Design and fabrication of an organic DBR laser with MEH ... · MEH-PPV as active layer Design and...

Transcript of Design and fabrication of an organic DBR laser with MEH ... · MEH-PPV as active layer Design and...

Boxuan Gao

MEH-PPV as active layerDesign and fabrication of an organic DBR laser with

Academic year 2015-2016Faculty of Engineering and ArchitectureChair: Prof. dr. ir. Rik Van de WalleDepartment of Electronics and Information Systems

Master of Science in Photonics EngineeringMaster's dissertation submitted in order to obtain the academic degree of

Counsellor: Ir. Michiel CallensSupervisor: Prof. dr. ir. Kristiaan Neyts

Boxuan Gao

MEH-PPV as active layerDesign and fabrication of an organic DBR laser with

Academic year 2015-2016Faculty of Engineering and ArchitectureChair: Prof. dr. ir. Rik Van de WalleDepartment of Electronics and Information Systems

Master of Science in Photonics EngineeringMaster's dissertation submitted in order to obtain the academic degree of

Counsellor: Ir. Michiel CallensSupervisor: Prof. dr. ir. Kristiaan Neyts

Acknowledgements

On the completion of my thesis, there comes the realization that so much I have experienced

and learned, the way I view on my topic and the studying has also been refreshed. All of these

are attributed to the help and guidance I received during my thesis, I would like to express my

deepest gratitude to all those whose kindness and advice that have made this happen.

First, I am very thankful to my promoter Professor Kristiaan Neyts for giving me the oppor-

tunity to be able to complete my thesis at the Liquid Crystal group, it is really a valuable

experience for me. Your advice have always provided me with new ways of thinking and help

me make improvement in my thesis studying. I am also greatly indebted to Michiel Callens, a

responsible supervisor who has spent a lot of time on guiding me during my thesis and giving

me multitudes of valuable instructions on the process of my thesis as well as the thesis writing.

I am very appreciate for his help and patience in every stage of my thesis, I have benefited a

lot from all those discussion with him not only for the thesis but also for my future studying.

Without his tutoring and impressive kindness, this thesis could not be kept proceeding in the

right direction and completed in the end.

Moreover, I shall also convey my sincere thanks to all the other people who has offered me

advice during my studying and all the other aspects, which help me smooth away difficulties as

well as giving me confidence.

Last my thanks would go to my beloved family and friends. During my two years studying in

Gent, they have always been so supportive for me no matter where they are. I can only get

over all the difficulties and finally complete my study with their encouragement. Thank you for

being there for me all the time.

Boxuan Gao

June, 2016

Permission for user on loan

The author gives permission to make this master dissertation available for consultation and to

copy parts of this master dissertation for personal use. In all cases of other use, the copyright

terms have to be respected, in particular with regard to the obligation to state explicitly the

source when quoting results from this master dissertation.

June, 2016

Design and fabrication of an organic DBR laser

with MEH-PPV as active layer

Boxuan Gao

Supervisor: Prof. dr. ir. Kristiaan Neyts

Counsellor: Ir. Michiel Callens

Master’s dissertation submitted in order to obtain the academic degree of

Master of Science in Photonics Engineering

Department of Electronics and Information Systems

Chair: Prof. dr. ir. Rik Van de Walle

Faculty of Engineering and Architecture

Academic year 2015-1016

Abstract

This thesis describes the design and fabrication of an organic DBR laser with conjugated

polymer MEH-PPV as amplifying medium. As organic semiconducting materials com-

bine the advantages of both semiconductors and organic materials, they become promising

candidates for laser development. Conjugated polymers such as MEH-PPV, has a four-

level system and large cross section, make it a proper amplifying medium for lasers. In

this thesis, a net thin MEH-PPV film was made to be the amplifying material by spin

coating, because it is soluble in common organic solvents. Furthermore, the light propa-

gation is also controlled by an organic component–an organic DBR consists of alternative

BDAVBi and TAPC layers, together with a silver mirror to provide high reflectivity, a

laser resonator is achieved, leading to a vertical surface emitting modality. A green laser

functioned as the pump for this organic laser.

Keywords

Organic semicondutors, MEH-PPV, DBR laser

Abstract—this thesis is concerned with the design

and fabrication of an organic DBR laser. A net thin

film of conjugated polymer MEH-PPV is spin coated

as amplifying medium of the laser and an organic

DBR comprising alternative BDAVBi and TAPC

layers serves as the resonator mirror, while the other

mirror is silver. A green laser functions as the pump

device.

Keywords—organic semiconductors, MEH-PPV,

spin coating, organic DBR

I. INTRODUCTION

N recent years, organic semiconductors have

emerged as a promising new material for its

combination of the advantages of both

semiconductors and organic material, providing

possibilities to make easy fabricated tunable

devices, thus being used in various electronics

and optoelectronics applications, for example

light emitting diodes[1] and thin film

transistors[2]. The conjugated polymer

2-methoxy-5-(2'-ethylhexyloxy)-1,4-phenylene-

vinylene (MEH-PPV) with its large absorption

cross-section and high photoluminescence

quantum yield has already been studied as

amplifying medium for organic lasers [3][4] and

proven to be a versatile semi-conducting polymer

for use in optoelectronic devices[5]. However

mostly, the MEH-PPV was used in a dilute

solution. Moreover, light propagation in the

organic semiconductor devices has always been

controlled by inorganic materials such as metals

and dielectric insulators, the refractive indices

difference in organic semiconductors are barely

considered to affect the propagation of light. In

this thesis, a net MEH-PPV thin film is spin

coated on a silver coated substrate as the

amplifying medium and an organic distributed

Bragg reflector (DBR) is deposited on top of the

film to form the laser cavity, controlling the light

reflection. Finally, a green laser is used to provide

population inversion for lasing.

II. BASIC PRINCIPLE OF LASER

LASER is the acronym for Light Amplification by

Stimulated Emission of Radiation. To obtain the

stimulated emission, three basic components are

needed, namely an amplifying medium, a

resonator and a pump device, as illustrated in

Figure 1.

The resonator is formed by two mirror to provide

feedback, light in the resonator will bounce back

and forth. If constructive interference is achieved,

standing waves will be built, which is called

lasing modes.

Figure 1 Schematic of a basic laser set up.

Reprinted from "Lasers", Chapter 1[6]

The condition for the wavelengths of these modes

are expressed below:

][2 LN

Where [L] is the optical path length and N is the

longitudinal mode numbers. Only light with

certain wavelengths can lase.

The amplifying medium is the place where

population inversion occurs, which is necessary

Supervisor: Prof. dr. ir. Kristiaan Neyts

Counsellor: Ir. Michiel Callens

Boxuan Gao

Design and fabrication of an organic laser

with MEH-PPV as active layer

I

to achieve stimulated emission. To have a laser in

stable state, the net round trip gain should be

equal to 1, as shown below:

1)1)(1( ][221 LgeTT

Where 1T and 2T represent the losses at two

mirrors, respectively, and g the gain factor. It

could be realized that with a certain gain factor,

the optical path length should be long enough to

satisfy this condition. In this thesis, the

amplifying medium is a thin film of MEH-PPV.

The pump is provided by a green laser in this

thesis.

III. AMPLIFYING MEDIUM—MEH-PPV

A. Spin coating procedure

Because MEH-PPV can dissolve in common

organic solvents, the thin film is obtained by

casting from solution. In order to produce

uniform film, different solvents have been tried.

According to the formula to obtain stable state

of lasing, the thickness for the film should be

several hundreds of nanometers. First the

MEH-PPV was dissolved in chloroform with

two different concentration 1mg/ml and 3mg/ml.

After completely dissolved, the solution was

spin coated with spin speed varied from

2000rpm to 3000rpm. However, the resulting

films were too thin to meet the requirement.

Then MEH-PPV in Tetrohydrofuran (THF) with

concentration 7.65mg/ml was tested. The

difference is that the spin speed was set to be

600rpm. This time the film seemed much thicker.

As indicated in Figure 2. All the work above

were done in cleanroom.

Figure 2 MEH-PPV flim cast from MEH-PPV in THF

mixture with concentration 7.65mg/ml

B. Optical characteristics

The optical characteristics correspond to lasing

were measured in the lab. For the emission

property, the sample was excited by a green laser

with wavelength 532nm and a broad band

emission spectrum was shown. By adjusting the

parameters of the incident laser beam (repetition

rate, incident intensity) and the position of the

sample, amplified spontaneous emission (ASE)

was obtained with peak at wavelength of around

620nm, suggesting the realization of population

inversion and the possibility of getting lasing

once the resonator is ready.

Figure 3 Up: transmission spectrum of MEH-PPV.

Down: emission spectrum shows the peak of

amplified spontaneous emission

One drawback is that under high incident laser

intensity, there is bleaching effect. To solve this,

the sample was put in a vacuum chamber.

The transmission spectrum is also shown above.

It can be observed that the absorption at

wavelength 532nm is high and for the emitted

light the absorption is low.

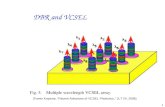

IV. ORGANIC DBR

DBR is a layered structure with alternative high

refractive index and low refractive index layer.

The thickness for each layer is calculated using

the following formula:

4

nd

Where n is the refractive index of that layer and d

is the corresponding thickness. For emission

wavelength 620nm, the thicknesses for

4,40-Bis[4-(diphenylamino)styryl]biphenyl

(BDAVBi) and 1,1-bis[4-[N,N-di(p-tolyl)amino]

-phenyl]cyclohexane (TAPC) are 81.7nm and

93.1nm, respectively. The layers were deposited

on the MEH-PPV film in a vacuum chamber by

physical vapor deposition in cleanroom. These

two materials were chosen because they have

relatively high refractive indices contrast at

620nm. As the reflectivity curve of DBR can shift

by changing the thicknesses of the layers and low

reflection of incident laser at 532nm is preferred,

the BDAVBi layer was made 6nm thicker. The

final reflectivity curve simulated in Matlab is

shown in Figure 4.

Figure 4 Reflectivity of organic DBR

V. THE COMPLETE ORGANIC LASER

When spin coating the MEH-PPV film on the

silver coated substrate and then depositing the

organic DBR on top of the film, the organic laser is

completed. As in Figure 5.

Figure 5 Complete organic DBR laser

The small dots are the silver mirrors, the red film

is MEH-PPV film and the green strip indicates the

positon of the DBR. This sample was excited by a

green laser in the effort to obtain lasing. However,

the lasing did not appear in the end and the DBR

was damaged to some extent. Possible reasons

maybe the thickness of the film cannot support

the lasing mode, the DBR has been burned by the

incident laser energy and the aggregation of the

MEH-PPV polymers. Future works are required

for the acquirement of lasing.

VI. CONCLUSION

In this thesis, a DBR laser was designed and

fabricated using organic materials. The

fabrication procedure has proved to be simple

and the broad band emission spectrum promises

the possibility for tunable laser. Although it is a

pity that the lasing was not achieved in the end,

the appearance of ASE has shown that lasing is

available if all the conditions are met. Therefore

future efforts are needed for the achievements of

a working organic DBR laser.

REFERENCES

[1] Christopher J Tonzola, Maksudul M Alam,

and Samson A Jenekhe. “New soluble n-type

conjugated copolymer for light-emitting

diodes.” Advanced Materials, 14(15):

1086-1090, 2002.

[2] Henning Sirringhaus, Nir Tessler, and

Richard H Friend. “Integrated optoelectronic

devices based on conjugated polymers”.

Science, 280(5370):1741-1744, 1998.

[3] Daniel Moses. “High quantum efficiency

luminescence from a conducting polymer in

solution: A novel polymer laser dye.” Applied

Physics Letters, 60(26):3215-3216, 1992.

[4] Ifor David Williams Samuel and Graham

Alexander Turnbull. “Organic semiconductor

lasers.” Chemical Reviews, 107(4):1272-1295,

2007.

[5] F. Hide, B. J. Schwartz, M. A. Díaz-García, and

A. J. Heeger. “Laser emission from solutions

and films containing semiconducting polymer

and titanium dioxide nanocrystals.” Chemical

Physics Letters, vol. 256, no.4, pp.424–430, 1996.

[6] Prof.Geert Morthier(UGent), Prof.Nathalie

Vermeulen(VUB). “Laser.” 2014.

Table of Contents

List of Figures iii

List of Tables vi

Abbreviations vii

1 Introduction 1

2 Organic Semiconducting Materials 3

3 Laser 7

3.1 Basic Discipline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.2 Amplifying Medium . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.3 Resonator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.3.1 DBR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.3.2 DFB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.4 Conclusion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4 Amplifying Medium–MEH-PPV 17

4.1 Introduction of Amplifying Material . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.2 Deposition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.2.1 Spin-coating Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.2.2 Literature Study and Realization . . . . . . . . . . . . . . . . . . . . . . . 19

4.2.2.1 Chloroform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.2.2.2 Tetrohydrofuran . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.2.3 Solution Chosen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.3 Optical Characterization of Amplifying Medium . . . . . . . . . . . . . . . . . . 21

4.3.1 Emission Properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.3.2 Transmission Property . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.4 Result and Discussion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5 Resonator Mirror–DBR 28

5.1 Material Chosen and Composition . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.2 Properties Verification by Simulation . . . . . . . . . . . . . . . . . . . . . . . . . 29

5.2.1 Simulation Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

5.2.2 An Ideal Referential DBR . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

5.2.2.1 Contrast in Refractive indices . . . . . . . . . . . . . . . . . . . 30

5.2.2.2 Number of Layer pairs . . . . . . . . . . . . . . . . . . . . . . . . 30

i

TABLE OF CONTENTS ii

5.2.2.3 Thickness Uncertainty . . . . . . . . . . . . . . . . . . . . . . . . 32

5.2.2.4 Variation of Incident angle . . . . . . . . . . . . . . . . . . . . . 33

5.2.3 Organic DBR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

5.2.3.1 Number of Pairs of Layers . . . . . . . . . . . . . . . . . . . . . 35

5.2.3.2 Thickness Uncertainty . . . . . . . . . . . . . . . . . . . . . . . . 36

5.2.3.3 Variation of Incident Angle . . . . . . . . . . . . . . . . . . . . . 37

5.2.3.4 Conclusion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

5.3 Fabrication of Organic DBR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

5.4 Transmission Measurement and Comparison . . . . . . . . . . . . . . . . . . . . . 40

5.4.1 Angle Variation Measurement . . . . . . . . . . . . . . . . . . . . . . . . . 40

5.4.2 Thickness Uncertainty Measurement . . . . . . . . . . . . . . . . . . . . . 42

5.5 Result and Discussion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

6 Organic DBR Laser 44

6.1 Fabricated Structure of Organic DBR laser . . . . . . . . . . . . . . . . . . . . . 44

6.1.1 Silver Coated Substrate . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

6.1.2 MEH-PPV and DBR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

6.1.3 Fabricated Samples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

6.2 Property Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

6.2.1 Experimental Setup and Devices . . . . . . . . . . . . . . . . . . . . . . . 48

6.2.2 Measurement Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

6.3 Result and Discussion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

7 Conclusion and Perspective 54

Bibliography 56

List of Figures

2.1 The structure of energy bands in semiconductor materials. Source:http://www.optique-ingenieur.org/[1]. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.2 Overview of diverse III-V semiconductors in lattice constant vs.band-gap dia-gram. Reprinted from [2]. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.3 Schematic of line defection. Reprinted from [3]. . . . . . . . . . . . . . . . . . . 4

2.4 Chemical structures of typical organic semiconductors used for lasers: (a) an-thracene; (b) aluminum tris(quinolate); (c) generic poly(para-phenylene vinylene)derivative; (d) generic polyfluorene derivative; (e) bisfluorene cored dendrimer;(f) spirolinked oligomer. Reprinted from I.D.W.Samuel, G.A.Turnbull, “OrganicSemiconductor Lasers”, Chem.Rev.2007, 107,1272-1295[4]. . . . . . . . . . . . . 5

2.5 Energy level diagram for organic semiconductor gain medium with vibrationallevels. Reprinted from I.D.W.Samuel, G.A.Turnbull, “Organic SemiconductorLasers”, Chem.Rev.2007, 107,1272-1295[4]. . . . . . . . . . . . . . . . . . . . . 6

3.1 Schematic of stimulated emission by a two-level system. Reprinted from Prof.NathalieVermeulen(VUB), Prof.Geert Morthier(UGent), “Lasers”, Chapter1[5]. . . . . 8

3.2 Schematic of a basic laser set up. Reprinted from Prof.Nathalie Vermeulen(VUB),Prof.Geert Morthier(UGent), “Lasers”, Chapter1[5]. . . . . . . . . . . . . . . . 9

3.3 Schematic of the first laser. Reprinted from Prof.Nathalie Vermeulen(VUB),Prof.Geert Morthier(UGent), “Lasers”, Chapter1[5]. . . . . . . . . . . . . . . . 9

3.4 Thin slice of an amplifying medium. Reprinted from Prof.Nathalie Vermeulen(VUB),Prof.Geert Morthier(UGent), “Lasers”, Chapter1[5]. . . . . . . . . . . . . . . . 10

3.5 Cross section as a function of frequency. Reprinted from Prof.Nathalie Ver-meulen(VUB), Prof.Geert Morthier(UGent), “Lasers”, Chapter1[5]. . . . . . . 11

3.6 Small-signal saturated gain as functions of frequency. Reprinted from Prof.NathalieVermeulen(VUB), Prof.Geert Morthier(UGent), “Lasers”, Chapter1[5]. . . . . 12

3.7 Lasing modes of the laser. Reprinted from Prof.Nathalie Vermeulen(VUB), Prof.GeertMorthier(UGent), “Lasers”, Chapter1[5]. . . . . . . . . . . . . . . . . . . . . . 12

3.8 Schematic of Bragg reflector. Reprinted from Prof.Dries Van Thourhout, Prof.RoalBaets (UGent), Prof.Heidi Ottevaere (VUB), “Microphotonics”[6]. . . . . . . . 13

3.9 Reflection mechanism of Bragg reflector. . . . . . . . . . . . . . . . . . . . . . . 13

3.10 Reflection curve for an ideal DBR. . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.11 Schematic of a VCSEL. Reprinted from Prof.Nathalie Vermeulen(VUB), Prof.GeertMorthier(UGent), “Lasers”, Chapter7[5]. . . . . . . . . . . . . . . . . . . . . . 15

3.12 Schematic of a DFB laser. Reprinted from Prof.Nathalie Vermeulen(VUB),Prof.Geert Morthier(UGent), “Lasers”, Chapter7[5]. . . . . . . . . . . . . . . . 15

iii

List of Figures iv

3.13 Waveguide structure of DFB laser. Reprinted from G.A.Turnbull, P.Andrew,W.L.Barnes, I.D.W.Samuel,“Operating characteristics of a semiconducting poly-mer laser pumped by a microchip laser”,2003[7]. . . . . . . . . . . . . . . . . . 16

4.1 Chemical structure of MEH-PPV. Reprinted from Operating characteristics of asemiconducting polymer laser pumped by a microchip laser”,2003[[7]. . . . . . . 18

4.2 Process of spin coating. First the solution applying, then the spin makes anuniform, thin film. Reprinted from [8]. . . . . . . . . . . . . . . . . . . . . . . . 18

4.3 Spin coating film of MEH-PPV dissolved in chloroform with concentration 1mg/ml,spin speed:3000rpm. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.4 Spin coating film of MEH-PPV dissolved in chloroform with concentration 3mg/ml,spin speed:2300rpm. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.5 Spin coating film of MEH-PPV dissolved in THF with concentration 7.65mg/ml,spin speed:600rpm. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.6 Experimental set up for measuring emission spectrum. A: lens with focal length50mm. B: sample position. C: lens system to converge the emission light. D:fiber of spectrometer. E: filter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.7 Emission spectrum of MEH-PPV film. . . . . . . . . . . . . . . . . . . . . . . . 23

4.8 Emission spectrum of MEH-PPV film with ASE peak. . . . . . . . . . . . . . . 23

4.9 Bleached sample. The round spots indicate the places that have been bleached. 24

4.10 Bleaching effect. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.11 Comparison of bleaching effect with/without vacuum. . . . . . . . . . . . . . . . 25

4.12 Transmission curve for MEH-PPV, extracted from article (with chloroform assolvent) and measured from experimental samples. . . . . . . . . . . . . . . . . . 25

4.13 Transmission curve of a glass substrate. . . . . . . . . . . . . . . . . . . . . . . . 26

4.14 Comparison of transmission and emission spectra of MEH-PPV film . . . . . . . 27

5.1 Molecule structures of BDAVBi and TAPC, adapted from[9]. . . . . . . . . . . . 29

5.2 Difference in refractive indices for BDAVBi and TAPC. The large difference inrefractive indices of these two materials at wavelength 600nm could make a goodorganic DBR. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5.3 Reflectivity of DBR versus wavelength with different refractive indices contrast.Higher contrast gives higher reflectivity and broader bandwidth. . . . . . . . . . 31

5.4 Reflectivity of DBR versus wavelength with different number of pairs. The morethe number of pairs, the better the reflectivity is. . . . . . . . . . . . . . . . . . . 31

5.5 Schematic description of thickness uncertainty of layers. . . . . . . . . . . . . . . 32

5.6 Reflectivity of DBR versus wavelength with thickness uncertainty, with thickerlayers than the design, reflectivity curve shifts to longer wavelength. . . . . . . . 33

5.7 Schematic description of different incident angles. . . . . . . . . . . . . . . . . . . 33

5.8 Reflectivity of DBR versus wavelength with incident angle variations, with largerincident angle, the curve shifts to shorter wavelength. . . . . . . . . . . . . . . . 34

5.9 Change in optical path length because of incident angle, which becomes shorterthan before. Reprinted from[6]. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

5.10 Reflectivity of organic DBR versus wavelength with different number of pairs.Same explanation as for Fig.5.4. . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

5.11 Reflectivity of organic DBR versus wavelength with thickness uncertainty, in-creased thickness of the high refractive index layer makes the reflectivity at 532nmreach the bottom of the curve. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

List of Figures v

5.12 Reflectivity of organic DBR versus wavelength with different incident angles,same explanation as for Fig.5.8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

5.13 Reflectivity of organic DBR. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

5.14 Physical vapor deposition chamber. Reprinted from[10]. . . . . . . . . . . . . . . 38

5.15 DBR sample with uniform thicknesses. . . . . . . . . . . . . . . . . . . . . . . . . 39

5.16 DBR sample with continuously changing thicknesses. . . . . . . . . . . . . . . . . 39

5.17 Simulation reflectivity of the organic DBR with different angles. . . . . . . . . . . 40

5.18 Comparison between experiment and simulation: angle 0. . . . . . . . . . . . . . 41

5.19 Comparison between experiment and simulation: angle 18.9. . . . . . . . . . . . . 41

5.20 Comparison between experiment and simulation: angle 27.5. . . . . . . . . . . . . 42

5.21 Comparison between experiment and simulation for all three angles. . . . . . . . 42

5.22 Measurements for sample 2, different thickness were taken at different position. . 43

6.1 Silver coating present as small round dots. . . . . . . . . . . . . . . . . . . . . . 44

6.2 Reflectivity curve of silver coated on glass substrate. . . . . . . . . . . . . . . . 45

6.3 Comparison of transmission curves among MEH-PPV film, organic DBR andtheir combination. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

6.4 Sample with small silver dots. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

6.5 Sample with non-uniform MEH-PPV film thickness. . . . . . . . . . . . . . . . . 47

6.6 Sample with thick MEH-PPV film, the device holding it is a vacuum chamber. . 47

6.7 Lasing measurement setup. A: green laser. B: half wave plate. C: polarized beamsplitter. D: bi-convex lens, f=75mm. E: sample to be measured. . . . . . . . . . 48

6.8 Detection device of the power meter. . . . . . . . . . . . . . . . . . . . . . . . . 49

6.9 Damage of the DBR on sample. A: caused by focused 1000Hz beam. B:causedby focused 50Hz beam. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

6.10 Damage of the DBR on another sample. . . . . . . . . . . . . . . . . . . . . . . 50

6.11 Damage of the DBR on small mirror dots sample. . . . . . . . . . . . . . . . . . 51

6.12 ko and ke value of BDAVBi, adjusted from [9]. . . . . . . . . . . . . . . . . . . . 52

6.13 k value of TAPC, adjusted from [9]. . . . . . . . . . . . . . . . . . . . . . . . . . 52

List of Tables

4.1 Solvents used for spin coating with corresponding results . . . . . . . . . . . . . . 21

6.1 Incident versus reflected laser intensity . . . . . . . . . . . . . . . . . . . . . . . . 49

vi

Abbreviations

ASE Amplified Spontaneous Emission

BDAVBi 4,4′-Bis[4-(diphenylamino)styryl]biphenyl

CP Conjugated Polymer

DBR Distributed Bragg Reflector

DFB Distributed Feed Back

MEH-PPV 2-methoxy-5-(2′-ethylhexyloxy)-1,4-phenylenevinylene

TAPC 1,1-bis[4-[N,N-di(p-tolyl)amino]phenyl]cyclohexane

THF Tetrohydrofuran

VCSEL Vertical Cavity Surface Emitting Laser

vii

Chapter 1

Introduction

Ever since the first ruby laser was introduced in the 1960s, leading to a revolution in science,

multitudes of applications have been developed in different aspects. Plenty of them are found

in our daily life such as printers, anti-theft gates, smoke detections and others, making them an

indispensable part of our lives.

Materials developments have been playing a significant role in the new lasers development.

Conventional lasers are made of inorganic materials, for example, neutral-gas laser He-Ne laser,

molecular gas laser CO2 laser, dye lasers, Nd:YAG laser and other kinds [11]. Recently, the

fact that organic semiconductors combine different attractive optoelectronic properties makes

them competitive candidates in this field. Dating back to 1992, the first semiconducting laser

was reported by Moses [12], of which the amplifying medium is a dilute solution of the poly-

mer poly(2-methoxy-5-(2′-ethylhexyloxy)-1,4-phenylenevinylene), MEH-PPV, making use of the

interesting properties and ease of manufacturing of this semiconducting polymer. However,

light propagation in the organic semiconductor devices has always been controlled by inorganic

materials such as metals and dielectric insulators, the refractive indices difference in organic

semiconductors are barely considered to affect the propagation of light.

In this thesis, as indicated by the title, an organic laser is built, meaning that besides the

gain medium, organic semiconductors also occupy a place in the light propagation control in

this device. Conjugated polymer (CP) MEH-PPV is chosen as the gain medium as it has

been used in many organic lasers [4, 12]. Distributed Bragg reflectors (DBRs) consisting of

vacuum-deposited amorphous organic semiconductor films are selected for light control. Be-

cause of the linear molecular shape of the 4,4′-Bis[4-(diphenylamino)styryl]biphenyl (BDAVBi)

1

CHAPTER 1. INTRODUCTION 2

molecules, large optical anisotropy is achieved due to the different molecular orientation, thus

it has a much higher ordinary refractive index than the extraordinary refractive index. Tak-

ing advantage of BDAVBi’s ordinary refractive index in combination with a low-index isotropic

organic material 1,1-bis[4-[N,N-di(p-tolyl)amino]phenyl]cyclohexane (TAPC), a DBR with high

reflectance demonstrates that light control is obtained. Also, as these vacuum-deposited amor-

phous organic films have smooth surfaces, it will not cause troubles in stacking the films and

allows flexible thicknesses design.

Chapter 2 gives more insight into the organic materials, their structures and advantages as

components of lasers. In Chapter 3, general laser structures are introduced to understand the

principles of a laser and how it works, brief introduction of the amplifying medium, resonator

and pump is given. The two mirror like structures DBR and Distributed Feedback (DFB) Laser

are paid special attention to as they have been used in the development of organic lasers [7, 9].

Chapter 4 focuses on the amplifying medium. The detailed description of the material MEH-

PPV, the deposition technology to get uniform and thick film for required lasing threshold, and

the related properties as amplifying medium are present. In Chapter 5, the Bragg reflector,

built by stacking two organic materials, is treated. First, different aspects of properties are

tested by simulation, then the deposited reflector is measured to obtain the realistic parameters

of these properties, showing its ability to function well in the laser. In Chapter 6, the complete

organic laser is described, including the deposition, the metallic mirror, the pump method and

the attempt to get it lasing. Finally, Chapter 7 gives the general conclusion and perspective.

Chapter 2

Organic Semiconducting Materials

Among the daily life materials, there are semiconductors and organic materials. Semiconductors

such as Si and GaAs, which are inorganic materials, are common materials used in electronics

and optoelectronics, especially in integrated circuits. Some examples of integrated circuits

containing devices are laptops and cellphones. They have also been used in lasers[11]. As shown

in Fig.2.1, the band-gap between the valence band and the conduction band of the semiconductor

is relatively low, makes it possible for the realization of stimulated emission, the basic principle

of laser emission. Fig.2.2 gives examples of different semiconductors used for fabricating laser

Figure 2.1: The structure of energy bands in semiconductor materials.Source:http://www.optique-ingenieur.org/[1].

diodes with their band-gap and lattice constant. Semiconductors have crystalline structures, in

order to grow these materials on top of each other, their lattice constants have to be extremely

close, otherwise the mismatch of the lattice could cause defect in the growth and thick film is

beyond reach.

3

CHAPTER 2. ORGANIC SEMICONDUCTING MATERIALS 4

Figure 2.2: Overview of diverse III-V semiconductors in lattice constant vs.band-gap diagram.Reprinted from [2].

Figure 2.3: Schematic of line defection. Reprinted from [3].

Another widespread type of material is organic materials. For example polymers, which are

involved in applications as packaging and tapes. These materials have a huge range of structures,

resulting in various and tunable properties. Also, the amorphous structure of organic materials

makes it much easier to fabricate. Compared with the demanding epitaxial growth of inorganic

semiconductors, vacuum evaporation and solution spin coating for amorphous organic materials

are more accessible.

The organic semiconducting materials acquire the advantages of both semiconductors and or-

ganic materials, and as such are promising materials for laser development. The recent use

of organic semiconductors based on the organic light emitting diodes is already commercially

available. The semiconducting behavior of the organic materials originates from the alternating

CHAPTER 2. ORGANIC SEMICONDUCTING MATERIALS 5

π− and σ−bonding, converting the two p orbitals, causing the delocalization of the π− elec-

trons with respect to the conjugated bond, forming the freely moved carrier charges, for which

the energy needed is decreasing with the increasing number of conjugations in the material[13].

There are several types of organic semiconductors, as shown in Fig.2.4, defined according to how

the structural features are combined and the procession. Common ones are small molecules,

conjugated polymers (used as gain medium in this thesis), conjugated dendrimers[14] and spiro-

compounds[15–18].

Figure 2.4: Chemical structures of typical organic semiconductors used for lasers: (a)anthracene; (b) aluminum tris(quinolate); (c) generic poly(para-phenylene vinylene) deriva-tive; (d) generic polyfluorene derivative; (e) bisfluorene cored dendrimer; (f) spirolinkedoligomer. Reprinted from I.D.W.Samuel, G.A.Turnbull, “Organic Semiconductor Lasers”,

Chem.Rev.2007, 107,1272-1295[4].

Roughly speaking there are 5 advantages in organic semiconducting materials for the use in

lasers.

1. Due to the various structures, light can be emitted with different wavelengths, covering

from the visible spectrum to the near ultraviolet and infrared. By adjusting the structure

of the materials, tunable laser can be realized.

2. The absorption coefficients of these materials are strong and light can be absorbed in very

short distance. Since the gain factor is related to the absorption of light, large gain is

possible and high amplification is obtained.

CHAPTER 2. ORGANIC SEMICONDUCTING MATERIALS 6

3. The electronic energy levels of these materials can be subdivided into vibronic sublevels,

see Fig.2.5. The excited molecule will first experience a rapid transition to the lowest

vibrational level before the radiative decay. As a result, the absorption and fluorescence

spectra are separated, avoiding the absorption of emitting light.

Figure 2.5: Energy level diagram for organic semiconductor gain medium with vibra-tional levels. Reprinted from I.D.W.Samuel, G.A.Turnbull, “Organic Semiconductor Lasers”,

Chem.Rev.2007, 107,1272-1295[4].

4. The organic semiconductors are also able to transport charges, providing the possibilities

for electronic pump.

5. The simple fabrication methods as vacuum evaporation and spin coating (see more details

in Chapter 4 and Chapter 5) compared with inorganic semiconductors.

For more information, refer to references [2, 13–18].

Chapter 3

Laser

Before we start making a laser, it is necessary to review the general principles. In this chapter,

a brief introduction will be given to LASERs. Especially, two kinds of “mirror” DFB and DBR

will be discussed.

3.1 Basic Discipline

LASER is the acronym for Light Amplification by Stimulated Emission of Radiation, plainly

speaking, laser is an amplifying device for light, functioning based on one special mechanism,

stimulated emission, which leads to the special properties of a laser beam. In order to describe

the principle of lasing, quantum mechanics will be needed and atoms are considered as systems

with discrete energy levels, introduced by Albert Einstein in 1916. Fig.3.1 shows a model of

two-level system where light is amplified by stimulated emission. When a photon is incident on

an excited atom with energy identical to the energy difference between the two levels, the atom

will be stimulated to return to its ground state, at the same time, a new photon will be created.

Similarly, if a light beam is incident on this matter, a new beam will be created.

The new beam has the following properties.

• Monochromatic, the new light beam has the same frequency as the incident one.

• Collimated, the new light beam is emitted in the same direction as the incident one.

• Coherent, the new light beam has the same phase as the incident one.

7

CHAPTER 3. LASER 8

Figure 3.1: Schematic of stimulated emission by a two-level system. Reprinted fromProf.Nathalie Vermeulen(VUB), Prof.Geert Morthier(UGent), “Lasers”, Chapter1[5].

Due to these properties, it is obvious that the light beam is amplified, which is the basis of laser

action.

Besides stimulated emission, there also exists other phenomena in this system, absorption and

spontaneous emission, compared with stimulated emission, spontaneous emission is the tran-

sition of an excited quantum system to a lower energy state, the emission is not coherent. To

make the stimulated emission the dominant one, the number of atoms in the excited state must

be larger than in the ground state. This condition is called population inversion, maintained by

the pumping process. The material in which population inversion is realized acts as a amplifying

medium.

Another problem is that the amplification through the amplifying medium is rather small. To

solve this problem, the amplifying medium is enclosed between two mirrors, thus light reflected

by the mirrors can bounce back and forth in the medium. With tens of hundreds of times passing

through the amplifying medium, the light will gain enough amplification. The two mirrors form

the laser resonator. One of the mirrors has reflectance less than 100% to couple the light out of

the resonator, giving rise to lasing action.

To sum up, a laser should contain three basic blocks, a pump system, an amplifying medium

and a resonator. The schematic for a basic laser set up is shown in Fig.3.2.

The first laser is a ruby laser built by Ted Maiman. It was realized in 1960, a ruby crystal

constituted the amplifying medium. Fig.3.3 shows the structure of the first laser. The amplifying

medium for the first laser was a ruby crystal with chromium ions dissolved in as active atoms.

The flash tube around the ruby served as a optical pump. The two facet ends were polished

CHAPTER 3. LASER 9

and covered with silver to form the laser resonator. This configuration is still present in some

lasers nowadays.

Figure 3.2: Schematic of a basic laser set up. Reprinted from Prof.Nathalie Vermeulen(VUB),Prof.Geert Morthier(UGent), “Lasers”, Chapter1[5].

Figure 3.3: Schematic of the first laser. Reprinted from Prof.Nathalie Vermeulen(VUB),Prof.Geert Morthier(UGent), “Lasers”, Chapter1[5].

CHAPTER 3. LASER 10

3.2 Amplifying Medium

As explained in last section, light bounces back and forth in the amplifying medium, if con-

structive interference is achieved, standing waves will be built, which are called modes. The

condition for the wavelengths of these modes are expressed as:

Nλ = 2[L] (3.1)

Where [L] is the optical path length and N is the longitudinal mode number. From equation3.1,

it can be concluded that there can exist more than one mode. For example, a laser cavity with

[L] ≈ 6µm and λ ≈ 600nm, the number of mode is 10.

Fig.3.4 shows a simple model of gain mechanism in the amplifying medium. Consider a two-

Figure 3.4: Thin slice of an amplifying medium. Reprinted from Prof.Nathalie Ver-meulen(VUB), Prof.Geert Morthier(UGent), “Lasers”, Chapter1[5].

level system with population N1 and N2 for high energy level and low energy level, respectively.

Then the optical power increment is related with the incident power as:

dP = Pσ(N2 −N1)dz (3.2)

CHAPTER 3. LASER 11

where σ is defined to be the cross section, surface of one atom. Then the power growth after

propagation through the medium can then be expressed by an exponential equation:

P (z) = P (0)egz (3.3)

In equation 3.3, g is the gain factor and z is the path length. For one roundtrip, the path length

equals two times the laser cavity length. The expression for g is given by:

g = σ(N2 −N1) (3.4)

The unit of g is often given in cm−1 or mm−1. However, the interaction between the quantum

system and the incident light can also happen at frequencies close to but not exactly at the

resonant frequency, thus the cross section σ depends on the frequency f (Fig.3.5), resulting in

a frequency dependent gain according to equation 3.4, indicated by Fig.3.6. This phenomenon

is called line broadening. The line broadening indicates that as long as the modes are in

the gain region, they can be amplified, meaning that the gain modes are not limited to one

certain frequency, i.e. more than one modes can experience lasing action. Fig.3.6 also indicates

saturation, the decreasing of gain when power increases because the increasing power takes too

much energy from the pump and the population inversion decreases, not strong enough to keep

up the gain. Then the system gradually comes to the steady state, where the roundtrip gain

becomes 1. As a result, only part of the modes get to be amplified, shown in Fig.3.7. These are

the lasing wavelengths.

Figure 3.5: Cross section as a function of frequency. Reprinted from Prof.Nathalie Ver-meulen(VUB), Prof.Geert Morthier(UGent), “Lasers”, Chapter1[5].

CHAPTER 3. LASER 12

Figure 3.6: Small-signal saturated gain as functions of frequency. Reprinted fromProf.Nathalie Vermeulen(VUB), Prof.Geert Morthier(UGent), “Lasers”, Chapter1[5].

Figure 3.7: Lasing modes of the laser. Reprinted from Prof.Nathalie Vermeulen(VUB),Prof.Geert Morthier(UGent), “Lasers”, Chapter1[5].

3.3 Resonator

In this section, two special light reflection mechanisms-DFB and DBR-are present, as they are

used in organic lasers.

3.3.1 DBR

DBR is the acronym for Distributed Bragg Reflector, which is a layered structure consisting

of alternating quarter-wave layers of two different materials, a schematic view of this kind of

structure is shown in Fig.3.8. One high refractive index layer and one low refractive index layer

is called one pair of layers.

For the incident light with certain wavelength λ0, the thicknesses d1 and d2 of the two materials

with refractive indices n1 and n2 are calculated by the following formula:

n1d1 = n2d2 =λ04

(3.5)

CHAPTER 3. LASER 13

Figure 3.8: Schematic of Bragg reflector. Reprinted from Prof.Dries Van Thourhout,Prof.Roal Baets (UGent), Prof.Heidi Ottevaere (VUB), “Microphotonics”[6].

Then the reflected light will interfere constructively, a high reflectance is obtained at this par-

ticular wavelength. A graphic explanation is given below. As shown in Fig.3.9, light incident on

Figure 3.9: Reflection mechanism of Bragg reflector.

the surface will be reflected at the interfaces of different layers. The first reflection happens at

the interface between air and the first layer. Because the refractive index of air is smaller than

n2, there is a π shift in the reflection compared with the incident light. When the reflection at

the second interface goes back in the air, there is also a π shift because it experienced an extra

λ2n2

path length (no phase shift when light is incident from low refractive index material to high

refractive index material). Similarly, the phase shift for the reflection from the third and forth

layers is 3π and so forth, the differences between these phase shifts are always the multiples

of 2π. Then the reflected light at the air-first layer interface interferes constructively, a high

reflection is formed.

The peak reflection can be given using the matrix method,

RHR,max =

(1− (ns

na)(n1n2

)2N

1 + (nsna

)(n1n2

)2N

)2

(3.6)

CHAPTER 3. LASER 14

Where ns is the refractive index of the substrate, na that of air and N the number of periods.

It is seen that the reflection converges to 1 with increasing periods. Increasing the contrast

between the refractive indices of the two materials can also increase the reflection.

The frequency bandwidth for the stop band is given by equation3.7,

δf0f0

=4

πarcsin

(n2 − n1n2 + n1

)(3.7)

Where refractive indices contrast is again seen to play a role, larger contrast gives rise to wider

bandwidth.

Figure 3.10: Reflection curve for an ideal DBR.

Compared to conventional mirror, DBR serves as a wavelength selective element of laser. A

mirror reflects all the incident light regardless of the wavelengths, resulting in broadband modes,

while a narrow band of wavelengths is achieved by using a DBR. Fig.3.10 shows a reflection

curve for a DBR, the refractive indices for the two layer materials are 2 and 1, respectively and

the number of pairs is set to be 5. The thicknesses of the layers are calculated by equation 3.5

assuming the wavelength is 550nm. The bandwidth is around 300nm wide. More information

shall be given in Chapter 5.

Fig.3.11 presents a Vertical Cavity Surface Emitting Laser (VCSEL) with DBRs, the cavity

length is the thickness of the amplifying medium. This structure is similar to the structure we

will use in this thesis.

CHAPTER 3. LASER 15

Figure 3.11: Schematic of a VCSEL. Reprinted from Prof.Nathalie Vermeulen(VUB),Prof.Geert Morthier(UGent), “Lasers”, Chapter7[5].

3.3.2 DFB

DFB is the acronym for Distributed Feedback. The principle is similar to DBR. For DFB laser,

there is a diffracting grating below or above the active layer, see Fig.3.12. By tuning the period

of the grating, it can act as a Bragg reflector, light wave with desired wavelength then can

bounce back and forth in the cavity. Different from the DBR case, the cavity length is in the

surface parallel with the DFB, direction is dependent on the choosing of facets. When used in

an organic laser, the organic film itself can form the polymer layer with an average thickness of

∼ 100nm in this structure[7], as shown in Fig.3.13.

Figure 3.12: Schematic of a DFB laser. Reprinted from Prof.Nathalie Vermeulen(VUB),Prof.Geert Morthier(UGent), “Lasers”, Chapter7[5].

CHAPTER 3. LASER 16

Figure 3.13: Waveguide structure of DFB laser. Reprinted from G.A.Turnbull, P.Andrew,W.L.Barnes, I.D.W.Samuel,“Operating characteristics of a semiconducting polymer laser

pumped by a microchip laser”,2003[7].

3.4 Conclusion

In this chapter, the lasing mechanism was treated which originates from stimulated emission

and amplified by the lasing mode bouncing back and forth in the laser cavity. In order to gain

stimulated emission, a pump laser is needed to provide population inversion for the amplifying

medium, which is made of organic material in this thesis. The laser resonator is enclosed by two

mirrors for the feedback of light. The optical length of the laser cavity determines the lasing

modes.

Chapter 4

Amplifying Medium–MEH-PPV

In this chapter, the fabrication and characterization of the amplifying medium–MEH-PPV–are

described. The fabrication is realized by the deposition of the material by spin-coating wherein

different solutions were tested. The related optical properties, more specifically, emission and

transmission properties of this material are discussed.

4.1 Introduction of Amplifying Material

As mentioned in Chapter 1, organic semiconductors such as conjugated polymers are of great

interest for its combination of both semiconductor and polymer properties, thus being used

in various electronics and optoelectronics applications, for example light emitting diodes[19]

and thin film transistors[20]. Substituted PPV’s emerge as promising candidates as laser am-

plifying medium because of their large absorption cross-section and high photoluminescence

quantum yield, among which MEH-PPV (shown in Fig.4.1) has been studied as amplifying

medium for organic lasers[4, 12] and has proven to be a versatile semi-conducting polymer for

use in optoelectronic devices[21], research have also been conducted regarding to the deposition

methodology[22, 23]. The solubility of MEH-PPV in some common organic solvents comes from

the asymmetric alkoxy side chains, allowing deposition techniques such as spin coating and drop

casting. In this thesis, MEH-PPV material is chosen as the active film for the organic DBR

laser.

17

CHAPTER 4. AMPLIFYING MEDIUM–MEH-PPV 18

Figure 4.1: Chemical structure of MEH-PPV. Reprinted from Operating characteristics of asemiconducting polymer laser pumped by a microchip laser”,2003[[7].

4.2 Deposition

4.2.1 Spin-coating Process

Spin coating has been used for several decades for applying uniform thin films to flat substrates.

The general procedure is presented in Fig.4.2. An excess amount of a solution is dropped onto

a clean substrate mounted on a spin coater. The substrate is then rotated at a high speed,

causing the solution to spread out on it. Excess solution will eventually spin off the edge of

the substrate until the desired thickness is achieved. The applied solvent is usually volatile and

evaporation happens during the process. There are four basic stages of the process:

1. Application of the solution on the substrate.

2. Acceleration of the substrate to the desired rotation speed.

3. Constant spinning, spread of fluid.

4. Constant spinning, evaporation of solvent

Figure 4.2: Process of spin coating. First the solution applying, then the spin makes anuniform, thin film. Reprinted from [8].

Final film thickness is related to the spin speed, solution concentration and also the viscosity,

in general, for polymer materials, slower speeds and higher concentrations give rise to thicker

films[24].

CHAPTER 4. AMPLIFYING MEDIUM–MEH-PPV 19

4.2.2 Literature Study and Realization

As introduced in Chapter 3, light bouncing back and forth in the amplifying medium will

experience amplification. In order to maintain the steady sate regime of the laser, the total loss

should equal the total gain, which yields:

(1− T1)(1− T2)e2gl = 1 (4.1)

Where T1 and T2 represent the losses at the two mirrors, respectively, g represents the gain factor

and l is the laser cavity length. To achieve this condition, as calculated from equation4.1, the

film thickness of MEH-PPV should be 500nm, with the gain factor used from[25], and assuming

the pump energy is around 10µJ/cm2. For the realization of the desired thickness, different

spin coating settings and several solvents have been tested. The spin coating was conducted on

a glass substrate which was cleaned before use. The cleaning was also done in the cleanroom.

Procedures for cleaning are expressed below.

• Put glass substrates in the substrate holder, immerse the holder in a beaker filled with

soap water. Put the beaker in ultrasonic for 15 minutes.

• Rinse with DI water and dry. Put the holder in another beaker and immersed with

Acetone, put in ultrasonic for 15 minutes.

• Rinse with DI water and dry. Repeat the previous procedure with IPA.

• Rinse with DI water and dry it thoroughly.

The MEH-PPV powder was purchased from SIGMA−ALDRICH.

4.2.2.1 Chloroform

First, chloroform as a solvent was chosen, for it has been used in dissolving MEH-PPV for

spin coating solution[22]. The chloroform was purchased from SIGMA−ALDRICH. To gain

a general idea of the thickness of the film, a piece of tape was attached to cover part of the

substrate, resulting in a no-film region. Starting concentration was 1mg/ml, the spin speed

ranged from 1400rpm to 3000rpm with spin time 15 seconds. The higher speed provides more

uniform and thinner films. The sample with spin speed 3000rpm is shown in Fig.4.3. Part of

CHAPTER 4. AMPLIFYING MEDIUM–MEH-PPV 20

Figure 4.3: Spin coating film of MEH-PPV dissolved in chloroform with concentration1mg/ml, spin speed:3000rpm.

the substrate is covered with the film, the boundary is marked with red dash line. It is obvious

that the boundary is barely seen, meaning the film is too thin.

The second concentration tested was 3mg/ml. The spin speed varied from 1900rpm to 2800rpm

and the spin time stayed the same. One obtained sample with spin speed 2300rpm is shown

in Fig.4.4. Compared with Fig.4.3, the film is visibly thicker and quite uniform. However, the

Figure 4.4: Spin coating film of MEH-PPV dissolved in chloroform with concentration3mg/ml, spin speed:2300rpm.

thickness is still not satisfactory thus can not fulfill the requirement. More research in literature

is needed.

4.2.2.2 Tetrohydrofuran

After a more in depth literature study, tetrahydrofuran (THF) emerged as another solvent

material[26]. MEH-PPV dissolved in THF with concentration 7.65mg/ml was made. The THF

was purchased from SIGMA−ALDRICH. Two spin speeds–600rpm and 800rpm–were tried

CHAPTER 4. AMPLIFYING MEDIUM–MEH-PPV 21

according to the article[26] and the films seem to be better than chloroform. Fig.4.5 shows the

sample with spin speed 600rpm and spin time 15 seconds. The red color is darker than before

Figure 4.5: Spin coating film of MEH-PPV dissolved in THF with concentration 7.65mg/ml,spin speed:600rpm.

and the measured thickness is ∼ 200nm, which fulfils the requirement on the film thickness.

4.2.3 Solution Chosen

The total results are shown in Table 4.1, after comparison, THF was chosen as the solvent for

the amplifying medium deposition.

Table 4.1: Solvents used for spin coating with corresponding results

Solvent Chloroform THF

Concentration 1mg/ml 3mg/ml 7.65mg/mlSpin speed 2000rpm∼3000rpm 600rpm, 800rpmThickness too thin thin acceptable, ∼200nmUniformity uniform uniform uniform

4.3 Optical Characterization of Amplifying Medium

An amplifying medium is the place where laser light is produced and amplified, the emission

and transmission properties of the amplifying medium are of great importance and related to

the characteristic of the laser. In the following, these two properties of the MEH-PPV film are

discussed.

CHAPTER 4. AMPLIFYING MEDIUM–MEH-PPV 22

4.3.1 Emission Properties

The emission wavelength of MEH-PPV is relatively long according to previous research[26], in

this experiment, a green laser PNG −M02010 − 130 which is a pulsed laser with maximum

repetition rate 1000Hz, pulse width smaller than 400ps and working wavelength 532nm served

as the pump, a spectrometer Ocean Optics QE Pro was used for the emission spectrum. The

setup is shown in Fig4.6. As shown in Fig.4.6, the laser beam going out of the green laser

Figure 4.6: Experimental set up for measuring emission spectrum. A: lens with focal length50mm. B: sample position. C: lens system to converge the emission light. D: fiber of spectrom-

eter. E: filter.

shining on the sample will excite the material to obtain the emission beam. The pump laser

beam first goes through the combination of a half wave plate and a polarized beam splitter.

As the polarized beam splitter only allows light with a certain polarization to go through and

the half wave plate is able to change the polarization of light, this combination allows for the

tuning of the outcome intensity of the laser beam. Position A located a lens with focal length

50mm, sliding of the lens will change the laser spot diameter on position B, the MEH-PPV

sample, which was made by spin coating the MEH-PPV in THF mixture with concentration

7.65mg/ml. At position C is a lens system consists two lenses with focal length 50mm and

75mm respectively, the sample at position B sits at the focus. In this way the system transmits

the emission as much as possible to position D. The sample (position B) is put at an angle to

avoid the strong green laser beam destroying the spectrometer. E is a filter to filter out the

lasing wavelength from the green laser, trying to eliminate the influence of the remained laser

beam, there is also a pair of goggle for the same purpose. The obtained emission spectra are

shown in Fig.4.7 and Fig.4.8.

CHAPTER 4. AMPLIFYING MEDIUM–MEH-PPV 23

Figure 4.7: Emission spectrum of MEH-PPV film.

Figure 4.8: Emission spectrum of MEH-PPV film with ASE peak.

When exited by the green laser beam with repetition rate 1000Hz and put in an appropriate

position, the MEH-PPV emission spectrum can be reconstructed by the spectrometer with

wavelength from around 550nm to a little larger than 730nm, shows a broad emission band. By

carefully tuning the sample position to gain the maximum pump energy, population inversion

may occur and amplified spontaneous emission (ASE) is reached, that is the high peak shown

in Fig.4.8 at around 620nm. The amplified spontaneous emission peak is relative narrow with

bandwidth around 10nm and indicates the possibility for the lasing action.

The reflection band of DBR should also be between 550nm and 730nm, corresponding with the

emission band.

Under the light exposure, there is also bleaching effect which destroys the molecules thus re-

duces the emission intensity (Fig.4.9). To verify this effect, the MEH-PPV sample was kept

under exposure and the emission spectra were stored every 20 seconds for 100 times, thus a

total exposure time 2000 seconds. The average emission intensity values around the peak was

CHAPTER 4. AMPLIFYING MEDIUM–MEH-PPV 24

normalized and drawn as a function of time. By changing the position of the lens at spot A in

Fig.4.6, relation between the pump laser intensity and bleaching effect was discovered, which is

drawn in Fig.4.10. The spectrometer used for this detection was QWave compact USB. The

Figure 4.9: Bleached sample. The round spots indicate the places that have been bleached.

Figure 4.10: Bleaching effect.

bleaching effect is stronger for higher laser intensity as shown above. To solve this problem,

the sample was put in a vacuum holder to weaken the effect. The emission spectra were stored

every 1 second for 600 times (in total 600 seconds under exposure) both with and without vac-

uum. Then the normalized average emission intensity value around the peak region was drawn

as a function of time, as shown in Fig.4.11. Because of the change of positions under the two

cases, the starting emission intensities were different. For the case with vacuum, the starting

intensity was 1500.6 (absolute value, as in Fig.4.7 and Fig.4.8) and for without vacuum was

1104.3, meaning the bleaching effect should be stronger for the vacuum case. On the contrary,

CHAPTER 4. AMPLIFYING MEDIUM–MEH-PPV 25

Figure 4.11: Comparison of bleaching effect with/without vacuum.

as in Fig.4.11, with vacuum the emission decline is 2.74% while for its counterpart is 22.9%.

The bleaching effect is indeed suppressed under the vacuum condition.

4.3.2 Transmission Property

The transmission property of MEH-PPV film is measured in PerkinElmer UV/V IS Spectrometer,

the collected data was plot and compared with curve abstracted from an article[22], of which

the MEH-PPV film is spin coated from chloroform mixture on the glass substrate. Results are

shown in Fig.4.12. Also, a transmission spectrum of a glass substrate is shown in Fig.4.13.

Figure 4.12: Transmission curve for MEH-PPV, extracted from article (with chloroform assolvent) and measured from experimental samples.

CHAPTER 4. AMPLIFYING MEDIUM–MEH-PPV 26

Figure 4.13: Transmission curve of a glass substrate.

The samples being measured are MEH-PPV film spin coated from THF mixture with concentra-

tion 7.65mg/ml and different spin speeds and spin times, as shown in the legend. The tendencies

of the curves are similar with an absorption dip around wavelength 500nm, however for THF

as solvent, the absorption range is noticeably wider. The phenomenon that the absorption

spectrum of MEH-PPV film varies when spin coated from different solvents was also observe in

article[22]. The different concentrations of the solution, different solvate of the polymer chain

and different molecule weights can all take on a role in leading to various spectra. When com-

pared with emission spectrum, it verifies that these two spectra are separated, avoiding the

absorption of emitting light, shown in Fig.4.14, as mentioned in Chapter 2.

4.4 Result and Discussion

In this chapter, a detailed discussion about the amplifying medium–MEH-PPV–was given, from

the properties of this material to its deposition then the optical characteristics regarding to

absorption and gain. MEH-PPV is a promising organic material takes on the role as a laser

amplifying medium as it contains advantages of both semiconductors and polymers. The powder

of MEH-PPV dissolved in organic solvent THF formed a solution with concentration 7.65mg/ml,

from which the solid net uniform MEH-PPV film cast could end up in thickness of around 200nm,

thick enough to provide required gain. Excited by a pump laser, this film has shown a broad

spontaneous emission band ranges from 550nm to 730nm and ASE has also been realized in

certain condition, indicating the realization of population inversion. The absorption band is

CHAPTER 4. AMPLIFYING MEDIUM–MEH-PPV 27

Figure 4.14: Comparison of transmission and emission spectra of MEH-PPV film

also well separated from the emission band, avoiding absorbing of the emitted light. Concluded

above, MEH-PPV has proven to be a qualified amplifying medium material. The next step shall

be the design and fabrication of corresponding DBR structure.

Chapter 5

Resonator Mirror–DBR

As described in Chapter 3, a DBR serves as the resonator mirror that only reflects light at a

certain wavelength range. In this chapter, properties of the DBR and various influencing factors

are treated. Then, special attention is given to the organic DBR used in the organic laser.

5.1 Material Chosen and Composition

Organic semiconductors have different refractive indices and anisotropies depending on the

molecule structures and molecular orientation. By controlling the refractive indices of the

organic semiconductors, an organic DBR with the desired properties, that consisting of these

amorphous vacuum-deposited organic semiconductor films can be used for light control, thus

realizing the mirror function with organic materials.

As mentioned in section3.3.1, a larger refractive index contrast contributes to higher mirror

reflectivity and wider bandwidth. BDAVBi is an organic semiconductor with molecular orien-

tation in the horizontal direction in vacuum-deposited amorphous films because of its linearly

molecular shape. Since it has a certain molecular orientation, birefringence takes place, leading

to a much higher ordinary refractive index no in the horizontal direction than the extraordinary

refractive index ne in the vertical direction. This high no provides a possibility for a high refrac-

tive index layer in our DBR. On the other hand, TAPC molecules have an isotropic orientation

and consequently isotropic optical constants[27, 28]. Because of its saturated hydrocarbons, the

lower molar refractions give rise to a relatively low refractive index of this material[29]. A low

28

CHAPTER 5. RESONATOR MIRROR–DBR 29

refractive index layer for the DBR is obtained. The molecular structures of BDAVBi and TAPC

are shown in Fig.5.1. Fig.5.2 shows the difference in refractive indices of these two materials,

it can be seen that at wavelength 600nm (in MEH-PPV emission range), the difference is ap-

proximately 0.3. Because of a smooth film surface, stacking films of these two materials makes

a functioning organic DBR.

Figure 5.1: Molecule structures of BDAVBi and TAPC, adapted from[9].

Figure 5.2: Difference in refractive indices for BDAVBi and TAPC. The large difference inrefractive indices of these two materials at wavelength 600nm could make a good organic DBR.

5.2 Properties Verification by Simulation

In this section, different factors that influence the behavior of the DBR are discussed, through

which a general idea about the behaviour of the DBR is acquired and the fabrication variation

can be analyzed. First, the simulation was carried out on a simple model of a DBR, isotropic

and without dispersion. Then the parameters for the real materials were added in the code

CHAPTER 5. RESONATOR MIRROR–DBR 30

to simulate the realistic organic DBR. Finally, a comparison between this simulation and the

measurement of the fabricated DBR was performed.

5.2.1 Simulation Method

The simulation method is implemented in Matlab, wherein uniaxial anisotropic films are rep-

resented by their refractive indices, assuming the optical axis is perpendicular to the surface.

The number, the thickness of the films and the incident angle of the light can be modified. As a

result, the refection as well as the transmission can be plot as function of wavelength. Detailed

explanation on the simulation method can be found in[30].

5.2.2 An Ideal Referential DBR

To begin with, a simple model of DBR was simulated. In this case, the high and low refrac-

tive indices were set with certain values, respectively. The films were assumed to be isotropic

without dispersion, that is, the refractive indices stay the same with different incident angle

and are wavelength independent. The surrounding environment was air with refractive index 1.

The factors under simulation are contrast in refractive indices of the layers, number of layers,

thickness uncertainty of layers and variation of incident angle.

5.2.2.1 Contrast in Refractive indices

In this simulation, the incident angle was 0 degree (in the code it was set to be 0.0000001 to

avoid mistake), wavelength range was 300nm–800nm and there were 5 pairs of layers. The

design wavelength for this DBR was 550nm. Three different contrasts, 1.51 , 2

1 , 2.51 were tested

while other parameters remained unchanged during the simulation. As shown in Fig.5.3, with

larger contrast, not only the reflectivity is higher but also the bandwidth is wider, which agrees

with the theory explained in Chapter 3.

5.2.2.2 Number of Layer pairs

Then the refractive indices were fixed to be 2 and 1 for the high refractive index layer and the

low refractive index layer, respectively. The variable for this simulation is the number of pairs

CHAPTER 5. RESONATOR MIRROR–DBR 31

Figure 5.3: Reflectivity of DBR versus wavelength with different refractive indices contrast.Higher contrast gives higher reflectivity and broader bandwidth.

and the other parameters were the same as the simulation in section 5.2.2.1. Fig.5.4 shows

the result. From Fig.5.4, it is clear that with more layers, the reflectivity is higher and the

Figure 5.4: Reflectivity of DBR versus wavelength with different number of pairs. The morethe number of pairs, the better the reflectivity is.

shape of bandwidth is more concentrated, which corresponds with equation 3.6 in Chapter 3,

however the width does not change very much, compared with the contrast difference. With

other optical parameters the same as this model, 5 pairs of layers can already result in a well

performed DBR.

CHAPTER 5. RESONATOR MIRROR–DBR 32

5.2.2.3 Thickness Uncertainty

The third variable is the thickness, which is also the optical path length in this case. During

the fabrication, exactly the same thicknesses as designed may not be guaranteed, thus the

uncertainty of thickness is of importance to be analyzed. A schematic representation of this

phenomenon is shown in Fig.5.5. The number of pairs was fixed to be 5, for the parameters set as

Figure 5.5: Schematic description of thickness uncertainty of layers.

above, from equation 3.5 in Chapter 3 the optimal thickness for the high refractive index layer

and the low refractive index layer were calculated to be 68.75nm and 137.5nm, respectively.

A 10nm variation was introduced to these layers both separately and together. Result is in

Fig.5.6. With increasing thickness, the curve shifts to the longer wavelength. This can be

explained from equation 3.5, the thickness is proportional to the design wavelength, when the

thickness increases, the design wavelength will increase accordingly, resulting in the curve shift.

It is also shown that for the same thickness variation of 10nm, when the variation is on the

high refractive index layer, the curve shift is around 33.5nm while for its counterpart the shift is

around 16.5nm. This is because the high refractive index layer is thinner compared with its low

counterpart, so the relative change in thickness for it is actually higher. If both layers become

10nm thicker, the total influence is simply the sum of the two single influence.

CHAPTER 5. RESONATOR MIRROR–DBR 33

Figure 5.6: Reflectivity of DBR versus wavelength with thickness uncertainty, with thickerlayers than the design, reflectivity curve shifts to longer wavelength.

5.2.2.4 Variation of Incident angle

The last factor that is going to be discussed is the incident angle. Incident light cannot always be

perpendicular to the surface of DBR, as shown in Fig.5.7, different incident angles also influence

the reflectivity. Keeping all the other parameters set to the original values, three incident angles

Figure 5.7: Schematic description of different incident angles.

were chosen, 0 degree, 20 degrees and 40 degrees. The simulation result is shown in Fig.5.8. It

can be seen that the curve shifts to shorter wavelength. This can be explained as follows. The

high reflection comes from the constructively interference of the reflected wave, so the phase

difference between wave reflected at different layers has a certain value, that is, the multiple of

CHAPTER 5. RESONATOR MIRROR–DBR 34

Figure 5.8: Reflectivity of DBR versus wavelength with incident angle variations, with largerincident angle, the curve shifts to shorter wavelength.

2π. The phase difference caused by the propagation of light is expressed as:

φ =2π

λ0ndcosθ (5.1)

Where λ0 is the design wavelength, d is the layer thickness and θ is the incident angle. When

incident angle increases, to maintain the certain value of the phase difference, design wavelength

has to decrease. Fig.5.9 gives a more intuitive explanation. When there is an incident angle, the

Figure 5.9: Change in optical path length because of incident angle, which becomes shorterthan before. Reprinted from[6].

optical path length changes from |AB| to |AB′|, since the phase difference is defined from the

distance between the phase fronts through points A and B. As a result the optical path length

decrease, as explained in section5.2.2.3, the curve should shift to the shorter wavelength.

CHAPTER 5. RESONATOR MIRROR–DBR 35

5.2.3 Organic DBR

After simulation with a simple DBR model, a general idea about the properties of DBR has

been obtained. Now a real organic DBR is considered. As mentioned above, the materials for

this organic DBR are BDAVBi and TAPC, where BDAVBi plays the role of the high refractive

index layer and TAPC the other. Both materials are dispersive and anisotropic (in fact, the

ordinary refractive indices and extraordinary refractive indices of TAPC are so close that this

material can be considered isotropic), meaning that different refractive indices are experienced

by light with different wavelengths and incident angles. According to the emission range of

MEH-PPV mentioned in Chapter 4, design wavelength was set to be 619nm and the thicknesses

were calculated for this wavelength and the corresponding ordinary refractive indices. The

surrounding environment for the DBR is air and the substrate is MEH-PPV, which is also a

dispersive material, so the refractive indices of MEH-PPV should also be considered. After

modifying the code, similar simulations as for the simple DBR case were performed again.

5.2.3.1 Number of Pairs of Layers

For this simulation, the incident angle was 0 degree and the wavelength range was from 500nm

to 700nm as shown in Fig.5.10. Compared with Fig.5.4, the reflectivity for this realistic organic

Figure 5.10: Reflectivity of organic DBR versus wavelength with different number of pairs.Same explanation as for Fig.5.4.

DBR is much smaller and the bandwidth is thinner, around 100nm. Because the contrast of

CHAPTER 5. RESONATOR MIRROR–DBR 36

refractive indices at wavelength 619nm is 1.891.66 ≈

1.141 instead of 2

1 . This again indicates that

contrast of refractive indices plays an important role in the reflectivity.

5.2.3.2 Thickness Uncertainty

As simulated above, the change in thickness can shift the reflectivity curve. By tuning the

thickness, the desired curve can be obtained. For this organic laser, the pump is a green laser

with wavelength 532nm illuminating the amplifying medium, thus the DBR reflectivity should be

as low as possible for better absorption of the pump energy. The original calculated thicknesses

for BDAVBi and TAPC were 81.7nm and 93.1nm, respectively. If 6nm increment is added on

the high refractive index layer, i.e. the thickness for BDAVBi layer is 87.7nm the minimum

reflectivity can be reached at wavelength 532nm. As shown in Fig.5.11. For this simulation, the

incident angle was 0 degree and the number of pairs was 7. From the figure, the reflectivity for

Figure 5.11: Reflectivity of organic DBR versus wavelength with thickness uncertainty, in-creased thickness of the high refractive index layer makes the reflectivity at 532nm reach the

bottom of the curve.

wavelength 532nm is now 3.894%, also the curve has shifted to longer wavelength, the reflectivity

for wavelength 619nm changes from 72.87% to 65.93%, which is still a high value.

CHAPTER 5. RESONATOR MIRROR–DBR 37

5.2.3.3 Variation of Incident Angle

Last is the variation of the incident angle. Since the lasing direction is perpendicular to the

surface, it will cause some trouble if the incident pump light is also vertical. However, in order

to not change the shape of the reflectivity curve too much, small angles are simulated here.