Development of Dissolution Methodology for Dry …batches. Decreasing API particle size results in...

Transcript of Development of Dissolution Methodology for Dry …batches. Decreasing API particle size results in...

Pfizer Global Research & DevelopmentSandwich Kent CT13 9NJ DCoE

Devices Centre of Emphasis

Development of Dissolution Methodology for Dry Powder Inhalation AerosolsJason Mees, Craig Fulton, Suzanne Wilson, Nicola Bramwell, Marilyn Lucius & Andrew Cooper

Inhaled Product Development, Devices Centre of Emphasis, Pfizer Worldwide R&D, Sandwich, CT13 9NJ, UK

Introduction

Experimental

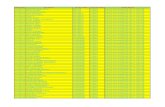

Results: Effect of API Size on Dissolution Rate Ongoing Work

In recent years, a number of authors have described the development of methodology to assessin-vitro dissolution of the respirable fraction of inhaled products1-5. The respirable dose istypically captured either using a filter or modified stage within a cascade impactor. Dissolutionmeasurement is carried out using flow-through, diffusion cell or paddle apparatus. None ofthese methods can be regarded as standard; and each has strengths and limitations6. In-vitrodissolution testing has obvious application in the development of modified release inhaledproducts, where a link to in-vivo performance has been demonstrated7. The significance ofdissolution for in-vivo performance of conventional inhaled products has yet to be established.The small size of respirable particles is likely to enable rapid dissolution. Nevertheless,dissolution may be a factor limiting in-vivo absorption of very poorly soluble molecules8,representing a potential obstacle to development of such drugs.

The methodology described here differs from that previously published in the combination ofapproaches used for dose collection and dissolution measurement. The dose is collected usinga filter inserted above stage 3 of the NGI, an approach described previously by Davies &Feddah1 and by Riley et al2.. This approach was preferred to the alternative published approachof capturing particles on the impaction stages (as described by Son et al3,4 and Arora et al5 ) asit allows dissolution assessment on the entire fine particle dose as a single fraction anddisperses the dose over a greater surface area. A stainless steel filter is used in preference toglass fibre used by previous authors, as this was found to be more compatible with the selectedpaddle dissolution apparatus. A “paddle over disk” dissolution set-up was found to be morepracticable and robust than the flow-through approach described by previous authors.

Using the above approach, a dissolution method has been developed for a drug in a dry powderinhaler formulation. This drug has very low aqueous solubility (<0.1 µg/ml). A surfactant-containing medium was therefore used to maintain sink conditions and achieve a measurabledissolution rate. The use of a surfactant in the medium has a degree of bio-relevance, since highsurfactant levels are known to be present in the lungs. These modify surface tension of the lungtissues to aid with breathing and may play a part in absorption of hydrophobic drugs9.

The capability of the method has been demonstrated by application to formulations containingingoing API of differing particle size.

A number of factors have been shown to affect the accuracy and reproducibility of the dataobtained from the method described. Work is ongoing to refine the methodology to addressthese sources of variation.

• Recovery of Fine Particle Dose: Recovery of the fine particle dose by the filter typicallyvaries between individual replicates from 50 to 80% of the expected FPD. This source ofvariability is addressed by expressing the dissolution profile as % of total dissolved.Significant amounts of the fine particle fraction pass downstream into the lower NGI stages,and give a distribution between the stages similar to that from a conventional NGIdetermination on the same formulation. This indicates that the sample collected on the filteris representative of the whole, nevertheless complete recovery of the FPD for dissolutionwould be desirable.

• Filter Orientation in the Dissolution Bath: Slower dissolution is observed if the filter isplaced collection-side down in the dissolution bath. Controlling the orientation of the filterwhen it is dropped in the dissolution bath is therefore required.

• Effect of Mass on Dissolution Rate: As shown in Figure 3, a slower relative dissolution rateis observed when greater mass of a given formulation is collected on the filter (achieved byvarying the number of actuations). This effect has been reported by other workers usingalternative approaches4,5 , and is thought to be due to formation of in-situ agglomerates onthe filter during dose collection, so that the entire drug surface area is not fully exposed to themedium during dissolution. This effect creates a challenge when comparing formulationswith differing fine particle fractions.

Fine Particle Dose Collection

A stainless steel filter was placed above thestage 3 nozzles in the body of the NGI (Fig.1(a)). Two actuations of the per dry powderinhaler device were performed at 60 Lpm to givea measurable drug loading on the filter.

Filter

Figure 2 shows dissolution profiles obtained from a series of batches of the same lactose-basedDPI formulation manufactured using ingoing API batches of differing particle size (determined bylaser diffraction). The dissolution method is shown to be capable of discriminating between thesebatches. Decreasing API particle size results in increasing dissolution rate, as expected fromtheory (e.g. Noyes-Whitney equation),

Figure 2. Effect of API particle size on dissolution rate of a low-solubility drug in a dry powder inhaler formulation

Figure 3. Effect of mass on dissolution rate

AB

Fig. 1 (a) Fine particle dose collection in the NGI (b) Paddle dissolution set-up

References

• In-vitro dissolution methodology has been developed for a dry powder inhaler (DPI) product in which the fine particle fraction is collected on a filter placed above the nozzles at stage 3 of the Next Generation Impactor (NGI) and dissolution is carried out using standard paddle dissolution apparatus.

• Discrimination could be observed between formulations of a low solubility drug varying in particle size distribution of ingoing active pharmaceutical ingredient. As expected, smaller ingoing API size resulted in faster dissolution of the respirable fraction.

• Work is ongoing to address a number of challenges with the methodology, including variable recovery of the fine particle fraction and dependence of dissolution rate on mass loading.

1. Davies NM, Feddah MR, Int J Pharmaceutics 255 175-187 (2003).2. Riley T, Jones AR, Bogalo Huescar M, Roche TC, Respiratory Drug Delivery 2008 p.541.3. Son Y-J, McConville JT, Int J Pharmaceutics 382 15-22 (2009).4. Son Y-J, Horng M, Copley M, McConville JT, Dissolution Technologies May 2010 pp.6-12.

Dissolution Testing

After FPD capture the filter was removed from the NGIbody and placed into one of the vessels of a USP 2dissolution bath (Fig. 1(b)) containing 400ml of dissolutionmedium: 20 mM piperazine-1,4-bis(2-ethanesulfonic acid)(PIPES) buffer pH 6.8 containing 134 mM sodium chlorideand 5 mM sodium dodecyl sulfate (SDS). The bathtemperature was set to 37ºC and the paddle speed 50 rpm.An automated fraction collector was used to take samplesat periodic time intervals up to 16h. The resulting solutionswere analysed by UPLC.

0%

10%

20%

30%

40%

50%

60%

70%

80%

90%

100%

0 2 4 6 8 10 12 14 16

% D

isso

lved

Time, h

API D50 = 1.3 µm

API D50 = 1.9 µm

API D50 = 2.5 µm

Error Bars = 90% CI

7. Hochhaus G, Möllmann H, Derendorf H, Gonzalez-Rothi RJ, J Clin Pharmacol 37 881-892 (1997).

8. Schurch S, Lee M, Gehr P, Pure Appl Chem 64 1745-1750 (1992).

5. Arora D, Shah KA, Halquist MS, Sakagami M, Pharm Res 27 786-795 (2010).6. Riley T, Christopher D, presented at IPAC-RS Conference, Mar 28-30 2011, Bethesda, MD.7. Coowanitwong I, Arya V, Patel G, Kim W-S, Cracum V, Rocca JR, Singh R, Hochhaus G, J Pharm

Pharmacol 59 1473-1484 (2007).

0%

10%

20%

30%

40%

50%

60%

70%

80%

90%

100%

0 0.5 1 1.5 2 2.5 3 3.5 4

% D

isso

lved

Time, h

1 actuation2 actuations5 actuations10 actuations