Developing business models for efficient use of biomass · Jedlicze petroleum refinery in...

Transcript of Developing business models for efficient use of biomass · Jedlicze petroleum refinery in...

Public

Dr. Gloria GaupmannPublic Affairs, Technology & Innovation22.10.2019

IEA Bioenergy ExCo84

Workshop

Developing business models

for efficient use of biomass

Clariant Presentation, 01.10.2019Clariant Presentation, 01.10.2019

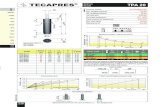

Clariant at a Glance – A Globally Leading Company in Specialty Chemicals

Public, Performance, Growth and Innovation2

Business Areas

Net result 2018 (CHF m)

from continuing operations

Sales 2018 (CHF m)

from continuing operations

4 404

213

3 17901EBITDA 2018 (CHF m)

after exceptionals from

continuing operations

13.8%

605

EBITDA margin 2018

after exceptionals from

continuing operations

Employees 2018

(including discontinued operations)

154companies countries

53in

(including discontinued operations)

Dr. Gloria Gaupmann, Public Affairs, Technology & Innovation, 22.10.2019

33

sunliquid® technology platform providing access to 2nd generation sugars and biofuels made from agricultural residues

CELLULOSIC

ETHANOL

biotechnology

BIO-BASED

CHEMICALS

catalytic conversionCELLULOSIC

SUGARS

SUNLIQUID®

biotechnology

catalytic conversion

sunliquid® TECHNOLOGY

− Sugar platform standalone

− Development opportunities

for bio-based products

− Extensive know-how in

biocatalysis, strain optimization

and heterogenous catalysis

Confidential, Developing business models for efficient use of biomass

AGRICULTURAL

RESIDUES

SUNLIQUID®

biotechnology

Dr. Gloria Gaupmann, Public Affairs, Technology & Innovation, 22.10.2019

Clariant flagship

commercial plant

Romania

First license

commercial plant

Slovakia

sunliquid® commercial plants footprint in EU

4

• Clariant’s own investment in cellulosic EtOH flagship plant

• Greenfield site in Podari, Romania (near Craiova)

• Plant capacity 50,000 tpa

• Processing 250,000 tons of straw annually

• Investment value: over 100 million Euros

• Construction completion in 2020

• Receives funding from the European Commission

and the Bio-Based Industries Joint Undertaking*

• First sunliquid® cellulosic EtOH license plant

• Acquired by Slovakia’s biggest EtOH producer, Enviral

• 2G plant to be integrated into the existing 1G facilities at Enviral’s

Leopoldov site in Slovakia

• Plant capacity 50,000 tpa

• Project based on excellent test results of Enviral’s feedstock at Clariant’s

pre-commercial sunliquid® plant in Straubing (GER)

1G 2G

* The project receives funding from the European Union’s Seventh Framework Program for research, technological development and demonstration under Grant Agreement no. 322386 (FP7 SUNLIQUID)

and from the Bio-Based Industries Joint Undertaking under the European Union's Horizon 2020 research and innovation program under Grant Agreement no. 709606 (BBI LIGNOFLAG)

2G

Second license

commercial plant

Poland

• Second sunliquid® cellulosic EtOH license agreement signed on 20th September 2019

• Acquired by ORLEN Południe, a member of ORLEN group, the leading player in the fuels and energy market & largest company in CEE

• 2G plant to be integrated into the existing Jedlicze petroleum refinery in south-eastern Poland

• Plant capacity 25,000 tpa

• Using locally sourced feedstock such as straw

Oil 2G

Confidential, Developing business models for efficient use of biomass

Dr. Gloria Gaupmann, Public Affairs, Technology & Innovation, 22.10.2019

5 Confidential, Developing business models for efficient use of biomass

Where we come from: Burning straw on the fields

Pictures taken in Romania.

Dr. Gloria Gaupmann, Public Affairs, Technology & Innovation, 22.10.2019

sunliquid® flagship plant progress: en route to commercialization

6 Confidential, Developing business models for efficient use of biomass

* The project receives funding from the European Union's Seventh Framework Program for research, technological development and

demonstration under Grant Agreement no. 322386 (FP7 SUNLIQUID) and from the Bio-Based Industries Joint Undertaking under the

European Union's Horizon 2020 research and innovation program under Grant Agreement no. 709606 (BBI LIGNOFLAG)

HARVESTED 2,7K

TONS OF STRAW

HARVESTED 20K

TONS OF STRAW

CLARIANT PLANT

ROMANIA

Approval to invest in

building a 50 kta plant

in Romania

2018

GROUNDBREAKING

PLANT ROMANIA

12. September 2018

2017 2019 2020

CONSTRUCTION

UNDERGOING

WORKSHOP WITH

FARMERS IN OLTENIA

2021

“TECHNOLOGY

PROVIDER OF THE

YEAR” PRIZE BY

DIPLOMAT ROMANIA

MANAGEMENT TEAM

FORMED

ISCC

CERTIFICATION

CONSTRUCTION

COMPLETED

Dr. Gloria Gaupmann, Public Affairs, Technology & Innovation, 22.10.2019

Feedstock: no wheel to invent, abundant feedstock availability, clear & executable value chain from field to plant

Confidential, Developing business models for efficient use of biomass7

• 1 ha of cropland/degraded land =

between 4–20t straw/energy crops

• Worldwide abundance of agricultural

residues & waste is a given1

• Agricultural residues value chains

already established at commercial

level

• 250kta long-term contracts with ~250 farmers

• Effective interface management of stakeholders

along supply chain (bailing to storage)

• Operations managed digitally: straw harvest &

logistics

• Network systems designed for straw storing &

delivery JIT

• ISCC certification as 1st gathering point

2018 2019 2020

HARVESTED 2,7KT

OF STRAW

HARVESTED

20KT OF STRAW

EXPECT CIRCA 100KT

STRAW HARVESTED

2021

No need to reinvent the wheel

1 Source: Food and Agriculture Organization of the United Nations (FAO), FAOSTAT2 https://certificates.iscc-system.org/cert-pdf/EU-ISCC-Cert-DE100-77982019.pdf

How we can support you

• Dedicated feedstock team

• Feedstock availability assessment

• Value chain contracts systems

• Whole value chain assessment (from bailing to

storage)

How we secured 250kta straw

HARVESTED

20KT OF STRAW

Public

Dr. Gloria GaupmannPublic Affairs, Technology & Innovation22.10.2019

Thank you for your attention!