AC DRIVES ABB Low Voltage Drives ACS350 0.5 to 15 Hp @ 240Vac

DIGITAL RO CONTROL PANEL · Page Number 1.0 SPECIFICATIONS: 1.1 Direct operations. 1.2 Features....

Transcript of DIGITAL RO CONTROL PANEL · Page Number 1.0 SPECIFICATIONS: 1.1 Direct operations. 1.2 Features....

USER MANUAL & WARRANTY CARD

DIGITAL RO CONTROL PANEL

16x2 LCD DISPLAY WITH TOUCH KEYPAD

POWERED BY INNOVATION&

DRIVEN BY TECHNOLOGY

01

APDP

ACCORD POWER DIGITAL PRODUCTS

INTRODUCTION

Welcome to ACCORD family.

We thank you for choosing APDP RO Control Digital Panel for your RO plant.

ACCORD POWER Digital Products, well reputed Indian manufacture of

SMPS based power supplies & digital control panel for RO (Domestic and

Commercial) and softeners.

ACCORD POWER products manufactured in well established quality systems

with international manufactured standards.

Accord Power Digital Products (APDP) designed by using micro-controller to

enhance and simplify the RO water plant working operations.

SILENT FEATURES:Ÿ BRAND PROMOTION: The control panel introduced first time for keeping OEM’s brand name on LCD display.

Ÿ Program your brand name for your brand building.

Ÿ Feed the intervals time from backwash to backwash of filters (Sand & Carbon) and followed by rinse.

Ÿ Accord power Digital Products is perfect solution for operational problems.

02

Models & Features:

1. LAACRRR001 1:1 Voltage & Current Sensing.2. LAACRRR002 1:3 Regular.3. LAACRRR003 3:3 Regular.

4. LABCRRR001 1:1 TDS, Voltage & Current Sensing.5. LABCRRR002 1.:3 TDS, Voltage & Current Sensing.6. LABCRRR003 3:3 TDS, Voltage & Current Sensing.

7. IAACRRR001 1:1 Voltage & Current Sensing.8. IAACRRR002 1:3 Regular.9. IAACRRR003 3:3 Regular.

Accord Power Digital Products - APDP Models: 1 - 1 / 1 - 3 / 3 - 3

Table of Contents: Page Number

1.0 SPECIFICATIONS: 1.1 Direct operations. 1.2 Features. 1.3 LED Indications. 1.4 LCD Display. 1.5 Flow Diagrams. 1.6 Mechanical Dimensions. 1.7 Input, Output & Auto Multiport Value Connection Diagram.

2.0 OPERATING INSTRUCTIONS: 2.1 Key Functions. 2.2 Selection of letters, Space(Gap) and Numbers. 2.3 Enter into the Edit Setting. 2.4 Editable Features.

3.0 INSTALLATION & SAFETY INSTRUCTIONS.

4.0 PCB INPUT & OUTPUT CONNECTING INFORMATION.

5.0 TROUBLE SHOOTING GUIDE LINES.

6.0 APCP MODELS AND SIZES.

7.0 RO Control Panel Configure with 2-Multiport Valve:

8.0 INPUT & OUTPUT CONNECTION DIAGRAM.

9.0 WARRANTY & CUSTOMER DETAILS.

03

0404040808091011

1212121313

18

19

20

21

22

23

24

1.0 SPECIFICATIONS:

1.1 DIRECT OPERATIONS: APDP will operates directly Raw water pump, High pressure pump, dosing pump, flushing Solenoid valve & UV System, available in 1 phase (0.5 to 3 HP) & 3-phase 0.5 to 5.0 HP with phase monitoring Options available with Contactor & Relay, it can be chosen depends upon the requirement.

1.2 FEATURES :

Ÿ TDS DISPLY: APDP will monitor & display the treated water TDS.

Ÿ LOW VOLTAGE: APDP will monitor the low voltage, when voltage is lower than the set value switches OFF all the pumps & automatically switches ON when voltage level reached to set value. It will protect pumps from the low voltage.

Ÿ HIGH VOLTAGE: APDP will monitor the high voltage, when voltage is higher

than the set value switches OFF all the pumps & automatically switches ON

when voltage level reached to set value. It will protect pumps from high voltage.

Ÿ 3-PHASE MONITORING: It will shows on the LCD display R, Y, B voltage, In case of input AC phase un-balace voltages found or phase failure, The APDP switches OFF all the pumps and automatically restart when AC input voltage found in order. Display shows the voltage un-balance. .

Ÿ RWP AMPS SETTING: It will shows on the LCD display Raw Water Pump Amps, When Amps is higher than the set value Switches OFF all the pumps, display shows the Raw Water Pump over load. To restart the plant press the Reset Key. .

Ÿ HPP AMPS SETTING: It will shows the LCD display High Pressure Pump Amps. When Amps is higher than the set value switches OFF all the pumps, display shows the HPP over load. To restart the plant press the RESET key.

Ÿ FLOW SENSORS: APDP will shows the flow rate of the water, this option can be used as a RO System logbook for water delivery account. .

04

Ÿ HOOTER RELAY: This features very much use full in any failure inputs & protection observed it will switch OFF all the pumps & switch on Hooter relay by connecting the indicators / buzzers.

Ÿ AUTO MULTIPORT VALUE : APDP will configure with Auto Multi port value.

Ÿ BRAND NAME DISPLAY: APDP will allow RO manufacturer to program their brand name on LCD display for their business promotion and brand building.

Ÿ SERVICE CONTACT NUMBER: APDP will allow RO manufacturer to program

their Customer care number to make the end user convenient incase of any

Service support required.

Ÿ RAW WATER TANK FLOAT: APDP will monitor the raw water tank level, when

water reaches to low set level, it will switches OFF all the pumps & automatically

switches ON when water level reached to set level. This will protect pumps

dry run.

Ÿ TREATED WATER TANK FLOAT: APDP will monitor the treated water tank level,

when water reaches to high set level, it will switches OFF all the pumps

automatically switches ON when water level reached to Low set level. This will

protects purified water wastage & maintain the tank level.

Ÿ LOW PRESSURE SWITCH: APDP will monitor the input water pressure, incase

of low pressure or NO water found, will make the pumps to switches OFF the

pumps & protect from dry run.

Ÿ HIGH PRESSURE SWITCH: APDP will monitor the input water pressure with Set

pressure and switches OFF the pump incase of high pressure found on set

Level in order to protect the pipe line, multiport valve, sand & carbon vessel.

Ÿ DOSING FLOAT: APDP will monitor the dosing tank level, when dosing chemical reaches to low set level, it will switches OFF all the pumps & automatically . switches ON when level reached to set level. This will protect the RO membrane

05

Ÿ SERVICE TIME: APDP will allow user to program the service time in (Back wash,

rinse sand & carbon filter) as per the input water quality & depends upon

w the system design

Ex: Service time - 600 Minutes. Once completion of service time, the APDP

will switches OFF the pumps and goes to back wash/rinse mode.

Ÿ TRIP TIME: APDP will allow user to program the pump running time. This is

applicable where floats are not installed and required to switches OFF the

pump after tank full by calculating its time in minutes.

Ex: Pump flow rate 1000 Litters / Hour

Tank capacity 2000 Litters

Required pump run time = 2000/1000,

2 Hours, which equals to 120 Minutes

Trip time to be programmed as 120 Minutes.

If floats are installed this has to be put in OFF mode

Ÿ LPS DELAY TIME : APDP will allow user to program Pump ON time to LPS switch

ON time, this delay can be programmed in number of seconds. This delay

setting prevents high pressure pump chanting.

Ÿ BACK WASH TIME: APDP will allow user to program the back wash time

depends upon the RO system design. This feature will avoids user confusion

on back wash time,further it enhances membrane life, sand & carbon filter life.

This feature is very important where Auto Multiport Value can’t be used. .

Example: Back wash time 15 minutes.

Ÿ On APDP, once service time is over the LCD display shows the back wash

time.

Ÿ Manually change the multiport valve position from service mode to back

wash mode.

Ÿ Press the start switch.

Ÿ APDP will run the only raw water pump until back wash set time &

switches OFF the pump and goes to rinse time.

Ÿ Press the start switch on APDP.

06

Models: 1 - 1 / 1 - 3 / 3 - 3 Accord Power Digital Products - APDP

Models: 1 - 1 / 1 - 3 / 3 - 3 Accord Power Digital Products - APDP

Ÿ RINSE MODE : APDP will allow user to program the rinse time, depends upon the

RO system design. This will ensures proper rinse to enhance membrane life

and sand, carbon filter life.

Example: Rinse time 05 minutes.

Ÿ On APDP, once Backwash time is over the LCD display shows rinse mode.

Ÿ Manually change the multiport valve position from backwash mode to

rinse mode.

Ÿ Press the start switch on APDP.

Ÿ APDP will run the raw water pump until rinse set time and switches OFF

the pump and goes to back wash mode of another filter (Carbon).

Ÿ In case any other filter/softener needs regeneration, the APDP will allow user

to do the same. otherwise, after changing the multiport valve from rinse

mode to service mode, press the reset switch on APDP to go into service

mode.

Ÿ FLUSHING TIME : APDP will flush the RO membranes at the time of every start-up.

This will enhance the membrane life & it improves the water quality. Flush time

seconds can be programmed as per the RO system design.

Ÿ AUTO CLEAN TIME : APDP will allow user to program the required auto clean time

seconds as per the RO system design to enhance membrane life. auto clean

function start every tank full time, service & trip time over.

Ÿ HOUR METER: APDP having feature to show the RO system total run time. This

option can be used as a RO system log book for water delivery account.

Ÿ MANUAL / AUTO MODE : APDP having option to work in manual or auto mode.

This feature will helps user to run the RO system without any interruption.

Ÿ PASSWORD PROTECTION : APDP will allow RO manufacturer to feed the brand

name, model number, serial number, date of installation, customer care phone

Number. These information shall be kept with password protected to avoid

un-authorised changes.

07

Ÿ FLUSHING INTERVAL TIME: APDP will flush the RO membranes as per the

f lushing interval time. This will enhance the membrane life & it improves the

water quality. Flush time seconds can be programmed as per the RO system.

Ÿ ON/OFF SETTINGS : APDP having option to edit the settings as per the site

requirement, while installation if any of below process not required that can

be programmed as OFF.

This includes Trip time, Flushing Interval time, LPS delay time, HPS1, Dosing

Raw water tank float, Treated water tank float.

1.3 LED INDICATIONS : Power ON, Raw water pump ON, High pressure

Pump ON & check any failure.

1.4.LCD DISPLAY :

Ÿ PROCESSING CONDITIONS : APDP LCD display shows LPS delay time, flushing

Time, HPP Pump delay time, incase of NO water found in hard water tank

it will show as “Raw Water Tank Empty” and when tank is full it will show as

“Treated Tank Full”, after every service time, trip time and tank full condition

the display shows as “Auto clean”, Voltage, R-Phase, Y- Phase, B-Phase

Voltages, Phase Unbalanced, Low Voltage, High Voltage, Raw Water Pump

Amps, High Pressure Pump Amps, Flow Liters & Treated Water TDS.

Ÿ WORKING CONDITIONS: Brand name, continuous decremented service time

and trip time, Voltage, Treated water TDS, Raw water pump Amps, High

Pressure pump Amps & Flow liters .

Ÿ CLEANING CONDITIONS : Display while system doing cleaning as (sand &

carbon filter) “back wash time” and after this it will display as “Rinse time”.

APDP Configure with AMPV the display shows “Filter back wash”.

Ÿ FAULT CONDITIONS : LCD displays shows in case of any failure conditions like,

LPS failure, HPS failure, Dosing tank empty, Low voltage, High voltage,

phase unbalanced, Raw water tank overload, Raw water pump overload,

High pressure pump overload & Auto multiport value not working.

08

1.5.0 FLOW DIAGRAM:

09

RA

W W

AT

ER

TA

NK

RW

T F

LO

AT

SV

-1

RA

W W

AT

ER

PU

MP

LP

S

PM

AN

TI S

CA

LIN

G&

PU

MP

H.P

.PU

MP

PM

HP

SS

V2

F.R

.VA

LV

E

UV

CH

OK

E

R.O

.WA

TE

R T

AN

K

TW

T F

LO

AT

TO

DR

AIN

ED

TO

RE

JE

CT

WA

TE

R

PU

RE

WA

TE

R (

R.O

.WA

TE

R)

SANDFILTER

P.P.FILTER-1

P.P.FILTER-2

R.O

.ME

MB

RA

NE

CARBONFILTER

FL

OW

ME

TE

R

FL

OW

ME

TE

RU

.V.C

HA

MB

ER

RW

T F

LO

AT

SE

NS

ING

LP

S

HP

S S

EN

SIN

GT

WT

FL

OA

TS

EN

SIN

G

1.6.0 Mechanical Dimensions:

1.5.1 Dimensions: Length x Width x Height = 185 x 160 x 210 mm.

10

TOP VIEW

FRONT VIEW LEFT SIDEVIEW

Models: 1 - 1 / 1 - 3 / 3 - 3 Accord Power Digital Products - APDP

RAW WATER PUMPMAX. LOAD 5HP

INPUT POWER 3-PHASES.V.FLUSH230V AC

R Y BB N R Y B N P R Y

HPP - 440V ACMAX. Load 5HP

DOSING230V AC

UV230V AC

N P N P

N P BN R Y B N P N R Y

FLUSH-SV230V AC

DOSING230V AC

RWP- 230V ACMax. Load 2HP INPUT POWER 3-PHASE

HPP - 440V ACMax. Load 5HP

P N P

UV230V AC

RWP- 230V ACMax. Load 2HP

P PN P N P N P N P NN

INPUT- 230V AC FLUSH- 230V AC UV - 230V AC DOSING - 230V ACHPP- 230V ACMax. Load 2HP

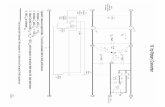

1.7.0 Input, Output & Auto Multiport Value Connection Diagram:

RO PANEL - 1:1: ELECTRICAL CONNECTING DIAGRAM

SENSING DIAGRAM PANEL - 1-1

SENSING DIAGRAM PANEL - 1-3

SENSING DIAGRAM PANEL - 3-3

11

RWT TWT HPS1 DOSING IP2 AMPV IP1NC C NO C NC C NC C NO

LPSNO C NC

RWT TWT HPS1 DOSING IP2 AMPV IP1NC C NO C NC C NC C NO

LPSNO C NC

RO PANEL - 1:3: ELECTRICAL CONNECTING DIAGRAM

RO PANEL - 3:3: ELECTRICAL CONNECTING DIAGRAM

AUTO MULTI PORT VALVE

4 5 12 9 14 15 IP1 C IP2

RO CONTROL PANEL

4 5

Blu

e

Red

Bla

ck

Bla

ck

Red

Bla

ck

Blu

e

Gre

en

Ye

llow

Gre

en

Ye

llow

Down

START

Menu

RESET

Helps to enter into settings.Confirmation of selection of your choice.Also works as RIGHT KEY FUNCTION .

Upward Movement.Increment of numbers & alphabets.ON to OFF & OFF to ON.(Only ON/OFF Setting Mode)

Downward Movement.Decrement of numbers & alphabets.ON to OFF & OFF to ON.(Only ON/OFF Setting Mode)

Start the back wash time and rinse time.Start of raw water pump.(Back wash / Rinse Mode)At the time of back wash & rinse time.

Service Mode to Cleaning Mode.Cleaning Mode to Service Mode.Reset the trip time, HPS1 & Pumps overload.

Back

Previous Menu to Service Mode. One step backwards.Also works as LEFT KEY FUNCTION .

UP

2.2 SELECTION OF LETTERS, SPACE (GAP) AND NUMBERS:

Ÿ Selection of capital letters [A].

Ÿ Selection of space word to word gap likes [Good Morning].

Ÿ Selection of numbers like 012345_ _ _ _9

Ÿ This letters are available at the time of company name editing.

Ÿ Space available before “A” and After “Z”.

Ÿ By pressing up & down keys to get numbers 0123_ _ _789

after 0123_ _ _789 before 0 is 9.

Ÿ This numbers are available only at the time of numbers editing.

2.0 OPERATING INSTRUCTIONS:

2.1 KEY FUNCTIONS:

12

Models: 1 - 1 / 1 - 3 / 3 - 3 Accord Power Digital Products - APDP

Ÿ Press menu key - Display shows read settings.

Ÿ Press up key - Display shows edit settings.

Ÿ Press menu key - Display shows company settings.

Ÿ Press up key - Display shows process settings.

Ÿ Press up key - Display shows on/off settings.

Ÿ Press up key - Display shows user settings.

Ÿ Edit above settings first select any one, and press menu key.

2.4 EDITABLE FEATURES: 1. Enter the password. 14. Low Voltage.

2. Edit password. 15. High Voltage.

3. Company Name. 16. Raw Water Pump Amps.

4. Service Contact Number. 17. High Pressure Pump Amps.

5. Date of Installation. 18. Low TDS Set Point.

6. LPS Delay Time. 19. High TDS Set Point.

7. Service time.

8. Trip time edit (Where TW float not installed).

9. Back wash time.

10.Rinse time.

11.Flushing time.

12.Auto clean time.

13.ON/OFF settings.

1.ENTER THE PASSWORD(Factory default password 0000 all zeros):

Ÿ Press menu key - Display shows read setting

Ÿ Press up key - Display shows edit setting

Ÿ Press menu key - Display shows company settings

Ÿ Press menu key - Display shows pass word

Ÿ Method to keep password - 5678 (Taken for Example)

Ÿ Using up & down keys till you read 5, then press menu key for keeping.

Ÿ Curser moves to next digit, Use up & down key to select 6, then press menu

key for keeping.

Ÿ Curser moves to next digit, Use up & down key to select 7, then press menu

Key for keeping.

2.3 ENTERING INTO EDIT SETTINGS:

13

Ÿ Curser moves to next digit, Use up & down key to select 8, then press menu

key for keeping.

Ÿ Display shows password ok - Press menu key for enter the password.

Note: The above password will allow user to edit below features.

Ÿ Edit company name.

Ÿ Service phone number.

Ÿ Model number.

Ÿ Serial number.

Ÿ Change password.

Ÿ Hour meter & date of installation.

2. EDIT PASSWORD(Factory default password 0000 all zeros):

Display shows edit password

Ÿ Press menu key - Display shows password

Enter the old password . Example: 5678

Ÿ Press menu key - Display shows ok password

Ÿ Press menu key - Display shows new password

Enter new password as per your choice Ex: 1234.

Ÿ Press menu key - Display shows new password ok

Ÿ Press menu key - Display shows conform password

Ÿ Enter new password again1234.

Ÿ Press menu key - Display shows conform password ok.

Ÿ Press menu key - Display shows password set, Press back key

3. EDIT COMPANY NAME:

Ÿ Press menu key - Display shows read settings.

Ÿ Press up key - Display shows edit settings.

Ÿ Press menu key - Display shows company settings.

Ÿ Press menu key - Display shows password

Ÿ Enter password - Display shows company name/ accord power.

Ÿ Press menu key - Cursor indicate edit letter.

Ÿ Example edit/enter new company name - INTRA.

Ÿ Keep on pressing up down keys till you read [I]

Ÿ Press menu key letter [I] is registered cursor move to next letter

14

Models: 1 - 1 / 1 - 3 / 3 - 3 Accord Power Digital Products - APDP

Ÿ Press up down key till read [N].

Ÿ Press menu key[N]is registered cursor move to next letter.

Ÿ Press up down key till read (T).

Ÿ Press menu key letter (T) registered cursor move to next letter.

Ÿ Use up down keys till read (R).

Ÿ Press menu key letter(R) registered cursor move to next letter.

Ÿ Use up down keys till read (A)

Ÿ Press menu key letter (A) registered cursor move to next letter.

Ÿ Keep on pressing menu key up to display shows setting changed.

Ÿ Again press menu key display shows company name INTRA.

4.EDIT SERVICE CONTACT NUMBER. Example: +919963800466

Ÿ Press menu key - Display shows read setting

Ÿ Press menu key - Display shows edit settings

Ÿ Press menu key - Display shows company settings

Ÿ Press menu key - Display shows password

Ÿ Enter the password - Display shows password ok

Ÿ Press menu key - Display shows company name ACCORD POWER

Ÿ Press up key - Display shows service contact no.as

+919963800866

Edit the service contact number as per above example.

Press menu key - cursor display shows the edit number

Use up down keys till you read 9, Press menu key the number 9 registered.

Cursor move to next number automatically.

Use up down keys till you read 9, Press menu key the number 9 registered.

Cursor move to next number automatically.

Use up down keys till you read 6, Press menu key the number 6 registered

Cursor move to next number automatically.

Use up down keys till you read 3, Press menu key the number 3 registered

Cursor move to next number automatically.

Follow the same method to feed complete phone number then press menu

key, display shows setting changed to confirm press menu key.

Display shows contact number +919963800466.

15

5. DATE OF INSTALLATION:

Ÿ Press menu key once - Display shows read settings.

Ÿ Press up key once - Display shows edit setting.

Ÿ Press menu key once - Display shows company settings.

Ÿ Press menu key once - Display shows password.

Ÿ Enter default password - Display shows company name.

Ÿ Press up key - Display shows service contact phone number.

Ÿ Keep on pressing up key - Display shows installed date.

Ÿ Press menu key - Display shows default date.

Ÿ Select the number feed install date use up/down keys and menu key to

move next digit.

Ÿ Press menu key - Display shows settings changed.

Ÿ Press menu key - Display play shows confirming the same.

Ÿ Press back key once, to come one step back.

Ÿ Press menu key - Display shows read settings.

Ÿ Press up key - Display shows edit settings.

Ÿ Press menu key - Display shows company settings.

Ÿ Press up key - Display shows process settings.

Ÿ Press up key - Display shows on/off settings.

Ÿ Press up key - Display shows user setting.

Ÿ Edit above settings first select any one, and press menu key.

6. RWP PUMP AMPS SETTING:

Ÿ Press menu key once - Display shows read settings.

Ÿ Press up key once - Display shows edit setting.

Ÿ Press menu key once - Display shows company settings.

Ÿ Press up key once - Display shows processes settings.

Ÿ Press menu key - Display shows trip time.

Ÿ Press up key upto - Display shows RWP Amps.

Ÿ Press menu key - Cursor blinking on first digit use menu key, UP &

DOWN Keys edit required Pump Amps.

Example: Raw water pump required 12.5A.Edit like this 12500(Milli Amps).

Ÿ Keep on pressing menu key up to display shows setting changed.

Ÿ Again press menu key save the programed value and cursor move to right

Side corner

16

Models: 1 - 1 / 1 - 3 / 3 - 3 Accord Power Digital Products - APDP

Models: 1 - 1 / 1 - 3 / 3 - 3 Accord Power Digital Products - APDP

6. HPP PUMP AMPS SETTING:

Ÿ Press menu key once - Display shows read settings.

Ÿ Press up key once - Display shows edit setting.

Ÿ Press menu key once - Display shows company settings.

Ÿ Press up key once - Display shows processes settings.

Ÿ Press menu key - Display shows trip time.

Ÿ Press up key upto - Display shows HPP Amps.

Ÿ Press menu key - Cursor blinking on first digit use menu key, UP &

DOWN Keys edit required Pump Amps.

Example: HPP pump required Amps 24.5A.Edit like this 24500(Milli Amps).

Ÿ Keep on pressing menu key up to display shows setting changed.

Ÿ Again press menu key save the programed value and cursor move to right

Side corner

NOTE: Follow the same method to other Editable Features (2.4)

setting times.

TRIP TIME ON/OFF SETTING:

Ÿ Press menu key once - Display shows read settings.

Ÿ Press up key once - Display shows edit setting.

Ÿ Press menu key once - Display shows company settings.

Ÿ Press up key once - Display shows processes settings.

Ÿ Press up key - Display shows ON/OFF settings.

Ÿ Press menu key - Display trip time ON/OFF.

Ÿ Press menu key - Editing selection of trip time ON/OFF.

Ÿ Feed trip time use up/down keys and to move next digit.

Ÿ Press menu key - Display shows setting changed.

Ÿ Press menu key - Confirming the same.

NOTE: Follow the same method to other ON /OFF settings.

17

To Comply with the published safety standards, The following must be served

when using this control panel.

Ÿ Applicable Models: RO Control 1-1, RO Control 1-3 & RO Control 3-3.

Ÿ Allow sufficient space around the control panel for proper air circulation.

Ÿ RO Control designed to operate for “ INDORE USE ONLY “.

Ÿ Operating voltage for single phase 230V & 3 - phase 440V only.

Ÿ High voltage inside to be serviced by trained persons only.

Ÿ Protect the RO control from the water dropping.

Ÿ Do not connect more the specified load HP on the relays.

Ÿ Connect the proper earthlings.

Ÿ Connect the input connecting wires 2.5 Sqmm.

Ÿ Connect the proper phase sequence RYB & Neutral.

Ÿ Fix the panel properly with the nut bolts.

Ÿ Ro Control Panel can be fixed on the plain surface.

Note: Read manual completely before use APCP RO panel.

3.0 INSTALLATION & SAFETY INSTRUCTIONS:

18

FLUSHING RELAYPCB LAYOUT

12V

GG

12V

RO

PC

BS

MP

S

GN

D

PN

NP

F4

5

Blu

e

Yello

w

12V

G

4.0 PCB INPUT & OUTPUT CONNECTION INFORMATION:

19

FLOWSENSOR- 2

OL

R1

OL

R2

UV

GN

D(C

OM

N)

GN

D.

Bla

ck

PU

LS

Ye

llow

+5V

Red

GN

D.

Bla

ck

PU

LS

Ye

llow

+5V

Red

IP1

IP2

DO

US

ING

HP

S

LP

S

TW

T

RW

T

GN

D

SENSING CONNECTOR

FeedWater

ROWater

TDS2

CT

2C

T3

CT

4

12V

DV

GN

DR

WP

HP

P

RW

P

HP

P

FL

S

MP

V

HO

OT

ER

TD

S

12V

12V

PH

R

GN

D B Y R

KEYPAD

LC

DMAIN RO CONTROL PCB

CT

1

TDS1FLOW

SENSOR- 1

4 5 6 7 8 9 10 11 12 13

M P TDS - SV HOOTER R R N Y N B

12

VG

12V

G

SM

PS

RO

PC

B

RY B G PH12V

6 RELAY PCB LAYOUT

12 130 1 2 3

G R H F

2 RELAY PCB LAYOUT

12V G G 12V

RO PCB SMPS

HPP RWP

CT2 CT1

PN

NF

P

Blu

e

Yello

w

45

12V

GND

V1

C2

C1

GN

D

5.0 TROUBLE SHOOTING GUIDE LINES:

Message ON Display Cause & Action

1. Raw Water Tank Empty

2. LPS Failed

3. HPS1

4. Dosing

5. Phase Error

6. Treated Water Tank Full

7. RWP Overload

8. HPP Overload

9. Low Voltage

10. High Voltage

11. High TDS

12. Phase Inbalance

Ÿ Actually tank is empty.

Ÿ Floaty is not connected.

Ÿ Check the float & wires.

Ÿ Pressure lower then the set value.

Ÿ Check the input water pressure.

Ÿ Check the LPS Connections.

Ÿ Pressure Higher then the set Value .

Ÿ Check the sand, Carbon Filters.

Ÿ Check the HPS1 Connections.

Ÿ Actually tank is empty.

Ÿ Floaty is not connected.

Ÿ Check the float & wires.

Ÿ Check the phase Connections.

Ÿ Check the input Voltage.

Ÿ Check the 3 - Phase board.

Ÿ Actually tank is Full.

Ÿ Floaty is not connected.

Ÿ Check the float & wires.

Sl.No.

20

Ÿ Check the Pump Amps rating.

Ÿ Check the Pump Amps rating.

Ÿ Check Low Voltage set point Or Low Voltage.

Ÿ Check High Voltage set point or High Voltage.

Ÿ Check High TDS set Value .

Ÿ Check 3- Phase Voltage .

Models: 1 - 1 / 1 - 3 / 3 - 3 Accord Power Digital Products - APDP

Models: 1 - 1 / 1 - 3 / 3 - 3 Accord Power Digital Products - APDP

6.0 APDP MODELS AND SIZES:

21

L-SERIES

Variants

L-SERIES TDS

Variants

ENCL. SIZES

(L x W x H)

I-SERIESVariants

DOMESTICVariants

ENCL. SIZES

(L x W x H)

ENCL. SIZES(L x W x H)

ENCL. SIZES(L x W x H)

1:1 - RWP & HPP

Single Phase.

1:3 - RWP Single.

HPP 3 - Phase.

3:3 - RWP & HPP

3 - Phase.

1:1 - RWP & HPP

Single Phase.

1:3 - RWP Single.

HPP 3 - Phase.

3:3 - RWP & HPP

3 - Phase.

1:1 - RWP & HPP

Single Phase.

1:3 - RWP Single.

HPP 3 - Phase.

3:3 - RWP & HPP

3 - Phase.

Non - TDS Models

TDS Models

With Enclosure

Without Enclosure

L = 185.0 mm

W = 160.0 mm

H = 210.0 mm

L = 185.0 mm

W = 160.0 mm

H = 210.0 mm

L = 295.0 mm

W = 120.0 mm

H = 345.0 mm

I-SERIES Domestic22

7.0 RO Control Panel Configure with 2-Multiport Valve:

1

2

3

45

6

7

8

9

1

0

14

1

5

NO

NO

NO

CN

C

11

12

13

CC

1

2

3

45

6

7

8

9

1

0

14

1

5

NO

NO

NO

CN

C

11

12

13

CC

54

IP-2

NC

CO

MIP

-1N

O

AM

PV

-1

SA

ND

AM

PV

-2

CA

RB

ON

AM

PV

- 1

A

MP

V -

21

07

AM

PV

- 1

A

MP

V -

21

51

4

AM

PV

- 1

& 2

12

- 1

2IP

1

-

RO

PA

NE

L

RO

PA

NE

L -

CO

M -

9 C

OM

- 1

4 C

OM

-

9 C

OM

AM

PV

- 2

AM

PV

- 1

AM

PV

- 1

Models: 1 - 1 / 1 - 3 / 3 - 3 Accord Power Digital Products - APDP

23

8.0 Input & Output Connection Diagram:

RAW WATER PUMP 2.0 HP SINGLE PHASE

HIGH PRESSURE PUMP 2.0 HP SINGLE PHASE

ELECTRICAL CONNECTING DIAGRAM

SENSING DIAGRAM PANEL - 1-1

RAW WATER PUMP 2.0 HP SINGLE PHASE

HIGH PRESSURE PUMP 5.0 HP 3 - PHASE

ELECTRICAL CONNECTING DIAGRAM

SENSING DIAGRAM PANEL - 1-3

RAW WATER PUMP 5.0 HP 3 - PHASE

HIGH PRESSURE PUMP 5.0 HP 3 - PHASE

ELECTRICAL CONNECTING DIAGRAM

SENSING DIAGRAM PANEL - 3-3

Ÿ RO PANEL - 1-1:

Ÿ RO PANEL - 1-3:

Ÿ RO PANEL - 3-3:

RWP- 230V ACMax. Load 2HP

P PN P N P N P N P NN

INPUT- 230V AC FLUSH- 230V AC UV - 230V AC DOSING- 230V ACHPP- 230V ACMax. Load 2HP

N P BN R Y B N P P R Y

FLUSH-SV

UV & DOSINGRWP- 230V ACMax. Load 2HP INPUT POWER 3-PHASE

HPP - 440V ACMax. Load 5HP

RAW WATER PUMPMAX. LOAD 5HP

INPUT POWER 3-PHASE S.V.FLUSH

R Y BB N R Y B N P R Y

HPP - 440V ACMAX. Load 5HP

RWT TWT HPS1 3-PHASE IP2 AMPV IP1NC C NO C NC C NC C NO

LPSNO C NC

RWT TWT HPS1 3-PHASE IP2 AMPV IP1NC C NO C NC C NC C NO

LPSNO C NC

RWT TWT HPS1 3-PHASE IP2 AMPV IP1NC C NO C NC C NC C NO

LPSNO C NC

9.1 Warranty voids if overload connected to the APDP.

9.2 Warranty covers against only manufacturing defects.

9.3 Standards warranty 12 months from date of purchase.

9.4 Keep this warranty card safely.

9.5 In case of water found inside warranty voids.

9.6 Follow the user manual instructions strictly before use.

Customer Name: ......................... Ph.No: ...................

Dealer / Distributor: .......................... Sign: .......................

Stamp: ............................................... Date: ......................

Product Serial No.: .....................................................

Product Model No.: ...................................................

CUSTOMER SUPPORT:

E-Mail: [email protected]

Phone No.: 040 - 27144666.

9.0 WARRANTY:

24

AP

DP

/ M

NL

/ 6

8 /

00

Manufactured By:

nd Plot No. : 34/A, 2 Floor Electronic Complex, Kushaiguda, Hyderabad - 500 062, T.S, INDIA.Ph.: 09963 800 466. www.accordpower.co.in.

ACCORD POWER DIGITAL PRODUCTS

![ตัวเร่งปฏิกิริยาออกไซด์ NiCr และ NiAl … · in catalytic liquid-phase oxidations [9]. It was spinel (Cu 0.5 Ni 0.5 Cr 2O4) catalyzed](https://static.fdocuments.in/doc/165x107/5ed29ac7ed9b4164fd5fb12c/aaaaaaaaaaaaaaaaaaaaaaaoe-nicr-aaa.jpg)