Design of a Truss Spar

-

Upload

eduardo-sanchez -

Category

Documents

-

view

139 -

download

3

Transcript of Design of a Truss Spar

OCEN 407 Design of Ocean Engineering Facilities

Ocean Engineering Program

Texas A&M University

College Station, TX

Team Members:

Michael BoenischEduardo SanchezJennifer HulseyColton Gaitan

Timothy Church

May 4, 2012

Design of a Spar Platform in the Gulf of Mexico Spring 2012

Table of Contents

Table of Contents....................................................................................................................................1

Abstract...................................................................................................................................................3

Acknowledgements.................................................................................................................................4

List of Figures.........................................................................................................................................5

List of Equations.....................................................................................................................................6

List of Tables..........................................................................................................................................7

Executive Summary.................................................................................................................................8

Background.............................................................................................................................................9

Introduction...........................................................................................................................................10

Purpose..............................................................................................................................................10

Design Requirements.............................................................................................................................10

Proposed Location.............................................................................................................................10

Design................................................................................................................................................11

Environmental Storm conditions.......................................................................................................12

Stability.............................................................................................................................................12

Upending...........................................................................................................................................14

Environmental Loading.....................................................................................................................15

Mooring.............................................................................................................................................19

Risers.................................................................................................................................................22

Pipeline Installation...........................................................................................................................22

Dynamics...........................................................................................................................................23

Strakes...............................................................................................................................................27

Stiffeners...........................................................................................................................................27

Modeling with Solidworks.................................................................................................................28

Future Considerations............................................................................................................................29

Domain Analysis...............................................................................................................................29

Fatigue...............................................................................................................................................29

1 | P a g eOCEN – 407 Design of Ocean Engineering Facilities

Design of a Spar Platform in the Gulf of Mexico Spring 2012

Results and Analysis..............................................................................................................................30

Stability.............................................................................................................................................30

Upending...........................................................................................................................................31

Stiffness.............................................................................................................................................31

Mooring.............................................................................................................................................33

Analysis Dynamics............................................................................................................................34

Vortex induced Moments..................................................................................................................36

Costs..................................................................................................................................................37

References.............................................................................................................................................38

Appendix-1............................................................................................................................................40

Appendix- 2...........................................................................................................................................43

Appendix- 3...........................................................................................................................................44

Appendix- 4...........................................................................................................................................45

Appendix-5............................................................................................................................................46

Appendix- 6...........................................................................................................................................48

Appendix- 7...........................................................................................................................................52

Appendix- 8...........................................................................................................................................53

Appendix- 9...........................................................................................................................................56

2 | P a g eOCEN – 407 Design of Ocean Engineering Facilities

Design of a Spar Platform in the Gulf of Mexico Spring 2012

“Design of a SPAR Platform in the Gulf of Mexico”

Abstract

The senior Texas A&M Ocean engineering SPAR group, with the help of Ravi Kota, John

Halkyard, and Jun Zou, designed a SPAR Platform for use in the Gulf of Mexico. This report

emphasizes the design process needed to come up with a configuration to withstand 100-year

storm conditions.

The environmental data for the 100-year storm conditions in the Gulf of Mexico included a

maximum wind speed of 57.62 m/s, a max current of 2.2 m/s, a significant wave height at 14.4

m, with a peak period of 15.4 seconds. The hull size for the spar platform was designed based on

topsides and the production rate. The stability was checked for the SPAR by the buoyancy and

displacement as well as the weight of the topsides.

The mooring system was designed for 1305 m (4288ft) water depth and is 16 semi-taunt chain-

polyester-chain mooring lines.

3 | P a g eOCEN – 407 Design of Ocean Engineering Facilities

Design of a Spar Platform in the Gulf of Mexico Spring 2012

Acknowledgements

The senior design spar group would like to take this opportunity to thank everybody that

supported our spar project. Throughout this semester Dr. Falzarano has always provided us with

the critical information that we needed to accomplish designing a truss SPAR. We would also

like to give a special thanks to Ravi Kota, John Halkyard, and Jun Zou for their assistance with

the project. Ravi Kota gave us great advice on OrcaFlex which was used in the analysis of

mooring design. John Halkyard gave us great guidelines and recommendation on sizing of the

components. We would also like to thank Jun Zou for giving us general information on spar

platform and showing us some example processes that take place when designing a truss spar.

4 | P a g eOCEN – 407 Design of Ocean Engineering Facilities

Design of a Spar Platform in the Gulf of Mexico Spring 2012

List of Figures

Figure 1-Proposed location for truss spar........................................................................................9Figure 2: Storm condition data used in the design of the truss SPAR...........................................10Figure 3-Loading profile................................................................................................................15Figure 4-loading profile.................................................................................................................16Figure 5-Different wave force regimes..........................................................................................18Figure 6-OrcaFlex model of an FPSO system with releasable turret............................................19Figure 7- Deformed Static response..............................................................................................20Figure 8-Offshore mooring analysis using OrcaFlex....................................................................20Figure 9-EOM model.....................................................................................................................22Figure 10- Ratio to mass coefficient..............................................................................................23Figure 11- Surge stiffness..............................................................................................................32Figure 12- Uncoupled Response....................................................................................................33Figure 13- Uncoupled response.....................................................................................................34

List of Equations

1- Steel weight...............................................................................................................................102- Center of Gravity.......................................................................................................................113-Center of Buoyancy....................................................................................................................114- BM.............................................................................................................................................115-Radius of Gyration- Cylinder.....................................................................................................126-Radius of Gyration- Cube...........................................................................................................127-Radius of Gyration- COB...........................................................................................................128-Rolling Period.............................................................................................................................129-Angular Momentum...................................................................................................................1310-Wave Induced particle velocity................................................................................................1511-Wave induced particle acceleration..........................................................................................1512-wind velocity............................................................................................................................1613-Drag force.................................................................................................................................1714-Inertial force.............................................................................................................................17

5 | P a g eOCEN – 407 Design of Ocean Engineering Facilities

Design of a Spar Platform in the Gulf of Mexico Spring 2012

15-Drag and inertial force..............................................................................................................1816-Summation of dynamic forces..................................................................................................2317-Linearization of damping.........................................................................................................2418-Hookes law...............................................................................................................................2519-Rotational stiffness...................................................................................................................2520-Response equation....................................................................................................................2521-Response variables...................................................................................................................26

6 | P a g eOCEN – 407 Design of Ocean Engineering Facilities

Design of a Spar Platform in the Gulf of Mexico Spring 2012

List of Tables

Table 1-Overall Design for Truss Spar......................................................................................................16Table 2-Mooring design parameters..........................................................................................................23Table 3- Center of Gravity.........................................................................................................................35Table 4- Center of Buoyancy.....................................................................................................................35Table 5- Upending.....................................................................................................................................36Table 6- Periods.........................................................................................................................................36Table 7-Maximum surge conditions..........................................................................................................39

7 | P a g eOCEN – 407 Design of Ocean Engineering Facilities

Design of a Spar Platform in the Gulf of Mexico Spring 2012

Executive Summary

Spar platforms are more economical than other offshore platforms by being 30% cheaper than

other deep water options as shown in the cost comparison. The truss spar designed is an

improvement on the classic spar that will help functionality. To aid in the design, OrcaFlex,

Autocad, StabCAD, and Wamit were programs used in calculating different components.

Poseidon will be located in 1305 m depth of water in the Gulf of Mexico located at latitude of 28

and longitude of -89. The hull will be 78 m long and 30 m diameter; the truss will be 99m long,

an overall length of 181.5m with 3 heave plates. It is designed to withstand 100 yr storm

conditions. By using SolidWorks, 3D rendering of Poseidon were made possible. The design

requires 16 polyester-chain mooring lines that will have an intact chain factor of safety of 1.67

and an intact polyester factor of safety of 1.43. There will be 8 dry-tree top tensioned risers

without buoyancy cans. This allows direct vertical well access into the reservoir and the well

control can be managed at the surface. Platform heave contributes heavily to riser upstroke and

down stroke, with tide also contributing significantly to down stroke; therefore a Spar platform is

the perfect design considering the minimal to no heave that it produces.

In conclusion, a Spar platform should be used as opposed to other offshore platform options

because of its potentially easier management and its economic feasibility to build and maintain.

Future considerations should include fatigue analysis, upending moment, and further pipeline

design. Total costs were approximated to be $620 million USD.

8 | P a g eOCEN – 407 Design of Ocean Engineering Facilities

Design of a Spar Platform in the Gulf of Mexico Spring 2012

Background

As technology progresses, innovative solutions arise to help solve society’s problems and meet

our needs. The spar platform came as an alternate solution to other offshore platforms such as

steel jacketed platforms. Economically speaking, the spar platform is the most feasible for ultra-

deep water. Also, by utilizing a mooring system instead of permanent legs, you can greatly

reduce material which reduces costs. There are three basic designs for the SPAR platforms.

1. Classic SPAR

2. Truss SPAR

3. Cell Spar

Each of these types of spars reflects industry innovation. Traditionally, the newer designs are an

improvement of the original classic SPAR. The world’s first classic SPAR was the Neptune

SPAR and it was installed in the Gulf of Mexico in 1996. This hull on the first SPAR was

basically a cylinder that was broken down into three components.

1. Upper Section

Filled with air to provide buoyancy

2. Centerwell

Flooded with seawater

3. Keel section or soft tank

Was compartmentalized to help with transportation

Innovation has led to fourteen SPARs in production at the moment with the Perdido Spar being

the deepest.

9 | P a g eOCEN – 407 Design of Ocean Engineering Facilities

Design of a Spar Platform in the Gulf of Mexico Spring 2012

Introduction

Oil and gas is the number one source of energy in the world. We depend on this energy for

transportation, lighting and many other daily uses. The use has been substantially increasing over

time but the availability of oil and gas has started to decline. As more prospects are explored to

fill this need, more innovative solutions have been conducted. The ocean has always been seen

as unexplored and untainted but as technology has progressed, we have the solutions to seek out

oil out in the deep waters. A truss spar can be a possible solution to this problem of producing oil

in the deep ocean.

Purpose

A truss spar was chosen by our group for the following reasons.

Relatively cheaper than FPSO

There is a smaller amount of heave motion associated with a spar platform

We can tap into an already existing pipeline infrastructure off the coast.

Design Requirements

Proposed Location

Our proposed location was in the Gulf of Mexico about latitude 28 and longitude -89. This

location exists with a water depth of 1305 meters and is approximately 100 miles from the shore.

This is the ideal location for our truss spar because according to pipeline infrastructure

information that was found, it can easy be tapped into an existing oil pipeline. This helps reduce

cost since it would be inefficient to lay down pipeline as well as construct the truss spar.

10 | P a g eOCEN – 407 Design of Ocean Engineering Facilities

Design of a Spar Platform in the Gulf of Mexico Spring 2012

Figure 1-Proposed location for truss spar

Design

When designing this spar a basic design spiral was used. The first step was the principle

dimensions. Some of these were predetermined as part of the design criteria such as topside

weight and production rate. In order to determine initial conditions, several graphs/plots were

constructed to display dimensionless ratios that were gathered from previously built truss spars.

Once the points were plotted a line was drawn to find the average. While these points didn’t

always follow the line, it provided an estimated starting point for the design. The next step in the

process was to determine the initial stability of the spar. If the design did not fall within the

accepted range, the loop was restarted and the design altered accordingly. Following the stability

analysis, the EoM and dynamics were considered. These were reviewed and the design was again

altered to assure that everything was within the acceptable range. The finally step before the final

design was to estimate the cost of the project. Once each of the steps was acceptable, the design

was finalized.

11 | P a g eOCEN – 407 Design of Ocean Engineering Facilities

Design of a Spar Platform in the Gulf of Mexico Spring 2012

Environmental Storm conditions

Thanks to Delmar, information was obtained for the proposed location dealing with the 1000 yr.

and 100 yr. storms. This was especially useful since the spar is to withstanding these conditions.

The information that we incorporated when designing the spar was a velocity of 57.62m/s, the

max current of 2.22m/s, the significant wave height of 14.4m and the peak period of 15.4 s.

Figure 2: Storm condition data used in the design of the truss SPAR

Stability

In order to determine the initial stability of the truss spar, a step-by-step process of basic naval

architecture was followed. Having already concluded the design variables from the previous step

in the design loop, the buoyancy and displacement were calculated. While the topside weight

was previously set as one of the design criteria, the rest of the truss spar system’s weight was

found by estimating the volume of steel that would be needed and multiplying that by the density

of A36 steel.

1- Steel weight

W =Ñ ρ

12 | P a g eOCEN – 407 Design of Ocean Engineering Facilities

Design of a Spar Platform in the Gulf of Mexico Spring 2012

If a part of structure contained seawater, such as the soft tank, the weight provided by that water

was added to the weight measurements to counter the displacement. The displacement was then

found and used with the density of the seawater to provide the buoyancy. Once the total weight

and buoyancy force were found, their difference was used to calculate how much the variable

ballast tanks would need to be filled. The next step was the stability equations. Using the

centroid height of each section, the weight and buoyancy were multiplied by their moment arms

to find the center of gravity and center of buoyancy respectively.

2- Center of Gravity

CoG=∑ MomentArm

∑ Weight

3-Center of Buoyancy

CoB=∑ MomentArm

∑ Displacement

Then the second moment of area (area moment of inertia) was found and divided by the total

displacement volume to provide the BM (the distance between the center of buoyancy and the

metacenter).

4- BM

BM= IV

Due to the prospectively low water plane area of a spar system, this number is nearly negligible.

This height minus the height of the center of gravity resulted in our righting arm (GM). The final

step in insuring that the design was properly stable was to assure that the rolling period fell

within the given accepted range. The first step in determining this was to find the radius of

13 | P a g eOCEN – 407 Design of Ocean Engineering Facilities

Design of a Spar Platform in the Gulf of Mexico Spring 2012

gyration. Using the radius of gyration equation for a cylinder [] and for a cube [] each area was

again compartmentalized and summed.

5-Radius of Gyration- Cylinder

k=√9 r 2+3 L2

6

6-Radius of Gyration- Cube

k=√ x2+z2

12

Since each of the equation only accounted for the radius of gyration of that shape around its

central axis, the parallel axis theorem was used to find the radius of gyration about the center of

buoyancy.

7-Radius of Gyration- COB

k t=√kc2+d2

The rolling period was finally determined using the following equation. Once the period fell

within the set parameters the design was consider initially stable.

8-Rolling Period

T rp=2 p√ k t2+M a

GM

14 | P a g eOCEN – 407 Design of Ocean Engineering Facilities

Design of a Spar Platform in the Gulf of Mexico Spring 2012

Upending

One of the key concerns during the installation of a spar system is the upending process. Having

already predetermined the weight distribution of the spar segment, the shearing stress was found

at the point where the truss and hard tank are joined. This provided a minimum amount of area

required by the truss columns to insure that the system would not bend. The system was then

analyzed to insure that it would initially float to begin the upending process. Once the spar was

off the towing vessel, the soft tank would be filled with water. The period for upending was then

found by analyzing the angular momentum with the following equations.

9-Angular Momentum

L=r ´ p

L=Iw

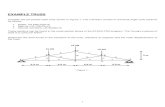

Table 1-Overall Design for Truss Spar

—Water Depth: 1305 meters

—Diameter: 30 meters

—Hard Tank Length: 78 meters

—Overall Length: 181.5 meters

—Moon-pool Length: 13 meters

—Heave Plates 3

—Risers 8

—Mooring Lines 16

—Topsides: 45 X 60 meters

Production Rate

Environmental Loading

Modeling is an important tool in engineering for realistic environmental loading. This

introduction is divided into two sections, Environmental conditions/loading and Equations of

Motions. Each section will describe the theory used, some potential issues, and possible errors.

15 | P a g eOCEN – 407 Design of Ocean Engineering Facilities

Design of a Spar Platform in the Gulf of Mexico Spring 2012

The environmental loading was comprised of wind, wave, current and gust loading. With the

given environmental conditions, peak period is 15.4 sec, significant wave height is 14.5 m and

current velocity is 2.22 m/s. The water depth was determined to be deep, which resulted in the

following equations:

10-Wave Induced particle velocity

x=πHT

ekz

11-Wave induced particle acceleration

x=2 π2 HT 2 ekz

Wave x is particle velocity, x is particle acceleration, T is the peak period, H is wave height, k is

the wave number and z is the depth. The velocity, acceleration and current are presented in

Figure 3-Loading profile

16 | P a g eOCEN – 407 Design of Ocean Engineering Facilities

Design of a Spar Platform in the Gulf of Mexico Spring 2012

Figure 3-Loading profile

The wind velocity was determined from the given equation:

12-wind velocity

x=U ( z33 )

18

Where x is velocity , U is the wind speed at a reference of 33 feet ( ~10 meters) , z is the height

above the MWL. The wind profile is shown below in Figure 4-loading profile

17 | P a g eOCEN – 407 Design of Ocean Engineering Facilities

Design of a Spar Platform in the Gulf of Mexico Spring 2012

Figure 4-loading profile

The given velocity equations determined the magnitude of the force that was applied to the body.

For the initial analysis Morrison’s drag equation was used (below).

13-Drag force

F=12

ρA Cd x|x|

Where ρ is the density of the fluid (1025 kg/m^3 for sea water and 1.225 kg/m^3 for air), A is

the cross sectional area that is normal to the flow, Cd is the drag coefficient, which is discussed

later (Dynamics) and V is the velocity. It is important to note that the drag equation models the

directionality of the force on a given body, this will be important later. In addition to drag,

inertial forces were taken into account, displayed below:

14-Inertial force

18 | P a g eOCEN – 407 Design of Ocean Engineering Facilities

Design of a Spar Platform in the Gulf of Mexico Spring 2012

F=ρ C I∀ x

Where C I is the inertial coefficient (discussed below), ∀ is the displaced volume and ∂ v∂ t

is the

acceleration as a function of time. When the diameter of a cylinder is relatively “small” (D/λ

<0.2) compared to the wave length, it can be assumed that diffraction and radiation do not affect

the vessel (Kim) . In addition the drag and inertial forces are out of phase with one another, thus

using the magnitude of both would be an overdesign. The criterion is displayed below:

15-Drag and inertial force

Fmax={FD+F I

2

4 FD

,∧F I

2 FD

<1

F I ,F I

2F D

≥ 1

In the case of a cylinder another guideline can be used to determine the effect of the loading. In

the API recommended practice (Det Norske Veritas, October 2010) a plot was given (shown

below) that allows an informed decision on whether to include drag, inertia, both or diffraction.

19 | P a g eOCEN – 407 Design of Ocean Engineering Facilities

Design of a Spar Platform in the Gulf of Mexico Spring 2012

Figure 5-Different wave force regimes

Mooring

Mooring analysis analyzes a body connected to the sea floor by a system of tendons composed of

chain, polyester and/or wire. The purpose of these catenary lines is to keep our spar within

reasonable proximity of a target location and prevent over excitation of the risers. There are two

main forces that are exerted on our spar. These are the forces which the lines exert on the body

and the forces which the environment exerts on the body. We usually plot these as a function of

horizontal distance and tension. The tension must always be greater than the horizontal distance.

When we plot all these forces we get the horizontal force of a line, the tension in the line, and the

derivative of the horizontal force.

20 | P a g eOCEN – 407 Design of Ocean Engineering Facilities

Design of a Spar Platform in the Gulf of Mexico Spring 2012

Figure 6-OrcaFlex model of an FPSO system with releasable turret

In order to get all these plots we use a program called OrcaFlex which is the world’s leading

package for dynamic analysis of offshore marine systems. OrcaFlex can be used to simulate a

variety of items such as risers, towed systems, mooring, and buoy systems. For our Spar we will

use OrcaFlex for the sole purpose of doing mooring analysis. We decided on a taunt mooring

system with 16 catenary lines. These lines have been attached to the body and are labeled as a

chain-polyester-chain configuration which will have an effect on the restoring forces and

excitation. Excitation deals with

Static forces: current, wind and mean wave forces.

Direct wave frequency forces: forces at the wave period.

Non wave frequency forces: wave drift and wind gusts

These static forces are fairly easy to determine. With OrcaFlex, we simulated using a simple

static analysis which gives us a simulation:

21 | P a g eOCEN – 407 Design of Ocean Engineering Facilities

Design of a Spar Platform in the Gulf of Mexico Spring 2012

Figure 7- Deformed Static response

We analyzed using information regarding specifics such as wave height, water depth, chain

material, etc. Once all the required information was assigned, OrcaFlex simulated it and we

selected relevant information we wanted to display. Below is a figure of the major components:

22 | P a g eOCEN – 407 Design of Ocean Engineering Facilities

Figure 8-Offshore mooring analysis using OrcaFlex

Design of a Spar Platform in the Gulf of Mexico Spring 2012

In the initial phase, the design parameters for a semi taut mooring configuration are tabulated below:

Table 2-Mooring design parameters

Inclination Angle 29.1

Angle Between 5

Aspect:Depth 1.5 ~ 2.0

These relations were applied for the basic mooring design; initial diameters were selected from

equations presented in (appendix 7). Only one constraint was followed in the analysis, although

others were recommended, the API utilization factor. This factor contains maximum breaking

strength over allowable. Below is a table which

Risers

Eight dry tree top-tensioned risers with the main advantages being that well control is at the

surface around people with direct vertical access into reservoirs. This requires a floater with low

heave because platform heave (coupled with pitch) contributes significantly to the riser up-stroke

and down-stroke and should never be greater than ±15ft. Rising tide will increase down-stroke.

Poseidon will not have buoyancy cans, but will have hydraulic tensioners. This eliminates the

need for the drilling riser slot to be increased in diameter to fit larger buoyancy cans that might

be needed for drilling.

Pipeline Installation

To transport the oil, subsea pipelines will be used as a shuttle since the platform is approximately

100 miles offshore.

To find the size of the liquid lines, there are several equations that can be utilized and should be

based on the flow velocity.

23 | P a g eOCEN – 407 Design of Ocean Engineering Facilities

Design of a Spar Platform in the Gulf of Mexico Spring 2012

16-Flow Velocity

V 1=.012Q 1

d12

Where V1 is the average liquid flow velocity in feet/seconds, Q1 is the liquid flow rate in

barrels/day, and d1 is the pipe inside diameter in inches

17-Pressure Drop

∆ P=.00115 f Q1

2 S1

d15

Where S1 is the liquid specific gravity and F is the Moody friction factor.

Since f is a function of the Reynolds number, the Reynolds number is then found and then f is

found using the Moody diagram. The Reynolds number can be found using:

18-Reynolds Number

ℜ=ρ1d1 V 1

μ1

Where ρ1 is the liquid density in lb/ft3 and µ1 is the liquid viscosity in lb/ft-sec.

Dynamics

Without the aid of computer program, we used a basic, one degree of freedom system to model

the position and acceleration of the structure. Although a one-DOF system will not sufficiently

model the motions, it will give approximate values allowing for a more in-depth, nonlinear

model to be examined. Below, Figure 9-EOM model models the forces on the structure.

24 | P a g eOCEN – 407 Design of Ocean Engineering Facilities

Design of a Spar Platform in the Gulf of Mexico Spring 2012

19-Summation of dynamic forces

( M +ma ) x+C¿ x+K ¿ x=∑ Fenvironmental

Where M is the overall mass, ma is the added mass, C*is the damping due to drag forces, and K*

is the overall stiffness. The environmental forces were mentioned in the environmental loading

section. The mass was fairly straight forward to compute, the assumed density of steel was taken

to be 7850 kg/m3 . Two conditions were of concern in the response, heave and surge. Below is

the equation used:

20-Heave natural period

T heave=2π √ M + AρgS

21-Surge natural period

T Surge=2π √ M + AKm

Where M is the mass, A is the added mass; S is the water plane area and Km is the stiffness

attributed to mooring. The added mass was found using the relation displayed below:

25 | P a g eOCEN – 407 Design of Ocean Engineering Facilities

Figure 9-EOM model

Design of a Spar Platform in the Gulf of Mexico Spring 2012

0 1 2 3 4 5 6 7 8 9 100

0.2

0.4

0.6

0.8

1

1.2

Ratio

Mass

Co

effi

cie

nt

Figure 10- Ratio to mass coefficient

In this figure the ratio (diameter: length) is on the horizontal axis and the coefficient used is on

the vertical. This figure was computed using notes from Dynamics of Offshore Structures

(M.H.Kim). Next in the EOM was the damping aspect, C ¿, which is a nonlinear term modeled

from Morrison’s drag equation . Although nonlinear terms, can be computed, linearization was

conducted to give an approximated value, below is the relationship.

22-Linearization of damping

ce=8

3π|x|

Above, the C* value is approximated to be equal toce x, in which x is the velocity of the

platform. This relationship must be iterated until convergence; therefore several position models

will be performed.

Stiffness was determined using two methods, 1) using OrcaFlex and 2) classical mechanics.

Using OrcaFlex, the given Mooring configuration was displaced under various loadings centered

at the structure and a displacement was recorded. Below is Hooke’s law, which was used to

determine the spring stiffness of the system.

26 | P a g eOCEN – 407 Design of Ocean Engineering Facilities

Design of a Spar Platform in the Gulf of Mexico Spring 2012

23-Hookes law

K= Fx

In the above , K is the spring stiffness used, F is the force acting on the body, and x is the

displacement induced by the loading. For this assessment wave, current and wind forces were

neglected and a resultant force was applied through the centroid of the body. A vertical and

moment force were applied, the equation for rotational stiffness is below.

24-Rotational stiffness

Kθ=Mθ

In the above 24-Rotational stiffness , M was an applied moment, θ is a pitch angle and Kθ is the

rotational stiffness induced.

The was solved into a position equation shown below.

25-Response equation

x (t )=e−ζωt( Acos (Ω t )+Bsin ( Ωt ))

In 25-Response equation the system will act as a decaying function, where each of the variable

are described below. This case is for free vibration, which will be analyzed and compared with

OrcaFlex forced response.

27 | P a g eOCEN – 407 Design of Ocean Engineering Facilities

Design of a Spar Platform in the Gulf of Mexico Spring 2012

26-Response variables

ω=√ K ¿

M ¿

ζ = C ¿

2m¿ω

Ω=ω√1−ζ 2

Where ω is the SPAR frequency, ζ is the damping ratio, and Ω is the damped natural frequency.

Strakes

Strakes are added to the structure to reduce the vortex induced motion. The strakes were computed using the relation given by John Halkyard found below. The strakes were found to be at 120 degree increments.

27- Strake Height

H=0.12 D

Where H is the strake height and D is the diameter of the structure. The height was calculated to

be 3.6 meters. However the strakes size and pitch may be altered from model testing analysis due

cut-away sections to allow for mooring line attachment.

Stiffeners

Stiffeners were computed as an initial hull design process. In order to compute the stiffeners that

are needed for the hard tank, the hard tank was simplified to an octagon and the sides were

treated as plates. The force was taken from appendix 8 and divided onto each individual plate.

The loads on the plate were then divided into quarter sections and then applied as a point load on

a one meter section of the stiffener. The stiffeners length was approximated to be the length of

28 | P a g eOCEN – 407 Design of Ocean Engineering Facilities

Design of a Spar Platform in the Gulf of Mexico Spring 2012

the sections in the hard tank. The maximum moment and maximum shear calculated and based

on the maximum moment and shear. Using AISC 14th edition Steel Handbook a W18x97 steel

member was determined to be the most adequate and cost effective stiffener.

Equation to find the approximate length of the beam was:

28-Beam length

L= π∗d8

L is the length of the beam, and d is the diameter of the hard tank.

Modeling with Solidworks

SolidWorksIn order to get a scale model SolidWorks was used to create renderings of specific parts of the

spar and then it was all brought together to get a completed model. SolidWorks is a 3D

mechanical CAD program that runs on Windows and was developed by Dassault Systèmes

SolidWorks Corp.

The spar platform model was developed using several components that were rendered separately

and then mated to have a final design. The components that were modeled included:

1. Hard tank

2. Truss

3. Soft tank

4. Heave plates

5. Risers

6. Strakes

7. Topsides

29 | P a g eOCEN – 407 Design of Ocean Engineering Facilities

Design of a Spar Platform in the Gulf of Mexico Spring 2012

Part 1-5 were modeled based on the initial dimensions which were chosen at the beginning of the

design process. Each individual part was modeled to scale using SI units. Part 6 was modeled

according to the hull size and the size of the wavelength that would be exerting force on the spar.

The topside was one of the components that needed special attention since it was modeled after

the size of the hull. The reason that this caused a bit of a problem was because initially the size

of the hull was picked by plotting the hull size versus water depth and getting the best possible

diameter. With the help of John Halkyard, the size of our topside was picked by doing a ratio of

one the recommended topside size and being able to make it fit the hull.

Future Considerations

Domain Analysis

Another future consideration would be to develop the frequency domain analysis for the spar

platform. The frequency domain analysis can help predict the responses in surge, heave, and

pitch degrees of freedom when the spar is subjected to random waves. In order to get good

approximations you can use the energy density spectrum: Pierson-Moskowitz (PM) spectrum

model to represent an appropriate density distribution of the sea wave of the site that is under

consideration. The expression for this model in terms of cyclic frequency may be written as

29- Energy Density Function

S ( f )=α∗g2

2 π 4 ∗f −5∗exp [−1.25∗( ff 0

)¿¿−4]¿

Where α is equal to 0.0081 and the peak frequency, f 0(w0

2 π), the peak frequency and the

significant height for the wave is ωo=.161∗g

H s, the weight height at this frequency is

H (f 1)=2∗2√2∗( f 1 )∗∆ f .

30 | P a g eOCEN – 407 Design of Ocean Engineering Facilities

Design of a Spar Platform in the Gulf of Mexico Spring 2012

FatigueFatigue is a byproduct of low amplitude oscillation in short waves, or waves that have periods of

less than 9 seconds. Therefore, cyclic loading is to be considered in the design of the Spar.

Analysis of stress cycles should not be limited to active service life; assembly, fabrication,

transport and installation also contribute to fatigue. Areas that cannot be inspected should be

subject to higher safety factors. A structural analysis program with spectral fatigue features will

be utilized.

To accurately predict fatigue of risers, accurate response in low sea states is important to

investigate. Primarily, riser fatigue is produced by riser VIV. For the hull, the frailest and most

critical structural element is the truss section with its connection and must be put under further

analysis of fatigue safety. To better understand fatigue behavior of the truss structure the stress

response power spectral density at various locations in the truss will be tested. The key project

considerations for the truss Spar are the hull diameter, center well size, compartment size,

freeboard, draft, and hard tank length and all need to refer to different codes of safety.

Results and Analysis

Stability

According to the tables listed below (, Table 4- Center of Buoyancy ) and the analysis performed

by StabCAD ( Appendix-1) show that the spar is absolutely stable. The calculations performed

by hand matched closely to the analysis performed by

StabCAD.

Table 3- Center of Gravity

Section Centroid Height (m) Section Weight (Tonne) Moment Arm (Tonne*m)

31 | P a g eOCEN – 407 Design of Ocean Engineering Facilities

Design of a Spar Platform in the Gulf of Mexico Spring 2012

Soft Tank 1 3,054 3,054

Truss 51.5 11,031 568,105

Hard Tank 140 11,147 1,560,580

Top Side 185 12,000 2,220,000

Added Ballast 106.56 7,459 794,879

Total 444,691 5,146,617

Center of Gravity 115.16

Table 4- Center of Buoyancy

Section Centroid Height (m) Section

Displacement

(Tonne)

Moment Arm

(Tonne*m)

Soft Tank 1 1,550 1,550

Truss 51.5 1,196 61,590

Hard Tank 137.06 34,486 4,726,731

Total 37,232 4,789,871

Center of Buoyancy 128.65

Upending

Table 5- Upending

Empty Weight 12,446 Tonne Full Weight 14,085 Tonne

32 | P a g eOCEN – 407 Design of Ocean Engineering Facilities

Design of a Spar Platform in the Gulf of Mexico Spring 2012

Min Shear Str Max Shear Str Min F.S. Max F.S.

Area Required

Empty

0.407 m2 0.295 m2 2.47 3.4

Area Required Full 0.46 m2 0.334 m2 2.18 3

Area Given by 42 In pipe 1 m2

Stiffness

The computed periods for surge and heave are presented below and compared to those

recommended in the API code (Det Norske Veritas, October 2010).

Table 6- Periods

Computed Values (sec) API Recommendations (sec)

Surge 177.31 >100

Heave 25.76 20-35

The table above, indicates various periods based on equations (20-Heave natural period, 21-

Surge natural period) Specific values of mass, force, period, and stiffness are shown in

Appendix- .

Using OrcaFlex, a force was applied to the surface buoy and a maximum displacement

was recorded. The relationship allowed for stiffness to be determined. Below is a figure of the

stiffness in the surge direction, tabulated values can be found in Appendix-1

33 | P a g eOCEN – 407 Design of Ocean Engineering Facilities

Design of a Spar Platform in the Gulf of Mexico Spring 2012

0 20 40 60 80 100 120 140 1600

2000400060008000

10000120001400016000

f(x) = 111.091755327511 x − 1275.1143745921R² = 0.988131857602342

Horizontal Stiffness

Horizontal Displacement, X (m)

Appl

ied

Horiz

onat

l Loa

d (k

N)

Figure 11- Surge stiffness

Above is the figure of Horizontal Displacement, meters, versus an applied load. The slope of the

load gave the stiffness. Other stiffness’, which were not used in analysis, are tabulated in

Appendix- .

Mooring

Using OrcaFlex, a configuration (Appendix- 7) was used to model the mooring system. All

values were under the design criteria and their graphical representation is found in Appendix- 6.

The characteristic dimensions are found below :

Table 7- Mooring layout

Material Length (m) Diameter (m)Chain 200 0.152Polyester 2,075 0.260Chain 200 0.152

Although the dimensions sufficed, more optimization should be made. Costs were not completely know,

and optimization would follow along those guidelines.

34 | P a g eOCEN – 407 Design of Ocean Engineering Facilities

Design of a Spar Platform in the Gulf of Mexico Spring 2012

Analysis Dynamics

The results gathered from Equation 25-Response equation are plotted below:

0 50 100 150 200 250 300 350

-60

-40

-20

0

20

40

60

Un-Coupled Surge Response

Surg

e Di

spla

cem

ent (

m)

Figure 12- Uncoupled Response

The above graph shows the displacement (m) of the centroid versus time. The plot is a free

response, which does not include external forces, and just models an initial displacement which

was found using, . Hookes law allowed for a maximum distance that would be induced in the

platform, which is modeled. Although iteration for damping due to velocity was computed and

applied (Appendix- ), the damping coefficient (and the ratio) was found to be negligible. It was

recommended to ignore damping, due to its nonlinearity, and these results for future applications

show that the recommendation was sound. These results were also modeled using OrcaFlex,

which is presented in Figure 13- Uncoupled response:

35 | P a g eOCEN – 407 Design of Ocean Engineering Facilities

Design of a Spar Platform in the Gulf of Mexico Spring 2012

0 10 20 30 40 50 60 70 80

-40

-30

-20

-10

0

10

20

30

40

50

60

Un-Coupled Surge Response

Linearized Uncoupled ResponseComputer Modeling

Surg

e Di

spla

cem

ent (

m)

Figure 13- Uncoupled response

The above plot shows the calculated values (blue line), which do not include forced response,

against the given values from OrcaFlex. As seen in the figure, the linear model estimated was

fairly accurate. The only variation is estimated to be force induced, which is shown to not be a

primary factor in displacement.

Table 8-Maximum surge conditions

Linearized Model Computer Model

Maximum Displacement (m) 50.96 54.62

Maximum Acceleration

(m/s^2)

0.65 1.4

36 | P a g eOCEN – 407 Design of Ocean Engineering Facilities

Design of a Spar Platform in the Gulf of Mexico Spring 2012

Vortex induced Moments

The vortex induced moments for moored Spars are characterized by a number of dimensionless

parameters. These are defined as:

30-Strouhal number

st=f viv∗D

UC

31-Reduced velocity

UR=UC∗T sway

D

32-Dimensionless amplitude

AD

=(Amax−Amin)

2∗D

Where UC is the free stream current velocity, D is the diameter of the Spar, υ is the kinematic

viscosity, f viv is the vortex shedding frequency, TSWAY is the natural period for sway of the

Spar, and A is the single sway amplitude.

The Strouhal number is a dimensionless number that helps describe oscillating flow mechanisms.

For the Strouhal number that was calculated for the Poseidon spar, Dr. Kim’s comprised notes

were used to reference relevant equations given by:

37 | P a g eOCEN – 407 Design of Ocean Engineering Facilities

Sr= .23Cd

Design of a Spar Platform in the Gulf of Mexico Spring 2012

Where Cd is the drag coefficient and was equal to one.

33- KC Number

All relevant information needed to solve these equations was obtained by:

Costs

For costs, we divided the components of the platform, and looked at cost per unit to then total the

prices found to find a good estimate.

Quantity Cost/unit Cost ($) Includes Excludes

Suction Pile Anchors

16$975K each

$15.6 Million

Polyester Rope

16 $8.8/kg $249,705

Steel44,250

tons$10000/

ton$442

Million

Risers 8 -- $350,000

Contingency --12% of Total

$22.6 Million

--Excludes Transport, installation

Additional Marine Costs

-- --$135

Million

Includes Yard Engineering,

Trails, Commissioning,

Class,

38 | P a g eOCEN – 407 Design of Ocean Engineering Facilities

Kc=U∗TD

Design of a Spar Platform in the Gulf of Mexico Spring 2012

References

Det Norske Veritas. (October 2010). Recommended Practice DNV-RP-C205. American Petroleum Institute, 63-74.

M.H.Kim, P. (n.d.). Dynamics of Offshore Structures.

Prislin, I., Steen, A., Halkyard, J., (2001), Upending of a Spar Offshore Platform: Prediction of Motions and Loading.

Halkyard, J., Spar Design (PowerPoint Presentation).

Constantinides, Y., Oakley Jr., O., Holmes, S., (2006), Analysis of Turbulent Flows and VIV of Truss Spar and Risers.

Stanton, P., (2006), Overview of Deepwater Drilling and Production Risers (PowerPoint Presentation).

Kavanagh, W., Imas, L., Thompson, H., Lee, L., (2000), Genesis Spar Risers: Interference Assessment and VIV Model Testing.

Chedsoy, C., Lim, F., (Date Not Listed), Design Challenges of Deepwater Dry Tree Riser Systems for Different Vessel Types.

Det Norske Veritas, (2010), Dynamic Risers.

Botros, F., Burke, A., Magee, A., Lu, X., Leung, M., (2006), Coupled Analysis and Tensioning System for Holstein Dry-Tree Risers.

Cornut, S., Vandiver, J., (2000), Offshore VIV Monitoring at Schiehallion-Analysis of Riser VIV Response.

No Author Listed, No Date Listed, A05 Steel Catenary Riser Systems.

Briggs, M., McCormick, M., (2006), Civil Engineering in the Oceans VI.

Wang, J., Lu, R., Lu, N., (2003), Truss Spar Strength and Fatigue Analysis for Wet Tow.

No Author Listed, (2010), Platforms-Hosts to Provide Buoyancy and Stability.

Chakrabarti, S., (2005), Handbook of Offshore Engineering Volume I.

Thethi, R., Howells, H., Natarajan, S., Bridge, C., (2005), A Fatigue Monitoring Strategy and Implementation on a Deepwater Top Tensioned Riser.

39 | P a g eOCEN – 407 Design of Ocean Engineering Facilities

Design of a Spar Platform in the Gulf of Mexico Spring 2012

API, (2001), Recommended Practice for Planning, Designing, and Constructing Floating Production Systems.

"Spar Platform Leadership: Evolving and Successful Know How." 302 Found. Web. 03 May 2012. <http://www.technip.com/en/media-center/webzine/spar-platform-leadership-evolving-and-successful-know-how>.

40 | P a g eOCEN – 407 Design of Ocean Engineering Facilities

Design of a Spar Platform in the Gulf of Mexico Spring 2012

Appendix-1The following table shows the beta file of the StabCAD spar model. The beta file allows the

inputs of “Cards” these “Cards” are necessary to analyze the model. The beta file can also be

used to add the joints and the plates without using the graphical input. This beta file was used to

build the model and to calculate hydrostatic forces and basic stability analysis.

ALPID 3D View 0.707 0.707 -0.424 0.424 0.800 1ALPID Global XY Pl 10.000 10.000ALPID Global YZ Pl 10.000 10.000ALPID Global XZ Pl 10.000 10.000ALPID 3D1 0.955 0.297 -0.182 0.587 0.789 1ALPREF 3D View 5.0 0.0 0.75 1 GROUP 2 SPAR MODELSTBOPT ME MEDRAFT 173.5 110.7 USER USERINTACT 0. 30. 5.CFORM 10. 190. 10.JOINT 1 0.000 0.000 0.000JOINT 2 15.000 15.000 0.000JOINT 3 15.000-15.000 0.000JOINT 4 -15.000 15.000 0.000JOINT 5 -15.000-15.000 0.000JOINT 6 0.000 0.000 4.500JOINT 7 15.000 15.000 4.500JOINT 8 15.000-15.000 4.500JOINT 9 -15.000 15.000 4.500JOINT 10 -15.000-15.000 4.500JOINT 11 0.000 0.000 28.875JOINT 12 15.000 15.000 28.875JOINT 13 15.000-15.000 28.875JOINT 14 -15.000 15.000 28.875JOINT 15 -15.000-15.000 28.875JOINT 16 0.000 0.000 29.375JOINT 17 15.000 15.000 29.375JOINT 18 15.000-15.000 29.375JOINT 19 -15.000 15.000 29.375JOINT 20 -15.000-15.000 29.375JOINT 21 0.000 0.000 53.750

41 | P a g eOCEN – 407 Design of Ocean Engineering Facilities

Design of a Spar Platform in the Gulf of Mexico Spring 2012

JOINT 22 15.000 15.000 53.750JOINT 23 15.000-15.000 53.750JOINT 24 -15.000 15.000 53.750JOINT 25 -15.000-15.000 53.750JOINT 26 0.000 0.000 54.250JOINT 27 15.000 15.000 54.250JOINT 28 15.000-15.000 54.250JOINT 29 -15.000 15.000 54.250JOINT 30 -15.000-15.000 54.250JOINT 31 0.000 0.000 78.625JOINT 32 15.000 15.000 78.625JOINT 33 15.000-15.000 78.625JOINT 34 -15.000 15.000 78.625JOINT 35 -15.000-15.000 78.625JOINT 36 0.000 0.000 79.125JOINT 37 15.000 15.000 79.125JOINT 38 15.000-15.000 79.125JOINT 39 -15.000 15.000 79.125JOINT 40 -15.000-15.000 79.125JOINT 41 0.000 0.000103.500JOINT 42 0.000 0.000 181.5JOINT 43 30.000 30.000 181.5JOINT 44 30.000-30.000 181.5JOINT 45 -30.000 30.000 181.5JOINT 46 -30.000-30.000 181.5JOINT 47 30.000 30.000 188.5JOINT 48 30.000-30.000 188.5JOINT 49 -30.000 30.000 188.5JOINT 50 -30.000-30.000 188.5PANEL BST 5 3 2 4PANEL TST 10 9 7 8PANEL SFT 10 8 3 5PANEL SFT 8 7 2 3PANEL SFT 4 2 7 9PANEL SFT 9 10 5 4PANEL HV1 15 13 12 14PANEL HV1 20 19 17 18PANEL HV1 20 18 13 15PANEL HV1 18 17 12 13PANEL HV1 14 12 17 19

42 | P a g eOCEN – 407 Design of Ocean Engineering Facilities

Design of a Spar Platform in the Gulf of Mexico Spring 2012

PANEL HV1 19 20 15 14PANEL HV2 25 23 22 24PANEL HV2 30 29 27 28PANEL HV2 30 28 23 25PANEL HV2 28 27 22 23PANEL HV2 24 22 27 29PANEL HV2 29 30 25 24PANEL HV3 35 33 32 34PANEL HV3 40 39 37 38PANEL HV3 40 38 33 35PANEL HV3 38 37 32 33PANEL HV3 34 32 37 39PANEL HV3 39 40 35 34PANEL TOP 45 46 44 43PANEL TOP 47 48 50 49PANEL TOP 50 48 44 46PANEL TOP 48 47 43 44PANEL TOP 47 49 45 43PANEL TOP 49 50 46 45CYLIND W TR1 11 6 30.000CYLIND W TR2 21 16 30.000CYLIND W TR3 31 26 30.000CYLIND W TR4 41 36 30.000CYLIND H HRD 42 41 30.000END

43 | P a g eOCEN – 407 Design of Ocean Engineering Facilities

Design of a Spar Platform in the Gulf of Mexico Spring 2012

Appendix- 2

Used OrcaFlex Mooring System and applied force/moments to buoy, recorded distances and got

Stiffness Values

Applied Load (kN)

Horizontal Displacement

(x)Horizontal Stiffness

1000 15.745 111.091500 22.9232000 29.8083000 42.4928000 91.74

15000 140.708

Above is the table when an applied load in the vertical direction. This stiffness wasn’t included

due to interference with buoyancy stiffness (based on a difference in water plane area) and due to

damping in the z direction. Below the tabulated value for rotational stiffness was computed by

inducing a moment from 24-Rotational stiffness

44 | P a g eOCEN – 407 Design of Ocean Engineering Facilities

Applied Load (kN)

Vertical Displacement (z) Vertical Stiffness

100 27.968 14285.71200 27.975400 27.989500 27.996

Applied Moment (kN*m)

Rotation (degrees)

Rotational Stiffness

1000 -3.2773 11437344.082000 -3.27745000 -3.2776

15000 -3.278645000 -3.2813

135000 -3.289

Design of a Spar Platform in the Gulf of Mexico Spring 2012

Appendix- 3

Mass 104951055.9 Time Position Velocity Velocity^2

Stiffness 111090 1 2.00E+00 9.67E-01 0.9349589

C* 993.13 2 3.00E+00 9.33E-01 0.8701949

w 3.25E-02 3 3.99E+00 8.98E-01 0.8059821

ζ 1.45E-04 4 4.98E+00 8.62E-01 0.7425921

w_d 3.25E-02 5 5.96E+00 8.25E-01 0.6802933

B 3.07E+01 6 6.94E+00 7.87E-01 0.6193492

A 1 7 7.91E+00 7.48E-01 0.5600177

y_0 1 8 8.88E+00 7.09E-01 0.5025499

y_0* 1 9 9.83E+00 6.69E-01 0.4471888

C*_NEW 983.657642 10 1.08E+01 6.28E-01 0.3941688

[V] 0.990462117 11 1.17E+01 5.86E-01 0.3437142

Mass 104951055.9 Time Position Velocity Velocity^2Stiffness 111090 1 5.09E+01 -1.66E+00 2.748264272C* 983.657642 3 5.07E+01 -4.97E+00 24.66417351w 3.25E-02 5 5.03E+01 -8.25E+00 68.12417516ζ 1.44E-04 7 4.96E+01 -1.15E+01 132.3920678w_d 3.25E-02 9 4.88E+01 -1.47E+01 216.3797812y_0* 0 11 4.77E+01 -1.79E+01 318.6657903B 7.34E-03 13 4.65E+01 -2.09E+01 437.5191682A 5.10E+01 15 4.50E+01 -2.39E+01 570.9288709y_o 50.96403757 17 4.34E+01 -2.68E+01 716.6377576[V] 35.41644496 19 4.15E+01 -2.95E+01 872.1807723C*_NEW 942.35475 21 3.95E+01 -3.22E+01 1034.92664

Above are the assumptions and iterations for the dynamic response to converge on damping coefficient.

45 | P a g eOCEN – 407 Design of Ocean Engineering Facilities

Design of a Spar Platform in the Gulf of Mexico Spring 2012

Appendix- 4

All data is in (N,kg,m,s) Dimensions

Mass Stiffness Subject Description Value

Topside 12000000Surge Stiffness 111.09

AWPWater Plane Area 537.5

Hull 11147000Heave Stiffness 14285.71

DDiameter 30

Mooring Lines 312696 Buoyancy 5404.696

P_SDensity of Water 1025

Riser 67744.09 Rotational 11437344 P_ST Density of Steel 7850Water Reserve 10913175

HTLHard Tank Length 78

Truss 11031000 STL Soft Tank Length 4.5

Total 45471615 NR Number of Risers 8Forces Natural Periods NM Number of Mooring Lines 16

Wind 705571.3 Heave 25.76078 HP Peak Wave Height 14.4Wave 73681156 Surge 177.3073 TP Peak Wave Period 15.4Current 5568778 WL Wave Length 370.4681

Gust 5324.05 K Wave Number 0.016952pi Pi 3.14g Gravity 9.81H_1000 1000 Year Wave Height 16.5T_1000 1000 Year Wave Period 16.3P_A Density of Air 1.225CD_C Coefficient-Drag Cylinder 1CD_B Coefficient-Drag Box 0.9CI Coefficient-Inertial 1.94746CM Coefficient - Added Mass 0.94746WS Wind Speed 50.93CS Current Speed 2.22

CI-VInertial Coefficient

Vertical 2.6TG Gust Period 200

46 | P a g eOCEN – 407 Design of Ocean Engineering Facilities

Design of a Spar Platform in the Gulf of Mexico Spring 2012

Appendix-5

94.24778 kips11 36.08

1688554 379.5869211069.219188.111266415 86.777 kips-ft

Available Moment94 kips-ft

The above charts were used to calculate all the components that led to picking a member

for the stiffeners. The maximum moment and maximum shear calculated and based on the

maximum moment and shear. Using AISC 14th edition Steel Handbook a W18x97 steel member

was chosen

47 | P a g eOCEN – 407 Design of Ocean Engineering Facilities

Force over Area Force on beam Moment from A Moment Stuff1 1688554 211069.2335 52767.30838 52767.30838 274558.2409 221790.9325 221790.93252 1660172 207521.4428 51880.3607 103760.7214 169910.5718 391701.50433 1632266 204033.2857 51008.32142 153024.9643 118902.2504 510603.75474 1604830 200603.7598 50150.93995 200603.7598 68751.31045 579355.06525 1577855 197231.8796 49307.96991 246539.8496 19443.34053 598798.40576 1551333 193916.6763 48479.16907 290875.0144 -29035.82854 569762.57727 1525258 190657.197 47664.29926 333650.0948 -76700.1278 493062.44948 1499620 187452.5053 46863.12632 374905.0105 -123563.2541 369499.19529 1474413 184301.6801 46075.42002 414678.7802 -169638.6741 199860.5211

10 1449631 181203.816 45300.95401 453009.5401 -214939.6281 -15079.1070211 1425264 178158.0229 44539.50573 489934.563 -259479.1339 -274558.240912 1401307 175163.4255 43790.85637 525490.2765 303269.9902 -303269.9902 -577828.2311

Reaction Forces shear diagram stuff

Design of a Spar Platform in the Gulf of Mexico Spring 2012

Appendix- 5aThe following charts show the force acting on each individual stiffener and the shear diagram of the member.

1 2 3 4 5 6 7 8 9 10 11 120

10000

20000

30000

40000

50000

60000

Force acting on a stiffener

Length position

Forc

e on

Bea

m (N

)

1 2 3 4 5 6 7 8 9 10 11 12

-400000.0

-300000.0

-200000.0

-100000.0

0.0

100000.0

200000.0

300000.0

Shear Diagram

Position (m)

Shea

r (N

)

48 | P a g eOCEN – 407 Design of Ocean Engineering Facilities

Design of a Spar Platform in the Gulf of Mexico Spring 2012

Appendix- 6

C1 D1

C2 D2

C-2 D-2

C-1D-1

49 | P a g eOCEN – 407 Design of Ocean Engineering Facilities

Design of a Spar Platform in the Gulf of Mexico Spring 2012

A1 B1

A2 B2

A-2 B-2

A-1 B-1

50 | P a g eOCEN – 407 Design of Ocean Engineering Facilities

Design of a Spar Platform in the Gulf of Mexico Spring 2012

C1 Dynamics D1 Broken

Riser DynamicsRiser Statics

Each of these plots are from OrcaFlex. The first two charts (lines ABCD) are static results of lines ordered similarly to ().

51 | P a g eOCEN – 407 Design of Ocean Engineering Facilities

Design of a Spar Platform in the Gulf of Mexico Spring 2012

Heave Motions

Pitch Angle

Surge Motions

52 | P a g eOCEN – 407 Design of Ocean Engineering Facilities

Design of a Spar Platform in the Gulf of Mexico Spring 2012

Appendix- 7

Above is the mooring configuration for which was used and referenced in Appendix- 6. Below is a design criteria applied in selecting various diameters. (American Petroleum Institute)

Fibre rope type Weight per unit length (N/m)Polyester 0.0067(d)^2 {d inmm)Aramid 0.00565(d)^2 (din mm)HMPE 0.0062(d)^2(din mm)

Fibre rope type Breaking Strength (N) d(mm)

Polyester 250d^2Aramid 450d^2HMPE 575d^2

53 | P a g eOCEN – 407 Design of Ocean Engineering Facilities

Design of a Spar Platform in the Gulf of Mexico Spring 2012

Appendix- 8

Below is the loading per meter water depth for the cylinder. The current force is modeled using equation , the inertial force was modeled using 14-Inertial force, and the total wave force is in column ‘total’ which was solved using 15-Drag and inertial force.

Current Drag Force

Inertial Wave Force

Drag Wave Force Total

75774.15 1688553.868 132543.3561 176432875658.14393 1660171.542 128125.0516 173583075542.22674 1632266.285 123854.0304 170780975426.3984 1604830.078 119725.3827 1680256

75310.65894 1577855.037 115734.3626 165316675195.00834 1551333.41 111876.3824 162652875079.44662 1525257.576 108147.007 160033774963.97375 1499620.042 104541.9497 157458474848.58976 1474413.441 101057.0661 154926274733.29463 1449630.528 97688.35035 152436474618.08838 1425264.183 94431.93004 149988274502.97098 1401307.404 91284.06181 147581074387.94246 1377753.306 88241.1271 145214174273.0028 1354595.121 85299.62796 1428868

74158.15202 1331826.194 82456.18307 140598474043.39009 1309439.982 79707.52381 138348373928.71704 1287430.052 77050.49052 136135973814.13285 1265790.079 74482.02886 133960473699.63754 1244513.846 71999.18633 131821373585.23108 1223595.237 69599.10882 129718073470.9135 1203028.242 67279.03739 1276499

73356.68478 1182806.951 65036.30504 125616473242.54494 1162925.553 62868.33369 123616873128.49395 1143378.334 60772.63121 121650773014.53184 1124159.678 58746.78852 119717472900.65859 1105264.061 56788.47687 117816572786.87422 1086686.055 54895.44511 115947372673.1787 1068420.32 53065.51717 1141093

72559.57206 1050461.607 51296.58948 112302172446.05428 1032804.756 49586.62862 110525172332.62538 1015444.694 47933.66894 108777772219.28533 998376.4303 46335.81032 1070596

54 | P a g eOCEN – 407 Design of Ocean Engineering Facilities

Design of a Spar Platform in the Gulf of Mexico Spring 2012

72106.03416 981595.0616 44791.21597 105370171992.87185 965095.7651 43298.11035 103708971879.79842 948873.7997 41854.77708 102075471766.81384 932924.5038 40459.55702 1004691

71653.91814 917243.2942 39110.84633988897.

2

71541.1113 901825.6646 37807.09461973366.

8

71428.39334 886667.1847 36546.80318958095.

6

71315.76423 871763.4986 35328.5233943079.

3

71203.224 857110.3234 34150.85452928313.

5

71090.77263 842703.4485 33012.44307913794.

2

70978.41014 828538.7337 31911.98033899517.

1

70866.1365 814612.1089 30848.20128885478.

2

70753.95174 800919.5719 29819.88307871673.

570641.85584 787457.1881 28825.84364 858099

70529.84882 774221.089 27864.94029844750.

9

70417.93065 761207.4709 26936.06845831625.

4

70306.10136 748412.5942 26038.16036818718.

7

70194.36093 735832.7823 25170.18384806027.

1

70082.70938 723464.4201 24331.14114793547.

1

69971.14668 711303.9536 23520.06774781275.

1

69859.67286 699347.8881 22736.03131769207.

6

69748.2879 687592.7881 21978.13056757341.

1

69636.99182 676035.2756 21245.49426745672.

3

69525.78459 664672.0293 20537.28025734197.

8

69414.66624 653499.784 19852.6744722914.

569303.63675 642515.3291 19190.88973 711819

69192.69614 631715.5082 18551.16552700908.

269081.84438 621097.2177 17932.76638 690179.

55 | P a g eOCEN – 407 Design of Ocean Engineering Facilities

Design of a Spar Platform in the Gulf of Mexico Spring 2012

1

68971.0815 610657.4065 17334.98144679628.

5

68860.40748 600393.0746 16757.12353669253.

5

68749.82234 590301.2722 16198.5284659051.

1

68639.32605 580379.0996 15658.55391649018.

4

68528.91864 570623.7053 15136.57936639152.

6

68418.60009 561032.2862 14632.00472629450.

9

68308.37042 551602.0859 14144.24996619910.

5

68198.2296 542330.3947 13672.75441610528.

6

68088.17766 533214.5481 13216.97606601302.

7

67978.21458 524251.9268 12776.39098592230.

1

67868.34038 515439.955 12350.49272583308.

3

67758.55503 506776.1007 11938.79168574534.

7

67648.85856 498257.8741 11540.81461565906.

7

67539.25095 489882.8275 11156.10402557422.

1

67429.73222 481648.5543 10784.21767549078.

367320.30234 473552.6881 10424.72808 540873

67210.96134 465592.9025 10077.22199532803.

9

67101.7092 457766.9103 9741.299946524868.

6

56 | P a g eOCEN – 407 Design of Ocean Engineering Facilities

Design of a Spar Platform in the Gulf of Mexico Spring 2012

57 | P a g eOCEN – 407 Design of Ocean Engineering Facilities

Design of a Spar Platform in the Gulf of Mexico Spring 2012

Appendix- 9

The tables above display the weight and buoyancy of the different parts of the structure.

58 | P a g eOCEN – 407 Design of Ocean Engineering Facilities

Weight (tonne)

TopsideTotal 12000

Hard TankHorizontal walls 4333

Outer Shell 5715Inner Shell 736

Vertical Walls 363Total 11147

TrussPoles 2124

Heave Plates 8845Support Cables 62

Total 11031Soft Tank

Empty 1415Full 3054

TotalTotal 37232

Buoyancy (tonne)

Hard TankMax Buoyancy 536354

Buoyancy at Freeboard 41945

TrussPoles 25

Heave Plates 1162Support Cables 8

Total 1196Soft Tank

Buoyancy 1550Total

Max Buoyancy 56381Buoyancy at

Freeboard 44691