din 58405-3-1972 eng

-

Upload

osmin-diaz -

Category

Documents

-

view

1.734 -

download

161

Transcript of din 58405-3-1972 eng

üDC 621.833 : 681 DEUTSCHE NORMEN h y 1972

Spur Gear Drives for Fine Mechanics indications in Drawings, &les for Calculation

DIN 58405

I Sheet 3

Stirnradgetriebe der Feinwerktechnik; Angaben in Zeichnungen, Berechnnngsbeispiele

The references to the other Sheets of this Standard relate to the b y 1972 issues.

Dimensions in mm

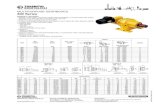

I. Indications in the spur Rear &a* The drawing contains only data f o r the gear blank and the surface finish symbols f o r the tooth system (see Figure I). All the gearcutting data are presented jointly in a Table (see Figure 2). In the title block of the drawing the row intended for the description will generally contain the entry "straight spur gear" or "helical spur gear".

1.1. Data for the gear blank ------------------ --------- (I I

(2)

(3)

(

(

(

(

a

(

(

(1

I.

1. 1. 1. II 1. 1. DI 1. Wï 1. II I.

-_

For tip circle diameter ak see DIB 58405 Sheet 1, Section 3.1. Tolerance according to DIN 58405 Sheet 2, Section 2.1. In the case of topped spur gears this is only the outside diameter of the gear blank. For machining allowance and tolerance, see DIN 50405 Sheet 2, Section 2.1.2.

Pace width.

Reference diameter f o r axial - - -^. - - - . * - " . . --,,

Anwenderinformation

Die Originalfassung der Norm enthält Elemente, z.B. farbige Abbildungen oder Tabellen, die in dieser gescannten Form der Norm nicht originalge- treu darstellbar sind. Dies muß bei der Anwendung

-

T" -P. I berücksichtigt werden. Maßgebend für das Anwen- s -

den jeder DIN-Norm ist deren Originalfassung mit

sich bitte in den DIN-Mitteilungen, im .aktuellen DIN-Katalog mit dem neuesten Ergänzungsheft oder in der aktuellen Ausgabe der PERINORM.

dem neuesten Ausgabedatum. Vergewissern Sie ?

Y T A " - A._& "--..-.y

In the case of straight spur gears a horizontal stroke is indicated. In a drive with extemuillg toothed helical spur gears, one gear of the pair is always right-handed and the other left- handed. Continued on pages 2 to 19

DIH 58405 B1.3 engl. Preisgr.' lleinverkauf der Normblätter durch Beuth-Vertrieb GmbH, Berlin 30 und Köln

--``,`,,`,,```,,`,`,,,``,```,`-`-`,,`,,`,`,,`---

üDC 621.833 : 681 DEUTSCHE NORMEN h y 1972

Spur Gear Drives f o r Fine Mechanics Indications in Drawings, &les for Calculation

DIN 58405

I Sheet 3

Stirnradgetriebe der Feinwerktechnik; Angaben in Zeichnungen, Berechnnngsbeispiele

The references to the other Sheets of this Standard relate to the b y 1972 issues.

Dimensions in mm

I. Indications in the spur Rear &a* The drawing contains only data f o r the gear blank and the surface finish symbols for the tooth system (see Figure I). All the gearcutting data are presented jointly in a Table (see Figure 2). In the title block of the drawing the row intended for the description will generally contain the entry "straight spur gear" or "helical spur gear".

1.1. Data f o r the gear blank ------------------ --------- For tip circle diameter ak see DIB 58405 Sheet 1, Section 3.1. Tolerance according to DIN 58405 Sheet 2, Section 2.1. In the case of topped spur gears this is oniy the outside diameter of the gear b l a . For machining allowance and tolerance, see DIN 58405 Sheet 2, Section 2.1.2.

Pace width.

Reference diameter for axial run-out (see DIN 58405 Sheet 2, Section 2.3).

Permissible axial run-out according to DIN 58405 Sheet 2, Section 2.3 (Table 51, surface quality.

Permissible non-parallelism instead of (5) according to DIN 58405 Sheet 2, Section 2.3.

Machining method and surface quality of tooth flanks according to DIN 58405 Sheet 2, Table 1, columns 5 and 6. Permissible radial run-out relative to mounting bore according to DIN 58405 Sheet 2, Section 2.2 (Table 3 o r 4). Surface quality, particularly when tolerancing according to Table 4.

Gear bore (mounting bore). Tolerance and surface quality according to DIN 58405 Sheet 2, Table 1, columns 8 and 9.

Material, recommendation according to DIN 58405 Sheet 2, Table 1, column 7.

Figure 1. Spur gear drawing 1.2. Data for gearcutting 1.2.1. T o o l b a s i c r a c k p r o f i l e a c c o r d i n g t o Dm5M12 1.2.2. N u m b e r o f t e e t h z 1.2.3. E o d u 1 e m In the case of helical spur gears the normal module mn should be stated. 1.2.4. P i t c h c i r c l e d i a m e t e r 1.2.5. B a s i c r a c k p r o f i l e DIN 58400 or DIN 867 (see DIN 5 W 5 Sheet I, Section 2.1). 1.2.6. A d d e n d u a m o d i f i c a t i o n f a c t o r x When x = O the value entered is O. 1.2.7. H e 1 i x a n g 1 e ß o In the case of straight spur gears, O is entered. 1.2.8. F a c 2 a 1 i g n m e n t

Right .C right-handed Left 0 left-handed

In the case of straight spur gears a horizontal stroke is indicated. In a drive with extemuillg toothed helical spur gears, one gear of the pair is always right-handed and the other left- handed.

einverkauf der Normblätter durch Beuth-Vertrieb GmbH, Berlin 30 und Köln

-------------- ---------

Continued on pages 2 to 19

DIN 58405 B1.3 engl. Preisgr.'

--``,`,,`,,```,,`,`,,,``,```,`-`-`,,`,,`,`,,`---

Page 2 D I N 58405 Sheet 3

1.2.9. G e a r f i t a c c o r d i n g

"he pa r t i cu la r s t o be indicated a r e the geaI f i t selected according t o DIN 58405 Sheet 1, Section 4, i n conjunction w i t h DIìü 58405 Sheet 2, Section 1, and a l so the symbol f o r the spec i f ied acceptance t e s t i n g (e.g. 7 J/7 f S"). 1.2.10. P e r m i s s i b 1 e t o t a 1

e r r o r r a n g e Ff Depending on t he gear f i t se lec ted , t h e to t a e r r o r range according t o D I N 58405 Sheet 2, Section 6, permitted f o r the Rear should be

t o Dm 58405 Sheet 2

- entered. For V too th systems the t o t a l e r r o r range I'$ obtained from Section 6 could i f necessary b multi l i e d by the f a c t o r L according t o equa t i o n p51) Sheet 2. 1.2.11. P e r m i s s i b 1 e t o o t h

t o t o o t h c o m p o s i t e e r r o r f p

Depending on the gear f i t se lec ted , t he too t t o tooth composite e r r o r according t o DIN 58405 Sheet 2, Section 6, permitted f o r the gear should be entered. In the case of V too th systems the too th t o tooth composite e r r o r f i obtained from Sec- t i on 6 should i f necessary be multiplied by the f ac to r L according t o equation (51) Sheet 2. 1.2.12. P e r m i s s i b l e f a c e

Depending on the gear f i t se lec ted , the permissible f ace alignment e r r o r according t o DIB.58405 Sheet 2 , Section 6, should be entered. 1.2.13. D u a l c o n e w i d t h N The dimension entered a s the dual cone width

fß a l i g n m e n t e r r o r

Number of teeth

Module m l I Pitch c i r c l e diameter dn I I Basic rack prof i l e I DIN I Addendum modification factorx

Helix angle fi0

Face alignment

Dual cone width I I Centre distance i n the dual flank r o l l t e s ter with master gear Number of mating gear

Centre distance i n housing a I I Base tangent length =

almeasured over z' = I Teeth

b)measured indirectly over t i p c i r c l e 1 is the nominal dimension N according t o DIN 58405 Sheet I , Section 3.5, D l U S the Figure 2. Gearcutting tab le upper dual cone width allowance according t o D I N 58405 Sheet 2, Section 6, corresponding t o the gear f i t selected. The d i f fe rence between the upper and the lower dual cone width allowance i s appended a s a minus variation. Exampl e : Nominal dimension of dual cone width N = 30.845 Upper dual cone width allowance ANO = -0.078 Lower dual cone width allowance AN^ = -0.064 The dual cone width t o be entered i s therefore: 30.807 - 0.026. 1.2.14. C e n t r e d i s t a n c e a" i n t h e d u a l f l a n k r o l l

t e s t e r w i t h m a s t e r g e a r Upper l i n e The dimension entered is the nominal dimension a" according t o equation (40) or (41) i n D I N 58405 Sheet 2 p lus the upper allowance on the dual f lank roll t e s t distance according t o equation (42) or (44) from Section 4.1 or equation (47) or (49) from Section 4.2. The d i f fe r - ence between the upper and lower allowances of the dual f lank r o l l t e s t distance is appended as a minus var ia t ion . In p r inc ip l e the example i n Section 1.2.13 applies. Lower l i n e Desimation of t he master Rear. 1.2.75. N u m b e r o f - m a t i n g e a r The drawing number of the mating gear i s entered. I f t he spur gear i s t o be pa i red with sever- a l d i f fe ren t mation Rears, care should be taken t o ensure t h a t t he matina Rears a l so have the - - same tolerance zones-and grades a s the spur gear. 1.2.16. C e n t r e A i s t a n c e i n h o u s i n g a The centre distance and AaU according t o D I N 58405 Sheet 2, Section 6, should be entered according t o the gear f i t selected. 1.2.17. B a s e t a n g e n t l e n g t h W "he dimension entered a s t he base tangent length i s the nominal dimension W according t o D I N 58405 Sheet 1, Section 3.4, plus the upper base tangent length allowance according t o DIN 58405 Sheet 2, Section 6, according t o the gear fit selected. The difference between t h e upper and the louer base tangent length allowance is appended as a minus variation. I n pr inc ip le the example in Section 1.2.13 applies. The number of t e e t h e ' over which the base tangent length i s measured i s obtained from the Tables i n D I N 58405 Sheet 4. I f , i n the case of topped spur gears ( too l bas ic rack p ro f i l e s U 1 or U according t o D I N 58412) the base tangent length i s t o be measured ind i r ec t ly over the t i p c i r c l e , the dimension obtained from equation (34) i n D I N 58405 Sheet 1 should be entered i n the l a s t l i n e of t he Table. For a spur gear, however, m l y the da ta f o r t he d i r e c t or t he ind i r ec t method may be entered. 2. Indications in the housinu drawinq "he dimension indicated i n the drawing is the nominal dimension equation (5) i n D I N 58405 Sheet 1 plus the allowances Bao and Bau according t o DIN 58405

a according t o equation (5) i n DIN 58405 Sheet 1 and the allowances Aa0

a calculated according t o

--``,`,,`,,```,,`,`,,,``,```,`-`-`,,`,,`,`,,`---

following pa r t i cu la r s a r e stated: 2.1. Centre distance a The nominal dimension of the centre distance i s entered. 2.2. Grade and tolerance zone according t o

DIN 58405 Sheet 2 and cent re distance allowance

......................

____________________------------_----- --- ______________________------------_-- ___-____ -

The symbol f o r t he allowances of the centre distance corresponding t o the gear f i t se lec ted (e.g. 8 J ) i s s t a t ed , plus the numerical value of the allowances toge ther with any tolerance

\

Centre Tolerance zone Permissible er- according to ror in axial

DIN 58405 Sheet parallelism f and centre dis- ' ref. to 100 u& tance allowances length of axis

distance

a

20.592 8J _+ 0.032 O, 028

\ Figure 6. Gear sha f t with p l a in bearings and

intermediate bush

k earing seating Figure 5. Gear shaf t with ro l l i ng bearings

4. Individual e r ro r s Further individual errors, the values of which a r e required t o be l imi ted , should a l s o be l i s t e d i n the drawings toge ther with t h e i r symbols and permissible l imi t ing values.

--``,`,,`,,```,,`,`,,,``,```,`-`-`,,`,,`,`,,`---

Page 4 DïN 58405 Shekt 3

D I N 58405 Equat ion or remark6 Sheet/ Sheet/

Table Section

2.1. Number of t e e t h z - 112.5

2.2. Module m - 1/2.2

2.3. Gear f i t 2/1 d m a % - from n, and S x c o r d i n g t o Sections 1.1 and I I

5. &les for ca lcu la t ion For the examples below the ca lcu la t ion proforma according to DIN 58405 Supplementary Sheet 1 has been used. For c learer d i f f e ren t i a t ion , pa r t i cu la r s concern- ing the examples a re pr in ted i n red. 5.1. Design ca lcu la t ion for a gear dr ive f o r --------- .................... __-----_____-

s e t t i n g the counter mechanism of an electro- ------ ..................................... mecoanicai-oe1ice

I. Given for gear 1 1.1. Speed n1 1.2. & t i o i - 2

1.3. Mean tors iona l backlash Sdm = 0' 1 5 '

- 40 'J/min

..

Result

Gear 1 Gear 2 Unit

48 96 - 095 mm

8 Ji8 f -

Helix angle ßo - 112.4

Basic rack p r o f i l e of t o o l according t o D I N 58412

Material

- - U I topping N = non-topping

- 2/1

Face w i d t h b - I 112.7 I Bas ic rack p r o f i l e -

, Interme bush

,Shaft

d i a t e

Gear 2

Gear ,i'-' ,

~1.4. Maximum tors iona l backlash Sa max = - re fer red t o the l a rge gear

1.5. Exis t ing cent re distance a I -

re fer red t o the l a rge gear

2. Conditions selected

- 1 - 1 - O - l o 2.4.1.

2.5.

- 2.6.

2.7. - 2.8. 112.1 I

3 . Calculated da ta

3.1. 112.6 P i t c h c i r c l e diameter

32. 113.2.1

3.2.1. 113.2.3 To avoid undercut t ing i / Fig. 1 4 a.5

"gT - = x = (Y, + AY,) ___

'I: T 3.2.2. To y i e ld exis t ing

centre d is tance a according t o 1.5

llequa- t ions 1 5 ) t O (91

x1 + 22 = (evab, - evao,) x

z1 + z2 X

2 tan aon abs from:

m" 21 + "2 cosab, =-e- cospe 2

cos aop

a X-

aos from:

tanaon tan ao6 = ~

cos Bn . " making sure that no under- c u t t i n g is thereby introduced

--``,`,,`,,```,,`,`,,,``,```,`-`-`,,`,,`,`,,`---

DIN 58405 Sheet 3 Page 5

DIN-& 405 Sheet/ Sheet/ Table I Section Equation Result

or remarks

- 1p.i

- ip.1.1

Tip circle diameter dl (tip easing possibly needed in the event of addendum modification according to 3.2)

Centre distance a

3.3.

3.4.

I 25'1 I 49*1

di, = d ~ + Z m , ( z + y ) - Z k m ,

cos aor,

cos ab 'or -

see DIN 58405 Sheet 4, iection 2

3.5. Base tangent length Y 411 W = w ' + A W AW = 2r.m,sinir0,

8,454 16,171

Measured over z ' 3.5.1.

3.6. Dual cone width N 1/33 - I - 4,Tolerances

4.1. Spur gear

4.1.1. Tip circle diameter 212.1

212.1.1

only for gear blank

h9 h9 1 - IS0 tolerance zone (non-topped)

Tolerance (topped) mly for gear blank 212

213a.4

2/21 1

212.2 -

Pip circle is n o t used Tor setting

56 Permissible radial run-out T rk

4.1.2. Permissible axial run- out of transverse planes Tsa

215

211

2Ifrom Sect. 6 ilfrom

Sect. 6 2lfrom

Sect. 6

Zlfrom Sect. 6

2/23

-

dpriifl= -

dprUfz = 46 mm

Note DIN 58405 Sheet 2, Sec- tion 1.2 e and Footnote 12)

H7 4.1.3. IS0 tolerance zone for mounting bore

4.1 A. Permissible total er- 32 214.3

214.4 ror range FY Permissible tooth to 21 4.1 5. tooth composite error f: Permissible face alignment error fß

4.1.6. 9 2/45

214.1 - 21

4.1 7. Base tangent Aw0 length allowances -

AWu

The baae tangent length or the dual cone width accord- ing to DIN 58405 Sheet 3 , Section 1.2.17 or 1.2.13 should be entered in the drawing.

- 41

- - 4.1.8.

T- Dual cone width A N O allowances

A N u

Allowances Adk of tip circle diameter with indirect base tangent length measurement (only for topped spur gears)

Plfrom Sect. 6

- 2/45

213.1 4.1.9.

1."

The tip circle diameter d' according to equation (349 should be entered in the drawing.

--``,`,,`,,```,,`,`,,,``,```,`-`-`,,`,,`,`,,`---

Page 6 D W 58405 Sheet 3

DIN 58405 Result Unit Gear 1 I Gear 2

Equation or remarks

Equation (40) or (41) Sentre distance a" in aual flank roll tester with master gear Dual flank roll ABo tester centre ~

aistance allow- A i u ances

Shaft

Equation (42) to (45) or (47) to (50)

'- I 24

Permissible radial run- out frw y

211.2 d

Tolerance to be split if intermediate bushes and/or rolling bearing inner rings

Note DIN 58405 for gear Sheet 2, Sec- tion 1.2 c bearing

IS0 grade of seating diameters of gear and bearing

Bearing

Permissible radial clearance SL

for gear 2 : IS0 clearance fit H51g5; @ tí

Dimensional, geometrical and running accuracy

for gear 2: Eccentricity of seatings on shaft

Permissible radial run- out of rolling bearing outer ring f rL

Housing

Centre distance allow- ancee

* a o and 'au

2 / fro 215.1 1 ;ect. 6 When rolling bearings and insert plain bearings are used, equations (52) and (53) should be applied.

f o r gear 2: IS0 tolerance zone of a x i a l bore 2" I 211-2c HH- IS0 tolerance zone of

bearing bores

28 I Permissible error in axial parallelism f

P

2. Check calculation

* I 'd max + 'd min ' d m S i = 2

113.6

1 /3.3 -

f 0,6 'd m i r - 'd min

n L

',I max and 'd min from equations (25) and (261, with 100 % absolute tolerance addition equations (27) and (28) should be used

- 59. I Contact ratio E --``,`,,`,,```,,`,`,,,``,```,`-`-`,,`,,`,`,,`---

DIN 58405 Sheet 3 Page 7

6. Auxiliam calculations and remarks

re 3.1.

re 3.3.

re 3.4.

re 4.1.2.

re 4.1.10.

re 4.2.1.

re 4.2.2.

re 4.4.1.

do = 4 8 . 0 , s do 2 = 96 ' 0,5

do = 24mm do2=48mni

dki = 25, l mm d ~ 2 = 49,l mm

I I 24 + 3 8 a

a , = 31 mm

1 - 2

Shaft 1: Seatings for gear and bearing ground overall, hence only the radial run-out of the

Shaft 2 : Only the running and intermediate bushes belong to shaft 2.

rolling bearing inner ring ( I O pm£ PO 2 , see 4.3.2) is effective.

Running hush: f,, = 12 pm

f r w = 24 vm

Intermediate bush: f,, = 12 pm -____

N o t e : The eccentricities of the seatings on the shaft must be allowed for in the centre distance tolerance.

*Grade of bore in the intermediate bush in this case

For Aa a value of 5 2 pm is entered in the drawing of the gears.

For the drawing of the housing equation (52) applies.

Ti3 = 64 - 15 - 6

T B = 43 piii I I f ,i = t 22 pm

--``,`,,`,,```,,`,`,,,``,```,`-`-`,,`,,`,`,,`---

page 8 DIN 58405 Sheet 3

Pitch c i r c l e diameter Q

Basic rack p r o f i l e

Addendum modification fac torx

A l Gear , ; ...... ............ <_.....<..<.<<<._.....,......,

Drawing number

24 DIN 58400

..

Number of t e e t h z 48

Module m 0.5 I

Helix angle 00

Face alignment

Gear f i t t o DIN 58405

0 -

8.1 18f

Helix angle 43 I o Face alignment - I Perm. t o t a l e r r o r range 6" Permis 'b le tooth t o tooth'; composfte e r r o r Perm. face alignment e r r o r fn

I

Gear f i t t o D I N 58405 I 8 J i 8 f I 0,032

0,011

0,009 -

Dual cone width

Centre dis tance i n the dual f lank r o l l t e s t e r with master pear

KJ.')f,i ( I (129

/;o - O.? o Number of mating gear I A 2

Centre d is tance i n housingL I XI ' (i,n?L

b)measured i n d i r e c t l y over t i p c i r c l e I

4 7 Gear 2i Drawing number

N 1 DIN 58412 Tool bas ic rack p r o f i l e

Number of t e e t h

Module 0.5 ~

P i t c h c i r c l e diameter d0 48

Basic rack p r o f i l e DIN 58 400

Addendum modification f a c t o r 4 -

0,036 Perm. t o t a l e r r o r range 6" Permissible tooth t o tooth f," comDosite e r r o r Perm. face a l i m e n t e r r o r In

0,012 0.009

Dual cone width

dual f lank r o l l t e s t e r

Number of mating gear A l I Centre dis tance i n housina ,t I y 0.012

Base tangent length - 16.1 4 8 ~ 0 , o -

0) measured over z' 1 1 teeth

b) measured i n d i r e c t l y over t i n c i r c l e I

--``,`,,`,,```,,`,`,,,``,```,`-`-`,,`,,`,`,,`---

DIN 5 M 5 Sheet 3 Page 9

11 Fig.4 and 5

-

lp.2.3

i/ equa- t ions (5) t o (91

5.2. De S i ~ - c a i c ~ i a 4 , i o o _ f o ~ - ~ - ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ o a ~ - ~ ~ ~ ~ ~ - ~ ~ ~ a servo rrontrol ---------------

I. Given for gear I 1.1. Speed nl I 4000 U/min 1.2. Ratio i I 3.125 I. 3. Mean torsional backlash Sdm I 00 6 '

referred t o the large gear

referred t o the large gear 1.4. MaxMum torsional backlash Sa Ip8x .I 0' 10'

1.5. Existing centre distance a 0 41.400 ITIIU

-Gear 2

-Interme bush

!dia te

2. Conditions selected

2.1.

2.2.

2.3.

2.4.

2.4.1.

2.5.

2.6.

2.7.

2.8.

3. Calculated data - 19,877

0,240

mm

- mm

Pitch c i r c l e diameter dg

Addendum modification x - mn To avoid undercutting

62,116

- I1/3.2.1 0,176

32.1. ZgT - = f: = (Yw + AYw)-----

Po yie ld ex is t ing centre distance a according t o 1.5

X I + x2 = ( evabs - evao,) x 21 + 22

X 2 tan ao,,

aba from: mn 21 + 22 cosaha = -1-

c o s ß o 2

-t 0.300 t 02?0

cos aoe

a X-

aOe from: tan ao,,

tanaOs = ~

cos Bo laking 8ure that no under- :utting is thereby introduced

--``,`,,`,,```,,`,`,,,``,```,`-`-`,,`,,`,`,,`---

Page IO D I N 58405 Sheet 3

3 405 Sheet/

Sect ion

ip.1

113.1.1

DIN Sheet/ Table - -

Result Equation o r remarks Uni1 -

mm

Tip c i r c l e diameter dk ( t i p easing possibly needed i n t h e event of addendum modification according t o 3.2)

3.3.

3.4. Centre dis tance a 41.400 mm

- mm

cos "0,

cos abs ?or -

3ee D I N 58405 Sheet 4, section 2

Base tangent length W W = w ' + A W AW = 2 x . mn sin aOn

3.5.

3.5.1.

411

411

113.4

- Heasured over z '

Dual cone width N N = do + 2 x . m - 2 hkM 1/33 3.6.

4. Tolerances

4.1. Saur gear

4.1.1. 212.1 Tip c i r c l e diameter

IS0 tolerance zone (non- topped)

only f o r gear blank

h9 I h9 I - 212.1.1

212.1.2 Tolerance (topped)

Permissible r a d i a l run-out Trk

only f o r gear blank

213 ad Tip c i r c l e is n o t used f o r s e t t i n g

212.2

212.3 Permissible a x i a l run- out of t ransverse planes Tsa

IS0 tolerance zone for mounting bore

215 dpriifl= - $ruf2 = 59 111111

Note D I N 58405 Sheet 2, Sec- t i o n 1.2 e and Footnote 12

4.1 2.

4.1 3. 211 _.__.

2 If rom 3ect. 6

2 If rom ìect . 6

2Ifrom sect. 6

- 214.3

214.4

Permissible t o t a l er- ror range FY Permissible tooth t o tooth compositeerror f l

Permissible face alignment e r r o r fp

4.1 -4.

4.1.5.

2/45 4.1.6.

4.1.7.

~

A , , * w u

Base tangent length allowances - 214.1

The base tangent length or the dual cone width accord- ing t o D I N 58405 Sheet 3, Sect ion 1.2.17 o r 1.2.13 should be entered i n t h e drawing.

- 17 - 23 pm

- 28 - 38 pm ?/from

gect. 6

2 If rom ject. 6 214.2 Dual cone width A N o

allowances A N u

4.1 .a.

4.1.9. 213.1 A W O A d k o =

Allowances Adk Of t i p c i r c l e diameter with i n d i r e c t base tangent length measurement (only f o r topped spur gears)

*wu f, w A d k u = - + --

s i n a O n tanaon

The t i p c i r c l e diameter d according t o equation (34f should be entered i n t h e drawing.

--``,`,,`,,```,,`,`,,,``,```,`-`-`,,`,,`,`,,`---

Dm 58405 Sheet 3 Page 11

DIN 58405 I Sheet/ pt/ I Table ec t ion

Equation or remarks I

4.1.10.

4.2.

1 - 1

Centre d is tance a" i n - 2/4.1 Equation (40) or (41) 41,693 62,649 mm dual. f lank roll t e s t e r or 4 2 with master gear Dual f lank roll t e s t e r cen t re

ances

Equation (42) t o (45) or (47) - 25 - 35 IJm A:: O t o (50)

distance allow- A''" - 39 - 56 ym

Shaft

42.1.

4.2.2.

outer ring f rL

Permissible r a d i a l run- 2/1 3/3 ~ ~ t ~ m ~ d ~ a ~ ~ b ~ s ~ ~ Q i ~ ~ ~ o r 12 16 Iim out frw rolling bearing inner r i n g s

present

IS0 grade of s e a t i n g 2/1 3/3 ~ ~ , " ~ ~ ~ 5 - diameters of gear and 5 5

bearing t i o n 1.2 c bearing

4.3.

4.3.1.

4.3.2.

4.3.3.

B e a r k g

Permissible r a d i a l 2/1 2/1.2 d 7 7 IJm

Dimensional, geometrical 2/1 - clearance SL

and running accuracy

Permissible r a d i a l run- - - out of r o l l i n g bearing

P52 P52 - 5 5 Iim

4.4. Rousing

7 58 k 27

~

4.4.1. Centre d is tance allow- 21 fro 2/51 When r o l l i n g bearings and i n s e r t p l a i n bearings are used, equations (52) and (53) should be applied.

ances 1 Sect. 6 A a , rndA.3"

4.4.2.

4.4.3.

IS0 tolerance zone of 2/1 211.2 c H 6 H6 - bearing bores

Permissible e r r o r i n 21from 2/52 17 IJm a x i a ï para l le l i sm f Sect. 6

P

5.1. Torsional backlash Sd -

5.2. Contact r a t i o 6 -

f 'd max + 'd min

o,6 'dmax - 'dmin

1 /3.6

'dmSt = 2

2

'dmax and 'dmin from equations (25) and (261, with 100 % absolute tolerance addi t ion equations (27) and (28) should be used

lP.3

r e 3.1. 75 .0,8 do , = ~-

21 - 0,8 0.965 93 0,965 93

d o , = --

do l = 19,877 mm do , = 62,116 mm

--``,`,,`,,```,,`,`,,,``,```,`-`-`,,`,,`,`,,`---

Page 12 DIN 58405 Sheet 3

~

r e 3.2.2.

r e 3.3.

r e 3.1.

re 3.5.

*e 4.1.2.

-e 4.1.10.

*e 4.2.1.

0,363 97 0,965 93

tan aoe ~

O,$ 24 + 75 0,93575 0,965 93 2 41,400

ah = ~. ~. ~

t an aos = 0,37680 C O 6 nhs = 0,92663

ahs = 22'5' ao = 20" 39'

24 + 75 2 .O,363 97 z1 4- 2 2

x1 f x2 = 0,52î

(20,2918 - 16,461 1).

adopted: 11 = I 0,300 x2 f 0,220 -.

19,8772 i 62,1163 2

k m,, - 40,9967 f (0,3 f 0.22) 0.8 - 41,400

lc m, = 0,0127 min "O

ao - 40,9967 rnm

dk = 19,877 + 3 .0,8 (0.3 T i , i ) - 2 '0 ,0127

d k = 22,092 inni

dk2 = 62,116 4- 2 0.8 (0.22 4 1,l) - 2 0.0127

d L 2 = 64.203 miri

= 8,563

A W i =z 2 .0,3 . 0,8 .0,342 02

Awl = 0,1642

W, = 8,5628 0,1642

W , - 8,727 mni

UJ; - 23.364

3w2 = 2 8,22 0,8 0,342 02

AW, = 0,1204

W 2 = 23,3639 + 0,1204

W? = 23,484 IIIICI

åpruf2 = 62,116 - 4 . 0,8

dpruf2 xz 59 mni ______

Assumed master gear: z = 76; rn = 0,8; ßo -- 15', 2 h: A W i s t = - 2 pm

I I 19,877 + 62.945 0.93571 al=---'- 2 0,92742

= 41.693 mm ~ _ _ _ _ _ _ _ _ _ _ -

.1 62 116 + 62.945 0,93571 o =_i-..- 2 0,9354 '2

ai = 62,649 mm

0.5321 0,37746 A i n : = -__ [(- 23) + (- 2 ) ]

f o r gear 1: bear ing sea t ing 8,5 bear ing inner 3,5 r i n g 12.0 pin

fcr gear 2 : bearing sea t ing 4.0 bear ing inner r i n g 3,5 s e a t i n g f o r interme- 4,O d i a t e bush intermediate bush 4 5

16,O pm -~

--``,`,,`,,```,,`,`,,,``,```,`-`-`,,`,,`,`,,`---

DIN 58405 Sheet 3 Page 13

r e 4.4.1.

r e 5 1.

r . l a = I 20 ( 20) T"+40 5 - 5

= + 40 Itm + 30 pm T g 2 ? 15 vrn

Torsional backlash with absolute to le rance addi t ion :

1,064 0,96593

Sdlnax - - [( ~ 28) i ( - 38)] __- -t 2.15.0,40572

S,jmax = 85 piil

r e fe r r ed t o the l a r g e s,j = 412.6. ~- near : 62.116 ["I - s,, = 9'25"

~ _ _ _

r e fe r r ed t o t h e l a r g e cear: 62,116

S<lrnin = 41296 Y s,, i i i i i i = 3'30"

9'24" + 3':10" S,I ni = -, Torsional backlash with c t 2 t i s t i c d to l e r ince addi t ion :

84.97 + 31,93 0.6 Ap-l!~':- 81 9; - . Sd st = ~~

0 . 4 "

2 -

.S(,

r e fe r r ed t o t h e l a r g e

';, = 58 f 27 U n i

.,- ~

sgi s, = 112.6 -58- * 1-12.6. --d- e a r : 62.116 62,116

,,i 5 t = 386" t 13"

Torsional backlash with 100 j, toler?iice addi t ion :

0,035 75 - _-___. 40.9967 CO5 X i l s =

41,100 + 0,020 + 0,006 + 0,008 -+ 0,0035 + 0.0035 cosah. = 0,92572

aíl8 = 22" 13'

s,, I'ldX = 100 P

1064 'd max = - [( - 28) f ( - 38)] --

0,965 Y3 [ 2 . (+ 20) + 12 + 16 + 7 f 71 .0,408 42

Silmax = 412,6 .__- 62,116 i" 1 r e fe r r ed t o the l a r g e

gezr :

Sdmox = 11'12"

40.9967 41,400 - 0,020 - 0,006 - 0.008 - 0,0035 - 0,0035

cos al,* = - .0,935 75

Silinin == 17 yrn

r e fe r r ed t o the large Sdnii i i = 412,6 62,116 gear: ['I

SII I r l i l i = 1'12'( _ _ _ ~

11'1.2" + 1'12" s,, = 2

= 6'27" ~

--``,`,,`,,```,,`,`,,,``,```,`-`-`,,`,,`,`,,`---

Page 14 D M 58405 Sheet 3

Tool bas ic rack p r o f i l e

Number of t e e t h Z

r e 5.2.

N DIN 58Uì

15

d , l = 19,877 .0,935 75 d , 2 = 62,116 ' 0,935 75

d,, = 18.60 mrn d , , = 58,125 nim

Addendum modification factorx

Helix angle

Yace alignment ß0

18,60 0,92665

dbl = ~

' 15''

Lef t

58,125 0,926 65

d , , =-

Perm. t o t a l e r r o r range 5'' Permissible tooth t o tooth,.;. composite error Perm. face alignment e r r o r f"

d b l = 20,072 mm

1 1 -(b'22,092' - 18<60' + v6.1,203' - 58,25') - - (20,072 + 62,862). 0,37595 2 2

d b 2 = 62,725 mm _ _ _ -

0,018

0.006

0.005

- ~

i = - I' ~. 3.14. 0,93571

0.965 93

Dual cone width

Centre dis tance i n the dual f lank r o l l t e s t e r with master gear

Number of matina gear

0,26795 0,96593 t = 1 0 . ~~~

RP 0.8 . 3,14

~

41.668 - 0.014

Z 76 - 0,8 ~ 1.5

R 2

7. Summan

11 1 Gear Drawing number

Tool basic rack p r o f i l e N DINSBCI,

Number of t e e t h z I 2-1

Module m 0.11

Pi tch c i r c l e diameter d,, I 19.817

Basic rack p r o f i l e IDIN 58 400 Addendum modification fac torx t- 0.X~O

Helix angle n,, I 15'

I Right Face alignment

Gear f i t t o D I N 58405 I 6 . f ! 6 e S i '

Centre dis tance i n housin& I 41.400 t o.nzo Base tangent length = 8 , n n - 0,011

a)measured over z ' = 2 t ee th

b) measured i n d i r e c t l y over t i p c i r c l e -

ß 2 Drawing number

Gear 2;

Module m 0,II I P i t c h c i r c l e diameter do 62,116 Basic rack p r o f i l e I DIN 5X 400

Gear f i t t o D I N 58405 I 6 J 1 6 e S "

Perm. t o t a l e r r o r range F."I 0.022 - I

O toothf; I 0,008 Permissible too th t composite e r r o r Perm. face a ï imment e r ror f , I 0.005 I Dual cone width I - I Centre d is tance i n t h e dual f lank r o l l t e s t e r with master gear

Number of mating Gear

Base tangent length = 23,461 ~~ 0,015

o) measured over z ' = 10 t e e t h

b) measured i n d i r e c t l y over t i p c i r c l e - I

--``,`,,`,,```,,`,`,,,``,```,`-`-`,,`,,`,`,,`---

DIN 58405 Sheet 3 Page 15

DIN 58405 Sheet/ Sheet,' Table Section

- 1 /2.5 Number of teeth z

Equation Result or remarks Unit

Gear 1 Gear 2

80 - 16

Face alignment - - - - -

Helix angle ß, - 1 /2.4 - O

Material I

- - 37 MnSi 37 MnSi 5 v 5 Y

2/1

2-30 D e s i g o - c a l c o a t i o o - o o E _ a - ~ o ~ ~ - ~ ~ ~ ~ - ~ ~ i ~ ~ - ~ ~ ~ - ~ ~ ~ with a s p c h r o t ransmi t te r -_------ -----------------

I. Given for gear 1 1.1. Speed nl 1.2. Ratio i 1 5

= 100 ü/min

I. J. Mean tors iona l backlash Sdm P -

re fer red t o the la rge gear

re fer red t o the la rge gear 1.4. Maximum to rs iona l backlash Sa max = go 8 '

1.5. B i s t i n g centre dis tance a I -

-Gear 2

Gear 1

2. Conditions selected

2.1.

Module m I - I 112.2 I 22.

2.3. Gear fit I 5 J/5 f S" 1 - from n1 and Sd max according to Sections 1.1

2.4.

2.4.1.

2.5. I - Basic rack profile of tool according to DIN 58412

U = topping - 1 N I non-topping 2.6.

27. Face width b I - I 1p-7 I I 4 I 3 I m m

28. Basic rack profile I - 1 1/2.i I I DIN 58400 1 -

Calculated data

3.1. I Pitch circle diameter d I

39. Addendum modification X - mn

3.2.1. To avoid undercutting

3.29. To yield existing centre distance a according to 1.5

CO8 ao ~

X- a

aos from: tan mon

tan aos = - making sure that no under- cutting is thereby introduce,

cos Bo

--``,`,,`,,```,,`,`,,,``,```,`-`-`,,`,,`,`,,`---

Page 16 DIN 58405 Shhet 3

3.3. Tip c i r c l e diameter dk ( t i p easing possibly needed i n the event of addendum modification according t o 3.2)

3.6. Dual cone width N

Spur gear

Tip c i r c l e diameter - 212.1 only f o r gear blank

Tolerance (topped) 212 212.1.2 only f o r gear blank

IS0 tolerance zone f o r mounting bore

Permissible t o t a l e r - r o r range FI Permissible tooth t o tooth composite e r r o r fy Permissible face alignment e r r o r fß

Base tangent A W o length allowances -

A,,,

Note DIN 58405 Sheet 2, Sec- t i o n 1.2 e and Footnote 12

2/1

" frcm 2/43

from 214.4

21 from 2/45

Sect. 6

Sect . 6

Sect . 6

The base tangent length o r

ing t o D I N 58405 Sheet 3, ' I from 214.1 the dual cone width accord-

Sect. 6 .. I

Dual cone width allowances

Section 1.2.17 o r 1.2.13 should be entered i n the

" from 2/45 drawing. Sect . 6

DIN 58405 Equation

o r remarks

Result Unit Sheet/

Table - - -

Sheet/ Section

113.1 ~~ ~

dk = do + 2 m,(. + y ) - 2 k . m , ip.1.i

-

411

411

19,355 rnm

cos ao# -- cos abm

-1 hen 21 and 2 2 = o ,

cos ao* D r ~

ee Table 2 i n Sheet 4

cosab,

rnm 3.5. IBase tangent length W

3.5.1. Measured over z '

W = w ' + A W AW = 2 z . rn, sin aon

4.1.

4.1.1 7,890 $3,110

I - IS0 tolerance zone (non-topped)

212.1.1 I -

-- 8,08

Tip c i r c l e LE n o t u s e d f o r s e t t i n g 212*2 I Permissible r a d i a l

run-out T rk

dpriiff = - ciprUf =;O.& 1 0 0 ~

Permissible a x i a l run- out of t ransverse planes Tsa

4.1.2

H 5

12

4.1.3

4.1 A

495

4

3,5

4

4.1.5

4.1.6

4.1.7

4.1.8

Allowances Adk of t i p c i r c l e diameter w i t h i n d i r e c t base tangent length measurement (only f o r topped spur gears)

4.1.9 r - - L a

- 35

-

- i a

- 23

- The t i p c i r c l e diameter dk according t o equation (34) should be entered i n the drawing.

--``,`,,`,,```,,`,`,,,``,```,`-`-`,,`,,`,`,,`---

D I N 58405 Sheet 3 Page 17

113.6 'dmax -t 'dmin 'dmSt = 2

1405 Sheet/ iection

214.1 o r 4.2

DIN Sheet/ Table

Equation o r remark6

Equation (42) t o (45) or (47) to (50)

bearing inner r i n g s

:entre d is tance a" i n 9ual f lank r o l l t e s t e r d i th master gear

Dual f lank r o l l AB, t e s t e r cen t re - distance al low- A P U =ces

Shaft

Permissible r a ä i a l run- out fFW

313

~~

IS0 grade of s e a t i n g diameters of gear and bearing

313

Bearing

211.2 d Permissible r a d i a l clearance SL

Dimensional, geometrical and running accuracy

211

- -

21 fro iect. 6

~~

211

Z/fron Sect.

I ,a I I V r n Permissible r a d i a l run- out of r o l l i n g bearing outer r i n g frL

Housing

When r o l l i n g bearings and i n s e r t p l a i n bearings a r e used, equations ( 5 2 ) and (53) should be applied.

Centre dis tance allow- a ces 'a o 2nd A a u

215.1

211.2 c IS0 tolerance zone of bearing bores

Permissible e r r o r i n a x i a l para l le l i sm f

P I *m

1% 2/52

5. Check calculations

5.1.

'drnax and 'dmin from equations ( 2 5 ) and (261, with 100 7d absolute tolerance addi t ion equations (27) and (28) should be used

1/33 I I 2 I - I - Contact r a t i o € 5.2. --``,`,,`,,```,,`,`,,,``,```,`-`-`,,`,,`,`,,`---

Page 18 DIN 58405 Sheet 3

6. Auxiliam calculations and remarks

r e 3.1.

r e 3.2.1.

re 3.3. and 3.4.

r e 4.1.1.

r e 4.1.2.

~ dol = 16-0 ,4

2.0,36397-0,4 + e , abs = 16 + 80

e*

6,L. + 32 ao = ~

2 ao = 19,2 mm

k .Inl, = 19,2 i- 0 , 4 . 0,4 - 19,355

= 0,017 937 5 mm

a = 19,2. 1,008 09

= 19,355 mm_

Ir ' rrlII = 0,005 m111

d k l = 6,4 f 2 . 0,4 (0,4 f 1, l ) - 2 . 0,005 d , , - 32 + 2 . 0,4. 1,1

d , 1 =; 7,590 111111 d k 2 E 32,880 mm ~

according t o Sheet 2 T a b l e 2 : T i p c i r c l e diameter wit!i machinina r l l o w n n c e f o r teni- blank:

-- 8.5 ~ - - - 0,34202

I Assumed va r i a t ion i n t o o t h t l i ickness of t o o l : f,, = + 5 p n

- 13 + 5 ~ rn +

- 17 5 0,342 O2 0,363 97

A d h i ~ 2 ~ t __-

r e 4.1.10

r e 4.2.

re 4.4.1.

= 21,756 min

.4 io l = 1,4118 [(- 6,5) f (- 3)]

AiOl = - 14 pm

A ~ , , i = 1,4618 [(- 13) f (- 3)]

A y , l l = - 23pm

f o r gear 1 :

o n l y bearing inner 2,s pin r i n g :

A i u 2 = 1,4619 [(- 17) f (- 3)]

A i u 2 = - 29 wrn ~~

ror Lem 2:

s h a f t : 6,5 bearing inner 2 , s r i n g :

___ 9.0 uni

--``,`,,`,,```,,`,`,,,``,```,`-`-`,,`,,`,`,,`---

DIN 58405 Sheet 3 page 19

'001 basic rack p r o f i l e

lumber of tee th Z

r e 5.1.

re 5.2.

u D(N58412

16

Sdrns, == 25 If: 81"" - 1 _ _ _ ~ -(l/7,590' - 6,014' f 132,870' - 30,888L) - I (6,4 + 3 2 ) . 0,3420 2

0,4 ' 3,14 . 0,939 69 t =2 ,0

2 ~~ F =

I'

P

Fool basic rack p r o f i l e

Module m Z Number of t e e t h

Pitch c i r c l e diameter do Basic rack p r o f i l e

Addendum modification fac torx

Helix angle 00

7. Summary

Gear 1; c1

DINSBLI; 80

034

32

D1N 58400 -

O

Perm. t o t a l e r r o r range 6'' ?ermiss'ble tooth t o toothf; :omposi$e e r r o r Perm. face alignment e r r o r f,,

Dual cone width Centre dis tance i n the dual f lank r o l l t e s t e r with master gear Number of mating gear

' i t ch c i r c l e diameter do I 6,4 iasic rack p r o f i l e IDIN 58 500

0,012

0,0045

0,004 -

34,383 - 0.012

c1 z92-n,4-(

ddendum modification f a c t o r XI 0.4

Centre dis tance i n the dual f lank r o l l t e s t e r with master gear Number of mating gear

e l i x angle 00 I o ace alignment - I

21,742 -- n,oov

7.92 -0.4 - 0 c2

Sear f i t t o D I N 58405 I 5 515 f S ' ?erm. t o t a l e r r o r range fi** I 0,010

0,0035 'ermiss.ble tooth t o toothf; :omposiie e r r o r ?ern. face alignment e r r o r f, 0,004 h a 1 cone width ~. I

Centre dis tance i n housing; I 19.355 0.011

Base tangent length = - 0)measured over z ' = - t e e t h

measured i n d i r e c t l y over b) t i u c i r c l e 7,571 - 0,004

Li -I\ aoos 2, Applies t o the machining of the blank.

c2 Drawing number

Gear 2 ;

I - Face alignment

;ear f i t t o D I N 58405 I 5 J / 5 f S"

_ _ I

Centre dis tance i n housing; [ 2 o.o11

Base tangent length = - a) measured over z ' = - t e e t h

measured i n d i r e c t l y over b) t i p c i r c l e 32,855 - 0.010

a ooa --``,`,,`,,```,,`,`,,,``,```,`-`-`,,`,,`,`,,`---