Dgtww201011 Def Dl

-

Upload

ratninp9368 -

Category

Documents

-

view

972 -

download

10

description

Transcript of Dgtww201011 Def Dl

www.dieselgasturbine.com

November 2010

WW Nov Cover.indd 1 10/18/10 11:15:16 AM

Unique slide valve accommodates fluctuations, delivers dramatic savings

Switching from a centrifugal or reciprocating compressor to a KOBELCO screw fuel gas compressor can save millions of dollars over time in fuel gas boosting service. KOBELCO screw compressors have a unique slide valve mechanism that instantly and automatically maintains constant discharge pressure – despite fluctuations in suction gas pressure or gas turbine load. So you’ll significantly reduce power consumption and costs.

For example, a KOBELCO screw compressor is reducing power costs by anaverage 1,250 kW/hr (compared to centrifugal or reciprocating compressors) in one fuel gas boosting application due to suction gas pressure fluctuation.That projects to a savings of approximately $10 million over a typical 20-yearlife cycle.

Power and PerformanceWith discharge pressures up to 1,500 psig (100 barg), KOBELCO screw fuel gas compressors easily handle the latest industrial and aeroderivative gas turbines. And with up to six years of continuous operation between overhauls,you’ll maximize availability while minimizing maintenance costs.

KOBELCO screw fuel gas compressors – isn’t it time to boost your profitability?

Kobelco Screw Fuel Gas Compressors

Boost fuel gasand profits for

gas turbines

Screw fuel gas boosting compressorused with aeroderivative gas turbine(output: 50 MW)

Tokyo +81-3-5739-6771Munich +49-89-242-18424www.kobelco.co.jp/compressor

Kobelco EDTI Compressors, Inc.

Houston, [email protected]

SEE DIRECTLINK @ WWW.DIESELGASTURBINE.COM

KobeSteel.qxp 6/14/10 9:09 AM Page 1

Diesel&Gas Turbine WW_full pg_Oct10_hires.pdf 1 10/11/2010 11:10:16 AM

SEE DIRECTLINK @ WWW.DIESELGASTURBINE.COM

Capstone.indd 1 10/12/10 11:46:34 AM

2 November 2010 Diesel & Gas Turbine Worldwide

DIESEL & GAS TURBINE PUBLICATIONSChairman of the Board ................Russell PalmerPresident ................................ Michael J. OsengaSenior Vice President ......... Michael J. Brezonick

Editor & Publisher ...........................Brent HaightManaging Editor .................... Amanda M. KlempSenior Editor ..............................Joseph M. KaneSenior Editor ...........................D. Phillip BurnsideSenior Editor .............................. Dawn M. GeskeSenior Editor ................................... Patrick CrowRegional Manager/Editor ..........Roberto ChelliniRegional Manager/Editor ...............Ian CameronRegional Manager/Editor ........... Roberta PrandiField Editor/Business Manager .....Bo SvenssonAssociate Editor ..............................Kyle KopplinAssociate Editor ...................................DJ SlaterCopy Editor ........................... Melissa C. McNultyAdvertising Manager .................. John BlombergProduction Manager ................Marisa J. RobertsGraphic Artist ........................Brenda L. BurbachGraphic Artist ............................. Carla D. LemkeGraphic Artist ........................... Amanda J. RyanGraphic Artist ................................Alyssa LoopeCirculation Manager ...................... Sheila Lizdas

PUBLICATION HEADQUARTERS20855 Watertown Road, Suite 220

Waukesha, Wisconsin 53186-1873, U.S.A.Telephone: +1 262-754-4100 Telefax: +1 262-754-4175

UNITED STATES - HOUSTONBrent Haight, Editor & Publisher

15814 Champion Forest Drive, #308Spring, Texas 77379, U.S.A.

Telephone: +1 832-717-4549

GERMANYLisa Hochkofler, Advertising Manager Gabriele Dinsel, Advertising Manager

Niemöllerstr. 9 73760 Ostfildern, Germany

Telephone: +49 711 3416 74 0 Telefax: +49 711 3416 74 74

UNITED KINGDOMIan Cameron, Regional Manager/Editor Linda Cameron, Advertising Manager

40 Premier Ave., AshbourneDerbyshire, DE6 1LH, United Kingdom

Telephone: +44 20 31 79 29 79 Telefax: +44 20 31 79 29 70

ITALYRoberto Chellini, Regional Manager/Editor

44, Via Delle Forbici I-50133 Firenze, Italy

Telephone: +39 055 50 59 861 Telefax: +39 055 57 11 55

Roberta Prandi, Regional Manager/EditorVia Fitta 21A

I - 38062 Arco, ItalyTelephone: +39 0464 2430891 Telefax: +39 0464 244529

SWEDENBo Svensson, Field Editor/Business Manager

Dunderbacksvagen 20 612-46 Finspong, Sweden

Telephone: +46 70 2405369 Telefax: +46 122 14787

JAPANAkiyoshi Ojima, Branch Manager

51-16-301 Honmoku Sannotani, Naka-kuYokohama, 231-0824 Japan

Telephone: +81 45 624 3502 Telefax: +81 45 624 3503

HONG KONGS.H. Mok, Branch Manager Rm 1405, Kowloon Building

555 Nathan RoadKowloon, Hong Kong

Telephone: +852 3118 7930 Telefax: +852 3110 3572

KOREAMyung-Shin Lee, Sales Manager

191-1, Pyungchang-dong, Chongno-kuSeoul, Korea 100-648

Telephone: +82 2 391 4254 Telefax: +82 2 391 4255

Reprints of all articles published inDiesel & Gas Turbine Worldwide are available.

Please address inquiries to:[email protected]

Tel: +1 262-754-4137 • Telefax: +1 262-754-4176

The Obama administration lifted the moratorium on deepwater drilling that it imposed in the wake of BP’s di-saster in the Gulf of Mexico.

The six-month ban had been scheduled to expire Nov. 30, but In-terior Secretary Ken Salazar said he was moving up that deadline, “be-cause new rules imposed after the spill have strengthened safety mea-sures and reduced the risk of another catastrophic blowout.”

Federal reports have quantified job loss due to the moratorium be-tween 8000 and 12 000 in the U.S. Gulf region.

While the temporary ban on ex-ploratory oil and gas drilling is lift-ed immediately, drilling companies must comply with new safety regula-tions before new permits are issued, which means those out of work due to the moratorium still face consider-able uncertainties.

The Department of Interior (DOI) offers a report on its website (www.doi.gov) titled Fact Sheet: Enhanced Requirements to Resume Deepwater Drilling Activities, which outlines the specific details.

Under the new rules, a professional engineer must independently inspect and certify each stage of the drilling process. Blowout preventers — the emergency cutoff equipment designed to contain a major spill — must be independently certified and capable of severing the drill pipe under severe pressure. Companies will be required to develop comprehensive plans to manage risks and improve workplace safety. Also, the CEO of a company re-sponsible for a well must certify it had complied with all regulations.

In addition to the recently issued Drilling Safety Rule, Secretary Salazar said he anticipates the DOI and Bureau of Ocean Energy Management, Regula-tion and Enforcement (BOEM) will un-dertake further rulemaking that consid-ers additional safety measures — such

as redundant blind shear rams, remote activation systems for BOPs, and en-hanced instrumentation and sensors on BOPs — to further enhance recent safety improvements.

In a press statement, Salazar offers, “In light of the Deepwater Horizon oil spill, we must continue to take a cautious approach when it comes to deepwater drilling and remain aggres-sive in raising the bar for the oil and gas industry’s safety and environmen-tal practices. We have more work to do in our reform agenda, but at this point we believe the strengthened safety measures we have implemented, along with improved spill response and blowout containment capabilities, have reduced risks to a point where operators who play by the rules and clear the higher bar can be allowed to resume. The oil and gas industry will be operating under tighter rules, stronger oversight, and in a regulatory environment that will remain dynamic as we continue to build on the reforms we have already implemented.”

With tighter regulation and more intense monitoring, companies and regulators are going to be extremely careful going forward, which means a slow return to activity in the region.

Michael Bromwich, director of the Minerals Management Service, ex-pects his agency to begin issuing per-mits by the end of the year.

Analysts expect regulators to take an extremely cautious approach to new permit approvals, and some fear that regulators will be ill-equipped to tackle new permitting requirements — causing further delay in the per-mitting process.

Regardless, most do not expect to see idle rigs returning to work in the U.S. Gulf until midyear 2011. A

HaigHt Notes

A Member of the Diesel & Gas Turbine Publications Group

Gulf Gets Green Light, But Slow Return Expected

Brent [email protected]

WW107.indd 1 10/15/10 2:29:48 PM

November

2010

On The Cover: Turbine Tech 2010 — our annual guide to turbine manufacturers, com-plete with contact details, recent developments and specs, begins on page 11.

Follow dgtww on:

Global Markets

Global Coverage

www.dieselgasturbine.com

MEMBER OF BPA WORLDWIDE®

DIESEL & GAS TURBINE WORLD WIDE (ISSN 0278-5994) Volume 42, No. 9 — Published monthly except, Jan/Feb & July/Aug issues combined, by Diesel & Gas Turbine Pub lications, 20855 Water town Road, Waukesha, WI 53186-1873 U.S.A. Subscription rates are $75.00 per year/$10.00 per copy worldwide. Periodicals postage paid at Waukesha, WI 53186 and at additional mailing offices. Copyright 2010 Diesel & Gas Turbine Pub li cations. Canadian Publication Mail Agreement # 40035419. Return Undeliverable Canadian Addresses to: P.O. Box 456, Niagra Falls, ON L2E 6V2, Canada. E-mail: [email protected]. POSTMASTER: Send address changes to: Circulation Man ager, Diesel & Gas Turbine Worldwide, 20855 Watertown Road, Suite 220, Waukesha, WI 53186-1873 U.S.A.

PRINTED IN THE U.S.A.

Diesel & Gas Turbine Worldwide November 2010 3

INDUSTRy NEWS

GE To Buy Dresser Inc. ...........................................................................................5

Gas Turbine Controls ...........................................................................................36

Which Route For Marine Engines? ........................................................................42

POWER PLANT MAINTENANCE

Laser Measurements Guide Improvements .............................................................6

ComAp Launches New Monitoring System ..........................................................10

Continuous Improvement In Medium-Sized Gas Turbines ..................................28

Contract And Engineering Activity Directed At Total Plant Maintenance ............30

RAIL — EMISSION CONTROL TEChNOLOGy

Idle Work At The Rail Yard ....................................................................................8

MTU Expands Powerpack Range ..........................................................................31

Emitec Lowers Locomotive Emissions .................................................................48

TURBINE TECh 2010

Gas And Steam Turbine Review ........................................................................... 11

POWER GENERATION

Wärtsilä Introduces New Engine ..........................................................................24

Integrating Fuel Injection .....................................................................................34

An Order For OPRA’s New Gen-Set ......................................................................37

EMISSIONS WORLDVIEW

A Case For Slow Sailing ........................................................................................32

MARINE PROPULSION

Moteurs’ New Marine Engine ................................................................................38

Navigating Fuel Consumption Measurement ........................................................45

Wärtsilä Launches Vessel Enhancements .............................................................46

Biodegradable Gear Oil ......................................................................................... 47

RAIL TRACTION

Caterpillar On Track For Growth ........................................................................41

First Voith Engine For Rail ..................................................................................44

Features

CoNteNts

Industry Drivers ......................................................................................................4

Dateline ...................................................................................................................9

Featured Products .................................................................................................40

Newsmakers ..........................................................................................................43

Advertisers’ Index .................................................................................................49

Marketplace ...........................................................................................................49

World Viewpoint ...................................................................................................52

DepartmeNts

Cov

er d

esig

ned

by B

rend

a Bu

rbac

h

WWNovemberTOC_new.indd 1 10/18/10 1:55:59 PM

MITSUBISHI HEAVY INDUSTRIES

MMitsubishi Heavy Industries has developed the MET83MAG, a

generator-integrated hybrid turbocharger for marine propulsion diesel engines. The turbocharger uses engine exhaust gas to drive itself and generate electricity, ac-cording to the company.

The turbocharger’s generator can pro-duce a maximum power output of 754 kW at an engine speed of 9500 r/min. It can also act as an auxiliary blower to enhance its performance when the engine speed is not fast enough.

The turbocharger will be installed and tested on a bulk carrier currently under construction by Universal Shipbuilding for NYK Line and scheduled to go into service in 2011. That event will mark the first onboard testing of a hybrid turbo-charger using a commercial ship in actual operation, Mitsubishi said.

COLFAX

IColfax Corp., a manufacturer of fluid-handling products for critical appli-

cations, acquired Baric Group, a supplier of fluid-handling systems mainly for lubrica-tion applications in the oil and gas, petro-chemical and power generation markets.

Baric Group, headquartered in Mor-peth, U.K., has annual pro forma sales for this year expected to be about US$21.7 million, and current backlog, which has been increasing, is about US$43.4 mil-

lion. Colfax expected the transaction to be accretive over the next 12 months.

FUELCELL ENERGY

PFuelCell Energy Inc., a manufac-turer of power plants, announced

the sale of a 1.4 MW DFC1500 fuel cell power plant to G3 Power Systems Inc. The power plant will be installed at Oli-vera Egg Ranch, a poultry ranch located in French Camp, California, U.S.A.

The power plant will use renewable bio-gas for fuel, converting a waste problem at the ranch into clean electricity, according to FuelCell. The ranch currently uses a solid waste lagoon for its waste disposal, which emits ammonia, methane and other gases. An anaerobic digester will take in the waste stream, using heat and micro-organisms to reduce the volume of waste and create methane gas as a byproduct. The gas will then be used as fuel to gener-ate renewable electricity, FuelCell said.

FuelCell will service the power plant under a five-year service agreement. The sale of this power plant is the first order by G3 under an agreement with FuelCell.

CATERPILLAR

OCaterpillar Motoren has made the IMO II-compliant configuration of

the M 20 C medium-speed engine avail-able nearly six months before the IMO regulations take effect for the marine in-dustry on Jan. 1, 2011.

The M 20 C is available for purchase

globally in six- and eight-cylinder config-urations, and can produce between 1020 to 1520 kW at 900 to 1000 r/min. It also is capable of operation on heavy fuel oil or marine diesel oil.

Manufactured in Kiel, Germany, at the Kiel Engine Center, the M 20 C was redesigned with a new plunger for emis-sion optimization in alignment with new timing for fuel injection, combustion inlet and exhaust outlet. For current M 20 C owners, a retrofit kit is available in order to meet IMO 2 regulations.

ELOS FIXTURLASER

IElos Fixturlaser AB, a global pro-vider of laser-based shaft alignment

tools, has formed a new sales company in Italy called Fixturlaser S.R.L. Fixturlaser S.R.L. will be responsible for all sales of Elos Fixturlaser’s products in Italy.

The company, located in the Milan area, also plans to carry out repairs and calibra-tions of these products in the near future. It has two employees with experience in laser-based shaft alignment, Elos Fixturlaser said.

4 November 2010 Diesel & Gas Turbine Worldwide

Industry drIvers

ABB TurbochargingQuality you can trust.

Original ABB spare parts are yourassurance of the highest quality andprecision. For further information please contact your nearest ABB Turbocharging service station.www.abb.com/turbocharging

ABB Turbo Systems Ltd CH-5401 Baden/Switzerland Phone: +41 58 585 77 77 E-mail: [email protected]

ABBturbo_Nov09_WW.qxp 9/30/09 11:31 AM Page 1

continued on page 8

see directlink @ www.dieselgasturbine.com

IndDrivers_Nov.indd 1 10/15/10 1:31:16 PM

GE is living up to the pledge it made shareholders in its 2009 an-nual report when it vowed that “GE must be an industrial company first.” In October, the company announced plans to acquire Dresser Inc. for US$3 billion in its latest move to grow its energy business.

The addition of Dresser’s portfolio — which includes technologies for gas engines, control and relief valves, measurement, regulation and control solutions for gas and fuel distribution — will expand GE’s core energy offer-ings and extend its reach into adjacent offerings for its energy and industrial customers around the world.

“Dresser is a great fit for the GE business model,” said John Krenicki, vice chairman of GE and president and CEO of GE Energy. “Dresser’s technology complements our existing gas engine portfolio and adds offer-ings complementary to those of GE in the US$45 billion flow technology industry, including product offerings in the highly engineered valve seg-ment. Eighty-five percent of Dresser’s revenue is from energy customers, and it has developed a large installed base of equipment, which is a big rea-son why 40% of its total revenue is

derived from aftermarket service of-ferings, and there is a lot of room for future expansion.”

Krenicki added, “Dresser has a global franchise and brand with 60% of revenues outside of North America, which will be accelerated by GE’s global footprint. Through the acquisition, we will bring to bear our focus on research and develop-ment to Dresser’s highly engineered custom solutions and create an op-portunity for Dresser’s 6300 talented employees to dramatically expand their businesses.”

Headquartered in Addison, Texas, U.S.A., Dresser operates in more than 100 countries, delivering compres-sion, flow technology, measurement and distribution infrastructure and services to customers in more than 150 countries.

The deal includes Dresser’s Wauk-esha engine brand. Waukesha will join with GE’s Jenbacher line in a now expanded portfolio of oilfield gas engines.

Dresser’s gas engines will give GE low-emissions, fuel-flexible mechanical-drive technology that can be applied to the small-scale compression seg-ment of the oil and gas industry.

Diesel & Gas Turbine Worldwide November 2010 5

Industry news & AnAlysIs

GE To Buy Dresser Inc. US$3 billion deal expands GE’s energy offerings and extends its global reach

GE Jenbacher’s experience in fuel-flexible, high-efficiency, power-generation engines, combined with Dresser’s experience in low-emissions, fuel-flexible rich-burn mechanical drive engines, should deliver benefits to both engine lines.

Dresser will also further the devel-opment of GE Energy’s monitoring, diagnostics and performance optimi-zation offerings. Dresser’s pressure relief and control valve technologies will be complemented by GE’s do-main experience, which should create opportunities to bring additional tech-nology and applications to Dresser’sofferings. GE plans to build out so-lutions it offers to help customers manage the pressure and relief flows in pipelines, processing plants and power generation facilities.

“Our track record integrating pre-vious acquisitions such as Nuovo Pignone (Oil & Gas), Jenbacher (gas engines), Bently Nevada (condition-ing and monitoring) and Enron Wind (renewable energy), gives us great confidence to build upon as we move forward with Dresser,” said Krenicki. “Our team is committed to technol-ogy leadership, globalization and op-erating discipline.”

The deal is subject to customary closing conditions and is expected to close quickly following regulatory ap-proval. Look for additional reporting from Diesel & Gas Turbine Worldwideonce the details are finalized. A

WW106.indd 1 10/14/10 5:10:49 PM

With the life cycle of a fossil fuel power plant spanning upward of 30 to 50 years, maintenance — and im-provements — are inevitable. Over time, parts wear down and regulations change, requiring operators to make repairs and efficiency upgrades.

While the plants may be 30 years old, the technology to evaluate the equipment is much more up to date, no longer requiring days of maintenance shutdown to take measurements.

Minnesota, U.S.A.-based GKS Glob-al Services, a Laser Design company, offers 3-D laser scanning and measure-ment, which can often be done in a day and greatly reduces the risk of human error and inconsistencies, said David Rock, senior on-site engineer at GKS.

“Basically, what we’re doing,” said Rock, “is reverse engineering for up-dates that improve current function-ality and output.

“A lot of our customers want to cre-ate a new product that will give them more output, so they can produce more energy more efficiently.

and repairs need to be made or to bid a project.

GKS goes into the plants and sets up the laser and scanning equipment to get an overall 3-D point cloud model of the unit. For smaller components, handheld laser devices and some more traditional methods are used.

“We’ll set up the scanner in optimal locations, and in one day we can usu-ally scan the entire generator — get-ting overall length, bar location and bar length. In the past, these custom-ers have used piano wire, calipers and other primitive manual measuring de-vices to gather dimensional informa-tion, which usually took them several days,” said Rock.

“Some hand measurements are still done on-site to corroborate the laser checks,” Rock explained. “Occasion-ally an engineer from our customer’s company will work with us to take hand measurements. We call this practice a sanity check. It verifies that their hand measurements and our la-ser measurements are very similar to each other.”

Tolerances for these power plant components are very small — even thousandths of an inch. GKS’s equip-ment receives calibration from the la-ser equipment manufacturers.

Once the data is collected, either GKS or the customer will map out the components and system in a CAD pro-gram. This helps to determine how the power plant deviates from the original print and what flaws may have devel-oped over time. The data provides a launching pad to determine what im-provements can be made. A

SEE DIRECTLINK @

WWW.DIESELGASTURBINE.COM

3-D laser scanning and measurement helps to create data and diagnose issues with older pow-

er plants. Using this data, plant operators can develop maintenance and upgrade plans.

“They’re trying to increase produc-tion with less impact to the environ-ment, and what the scanning process can tell them is where the design flaw is that causes them to lose X amount more product and create X amount more pollution. The newer systems that will replace the old ones will do a much better job at reducing impact,” he said.

While GKS does the work at the utility plants, the customers are generally the turbine manufacturers and service providers looking for information on what improvements

6 November 2010 Diesel & Gas Turbine Worldwide

Power Plant Maintenance by amanda m. klemp

Laser Measurements Guide ImprovementsGKS offers 3-D modeling of power plants for upgrades and maintenance

The collected data is trans-

ferred to a CAD rendering,

enabling customers to use the

data with their own systems.

WW097.indd 1 10/14/10 5:11:48 PM

The extraction of recoverable subsea oil and gas resources has become extremely costly

and complex. Efficiency is the name of this game, bottom line results its scoreboard. This is

our game, and we love it. For decades, MAN Diesel & Turbo have been investing exten-

sively in the research and development of compression and power generation technologies.

The result is a comprehensive product portfolio, unique in its depth and level of innovation.

These are products built for uncommonly tough times and requirements. For total relia bility,

absolute availability, and uncompromising efficiency. This is our contribution to your bottom

line. Find out more at www.mandieselturbo.com

Marine Power Plants Turbomachinery PrimeServ

MAN Diesel & Turbo insideSolutions for offshore oil and gas production

Centrifugal compressorsScrew compressors

Steam turbines

Pic

ture

by

cou

rtes

y o

f S

BM

Off

sho

re

Gas turbines

Integrally geared compressors

see directlink @ www.dieselgasturbine.com

ManDiesel.indd 1 10/12/10 1:34:36 PM

Kansas City Southern Railroad (KCS) has been recognized for its efforts in reducing CO2 and NOx emissions, ac-complished by installing anti-idling devices on five switch locomotives operating in the yards. The instal-lation of the anti-idling devices was made possible through 75% funding provided by a grant from the Mid-America Regional Council, which re-ceived its funding from Missouri’s De-partment of Natural Resources, which was allocating Diesel Emission Re-duction Act funds from the American Recovery and Reinvestment Act.

KCS executive chairman said, “This project has resulted in a CO2 emission reduction of 275 tons and as much as 550 tons per year; a NOx emission re-duction of 7.3 tons and as much as 14 tons per year; and a total fuel savings per year of 25 000 gallons [94 635 L]. The data collected so far indicates that emission reductions are significantly greater than originally anticipated.” The company estimates idling time is reduced by about 350 hours per month and the switch locomotives burn about 9.5 L of fuel per hour.

The switching locomotives are powered by EMD switch engines from the 1970s with outputs rated at about 895 kW.

WÄRTSILÄ

MWärtsilä and Deltamarin have intro-duced a series of ferry designs during

the 35th Interferry Conference in New York. The companies discussed the parametric design method, which allows designers to make a clear distinction between the market-able and nonmarketable features of a vessel. This allows designers to tailor the marketable features, such as the ship’s recreation area, to each customer’s needs, while using a more industrial method for the nonmarketable as-pects, such as the engine room layout.

The industrial engineering of ship sys-tems and the serial effect created from pre-design modules are estimated to result in a cost savings of 15%, according to Wärtsilä. The fuel economy of these ferries could also improve by 15%.

The partnership between Wärtsilä and Deltamarin also allows the pair to gener-ate customized ferry concept designs for each owner’s budget more quickly, said the company.

TOGNUM

PTognum received a contract to de-liver 36 MTU on-site energy gen-

sets, worth US$12 million, to energy pro-vider Electricidade do Brasil.

The gen-sets are based on MTU 16V 4000 G83 engines and are mounted on base racks along with the accompanying generators and control equipment. They generate 1.5 MW each, for a total of 54 MW of electri-cal power. The Amazonas State Electricity Corp. will operate the gen-sets on behalf of Electricidade do Brasil, near the city of Manaus in northwestern Brazil. The systems are designed to run continuously to gener-ate additional electrical power for local net-works on the city’s periphery.

The work cycle on switching loco-motives calls for a lot of idling time be-tween moving back and forth between the rail cars. This uses a lot of fuel and, in turn, generates the proportionate emissions. By installing ZTR Control Systems’ SmartStart system, the engine is monitored to determine if an idling locomotive can be shut down.

ZTR Control Systems, with offices in the United States and Canada, designs and manufactures monitoring and control systems for railway, power and industrial applications worldwide.

The SmartStart system monitors out-side ambient temperature, engine cool-ant temperature, battery charging rate, battery voltage, brake cylinder pressure, reverser position, throttle position, po-sition of the autostart enable switch and the amount of time the throttle is in idle. If a locomotive is idle for 15 min-utes and all conditions are acceptable, then the locomotive will shut down. If monitored conditions change, such as the engine water temperature, the en-gine starts back up and recycles.

Based on the results of these five SmartStart systems, KCS said it plans to install the units on additional switching locomotives. A

SEE DIRECTLINK @

WWW.DIESELGASTURBINE.COM

8 November 2010 Diesel & Gas Turbine Worldwide

Rail — Emission ContRol tEChnology

Idle Work At The Rail YardKansas City Southern Railroad employs ZTR Control Systems’ anti-idling devices on switch locomotives

Kansas City Southern Railroad

has installed ZTR’s SmartStart

anti-idling devices on five of its

switch locomotives, reducing idling

time and, in turn, reducing fuel con-

sumption and emissions.

industRy dRivERs

continued on page 10

WW099.indd 1 10/15/10 1:32:53 PM

* Boldface indicates shows and conferences in which Diesel & Gas Turbine Worldwide is participating. A more complete listing of trade shows is available at www.dieselgasturbine.com

Diesel & Gas Turbine Worldwide November 2010 9

novemBerNov 1-3 Power-Gen Middle East 2010 - Qatar Int’l Exhibition Centre, Doha, Qatar; PennWell Global Energy Group, Pennwell House, Upshire EN9 3RS, U.K. Tel: +44 192 656 610Fax: +44 1992 656 700Web: www.power-gen-middleeast.com

*Nov 3-5 2010 SNAME - Seattle, Washington, U.S.A.; The Society of Naval Architects and Marine Engineers, 601 Pavonia Ave., Jersey City, New Jersey 07306, U.S.A.

Tel: +1 (800) 798-2188 Fax: +1 (201) 798-4975 E-mail: [email protected] Web: www.sname.org

*Nov 16-17 APPrO 2010 - Metro Toronto Con-vention Centre, Toronto, Ontario, Canada; Association of Power Producers of Ontario (APPrO), 25 Adelaide St. East, Suite 1602, Toronto, Ontario, Canada M5C 3A1.Tel: +1 (416) 322-6549Fax: +1 (416) 481-5785Web: www.appro.org

Nov 25-27 Shanghai 5th International Petroleum Petrochemical Natural Gas Technology Equipment Exhibition, Shanghai New International Expo Center, Shanghai, China; Shanghai AiExpo Exhibition Services Co. Ltd., 501 Guang Yue Road, 5th floor, Shanghai, China.Tel: +86 21 659 29 965Fax: +86 21 652 82 319E-mail: [email protected]: www.sippe.org.cn

Nov 30-Dec 2 Seatrade Med Cruise Convention - Palais des Festivals et des Congres, Cannes, France; Seatrade, 42 N. Station Road, Colchester, CO1 1 RB, U.K.Tel: +44 12 06 54 51 21Fax: +44 12 06 54 51 90E-mail: [email protected]: www.seatrade-med.com

DecemBer*Dec 1-3 International WorkBoat Show,

Morial Convention Center, New Or leans , Lou is i ana , U .S .A . ; Diversified Communications, 121 Free St. P.O. Box 7437, Portland, Maine 04112, U.S.A.

Tel: +1 (207) 842-5500 Fax: +1 (207) 842-5503 E-mail: [email protected] Web: www.workboatshow.com

Dec 8-10DeepGulf 2010 - Galveston Island Convention Center, Galveston, Texas, U.S.A.; Quest Offshore, 1600 Highway 6, Suite 300, Sugar Land, Texas 77478, U.S.A. Tel: +1 (832) 424-7048

Dateline follow dgtww on

see directlink @ www.dieselgasturbine.com

Fax: +1 (832) 242-7136E-mail: [email protected]: www.deepgulfconference.com

*Dec 8-10 W o r l d E n e r g y E n g i n e e r i n g

Conference, Washington Convention Center, Washington, D.C., U.S.A.; Association of Energy Engineers, 4025 Pleasantdale Road, Suite 420, Atlanta, Georgia 30340, U.S.A.

Tel: +1 (770) 447-5083

Fax: +1 (770) 447-4354 E-mail: [email protected] Web: www.energycongress.com

*Dec 14-16PowerGen International - Orange County Convent ion Center , Orlando, Florida, U.S.A.; PennWell International, 1421 South Sheridan Road, Tulsa, Oklahoma 74112, U.S.A. Tel: +1 (918) 832-9225Fax: +1 (918) 813-9875E-mail: [email protected]

WE’RE BUILDING BETTER EMISSIONSCONTROL SOLUTIONS.

The MIRATECH Ground Access Catalyst-Silencer Combo. Totallyself-supporting vertical configuration – with easy maintenance atground-level. No more scaffolding or ladders. Improved safety. Lowerinstallation costs. For large-engine applications, it’s simply a bettersolution. And just another example of the innovations that havemade MIRATECH the smart choice in industrial engine compliance.

Catalytic Converters | SCR | Silencers | AFRs | Field Service | Training

Over 12,000 systems installedLearn more. Visit our website. Send us an e-mail or give us a call.

9 1 8 - 7 9 4 - 9 3 6 5 | m i r a t e c h c o r p . c o m | i n f o @ m i r a t e c h c o r p . c o m

FROM THE GROUND UP.

Miratech.indd 1 10/18/10 11:43:31 AM

November_Dateline.indd 1 10/18/10 11:45:40 AM

A new service for operators of gener-ator fleets or similar plant equipment has been launched by Czech Republic-based electronics company ComAp.

According to ComAp, based in Prague, its new WebSupervisor sys-tem enables the monitoring of equip-ment fitted with various types of ComAp controllers via the Internet from a remote PC or other web-en-abled devices including smart phones, i-phones and/or web book.

The web-based system addresses problems associated with monitoring the status of a large number of assets in the field by centralizing the data onto a secure central server, which the client can then access locally.

“In the modern competitive world, fleet operators are looking to save op-erating costs any way they can,” said Mirek Novotny, ComAp’s product manager. “WebSupervisor helps them meet this goal by coordinating service teams with real time requirements.”

To use the system, the operator goes to the WebSupervisor webpage and after entering a username and password can view remote assets reg-istered to that account.

The fleet’s status can be viewed and operating changes made to op-timize performance. The system can also issue an e-mail alert if needed by the operator.

A view of an active map on WebSupervisor.

Individual users can have assets re-moved or added to their accounts. In-dividual rights can also be controlled, which means remote support teams can view the fleet in their area and coordinate activities locally without needing local infrastructure connect-ed to the remote assets, said ComAp.

Other features include a range of reporting options allowing detailed reports for the individual fleet us-ers and the ability to provide energy production reporting for cogen-eration plants to monitor efficiency and availability.

There is also the option of control-ling multiple embedded generators used by electricity utilities to meet peak demands. The operator can re-motely select which of the generators are part of the scheme and then start them when requested by the utility.

Regular updates via the Internet are provided and individual equipment can be checked to determine operat-ing parameters and alarms, and gen-eral status and historical data can be kept, said ComAp.

It added that the system is aimed specifically at operators of large remote fleets of equipment such as cellular telecoms, generator sets, rental genera-tors, pumps and compressors. A

SEE DIRECTLINK @

WWW.DIESELGASTURBINE.COM

10 November 2010 Diesel & Gas Turbine Worldwide

Power Plant Maintenance by ian cameron

ComAp Launches New Monitoring SystemWeb-based system centralizes data onto a secure server

industry drivers

Ge

RGE Transportation signed a contract with Brazilian rail operator MRS

Logistica S.A. (MRS) for the supply of 115 AC44i locomotives with the option of a fur-ther 100. GE’s Grove City, Pennsylvania, U.S.A., factory will supply the components, which include a 12-cylinder FDL diesel en-gine, while GE Transportation’s Contagem, Brazil, plant will build the locomotives.

The new locomotives, which will be delivered between 2011 and 2015, are designed to reduce greenhouse gas emis-sions and operating costs up to 15%, ac-cording to GE.

man DieSeL & TUrbo

IMAN Diesel & Turbo has signed a four-stroke license agreement with

Rong An Power Machinery, Anhui Prov-ince, Eastern China. The agreement is part of Rong An Power Machinery’s plan to develop into a composite industry park, starting with low-speed diesel production and moving into medium-speed produc-tion. The company ultimately wants to provide products to ship power systems.

The new agreement is the second be-tween the two companies; Rong An Power Machinery signed a two-stroke license agreement with MAN Diesel & Turbo in September 2008. Rong An Power Machin-ery has also started production on the first MAN B&W 6S70MC6 engine.

DreSSer WaUKeSHa

ODresser Waukesha, a manufacturer of natural gas engines, has received

a contract to supply three of its new 16V275GL+ engines to a Horn River Ba-sin gas production site in northeast British Columbia, Canada.

The three 16V275GL+ units rated 3610 kW at 1000 r/min will join three of the company’s 3360 kW 16V275GL engines already on the site. Like the three prior units, Dresser Waukesha’s Canadian dis-tributor, Enerflex Ltd., will package the 16V275GL+ engines.

The 275GL Series engines are designed to simplify and improve packaging, operation and service, said the company. The 275GL engines with the “+” designation include a 0.5 g/bhp-hr NOx capability and 2% better fuel efficiency, Dresser Waukesha said.

continued on page 23

WW103.indd 1 10/15/10 1:34:16 PM

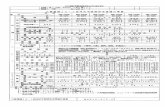

Turbine Tech2010

— SpecS-AT-A-GlAnce —

SponSored By

VM600 System Why monitor your gas turbine?

2010TurbineTechInsert.indd 1 10/13/10 9:34:05 AM

HigHer macHine availability

ALSTOM

ANSALDOENERGIA

CAPSTONE

DONGFANG TURBINE CO. LTD.

GE MARINE

GE OIL & GAS

HARBIN TURBINE CO.

HITACHI

DRESSER-RAND

ELLIOTT

FINCANTIERI

KAWASAKI

GE ENERGY

AVIC HARBIN DONGAN ENGINE (GROUP) CO. LTD.

30029028027026025024023022021020019018017016015014013012011010090807060504030201050

56.2 to 289.1 MW

100 to 1200 MW

75 to 294 MW

80 to 1200 MW

1 to 3 MW

.03 to 10 MW

212 to 400 MW

0.5 to 1000 MW

23.4 to 49.8 MW1.9 to 50.5 MW

0 to 75 MW0 to 100 MW

0.5 to 35 MW0.5 to 35 MW

18 to 280 MW

100 to 1600 MW

4 to 45 MW4 to 42 MW

5 to 100 MW5 to 100 MW

25 to 300 MW

100 to 1000 MW

17 to 31 MW

1.5 to 18 MW

300 to 2600 MW

12 to 130.1 MW11.3 to 126.1 MW

0.02 to 100 MW0.02 to 100 MW

2010TurbineTechInsert.indd 2 10/13/10 9:34:17 AM

Improved machIne effIcIency

MAN DIESEL & TURBO

MITSUBISHI

NIIGATA

NPO SATURN

SIEMENS

SOLAR

URAL

VERICOR

OPRA

POWER MACHINES

ROLLS-ROYCE ENERGY

ZORYA-MASHPROEKT

SHENYANG LIMING AERO-ENGINE

NANJING TURBINE & ELECTRIC MACHINERY

30029028027026025024023022021020019018017016015014013012011010090807060504030201050

6 to 26 MW6 to 13 MW

1.5 to 160 MW1.5 to 160 MW

5.9 to 320 MW

39.62 to 49.35 MW

6 to 330 MW

0.3 to 7.8 MW0.2 to 10.6 MW

4 to 16 MW2.5 to 110 MW

1 to 2 MW

65 to 160 MW

0 to 1000 MW

4.1 to 52.5 MW3.8 to 64 MW

0.95 to 18.5 MW

5 to 32 MW5 to 340 MW

0.04 to 150 MW0.04 to 1900 MW

1.2 to 22 MW1.2 to 22 MW

6 to 25 MW6 to 300 MW

0.05 to 4.5 MW0.4 to 4.3 MW

3 to 25 MW2.5 to 110 MW

Gas TurbIne mechanIcal drIve sTeam TurbIne mechanIcal drIve

Gas TurbIne elecTrIc GeneraTor drIve sTeam TurbIne elecTrIc GeneraTor drIve

2010TurbineTechInsert.indd 3 10/15/10 3:42:07 PM

Reduce life costs throughperformance optimisation

Meggitt Sensing SystemsRoute de Moncor 4

PO BoxCH - 1701 Fribourg

Switzerland

Tel: +41 (0)26 407 11 11Fax: +41 (0)26 407 13 01

www.meggittsensingsystems.com

www.meggitt.com

ww

w.a

pp

yco

mm

un

icat

ion

s.co

m

Meggitt Sensing Systems' integrated protection andcondition monitoring systems for turbo machineryare broadly used and proven. They optimiseoperation in thousands of plants worldwide, with:

• Continuous on-line protection

• Combustor instability control

• Expert systems for predictive maintenance

• Performance monitoring

Our transducers collect and process data in extreme environments (>700oC):

• Widest range of high-temperature vibration sensors

• Range of unique high-temperature dynamic pressure sensors

• Speed probes, air gap monitoring sensors and eddy current probes

see directlink @ www.dieselgasturbine.com

Vibrometer_Nov10WW.indd 1 10/14/10 2:56:45 PM2010TurbineTechInsert.indd 4 10/14/10 3:07:34 PM

ALSTOMAlstom Power Systems3, Avenue MalrauxImmeuble “Sextant,” 92309 Levallois-Perret Cedex, FranceTel: +33-1-41-49-27-22Fax: +33-(0)-1-41-49-27-74E-mail: [email protected]: www.power.alstom.comGas Turbine Power RangeElectric Generator Drive: 56.2 to 289.1 MWSteam Turbine Power RangeElectric Generator Drive: 100 to 1200 MW

ANSALDO ENERGIAAnsaldo EnergiaVia Lorenzi 816152 Genova, ItalyTel: +39-010-6551Fax: +39-010-6556209E-mail: [email protected]: www.ansaldoenergia.itGas Turbine Power RangeElectric Generator Drive: 75 to 294 MWSteam Turbine Power RangeElectric Generator Drive: 80 to 1200 MWRecent Orders

Ansaldo Energia won a contractto supply a power-generation unit based on two AE94.2 gas turbines from Fingrid, the Finnish national operator for the production and dis-tribution of electricity to be built in Forssa, Finland.Company News

The company opened a new gas

ment project for container-type gas tur-bine generating units in 2007. The new QD15 has a rated power of 1.5 MW and a design life of 15 years. Based on the vehicle-mounted gas turbine generator sets, the engineering team focused on performance optimization, structural integration and environmental adapt-ability, the company said. Additional features include resistance against salt fog corrosion, heat and humidity and an anti-mold design to ensure high en-vironmental adaptability and extended product life.

CAPSTONECapstone Turbine Corp.21211 Nordhoff Street Chatsworth, California 91311, U.S.A. Tel: +1-866-4CAPSTONE (USA)Fax: +1-818-936-0523E-mail: [email protected]: www.capstoneturbine.comGas Turbine Power RangeElectric Generator Drive: 30 kW to 10 MWTechnology

Capstone, in conjunction with He-lioFocus, demonstrated a technol-ogy that converts sunlight to elec-tricity with a solar receiver driving a microturbine.

The demonstration was conducted with a C65 microturbine, and the company said the technology could be scalable from Capstone’s C30 to the C100 with output ratings from 30 kW to 5 MW. To generate power, the HelioFocus Solar Concentrator focus-es enough sunlight energy to provide heat to drive the microturbine, which generates electricity.Product News

Capstone’s 1 MW C1000 received UL certification in accordance with UL 2200 and UL 1741. The C1000 features Capstone’s air bearing, remote monitoring and diagnostic capabilities

turbine repair center at the Indus-trial City of Abu Dhabi (ICAD III) in Musaffah. The new service center is called Ansaldo Thomassen Gulf and spans 3200 m2. Shrouds, seals, nozzles and the machining of turbine blades along with coating and heat treatments will all be offered and per-formed at the new workshop.

AVIC HARBIN DONGAN ENGINE (GROUP) CO. LTD.AVIC Harbin Dongan Engine (Group) Co. Ltd.51 Baoguo Street Pingfang DistrictHarbin, Heilongjiang Province 150066, China Tel: +86-451-86572114E-mail: [email protected]: http://www.dongangroup.cnGas Turbine Power RangeElectric Generator Drive: 1 to 3 MWProduct News

Harbin Dongan Engine is a sub-sidiary of Aviation Industry Corp. of China (AVIC). In January 2010, the company announced a container-type gas turbine generator set developed with indigenous efforts has passed validation. According to Dongan, this is the first container-type gas turbine generator set produced in China and has wide applications including ur-ban emergency power generation, medical services, power protection and telecommunications.

Dongan’s product portfolio com-prises both stationary and mobile gas turbine units.

The company launched the develop-

Diesel & Gas Turbine Worldwide November 2010 11

Gas And SteamTurbine Review

continued on page 12

WW093.indd 1 10/15/10 2:20:02 PM

12 November 2010 Diesel & Gas Turbine Worldwide

Turbine Tech 2010

and integrated utility synchronization and protection, said the company.

“We are pleased to have achieved this significant milestone for the new C1000 series product,” said Darren Jamison, Capstone’s president and chief executive officer. “This will open the megawatt scale U.S. market for distributed generation, energy ef-ficiency and renewable biogas solu-tions to Capstone.”Recent Orders

Capstone has been increasing its presence in the gas production are-na with a recent order for 18 C65 microturbines for a large oil and gas company exploring large shale reserves and an order for a C1000 Power Package from an independent oil and natural gas company explor-ing in the Piceance Basin in the Unit-ed States.

Additionally, the company received an order for a C1000 Power Package from an Australian data center. The Power Package is expected to supply 1 MW of prime power.

DOnGfanGTuRbine CO. LTD.

Dongfang Turbine Co. Ltd.No.666, Jin Sha Jiang Xi LuHigh New Technology ParkDeyang City, Sichuan Province618000, China Tel: +86-838-2432114Fax: +86-838-2825968Website: www.dfstw.comGas Turbine Power RangeElectric Generator Drive: 212 to 400 MWSteam Turbine Power RangeElectric Generator Drive: 0.5 to 1000 MWCompany news

In May 2010, just two years after the devastating earthquake struck Si-chuan Province, Dongfang Turbine has completely rebuilt operations at its relocated manufacturing base in Deyang City nearby, 15 months ahead of the scheduled reconstruction plan.

The new manufacturing base boasts 20 workshops spanning over a total area of 660 000 m2. The new facilities are expected to help double the com-

pany’s production to over 20 billion Chinese yuan this year.

On July 1, 2010, trucks carrying Dongfang Turbine’s F-Class gas tur-bine left the Sichuan engine campus and headed for Leshan, an inland port on the Yangtze River. Its final desti-nation was Minsk, capital of the Re-public of Belarus, where installation took place at the No. 5 thermal power plant of the former Soviet state.

Dongfang’s M701f gas turbine.

This represents the 15th M701F gas turbine produced by Dongfang using technology licensed from Mitsubishi Heavy Ind. (MHI) and has a localiza-tion rate of over 70%. The delivery to Belarus signifies a major milestone in China’s export capability in heavy-duty gas turbines. The single-shaft unit has a capacity of 270 MW.

Also in July, Dongfang won the bid for two 350 MW gas-steam combined-cycle installations for the Dazhou Power Plant in Sichuan Prov-ince. This followed the award of a supply contract in June by the GTCC cogeneration facility located in Gao-beidian, near Beijing. The latter order covers two M701F gas turbines and a steam turbine. Delivery of the gas turbines is scheduled in February and March of 2011.

DReSSeR-RanDDresser-RandWest8 Tower Suite 100010205 Westheimer Road Houston, Texas 77042, U.S.A.Cedex 16 Paris 75784, FranceTel: +1-713-354-6100 (U.S.A.);

+33-156-26-71-71 (France)Fax: +1-713-354-6110 (U.S.A.);

+33-156-26-71-72 (France)E-mail: [email protected]: www.dresser-rand.com

Gas Turbine Power Range Mechanical Drive: 23.4 to 49.8 MWElectric Generator Drive: 1.9 to 50.5 MWSteam Turbine Power Range Mechanical Drive: 0 to 75 MWElectric Generator Drive: 0 to 100 MWCompany news

Within the last year, Dresser-Rand has expanded its aftermarket services and capabilities through two acqui-sitions and a memorandum of un-derstanding. Dresser-Rand acquired Leading Edge Turbine Technologies Inc., Houston, Texas, U.S.A.; formed a Memorandum of Understanding with KazTurboRemont in Astana, Kazakh-stan; and acquired assets of Turbo Machines Field Services in Centurion, South Africa. All three deals help the company to grow its global aftermar-ket services and reach. For more infor-mation, see the July-August issued of Diesel & Gas Turbine Worldwide.

Dresser-Rand now offers service guarantee contracts as part of its A+ service package. The service uses a site-service manager, who is responsible for offering Dresser-Rand’s customers 24/7 on-call availability, planning sup-port, maintenance procedure reviews, technical and scheduling coordination within Dresser-Rand, scheduled and unscheduled maintenance oversight, inventory managements, site and ma-chinery audits, performance evalu-ations and access to Dresser-Rand’s web-based training.notable Project

The company also announced thisyear it has been chosen to supply turbomachinery for three different clients for a total of four floating, production, storage and offloading (FPSO) vessels. Three of the vessels will operate in Petrobras’ pre-salt oil fields in the Santos Basin offshore Brazil, and the fourth will operate for the U.K. sector of the North Sea.

In total, Dresser-Rand will supply 14 centrifugal compressor trains compris-ing 18 casings, two DR-61G (LM2500) mechanical drive gas turbines and four DR-61GP (LM2500+) gas turbine gen-erator sets for these projects.

continued on page 14

WW093.indd 2 10/15/10 2:20:21 PM

www.rolls-royce.com

High in power, yet low in mass, the Rolls-Royce Trent 60 keeps the same dimensions whatever its power output. With an engine weighing less than 15 tons, Trent 60 arrives ready to produce 58MW with Dry Low Emissions, 64MW with Wet Low Emissions and up to 107MW when operating with

a steam turbine. Trent 60 also sports the twin Rolls-Royce strengths of unmatched reliability and customer service. For mechanical drive and power generation applications, onshore and offshore, Trent 60 provides the muscle for enduring profitability.

Impressive size to power ratio.

Trusted to deliver excellence

Small on size, big on power.

see directlink @ www.dieselgasturbine.com

RollsRoyce_Nov10WW.indd 1 10/14/10 6:02:39 PM

14 November 2010 Diesel & Gas Turbine Worldwide

Turbine Tech 2010

The compressor trains will be man-ufactured in Le Havre, France, and Olean, New York, U.S.A.; the gas tur-bine generator sets will be engineered by Dresser-Rand’s Kongsberg, Nor-way, gas turbine packaging center of excellence.

ELLIOTTElliott Group901 N. Fourth StreetJeannette, Pennsylvania 15644, U.S.A.Tel: +1-724-527-2811Fax: +1-724-600-8442E-mail: [email protected]: www.elliott-turbo.comSteam Turbine Power RangeElectric Generator Drive: 0.02 to 100 MW Mechanical Drive: 0.02 to 100 MWRecent Orders

Elliott has received two orders for compressor trains that also feature the company’s steam turbines.

The Elliott Group will supply the compressor trains for a 1.1 MTPA ethylene plant to be built in Dahej, India. The contract was awarded by The Linde Group of Germany. To-gether with consortium partner Sam-sung Engineering of Korea, Linde will build the turnkey plant for India’s ONGC Petro-additions Ltd. (OPaL). Elliott will supply the main cracked gas compressor train, including three of Elliott’s largest compressors, an 88MD2, an 88M4 and a 60M4/4I driven by an Elliott 2SNV-10 steam turbine with a rating of 65 MW. In addition to the cracked gas compres-sor train, the contract includes an ethylene compressor train consisting of a 70M8-6 compressor driven by an SNV-8 steam turbine, and a pro-pylene compressor train consisting of a 46M9-8 compressor and a 56M6I compressor driven by an SNV-6 steam turbine.

Elliott also won a contract to sup-ply 16 compressor trains for the Hab-shan 5 Process Plant, a part of Abu Dhabi Gas Industries (GASCO) inte-grated gas development (IGD) project in Ruwais, Abu Dhabi, United Arab Emirates. The contract was awarded by JGC Corp. and its venture partner

Tecnimont, the engineering procure-ment contractors for the new process-ing plant. Elliott will provide 16 com-pressor trains for the gas processing unit, with a variety of fixed speed and variable speed motor drives, as well as steam turbine drives, for seven dif-ferent services.

FINCANTIERIFincantieri — Cantieri Navali Italiani S.p.A.Fincantieri Marine Systems Business UnitVia Cipro 1116129 Genoa, ItalyTel: +39-010-599-5353Fax: +39-010-599-5352E-mail: [email protected]: www.fincantieri.comSteam Turbine Power RangeElectric Generator Drive: 0.50 to 35 MWMechanical Drive: 0.50 to 35 MW

GE ENERGYGE Energy1 River RoadSchenectady, New York 12345, U.S.A.Tel: +1-518-385-4593E-mail: [email protected]: www.ge-energy.comGas Turbine Power RangeElectric Generator Drive: 18 to 280 MWSteam Turbine Power RangeElectric Generator Drive: 100 to 1600 MWCompany News

GE Energy redesigned its Frame 7FA gas turbine to reduce power plant operators’ total cost of owner-ship and environmental impact by reducing the amount of fuel required to generate power. A typical power plant operating with two new 7FA gas turbines with a single steam tur-bine in a combined-cycle configura-tion could achieve a fuel cost savings of more than US$2.1 million per year at a natural gas price of US$6 per MMBtu, when compared to a similar plant using an earlier version of the 7FA, said GE.

GE also continues to expand its range of fuel-flexible gas turbines, in-troducing a heavy fuel oil availability package for Frame 7EA and 9E gas

turbines. Three Frame 9E gas turbines with the flexibility to burn heavy fuel oil will help the Kenitra Power Plant in Morocco meet increasing demand for electricity.

Further demonstrating the fuel flex-ibility focus, the company recently announced plans to supply a Frame 7EA gas turbine for a proposed waste energy recovery plant in Middletown, Ohio, U.S.A. This plant will produce power using low Btu byproduct gas from the adjacent AK Steel Corp. Middletown Works blast furnace.

To support the ongoing technol-ogy advancements in its gas turbine fleet, GE is expanding its gas turbine test capability at its Greenville, South Carolina, U.S.A., facility. The new test stand will enable GE to test new gas turbines under real-world condi-tions and beyond its normal operat-ing envelope.

Steam turbine technology devel-opment also continues with GE’s enhanced D-series combined-cycle steam turbines now providing inlet pressure capabilities up to 165.5 bar along with its High Efficiency Ad-vanced Technology (HEAT) exceed-ing 32 000 hours of operation.Recent Orders

GE will provide advanced Frame 6FA gas turbines for the Salalah Indepen-dent Water and Power Project, which is helping to support economic growth in the Dhofar region of southern Oman. The GE technology will help Oman’s citizens meet their rising demands for reliable power and usable water.

GE Energy redesigned its Frame 7FA gas

turbine.

GE will also supply power genera-tion equipment and services for two independent power projects in the

continued on page 16

WW093.indd 3 10/15/10 2:45:54 PM

» www.dresser-rand.comThe Americas: (Int’l +1) 713-354-6100 / EMEA: (Int’l +33) 2-35-25-5225Asia-Pacifi c: (Int’l +60) 3-2093-6633 / [email protected]

GREEN ENERGY IS ALL AROUND YOU. YOU JUST NEEDTO KNOW WHERE TO LOOK.

Clients are looking for green energy solutions with high reliability, low maintenance and maximum effi ciency. Dresser-Rand has considerable experience in steam turbine systems for combined cycle, cogeneration and waste-to-energy, among other applications. Our turbine generator sets feature rugged designs and produce power for pulp and paper, sugar, hydrocarbon and process industries, as well as universities and municipalities. If your vision is to develop clean, renewable energy, turn to Dresser-Rand and see what we have to offer.

Bringing energy and the environment into harmony.®

62784_DR_PowerGenAd10_DGTW.indd 1 9/14/10 3:46 PM

see directlink @ www.dieselgasturbine.com

Untitled-1 1 9/20/10 2:10:15 PM

16 November 2010 Diesel & Gas Turbine Worldwide

Turbine Tech 2010

Kurdistan region of northern Iraq. These projects will help support the region’s current and future power needs and the country’s overall efforts to develop its energy infrastructure.

Two Frame 7FA gas turbines will be used in the conversion of a conven-tional power plant into the first large-scale cogeneration plant in Mexico. The project supports the Mexican government’s initiative to promote co-generation as a key step in improving the efficiency of the country’s energy infrastructure.

GE shipped its first two 7F Syn-gas turbines to the Duke Energy IGCC facility in Edwardsport, Indi-ana, U.S.A. GE technology is help-ing Duke build a clean and efficient coal-fired power plant.

GE signed a service alliance with the Tennessee Valley Authority (TVA), the largest public power producer in the United States, covering TVA power plants over the next five years. The alliance will help TVA meet its strategic needs by ensuring the long-term reliability, efficiency and cost-effective operation of its power gen-eration equipment.

GE MARINEGE MarineOne Neumann WayMail Drop S-156Cincinnati, Ohio 25215, U.S.A.Tel: +1-513-552-5375Fax: +1-513-552-5005E-mail: jeff.mol,[email protected]: www.ge.com/marineGas Turbine Power RangeMechanical Drive: 4 to 45 MWElectric Generator Drive: 4 to 42 MWRecent Orders

In 2009, GE’s LM2500 gas turbine celebrated its 40-year anniversary in service with the United States Navy. The LM2500 gas turbines continue to be applied in a variety of naval con-figurations worldwide.

For instance, USS Makin Island (LHD 8) was commissioned by the U.S. Navy in late 2009 in San Diego, California, U.S.A. The vessel is pow-ered by two LM2500+ gas turbines and two diesel-electric generators in

a unique hybrid propulsion system. The U.S. Navy reported that the ves-sel’s hybrid propulsion arrangement will help save millions in fuel and maintenance costs.

The U.S. Navy will also use GE’s LM2500 gas turbines to power nine of its new Flight IIA ships under the DDG 51 Arleigh-Burke destroyer pro-gram. Separately, the U.S. Navy has ordered an additional 16 digital fuel control kits for LM2500 gas turbines aboard four ships.

GE’s LM2500 gas turbine celebrated its 40-

year anniversary in service with the United

States Navy.

In May 2010, the U.S. Coast Guard commissioned its USCGC Waesche at its home port of Alame-da, California, U.S.A. The second National Security Cutter is powered by one LM2500 in a COmbined Diesel And Gas (CODAG) turbine arrangement that propels the ship to speeds greater than 28 knots.

In the international naval arena, the Indian Navy commissioned the INS Shivalik stealth frigate powered by two LM2500s in a combined diesel or gas turbine configuration.

For the Royal Australian Navy (RAN), GE reported it completed acceptance testing on the first LM2500 gas turbine for the Air Warfare Destroyer (AWD) program. Each of the three AWDs to be built will be powered by two LM2500s in a CODAG arrangement.

The Republic of Korea Navy con-tinues the second phase of its PK(X) patrol boat program, employing GE’s LM500 gas turbines in a CODAG ar-rangement. GE is also providing on-going support throughout installa-tion, sea trials and commissioning.

GE OIL & GASGE Oil & GasNuovo Pignone S.p.A.Via Felice Matteucci, 2, 50127 Florence, ItalyTel: +39-055-423-2646Fax: +39-055-423-2800E-mail: [email protected]: www.ge.com/oilandgasGas Turbine Power RangeElectric Generator Drive: 11.3 to 126.1 MWMechanical Drive: 12 to 130.1 MWSteam Turbine Power RangeElectric Generator Drive: 5 to 100 MWMechanical Drive: 5 to 100 MWRecent Orders

GE Oil & Gas signed a three-year frame agreement with E.ON Ruhrgas A.G., the largest distributor of gas in Germany, for supply of new and re-placement turbocompression systems for gas transportation and storage projects worldwide.

The company also signed contracts to supply PGT25+G4 gas turbines, rated 34 MW each, and centrifugal compressors, as well as long-term service, to PNG LNG for two LNG trains at the Hides gas conditioning plant in Papua, New Guinea. The service contract covers the mainte-nance of 13 turbocompressor trains and other benefits, said GE. The PNG LNG project includes gas production and processing facilities, onshore and offshore pipelines and liquefaction facilities with the capacity of 6.6 mil-lion tons per year.

In another agreement JSC ZKMK, the Kazak precision engineering plant operator, will service GE’s fleet of oil and gas turbomachinery equipment installed in the Republic of Kazakh-stan and the Central Asia region. ZKMK will perform repair services on GE’s range turbines and centrifugal

WW093.indd 4 10/15/10 2:20:56 PM

Diesel & Gas Turbine Worldwide November 2010 17

Turbine Tech 2010

compressors installed in Kazakhstan and neighboring countries, including Kyrgyzstan, Turkmenistan, Uzbeki-stan and Azerbaijan.

GE Oil & Gas was awarded a US$160 million contract to supply gas turbine and compressor equip-ment to Petrobras Netherlands BV (PNBV), a subsidiary of Petrobras, for deployment in two FPSO units for exploration and production offshore Brazil. GE will supply eight 31.1 MW PGT25+ gas turbine generator sets and 12 motocompressor trains (either LP or HP) for the two vessels of up to 200 bar discharge pressure for natu-ral gas export/gas lift.

In addition, Slovensky Plynarensky Priemysel contracted GE to upgrade three pipeline compression stations that are part of a gas pipeline sys-tem in the Slovak Republic operated by Eustream, which is 100% owned by SPP. GE is supplying SPP with advanced dry-low emission systems technology and additional equip-

ment for the conversion of seven GE PGT25 gas turbines and one PCL602 gas compressor. The upgrade proj-ects will be implemented over the next five years, as the seven gas tur-bines progressively reach 50 000 operating hours. The final two units will be modified by 2015. The units feature LM2500 aeroderivative gas turbines that will be converted from standard annual combustors to dry-low emission systems for improved emission control. Upon upgrade they will achieve NOx emissions below 75 mg/m3 enabling the plants to meet the new emission regulations.

In addition, GE was awarded a contract by Hyundai Engineering & Construction Co. to supply eight gas turbines and related services for the Abu Dhabi Gas Industries (GASCO) integrated gas development project at Habshan in Abu Dhabi. Combined, the eight GE Frame 6B gas turbine units will provide more than 250 MW of power for the Habshan 5 plant.

Company NewsGE Oil & Gas entered into an

agreement to acquire a minority eq-uity interest in Shenyang Turbo Ma-chinery Corp., a large-scale Chinese state-owned enterprise dedicated to the design and manufacture of turbo-machinery equipment and the main operating subsidiary of Shenyang Blower Works Group Company Ltd. (SBW Group).

HARBIN TURBINE CO.Harbin Turbine Co.No. 345, Sanda Dongli RoadXiangfang District, HarbinHeilongjiang Province150046, ChinaTel: +86-0451-82953445,

8295345E-mail: [email protected]: www.htc.com.cnGas Turbine Power RangeElectric Generator Drive: 300 to 2600 MW

continued on page 18

Available for purchase.LM2500 Gas Turbine Generator

Coatings / Repairs / Parts

Strengthen your power producing capabilities with this reliable LM2500 Gas Turbine Generator. Only 7,144 hours of operation since new.

For specs, information and inquiries, please call Doug Barr, Regional Sales Director, at 713.255.0666 (offi ce) or 832.794.0321 (cell), or visit chromalloy.com/LM2500

CHRR 14855 DGTW_6.75x4.75_4C.indd 1 9/8/10 1:28 PM

Chromally.indd 1 9/8/10 1:42:43 PM

see directlink @ www.dieselgasturbine.com

WW093.indd 5 10/15/10 2:21:19 PM

18 November 2010 Diesel & Gas Turbine Worldwide

Turbine Tech 2010

Steam Turbine Power RangeElectric Generator Drive: 25 to 300 MWCompany News

HTC’s parent company Harbin Power Equipment Co. Ltd. (HPEC) is listed in Hong Kong. In the first half of 2010, HPEC acquired contracts worth a total of 15.43 billion Chinese yuan (US$2.29 billion), an increase of 17% over the same period last year.

In the six-month period from Janu-ary to June 2010, the company deliv-ered 26 steam turbines with a totaling capacity of 10.74 GW, 22 steam tur-bine generator sets with a total capac-ity of 8.72 GW and 18 water turbine generator sets with a total capacity of 1.85 GW.

According to Wu Weizhang, gen-eral manager of HPEC, as of early Au-gust, the company has uncompleted contracts worth 98 billion Chinese yuan (US$14.5 billion). About 50% of this total contract value is account-ed by thermal power equipment.

HITACHIHitachi Ltd.1-18-13 SotokandaChiyoda-ku, Tokyo101-8608, JapanTel: +81-3-4564-6139Fax: +81-3-4564-6179E-mail: [email protected]: www.hitachi.com/products/index.html, www.hitachi.comGas Turbine Power RangeElectric Generator Drive: 17 to 31 MWSteam Turbine Power RangeElectric Generator Drive: 100 to 1000 MW

KAWASAKIKawasaki Heavy Industries Ltd.Gas Turbine DivisionKawasaki-choAkashi-shi, 673-8666, JapanTel: +81-78-921-1842Fax: +81-78-923-6541Website: www.khi.co.jp/gasturbine/index_e.htmlGas Turbine Power RangeElectric Generator Drive: 1.5 to 18 MW

Product NewsKawasaki Heavy Industries Ltd.

has developed a 1.7 MW class gas turbine engine — the M1A-17 — designed for high efficiency and low emissions. Kawasaki is targeting the new turbine for regional heat and power, factories, universities and other utility applications.

The development of the M1A-17 is based on the 1.5 MW class M1A-13 gas turbine engine that was launched in 1988. The M1A-13 has an installed base of 320 units (Japan: 150 units, elsewhere: 170 units) de-livered to date.

Electric output and thermal efficien-cy of the M1A-17 have been improved by approximately 13% and 10%, re-spectively, compared with the current M1A-13 model, said Kawasaki. In ad-dition, the M1A-17 is able to reduce NOx emissions by about 50% to 15 ppm with its low NOx type dry-low emission (DLE) combustion system.Company News

Since 1976, Kawasaki has delivered more than 7000 baseload (GPB) and standby (GPS) gas turbine genera-tor sets around the world. Kawasaki baseload gas turbine generator sets have been installed in various indus-tries such as textile, petrochemical, pulp and paper, as well as at hotels, hospitals, universities, and regional heat and power providers utilizing combined heat and power.

Kawasaki provides industrial gas turbines for the domestic Japanese market and the European, North and South American, Asian as well as the Middle East markets and plans to ex-pand its business with the coopera-tion of its regional sales affiliates.

MAN DIESEL & TURBOMAN Diesel & Turbo SESteinbrinkstrasse 146145 Oberhausen, GermanyTel: +49-208-692-01Fax: +49-208-692-2019E-mail: [email protected]: www.mandieselturbo.comGas Turbine Power RangeMechanical Drive: 6 to 26 MWElectric Generator Drive: 6 to 13 MW

Steam Turbine Power RangeMechanical Drive: 1.5 to 160 MWElectric Generator Drive: 1.5 to 160 MWCompany News

The merger between MAN DieselSE and MAN Turbo AG to form MAN Diesel & Turbo SE, based in Augsburg, Germany, was completed in March 2010. By combining the product portfolios of the two firms, the merged company aims to grow and strengthen its position in the market. See the April 2010 edition of Diesel & Gas Turbine Worldwidefor more information.

MAN Diesel & Turbo’s gas turbine and screw compressor package flow line at its Oberhausen, Germany, facil-ity is now fully operational. The pack-aging process is independent from core engine production and enables the company to further reduce the lead times for customer equipment. Gas Turbines

The THM family now covers the power range from 9 to 13 MW. In-dependent of power output, all THM engines have the same frame size. This enables MAN Diesel & Turbo to upgrade existing gas turbine instal-lations by simply replacing the core engine alone.

The THM gas turbines can operate on a wide range of gaseous and liquid fuels, including methanol. In addition, a new lean premix combustion system has been developed and is now operat-ing successfully in a field application. With a compact design, the new com-bustion system is suitable for retrofit on existing machines. Low emissions are achieved in a wide power output range from 50 to 100% load without any part-load efficiency penalty.

A new gas turbine for the 6 to 8 MW power range has been de-veloped and is now in the engine testing phase. This gas turbine is suitable for mechanical drive and generator drive applications. Steam Turbines

The company has recently received an order for the supply of a steam tur-bine generator set with a power out-put of 50 MW from the Spanish Guz-

WW093.indd 6 10/15/10 2:21:33 PM

Diesel & Gas Turbine Worldwide November 2010 19

Turbine Tech 2010

man Energia S.l. It is planned to start generating electricity in spring 2012.

Masdar Abu Dhabi Future Co., Abu Dhabi, ordered a 125 MW steam tur-bine from MAN Diesel & Turbo for the Shams 1 power plant in Medinat Sayed, about 150 km from the capital Abu Dhabi.

MAN’s steam turbines can operate with so-

lar power.

MAN Diesel & Turbo has also sup-plied an 80 MW steam turbine to a waste-to-energy plant in southeast London, England. Beginning in 2011, the facility aims to generate energy from 585 000 tons of municipal and industrial waste per year. The 80 MW steam turbine will deliver electricity to around 66 000 households per year.

MAN Diesel & Turbo has also fo-cused on the energy-efficient use of waste heat and other waste products from industrial processes. As examples, two orders from a major Latin Ameri-can company commissioned MAN Diesel & Turbo to construct, supply and commission two complete steam turbine trains. The surplus electricity generated can be fed into the mains, for which an infeed payment is received.

MITSUBISHIMitsubishi Power Systems Americas Inc.100 Colonial Center ParkwaySuite 500Lake Mary, Florida 32746, U.S.A.Tel: +1-407-688-6100Website: www.mpshq.com

Gas Turbine Power RangeElectric Generator Drive: 5.9 to 320.0 MWGas Turbines

Mitsubishi Heavy Industries (MHI) has introduced the upgraded 50 Hz F Class M701F4 gas turbine, leading to higher turbine inlet temperature and increased air flow. The first up-dated M701F4 was installed at the Sendai plant in Japan. The combined cycle, incorporating the new turbine, is rated 446 MW and is installed in a single-shaft combined-cycle plant. MHI said the upgrades to the turbine design produce fewer emissions.Recent Orders

MHI has received an order for two sets of supercritical-pressure coal-fired boilers (pressure-containing parts) and steam turbine/generators from Jaiprakash Power Ventures Ltd. (JPVL) of India. The equipment will be deliv-ered for the power generation plant Units 1 and 2, at 660 MW each, to be constructed by JPVL in Nigrie, in Mad-hya Pradesh State, as part of a project aimed at easing electricity shortages associated with the region’s robust economic growth. Delivery of both sets is slated for the fiscal year ending March 2012.

The company also received an order for three sets of supercritical-pressure coal-fired boiler and steam turbines/generators from Maharashtra State Power Generation Co. Ltd. (Mahagen-co) of India. The equipment will be delivered for Units 8, 9 and 10, 660 MW each. Trial operations of Unit 8 are scheduled to begin in late 2013, followed by Unit 9 around mid-2014 and Unit 10 in late 2014. MHI will manufacture the core components of the boilers and turbines.

In another order, MHI will supply major components of natural gas-fired gas turbine combined-cycle (GTCC) power generation systems with heat supply capability, which will be in-stalled in a cogeneration facility to be built by Huaneng Power International Inc., one of the major electricity pro-viders in China. The order was placed through Dongfang Turbine Co. Ltd., a power generation equipment manu-

facturer in China, to which MHI has licensed its gas turbine technology. MHI will provide two M701F gas tur-bines as well as major components of a steam turbine. Delivery of the gas turbines is scheduled in February and March of 2011.

The facility with 920 MWe during the summertime, or 830 MWe as well as 660 MWt during the wintertime, will provide electricity and heat to meet the fast-growing demands in the nation’s capital city and surrounding area.

For the facility MHI will specifically supply two gas turbines, control system components and steam turbine compo-nents. Dongfang Turbine will deliver the gas turbine auxiliary system, steam turbine and its auxiliary system to Huaneng Power International through Dongfang Electric Corp., the parent company of Dongfang Turbine.

MHI and Marubeni Corp. have jointly received an order for two sets of a steam turbine and generator, 1000 MW each, for ultra-super-critical-pressure coal-fired power generation units of Korea East-West Power Co. Ltd. The two turbine/generator sets will be installed in the Unit #9 and #10 power plants under construction at EWP’s existing Dangjin Coal Fired Power Complex. Delivery of the tur-bines and generators is slated to begin in 2013.Company News

MHI has acquired a 40% equity stake in ATLA S.r.l., an Italian gas turbine parts manufacturing and re-pair company, to further enhance its operational structure for gas tur-bine maintenance services in Europe. Through collaboration with ATLA, MHI aims to boost its competitive-ness in the European power systems market by providing inspection and maintenance services for gas turbine components that are exposed to very high temperatures.

NANjING TURBINe & eleCTRIC MACHINeRy

Nanjing Turbine & Electric Machinery (Group) Co. Ltd. No. 80, Middle North Road

continued on page 20

WW093.indd 7 10/15/10 2:21:59 PM

20 November 2010 Diesel & Gas Turbine Worldwide

Turbine Tech 2010

Nanjing City, Jiangsu Province210007, China Tel: +86-025-84066020; 84066021Fax: +86-025-84066026E-mail: [email protected]: www.ntcchina.comGas Turbine Power RangeMechanical Drive: 39.62 to 49.35 MWSteam Turbine Power RangeElectric Generator Drive: 6 to 330 MWCompany News

In August 2010, assembly work on the first industrial steam turbine developed by Nanjing Turbine be-gan. The steam turbine forms part of the C330MW generating set and features a 50% capacity boiler feed pump. Machining of various com-ponents, including the high-pres-sure cylinder block, rear cylinder block, bearing seat and low-pres-sure nozzle set were all handled by an internal workshop.

For the month of August, the steam turbine division completed produc-tion of 11 steam turbines, including one 135 MW steam turbine, five high-pressure steam turbines and five con-ventional steam turbines. Such high monthly output during a high-temper-ature season is unprecedented in the company’s history, said Nanjing.

NIIGATANiigata Power Systems Co. Ltd.9-7, Yaesu 2-chomeChuo-ku, Tokyo104-0028 JapanTel: +81-3-6214-2800Fax: +81-3-6214-2809E-mail:[email protected]: www.niigata-power.comGas Turbine Power RangeMechanical Drive: 0.3 to 7.8 MWElectric Generator Drive: 0.2 to 10.6 MW

OPRAOPRA TurbinesOpaalstraat 60 7554 TS HengeloNetherlandsTel: +31-742452121Fax: +31-742452120

E-mail: [email protected]: www.opraturbines.comGas Turbine Power RangeElectric Generator Drive: 1 to 2 MWCompany News

OPRA Turbines develops, manufac-tures, markets and services power gen-erating sets in single or multiple instal-lations to cover electric power demand from 1.5 to 10 MW. The generator sets are designed for power generation in oil and gas, industrial, commercial and ma-rine applications. The core of the power generating sets is the unique OPRA all-radial single-shaft gas turbine OP16-3A/B rated from 1.5 to 2.0 MWe.

The combustion technology has been given particular attention both for multifuel capability and low emissions. The demands for the use of alternative fuels have led to the development of a combustor for burning low calorific fuels, such as biofuels. Due to the re-versed flow position of the combustion system, the extended cans required for these fuels fit into the general enclosure of the turbine. OPRA’s continuous re-search and development in DLE com-bustion technology has also enabled single-digit level of NOx on gas fuel.

In addition, a new combustor has been developed to achieve 100 ppmv NOx at 15% O2 on marine diesel fuel for ship-borne applications.