DIMENSIONS - BCD Inc. | Established in 1979, BCD Inc ... · clean outs, piping, piping accessories,...

Transcript of DIMENSIONS - BCD Inc. | Established in 1979, BCD Inc ... · clean outs, piping, piping accessories,...

ROOF JACK, MATCH ROOF COLOR

ROOF TOP UNIT

REVOLUTIONS PER MINUTE

SUPPLY AIR FAN

RJ

RPM

RTU

SAF

STATIC PRESSURESP

TCC

TSP TOTAL STATIC PRESSURE

WALL CAPWC

WALK IN COOLERWIC

WALK IN FREEZERWIF

ET EXPANSION TANK

ELECTRIC WATER COOLEREWC

TMV THERMOSTATIC MIXING VALVE

AFF ABOVE FINISH FLOOR

URINAL

SK SINK

MOP SINK

WATER CLOSET

WATER HEATER

CO CLEAN OUT

PLUMBING CONTRACTOR

STORM DRAIN

VENT THROUGH ROOF

SANITARY SEWER

ST STORAGE TANK

SD

SAN

CW COLD WATER DOMESTIC

PC

PRV

PSI

PRESSURE RELEIF VALVE

POUNDS PER SQUARE INCH

MS

LAV LAVATORY

HWS

HWR HOT WATER RETURN DOMESTIC

HOT WATER SUPPLY DOMESTIC

GPM GALLONS PER MINUTE

WH

GC GENERAL CONTRACTOR

VTR

UR

WC

FOOTFT

INCHIN

LEAVING AIR TEMPERATURE

LINEAR SLOT DIFFUSER

MANUAL

LAT

IR

MAN

LS

1000 BTUH

MECHANICAL CONTRACTOR

MOTOR CONTROL CENTER

MBH

MC

MCC

MFR MANUFACTURER

PRESSURE DROP

POOL DEHUMIDIFICATION UNIT

PACKAGE TERMINAL AIR CONDITIONER

POUNDS PER SQUARE INCH

PRESSURE RELEIF VALVE

PD

PDU

PTAC

PSI

PRV

INFRA-RED

AIR HANDLING UNIT

ACCU

AHU

BOTTOM OF DUCT

BACKDRAFT DAMPER

BOD

BDD

COMBUSTION AIR

CUBIC FEET PER MINUTE

CA

CFM

AIR COOLED CONDENSING UNIT

ENTERING AIR WET BULB

ENTERING AIR DRY BULB

DIAMETER

EAWB

EADB

Ø

DRY BULBDB

ELECTRICAL CONTRACTOR

EC

ELECTRIC WALL HEATER

EXHAUST FAN

EF

EWH

HOOD

EXTERNAL STATIC PRESSURE

ELECTRIC REHEAT COIL

H

ESP

ERC

E EXHAUST GRILLE OR REGISTER

FURNACE

FCU

F

FIRE DAMPER OR FLOOR DRAIN

FIRE AND SMOKE DAMPER

FD

FD/SD

FEET PER MINUTEFPM

FAN COIL UNIT

ABBREVIATIONS

UNLESS OTHERWISE NOTEDUON

TEMPERATURE CONTROL CONTRACTOR

REDUCED PRESSURE ZONED BACKFLOWRPZB

FSK FOIL SCRIM VAPOR BARRIER

RETURN AIRRA

SUPPLY AIRSA

EXHAUST AIR OR EACHEA

OUTSIDE AIROA

VARIABLE AIR VOLUME BOXVAV

FAN POWERED VAV BOXFPVAV

DEGREES FARENHEITDEG F

CND

HW

HWR

SD

SAN

RD

PIPING LINETYPES

CONDENSATE DRAIN

HEATING WATER SUPPLY DOMESTIC

HEATING WATER RETURN DOMESTIC

STORM DRAIN

SANITARY SEWER

COLD WATER DOMESTIC

ROOF DRAIN

SYMBOLS

COMPRESSED AIR

CW

CA

GREASE/OIL/DIRT DRAIN LINE GL

GASGAS NATURAL OR PROPANE

ANCHOR / HANGER

BALL VALVE

BUTTERFLY VALVE

EXPANSION JOINT

GATE VALVE

GLOBE VALVE

GAS METER

PIPE GUIDE

"P" TRAP

TEST PLUG

PLUG VALVE

WATER METER

UNION

THERMOMETER

"Y" STRAINER

PRESSURE GAUGE

BALANCING VALVE

CHECK, SWING VALVE

FLEXIBLE PUMP CONNECTION

FLANGED CONNECTION

DROP

PITCH DOWN IN DIRECTION OF ARROW

RUN OUT OFF BOTTOM OF MAIN

RUN OUT OFF TOP OF MAIN

RISER

TEE OFF SIDE OF MAIN

PIPING SYMBOLS

M

GM

P

PENDANT STYLE FIRE SUPPRESSION HEAD

PLUMBING SPECIFICATIONS

DIM

EN

SIO

NS

O

I

H

O

F

E

T

A

T

S

PR

O

F

E

S

S

I

O

N

A

L

E

N

G

I

N

E

E

R

TS

G

I

R

E

E

GOODERUM

O

DAVID R.

74178

R

E

D

GENERAL

1. BID INSTRUCTIONS: CONTRACTORS SHALL PROVIDE

BASE BID IN STRICT ACCORDANCE WITH DESIGN

BASIS EQUIPMENT AND MATERIALS. PROJECT DOES

ENCOURAGE COMPETITIVE PRICING AND ALLOWS

FOR SUBSTITUTIONS OF EQUIPMENT AND

MATERIALS AS ALTERNATE DEDUCTS TO BASIS OF

DESIGN BIDS. LIST ALL SUBSTITUTIONS ALONG WITH

DEDUCTS OFFERED ON BID. OWNER RESERVES THE

RIGHT TO REJECT SUBSTITUTIONS FOUND NOT TO

BE EQUAL TO ITEMS LISTED IN DESIGN BASIS.

2. PRIOR TO PROCUREMENT CONTRACTOR SHALL

SUBMIT TO ARCHITECT FULL SUBMITTALS FOR ALL

ENERGY CONSUMING OR PRODUCING ITEMS AND

FOR ALL PLUMBING FIXTURES, VALVES, DRAINS,

CLEAN OUTS, PIPING, PIPING ACCESSORIES,

INSULATION AND PIPING HANGERS. SUBMITTALS

SHALL BE DELINEATED WITH TAGS INDICATED ON

PRINTS, CONTRACTORS NAME, PROJECT NAME.

CLEARLY INDICATE ALL MODEL NUMBERS AND ALL

ACCESSORIES AND OPTIONS BEING PROVIDED.

SUBMISSIONS SHALL BE IN PDF FORMAT.ENGINEER

RESERVES THE RIGHT TO REJECT ANY SUBSTITUTE

ITEM.

3. CONTRACTOR SHALL BE RESPONSIBLE TO VISIT THE

SITE TO EXAMINE ALL CONDITIONS THAT MAY IN ANY

WAY AFFECT THE EXECUTION OF HIS WORK. HE

SHALL ALSO EXAMINE THE DRAWINGS AND

SPECIFICATIONS FOR OTHER BRANCHES OF WORK

MAKING REFERENCE TO THEM FOR DETAILS OF

EXISTING BUILDING CONDITIONS. NO EXTRAS WILL

BE ALLOWED FOR FAILURE TO INCLUDE ALL

REQUIRED WORK IN THE BID. CONTRACTOR SHALL

GUARANTEE ALL LABOR AND MATERIALS ENTERING

INTO CONTRACT FOR A PERIOD OF ONE (1) YEAR

FROM DATE OF ACCEPTANCE.

4. THE DRAWINGS IN THIS SECTION ARE

DIAGRAMMATIC AND ARE NOT INTENDED TO DEFINE

EXACT QUANTITIES, LOCATIONS OR CODIFIED

REQUIREMENTS. DRAWINGS SHOW GENERAL INTENT

OF SYSTEMS. P.C. SHALL PROVIDE AND PAY FOR ALL

REQUIRED PERMITS.

5. UPON COMPLETION OF THE PLUMBING

INSTALLATION, DEMONSTRATE TO THE ENGINEER

AND/OR THE OWNER'S SATISFACTION THAT THE

SYSTEMS HAVE BEEN INSTALLED IN ACCORDANCE

WITH THE DRAWINGS, SPECIFICATIONS AND

APPLICABLE CODES. DEMONSTRATE THE DYNAMIC

OPERATION OF EACH SYSTEM. VERIFY PROPER

OPERATION OF EQUIPMENT, FILTERS ARE CLEAN

AND COMPONENTS OF THE SYSTEM ARE INSTALLED

AND ADJUSTED IN FULL ACCORDANCE WITH

MANUFACTURER RECOMMENDATIONS.

6. PLUMBING WORK SHALL BE COMPLETE IN EVERY

DETAIL AND ALL MISCELLANEOUS ITEMS OF

MATERIAL AND LABOR NECESSARY TO COMPLETE

THE WORK DESCRIBED, SHOWN OR REASONABLY

IMPLIED ON DRAWINGS OR SPECIFICATIONS SHALL

BE INCLUDED IN THE CONTRACT. CONTRACTOR

SHALL MAKE MINOR ADJUSTMENTS TO THE WORK

WHERE REQUIRED, WHEN SUCH ADJUSTMENTS ARE

NECESSARY FOR PROPER OPERATION AND WITHIN

THE INTENT OF THE CONTRACT. CONTRACTOR

SHALL GUARANTEE ALL LABOR AND MATERIALS

ENTERING INTO CONTRACT FOR A PERIOD OF ONE

(1) YEAR FROM DATE OF ACCEPTANCE.

7. ALL WORK SHALL BE IN FULL ACCORDANCE WITH

CURRENT OHIO NON-RESIDENTIAL MECHANICAL

CODES. FOR MORE INFORMATION REFERENCE WEB

SITE.

http://www.com.ohio.gov/DICO/bbs/NonResidential

BuildingCodes.aspx#OMC

8. PLUMBING CONTRACTOR SHALL ACCEPT SOLE AND

COMPLETE RESPONSIBILITY FOR CONDITIONS OF

THE JOB SITE, INCLUDING SAFETY OF ALL PERSONS

AND PROPERTY DURING PERFORMANCE OF THE

WORK.

9. PLUMBING CONTRACTOR SHALL VERIFY AND BE

RESPONSIBLE FOR ALL WATER, GAS, STORM AND

SEWER UTILITY ROUGH-INS AND SHALL CONSULT

WITH THE CIVIL PLANS AND WITH LOCAL UTILITY

COMPANY(S) PROVIDING ALL MATERIALS AND LABOR

AND PAYING ALL COSTS NOT BORNE BY THE LOCAL

UTILITY COMPANY(S) FOR INSTALLATION OF

SERVICES INCLUDING SECURING AND PAYING FOR

ALL REQUIRED PERMITS.

10. PLUMBING CONTRACTOR SHALL ENSURE

EMPLOYEES ARE MEETING AND DOCUMENTING ALL

OSHA AND JOB SPECIFIC SAFETY REQUIREMENTS AS

REQUIRED BY LAW AND BY CONTRACT. PERSONAL

PROTECTIVE EQUIPMENT SHALL BE PROVIDED AND

UTILIZED AS REQUIRED. MECHANICAL CONTRACTOR

SHALL PAY ALL FINES LEVIED BY OSHA FOR FAILURE

TO COMPLY WITH OSHA REQUIREMENTS.

11. ALL PLUMBING MATERIALS INSTALLED IN RETURN

AIR PLENUMS SHALL BE INSTALLED OR COVERED

WITH MATERIALS AS REQUIRED TO PROVIDE FLAME

RATING OF NOT MORE THAN 25 AND A SMOKE

DEVELOPED INDEX OF NOT MORE THAN 50. PRIOR

TO ROUGH-IN CONSULT WITH M.C. TO VERIFY ALL

LOCATIONS OF RETURN AIR PLENUMS.

12. FURNISH AND INSTALL ACCESS PANELS FOR ALL

CONCEALED EQUIPMENT, PIPING VALVES,

CLEANOUTS, ETC. ACCESS PANELS SHALL BE OF

SUFFICIENT SIZE TO PROVIDE ADEQUATE WORKING

CLEARANCE AND ACCESS.

13. PLUMBING CONTRACTOR SHALL BE RESPONSIBLE

FOR ALL REQUIRED CUTTING AND PATCHING

INCLUDING SAW CUTTING AND PATCHING OF

EXISTING FLOORS AS REQUIRED TO ACCEPT NEW

FLOORING.

EQUIPMENT

1. PROVIDE EQUIPMENT AS SHOWN ON EQUIPMENT

SCHEDULES AND PLAN NOTES. SUBSTITUTIONS TO

LISTED EQUIPMENT SHALL BE AT RISK OF

CONTRACTOR. SUBSTITUTIONS SHALL ONLY BE

ALLOWED IF ITEMS ARE EQUAL IN ALL ASPECTS.

2. PROVIDE SUBMITTALS TO ELECTRICIAN AS

REQUIRED FOR COORDINATION OF ALL REQUIRED

ELECTRICAL POWER WIRING. INCLUDE WIRING

DIAGRAMS AND CABLING REQUIREMENTS FOR

REFERENCE. COORDINATE ALL INTERLOCKS AS

NEEDED. PROVIDE SINGLE POINT CONNECTION KITS

AS NEEDED.

3. INSTALL ALL EQUIPMENT IN FULL ACCORDANCE

WITH MANUFACTURERS RECOMMENDATIONS AND

CLEARANCE REQUIREMENTS. PROVIDE ALL

REQUIRED MOUNTING OR HOUSEKEEPING PADS.

G.C. SHALL PROVIDE LEVEL GRADE FOR EXTERIOR

MOUNTED EQUIPMENT. P.C. SHALL PROVIDE ALL

HOISTING AND RIGGING NEEDED TO SET ALL

PLUMBING EQUIPMENT.

4. ALL EQUIPMENT SHALL BE INSTALLED AS NEEDED

TO PREVENT OBJECTIONABLE NOISE AND/OR

VIBRATION. P.C. SHALL PROVIDE VIBRATION PADS,

SPRING ISOLATORS, ATTENUATORS AND

ACCESSORIES AS NEEDED.

5. PROVIDE ALL BLOCKING, HANGERS, SHELVES,

BRACKETS ETC. AS REQUIRED TO INSTALL ALL

PLUMBING EQUIPMENT.

2. INSTALL WATER HEATERS IN ACCORDANCE WITH

NFPA-70, AND THE NATIONAL ELECTRICAL CODE.

PROVIDE BRASS DRAIN VALVE, 3/4" RELIEF VALVE

AND COLD WATER DIP TUBE. INSTALL HEATERS PER

MANUFACTURES INSTALLATION INSTRUCTIONS.

PROVIDE SHUT-OFF VALVES FOR SERVICE WORK.

3. THERMOSTATS ON WATER HEATER SHALL NOT BE

USED FOR LIMITING HOT WATER TEMPERATURES.

P.C. SHALL PROVIDE MIXING VALVES FOR HOT

WATER TO ALL FAUCETS ACCESSIBLE TO

OCCUPANTS. MIXING VALVE SYSTEMS SHALL LIMIT

WATER TEMPERATURE AT FAUCETS TO 110 DEG F.

OR LESS.

4. PROVIDE SCHEDULE 40 PVC PIPING AND FITTINGS

FOR ALL COMBUSTION AIR AND VENT PIPING IN

ACCORDANCE WITH MANUFACTURERS

INSTRUCTIONS ON ALL DIRECT VENT WATER

HEATERS OR BOILERS.

FIXTURES

1. REFERENCE FIXTURE SCHEDULES ON PLANS AND

PROVIDE ALL REQUIRED CARRIERS, BLOCKING,

HANGERS, TAIL PIECES, TRAPS, RISERS,

ESCUTCHEONS, GRIDS, PUTTY, GASKETS, CAULKING,

ETC. AS REQUIRED TO INSTALL ALL PLUMBING

FIXTURES.

2. REVIEW SUBMITTALS FOR ALL OWNER PROVIDED

EQUIPMENT AND PROVIDE ANY REQUIRED

ACCESSORIES AS NEEDED FOR A COMPLETE

INSTALLATION. P.C. SHALL BE RESPONSIBLE TO

RECEIVE AND INSTALL ALL OWNER PROVIDED

FIXTURES.

2. FIXTURES DESIGNATED FOR HANDICAP

ACCESSIBILITY SHALL COMPLY WITH ANSI A 117.1,

LATEST EDITION, INCLUDING ADOPTED OHIO

AMENDMENTS.

3. PROVIDE ALL CODE REQUIRED BACKFLOW DEVICES

FOR PROCESS HVAC EQUIPMENT AND FOR WATER

SERVING ANY DRINKING OR FOOD PREPARATION

FIXTURES.

4. PROVIDE BELLOWS TYPE WATER HAMMER

ARRESTERS, STAINLESS STEEL CASHING AND

BELLOWS, 250 PSI, INSTALL PER PDI STANDARD

WH201.

PIPING

1. ALL EXPOSED SUPPLY PIPES AND METAL TRIM IN

CONNECTION WITH THE FIXTURES SHALL BE

CHROME PLATED RED BRASS OR BRONZE, PROVIDE

CHROME PLATED STOP VALVES IN ALL SUPPLIES TO

ALL FIXTURES. PLASTIC STOPS OR TRIM SHALL NOT

BE ACCEPTABLE. CAULK ALL FIXTURES WITH

WATERPROOF SILICONE CAULK. TRAPS SHALL HAVE

CLEANOUT PLUGS. INSTALL ONE PIECE CHROME

ESCUTCHEON PLATE AT WALL PENETRATIONS.

2. WASTE AND VENT PIPING MAINS SHALL BE PITCHED

AT 1/8" PER FOOT. LATERAL BRANCHES SHALL BE

PITCHED 1/4" PER FOOT TOWARD THE SANITARY

SEWER MAIN. THEY SHALL BE INSTALLED AND

TESTED IN ACCORDANCE WITH THE CURRENT

PLUMBING CODE AND TESTED PER AUTHORITY

HAVING JURISDICTION.

3. VERIFY LOCATION, DEPTH AND SIZE OF SANITARY

SEWER CONNECTION POINTS. CONNECT AS

REQUIRED. OUTSIDE SEWER SHALL BE INSTALLED

PER MUNICIPAL CODE. COORDINATE CONNECTIONS

WITH SITE CONTRACTOR AND LOCAL UTILITY

4. ALL OUTSIDE WATER PIPING SHALL BE COVERED

PER LOCAL REQUIREMENTS.

5. ALL INTERIOR PIPING PENETRATIONS THROUGH

WALLS, CEILINGS, ROOFS AND FLOORS SHALL BE

SLEEVED AND SEALED. PROVIDE UL LISTED FIRE

STOPPING WHERE REQUIRED.

6. ALL EXTERIOR UNDERGROUND PENETRATIONS OF

BUILDING FOUNDATIONS OR SLAB FLOORS SHALL BE

SLEEVED AND SEALED. PENETRATIONS BELOW

GRADE INTO BUILDING SPACES SHALL BE DONE

WITH MECHANICAL SEALS LIKE "LINK SEAL" OR

EQUAL.

7. NO PLUMBING PIPING SHALL PASS DIRECTLY OVER

ELECTRICAL PANELS OR DISTRIBUTION CABINETS.

PRIOR TO ROUGH IN COORDINATE WITH E.C.

8. DIELECTRIC UNIONS SHALL BE USED TO CONNECT

DISSIMILAR METALS OR METAL PIPING SHALL HAVE

METAL CONNECTIONS ON EACH END THREADED TO

MATCH THE ADJACENT PIPING. METAL

COMPONENTS SHALL BE SEPARATED BY A NYLON

INSULATOR TO PREVENT CURRENT FLOW BETWEEN

DISSIMILAR METALS. UNIONS SHALL BE SUITABLE

FOR THE SYSTEM OPERATING PRESSURES AND

TEMPERATURE WELD TYPE: ASTM A-234.

9. PIPING SLEEVES; INTERIOR OR EXTERIOR ABOVE

GRADE; GALVANIZED-STEEL-PIPE SLEEVES OR

PVC-PIPE SLEEVES. VERIFY, WITH FIRE AUTHORITIES

HAVING JURISDICTION, THAT PVC MATERIALS ARE

ALLOWED FOR SLEEVES. BELOW GRADE; ALL;

MECHANICAL GALVANIZED-STEEL PIPE SLEEVE

SYSTEM LIKE LINK-SEAL. ALL SLEEVES SHALL BE

FIRE STOPPED OR CAULKED. EXTERIOR SLEEVES

SHALL PROVIDE WATER/AIR TIGHT PENETRATION

SYSTEM.

10. PROVIDE HANGERS PER MSS AND IPC STANDARDS

BASED ON PIPING TYPES AND SIZES.

11. PIPING MATERIALS UNLESS OTHERWISE NOTED ON

THE PLANS SHALL BE AS FOLLOWS:

GAS ABOVE GRADE, 2" AND SMALLER; BLACK

STEEL SCHEDULE 40 TYPE E OR S PIPE

GRADE B; ASTM A53 / A53M, A105 OR A120

WITH THREADED ENDS; FITTINGS SHALL

BE MALLEABLE IRON THREADED FITTINGS

ASTM B16.3 CLASS 150.

ABOVE GRADE 2-1/2" AND LARGER: BLACK

STEEL SCHEDULE 40 TYPE E OR S PIPE

GRADE B; ASTM A53 / A53M, A105 OR A120

WITH PLAIN ENDS. FITTINGS; WROUGHT

STEEL WELDING FITTINGS TO ASTM A

234/A 234M FOR BUTT AND SOCKET

WELDING.

PROVIDE AND INSTALL VENTLESS GAS

REGULATORS LIKE MAXITROL 325 SERIES

TO REGULATE 2 PSIG DISTRIBUTION

PRESSURE TO APPLIANCE REQUIRED

PRESSURE AND FLOWS PER

MANUFACTURERS RECOMMENDATIONS.

PROVIDE AND INSTALL BRASS VALVE TAGS

ON ALL REGULATORS STAMPED WITH THE

SET PRESSURE AS DICTATED BY THE

APPLIANCE MANUFACTURER.

P.C. SHALL ENSURE ALL EXTERIOR ABOVE

GRADE METALLIC PIPING SHALL BE

PROTECTED AGAINST CORROSION BY

PAINTED IN AN APPROVED MANNER WITH

AN ALKYD/OIL BASE YELLOW PAINT.

WATER BELOW GRADE : ALL PIPING SHALL BE

COPPER TUBING (BELOW SLABS AND

EXTERIOR): ASTM B 88 TYPE 'K' SOFT

WATER TUBE ANNEAL TEMPERED. NO

JOINTS PERMITTED BELOW GROUND.

WATER IN WATER SERVICE ROOM AND WATER

HEATER ROOM ALL PIPING SHALL BE

COPPER TUBING ASTM B 88, TYPE 'L' HARD

WATER TUBE DRAWN TEMPER. WITH

CAST-COPPER SOLDER-JOINT FITTINGS:

ANSI B16.18. OR WROUGHT-COPPER

SOLDER JOINT FITTINGS: ANSI B16.22

WATER PEX WATER PIPING (TYPICAL ROOM UNITS)

SHALL BE WIRSBO OR UPONOR TUBING

ASTM F876 AND F877, BLUE FOR COLD AND

RED FOR HOT AND RE-CIRCULATION.

FITTINGS SHALL BE UPONOR ProPEX

SYSTEM C69300 BRASS FITTINGS ASTM

F877, F1960. MANIFOLDS: ProPEX TYPE L

TO ASTM F877 WITH BRASS BALL VALVES.

WATER RISERS AND MAINS LOCATED ABOVE

CEILINGS AND OUTSIDE OF SERVICE ROOM

AND HOT WATER HEATER ROOM. FLOW

GUARD GOLD - EQUAL SDR 11 CPVC;

PIPING ASTM D 2846 WITH SOCKET

WELDED FITTINGS ASTM F 493. MADE

FROM CPVC CELL CLASS 24448 ASTM D

1784. MANUFACTURED PER NSF 14 AND 61.

SEWER POLYVINYL CHLORIDE SEWER PIPE (PVC):

ASTM D2665 SOLID DRAIN WASTE AND

VENT OR ASTM F 891 CELLULAR CORE

SCHEDULE 40 WITH PVC SOCKET WELDED

FITTINGS DESIGNED TO FIT PIPING

DIAMETERS. INSULATED IN RETURN AIR

PLENUMS.

CONDENSATE COPPER DRAIN, WASTE AND VENT PIPE

MINIMUM SIZE 3/4" . INSULATED IN RETURN

AIR PLENUMS.

STORM LATERALS

POLYVINYL CHLORIDE SEWER PIPE (PVC):

ASTM D2665 SOLID DRAIN WASTE AND

VENT OR ASTM F 891 CELLULAR CORE

SCHEDULE 40 WITH PVC SOCKET WELDED

FITTINGS DESIGNED TO FIT PIPING

DIAMETERS. INSULATED IN RETURN AIR

PLENUMS.

STORM RISERS SAME AS STORM LATERALS.

PLUMBING INSULATION

1. ALL PIPING INSULATION MATERIALS SHALL HAVE A

FLAME SPREAD RATING OF 25 OR LESS (ON THE

FLAME SPREAD TEST SCALE) AND SMOKE

DEVELOPMENT OF 50 OR LESS (ON THE SMOKE TEST

SCALE) OR AS DEFINED BY NFPA 255 STANDARD

METHOD OF TESTING OF SURFACE BURNING

CHARACTERISTICS OF BUILDING MATERIALS, LOCAL

CODES AND LOCAL AUTHORITIES HAVING

JURISDICTION. ALL PVC PIPING LOCATED IN RETURN

AIR PLENUM SPACES OR EXPOSED SHALL BE

INSULATED.

2. INSULATION: INSTALL ALL INSULATION REQUIRED BY

THE OHIO ENERGY CODE IN STRICT ACCORDANCE

WITH MANUFACTURERS INSTRUCTIONS , IN A TIGHT

AND NEAT MANOR. NO SAGGING, FRAYED OR TORN

INSULATION WILL BE EXCEPTED. UNLESS

OTHERWISE NOTED ON PLANS. PIPING SHALL BE

INSULATED AS FOLLOWS:

ALL COPPER CW AND ALL HW LINES

SHALL BE INSULATED TO THE FOLLOWING

THICKNESS.

a. HW: 1/2" THICKNESS FOR PIPE SIZES

UP TO 1-1/2", 1" THICKNESS FOR

GREATER THAN 1-1/2.

b. CW: 1/2" THICKNESS FOR PIPE SIZES.

MATERIAL CHOICES SHALL INCLUDE:

PRE-FORMED TYPE I, 850 DEG F MINERAL

OR GLASS FIBERS BONDED WITH A

THERMOSETTING RESIN AND HINGED WITH

SELF SEALING LAP. COMPLY WITH

ASTM C 547, TYPE I, GRADE A, WITH

FACTORY-APPLIED ASJ.

FLEXIBLE ELASTOMERIC CLOSED CELL OR

EXPANDED RUBBER PIPE INSULATION

WITH PRESSURE SENSITIVE ADHESIVE

SYSTEM, ASTM C534, ASTM E84 CLASS A

300 DEG F.

EXTERIOR EXPOSED INSULATION SHALL

BE JACKETED WITH UV RESISTANT PVC

PIPE JACKETS AND PREFORMED FITTING

COVERS COMPLIANT WITH ASTM D257,

D638, D790, D792, D1784, D3679, E84 AND

E136.

CHECK TEST AND START UP REQUIREMENTS

1. CLOSE OUT: PROVIDE MANUFACTURERS OPERATION

AND MAINTENANCE MANUALS AND AS BUILT

DRAWINGS. PROVIDE (1) TRAINING SESSION TO

OWNER SELECTED PERSONNEL AS REQUESTED AND

PROVIDE WARRANTY INFORMATION FOR ALL

MANUFACTURERS WARRANTED EQUIPMENT.

2. FILL SYSTEMS WITH FRESH WATER AND INSPECT

ALL CONNECTIONS FOR LEAKAGE. REMOVE ALL

PACKING AND PROTECTIVE SHIPPING MATERIALS.

CLEAN ALL FIXTURES AND START-UP ALL WATER

HEATERS, PUMPS, AND EQUIPMENT. VERIFY PROPER

OPERATION. OPERATE ALL FAUCETS AND INSPECT

STOPS, RISERS, TRAPS AND DRAINS. CORRECT ALL

LEAKS, WATER HAMMER AND VIBRATIONS AS

REQUIRED.

SCHEDULES OF THROUGH PENETRATION FIRESTOP SYSTEMSCONCRETE FLOORS CONCRETE OR BLOCK WALLS

TYPE OF PENETRANTF-RATING

(HR)UL-CLASSIFIED

SYSTEM TYPE OF PENETRANT F-RATING UL-CLASSIFIEDSYSTEM

CIRCULAR BLANKOPENINGS

1 FA 0006,CAJ 0055,CAJ 0090

CIRCULAR BLANKOPENINGS

1 CAJ 0055, CAJ 0090

2 FA 0006,CAJ 0055,CAJ 0090 2 CAJ 0055, CAJ 0090

3 FA 0006, CAJ 0055,CAJ 0086, FA 0014 3 CAJ 0055, CAJ 0086

SINGLE METAL PIPESOR CONDUIT

1 CAJ 1226, FA 1028

SINGLE METAL PIPESOR CONDUIT

1 CAJ 1226, WJ 1067

2 CAJ 1226, FA 1028 2 CAJ 1226, WJ 1067

3 CAJ 1226, FA 1017 3 CAJ 1226, WJ 1041,WJ 1068

4 CBJ 1037, CBJ 1034 4CBJ 1034, CBJ 1037,WJ 1041, WJ 1042,

WJ 1068

SINGLENON-METALLIC PIPE

OR CONDUIT (I.E. PVC,CPVC, ABS, FRP, ENT)

1

FA 2053, FA 2025,CAJ 2109, CAJ 2098,CAJ 2271, CAJ 2167,CBJ 2021, CAJ 2342

SINGLENON-METALLIC PIPE

OR CONDUIT (I.E. PVC,CPVC, ABS, FRP, ENT)

1CAJ 2109, CAJ 2098,CAJ 2167, CAJ 2371,

CAJ 2342

2

FA 2053, FA 2025,CAJ 2109, CAJ 2098,CAJ 2271, CAJ 2167,CBJ-2021, CAJ 2371,

CAJ 2342

2CAJ 2109, CAJ 2098,CAJ 2167, CAJ 2371,

CAJ 2342

3FA 2054, CAJ 2109,

CAJ 2098, CAJ 2371,CAJ 2342

3 CAJ 2109, CAJ 2098,CAJ 2371, CAJ 2342

4 CBJ 2016, CAJ 2017 4 WJ 2057, WJ 2091

SINGLE INSULATEDPIPES

1FA 5015, FA 5017,

CAJ 5090, CAJ 5091,CAJ 5098

SINGLE INSULATEDPIPES

1 CAJ 5090, CAJ 5091,CAJ 5061, WJ 5042

2FA 5015, FA 5017,

CAJ 5090, CAJ 5091,CAJ 5090

2 CAJ 5090, CAJ 5091,CAJ 5061, WJ 5042

3 FA 5016, CAJ 5090,FA 5018 3 CAJ 5090, CAJ 5061

4 CBJ 5006 4 CBJ 5006, WJ 5028

NON-INSULATEDMECHANICAL

DUCTWORK WITHOUTDAMPERS

1 CAJ 7046, CAJ 7051,CAJ 7084 NON-INSULATED

MECHANICALDUCTWORK WITHOUT

DAMPERS

1 CAJ 7046, CAJ 7051,WJ 7021, WJ 7022

2 CAJ 7046, CAJ 7051,CAJ 7084 2 CAJ 7046, CAJ 7051,

WJ 7021, WJ 70223 CAJ 7046, CAJ 7051 3 CAJ 7046, CAJ 7051

INSULATEDMECHANICAL

DUCTWORK WITHOUTDAMPERS

N/A** N/A**

INSULATEDMECHANICAL

DUCTWORK WITHOUTDAMPERS

1 WJ 7029

2 WJ 7029

MIXED PENETRANTS

1 CAJ 8099, CAJ 8056,CAJ 8143

MIXED PENETRANTS

1 CAJ 8099, CAJ 8056,WJ 8007, CAJ 8143

2 CAJ 8099, CAJ 8056,CAJ 8143 2 CAJ 8099, CAJ 8056,

WJ 8007, CAJ 8143

3 CAJ 8099, CAJ 8056 3 CAJ 8041, CAJ 8056,WJ 8007, CAJ 8099

4 CAJ 8095 4 CAJ 8095, WJ 8007

WOOD FLOOR GYPSUM WALLBOARD ASSEMBLIES

TYPE OF PENETRANT F-RATING UL-CLASSIFIEDSYSTEM TYPE OF PENETRANT F-RATING UL-CLASSIFIED

SYSTEM

METAL PIPES ORCONDUIT

1 FC 1009, FC 1059

METAL PIPES ORCONDUIT

1 WL 1054, WL 1058,WL 1164

2 FC 1009, FC 10592 WL 1054, WL 1058,

WL 1164

4 WL 1110, WL 1111,WL 1165

NON-METALLIC PIPEOR CONDUIT

1FC 2232, FC 2030,FC 2160, FC 2127,

FC 2128 NON-METALLIC PIPEOR CONDUIT

1 WL 2078, WL 2075,WL 2128

2FC 2029, FC 2030,FC 2128, FC 2127,

FC 2160

2 WL 2078, WL 2075,WL 2128

4 WL 2184, WL 2245

INSULATED PIPES

1 FC 5004, FC 5037,FC 5036 CABLE TRAY

1 WL 4011, WL 40192 WL 4011, WL 40194 WL 8014

2 FC 5004, FC 5037 INSULATED PIPES

1 WL 5028, WL 5029,WL 5047

2 WL 5028, WL 5029,WL 5047

4 WL 5073NON-INSULATED

MECHANICALDUCTWORK WITHOUT

DAMPERS

1 FC 7013

NON-INSULATEDMECHANICAL

DUCTWORK WITHOUTDAMPERS

1 WL 7017, WL 7040,WL 7042, WL 7155

2 WL 7040, WL 7042,WL 7155

INSULATEDMECHANICAL

DUCTWORK WITHOUTDAMPERS

1 N/A** INSULATEDMECHANICAL

DUCTWORK WITHOUTDAMPERS

1 WL 7059, WL 7153,WL 7156, WL 7151

2 N/A** 2 WL 7059, WL 7153,WL 7156, WL 7151

MIXED PENETRANTS 1 FC 8009, FC 8014,FC 8026, FC8025 MIXED PENETRANTS

1 WL 1095, WL 80132 WL 1095, WL 80134 WL 8014

NOTES:1. Jobsite conditions of each through-penetration firestop system must meet ALL details of the UL-Classified Systemselected.2. Where more than one applicable UL-Classified System is listed in the schedules, choose the UL System which is mosteconomical for each through-penetration firestop system.3. Coordinate work with other trades to assure that penetration opening sizes are appropriate for penetrant locations, andvice versa.

SCHEDULES OF THROUGH PENETRATION FIRESTOP SYSTEMS

NOTES:1. Jobsite conditions of each through-penetration firestop system must meet ALL details of the UL-Classified Systemselected.2. Where more than one applicable UL-Classified System is listed in the schedules, choose the UL System which is mosteconomical for each through-penetration firestop system.3. Coordinate work with other trades to assure that penetration opening sizes are appropriate for penetrant locations, andvice versa.

FIRE PENETRATION SCHEDULE

DIM

EN

SIO

NS

O

I

H

O

F

E

T

A

T

S

PR

O

F

E

S

S

I

O

N

A

L

E

N

G

I

N

E

E

R

TS

G

I

R

E

E

GOODERUM

O

DAVID R.

74178

R

E

D

9

SCALE: N/A

MIXING VALVE DETAIL

SUPPLY INLET

SUPPLY INLET

DIELECTRIC UNION

VALVES RECOMMENDED

SUPPLIED

WATER OUTLET

TEMPERED

HOT SHUT

OFF VALVE

MIXING

VALVE

1-5/8 X 13/16 X 14" L

UNISTRUT

TEMPERATURE

GAUGE

TEMPERATURE

ADJUSTMENT

KNOB

CHECKSTOP

CHECKSTOP

MAX TEMP

SET SCREW

ISOLATION

25±1/4"

[635±6mm]

10

SCALE: N/A

HOT WATER RETURN DETAIL

CHECK VALVE

BALL VALVE

HOT WATER

RETURN

NEXUS UMS AUTOMATIC

FLOW CONTROL VALVE SEE

SCHEDULE FOR GPMS.

HOT WATER

SUPPLY

LAST BRANCH

ON LATERAL

BALL VALVE

FLOW SCHEDULE

SIZE

3/4"FS1

MARK FLOW

2.0

GPM

FS2 1.0

FS3 1.0

FS4 2.0

3/4"

3/4"

3/4"

QTY TOTAL

GPM

12 24.0

1

1

1

1.0

1.0

2.0

INSULATED PLUMBING PIPES.

RIGID MOLDED FIBERGLASS

INSULATION

METAL PROTECTION

SHIELDS

HANGING RODS

1

2

" MIN.

NUTS & LOCK

WASHERS

SUPPORT CHAIR

BOLTED TO CHANNEL

STEEL CHANNEL

ADEQUATE TO

CARRY LOAD

GENERAL NOTES:

1) PROTECTION SADDLES SHALL BE COPPER CLAD IF COPPER TUBE IS USED.

2) PROVIDE INTERMEDIATE HANGING ROD SUPPORT WHERE NUMBER OF

PIPES EXCEED FIVE(5).

TRAPEZE HANGER DETAIL

NO SCALE

5

PIPE

LENGTH OF

SHIELD

8"

12"

LENGTH OF SHIELD

SEE SCHEDULE

PIPE SIZE

1

2

" TO 6"

8" TO 12"

SHIELD SCHEDULE

16 GA. GALV. STEEL SHIELD

ADJUSTABLE CLEVIS HANGER

FIBERGLASS INSULATION

TYPICAL FOR ALL INSULATED

PIPING

ADD PIPE SLEEVE THAT HAS

AN INSIDE DIAMETER,

1

4

"±

LARGER THAN OUTSIDE DIA.

PIPE HANGER ROD CLIP

CONNECTION

TO STRUCT. MEMBER

"L" 6'-0"MAX.

ADD FRAMING CHANNEL

OR ANGLE WHEN "L" IS

GREATER THAN MAX.

LENGTH.

PIPE HANGER

SAME AS

OPPOSITE

SIDE

CLEAN OUT DETAIL

NO SCALE

1

SINGLE PIPE HANGER DETAIL

NO SCALE

8

FLOOR DRAIN

CONCRETE TO PROVIDE

CAP TO BE SET IN

SUITEABLE ANCHORAGE

SYSTEM

TO DOMESTIC

3"

NOT LESS THAN 8"

NOR MORE THAN 24"

DRAIN

INLET

2"

BACKFLOW PREVENTER DETAIL

NOT TO SCALE

2"

3"

SECURE ALL PIPING,

FITTINGS AND VALVES TO

WALL OR FLOOR PER

SPECIFICATIONS.

11

RPZB

RPZB

PLUG

VALVE

1-1/2"

1-1/2"

1-1/2"

1-1/2"

M.J. X FL. ADAPTER

ALL THR. ROD

WASHER

TIE BOLT

"J" BOLT OR

HEX NUT &

THRUST BLOCK

(PER NFPA 24)

U.G. PIPING

GARAGE FLOOR

D.I.P. RISER

4" CONNECTION

3

WATER SERVICE DETAIL

SLEEVE AND SEAL

WALL PENETRATION

(SIZE AS INDICATED

ON DRAWINGS

DISCHARGE PIPE

SCHEDULE 40

PVC W/REDUCER

AIR GAP = 2 X "D" OR 2" MIN.

FIN. FLR.

IN-DIRECT DRAIN CONNECTION

NO SCALE

7

S.S. CLAMPING RING

NON-INSULATED PIPE

SEALANT IN PIPE SLEEVE

URETHANE OR DOW CORNING

1/2" (MIN.) FOAM-IN-PLACE

RESILIENT FOAM PENETR.

#3-6548 SILICONE RTV

NON-INSULATED PIPE

EPDM FLASHING BOOT

WIRE MESH

STAINLESS STEEL

1/4"x1/4"

VENT THRU ROOF DETAIL

NO SCALE

2

SN

OW

L

OA

DIN

G H

GT

. R

QM

TS

.

EX

TE

ND

V

EN

TIN

G P

ER

4

SCALE: N/A

GAS CONNECTION DETAIL

ROOF LINE

MIRO PIPE STAND

ELBOW

ELBOW

UNION

MUA

4" DIRT LEG

WITH CAP

FIELD VERIFY LENGTH

AGA RATED GAS STOP

REGULATOR

12

ELEVATOR PIT DETAIL - WASTE

NO SCALE

6

SCALE: 1/4" = 1'-0"

ROOF DRAIN DETAIL

ROOF DRAIN

J.R. SMITH MODEL 1010Y ROOF

DRAIN NO-HUB WITH DUCO CAST

IRON BODY / FLASHING CLAMP AND

POLYETHYLENE DOME

ROOF GAS PIPING HANGER DETAIL

NO SCALE

13

MIRO #1.5 PIPE SUPPORT

W/ ACCESSORIES

ACCESSORIES

- 1.5 pipe guide

- 1.5 spacer

- Support pad

- Eternabond

} 2-sided tape

WATER HEATER PIPING IS

DIAGRAMATIC, INSTALL ALL

PIPING IN STRICT ACCORDANCE

WITH MANUFACTURERS

RECOMENDATIONS.

PIT LID

ELEVATOR WALL

SUMP PIT

AIR GAP REQD

FIN FLOOR

SUMP PUMP

PIT FLOOR

FD

2"Ø

2"Ø

(SLEEVE AND SEAL PENETRATION)

2"Ø

SP-1

TO ELECTRICAL SUPPLY

OIL SMART SYSTEM

ALARM PANEL

1. COORDINATE ALL WORK WITH ELEVATOR

EQUIPMENT INSTALLER.

2. ALL WORK IN FULL ACCORDANCE WITH OHIO

ELEVATOR CODE, (ASME A17.1-2010).

3. VERIFY LOCATION OF SUMP WITH ELEVATOR

COMPANY

SUMP/PUMP OPTIONS(OR APPROVED EQ)

LIBERTY MODEL 290 ELV OIL TECTOR SYSTEM,

3

4

HP, 115V 100 GPM @ 5' HEAD WITH SXL24-3 NEMA

4X SIMPLEX CONTROL PANEL, BCV150 CHECK

VALVE, XT24BX36 24"X36" FIBERGLASS SUMP AND

XC24P2395 PERFORATED STEEL COVER

ZOELLER MODEL 161 OIL GUARD SYSTEM,

3

4

HP,

115V 100 GPM @ 5' HEAD WITH 10-0126 NEMA 4X

SIMPLEX CONTROL PANEL, 300015 CHECK VALVE,

B24 18"X30" FIBERGLASS SUMP AND PERFORATED

STEEL COVER

NOTES

1-1/4" IRRIG. CONN.

(SEE LANDSCAPE PLANS)

DIM

EN

SIO

NS

O

I

H

O

F

E

T

A

T

S

PR

O

F

E

S

S

I

O

N

A

L

E

N

G

I

N

E

E

R

TS

G

I

R

E

E

GOODERUM

O

DAVID R.

74178

R

E

D

--

--

RPZB

1-1/2"1-1/2"

2"- 1/2" 3"

1/2"1/2"

SEE PLANS

-- -

FD

ITEM

PLUMBING FIXTURE SCHEDULE - PROVIDE HI APPROVED FIXTURE PACKAGEV

(inch)

WHW

(inch) (inch)

CW

(inch)

DESCRIPTION

WC-1H

L-1

SK-1

CO

HORIZONTAL CLEANOUT: SMITH 4020 SERIES CAST IRON BODY WITH ADJUSTABLE ROUND NICKLE BRONZE TOP.

-- -

1/2" 1/2" 3" 2"WC-1

MS

WH1,2,3,4

AMERICAN AMERICAN STANDARD RELIANT 3: 7385.000 RELIANT SINGLE CONTROL CENTERSET

1/2" 1/2" 1-1/2 1-1/2"

ELKAY UNDERMOUNT SINGLE BOWL SINK: ELU129 WITH MOEN 4904 SINGLE HANDLE HIGH ARC BAR FAUCET

1-1/2 1-1/2"

AMERICAN STANDARD: 2386.012 RIGHT HEIGHT CADET3 ELONGATED TOILET 1.6 GPF, 5325.024 RISE AND SHINE

CLOSED FRONT SEAT WITH LID.

ACORN: MOP SINK TDF-24, TERRAZZO WITH CHROME FINISH KFC, MOP HANGER WITH 3 GRIPS ON STAINLESS STEEL WALL BRACKET

KMH.

1/2" 1/2" 3" 1-1/2

-

1-1/2"

WOODFORD Y2 YARD HYDRANT FAUCET, SELF DRAINING, FREEZE PROOF WITH VACUUM BREAKER.

HB

-3/4" -

1-1/2"1/2" -

AO SMITH CYCLONE : BTH 199 GAS 199,999 BTUH 96% THERMAL EFFICIENCY, DIRECT VENT

FLOOR DRAIN: SMITH 2010-A05-NB SERIES CAST IRON BODY WITH FLASHING COLLAR, CONNECTION AND ADJUSTABLE 5" SQUARE

NICKLE BRONZE STRAINER.

REDUCED PRESSURE ZONE BACKFLOW PREVETER: WATTS MODEL 009M2QTS CAST BRONZE CONSTRUCTION WITH QUARTER TURN

FULL-PORT BALL VALVES AND BRONZE STRAINER.

SK-3

ELKAY RNSF8354 THREE COMPARTMENT 18 GAUGE, TYPE 302 STAINLESS STEa SINK W ITH SINGLE FAUCET HOLE ON DECK, 1.5 GPM

AERATOR, MCGUIRE 151A STRAINER, AND MCGUIRE 8912 P-TRAP. INSULATE DRAIN AND WATER UNES WITH "TRUBRO" LAVGUARD2

KIT.

1/2"1/2" 1-1/2 1-1/2"

- -- -

RP

ARMSTRONG H53 BRONZE BODY, CERAMIC THRUST BEARINGS. PLASTIC IMPELLAR, STAINLESS STEEL ROTOT AND SHAFT,

SELF-LUBRICATED GRAPHITE BEARINGS, EPDM DIAPHRAGM 230 F MAX WATER TEMPERATURE. 140 PSI MAX WORKING PRESSURE 20

GPM. 30' TDH.

JR SMITH 1010 WITH CLAMP AND SUMP.

RD-1

AMERICAN STANDARD: 2383.012 CADET ELONGATED TOILET 1.6 GPF, 5325.024 RISE AND SHINE CLOSED FRONT SEAT WITH LID.

2"- 1/2" 3"

WC-2

AMERICAN STANDARD: 2386.012 RIGHT HEIGHT CADET3 ELONGATED TOILET 1.6 GPF, 5901.100 ELONGATED HEAVY

DUTY BOWL OPEN FRONT SEAT LESS COVER. PROVIDE W/ AUTO FLUSH VALVE SYSTEM

L-2

1/2" 1/2" 1-1/2 1-1/2"L-3

1/2" 1/2" 1-1/2 1-1/2"

AMERICAN STANDARD LUCERNE WALL HUNG SINK: 0355.012 4" CENTERS GLAZED WITH AMERICAN STANDARD RELIANT 3: 7385.000

RELIANT SINGLE CONTROL CENTERSET FAUCET

AMERICAN STANDARD OVALYN UNDERCOUNTER SINK: 0495.300 GLAZED WITH AMERICAN STANDARD RELIANT 3: 7385.000 RELIANT

SINGLE CONTROL CENTERSET

SK-2

ELKAY WNSF82422 TWO COMPARTMENT, 18 GAUGE. TYPE 302 STAINLESS STEa SINK W ITH DUAL FAUCET HOLES IN BACKSPLASH, 1.5

GPM AERATOR. MCGUIRE 151A STRAINER. AND MCGUIRE 8912 P-TRAP. INSULATE DRAJN AND WATER UNES WITH TRUBRO"

LAVGUAR02 KIT.

4 21/2 1/2

TB-1

AMERICAN STANDARD NEW SALEM RECESS BATH: 0255 WITH MOEN TL183NH SINGLE-HANDLE TUB/SHOWER TRIM KIT

P.C. TO INSTALL OWNER PROVIDED HIX KOHLER FORTE SHOWER HEAD

4 21/2 1/2

TB-2

4 21/2 1/2

SH-1

SHOWER BASE BY OTHERS WITH MOEN 8346 SINGLE-HANDLE PRESSURE BALANCING SHOWE5R VALVE WITH HAND-HELD SHOWER

SYSTEM

AMERICAN STANDARD RECESS BATH: 0255 WITH MOEN 8346 SINGLE-HANDLE PRESSURE BALANCING SHOWER VALVE WITH

HAND-HELD SHOWER SYSTEM WITH MOEN 3931 DIVERTER SPOUT W/ SEAT AND GRAB BAR

EWS

BRADLEY S192240A1ADAD00 STAINLESS STEEL BOWL. TAILPIECE AND P-TRAP. COMPLETE WITH ANSI STANDARD Z358.1. SUPPLY

AND WASTE PIPES ARE GALVANIZED STEEL PROTECTEO WITH BRADTECT® SAFETY YELLOW COATING. UNIVERSAL IDENTIFICATION

SIGN AND INSPECTION TAG INCLUDED. EYEWASH EXCEEDS MINIMUM WATER FLOW OF 0.4 GPM AT 30 PSI. BARRIER-FREE DESIGN

-FULLY ACCESSIBLE TO PEOPLE WITH PHYSICAL 01SAB1UTIES

4 21/2 1/2

FSSIOUX CHIEF 861-22X FLOOR SINK

4 21/2 1/2

WB WASHER UTILITY BOX WITH AIR HAMMER ARRESTORS AND ELECTRICAL CONNECTION.

4

TD 6'-0" WATTS DEAD LEVEL PRE-SLOPED POLYPROPYLENE TRENCH DRAIN

WS-1,2

SOFTNER SYSTEM AQUA SYSTEM #2900 NT 14 DX SF70 #05010610 24 X 50 BRINE TANK SOLAR SALT 16 BAGS SYSTEM START UP

1/2" 1/2" 1-1/2 1-1/2"

WATER HAMMER ARRESTER SCHEDULEPCN/

FIG. NO.

P.D.I.

SYMBOL RATING

FIXTURE UNIT

SIZE

A B C D

5005

5010

5020

5030

5040

5050

A

B

C

D

E

F

1-11

12-32

33-60

61-113

155-330

114-154

3/4

1

1

1

1

1

3

3-5/8

5-1/8

5-1/2

6-5/8

3-1/4

3-1/4

3-1/4

3-1/4

3-1/4

1-7/16

5-1/4

4-1/8

3-1/4

2-1/4

1-3/4

FLOOR

MANUAL ISOLATION

VALVE (TYP)

FLOW SENSOR

2-1/2"

DUPLEX WATER

SOFTENER

2" 2"

1"

TERMINATE BACKWASH

INDIRECT CONNECTION TO FLOOR DRAIN

BRINE TANK

CONTROLLER

(TYP)

2"

2"

2

DUPLEX WATER SOFTENER DETAIL

SCALE: NOT TO SCALE

TO HOT WATER HEATERS

WS-1

WS-2

WATER SOFTENER PIPING IS

DIAGRAMATIC, INSTALL ALL

PIPING IN STRICT ACCORDANCE

WITH MANUFACTURERS

RECOMENDATIONS.

PRESSURE

GAUGE (TYP)

4 21/2 1/2

SH-2

SHOWER BASE BY OTHERS WITH MOEN 8346 SINGLE-HANDLE PRESSURE BALANCING SHOWE5R VALVE WITH HAND-HELD SHOWER

SYSTEM SEAT AND GRAB BAR

NOTE:

PROVIDE ALL FIXTURES WITH THE APPROPRIATE SUPPLIES, STOPS, NIPPLES, PLATES AND ESCUTCHEONS. ALL

EXPOSED PIPING TO BE CHROME POLISHED FINISH MATERIAL.

SEE PLANS

WATER HEATER SYSTEM PIPING DIAGRAM

SCALE: NONE

1

WH-2WH-1

CW CW CW CW

WH-3

GAS GAS GAS GAS GAS GAS GAS GAS GAS GAS GAS GAS GAS GAS GAS GAS GAS GAS GAS GAS GAS

CW CW CW CW CW CW CW CW CW CW

CW CW CW CW CW CW CW CW CW CW CW CW CW CW CW CW CW CW CW CW CW CW CW CW CW CW CW CW CW CW CW CW CW CW CW CW CW

HW

RH

WR

HW

R

CW

HW

SH

WS

HW

SH

WS

FLOOR DRAIN

SEE FLOOR PLANS

FOR LOCATION

PRESSURE GAUGE

(TYP)

CW

CW

CW

CHECK VALVE

(TYP)

2" THERMOSTATIC

MIXING VALVE

TMV

BALANCE VALVE

(TYP)

27"

1-1/4"

HEAT TRAP

4" PVC COMBUSTION AIR

& 4" PVC FLUE PER

MANUFACTURER

(TYP) INSTALLED BY P.C.

ASME T&P

RELIEF VALVE

(TYP)

TERMINATE RELIEF

OVER FLOOR DRAIN

HWS HWS HWS HWS HWS HWS HWS HWS HWS

HWR HWR HWR

HW

RH

WR

HW

RH

WR

HW

R

HWR HWR HWR

FLOOR

CW CW CW CW CW CW CW CW CW CW CW CW

120° HW

160° HW

CW

CW

CW

CW

2 1/2"

1 1/4"

WATER HEATER PIPING IS

DIAGRAMATIC, INSTALL ALL

PIPING IN STRICT ACCORDANCE

WITH MANUFACTURERS

RECOMENDATIONS.

RP

RP

FROM CITY WATER

SEE FLOOR PLANS

FOR CONTINUATION

GA

SG

AS

GA

SG

AS

GA

SG

AS

3/4"

CW

WH-4

GA

SG

AS

GA

SG

AS

HWR HWR HWR

HW

RH

WR

HWR

HWR

D D DD

FROM CITY GAS

EXPANSION TANK

REG REG REG REG

3"CW

2-1/2"CW

-- -

FD2

FLOOR DRAIN: SMITH 2010-A05-NB SERIES CAST IRON BODY WITH FLASHING COLLAR, CONNECTION AND ADJUSTABLE 5" SQUARE

CHROME PLATED BRASS

SEE PLANS

160°HW 160°HW 160°HW 160°HW160°HW160°HW160°HW160°HW

160°HW 160°HW

160°HW

NOTE:

ALL FIXTURES SELECTED TO BE PER HAMPTON BY HILTON BRAND STANDARDS MANUAL.

2506.03 Vending Area

2504.01 Food Prep

LAWLER THERMOSTATIC MIXING VALVE MODEL 66

TMV

1-1/4"G

AGA SHUT OFF VALVE, NIPPLE

AND CAP W/ MAXTROL TYPE

VENTLESS REGULATOR(TYP)

2-1/2"CW

1-1/2"1-1/2"

HUB DRAIN

SEE FLOOR PLANS

FOR LOCATION

DIM

EN

SIO

NS

O

I

H

O

F

E

T

A

T

S

PR

O

F

E

S

S

I

O

N

A

L

E

N

G

I

N

E

E

R

TS

G

I

R

E

E

GOODERUM

O

DAVID R.

74178

R

E

D

SCALE: NOT TO SCALE

HOT & COLD WATER - TYPICAL ISOMETRIC

1

HW

RH

WR

HW

RH

WR

HW

RH

WR

HW

RH

WR

HW

RH

WR

HW

RH

WR

HW

RH

WR

HW

RH

WR

HW

RH

WR

HW

RH

WR

HW

RH

WR

HW

SH

WS

HW

SH

WS

HW

SH

WS

HW

SH

WS

HW

SH

WS

HW

SH

WS

HW

SH

WS

HW

SH

WS

HW

SH

WS

HW

SH

WS

HW

SH

WS

CW

SC

WS

CW

SC

WS

CW

SC

WS

CW

SC

WS

CW

SC

WS

CW

SC

WS

CW

SC

WS

CW

SC

WS

CW

SC

WS

CW

SC

WS

CW

SC

WS

3/4"HWR

1"HW

1"CW

3/4"HWR

3/4"HW

3/4"CW

2ND FLOOR

3RD FLOOR

C

W

S

H

W

S

H

W

S

H

W

S

CW

SC

WS

HW

SH

WS

HW

SH

WS

H

W

S

H

W

S

H

W

S

SH-1

L-1

HW

SH

WS

HW

S

CW

S

CW

SC

WS

CW

SC

WS

CW

S

3/4"

3/4"

1/2"

1/2"

WC-1

C

W

S

H

W

S

H

W

S

H

W

S

CW

SC

WS

CW

S

HW

SH

WS

HW

SH

WS

H

W

S

H

W

S

H

W

S

SH-1

L-1

HW

SH

WS

HW

SH

WS

CW

SC

WS

C

W

S

CW

SC

WS

CW

SC

WS

CW

S

3/4"

3/4"

1/2"

1/2"

WC-1

2ND FLOOR

3RD FLOOR

ATTIC

SCALE: NOT TO SCALE

WASTE & VENT - TYPICAL ISOMETRIC

2

SA

NS

AN

SA

NS

AN

SA

NS

AN

SA

NS

AN

SA

NS

AN

SA

NS

AN

SA

NS

AN

SA

NS

AN

SA

NS

AN

SA

NS

AN

SA

NS

AN

SA

NS

AN

SA

NS

AN

SA

NS

AN

SA

NS

AN

SA

NS

AN

SA

N

SH-1

L-1

WC-1

3"VENT

2" WASTE

2"

3"

3"VTR

3"WASTE

C

W

S

H

W

S

H

W

S

H

W

S

CW

SC

WS

CW

S

HW

SH

WS

HW

SH

WS

H

W

S

H

W

S

H

W

S

SH-1

L-1

HW

SH

WS

HW

S

CW

S

CW

SC

WS

CW

S

3/4"

3/4"

1/2"

1/2"

WC-1

H

W

R

H

W

S

C

W

S

1ST FLOOR

1-1/4"CW

3/4"HWR

1-1/4"HW

S

A

N

S

A

N

SA

NS

AN

SA

NS

AN

SA

NS

AN

SA

NS

AN

SA

NS

AN

SA

NS

AN

SA

NS

AN

SA

NS

AN

SA

NS

AN

SA

NS

AN

SA

NS

AN

SA

NS

AN

SA

NS

AN

SA

NS

AN

SA

N

S

A

N

S

A

N

S

A

N

S

A

N

L-1

SH-1

WC-1

2"

3"

S

A

N

S

A

N

1ST FLOOR

3"WASTE

3"VENT

1-1/2"

1-1/2"

2" WASTE

L-1

1-1/2"

2" WASTE

SH-1

WC-1

2"

3"

S

A

N

S

A

N

3"VENT

G

J

H

E

F

K

L

M

2 18 19

3 45

6 7 8

9 10 11 12

13 14 15 16 17

3.9

9.9 11.1

16.11

C

A

10.4 12.6

B

D

G

J

H

E

F

K

L

M

C

B

D

KING

101

KING

103

MANAGER

029

COMPUTER/

PBX

027

WORK

AREA

026

FRONT

DESK

021

VESTIBULE

001

MAIN

LOBBY

006

ELEV.

LOBBY

191

MENS

RR

018

WMNS

RR

019

MTG.

STOR.

015

MEETING

ROOM

013

BREAKFAST

AREA

006

PANTRY

009

FOOD

PREP.

012

FOOD

PREP

STOR.

011

MECH.

010

KING

129

KING

131

ACCESSIBLE

KING

127

KING

128

KING

130

VEST.

003

VEST.

004

DOUBLE QUEEN

125

MECH.

MECH.

EMP.

RR

040

LINEN

STORAGE/

FOLDING

035

EMP.

BREAK

ROOM

038

FITNESS CENTER

020

POOL

050

MECH.

031

POOL

RR

052

GUEST

LAUND.

025

ELEV.

1

LAUNDRY

034

MAINTENANCE/

MECHANICAL/

ELECTRICAL

017

DOUBLE QUEEN

105

DOUBLE QUEEN

107

STORAGE

005

POOL PATIO

--

POOL

EQUIPMENT

051

TREATS

002

MECH.

016

ELEV.

2

VENDING

193

A

G.2 G.2

VTAC

ELECTRICAL

043

STAIR 2

181

STAIR 1

180

CORRIDOR

198

CORRIDOR

197

CORR.

199

DRYERS

036

1 2

SAN SAN SAN SAN SAN SAN SAN SAN SAN SAN SAN SAN SAN SAN SAN SAN SAN SAN SAN SAN SAN SAN SAN SAN SAN SAN SAN SAN SAN SAN SAN SAN SAN SAN SAN SAN SAN SAN SAN SAN SAN SAN SAN SAN SAN SAN SAN SAN SAN SAN SAN SAN SAN SAN SAN

SA

NS

AN

SA

NS

AN

SA

NS

AN

SA

NS

AN

SA

NS

AN

WC2

LV2

WC2

LV2

WC2 LV3WC1

LV1

SH1

LV1

SH1 WC1 WC1

LV1

TB1

LV1

TB1 WC1

SK2

EW

MS

SK1

LV1

TB1

WC1

LV1

SH2

WC1H

LV1

SH1

WC1

SH1

WC1

LV1

SH1

SH1

WC1 WC1

LV1 LV1

LV2

SK3

WC2 LV3

SA

N

SA

N

SA

N

SA

N

SA

N

SA

N

SAN SAN SAN

SA

N

SAN SAN

SAN SAN

SP

SAN

SAN

SA

NS

AN

SA

NS

AN

SA

N

GL

GL

SA

NS

AN

GI

SAN SAN SAN

FD

6"W

CO

CO

CO

SAN SAN

SAN SANSAN SANSAN SAN

CO

SA

N

HD

SA

N

SA

N

IE=-43.25"

6"W

6"W

6"W

6"W

6"W

6"W

6"W 6"W6"W

6"W6"W

6"W 6"W

2"W

3"W

3"W

3"W

3"W

3"W

3"W3"W3"W

4"W

2"W

3"W

2"W

HD

HD

HD

SA

N

SAN

FS

CO

HD

WB

2"W

2"W

3"W

3"W

2"W

2"W

2"W

2"W

2"W

2"W

2"W

3"W

2"W

2"W

2"W

SA

N

SA

N

SA

N

SA

N

2"W2"W

2"W2"W

3"W 3"W 3"W 3"W 3"W 3"W 3"W 3"W 3"W

3"W

3"W

3"W 3"W 3"W 3"W 3"W 3"W 3"W 3"W 3"W 3"W 3"W 3"W 3"W

4"W

4"W

4"W

4"W

4"W3"W

3"W

3"W 3"W

2"W

2"W

3"W

3"W

3"W

3"W

3"W

3"W 3"W

3"W3"W

3"W3"W

3"W

3"W

3"W

2"W

2"W

SAN SAN

TD

VV

V

V V V

V

V

V V V V V V V

VV

VV

V

V

SD

SD

V

WB

V V

V

V

V

V

V

V

V

V

V V

V

V

V

V

V

V

V

V

V

VV

V

V

V

V

VV

VV

V

FS

VV

VV

3"W

FD

SP

FD

SA

N

6"W

CAST IRON PIPE

AND FITTINGS REQD

FD2

FD2

FD2

FD2

2"W

FD2

SAN SAN

2"WFD FD

SA

NS

AN

S

A

N

S

A

N

SAN SAN

3"W

HD

HD

FD

FD

HD

SAN SAN SAN SAN SAN

2"W

3"W

3"W

3"W

3"W

FD2

NOTE: ALL POOL DESIGN INCLUDING DECK DRAINAGE TO BE

BY POOL CONTRACTOR AND/OR MFG SUPPLIER

FD2

KEY NOTES:

1. REFERENCE SHEET P-001 FOR LEGENDS,

ABBREVIATIONS, SPECIFICATIONS AND NOTES.

GENERAL NOTES:

1

DIM

EN

SIO

NS

O

I

H

O

F

E

T

A

T

S

PR

O

F

E

S

S

I

O

N

A

L

E

N

G

I

N

E

E

R

TS

G

I

R

E

E

GOODERUM

O

DAVID R.

74178

R

E

D

1

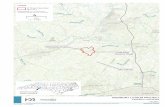

SCALE: 1/8" = 1'-0"

FIRST FLOOR PLUMBING WASTE PLAN

6" INCOMING SEWER SERVICE. SEE CIVIL PLANS

FOR CONTINUATION.

GREASE INTERCEPTOR. THERMOCO TRAPZILLA IS

POINT SOURCE AUTOMATIC GREASE REMOVAL

SYSTEM IN-GROUND MODEL TZ-160-ECA COMPLETE

W/ ACCESSORIES.

6" SUMP/ HUB DRAIN FOR POOL BACKWASH.

3" SOIL STACK AND 3" VENT STACK UP TO FLOORS

ABOVE. SEE ISOMETRIC DRAWINGS FOR

CONTINUATION.

2" SOIL STACK UP TO FLOORS ABOVE. SEE

ISOMETRIC DRAWINGS FOR CONTINUATION.

PROVIDE AND INSTALL NEW SUMP AND PUMP FOR

ELEVATOR HOISTWAY. PUMP TO BE LIKE:

LIBERTY MODEL 290,

3

4

HP, 115V 50 GPM @ 28'

HEAD WITH SXL24-3 NEMA 4X SIMPLEX

CONTROL PANEL, BCV150 CHECK VALVE,

XT24BX36 24"X36" FIBERGLASS SUMP AND

XC24P2395 PERFORATED STEEL COVER

PUMP UP TO SANITARY HUB DRAIN 2" DISCHARGE

LINE AND CONNECT WITH AIR GAP FITTING INTO

THE 3" HUB DRAIN.

PRIMARY ROOF DRAINS RISER DOWN FROM ATTIC

ABOVE AND ROUTED TO STORM WATER RISER AS

SHOWN ON P-101. SEE CIVIL PLANS FOR

CONTINUATION.

3" VENT STACK UP TO ATTIC ABOVE.

P.C. TO INSULATE ALL ICE MACHINE DRAIN TRAPS.

2

3

4

5

6

7

8

9

1

2

3

4

4

4

4

4

44

4

4

4

4

4

4

4

44

44

4

4

4

4

4

4

4

4

4

45

5

55

5

5

5

5

5

5

5

5

5

55

5

5 5

5

5

5

5

55

5

55

5

7

8

8

8

8

6

5

9

10

10

G

J

H

E

F

K

L

M

2 18 19

3 45

6 7 8

9 10 11 12

13 14 15 16 17

3.9

9.9 11.1

16.11

C

A

10.4 12.6

B

D

G

J

H

E

F

K

L

M

C

B

D

KING

101

KING

103

MANAGER

029

COMPUTER/

PBX

027

WORK

AREA

026

FRONT

DESK

021

VESTIBULE

001

MAIN

LOBBY

006

ELEV.

LOBBY

191

MENS

RR

018

WMNS

RR

019

MTG.

STOR.

015

MEETING

ROOM

013

BREAKFAST

AREA

006

PANTRY

009

FOOD

PREP.

012

FOOD

PREP

STOR.

011

MECH.

010

KING

129

KING

131

ACCESSIBLE

KING

127

KING

128

KING

130

VEST.

003

VEST.

004

DOUBLE QUEEN

125

MECH.

MECH.

EMP.

RR

040

LINEN

STORAGE/

FOLDING

035

EMP.

BREAK

ROOM

038

FITNESS CENTER

020

POOL

050

MECH.

031

POOL

RR

052

GUEST

LAUND.

025

ELEV.

1

LAUNDRY

034

MAINTENANCE/

MECHANICAL/

ELECTRICAL

017

DOUBLE QUEEN

105

DOUBLE QUEEN

107

STORAGE

005

POOL PATIO

--

POOL

EQUIPMENT

051

TREATS

002

MECH.

016

ELEV.

2

VENDING

193

A

G.2 G.2

VTAC

ELECTRICAL

043

STAIR 2

181

STAIR 1

180

CORRIDOR

198

CORRIDOR

197

CORR.

199

DRYERS

036

1 2

FP

CW

CW

CW

CW

CW

CW

CW

CW

CW

WC2

LV2

GAS GAS GAS GAS GAS GAS GAS GAS GAS GAS GAS GAS GAS GAS GAS GAS GAS GAS GAS GAS GAS GAS GAS GAS GAS GAS GAS

HWR HWR HWR HWR HWR HWR HWR HWR HWR HWR HWR HWR HWR HWR HWR HWR HWR HWR HWR HWR HWR HWR HWR HWR HWR HWR HWR HWR HWR HWR HWR HWR HWR HWR HWR HWR HWR

3/4"HWR,

2-1/2"HW &

2-1/2"CW

1"HWR,

2-1/2"HW &

2-1/2"CW

WC2

LV2

WC2 LV3WC1

LV1

SH1

LV1

SH1 WC1 WC1

LV1

TB1

LV1

TB1 WC1

SK2

EW

MS

SK1

LV1

TB1

WC1

LV1

SH2

WC1H

LV1

SH1

WC1

SH1

WC1

LV1

SH1

SH1

WC1 WC1

LV1 LV1

LV2

SK3

WC2 LV3

RPZ

RP

RP

GA

SG

AS

GA

S

TMV

1-1/4"C

W

Gas Service

1.7 mbh @ 2 psi

M

HW

SH

WS

HW

RH

WR

HWS

HW

SH

WS

HW

SH

WS

HW

S

CW

CW

CW

CW

CW

CW

CW CW

HWS HWS

HW

SH

WS

HW

SH

WS

HW

SH

WS

HW

S

CW

CW

CW

CW

CW

CW

CW

HWS

CW CW

HW

SH

WS

CW

CW

CW

GL

GL

GI

HW

R

GAS GAS

GA

S

3"W

2"W

SD

SD

8"STM 6"STM

3"STM

4"STM

8"STM8"STM

3/4"HWR,

1-1/2"HW &

1-1/2"CW

1"HWR,

2"HW &

2"CW

4"STM 5"STM 5"STM 4"STM 4"STM 5"STM 4"STM5"STM

1"HWR,

2"HW &

2"CW

1"HWR,

2-1/2"HW &

2-1/2"CW

1"HWR,

2-1/2"HW &

2-1/2"CW

1"HWR,

2-1/2"HW &

2-1/2"CW

1"HWR,

2-1/2"HW &

2-1/2"CW

3/4"HWR,

2"HW &

2"CW

3/4"HWR,

1-1/4"HW &

1-1/4"CW

(typ.)

1"HWR,

1-1/4"HW &

1-1/4"CW

(typ.)

3/4"HWR,

1-1/4"HW &

1-1/4"CW

(typ.)

GAS GAS GAS GAS GAS GAS GAS GAS GAS GAS GAS GAS

GA

SG

AS

GA

S

3/4"G

3/4"G

1-1/2"G

1-1/4"G

1-1/4"G

1"G

1-1/4"G1-1/4"G

1-1/4"G

1-1/4"G

1"HWR,

2-1/2"HW &

3"CW

M

3"CW 6"FP

3/4"CW

3/4"HW

1"CW

3/4"HW

1-1/4"160°HW

1-1/4"160°HW

1/2"CW

1/2"HW

HW

SH

WS

HW

SH

WS

HW

SH

WS

HW

S

CW

CW

CW

CW

CW

CW

CW

1"CW

1/2"HW

CW

WB

1"CW

1/2"HW

HW

SH

WS

HW

SH

WS

HW

SH

WS

CW

CW

CW

CW

CW

CW

3/4"CW

3/4"HW

CW

CW

CW

1/2"CW

FS

HB

HB

CW CW

3/4"CW

3/4"CW

GA

SG

AS

GA

SG

AS

GA

SG

AS

GAS

1"G

3/4"G

3"W

HB

HB

CAST IRON PIPE

AND FITTINGS REQD

160°HW

CW

CW

CW

CW

HB*

3" INCOMING DOMESTIC WATER SERVICE. SEE CIVIL

PLANS FOR CONTINUATION.

6" FIREPROTECTION WATER SERVICE. SEE CIVIL

PLANS FOR CONTINUATION.

2 PSI GAS SERVICE. P.C. TO SLEEVE AND SEAL

EXTERIOR WALL PENETRATION. COORDINATE WITH

LOCAL GAS COMPANY NEW GAS SERVICE TO

BUILDING.

STORM WATER RISER DROP FROM OVERHEAD

PIPING SYSTEM TO SITE STORM WATER

CONNECTIONS. SEE CIVIL PLANS FOR

CONTINUATION.

STORM WATER RISER DROP FROM CANOPY ABOVE.

RISERS TO BE LOCATED INSIDE COLUMN

ENLOSURE AND ARCHITECTURAL CHASE.

1" CW, 1" HW AND 3/4" HWR RISER LOCATION.

3" STORM RISER FROM ABOVE. TURN OUT PIPING

TIGHT TO STRUCTURE.

1-1/2" CW POOL WATER SUPPLY AND 3/4" GAS

SUPPLY TO POOL EQUIPMENT ROOM WITH 2 PSIG

TO 6" W.C. REGULATOR. P.C. TO PROVIDE AND

COORDINATE POOL EQUIPMENT CONNECTIONS W/

POOL CONTRACTOR. P.C. TO ENSURE POOL

CONTRACTOR IS PROVIDING BACK FLOW DEVICE. IF

NOT P.C. SHALL PROVIDE DEVICE AS REQUIRED.

PROVIDE 1/2" CW FEED FOR FUTURE WATER

COOLER IN FITNESS. ROUGH IN CW DOWN TO 1/2"

SHUT OFF VALVE. VERIFY WITH OWNER LOCATION

AND HEIGHT OF SUPPLY VALVE BOX.

3/4" ICE MACHINE COLD WATER SUPPLY DOWN TO

1ST FLOOR AND UP TO 2ND AND 3RD FLOOR

MACHINES. PROVIDE AND INSTALL 1/2" SUPPLY

VALVE IN BOX AT 12" AFF. P.C. TO COORDINATE

WITH OWNER ANY FILTRATION NEEDS FOR

MACHINES.

P.C. TO PROVIDE INTERIOR HOSE BIBB FOR POOL

EQUIPMENT ROOM WASH WATER. SET VALVE AT 42"

AFF. BOILER DRAIN TYPE W/ VACUUM BREAKER

STYLE HOSE CONNECTION.

PROVIDE 1/2" CW FEED FOR FUTURE COFFEE/JUICE

BAR. PROVIDE AND INSTALL 1/2" SUPPLY VALVE IN

BOX AT 12" AFF. P.C. TO COORDINATE WITH OWNER

ANY FILTRATION NEEDS.

KEY NOTES:

1. REFERENCE SHEET P-001 FOR LEGENDS,

ABBREVIATIONS, SPECIFICATIONS AND NOTES.

GENERAL NOTES:

1

DIM

EN

SIO

NS

O

I

H

O

F

E

T

A

T

S

PR

O

F

E

S

S

I

O

N

A

L

E

N

G

I

N

E

E

R

TS

G

I

R

E

E

GOODERUM

O

DAVID R.

74178

R

E

D

1

SCALE: 1/8" = 1'-0"

FIRST FLOOR PLUMBING WATER PLAN

2

3

4

5

6

1

2

3

4

4

5

5

6

6

6

6

6

6

66

6

6

6

6

66 6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

7

8

8

9

9

10

10

11

11

12

12

KING SOFA

200

KING SOFA

202

DOUBLE

QUEEN

204

DOUBLE

QUEEN

206

KING

201

KING

203

DOUBLE

QUEEN

205

DOUBLE

QUEEN

207

DOUBLE

QUEEN

209

DOUBLE

QUEEN

211

DOUBLE

QUEEN

213

DOUBLE

QUEEN

215

DOUBLE

QUEEN

219

DOUBLE

QUEEN

221

DOUBLE

QUEEN

223

DOUBLE

QUEEN

225

KING

231

KING

229

KING

230

KING

228

ACCESSIBLE

KING

226

ACCESSIBLE

KING

227

ACCESSIBLE

DOUBLE

QUEEN

216

STORAGE

294

ELEV.

1

ELECTRICAL/

HOUSE

KEEPING

295

ELEV.

2

G

J

H

E

F

K

L

M

2 18 19

3 45

6 7 8

9 10 11 12

13 14 15 16 17

3.9

9.9 11.1

16.11

C

D

G

J

H

E

F

K

L

M

C

D

STORAGE

292

G.2 G.2

DOUBLE

QUEEN

208

DOUBLE

QUEEN

210

DOUBLE

QUEEN

212

DOUBLE

QUEEN

214

DOUBLE

QUEEN

218

DOUBLE

QUEEN

220

DOUBLE

QUEEN

222

DOUBLE

QUEEN

224

D.5D.5

VENDING

293

ELEVATOR

LOBBY

297

CORRIDOR

291

CORRIDOR

290

STAIR 1

280

STAIR 2

281

WC1

LV1

TB1

LV1

TB1

LV1

TB1 WC1WC1

LV1

SH1 WC1

LV1

SH1

WC1

LV1

TB1

LV1

TB1

LV1

TB1

LV1

TB1

LV1

TB1

LV1

TB1

LV1

SH2

WC1H

LV1

SH2

WC1H

LV1

SH1

LV1

SH1

LV1

TB1

LV1

TB1

LV1

TB1

LV1

TB1

WC1

WC1 WC1 WC1

LV1

TB1WC1 WC1

LV1

TB1

WC1H

TB2

LV1

SH1

WC1

WC1 WC1WC1

WC1WC1 WC1

WC1

LV1 LV1

WC1

SH1

SH1SH1WC1

LV1

TB1 WC1

LV1

TB1 WC1

LV1

TB1 WC1

LV1

TB1

WC1

LV1

LV1

WC1

WC1

WC1

SA

N

SA

N

SA

N

SA

N

SA

N

SA

N

SA

N

SA

N

SA

N

SA

N

SA

N

SA

N

SA

N

SA

N

SA

N

SA

N

SA

N

SA

N

SA

N

SA

N

SA

N

SA

N

SA

N

SA

N

V V

V

V

V

V

V

V

V

V

V V

V

V

V

V

V

V

V

V

V

VV

V

V

V

V

2"W 2"W

2"W

2"W2"W

2"W2"W

2"W

2"W

2"W

2"W

2"W

2"W 2"W 2"W

2"W

2"W

2"W2"W

2"W2"W

2"W2"W

2"W 2"W

2"W

2"W

2"W

2"W

2"W

2"W

2"W

FS FD2

FD2

FD2

FD2

KEY NOTES:

1. REFERENCE SHEET P-001 FOR LEGENDS,

ABBREVIATIONS, SPECIFICATIONS AND NOTES.

GENERAL NOTES:

DIM

EN

SIO

NS

O

I

H

O

F

E

T

A

T

S

PR

O

F

E

S

S

I

O

N

A

L

E

N

G

I

N

E

E

R

TS

G

I

R

E

E

GOODERUM

O

DAVID R.

74178

R

E

D

1

SCALE: 1/8" = 1'-0"

SECOND FLOOR PLUMBING PLAN

3" WASTE STACK AND 3" VENT STACK

2" WASTE STACK

3" STORM RISER

1" GAS RISER

1" CW, 1" HW AND 3/4" HWR RISER

3" VENT STACK FROM 1ST FLOOR

P.C. TO INSULATE ALL ICE MACHINE DRAIN TRAPS.

3/4" CW SUPPLY UP TO ICE MACHINE. P.C. TO

PROVIDE 1/2" WATER SUPPLY VALVE AND BOX AT

12" AFF. COORDINATE WITH OWNER ANY

FILTRATION NEEDS.

1

2

3

4

5

1111111111111111

2222222222222222

3

3

3

33

3

3

3

4

5

5 5

5

5

5

5

5

5

5

5

5

5

5

5

5 5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

6

6

7

7

8

8

KING SOFA

300

KING SOFA

302

DOUBLE

QUEEN

304

DOUBLE

QUEEN

306

DOUBLE

QUEEN

308

DOUBLE

QUEEN

310

DOUBLE

QUEEN

312

DOUBLE

QUEEN

314

DOUBLE

QUEEN

320

DOUBLE

QUEEN

322

DOUBLE

QUEEN

324

KING

301

KING

303

DOUBLE

QUEEN

305

DOUBLE

QUEEN

307

DOUBLE

QUEEN

309

DOUBLE

QUEEN

311

DOUBLE

QUEEN

313

DOUBLE

QUEEN

315

DOUBLE

QUEEN

319

DOUBLE

QUEEN

321

DOUBLE

QUEEN

323

DOUBLE

QUEEN

325

KING

331

KING

329

KING

330

KING

328

ACCESSIBLE

KING

SOFA

316

ACCESSIBLE

KING

327

STORAGE

394

ELEV.

1

ELEV.

2

ELECTRICAL/

HOUSE

KEEPING

395

G

J

H

E

F

K

L

M

2 18 19

3 45

6 7 8

9 10 11 12

13 14 15 16 17

3.9

9.9 11.1

16.11

C

D

G

J

H

E

F

K

L

M

C

D

G.2 G.2

STORAGE

392

DOUBLE

QUEEN

318

ACCESSIBLE

KING

326

VENDING

393

ELEVATOR

LOBBY

397

CORRIDOR

391

CORRIDOR

390

STAIR 2

381

STAIR 1

380

WC1

LV1

TB1

LV1

TB1

LV1

TB1 WC1WC1

LV1

SH1 WC1

LV1

SH1

WC1

LV1

TB1

LV1

SH1

LV1

SH1

LV1

TB1

LV1

TB1

LV1

TB1

LV1

TB1

WC1

WC1 WC1 WC1 WC1

WC1

WC1

WC1

WC1

LV1

TB1

LV1

TB1

LV1

TB1

LV1

TB1

LV1

TB1

LV1

SH2

WC1H

LV1

WC1H

LV1

TB1 WC1

LV1

TB1

WC1H

TB2

LV1

SH1

WC1WC1

WC1WC1 WC1

WC1

LV1 LV1

WC1

SH1

SH1SH1WC1

LV1

TB1 WC1

LV1

TB1

WC1

LV1

LV1

WC1

LV1

TB1

LV1

TB1WC1 WC1

LV1

TB1

SA

N

SA

N

SA

N

SA

N

SA

N

SA

N

SA

N

SA

N

SA

N

SA

N

SA

N

SA

N

SA

N

SA

N

SA

N

SA

N

SA

N

SA

N

SA

N

SA

N

SA

N

SA

N

SA

N

SA

N

V V

V

V

V

V

V

V

V

V

V V

V

V

V

V

V

V

V

V

V

VV

V

V

V

V

2"W2"W

2"W

2"W2"W

2"W

2"W

2"W

2"W

2"W 2"W2"W

2"W 2"W 2"W

2"W

2"W

2"W2"W

2"W

2"W

2"W2"W

2"W2"W

FD2

2"W

2"W

2"W

2"W

2"W

2"W

SH2

FS FD2

FD2

2"W

FD2

3" WASTE STACK AND 3" VENT STACK

2" WASTE STACK

3" STORM RISER

1" GAS RISER

3/4" CW, 3/4" HW AND 3/4" HWR RISER

3" VENT STACK FROM 1ST FLOOR.

P.C. TO INSULATE ALL ICE MACHINE DRAIN TRAPS.

KEY NOTES:

1. REFERENCE SHEET P-001 FOR LEGENDS,

ABBREVIATIONS, SPECIFICATIONS AND NOTES.

GENERAL NOTES:

1

DIM

EN

SIO

NS

O

I

H

O

F

E

T

A

T

S

PR

O

F

E

S

S

I

O

N

A

L

E

N

G

I

N

E

E

R

TS

G

I

R

E

E

GOODERUM

O

DAVID R.

74178

R

E

D

1

SCALE: 1/8" = 1'-0"

THIRD FLOOR PLUMBING PLAN

2

3

4

5

1111111111111111

2222222222222222

3

3

3

33

3

3

3

4

5

5 5

5

5

5

5

5

5

5

5

5

5

5

5

5 5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

6

6

7

7

RS

RS RS

RS

RS RS

RS

RS

RSRSRS

RS

RD RD RD RD RD RD RD RD

3"Ø3"Ø3"Ø3"Ø3"Ø3"Ø3"Ø3"Ø

RD

3"Ø

RD

3"Ø

RD

3"Ø

SD

SD

SD

SD

SD

SD

SD SD SD SD

1213 SF

3"Ø

4"Ø

SD SD

3"Ø

GA

SG

AS

GA

SG

AS

GAS GAS GAS GAS GAS GAS GAS GAS GAS GAS GAS GAS GAS GAS GAS GAS GAS GAS GAS GAS GAS GAS GAS GAS GAS GAS GAS GAS GAS GAS GAS GAS

1"Ø

GAS

1"Ø

GA

S

ROOF DRAIN LOCATION. SEE DETAIL ON P-002 FOR

DETAIL.

4" CANOPY DRAIN DOWN IN COLUMN CHASE

ENCLOSURE BELOW.

3" CANOPY DRAIN DOWN IN CHASE BELOW.

1" GAS DOWN IN STORAGE ROOM BELOW.

4" VENT THRU ROOF. SEE DETAIL ON P-002.

GAS FIRED MAKE UP AIR UNIT. SEE CONNECTION

DETAIL ON P-002.

KEY NOTES:

1. REFERENCE SHEET P-001 FOR LEGENDS,

ABBREVIATIONS, SPECIFICATIONS AND NOTES.

GENERAL NOTES:

1

DIM

EN

SIO

NS

O

I

H

O

F

E

T

A

T

S

PR

O

F

E

S

S

I

O

N

A

L

E

N

G

I

N

E

E

R

TS

G

I

R

E

E

GOODERUM

O

DAVID R.

74178

R

E

D

1

SCALE: 1/8" = 1'-0"

ROOF PLUMBING PLAN

2

3

4

1

11

1

1

1

1

1

2

3

4

5

5

5

5

5

5

5

5

5

5

55

5

5

5

5

5

5

6

6