Design of Footings

-

Upload

tbcaccounts -

Category

Documents

-

view

38 -

download

3

description

Transcript of Design of Footings

-

Footings*

-

AcknowledgementThis Powerpoint presentation was prepared by Dr. Terry Weigel, University of Louisville. This work and other contributions to the text by Dr. Weigel are gratefully acknowledged.*

-

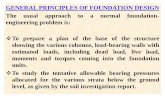

Footings*Design for load transfer to soil uses unfactored loadsSupport structural members and transfer loads to the soilStructural members are usually columns or wallsStructural design of footing is done with factored loads

-

Footings*Typically, bottom of footing must be located below frost lineFootings must be designed to prevent bearing failure, sliding and overturningFootings must be designed to prevent excessive settlement or tiltingExcavation may be required to reach a depth where satisfactory bearing material is located

-

Wall Footing*Wall footings enlargement of the bottom of the wall

-

Isolated Square Footing*Isolated or single column square footing loads relatively light and columns not closely spaced

-

Combined Footing*Combined footings support two or more columns heavily loaded columns; closely spaced columns; columns near property line

-

Mat Footing*Mat or raft foundation continuous concrete slab supporting many columns; soil strength relatively low; large column loads; isolated spread footings would cover more than 50 percent of area; reduce differential settlement

-

Pile Cap*Pile caps distribute column loads to groups of piles

-

Soil Pressure*Soil pressure is assumed to be uniformly distributed beneath footing if column load is applied at the center of gravity of the footingFootings supported by sandy soilsFootings supported by clayey soilsFootings supported eccentric loads

-

Assumed Soil Pressure*

-

Soil Pressure - Sandy Soil*

-

Soil Pressure - Clayey Soil*

-

Allowable Soil Pressure*Actual soil pressure is based on unfactored loadsAllowable soil pressure may be determined by a geotechnical engineerWhen soil exploration is not feasible, values provided by building codes may be usedFactor of safety is typically 3

-

Allowable Soil Pressure (Table 12.1)*

Maximum Allowable Soil PressureMaterialAllowable Pressure, ksfRock20% of ultimate strengthCompact coarse or fine sand, hard clay or sand clay8Medium stiff clay or sandy clay6Compact inorganic sand and silt mixtures4Loose sand3Soft sand clay or clay2Loose inorganic sand-silt mixtures1Loose organic sand-silt mixtures, muck or bay mud0

-

Design of Wall Footings*Generally, beam design theory is usedShear strength almost always controls footing depthCompute moment at the face of the wall (concrete wall) or halfway between wall face and its centerline (masonry walls)

-

Design of Wall Footings*

-

Design of Wall Footings*

-

Design of Wall Footings*

-

Design of Wall Footings*

-

Design of Wall Footings*Shear may be calculated at distance d from face of the wallUse of stirrups is not economical set d so that concrete carries all the shear

-

Design of Wall Footings*Design a 12-in wide stripSection 15.7 of ACI Code:Depth of footing above bottom reinforcement not less than 6 in for footings on soil and not less than 12 in for footings on pilesMinimum practical depth of footing is 10 in and 16 in for pile caps

-

Wall Footing Design Examples*

-

Example 12.1*Design a wall footing to support a 12-in. wide reinforced concrete wall with a dead load of 20 k/ft and a live load of 15 k/ft. The bottom of the footing is to be 4 foot below final grade, the soil weighs 100 lb/ft3 the allowable soil pressure is 4 ksf. The concrete strength is 3,000 psi and the steel is Grade 60.

-

Example 12.1*

-

Example 12.1*Assume a footing thickness of 12 in. With a minimum cover of 3 in., this gives a d value of about 8.5 in. Compute the footing weight and soil weight:

-

Example 12.1*Effective soil pressure and required width of footing:

-

Example 12.1*Factored bearing pressure for design of concrete:

-

Example 12.1*Compute design shear (at distance d from face of wall):

-

Example 12.1*

-

Example 12.1*

-

Example 12.1*

-

Example 12.1*Appendix Table 4.12, r = 0.00345 < 0.0136, section is tension controlled; f = 0.9Use No 7 at 10 in (As = 0.72 in2 / ft from Table A.6)

-

Example 12.1*Development length:

-

Example 12.1*

-

Example 12.1*Available length for development

-

Example 12.1*Temperature and shrinkage steelUse No 5 at 8 in (As = 0.465 in2 / ft)

-

Design of Isolated Square Footings*Most isolated square footings have a constant thicknessFor very thick footings, it may be economical to step or taper footingTwo types of shear must be considered one-way shear and two-way shear

-

Design of Isolated Square Footings*Constant thickness

-

Design of Isolated Square Footings*Stepped

-

Design of Isolated Square Footings*Tapered

-

One-way Shear*Same as for wall footings

-

One-way Shear*

-

Two-way Shear*ACI Code Section 11.11.1.2 states that critical section is at a distance d/2 from face of support

-

Two-way Shear*

-

Two-way Shear*

- Two-way Shear*

-

Two-way Shear*as = 40 for interior columnsas = 30 for exterior columnsas = 20 for corner columns

-

Flexural Design Isolated Square Footings*Flexural reinforcement is required in two directionsThe values of d for the layers of steel in the two directions will be differentFor square footings, design using the value of d for the upper layer is typicalFor square footings supporting non-square columns, moments are larger in the shorter direction of the column

-

Flexural Design Isolated Square Footings*Reinforcing steel areas required to resist moment are often less than minimum required steel: Code Section 10.5.4 states that minimum area and maximum spacing need only be equal to values required for temperature and shrinkage steel

-

Flexural Design Isolated Square Footings*Maximum steel spacing may not exceed three times the footing thickness or 18 in.

-

Load Transfer from Column to Footing*All forces at the base of the column must be transferred to the footingCompressive forces must be transferred by bearingTensile forces may be transferred by reinforcement or mechanical connectors

-

Load Transfer from Column to Footing*Columns transfer loads directly over the area of the columnLoad transfer into the footing may by assumed to occur over an effective area which may be larger than the column area For the same strength of concrete, the footing can support more bearing load than can the column

-

Load Transfer from Column to Footing*Bearing strength permitted at the base of the column -> Bearing strength permitted on the footing is the same value multiplied by -> See ACI Code Section 10.14.1

-

Definition of A1 and A2*A2 is the area of footing geometrically similar to and concentric with the columnA1 is the area of the column

-

Column Dowels*

-

Excess Bearing Load*Excess bearing load can be carried by dowels or column bars extended into footingACI Code Section 15.8.2 requires that the dowel area not be less than 0.005 times the gross cross-sectional area of the column

-

Development Length for Dowels*Development length of dowels must be sufficient to transfer column force to footingDevelopment length of dowels may not be less than the length required if bearing stress was not exceeded

-

Splice Length for Dowels*ACI Code does not permit splicing of No 14 or No 18 barsACI Code Section 15.8.2.3 does permit No 14 or No 18 bars to be spliced to No 11 (or larger) dowels in footingsThese dowels must extend into the column not less than the development length for the No 14 or No 18 bar, or the compression lap splice length for the dowels, whichever is larger

-

Splice Length for Dowels*These dowels must extend into the footing for a distance not less than the development length for dowels

-

Insufficient Development or Splice Length*Use a larger number of smaller dowelsUse a deeper footingAdd a cap or pedestal to the footing

-

Column Uplift*Development length must be those for tensionSplice requirements are those found in ACI Code Section 12.17

-

Isolated Rectangular Footings*Square footings are more econonical than rectangular footingsLong direction steel is uniformly distributed along short directionShort direction steel is non uniformly distributed along long direction

-

Isolated Rectangular Footings*ACI Code Section 15.4.4.2b is the ratio of the length of the footing in the long direction to the length in the short directionRemaining steel is distributed uniformly throughout the two portions of the footing outside the band

-

Isolated Rectangular Footings*

-

Footing Design Examples*

-

Example 12.2*Design a square column footing for a 16-in. square tied interior column that supports loads of D = 200 k and L = 160 k. The column is reinforced with eight No 8 bars, the bottom of the footing is 5 foot below final grade, the soil weighs 100 lb/ft3 the allowable soil pressure is 5 ksf. The concrete strength is 3,000 psi and the steel is Grade 60.

-

Example 12.2*Assume a footing thickness of 24 in. with a minimum cover of 3 in., this gives a d value of about 19.5 in. Compute the footing weight and soil weight:

-

Example 12.2*Effective soil pressure and required area of footing:

-

Example 12.2*Factored bearing pressure for design of concrete:

-

Example 12.2*Depth required to resist punching shear:

-

Example 12.2*

-

Example 12.2*Depth required to resist one-way shear:

-

Example 12.2*Flexural design

-

Example 12.2*Appendix Table 4.12, r = 0.00225 < rminUse nine No 8 (As = 7.07 in2)

-

Example 12.2*Development length:

-

Example 12.2*

-

Example 12.2*Available length for development

-

Example 12.3*Design for load transfer for the column and footing in Example 12.2. The strength of the sand-lightweight concrete (different from Example 12.2) in the column is 4 ksi.

-

Example 12.3*Bearing force at the column base:Design bearing force at the column base:

-

Example 12.3*Design bearing force in the footing concrete:Minimum dowel area:

-

Example 12.3*Dowel development length into the columnDowel development length into the footing

-

Example 12.3*Development length must not be less than:

-

Example 12.4*Design for load transfer for a 14-in. square column to a 13 ft square footing if Pu = 800 k. Normal weight concrete is used in both the column and the footing. The concrete in the column is 5 ksi and in the footing is 3 ksi. The column is reinforced with eight No 8 bars.

-

Example 12.4*Bearing force at the column base = 800 kDesign bearing force at the column base:

-

Example 12.4*Design bearing force in the footing concrete:

-

Example 12.4*Design dowels to resist excess bearing force:Use eight No 7 bars (As = 4.80 in2)

-

Example 12.4*Dowel development length into the column

-

Example 12.4*Dowel development length into the footing

-

Example 12.5*Design a rectangular footing for an 18-in. interior square column for D = 185 k and L = 150 k. The long side of the footing should be twice the length of the short side. The normal weight concrete strength for both the column and the footing is 4 ksi. The allowable soil pressure is 4000 psf and the bottom of the footing is 5 ft below grade.

-

Example 12.5*Assume a footing thickness of 24 in. with a minimum cover of 3 in., this gives a d value of about 19.5 in. Compute the footing weight and soil weight:

-

Example 12.5*Effective soil pressure and required area of footing:

-

Example 12.5*Depth required to resist one-way shear. Take b = 7 ft.

-

Example 12.5*

-

Example 12.5*Depth required to resist punching shear:

-

Example 12.5*

-

Example 12.5*Flexural design (steel in long direction)

-

Example 12.5*Appendix Table 4.13, r = 0.00467Use ten No 8 (As = 7.85 in2)

-

Example 12.5*Flexural design (steel in short direction)Too low for Table A.13

-

Example 12.5*Use 18 No 7 (As = 10.82 in2)

-

Example 12.5*Use 2/3 x 18 = 12 bars in band width

-

Example 12.5*

*****************************************************************************************************