill to a plastic container and carry to a fume-hood for later disposal. Allow fumes to evaporate in the fume-hood overnight or over a weekend. If the residual waste is hazardous, package all contaminated material in a suitable container, attach a label and submit for waste disposal.

Attachment 5 - Waste Management Procedure

Prepare a Waste Management Procedure that provides the exact nature and estimated volumes of all wastes to be generated in performing these experiments. Forward to EH&S Environmental Affairs Manager, Andrew Kaczmarek [email protected] for approval.

Attach a copy of the approval received from EH&S to this section of the ESP.

A) Contaminated ultrasonic bath water [Indicates that section was moved from another part of the document]Water used in the ultra-sonicating bath can be disposed of down the sink.[If any contaminant enters the water from the experiments, the water must be disposed of in the appropriate waste container (e.g. water soluble waste solvent, water insoluble waste solvent, halogenated waste solvent). Refer to relevant chemical MSDS before disposal.]

B) For the case of surface treatment with organic solvent inside the glove box:

Disposing syringes contaminated with organic solvents:

Syringes will be kept inside the fume hood and glove box as waste materials in a container specifically assigned to disposed syringes.

1. Substrate preparation:

Acetone and ethanol waste from the rinsing process will be disposed in flammable containers. Organic solvent wastes must be placed into clearly labeled, appropriate containers for Hazardous waste disposal. The volume of rinsing solvent is 200 milliliters.

2. Spin coating for depositing TiO2:In general, no hazardous situations should arise from typical operation of this equipment. For the case of TiO2, the solution will be evaporated during spin coating from substrate and inside the spin coater container.

3. Aqueous (acidic) waste from electrodeposition electrolyte: mixture SnSO4 and H2SO4

with additives will be disposed in container for acidic disposal. 4. Surface treatment:

In this step, solvent is evaporating inside the glove box and no waste left to be disposed. However, the procedures for the waste materials are added below.

5. Waste disposala. Attach a completed Hazardous Waste tag to all waste containers as soon as the

first drop of waste is added to the containerb. Store hazardous waste in closed containers, in secondary containment and in a

designated storage location.c. Double-bag dry waste using sealable transparent bags.d. Waste must be under the control of the person generating and disposing of it.e. Dispose of regularly generated chemical waste within 90 days.

6. Electrodepositing tin:

NMSU CHME ESP (rev. 11/07/2016) 15

In this step of experiment, the electrolyte will be remained for several usages and not considered as a waste. At the end cycle of electrodeposition, this electrolyte with the maximum volume of 250 milliliter will be disposed in the acidic waste container. 7. [Pb waste segregation

a. All lead related waste will be collected in a separate container and will be disposed through EH&S. This waste container will be stored in secondary containment under the fume hood.]

Attachment 6 – Hazard Identification and Mitigation

Identify ALL HIGH hazards associated with the experiment. The analysis must consider

all sources of energy (electric, chemical, hydraulics, mechanical, compressed gases), extreme conditions of pressure or temperature (from flame or steam to cryogenics), chemical storage, housekeeping, fire, and/or biological hazards.

Examples of HIGH hazards to include (list not exhaustive):

substances that are highly reactive, radioactive, highly flammable, pyrophoric, highly toxic, mutagenic, teratogenic, carcinogenic, or have very low exposure limits,

high voltage, high RF, x-ray, laser (class 3b or 4), high temperatures, and high pressure or pressurizing vessels.

When in doubt about whether a substance represents a HIGH HAZARD, ask for assistance.

For each HIGH hazard (use the checklist as a guide to identifying these hazards, chme.nmsu.edu/files/2013/11/Lab-PPE-selection1.pdf), provide the following information:

1. description of the HIGH hazard;

2. operational and engineering controls that will be used (based on identified industry best-practices used in addressing this safety hazard);

3. required PPE (beyond minimum) when this HIGH hazard is present; and

4. special training (beyond minimum) that is necessary.

Using the NMSU Lab (JHA) Hazard Assessment Checklist, the following hazards were considered: [This section was added to comply with the checklist requirements. The original mentioned a few of these hazards, but not all of them. The rest of them were added, along with engineering controls and training requirements]

A) Working with very cold equipment or dry ice1. Frostbite and hypothermia could persist2. The dry ice is contained in a Styrofoam container with a lid on top of it for additional

protection. 3. Safety glasses or goggles for large volumes, insulated gloves (impermeable insulated

gloves for liquids, steam), and lab coat must be worn when handling this material.4. Basic EH&S safety training

B) Glassware washing1. Lacerations2. Gently handle glassware when washing. Do not bang glassware on hard surfaces or

drop items3. Use heavy rubber gloves and wear a lab coat when washing glassware.4. No advanced training needed

C) Centrifuge1. Imbalanced rotor can lead to broken vials, cuts, or exposure2. Use centrifuge with its lid ON. 3. Wear safety glasses or goggles, lab coat, latex, vinyl, or nitrile gloves. 4. No advanced training needed

D) Ultrasonic bath

NMSU CHME ESP (rev. 11/07/2016) 17

1. Ear damage, exposure2. Settings on ultrasonic bath should never be so high as to create decibels high enough

to cause ear damage. If so, there might be a problem with the machine3. Use safety glasses, and goggles when operating, wear a lab coat, and latex, vinyl, or

nitrile gloves4. No advanced training required

E) Working with an apparatus with contents under pressure or vacuum1. Eye or ear damage2. Use vacuum as directed in instructions. Make sure to turn on and off at appropriate

times. 3. Wear safety glasses or goggles or face shield for high risk activities. Wear chemical

resistant gloves, lab coat or chemical-resistant apron for high risk activities.4. No advanced training required

F) Minor spill cleanup1. Skin or eye damage, respiratory damage2. Try to be careful when transporting chemicals so that spills don’t occur. Work in an

area with plenty of room so that overcrowding doesn’t occur.3. Wear safety glasses or goggles, chemical resistant gloves, and a lab coat. Wear

chemical-resistant apron and boot/shoe covers for high risk activities. Wear respirator as needed. Consider keeping silver shield gloves in the lab spill kit.

4. No advanced training required for minor spills. If spill is heavy, get help from safety officer.

G) Working with high and low temperatures1. Burns, splashes, or fires2. Make sure to always keep hands away from hot plates. When operating ovens, do not

touch hot surfaces. 3. Wear safety glasses, lab coat, and thermal insulated gloves when needed.4. No advanced training required

H) Working with toxic or hazardous chemicals1. Skin or eye damage, potential poisoning through skin contact2. Be careful when setting chemicals down. Don’t get your face too close to chemicals.3. Wear safety glasses or goggles for large quantities, light chemical resistant gloves,

and a lab coat. 4. No advanced training required

I) Working with small volumes (<4 liters) of organic solvents1. Skin or eye damage, potential poisoning through skin contact2. Keep lids on chemical containers when not in use. Keep a safe distance away from

organic solvents. If especially hazardous, only use in the glove box as mentioned in the attachment above.

3. Safety glasses or goggles, light chemical resistant gloves, lab coat4. No advanced training required

J) Working with large volumes of flammable liquids1. Increased potential for skin or eye damage2. Keep lids on chemical containers when not in use. Keep a safe distance away from

flammable liquids. Use secondary containment when pouring amounts out into vials or cylinders.

3. Wear safety glasses or goggles, chemical resistant gloves, lab coat and chemical-resistant apron.

4. No advanced training requiredK) Working with potentially explosive chemicals

1. Skin/eye damage, respiratory damage

2. Use the fume hood when using chemicals3. Safety glasses or goggles, chemical resistant gloves, lab coat, chemical resistant

apron and boot/shoe covers for high risk activities. 4. No advanced training required

The following information contains safety information for specific chemicals used in this experiment:

Standard operational procedures for handling carcinogens: It applies to solid or liquid mixtures containing more than 1.0% by weight or volume of regulated carcinogens. Restore carcinogenic substances in designated restricted controlled areas that have posted warning. Store breakable containers in chemically resistant containers.

General precautions are: Limit access to the restricted area to authorized employees, trained for hazards. Posted

signs: CANCER-SUSPECT AGENT/ AUTHORIZED PERSONNEL ONLY. Perform all work in a regulated area that precludes casual contact by others. At least two people should be present when working in the restricted area.

Operations should be provided with continual exhaust that is not discharged to regulated areas, non-regulated areas or the external environment unless decontaminated. If glove boxes are used, maintain at negative pressure, at least 0.5 inch of water lower than the surrounding environment, with a minimum of 2 air changes /min. Positive pressure glove boxes must be checked for tightness prior to each use.

If local exhaust is not feasible, wear a respirator with an absolute filter, N-100. Wear appropriate impermeable gloves, depending on the chemical in use.

Work surfaces should be covered by dry, absorbent, plastic backed paper, which is disposed of after every procedure. Alternatively, the work surface may be decontaminated if constructed of a impervious material.

Select appropriate clothing, suitable for the task, and specified in the procedure manual. Clothing must be removed, laundered or decontaminated after each use. Sorbents should be used for spilled liquids. Solids should be wet mopped or vacuumed

with a HEPA unit. DO NOT dry sweep-spilled solids. Contaminated waste must be properly labeled, stored and removed.

1. Standard Operating Procedures for working with tetrahydrofuran (THF):1.1. Potential hazards:

1.1.1.THF is extremely flammable. Its vapor can travel a significant distance through the air to an ignition source and flash back.

1.1.2.A 5% solution of THF in water is flammable. THF vapors form explosive air mixtures at concentrations of 2-12% by volume.

1.1.3.When exposed to air, THF forms peroxides that can explode if concentrated by distillation or evaporation. Light exposure may also exacerbate peroxide formation.

1.1.4.THF may react violently with strong oxidizers.1.1.5.THF is a severe eye irritant and skin irritant. Prolonged or repeated eye exposure

may cause conjunctivitis; prolonged skin contact can cause defatting and dermatitis.1.1.6.At lower air concentrations (100-200 ppm), THF irritates the eyes and respiratory

tract. At higher concentrations (25,000 ppm), THF can produce an anesthetic effect and cause headaches, fatigue, dizziness, and nausea. Chronic exposure may cause

abnormal liver, kidney, and/or lung damage. Studies show evidence of carcinogenic activity in lab animals chronically exposed to THF, however, the relevance of these studies to humans is unknown.

1.1.7.The OSHA Permissible Exposure Limit (PEL) for THF is 200 ppm as an 8-hour time-weighted average. OSHA also has a short-term exposure limit (STEL) of 250 ppm over 15 minutes. ACGIH has a threshold limit value (TLV) of 50 ppm as an 8-hour average and an STEL of 100 ppm over 15 minutes.

1.2. Transportation and storage: 1.2.1.Transport THF in secondary containment, preferably a polyethylene or other non-

reactive acid/solvent bottle carrier.1.2.2.THF should be stored with other flammables. Do not store THF near strong

oxidizing agents, acids, bases, or organic alkali compounds.1.2.3.THF must be stored in an air-impermeable container and placed in a dark area to

prevent further promotion of the peroxide-forming reaction.Suitable fire control devices (such as fire extinguishers) must be available at locations where flammable or combustible liquids are stored.

1.2.4.Open flames shall not be permitted in flammable or combustible liquid storage areas. A “No Open Flames” sign must be conspicuously posted in these areas.

1.2.5.Avoid storing THF on the floor.1.3. Waste disposal: Contact EH&S immediately to arrange for pick-up and disposal if:

1.3.1.Crystals are found around the lid of an THF container (do NOT open the container!) or Handle THF in hood. Check stock container weekly to check for peroxide crystals

1.3.2.The container tests positive for peroxides.2. Standard Operating Procedures for working with tert-butyl methyl ether:

Potential hazards and handling are the same as mentioned above.2.1. Waste disposal procedures:

Methyl chloromethyl ether and all Methyl chloromethyl ether waste shall be disposed of into waste containers specifically designated for Methyl-chloromethyl ether. Examples of Methyl chloromethyl ether waste material include gloves, pipette tips, paper towels that have been contaminated with Methyl-chloromethyl ether.

3. Standard Operating Procedures for working with Hexa-methyl-phosphor-amide (HMPA)3.1. Potential Hazard

3.1.1.Hexamethylphosphoramide (HMPA) is an acute toxin and a suspected carcinogen.3.1.2.Causes respiratory tract irritation. 3.1.3.Harmful if inhaled. 3.1.4.Causes eye and skin irritation. 3.1.5.May be harmful if swallowed or absorbed through the skin. 3.1.6.Targeted organs include the central nervous system, lungs, respiratory system,

gastrointestinal system, and male reproductive system. 3.2. Handling and storage requirements

3.2.1.Precautions for safe handling: Avoid contact with skin and eyes and inhalation. Avoid dust formation or breathing vapors, mist, or gas. Use only with adequate ventilation or respiratory protection. Keep away from heat or sources of ignition. Prevent any build-up of electrostatic charge.

3.2.2. Conditions for safe storage: Keep container tightly closed in a cool, dry, and well-ventilated place away from incompatible materials and conditions. Avoid dust generation, moisture, and heat. Keep cool and protect from sunlight.

3.3. Waste disposal3.3.1.Store hazardous waste in closed containers, in secondary containment and in a

designated location.3.3.2.Double-bag dry waste using transparent bags.3.3.3.Waste must be under the control of the person generating & disposing of it3.3.4.Dispose of regularly generated chemical waste within 90 days.

4. Standard Operating Procedures for working with Dimethyl sulfoxide (DMSO):4.1. Potential hazard:

Slightly hazardous in case of inhalation (lung irritant). Slightly hazardous in case of skin contact (irritant, permeator), of eye contact (irritant), of ingestion. Slightly hazardous in case of skin contact (irritant, sensitizer, permeator), of ingestion.

4.2. Personal protective equipment:4.2.1.As a last line of defense (i.e., after engineering and administrative controls have

been exhausted). When Permissible Exposure Limit (PEL) has exceeded or when there is a possibility that PEL will be exceeded.

4.2.2.Regulations require the use of a respirator. Wear protective gloves. Carnegie Melon university recommends double gloving when using DMSO. Nitrile or latex gloves may only be used when handling small quantities (<1ml) of DMSO.

4.2.3.There is potential for harmful exposure due to an atmospheric contaminant (in the absence of PEL)

4.2.4.As PPE in the event of a chemical spill clean-up process.

4.3. Handling and Storage Requirements4.3.1.Precautions for safe handling: Avoid inhalation of vapor or mist. Keep away from

sources of ignition - No smoking. Take measures to prevent the buildup of electrostatic charge.

4.3.2.Conditions for safe storage: Keep container tightly closed in a dry and well-ventilated place. [Keep at room temperature] Hygroscopic!

4.4. Waste Disposal Procedure: 4.4.1.1. Labeling the waste container as soon as the first drop of waste is added to

the container.4.4.1.2. Store hazardous waste in closed containers, in secondary containment

and in a designated location.4.4.1.3. Waste must be under the control of the person generating & disposing of

it. 4.4.1.4. Dispose of regularly generated chemical waste within 90 days4.4.1.5. Dispose as hazardous waste if it once held extremely hazardous waste

(irrespective of the container size).

5. Standard Operating Procedures for working with Diethylene Glycol:

5.1. Potential hazard:Hazardous in case of skin contact (irritant, permeator), of eye contact (irritant), of ingestion, of inhalation.

5.2. Handling and Storage:5.2.1.Precautions: Keep away from heat. Keep away from sources of ignition. Empty

containers pose a fire risk, evaporate the residue under a fume hood. Ground all equipment containing material. Do not ingest. Do not breathe gas/fumes/vapor/spray. Wear suitable protective clothing In case of insufficient

ventilation, wear suitable respiratory equipment If ingested, seek medical advice immediately and show the container or the label. Avoid contact with skin and eyes

5.2.2.Storage precautions: Keep container dry. Keep in a cool place. Keep container tightly closed. Keep in a cool, well-ventilated place. Combustible materials should be stored away from extreme heat and away from strong oxidizing agents.

5.3. Waste disposal procedure:Avoid contaminating ground and surface water. Prevent material from entering sewer and ground water systems. Do not flush to drain. Not a RCRA hazardous waste if discarded in its purchased form. It is the responsibility of the user to determine at the time of disposal, whether the product meets RCRA criteria for hazardous waste.

6. Standard Operating Procedures for working with diethylene glycol dimethyl ether6.1. Potential hazard:

6.1.1.Target organs: Male and female reproductive systems. If inhaled may be harmful. May cause respiratory tract irritation.

6.2. Personal protective equipment: Where risk assessment shows air-purifying respirators are appropriate use a full-face respirator with multi-purpose combination (US) or type ABEK (EN 14387) respirator cartridges as a backup to engineering controls. If the respirator is the sole means of protection, use a full-face supplied air respirator.Respirators should be used only under any of the following circumstances: As a last line of defense (i.e., after engineering and administrative controls have been

exhausted). When Permissible Exposure Limit (PEL) has exceeded or when there is a possibility

that PEL will be exceeded. Regulations require the use of a respirator. There is potential for harmful exposure due to an atmospheric contaminant (in the

absence of PEL). As PPE in the event of a chemical spill clean-up process

6.3. Handling and storage: Handle with gloves. Use proper glove removal technique to avoid skin contact with this product. Butyl-rubber gloves are recommended for full contact protection. Nitrile gloves are recommended for splash contact protection. Containers should be bonded and grounded for transfers to avoid static sparks. Keep away from heat, sparks, flames, and other sources of ignition. Use non-sparking type tools and equipment, including explosion-proof ventilation. Empty containers retain product residue (vapor and/or mist) and can be dangerous. Handle with care- protect against physical damage. Avoid inhalation of vapor and mist. Avoid contact with skin, eyes, and clothing. Take measures to prevent the buildup of electrostatic charge.

Storage: Ensure the container is tightly closed at all times. Keep in a cool, dry, well-ventilated area away from incompatible materials and

conditions. Outside detached storage is preferred.

Store away from sources of ignition. Containers that are opened must be carefully resealed and kept upright to prevent

leakage.

6.4. Waste disposal6.4.1.Attach a completed Hazardous Waste tag to all waste containers as soon as the first

drop of waste is added to the container6.4.2.Store hazardous waste in closed containers, in secondary containment and in a

designated storage location.6.4.3.Double-bag dry waste using sealable transparent bags.6.4.4.Waste must be under the control of the person generating and disposing of it.6.4.5.Dispose of regularly generated chemical waste within 90 days.

7. Standard operating procedures for working with diethyl ether and 1,2-dimethoxyethane. 7.1. Potential hazard:

7.1.1.Ether is highly volatile and extremely flammable as a liquid or vapor. It is considered one of the most dangerous fire hazards commonly used in the lab due to its volatility and extremely low ignition temperature.

7.1.2.Ether will spontaneously ignite at temperatures at or above 160°C (320°F).7.1.3.Ether vapor forms explosive mixtures in air at concentrations of 1.9-36% by

volume.7.1.4.Ether may react violently with halogens or strong oxidizers (e.g. perchloric acid,

nitric acid).7.1.5.Ether can form explosive peroxides upon storage in contact with air. This reaction

is promoted by light.7.1.6.Inhalation of high concentrations of ether vapor can result in sedation,

unconsciousness, and respiratory paralysis.7.1.7.Ether is mildly irritating to the eyes and skin. Repeated skin contact can result in

dryness and cracking due to removal of skin oils.7.1.8.Chronic exposure to ether vapors can lead to loss of appetite, exhaustion, dizziness,

drowsiness, and other central nervous system effects.7.1.9.The OSHA Permissible Exposure Limit (PEL) and ACGIH Threshold Limit Value

(TLV) are both 400 ppm as an 8-hour time-weighted average. ACGIH has a short-term exposure limit (STEL) of 500 ppm over 15 minutes.

7.2. Handling and storage: Transport diethyl ether in secondary containment, preferably a polyethylene or other non-

reactive acid/solvent bottle carrier. Ether should be stored with other flammables. Do not store ether near halogens or strong

oxidizing agents. Ether must be stored in an air-impermeable container and placed in a dark area to prevent

further promotion of the peroxide-forming reaction.Suitable fire control devices (such as fire extinguishers) must be available at locations where flammable or combustible liquids are stored.

Open flames shall not be permitted in flammable or combustible liquid storage areas. A “No Open Flames” sign must be conspicuously posted in these areas.

Avoid storing ether on the floor.

7.3. Waste disposal: Crystals are found around the lid of an ether container (do NOT open the container!) You

should check for crystals weekly. The container tests positive for peroxides.

Attachment 7 – Safety Data Sheets ( MSDS) for all chemicals used/generated in experiment

All of the material safety data sheets have been attached to this file.[The original ESP must have contained these attachments. When discussing with safety officer Miller, she did not mention any concern relating to the SDS.]

NMSU CHME ESP (rev. 11/07/2016) 25