Design and Analysis of Plastic Gear and Its Comparision With Metallic Gear for Gear Box of Moped

-

Upload

iaster-journals -

Category

Documents

-

view

21 -

download

6

description

Transcript of Design and Analysis of Plastic Gear and Its Comparision With Metallic Gear for Gear Box of Moped

-

Design and Analysis of Plastic Gear and its Comparison with Metallic Gear in the

Gear Box of Moped

Ashish N.Taywade1, Dr.V.G.Arajpure2 1Department of Mechanical Engineering, Bapurao Deshmukh College of Engg. Wardha, India 2Principal, Dr. Bhausaheb Nandurkar College of Engineering, Yevatmal, Maharashtra, India

International Journal of Research in Mechanical Engineering Volume 3, Issue 2, March-April, 2015, pp. 01-06

ISSN Online: 2347-5188 Print: 2347-8772, DOA : 09032015 IASTER 2014, www.iaster.com

ABSTRACT Performance of any gear is dependent on gear material and its properties .Nowadays advanced thermoplastics such as Nylon 66 provides good mechanical properties required for power transmission and are also contenders for replacement of gears of light load gear box. Nylon 66 has been selected for replacement of metallic gear which reduces weight, noise, vibration and to gives better strength. In this work attempt has been made to design helical gear and analyze it by keeping same parameter of existing metal helical gear. In this regard there is necessity of dynamic analysis of gears used in gear box before manufacturing and performance testing. The paper presents comparative design analysis of plastic helical gear for the replacement of metallic gear in the gear box of moped. In this three dimensional experimental model of gear pair used in the actual gear box of moped has been created using Pro Engineer and ANSYS is used to find stresses. This paper shows that design of plastic helical gear is convenient and the stresses induced in non metallic gear are lesser than metallic gear. Keywords: Nylon66, Helical Gear, Ansys, Pro Engineering, Analysis.

1. INTRODUCTION Gearing is considered to be a backbone in power transmission system. Plastic gears find increasing application due to advantages of noiseless running, light weight, resistance to corrosion, lower coefficient of friction, the ability to run without external lubrication, superior properties. Due to these added advantages plastic gearing puts benchmark in power transmission area [1]. In competitive technological world people are demanding economical vehicle having good performance along with smooth and noiseless operation. Plastic gears are easy to manufacture in various shapes and size and also they have greater consistency. Performance of helical plastic gear is quicker and smoother with a small helix angle as compare to spur gear. Face contact line is more and meshing more numbers of teeth simultaneous in helical plastic gear and also it has less wear than metal gear [2].Since there are many parameters responsible for gear failure out of which maximum shear stress, normal stress, bending stress, contact stress and von misses strain, maximum principal stress, are considered to be one of the main contributors for the failure of gear. The Nylon material has good mechanical strength [3], abrasion resistance property, and excellent wear resistance [4] and also has more load bearing capacity [5],

-

International Journal of Research in Mechanical Engineering Volume-3, Issue-2, March-April, 2015, www.iaster.com ISSN

(O) 2347-5188 (P) 2347-8772

2

resistant to the most of the chemicals and self- lubricant. Nylon66 is the most suitable to replace the metallic gear among different types of Nylons available. Plastic gear continues to replace metal gears in automobiles [6], robotics, appliances and machinery due to its good properties, economical considerations and simple manufacturing. Study of accurate analysis of the characteristics of gear systems is important in order to fulfill the requirement of effective power transmission [7]. Nowadays people are demanding highly reliable and light weight gear in automobile. Keeping in view, an attempt has been made to analyze and compare non metallic gear with metallic gear and to find the feasibility of replacement of metallic gear in moped. 2. AIM OF INVESTIGATION The aim of investigation is to analyze mating helical gear pair in order to find out stresses induced in both metals and non- metallic helical gear and to compare results obtained from them. Polymer gear has several merits compared to metal gear which comprises of less weight, good strength, less wear, low noise, low vibrations, corrosion resistance, self lubrication, wide choices of appearance, colors and better transparencies, design optimization, low electrical and thermal conductivity[8], it can be easily formed into complex shapes, wide choices of appearance, colors and transparencies better material, design optimization and better manufacturing processes and also economical cheaper. Development of polymer gear is convenient compared to metal gear [9]; considering above merits non metallic gear is always better than metallic gear. Due to this reasons topic is under taken for study. 3. TEST GEARS The Nylon 66 material selected for gear has superior mechanical strength [10] and comparative better properties. The helical gear having following specification and tolerances are designed and developed on Hobbing machine which gives good close tolerance ,good surface finishing and also economical cheaper, in addition to that it is convenient for manufacturing as compare to others. The original metal helical gear (SCM420H) also has same specification and tolerance. Design parameters of gear are Power = 2.69 KW, Speed = 6500rpm

TABLE I- Data for the Test Gear

S. No Specification Pinion Gear Driver Gear

1 Tooth profile Involute Involute 2 Material Nylon66 Nylon66

3 Normal Module 1.5 1.5 3 Normal Pressure angle 200 200 4 Helix angle 200 200 5 Direction of helix LH RH 5 Number of teeth 66 15 6 Pitch circle Diameter 105.35 23.94 7 Operating centre Distance (mm) 65.5 65.5

-

International Journal of Research in Mechanical Engineering Volume-3, Issue-2, March-April, 2015, www.iaster.com ISSN

(O) 2347-5188 (P) 2347-8772

3

Fig.1.Specimen Helical Gear in Meshing

4. METHODOLOGY OF ANALYSIS

Pro-engineering modeling software helps to developed accurate three dimensional helical gear model according to gear data. Properties and design data of Nylon 66 material applied on gear model which will behave as real as one gear. ANSYS is finite element-modeling package for numerically solving a plenty variety of mechanical engineering problems [4]. In this work the stresses of a helical gear material is checked by FEM software package ANSYS. In ANSYS software desired accuracy of result is obtained by using automatic mesh generation tool which divide the geometry in number of elements [11] .The stepwise procedure comprising the following steps which are carried out in computer software:

1. Three dimensional model of helical gear is prepared in Pro Engineering software. 2. 3D model is imported in Analysis software IGES file. 3. For meshing and desired accuracy selected type of element. 4. Both metal and non metal material properties specified. 5. Meshing the geometry by using desired geometrical parameter of gear.

5. COMPARISON OF ANALYSIS

Fig.2 Three Dimensional Model Fig.3 Meshing Fig.4 Force

5. I. Analysis of Nylon 66 Helical Gear

Fig.5 Total Deformation Fig.6 Maximum Shear Stress

-

International Journal of Research in Mechanical Engineering Volume-3, Issue-2, March-April, 2015, www.iaster.com ISSN

(O) 2347-5188 (P) 2347-8772

4

Fig.7 Von-Mises Strain Fig.8 Maximum Principle Stress

Fig.9 Normal Stress Fig.10 Bending Stress

Fig.11 Contact Stress Fig. 12 Materials Properties Of Nylon 66

5.II - Analysis of Metal Helical Gear

Fig.13 Total Deformation Fig.14maximum Shear Stress

-

International Journal of Research in Mechanical Engineering Volume-3, Issue-2, March-April, 2015, www.iaster.com ISSN

(O) 2347-5188 (P) 2347-8772

5

Fig.15von-Mises Strain Fig.16max Principal Stress

Fig.17 Normal Stress Fig.18 Bending Stress

Fig.19Contact Stress Fig.20 Material Properties of SCM420H

VI. RESULTS AND DISCUSSION

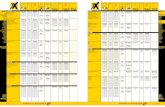

Fig. 21 Analysis of Nylon 66 Fig.22 Analysis of SCM420H

-

International Journal of Research in Mechanical Engineering Volume-3, Issue-2, March-April, 2015, www.iaster.com ISSN

(O) 2347-5188 (P) 2347-8772

6

The above figure 21 provide the data of total deformation, maximum shear stress, von-mises strain, maximum principal stress, normal stress, bending stress and contact stress induced in the Nylon66 gear and figure 22 provide the data of total deformation, maximum shear stress, von-mises strain, maximum principal stress, normal stress, bending stress and contact stress induced in the SCM420H gear .This data suggest that stresses induced in the Nylon66 gear are comparative lesser than Metallic gear. This study of comparative analysis indicates that Nylon66 material hold good for helical gear manufacturing and application in moped. VII. CONCLUSION The design analysis of both the metal and non metallic helical gears provide the data which shows that stresses induced in Nylon 66 helical gear are less comparative to metallic helical gear. The strength to weight ratio of Nylon 66 gear is higher than metallic gear. Nonmetallic material gear provides extra benefits like economical, less weight, self lubricating, low noise and vibrations and convenient for manufacturing. This noticeable difference in the stresses value is the evidence of application of non metallic gears in the small automobile has always been better than metallic helical gear and also it is one step toward replacement of metallic gear with non metallic gear. This study helps to promote the application of non metal in power transmission in coming years. REFERENCES

[1] Arajpure V.G, Padole P.M. and Kshitij Gupta Experimental Investigation Of Cutting Tool

Vibrations By Replacing Various Thermoplastic Gears And Its Comparison With Metal Gears In The Feed Box Of Lathe Machine, International Journal of Mechanics and Solids ISSN 0973-1881 Volume 5,Number 2 (2010), pp. 111-122

[2] K. Mao, W. Li et al, Friction and wear behaviour of acetal and nylon gears, wear 267, (2009), 639-645.

[3] Crippa, G., Davoli, P., Gorla, C., and Quaranta, S.,Nylon Gears for Engine Timing Drives: Design and Experimental Tests SAE Technical Paper 1993-25-0635, 1993.

[4] Govind T.Sarkar etal, Stress Analysis of Helical Gear by Finite Analysis Method IJMERR, Vol.2, No.4, October 2013.

[5] Shastri D.Ramamurthy S.,and ParabP.,Strategies for Automobile Material Selection, SAE Technical-28-0055, P2008, doi: 10 4271/2008-28-0055

[6] M.S.Zaamout, The Wear Behaviour of Nylon-66 and its Composites Under Impact Loading, JKAU: Eng. Sci., vol. 16 no. 1, pp. 85-101.

[7] Kapelevich, A. and McNamara, T., Plastic Gearing for Small Engine Applications, SAE Technical Paper 2006-32-0038, 2006, doi: 10.4271/2006-32-0038.

[8] K. Mao, W. Li et al, Polymer Gear Surface Thermal Wear and its Performance Prediction, Tribology International 43(2010), 433-439.

[9] V. Siva Prasad, Syed Altaf Hussain et al, Modeling and Analysis of Spur Gear for Sugarcane Juice Machine under Static Load Condition by Using FEA, International Journal of Modern Engineering Research (IJMER) Vol.2, Issue.4, July-Aug 2012 pp- 2862-2866.

[10] P.K. Harish Kumar, B.Kanimozhi, Design Analysis and Application of Nylon66 In Rotary Spars, Int. Journal of Engineering Research and Applications, Vol. 4, Issue 4(Version 1), April 2014, pp.331-334.

[11] N. Lenin Rakesh, A. Thirugnanam et al, Contact Analysis on Plastic Helical Gears by Using Ansys, Middle-East Journal of Scientific Research 14 (12): 1760-1762, 2013.