Description D6D · 2020. 6. 25. · Description D6D The D6D engine is a straight six cylinder,...

Transcript of Description D6D · 2020. 6. 25. · Description D6D The D6D engine is a straight six cylinder,...

-

Service Information

Document Title:

Description D6D

Function Group:

200

Information Type:

Service Information

Date:

2014/5/8 0

Profile:

EXC, EW200B [GB]

Description D6D The D6D engine is a straight six cylinder, direct-injected four-stroke diesel engine, with electronically controlled fuel injection

EMS (Engine Management System).

The engine meets the emission requirements according to EURO2.

The engine number is stamped on the name plate and on the engine block's right side.

Model and serial number must always be indicated when ordering spare parts.

-

Service Manual Information

Document Title:

Engine, removal

Function Group:

210

Information Type:

Service Information

Date:

2014/5/8 0

Profile:

EXC, EW200B [GB]

Engine, removal

Op nbr 210-01

Lifting links, min. 1000 kg

Hose with valve

WARNING Risk of burns - stop the diesel engine and allow it to cool down before starting any work.

NOTE!

Clamps that secure hoses and wiring should be removed and replaced when installing.

1. Turn off the electric power with the battery disconnector.

2.

Figure 1

Superstructure

1. Cover

2. Cover

Remove the covers over the diesel engine.

3. Remove the protective plates under the engine.

4. Connect a hose with valve (tool equipment) and drain the coolant from the radiator into a clean container. Filled

radiator contains approx. 22 litres.

5. Connect a hose with valve (tool equipment) and drain the hydraulic oil from the hydraulic oil tank into a clean

container. Filled tank contains approx. 190 litres.

6. Disconnect the connections to the sight glass for the hydraulic oil tank. Plug and mark.

7. Remove the hood opener.

https://www.heavymachineryequipment.com/downloads/volvo-ew200-akerman-excavator-repair-manual/

-

8.

Figure 2

Framework

1. Cover

2. Framework

3. Cover

Disconnect the outer framework and lift away the frame with the covers.

9.

Figure 3

Engine/hydraulic compartment

1. Intermediate wall

Remove the intermediate wall.

10.

Figure 4

Engine/hydraulic compartment

1. Framework

Remove the remaining framework.

-

11.

Figure 5

Radiator/engine

1. Cooling hose .6 Cooling hose

2. Cooling hose 7. Cooling hose

3. Cooling hose 8. Cabling

4. Intercooler hose 9. Induction hose to turbo

5. AC compressor 10. Induction hose to turbo

Disconnect the engine from the cooling hoses. Remove the upper intercooler hose and disconnect the lower from

the engine.

Disconnect the engine from the inductions hoses for the turbo.

Disconnect (if installed) the AC compressor from the engine, and remove the Vee-belts.

NOTE!

Do NOT loosen the hoses from the compressor.

12.

Figure 6

Exhaust pipe/muffler

1. Exhaust clamp

Loosen the exhaust clamp.

-

13.

Figure 7

Underside muffler bracket

1. Attaching bolts

Remove the attaching bolts for the muffler bracket and remove the muffler and bracket.

14.

Figure 8

Cover plate over starter motor

1. Cover plate

Remove the cover plate over the starter motor.

15.

Figure 9

Engine/Starter motor

-

1. Ground connection

2. Cabling

3. Cabling

Disconnect the cabling for the starter motor and ground connection.

16.

Figure 10

Fan pump

1. Hydraulic hose

2. Hydraulic hose

Disconnect the fan pump from the hydraulic oil hoses. Plug and mark up. (Only installed if machine is equipped

with hydraulic cooling fan.)

17.

Figure 11

Engine, side view

1. Cabling

2. Fuel line

3. Cooling hose

4. Cabling

5. Fuel line

Disconnect the engine from the cabling, fuel lines and cooling hose. Plug and mark up.

18. Remove the servo pump according to 914 Servo pump, removal.

19. Remove the working pump according to 913 Pump, removal.

-

20.

Figure 12

Hydraulic cooling fan

1. Elbow nipple

If hydraulically driven cooling fan (option): Remove the elbow nipple on the cooling fan and plug.

21.

Figure 13

Belt-driven cooling fan

1. Cooling fan

2. Attaching bolts

3. Belt pulley

If belt-driven cooling fan: Remove the attaching bolts for the belt pulley.

Remove the cooling fan.

-

22.

Figure 14

Lifting links on engine

1. Lifting links

2. Lifting eyes

Connect the lifting links in the engine's lifting eyes and in a lifting device.

Tighten up the lifting links.

23. Remove the bolted joints for the engine mounts.

24. Lift out the engine carefully.

25. Place the engine on stable supports.

-

Service Information

Document Title:

Engine, installation

Function Group:

210

Information Type:

Service Information

Date:

2014/5/8 0

Profile:

EXC, EW200B [GB]

Engine, installation

Op nbr 210-02

14360000 Vacuum pump

Lifting links, min. 1500 kg

1. Lift in the engine carefully.

2. Fit the bolted joints for the engine mounts.

Tightening torque: 687 ±68Nm.

3.

Figure 1

Belt-driven cooling fan

1. Cooling fan

2. Attaching bolts

3. Belt pulley

If belt-driven cooling fan: Fit the cooling fan and fit the attaching bolts for the belt pulley.

-

4.

Figure 2

Hydraulically driven cooling fan

1. Elbow nipple

If hydraulically driven cooling fan (option): Fit the elbow nipple on the cooling fan.

5. Fit the working pump according to 913 Pump, installation.

6. Fit the servo pump according to 914 Servo pump, installing.

7.

Figure 3

Engine, side view

1. Cabling

2. Fuel line

3. Cooling hose

4. Cabling

5. Fuel line

Fit cabling, fuel lines and cooling hose.

-

8.

Figure 4

Fan pump

1. Hydraulic hose

2. Hydraulic hose

Fit the fan pump's hydraulic oil hoses. (Only installed if machine is equipped with hydraulically driven cooling fan.)

9.

Figure 5

Engine/starter motor

1. Ground connection

2. Cabling

3. Cabling

Fit the cabling for the starter motor and the ground connection.

-

10.

Figure 6

Cover plate over starter motor

1. Cover plate

Fit the cover plate over the starter motor.

11.

Figure 7

Underside muffler bracket

1. Underside muffler bracket

Fit the muffler bracket with the muffler.

Fit the attaching bolts for the bracket.

12.

Figure 8

Exhaust pipe/muffler

1. Exhaust clamp

-

Fit the exhaust clamp.

13.

Figure 9

Radiator/engine

1. Cooling hose .6 Cooling hose

2. Cooling hose 7. Cooling hose

3. Cooling hose 8. Cabling

4. Intercooler hose 9. Induction hose to turbo

5. AC compressor 10. Induction hose to turbo

Fit the Vee-belts and the AC compressor.

Fit the upper and lower intercooler hose.

Fit the cooling hoses.

Fit the induction hoses for the turbo.

14.

Figure 10

Engine/hydraulic compartment

1. Framework

Fit the inner framework.

-

15.

Figure 11

Engine/hydraulic compartment

1. Intermediate wall

Fit the intermediate wall.

16.

Figure 12

Framework

1. Cover

2. Framework

3. Cover

Fit the covers and the outer framework.

17. Fit the hood opener.

18. Fit the connections for the sight glass for the hydraulic oil level.

19. Fill the hydraulic oil tank with hydraulic oil.

The tank's capacity is approx. 190 litres.

-

20.

Figure 13

Expansion tank

1. Cap

2. Sight glass

Remove the cap and fill coolant in the expansion tank until the level is in the middle of the sight glass.

21.

Figure 14

Radiator

1. Filling point

Fill completely in the radiator's filling point.

22. Check oil level in the engine.

Fill if needed.

23. Fit the protective plates under the engine.

-

24.

Figure 15

Superstructure

1. Cover

2. Cover

Fit the covers over the diesel engine.

25. Start the diesel engine, place the digging equipment in position A, see 091 Service positions.

26. Stop the diesel engine and check the hydraulic oil level, top up if needed.

Check the coolant level, top up if needed.

-

Service Information

Document Title:

Cylinder head, description

Function Group:

211

Information Type:

Service Information

Date:

2014/5/8 0

Profile:

EXC, EW200B [GB]

Cylinder head, description The cylinder head is made of cast iron and is common for all cylinders. The induction air enters vertically (A) and the

exhausts leave horizontally (B). Inlets and exhaust outlets are located on the same side of the cylinder block. On order for the

engine to fulfill governing emission standards, there are 3 cylinder head gaskets of different thicknesses between the

cylinder head and the piston.

Figure 1

-

Service Information

Document Title:

Pistons, description

Function Group:

213

Information Type:

Service Information

Date:

2014/5/8 0

Profile:

EXC, EW200B [GB]

Pistons, description D6E Engine

The pistons are made of special alloy aluminium. The piston's combustion compartment has a somewhat off -center

(eccentric) position in relation to the piston pin.

The pistons are provided with 3 piston rings. The first ring has a ring carrier made of cast iron.

The piston is cooled with oil sprayed up on the inside of the piston top.

The piston cooling nozzles are made of plastic and are mounted in the cylinder head by the main bearing positions.

The first piston ring has an asymmetric cross-section area (A). The cross-section area for piston ring number two

(compression ring) is tapered. When installing the piston rings, the marking TOP by the opening in the rings must face up.

The third ring is an oil ring with bevelled edge.

Figure 1

-

Service Information

Document Title:

Valve mechanism,

description

Function Group:

214

Information Type:

Service Information

Date:

2014/5/8 0

Profile:

EXC, EW200B [GB]

Valve mechanism, description The engines are equipped with one inlet and one exhaust valve per cylinder.

At the upper end of the valve guide, there's an O-ring seal against the valve spindle to prevent major oil consumption and to

reduce the amount of hydrocarbons in the exhausts.

The valves are rotated by the eccentric action of the rocker arms.

The new compressed tapered shape enables the valves to turn easily despite loading.

Rocker arm lubrication is part of the engine's force-feed lubrication system. The oil is supplied via the tappets and push rods.

-

Service Information

Document Title:

Valves, adjusting

Function Group:

214

Information Type:

Service Information

Date:

2014/5/8 0

Profile:

EXC, EW200B [GB]

Valves, adjusting

Op nbr 21412

1. Park the machine in a suitable service position, see 091 Service positions.

2. Disconnect the batteries with the battery disconnecting switch.

3. Remove the belt cover.

Figure 1

Engine

1. Belt cover

4. Remove the both cover hatches over the engine.

Figure 2

Superstructure

1. Rear cover hatch

2. Front cover hatch

5. Remove the parallel stay.

-

Thank you very much for reading.

This is part of the demo page.

GET MORE:

Hydraulic

System, Setting

Instructions, Functional

Description, Electrical

System And more

Click Here BUY NOW

System And more……

https://www.heavymachineryequipment.com/downloads/volvo-ew200-akerman-excavator-repair-manual/https://www.heavymachineryequipment.com/downloads/volvo-ew200-akerman-excavator-repair-manual/https://www.heavymachineryequipment.com/downloads/volvo-ew200-akerman-excavator-repair-manual/https://www.heavymachineryequipment.com/downloads/volvo-ew200-akerman-excavator-repair-manual/https://www.heavymachineryequipment.com/downloads/volvo-ew200-akerman-excavator-repair-manual/https://www.heavymachineryequipment.com/downloads/volvo-ew200-akerman-excavator-repair-manual/https://www.heavymachineryequipment.com/downloads/volvo-ew200-akerman-excavator-repair-manual/https://www.heavymachineryequipment.com/downloads/volvo-ew200-akerman-excavator-repair-manual/https://www.heavymachineryequipment.com/downloads/volvo-ew200-akerman-excavator-repair-manual/https://www.heavymachineryequipment.com/downloads/volvo-ew200-akerman-excavator-repair-manual/https://www.heavymachineryequipment.com/downloads/volvo-ew200-akerman-excavator-repair-manual/

-

Figure 3

Superstructure

1. Parallel stay

6. Loosen the oil trap.

Figure 4

Oil trap

1. Bolts

7. Loosen and remove the bolts for the valve cover.

Remove the valve cover.

Figure 5

Valve cover

The figures show valve adjustment on a removed engine.

-

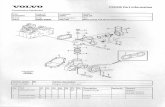

Figure 6

1, 3, 5, 7, 9,11: exhaust valve

2, 4, 6, 8, 10, 12: inlet valves

8. Rotate the engine with a fan blade until the valves on cylinder 1 rock (break over).

9. Adjust the clearance for the valves marked with black in the figure.

Inlet valve: 0.35 ±0.05 mm (0.014 ±0.0020 in)

Exhaust valve: 0.50 ±0.05 mm (0.020 ±0.0020 in)

Figure 7

10. Tighten the lock nut.

Tightening torque: 20 Nm (14.7 lbf ft)

Check the adjustment once again with the feeler gauge.

Figure 8

Valves, adjusting

11. Rotate the engine one full revolution until the valves on cylinder 6 rock (break over). Adjust the clearance for the

valves marked with black in the figure.