Direct Contact Heat Exchangers

-

Upload

leroy-nelson -

Category

Documents

-

view

33 -

download

3

description

Transcript of Direct Contact Heat Exchangers

DIRECT CONTACT HEAT

EXCHANGERSJacobs, Harold R.

DOI: 10.1615/AtoZ.d.direct_contact_heat_exchangers

Introduction

Direct contact heat exchangers have been used by heat transfer

practitioners for more than one hundred years. In fact, the success

of the industrial revolution has much to do with their initial use by

James Watt in creating the needed vacuum for efficient steam

engines. In 1900, Hausbrand's book, "Evaporation, Condensing and

Cooling Apparatus," published information dealing with several

types of direct contactors including barometric condensers. Despite

this early start, the development of a true understanding of their

nature lagged and still lags behind the understanding of surface-

type heat exchangers. Nevertheless, they are widely used as open-

feed water heaters in power plants, open-evaporative cooling

towers, barometric condensers throughout the petroleum industry,

and in gas (air) separation plants. Still another use is in absorption

refrigeration plants. Other applications are in rotary retorts, drying

processes, etc. Thus, knowledge of them as alternatives to

conventional regenerators or recuperators is necessary to

economically optimize systems that include heat exchange.

Direct contact heat exchange takes place between two process

streams. The streams can include combinations such as gas-solid,

gas-liquid, liquid-liquid, liquid-solid, or solid-solid streams. For

obvious reasons, gas-gas systems cannot be achieved directly;

however, two direct contactors can be used in series where a third

stream extracts heat from one gas stream and transfers it to

another. Thus, direct contactors can be used for almost all systems;

but, the complexity of multiple component systems may overcome

their economic advantage over surface type heat exchangers.

Advantages and Disadvantages in Utilizing Direct Contactors

The exchange of heat between two fluid streams can, in general, be

accomplished using either direct contact or surface-type heat

exchangers. There are, however, several limitations to the use of

direct contactors. First, if two fluid streams are placed in direct

contact, they will mix, unless the streams are immiscible. Thus,

stream contamination will occur depending on the degree of

miscibility. The two streams must also be at the same pressure in a

direct contactor, which could lead to additional costs. The

advantages in utilizing a direct contactor include the lack of

surfaces to corrode or foul, or otherwise degrade the heat transfer

performance. Other advantages include the potentially superior

heat transfer for a given volume of heat exchanger due to the

larger heat transfer surface area achievable and the ability to

transfer heat at much lower temperature differences between the

two streams. Still another advantage is the much lower pressure

drop associated with direct contactors as compared to their tubular

counterparts. A final advantage is the much lower capital cost as

direct contact heat exchangers can be constructed out of little more

than a pressure vessel, inlet nozzles for the fluid streams, and exit

ports. Of course, it is sometimes advantageous to provide internals,

as will be discussed later.

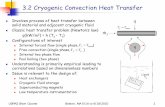

Varieties of Direct Contact Heat Exchangers

A typical direct contactor provides heat transfer between two fluid

streams. The processes include the simple heating or cooling of one

fluid by the other; cooling with the vaporization of the coolant;

cooling of a gas-vapor mixture with partial condensation; cooling of

a vapor or vapor mixture with total condensation; and cooling of a

liquid with partial or complete solidification. Most of the direct-

contact applications can be accomplished with the following

devices: a) Spray columns, b) Baffle tray columns, c) Sieve tray

or bubble tray columns, d) Packed columns, e) Pipeline contactors,

and f) Mechanically agitated contactors.

Figures 1-6 illustrate the general configurations of a) through f),

respectively. Except for the turbulent pipe contactor, all of the

devices are countercurrent devices and depend upon the relative

buoyancy of the dispersed phase through a continuous phase. While

the figures illustrate a less-dense dispersed phase being introduced

at the bottom of the column, it is possible for the dispersed phase to

be denser and introduced at the top, with the configuration

internals appropriately revised.

Figure 1. Schematics of spray columns for evaporation and

for sensible heating of the dispersed lighter phase.

Figure 2. Schematic of a disk and donut baffle tray column

for use as a steam condenser [Jacobs and Nadig (1987)].

Figure 3. Schematic of a sieve tray column used for

extracting heat from geothermal brine [Jacobs and Eden

(1986)].

Figure 4. A possible configuration of a packed bed condenser

[Jacobs and Eden (1986)].

Figure 5. Turbulent pipe contactor.

Figure 6. Typical mechanically agitated towers [Treybal,

(1966)].

The turbulent pipe contactor is a parallel-flow device and has the

limits of efficiency of all such systems, whether they be direct

contact or surface-type heat exchangers. That is, the maximum

temperature achieved by the cool stream is that of the mixing cup

temperature.

The size of the turbulent pipe contactor is dictated by the relative

mass flow rate and the nature of the turbulence. Turbulence

promoters can be installed to enhance the turbulence and, thereby,

reduce the length of contactor necessary to essentially obtain the

mixing cup temperature. If separation of the streams is desired, the

contactor must be followed by a separation device such as a settler,

a cyclone separator, or other mechanisms. While the turbulent pipe

conductor is very inexpensive, if separation is desired, the cost of

the settler will in all probability dictate the economics of the

process.

The remaining apparatus all have the heat transfer take place

between a continuous phase and a clearly defined disperse phase in

the form of drops, bubbles, jets, sheets, or thin supported films in

the case of packed beds. Heat exchangers with mechanical

agitators (Figure 6 ), while often superior as heat or mass transfer

equipment, are more difficult to design as the dispersed phase may

have a wide range or drop or bubble sizes. Thus, empirical data

from the manufacturer to establish performance is necessary.

Further, problems may result in seals at the penetration point of

the drive shafts. Special designs may therefore be necessary.

Figure 7. Drop characterization map [Grace (1983)].

Figure 8. Effective thermal diffusivity to molecular diffusivity

as a function of drop Peclet number [Jacobs and Eden

(1986)].

Figure 9. Schematic of a tray in a sieve tray column [Jacobs

and Eden (1986)].

Baffle tray columns may have similar problems in defining the

nature of the curtain of the dispersed phase. Depending on flow

rates and battle design, the dispersed phase may be a sheet, a

series of rivulets or defined streams, which can break up into drops.

If the baffles are, in fact, trays with serrated or notched rims, the

dispersed phase can be designed to be a series of well-defined

streams and the heat transfer is more easily analyzed. The

baffles/trays then result in mixing of the dispersed phase and

enhance the internal-to-the-dispersed phase mixing.

The spray column shown in Figure 1 is an open column whose only

internals are the inlet nozzles for the dispersed and continuous

phase. Ideally, such columns are capable of pure counterflow

operation, with the dispersed phase made up of nearly uniform

diameter drops. While it is possible to design the dispersed phase

inlet nozzle to achieve the desired characteristics, providing a

uniform flow in the continuous phase is more difficult. Great care

must be taken or maldistribution of the continuous phase may lead

to diminished heat transfer. Thus, the design of continuous phase

inlet nozzles is sometimes proprietary, or patented.

The bubble column or sieve tray column (see Figure 3 ) enhances

the internal heat transfer coefficient by repeatedly reforming the

drops at each tray. Proper tray or baffle design can lead to shorter

columns, and potentially small heat exchanger volume for the same

service. Their major disadvantage is fouling, corrosion or blockage

of some of the holes in the sieve tray. Details of design methods and

references to recent improvements are given by Jacobs (1988) and

Jacobs (1995a, 1995b).

References

1. Hausbrand, E. (1933) Condensing and Cooling Apparatus, 5th

ed, Van Nostrand, New York.

2. Jacobs, H. R. (1988) Direct Contact Heat Transfer for Process

Technologies. ASME Journal of Heat Transfer, Vol. 110, pp.

1259-1270.

3. Jacobs, H. R. (1995a) Direct Contact Heat Exchangers, Heat

Exchanger Design Handbook.

4. Jacobs, H. R. (1995b) Direct Contact Heat Transfer, Heat

Exchanger Design Handbook.