DesCalc Metric Aisc

-

Upload

alex-immanuel -

Category

Documents

-

view

52 -

download

4

description

Transcript of DesCalc Metric Aisc

METAL BUILDING SOFTWARE

CALCULATIONS MANUAL

(METRIC VERSION)

SEPTEMBER 5, 2000

METAL BUILDING SOFTWARE FARGO, NORTH DAKOTA

METAL BUILDING DESIGN is a program of Metal Building Software, Inc. (MBS) of Fargo, North Dakota. This program is to serve as a computational aid for the building designer. The building designers should familiarize themselves with the computations used in the program. The building designer is responsible for checking the computations produced by the program. Every effort has been made to ensure the accuracy of this program and MBS will not accept responsibility for any mistake, error, or misrepresentation in or as a result of the usage of this program.

This Manual is an updating and electronic representation of the material in the MBS Hand Calculations Manual.

This version of the manual is in Metric Units.

REVISION 1.0

Copyright 2000 by Metal Building Software, Inc.

1. INTRODUCTION The design of metal buildings includes: load generation, apply those loads to frame and components, structural analysis to calculate internal actions, and use the internal actions with the design code to select the members. This entire process is carried out by a series of computer programs that are inter-connected to operate as a single program. The program output is typically reviewed by the design engineer and either approved as is, or the output is modified and then approved. As the design engineer approves the design they are either approving all the steps taken by the computer program or if they differ with some of the steps, their differences will not significantly effect the program output. The objective in this manual is to illustrate all the steps taken by a computer program in the design of metal buildings. The illustration begins with drawings of the designed building. This is followed by the calculations that include reference to building codes and structural design codes. The building design is illustrated with a sample building that contains a number of features common to metal buildings. This building does not contain all possible building features. This manual will be enlarged, as other building features are included. Following the section on the sample building, the next section illustrates the application of building loads according to the 1996 MBMA recommendations. The remaining sections provide detailed calculations for each of the building design topics. Currently, designers are using either the 86 AISI code with the 89 addendum or using the 96 AISI code. These calculations illustrate the 86-89 code. The Appendix contains some of the reference material used in the design.

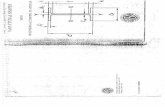

2. FEATURES OF THE SAMPLE BUILIDNG A three dimensional view of the sample building is shown on the next page. The building features are listed below the drawing and referenced to the drawing. As calculations reference the sample building it is necessary to know the building dimensions. These building dimensions are available on the erection drawings. The erection drawings are on the follow pages. Those drawings include: - Anchor Bolt Plan ............................................... 2-3 - Anchor Bolt Details ........................................... 2-4 - Anchor Bolt Reactions....................................... 2-5 - Roof Plan ........................................................... 2-6 - Rigid Frame Elevation....................................... 2-7 - Right Endwall .................................................... 2-8 - Left Endwall ...................................................... 2-9 - Back Sidewall .................................................. 2-10 - Front Sidewall.................................................. 2-11 - Erection Details ......................................... 2-12, 13

Calculations Manual 06/06 MBS, Inc. Page 2-1

Calculations Manual 06/06 MBS, Inc. Page 2-2

FEATURES OF THE SAMPLE BUILDING

(Roof Purlins Were Removed To Better See The Framing)

1. Interior Frame With Interior Column 2. Rigid Frame In Endwall 3. Portal Frame In Sidewall 4. X Bracing In Sidewall 5. Bypass Girts In This Sidewall 6. Flush Girts In This Endwall 7. Bypass Girts In This Endwall 8. Framed Opening 9. Walk Door 10. X Bracing In Roof 11. Post And Beam Endwall 12. Sliding Door

Calculations Manual 06/06 MBS, Inc. Page 2-3

Calculations Manual 06/06 MBS, Inc. Page 2-4

Calculations Manual 06/06 MBS, Inc. Page 2-5

Calculations Manual 06/06 MBS, Inc. Page 2-6

Calculations Manual 06/06 MBS, Inc. Page 2-7

Calculations Manual 06/06 MBS, Inc. Page 2-8

Calculations Manual 06/06 MBS, Inc. Page 2-9

Calculations Manual 06/06 MBS, Inc. Page 2-10

Calculations Manual 06/06 MBS, Inc. Page 2-11

Calculations Manual 06/06 MBS, Inc. Page 2-12

Calculations Manual 06/06 MBS, Inc. Page 2-13

Calculations Manual 06/06 MBS, Inc. Page 2-14

Calculations Manual 06/06 MBS, Inc. Page 2-15

Calculations Manual 06/06 MBS, Inc. Page 2-16

Calculations Manual 06/06 MBS, Inc. Page 2-17

3. LOADS ON METAL BUILDINGS 3.1 Wind Load Site Conditions.................................................................................. 3-1 3.2 Main Wind Framing............................................................................................. 3-1 A. Used for Wind Loads on .......................................................................... 3-1 B. Design Wind Pressure.............................................................................. 3-1 C. Transverse Wind ...................................................................................... 3-1 D. Summary of Transverse Wind ................................................................. 3-3 E. Longitudinal Wind ................................................................................... 3-3 F. Summary of Longitudinal Wind .............................................................. 3-4 3.3 Components and Cladding Wind Loads .............................................................. 3-5 A. Used for Wind Loads on .......................................................................... 3-5 B. Design Wind Pressure.............................................................................. 3-5 C. Panels ....................................................................................................... 3-5 D. Component Wind Loads by Design Program .......................................... 3-5 3.4 Seismic Loads ...................................................................................................... 3-6 A. Seismic Site Conditions ........................................................................... 3-6 B. Seismic Base Shear .................................................................................. 3-6 C. Seismic Coefficients for Longitudinal Load............................................ 3-6 D. Transverse Seismic Load on Rigid Frame ............................................... 3-6 3.5 Design Load Combinations.................................................................................. 3-6 A. MBMA 96 Code Requirements ............................................................... 3-6 B. General Rigid Frame Design Loads for MBMA 96 ................................ 3-7 C. Rigid Frame Design Loads for Crane and Seismic, MBMA 96 .............. 3-8

3. LOADS ON METAL BUILDINGS 3.1 WIND LOAD SITE CONDITIONS

Code: MBMA 96, Closed Building, Category II, V = 85 mph = 38.0 mps See Appendix A for the MBS description of the MBMA design loads. It contains the table referenced below as MBMA(96).

3.2 MAIN WIND MBMA (96) FRAMING

A. Used for Wind Loads on: - Interior Rigid Frames - Endwall Frames - X bracing in Roof, Sidewall, and Endwall

B. Design Wind Pressure, p

( )( ) ( )

( )[ ]aTableMBMAImpsV

mheighteaveBuildingHmkNHVq

GCqIp

w

pw

1.1.4.10.38

0.8,/,9.2010447.000256.0 2722

==

==⋅⋅=

⋅⋅=

]828.0[/83.0

/83.09.20108

477.03800256.0

2

2722

WindBasicmkN

mkNq

==

=⎟⎠⎞

⎜⎝⎛⋅⎟

⎠⎞

⎜⎝⎛⋅=

C. Transverse Wind Coefficients, (GCp)

a. Interior and end zone wind coefficients

From Table MBMA-1, roof slope < 2.11:12, enclosed building Load 1 Interior Zone: C1 = 0.25, C2 = -1.00, C3 = -0.65, C4 = -0.55 [D1] Load 2 Interior Zone: C1 = 0.65, C2 = -0.60, C3 = -0.25, C4 = -0.15 [D2] Load 1 End Zone: C1 = 0.50, C2 = -1.40, C3 = -0.80, C4 = -0.70 [D3] Load 2 End Zone: C1 = 0.90, C2 = -1.00, C3 = -0.40, C4 = -0.30 [D4]

Calculations Manual 06/06 MBS, Inc. Page 3-1

Wind design loads are the sum of the external and internal wind pressures as shown below.

External wind +

internal pressure External wind +

internal suction

From the above coefficients, it can be seen that the external wind coefficients are: C1 = 0.40, C2 = -0.80, C3 = -0.45, C4 = -0.30 and the internal pressure is + 0.20. Many building codes report the external and internal wind coefficients and the

designer is to calculate the net wind loads. The MBMA code reports the net wind coefficient on each building surface as in Table MBMA-1.

b. Width of end zone, see Table MBMA-1 End zone width = the larger of 20 feet and 2 times the edge strip width.

m

widthstripEdge

0.391.0363,2.13004.0

2.3840.0,0.33010.0

===⋅≥=⋅=⋅=≤

05.3,1.62

0.632,1.628.320==⋅=

=⋅==≥ama

widthzoneEnd

c. Wind coefficients for end frame based on interior zone and end zone, Ceff

Calculations Manual 06/06 MBS, Inc. Page 3-2

( ) ( )

endeff

endeff

CCaLFor

LaLaCCCC

aLFor

=⋅>

−⋅⋅⋅−+=

⋅≤

2

42

2intint

( ) ( ) 965.05.705.35.705.344 22 =−⋅⋅=−⋅⋅

LaLa

Wind load 1 C1 = ( ) 49.0965.025.050.025.0 =⋅−+

C2 = ( ) 39.1965.000.140.100.1 −=⋅−−− C3 = ( ) 79.0965.065.080.065.0 −=⋅−−− C4 = ( ) 69.0965.055.070.055.0 −=⋅−−− Note the calculated coefficients are nearly equal to the end coefficients. For

simplicity, the end and interior coefficients will not be combined for the MBMA 96 code. For other wind codes where the end zone width is much smaller the coefficients will be combined.

D. Summary of Transverse Wind

Rigid Frames only at interior locations Wind_1 = [D1], Wind_2 = [D2] Rigid Frames located at endwall Wind_1 = [D3], Wind_2 = [D4] Endwall Rafter Wind_1 = [D3], Wind_2 = [D4] Bracing Wind = [D3]

E. Longitudinal Wind a. Wind coefficients, roof and sidewall bracing

From Table MBMA(96)-2

C1 = ( )90.065.0 C2 = 83.0− C3 = ( )30.015.0 −−

- The values in ( ) are at the edge of the endwall over a distance ‘a’. - A single wind coefficient based on the interior and edge loading and the interior and

end zone width is:

Calculations Manual 06/06 MBS, Inc. Page 3-3

( )

( ) 18.030

30.00.320.323015.03

70.030

90.00.320.323065.01

=⋅⋅+⋅−⋅

=

=⋅⋅+⋅−⋅

=

C

C

b. Roof and Sidewall bracing, line 34 of roof input

C1 = 2/581.083.070.0 mkN=⋅ C2 = 2/689.083.083.0 mkN=⋅ C3 = 2/149.083.018.0 mkN=⋅

c. Wind coefficients, Interior rigid frame

Table MBMA-3 Load 1 C1 = - 0.70, C2 = -1.00, C3 = -0.65, C4 = -0.70 Load 2 C2 = - 0.30, C2 = -0.65, C3 = -0.25, C4 = -0.30 Note load 1 has greater loads than load 2. However, load 1 needs to be applied from

the left and right ends of the building in order to obtain a symmetrical frame. The design wind coefficients are: Load 1: C1 = - 0.70, C2 = -1.00, C3 = -0.65, C4 = -0.70 Load 2: C1 = - 0.70, C2 = -0.65, C3 = -1.00, C4 = -0.70

d. Rigid frame in endwall and endwall rafter Similar values from Table MBMA-3. Load 1: C1 = - 0.70, C2 = -1.40, C3 = -0.80, C4 = -0.70 Load 2: C1 = - 0.70, C2 = -0.80, C3 = -1.40, C4 = -0.70

F. Summary for Longitudinal Wind - Roof Design Input File:

- the wind loads from Section b. are on the wind pressure/suction line. - Rigid Frame Design Input File, “Wind Coefficients” line:

Calculations Manual 06/06 MBS, Inc. Page 3-4

- For frames only at interior locations - Use coefficients from Section c. - For frames located at endwall - Use coefficients from Section d. - Endwall Design Input File, “Wind Coefficients” line:

- The Wind_1 roof coefficients from Section d, however, a single longitudinal wind load is used and the maximum suction is used on both roof surfaces.

3.3 COMPONENTS AND CLADDING A. Used for Wind Loads on:

- Panels, girts, purlins, endwall columns, endwall roof extensions, sidewall roof extensions

B. Design Wind Pressure, p: The design wind pressure by building component and openings is given in Tables

MBMA(96)-2 and MBMA-4. Appendix A contains a description of the data. C. Panels

Example wall panel exterior wind coefficients are 1.2, -1.2, and (-1.4), the –1.4 is for wind loading on the end zone, a distance 'z' on the endwall and 2 times 'z' on the sidewall. If roof design parameter 17 is set to '2' the program will check the panels for the wind suction on the edge zone, else it will use the interior zone wind loading.

D. Component Wind Loads by Design Program Unless noted, C from Table MBMA(96)-2, Roof Slope, RS < 2.11:12 (10 degrees).

a. Sidewall Design (Line 14) Wall girt: C = 1.0, -1.1

p = 1.0 · 0.828 = 0.828 kN/m² p = -1.1 · 0.828 = -0.911 kN/m²

Wall panel: C = 1.2, -1.2 p = 1.2 · 0.828 = ±0.994 kN/m²

Door jamb: same as endwall columns

b. Endwall Design (Line 30) Endwall columns: C = 1.0, -1.0

p = 1.0 · 0.828 = ±0.828 kN/m² Endwall panel: C = 1.2, -1.2

p = 1.2 · 0.828 = ±0.994 kN/m²

c. Roof Design (Line 34) Purlins: C = -1.2

p = -1.2 · 0.828 = ±0.994 kN/m² Gable Extensions: C = -1.8

p = -1.8 · 0.828 = -1.490 kN/m²

Calculations Manual 06/06 MBS, Inc. Page 3-5

Panels: C = -1.3 p = -1.3 · 0.828 = -1.076 kN/m²

3.4 SEISMIC LOADS - See Appendix B for the MBS description of ASCE 7-98 Seismic Code. A. Seismic Site Conditions From Code Figure 9.4.1.1(a) the spectral response acceleration for a building in central

Alabama is 0.25. From Code Table 9.4.1.2.a for Ss = 0.25 and Site Class C, the Fa = 1.2. B. Seismic Base Shear

RW

RWV

RWSF

V sa

⋅=⋅⋅⋅⋅=

⋅⋅⋅⋅=

24.025.02.1322.1

2.1 32

C. Seismic Coefficient for Longitudinal Load for bracing 0.5=R

WWRWV ⋅=⋅=⋅= 048.0524.024.0

The seismic coefficient is on the “Basic Loads” line of the roof design input file. It is 0.048.

D. Transverse Seismic Load on Rigid Frame for moment resisting frames 0.4=R

)()( wallsroof WWW += ( )SLFLCLDLWidthSpacingBayW roof +++⋅⋅=)(

psfofloaddeadroofDL 0.2= 0.3ofloadcollateralCL = (roof design parameter 32 for other than 2psf) psfloaddeadframeFL 2== 0.30, usepsfloadsnowSL ∴<= psfSpacingBayHeightEaveW wall 222)( ⋅⋅⋅= (roof despar 33 for other than 2psf)

( )

k

W

7.182.15.17

222

2425023210025

=+=

⋅⋅⋅++++⋅⋅=

Seismic force at eave on frame kRW 12.147.1824.024.0 =⋅=⋅= One half of this force (0.56) is applied at each eave line on the frame. See “Basic

Loads” line in the rigid frame input file.

3.5 SNOW LOADS

Calculations Manual 06/06 MBS, Inc. Page 3-6

A. Flat roof snow load is: (Flat roof includes 1:12 roof slope) - See Appendix C for the MBS description of ASCE 7-98 Snow Loads. gtef pICCp ⋅⋅⋅⋅= 70.0 from Table 7-2, for a partially exposed roof in exposure C. ,

,,

0.1=eC from Table 7-3 for a heated structure without special thermal condition. 0.1=tC from Table 7-4 for a category II building 0.1=I from Figure 7-1 for a central Alabama location. psfpg 10=

psfp f 71011170.0 =⋅⋅⋅⋅= B. Minimum Roof Snow Load Minimum Pf is I · Pg = 1 · 10 = 10psf. Therefore, use a roof snow of 10psf. Enter the

10psf as the roof snow load on the building data entry screen. 3.6 DESIGN LOAD COMBINATIONS A. ASCE 7-98 Code Requirements

Section 2.4.1 of the ASCE 7-98 Code lists the following design load combinations: 1. D 2. D + (Lr or S) 3. D + (Lr or S) + (W or 0.7 E) 4. 0.6 D + W 5. 0.6 D + 0.7 E where: D = dead load, Lr = roof live load, S = snow, W = wind, and E = earthquake. The reference to loads from flood, soil, temperature, and rain were omitted from the

above list. Section 2.4.3 on load reduction states that when two or more loads are used with dead

load that the two or more loads should be multiplied by 0.75. Also, the design loads using the 0.75 can not have the one-third stress increase when wind load is present. However, since the one-third stress increase is used for all the loads involving wind, this design load is multiplied by 4/3. This results in a design load of 1.33 · D + L + W.

B. Rigid Frame Design Loads for ASCE7-98 The MBS program can use either the default design load combinations or use design load

combinations set specifically for each building code. PE 7-99-6 and 4-00-11 provide instructions on setting the rigid frame design loads as desired by the user.

The design load combination for the rigid frame using the ASCE-7 98 Code are shown on

the next page. The need for each design load is described below the list of loads.

Calculations Manual 06/06 MBS, Inc. Page 3-7

*(20)DESIGN LOADS: * --------------------Load_Coefficients------------------- *Load Live/ Live -Wind_1- -Wind_2- Long_Wind -Seismic-- *No Id Dead Coll Snow Right Lt Rt Lt Rt 1 2 Long Tran 18 1 1.00 1.00 1.00 .00 .00 .00 .00 .00 .00 .00 .00 .00 2 1.00 .00 .00 .00 .00 .00 .00 .00 .00 .00 .00 .00 3 1.33 1.00 1.00 .00 1.00 .00 .00 .00 .00 .00 .00 .00 4 1.33 1.00 1.00 .00 .00 1.00 .00 .00 .00 .00 .00 .00 5 1.33 1.00 1.00 .00 .00 .00 1.00 .00 .00 .00 .00 .00 6 1.33 1.00 1.00 .00 .00 .00 .00 1.00 .00 .00 .00 .00 7 .60 .00 .00 .00 1.00 .00 .00 .00 .00 .00 .00 .00 8 .60 .00 .00 .00 .00 1.00 .00 .00 .00 .00 .00 .00 9 .60 .00 .00 .00 .00 .00 1.00 .00 .00 .00 .00 .00 10 .60 .00 .00 .00 .00 .00 .00 1.00 .00 .00 .00 .00 11 .60 .00 .00 .00 .00 .00 .00 .00 1.00 .00 .00 .00 12 .60 .00 .00 .00 .00 .00 .00 .00 -1.00 .00 .00 .00 13 .60 .00 .00 .00 .00 .00 .00 .00 .00 1.00 .00 .00 14 .60 .00 .00 .00 .00 .00 .00 .00 .00 -1.00 .00 .00 15 .60 .00 .00 .00 .00 .00 .00 .00 .00 .00 .00 .70 16 .60 .00 .00 .00 .00 .00 .00 .00 .00 .00 .00 -.70 17 .60 .00 .00 .00 .00 .00 .00 .00 .00 .00 .70 .00 18 .60 .00 .00 .00 .00 .00 .00 .00 .00 .00 -.70 .00

Design Loads Comments 1 ASCE Load 2 2 ASCE Load 1

3 thru 6 ASCE Load 3 with 4 transverse wind loads and loads ‘L’ and ‘W’ are multiplied by 4/3 to permit the 1/3 stress increase for wind.

7 thru 10 ASCE Load 4 with 4 transverse wind loads 11 thru 14 ASCE Load 4 with 2 longitudinal wind

loads. Diagonal bracing forces from longitudinal wind are also included. One for longitudinal wind from either direction.

15 & 16 ASCE Load 3 and 5, transverse seismic to the right and left. Snow load is added if the snow loads exceeds 30 psf.

17 & 18 Same as 15 and 16 only it is longitudinal seismic from either direction.

Calculations Manual 06/06 MBS, Inc. Page 3-8

4. RIGID FRAME DESIGN 4.1 Introduction.......................................................................................................... 4-1 4.2 Composition Of Frame ........................................................................................ 4-1 A. Program Output: Design Summary Report.............................................. 4-1 B. Program Output: Member, Segment, and Splice ID ................................ 4-3 4.3 Loads On Interior Frame...................................................................................... 4-2 A. Dead, Live, and Collateral ....................................................................... 4-2 B. Wind_1 From Left ................................................................................... 4-2 4.4 Frame Analysis .................................................................................................... 4-4 4.5 Some Basic Load Reactions................................................................................. 4-4 4.6 Statics Check On Basic Load Reactions.............................................................. 4-4 A. Dead Load................................................................................................ 4-4 B. Collateral Load......................................................................................... 4-4 C. Live Load ................................................................................................. 4-5 D. Wind_1 From Left ................................................................................... 4-5 4.7 Internal Actions for Stress Check At Top Of Columns ....................................... 4-5 A. Program Output: Section Properties Report ............................................ 4-5 B. Sign Convention For Internal Actions ..................................................... 4-6 C. Dead Load................................................................................................ 4-6 D. Live Load ................................................................................................. 4-7 E. Wind_1 From Left ................................................................................... 4-7 4.8 Stress Check At Top Of Column ......................................................................... 4-7 A. Program Output: Actions and Stress Report............................................ 4-7 B. Member Plates ......................................................................................... 4-8 C. Shear Check ............................................................................................. 4-8 D. Member Unbraced Length ....................................................................... 4-9 E. Program Output: Unbraced Length Report.............................................. 4-9 F. Cb For Outside Flange, The Compression Flange ................................... 4-9 G. Actions For Outside Flange Stress Check ............................................... 4-9 H. Special Program For Stress Check......................................................... 4-10 I. Outside Flange Unity Check.................................................................. 4-10 J. Inside Flange Unity Check..................................................................... 4-12 4.9 Check Interior Column ...................................................................................... 4-14 A. Calculations............................................................................................ 4-14 B. Program Output: Interior Column Design Report ................................. 4-14

4.10 Check Number and Diameter Of Anchor Bolts................................................. 4-15 A. Calculations............................................................................................ 4-15 B. Program Output: Base Plate and Anchor Bolt Design........................... 4-16 4.11 Check Base Plate Thickness .............................................................................. 4-16 4.12 BEP Thickness ................................................................................................... 4-17 A. Calculations............................................................................................ 4-18 B. Program Output: Bolted End Plate Design ............................................ 4-21 4.13 BEP: Flange To End Plate Weld........................................................................ 4-22 4.14 Stiffener At Column To Rafter Splice ............................................................... 4-22 A. Calculations............................................................................................ 4-22 B. Program Output: Stiffener Report.......................................................... 4-24 4.15 Stiffener Above Interior Column....................................................................... 4-24 4.16 Interior Column Connection To Rafter Uplift ................................................... 4-25 A. Flange Bending From Tension in Bolts ................................................. 4-25 B. Total Tension Stress In Flange .............................................................. 4-27 4.17 Design of Interior Column Cap Plate................................................................. 4-27 A. Calculations............................................................................................ 4-27 B. Program Output: Interior Column Cap Plate ......................................... 4-27 4.18 Check Size Of Flange Brace .............................................................................. 4-28 A. Calculate Force In Flange Brace............................................................ 4-28 B. Member Stress Check ............................................................................ 4-28 C. Program Output: Flange Brace Report .................................................. 4-31 4.19 Check Flange Brace To Purlin Connection ....................................................... 4-30 4.20 Weld Of Web To Flange.................................................................................... 4-32 A. Calculations............................................................................................ 4-32 B. Program Output: Web to Flange Weld .................................................. 4-32 4.21 Check Web At Top Of Sidewall Column .......................................................... 4-33 A. Calculations............................................................................................ 4-33 B. Program Output: Special Segment Report............................................. 4-33 4.22 Check Flange At Top Of Sidewall Column....................................................... 4-33 4.23 Check Area Reduction in Tension Flange ......................................................... 4-33 A. Calculations............................................................................................ 4-33 B. Program Output: Influence of Holes in Tension Flange........................ 4-34

4.24 Calculating Live Load Deflection...................................................................... 4-34 A. Calculations............................................................................................ 4-34 B. Program Output: Deflection Report....................................................... 4-35 4.25 Calculating Drift Ratio....................................................................................... 4-35

4. RIGID FRAME DESIGN

4.1 INTRODUCTION

Based on the entered building data and options set by the designer the program prepares a preliminary design of the rigid frame. This design is in the rigid frame design input file. The program then designs the rigid frame in the output file. If the designer wants to change the program output, they can revise the input file and rerun the design. Consider the designed rigid frame to be satisfactory to the designer. This chapter will provide those calculations that will verify the program output. As the calculations are described it is often necessary to refer to the MBS program output. Portions of the program output are included where they are referenced. The program output is placed in boxes to separate it from the calculations.

4.2 COMPOSITION OF FRAME

Frame outside dimensions: see the erection drawing frame cross section on Pg. 2-5. For the size of web and flange plate, see the design summary as shown below.

A. Program Output: Design Summary Report

=============================================================================== Calc_Manual Design Summary Report 8/31/00 7:08am =============================================================================== MEMBERS: Mem Seg| Flange |Web_Depth| Plate_Thickness | Max_UCV | Max_UCO | Max_UCI Id Id | Len Wid|Strt End| Web O-flg I-flg|Id Ld Ucv|Id Ld Uco|Id Ld Uci --- --- ---- --- ---- ---- ----- ----- ----- -- -- ---- -- -- ---- -- -- ---- 1 1 7795 164 400 600 3.0 6.0 6.0 6 9 0.69 6 2 0.66 5 13 0.80 2 2 3232 164 600 571 5.0 6.0 6.0 7 1 0.33 7 2 0.50 7 2 0.44 2 3 8000 164 571 500 5.0 6.0 6.0 17 1 0.23 13 1 0.48 14 6 0.36 3 4 3000 164 500 660 5.0 6.0 8.0 20 1 0.49 20 1 0.62 20 1 0.66 4 5 2999 164 660 500 5.0 6.0 8.0 21 1 0.49 21 1 0.62 21 1 0.66 5 6 8000 164 500 571 5.0 6.0 6.0 24 1 0.23 28 1 0.48 27 9 0.37 5 7 3233 164 571 600 5.0 6.0 6.0 34 1 0.33 34 3 0.50 34 3 0.44 6 8 7795 164 600 400 3.0 6.0 6.0 35 6 0.68 35 3 0.66 36 12 0.80 No. Cycles For Plate Optimization= 9 LOAD COMBINATIONS: 1 - DL+CO+LL 2 - DL+WL1 3 - DL+WR1 6 - DL+LW1 9 - DL-LW2 12 - DL+CO+LL+WL2/2 13 - DL+CO+LL+WR2/2

Calculations Manual 06/06 MBS, Inc. Page 4-1

The first two columns refer to the Member ID and Segment ID. The “M” and “S” numbers for the frame are shown on the following page. This design graphic is available from the rigid frame design program.

4.3 LOADS ON INTERIOR FRAME

A. DEAD, LIVE, COLLATERAL

( )( )( ) ( )( )( ) kNcolumneriorW

mkNcollateralWkNrafterleftW

kNkgcolumnleftWmkNroofonW

mkNW

D

D

D

D

D

l

34.281.9239int/75.01.05.7

50.581.912243994.181.98.19/90.012.05.7

/5.460.05.7

=⋅==⋅=

=⋅+==⋅=

=⋅==⋅=

B. WIND_1 FROM LEFT

mkNWmkNW

mkNWmkNW

/42.3828.055.05.74/04.4828.065.05.73

/21.6828.00.15.72/55.1828.025.05.71

=⋅⋅==⋅⋅==⋅⋅==⋅⋅=

Calculations Manual 06/06 MBS, Inc. Page 4-2

B. Program Output: Member, Segment, and Splice ID

4.4 FRAME ANALYSIS

The program uses the stiffness method of analysis to determine the frame reactions. An example of a check on the program output with other software is given in Appendix C.

4.5 SOME BASIC LOAD REACTIONS The reactions report provides the basic load reactions shown below.

Load H1 V1 H2 V2 V3 DL 1.8 10.7 1.8 10.7 22.9 CL 1.1 5.2 1.1 5.2 12.2 LL 6.4 31.1 6.4 31.1 73.0

WL1 -23.4 -49.5 14.8 -22.7 -81.7

4.6 STATICS CHECK ON BASIC LOAD REACTIONS

A. DEAD LOAD Member + Interior Column Wt = (1518 + 239) · 9.81 / 1000 = 17.2 kN Length of roof slope = 15000/cos 5 = 15019 mm Sum of load = 15.0 · 7.5 · 2 · 0.12 + 17.2 = 44.2 kN Sum of reaction = 10.7 + 10.7 + 22.9 = 44.3 kN, Okay B. COLLATERAL LOAD Sum of load = 15.0 · 2 · 7.5 · 0.10 = 22.5 kN Sum of reactions = 5.21 + 5.21 + 12.2 = 22.6 kN, Okay

Calculations Manual 06/06 MBS, Inc. Page 4-4

C. LIVE LOAD Sum of load = 30 · 4.5 = 135.0 kN Sum of reactions = 31.1 + 31.1 + 73.0 = 135.2 kN, Okay D. WIND_1 FROM LEFT Vertical load = 6.21 · 15 + 4.04 · 15 = 153.8 kN Vertical reaction = 49.5 + 22.7 + 81.7 = 153.9 kN, Okay Horizontal load = 1.55 · 8 + 3.42 · 8 - (6.21 - 4.04) · 15 ·tan 5 = 37.9 kN Horizontal reaction = 23.4 + 14.8 = 38.2 kN, Okay

4.7 INTERNAL ACTIONS FOR STRESS CHECK POINT AT TOP OF COLUMN

The program provides stress checks at many points on the frame. These points are numbered from the lower left corner, moving clockwise around the frame. The location of stress check points, plate composition, and section properties are reported. That part of the Section Properties Report for the left column is shown below: A. Program Output: Section Properties Report

=============================================================================== Calc_Manual Section Properties 9/ 4/00 6:32pm =============================================================================== IM SN ID X Y WD WT FW TO TI AREA IXX SXO SXI RX RY RTO RTI cm cm mm mm mm mm mm cm2 cm4 cm3 cm3 mm mm mm mm -- -- -- ---- ---- ---- ---- --- ---- ---- ---- ---- --- --- --- --- --- --- 1 1 1 42 0 400 3.0 164 6.0 6.0 32 9711 471 471 213 37 43 42 1 1 2 44 144 440 3.0 164 6.0 6.0 33 11917 527 527 213 37 43 42 1 1 3 45 289 480 3.0 164 6.0 6.0 34 14386 585 585 213 36 42 42 1 1 4 47 433 520 3.0 164 6.0 6.0 35 17128 644 644 213 35 42 42 1 1 5 49 578 560 3.0 164 6.0 6.0 36 20153 705 705 213 35 42 42 1 1 6 51 722 600 3.0 164 6.0 6.0 38 23469 767 767 213 34 41 41

The internal actions for the top of the first column (ID=6) are given below. The hand calculations match the P, V, and M shown in this report.

Calculations Manual 06/06 MBS, Inc. Page 4-5

=============================================================================== Calc_Manual Actions & Stress Report 9/ 4/00 6:32pm =============================================================================== | ACTIONS(kN,kN-)|CALC. STRESS(MN/m2)|ALLOW STRESS(MN/m2)| UNITY CHECKS Sn Id | Axl Shr Mom | Axl Shr B-o B-i| Axl Shr B-o B-i| Shr O-f I-f | P V M | Fa Fv Fbo Fbi| Fa Fv Fbo Fbi| Ucv Uco Uci -- -- ---- ---- ------ ---- ---- ---- ---- ---- ---- ---- ---- ---- ---- ---- LOAD COMBINATION :28 DL 1 6 9.0 -1.7 12.1 2 1 16 -16 137 14 207 164 0.07 0.05 0.11 LOAD COMBINATION :29 LL 1 6 31.2 -6.0 43.1 8 3 56 -56 137 14 207 164 0.23 0.19 0.39 LOAD COMBINATION :30 WL1 1 6 -49.6 11.5 -123.4 -13 6 -161 161 276 19 218 276 0.33 0.74 0.63

X0 = 420 mm , X1 = 510 mm , Y1 = 7220 mm Slope of C.G. line = (510 - 420) mm in 7220 mm = 1.25 : 100 B. Sign Convention For Internal Actions

C. Dead Load [ ] = program output Fy = Reaction - Column Wt = 10.7 - 198 · 9.81 / 1000 = 8.8 kN [9.0] Fx = Reaction = 1.8 kN [1.7]

Calculations Manual 06/06 MBS, Inc. Page 4-6

M = 1.8 · 7.22 - 10.7 · (0.51 - 0.42) = 12.0 kN [12.0] D. Live Load Fy = Reaction = 31.1 kN [31.2] Fx = Reaction = 6.4 kN M = 6.4 · 7.22 - 31.1 · (0.51 - 0.42) = 43.4 kN-m [43.1]

Resolve X and Y forces to be parallel and normal to the C.G. line for the member. Shear = 6.4 + 31.1 · 1.25 / 100 = 6.0 kN [6.0]

E. Wind_1 From Left Fy = Reaction = -49.5 kN [-49.6] Fx = Reaction - Wind Load = 23.4 - 1.55 · 7.22 = 12.2 kN M = -23.4 · 7.22 + 49.5 · (0.51 - 0.42) + 1.55 · 7.22² / 2 = 124.1 kN-m [123.4] Shear = -12.2 + 49.5 · 1.25 / 100 = -11.6 kN [11.5]

4.8 STRESS CHECK AT TOP OF COLUMN The design summary report indicates the maximum unity checks for the column are at the

top of the column and the stress check point just below the top of the column. In this section, calculations will be made that check the program output for each of the stress check points. Note the design summary, Section 4.2, indicates a different load condition for each unity check.

A. Program Output: Actions and Stress Reports

=============================================================================== Calc_Manual Actions & Stress Report 9/ 4/00 6:32pm =============================================================================== | ACTIONS(kN,kN-)|CALC. STRESS(MN/m2)|ALLOW STRESS(MN/m2)| UNITY CHECKS Sn Id | Axl Shr Mom | Axl Shr B-o B-i| Axl Shr B-o B-i| Shr O-f I-f | P V M | Fa Fv Fbo Fbi| Fa Fv Fbo Fbi| Ucv Uco Uci -- -- ---- ---- ------ ---- ---- ---- ---- ---- ---- ---- ---- ---- ---- ---- LOAD COMBINATION : 2 DL+WL1 1 6 -40.7 9.8 -111.3 -11 5 -145 145 276 19 218 276 0.28 0.66 0.56 LOAD COMBINATION : 9 DL-LW2 1 6 29.3 23.7 -57.7 8 13 -75 75 182 19 218 276 0.69 0.38 0.21 LOAD COMBINATION :13 DL+CO+LL+WR2/2 1 5 43.8-11.1 72.1 12 7 102 -102 184 22 276 137 0.30 0.27 0.80

Calculations Manual 06/06 MBS, Inc. Page 4-7

This report includes just the three loading conditions that control the design of the column. B. Member Plates

See the Design Summary, Section 4.2, or Section Properties report, Section 4.7, for plate sizes. OUT Flange = 164 x 6 IN Flange = 164 x 6 Web = 600 x 3 (Id = 6), 560 x 3 (Id = 5) C. Shear Check

From Design Summary, the load that controls the shear at the top of column is DL - LW2. = Reactions from dead load and longitudinal wind + longitudinal wind load on

column up to the 7.22 m height. = 23.7 kN Shear Stress = 23.7 / (600 · 3) = 13.1 MN/m² [13]

( ) y

yv

Fth

FF

⋅

⋅⋅= 2

34.54500089.2

(F4-2)

( )23600

34.589.2

45000⋅=vF = 2.09 · 4 / 3 = 2.77 ksi = 2.77 / 0.145 = 19.1 MN/m² [19]

Unity Check = 13.1 / 19 = 0.69 [0.69]

Calculations Manual 06/06 MBS, Inc. Page 4-8

D. Member Unbraced Length See the rigid frame cross section where the outside girt and inside flange brace is at 6000 mm. The vertical distance to stress check point is 7220 mm (Id = 6) and 5780 mm (Id = 5). Therefore: Inside Flange Unbraced Length (Id = 5) = 6000 mm Outside Flange Unbraced Length = 7220 - 6000 = 1220 mm

Major Axis Unbraced Length = 7220 · 1.5 = 10830 mm The 1.5 is the sidewall column unbraced length factor set by the user.

These values are all reported in the unbraced length report as follows. E. Program Output: Unbraced Length Report

=============================================================================== Calc_Manual Stress Check Unbraced Lengths 9/ 4/00 6:32pm =============================================================================== Mem Seg Sec -------------------Cb------------------ Id Id Id Major Loc Minor 1 2 3 4 5 6 7 8 --- --- --- ----- --- ----- ---- ---- ---- ---- ---- ---- ---- ---- 1 1 5 10836 Top 1500 1.13 1.10 1.02 1.04 1.10 1.75 1.70 1.49 Bot 6000 1.75 1.75 1.75 1.75 1.75 1.75 1.75 1.75 1 1 6 10836 Top 1224 1.08 1.06 1.09 1.01 1.06 1.33 1.32 1.27 Bot 1224 1.08 1.06 1.09 1.01 1.06 1.33 1.32 1.27

F. Cb For Outside Flange, The Compression Flange Cb = 1.75 + 1.05 · M1 / M2 + 0.3 · (M1 / M2)² For the Outside Flange, on loading 2, M2 = Moment at top of column = 111.3 M1 = Moment at top girt = 97.2 M1 / M2 = 97.2 / 111.3 = - 0.87 Cb = 1.75 - 1.05 · 0.87 + 0.30 · (0.87)² = 1.06 [1.06] See the same value in the unbraced length report. G. Actions For Outside Flange Stress Check

Calculations Manual 06/06 MBS, Inc. Page 4-9

From the Design Summary (4.2), note the DL + WL1 controls. The internal actions for that loading can be calculated from the basic load values given previously. V = -1.8 + 11.6 = 9.8 kN [9.8] N = 8.8 -49.5 = 40.7 kN [40.7] M = 12.0 -124.1 = -112.1 kN-m [-111.3] These values match those in the “Actions and Stress Report” (4.8).

H. Special Program For Stress Check

The member properties and loading can be placed in a special program, W_STRESS, to obtain the controlling equations and unity checks. The values for the outside flange are shown below.

STRESS RATIO FOR WIDE FLANGE MEMBERS INPUT OUTPUT MEMBER Member Size - W-SECT Web Depth (mm) - 600.000 CALC'D ALLOW STRESS Web Thick (mm) - 3.000 ACTION STRESS STRESS RATIO Flange Width (mm) - 164.000 --------- ------ ------ ------ Top Flg Thick (mm) - 6.000 Axial -10.80 275.99 0.04 Bot Flg Thick (mm) - 6.000 D1 Yield Flange(MN/m2) - 345.000 Shear 5.44 19.11 0.28 Yield Web (MN/m2) - 345.000 F4-2 UNBRACED LENGTH Bend-T -145.11 218.29 0.66 Major Axis (mm) - 10860.000 A-B5-3 Minor Axis Top (mm) - 1224.000 Bend-B 145.11 275.99 0.53 Minor Axis Bot (mm) - 1224.000 F1-5 Cb Top - 1.060 Axl+Bnd_T 0.66 Cb Bot - 1.000 H2-1* Wind Adjust - 1.333 Axl+Bnd_B 0.56 ACTION H2-1 Axial (kn) - -40.700 Shear (kN) - 9.800 Axial Qs=1.00 Qa=1.00 Q=1.00 Moment (kN-m) - -111.300 Bend Qs=0.79

The AISC equations controlling the output are listed below each output.

I. Outside Flange Unity Checks

See the Section Properties Report (4.7), at Id point 6 for member section properties. See Actions and Stress Report, (4.8) for stresses for load 2.

Calculations Manual 06/06 MBS, Inc. Page 4-10

a. Calculated Stress fa = Force / Area

=mcm

cmkNMNkN ²100

²381

10007.40

⋅⋅⋅− = -10.7 MN/m² [-11]

fb = M / s

= 3100

1000³76713.111 ⎟

⎠⎞

⎜⎝⎛⋅⋅⋅−−

mcm

kNMN

cmmkN = -145.1 MN/m²[-145]

b. Allowable Axial Stress Tension allowable = 0.60 · Fy (D1)

= 0.60 · 345 · 4 / 3 = 276 MN/m² [276] c. Allowable Bending Stress

1. Check b/t Influence

7.1362

1642

=⋅

=⋅ t

bt

Fy - metric = 345 MN/m² Fy- english = 345 · 0.145 = 50.0 ksi AISC equations are set up for English units. Non compact limit = cy kF95 (TableE.5.1)

( )

( )

elementslender

k

ththk

c

c

∴<=

==

===

1200.8354.05095

354.020005.4

2003600,05.4

46.0

46.0

( ) cys kFtbQ ⋅⋅−= 00309.0293.1 (A-B5-3)

( ) 354.0507.1300309.0293.1 ⋅⋅−=

79.0= (Section H) [0.79]

ysb FQF ⋅= (B5.2.a)

Calculations Manual 06/06 MBS, Inc. Page 4-11

²/0.218345.16334560.079.0 mMN=⋅=⋅⋅= [218]

2. Check Unbraced Length Influence

5.4650

06.110200050

102000,8.35

2.341224

=⋅

=⋅

== b

t

Crl

Since 35.8 < 46.5, unbraced length does not reduce Fb. (F1-6)

d. Unity Check On Outside Flange

0.1≤+bx

bx

t

a

Ff

Ff

(H2-1)

626.0665.0039.0218145

2767.10

=+−=+−

Use bending stress only UC = 0.665 [0.66]

J. Inside Flange Unity Check

a. From the design summary (4.2), the controlling load (13) is DL + CO + LL + WR2/2. From the actions and stress report the actions at Id 5 are:

M = 72.1 kN-m, V = -11.1 kN, N = 43.8 kN b. Calculated Stresses fa = 43.8 kN / 36 cm² = 12.2 MN/m² [12] fb = 72.1 kN-m / 705 cm³ = 102.3 MN/m² [102] c. Check for Slender elements

Flange is the same as outside flange, Qs = 0.79 Qa = 1.0 since web is not uniformly compressed. Q = 1.0 · 0.79 = 0.79

d. Allowable Axial Stress, minor axis unbraced length is the girt spacing.

⎟⎠⎞

rKL major 8.50

21372205.1

=⋅

=

⎟⎠⎞

rKL minor 1.43

8.341500

==

Calculations Manual 06/06 MBS, Inc. Page 4-12

.1205079.0000,2922

14.32

=⋅

⋅=

⋅⋅=

yc FQ

EC π (A-B5-11)

423.01208.50, ==⎟⎠⎞

⎜⎝⎛ RC

rKL

c

4.13682.1

2.248

8423.0423.0

83

35

79.03452

423.01

883

35

21

3

2

3

2

=−

=−⋅+

⋅⋅⎥⎦

⎤⎢⎣

⎡−

=−⋅+

⋅⎥⎦

⎤⎢⎣

⎡−

=RR

FRQF

y

a

²/8.181344.136 mMN=⋅= [184]

e. Allowable Bending Stress Based on b/t of flange, the stress is limited to 218.29, see Section H.

Check Fb based on unbraced length. Cb = 1.75, see Unbraced Length Report, (4.8), for load 13 bottom flange.

2.1415.426000 ==trl

2.1419.10650

12.1000,510<=

∗ Therefore,

( ) yt

bb F

rC

F ⋅≤⎥⎥⎦

⎤

⎢⎢⎣

⎡ ⋅= 60.0

000,1702

l (F1-6)

²/13734145.09.149.14

2.14175.1170000

2 mMNksi =⋅==⎥⎦⎤

⎢⎣⎡ ⋅

= [137.]

f. Unity Check on Inside Flange

0.11 1

≤

⋅⎟⎟⎠

⎞⎜⎜⎝

⎛−

⋅+

be

a

bm

a

a

fFf

fCFf

(H1-1)

( )²/396

6.21272205.123

145.0000,2914.312/23

122

2

2

21 mMN

rKEF

bbe =

⎟⎠⎞

⎜⎝⎛ ⋅⋅

⋅⋅=

⋅⋅⋅

=l

π

Calculations Manual 06/06 MBS, Inc. Page 4-13

Cm= 0.85

718.0653.0065.0137

396121

10285.018412

=+=⋅⎟⎠⎞

⎜⎝⎛ −

⋅+

802.0745.0058.0137102

3456.012

60.0=+=+

⋅=+

⋅ bx

bx

y

a

Ff

Ff

[0.80]

4.9 CHECK INTERIOR COLUMN A. Calculations

- Selected member is 3019656, from the DS_WFRM file, the section properties are: Area = 385 cm², Depth = 300 mm, ry = 44.2 mm - Unbraced Length, floor to underside of rafter mm7866144.6602105tan150008000 =−−−°⋅+=

- 1782.44

7866==

rKL

- 9.106345

145.0000,29214.3214.3 =⋅

⋅=⋅

⋅=y

c FEC

( )2

2

2312

rklEFa

⋅⋅Π⋅

= (E2-2)

- ( )

²/5.3217823

145.0000,2914.3122

2

mMNFa =⋅⋅⋅

= [32]

- ²/1.281000

100²5.38

108 2

mMNkN

MNm

cmcmkNareaLoadfa =⎟⎟

⎠

⎞⎜⎜⎝

⎛⋅⎟

⎠⎞

⎜⎝⎛⋅== [28]

- Unity check = 28 / 32.5 = 0.862 [0.86]

B. Program Output: Interior Column Design Report

Calculations Manual 06/06 MBS, Inc. Page 4-14

=============================================================================== Calc_Manual Interior Column Design 9/ 5/00 7:48am =============================================================================== Actions Axial_Stress Bend_Stress Col Col Col Load Axl Mom Calc. Allow Calc. Allow Unity Id Loc. Size Id kN kN-m MN/m2 MN/m2 MN/m2 MN/m2 Check --- ----- -------- ---- ---- ----- ----- ----- ----- ----- ----- 1 15000 3019656 1 108.0 0.0 28 32 0 141 0.86 2 -61.1 0.0 -16 188 0 188 0.08 3 -61.1 0.0 -16 188 0 188 0.08 4 -24.2 0.0 -6 188 0 188 0.03 5 -24.2 0.0 -6 188 0 188 0.03 6 -56.6 0.0 -15 188 0 188 0.08 7 -56.5 0.0 -15 188 0 188 0.08 8 -56.6 0.0 -15 188 0 188 0.08 9 -56.5 0.0 -15 188 0 188 0.08 10 67.2 0.0 17 43 -0 67 0.40 11 67.2 0.0 17 43 -0 67 0.40 12 85.7 0.0 22 43 -0 67 0.51 13 85.7 0.0 22 43 -0 67 0.51 14 -24.7 0.0 -6 188 0 188 0.03 15 -24.7 0.0 -6 188 0 188 0.03 16 14.6 0.0 4 43 -0 67 0.09 17 14.6 0.0 4 43 -0 67 0.09 18 41.2 0.0 11 43 -0 67 0.25 19 41.2 0.0 11 43 -0 67 0.25 20 41.2 0.0 11 43 -0 67 0.25 21 41.2 0.0 11 43 0 188 0.25 22 16.7 0.0 4 43 -0 67 0.10 23 16.7 0.0 4 43 -0 67 0.10 24 16.7 0.0 4 43 0 188 0.10 25 16.7 0.0 4 43 0 188 0.10 26 58.0 0.0 15 32 -0 50 0.46 27 58.0 0.0 15 32 -0 50 0.46

4.10 CHECK NUMBER AND DIAMETER OF ANCHOR BOLTS A. Calculations

- Anchor bolts are selected on the basis of the allowable stresses in Table J3.3. - Maximum reactions are taken from the rigid frame reaction report. - For the left sidewall column the maximum uplift is 86.8. Bolts are compared on the

basis of no stress increase so the load appears as 86.8 * 0.75 = 65.1 kN. - Similarly, the maximum shear is from the diagonal bracing and the frame reaction: 1.3575.0²8.4²3.9 =⋅+ - Allowable shear on 2 3/4" A307 bolts Allowable shear stress = 10 ksi/0.145 = 69 MN/m²

Calculations Manual 06/06 MBS, Inc. Page 4-15

= ( ) 414.3100020692 2 ⋅⋅⋅ = 0.043 MN = 43.0 kN > 35.1 Okay - Allowable tension

Stress = 20 / 0.145 = 138 MN/m² Force = ( ) 1000410002014.31382 2⋅⋅⋅ = 86.6 kN > 65.1 Okay

B. Program Output: Base Plate and Anchor Bolt Design

=============================================================================== Calc_Manual Base Plate and Anchor Bolt Design 9/ 5/00 7:48am =============================================================================== Bolt Type = A307 Weak Column_Base Max_Reactions(kN) Axis ---Plate_Size(mm)--- ---Bolts(mm)--- Loc. Type Comp Tens Shear Tens Width Length Thick Row Diam Gage ----- ---- ----- ----- ----- ----- ----- ------ ----- --------- ---- Left P 47.0 -65.1 -35.1 0.0 164 460.0 12.0 2 20.0 100 Right P 47.0 -43.6 19.5 0.0 164 460.0 12.0 2 20.0 100 IC-1 P 108.0 -61.3 0.0 0.0 196 340.0 12.0 2 20.0 100

4.11 CHECK BASE PLATE THICKNESS

a. The base plate thickness must satisfy these requirements: - Thicknesses available in file: 12, 14, 16, 20, 22 - Thickness required for compression load, Pg. 3-107, AISC. - Thickness required for uplift, Page 15 of AISC publication "Steel Design Guide

Series 1, Column Base Plates". b. Thickness based on compression force. - Maximum downward load = 47 kN - Concrete bearing stress = 47 / 0.164 / 0.46 = 623 kN/m² - Allowable bearing stress = 7241 kN/m², unless set by design parameter BEP32. - Since 623 is < 7241, use minimum base plate size, 164 x 460. - From Pg. 3-107 of AISC,

y

pp F

fnt ⋅⋅⋅= '2 λ

4

' fbdn

⋅=

Calculations Manual 06/06 MBS, Inc. Page 4-16

( ) 0.14

2 ≤⋅+

⋅⋅⋅=

pf

fp

Fbd

bdfq

[ ]

0.1112

≤−−⋅

=q

qλ

where: fp = concrete bearing stress d = column depth bf = column flange width Fp = allowable bearing pressure

70.24.254

460164' =⋅⋅

=n

( )

0666.072414601644601646234

2 =⋅+⋅⋅⋅

=q

[ ] 263.00666.00666.0112 =−−⋅=λ

mmint p 54.14.250608.0345623.070.2263.02 =⋅=⋅⋅⋅=

c. Thickness based on column uplift.

fy

p bFgPt

⋅⋅⋅⋅

=2

2 when fb⋅2 < d 1642 ⋅ = 232 < 460 Okay

P = uplift force = 65.1 kN = 14.6 kip g = bolt gage = 100 mm = 3.94 in d = plate length = 460 mm = 18.1 in bf = flange width = 164 mm = 6.46 in Fy = 345 MN/m² = 50 kip/in²

mmusemmt p 120.9"355.05046.62

94.36.142==

⋅⋅⋅⋅

=

- See Section 4.11 for base plate size.

4.12 BOLTED END PLATE THICKNESS

Calculations Manual 06/06 MBS, Inc. Page 4-17

A. Calculations a. Program Selected Plate

h = 612 mm = 24.1" g = 100 mm = 3.94" bf = 196 mm = 7.72" pf = 59 mm = 2.32" pt = 65 mm = 2.56" tw = 3 mm = 0.118" End plate is 196 mm x 12mm = 7.72" x 0.47" Flange = 164 mm x 6 mm = 6.46" x 0.236" Moment with tension on top = 66 kN-m = 48.6 ft-kip Bolts = A325, plate yield = 345MN/m² = 50 ksi b. Design criteria is from a research report "Unification Of Flush End-Plate Design

Procedures" by D. M. Hendrick and others, March 1985, Report No. FSEL/MBMA 85-01, Civil Engineering Department University of Oklahoma, See the Design Example on page 60.

Step 1: Determine Mu and required plate thickness

60.0momentworkingM u =

The 57 ft-k moment is from a loading with wind that has been multiplied

by 0.75 to account for the stress increase permitted with wind.

75.294.372.75.05.0

8160.0/6.48

=⋅⋅=⋅⋅=

−==

gbs

kftM

f

u

( ) ( )

21

2112 ⎪

⎪

⎭

⎪⎪

⎬

⎫

⎪⎪

⎩

⎪⎪

⎨

⎧

⎥⎥⎦

⎤

⎢⎢⎣

⎡⋅++⎟

⎟⎠

⎞⎜⎜⎝

⎛+⋅⋅−

=

gsp

spb

ph

FMt

ff

ft

yup

( ) ( )

21

94.3275.232.2

75.21

32.21

272.756.21.24

501281

⎪⎪⎭

⎪⎪⎬

⎫

⎪⎪⎩

⎪⎪⎨

⎧

⎥⎦

⎤⎢⎣

⎡⋅++⎟

⎠⎞

⎜⎝⎛ +⋅⋅−

⋅=

Calculations Manual 06/06 MBS, Inc. Page 4-18

platexTry "47.0"72.7"40.07.1214.19 2

1

=⎭⎬⎫

⎩⎨⎧=

Step 2: Compute the flange force, Ff

( ) ( )k

thMF fuf

7.40

236.01.24120.81

=

−⋅=−=

Step 3: Find the thick plate limit, t1

( )yfff FbFpt ⋅⋅⋅= 21.41

( ) 0:""015.15072.77.4032.221.4 21 =>=⋅⋅⋅= QTherefore

Step 4: Find the thin plate limit, t11 "63.016 == mmdassume b

( )

( ) "17.30625.063.0272.7

0625.021

=+−=

+−= bf dbW

ksiboltofFF yyb 88==

[ ]

⎟⎟⎠

⎞⎜⎜⎝

⎛⋅+⋅⋅

⋅⋅Π−⋅⋅=

1

3

11

8.02

85.0

162)(

Wb

F

FdpFapproxt

fy

ybbff

[ ]

9.2902.180

17.38.0272.785.050

168863.032.27.402 3

=⎟⎠⎞

⎜⎝⎛ ⋅+⋅⋅

⋅⋅Π−⋅⋅=

= 0.787"

Check the shear limit of end plate

Okay

FtWF yf

,7.40144350787.017.32

32 111

>=⋅⋅⋅

⋅⋅⋅<

use the exact equation

Calculations Manual 06/06 MBS, Inc. Page 4-19

( )

2

111

21

2

11

2

3

11

233

2

162

⎟⎟⎠

⎞⎜⎜⎝

⎛⋅⋅

⋅−⋅+⎟⎟⎠

⎞⎜⎜⎝

⎛

⋅⋅−⋅

⋅⋅Π−⋅⋅=

tWF

FWbt

FF

b

FdpFt

fy

f

fy

f

ybbff

( )

3.1567.1872.180

787.017.327.4035017.3

72.7787.07.40350

272.7

168863.014.332.27.4022

22

2

3

+=

⎟⎠⎞

⎜⎝⎛

⋅⋅⋅−⋅+⎟

⎠⎞

⎜⎝⎛

⋅⋅−⋅

⋅⋅−⋅⋅=

= 0.727 which is near the approximate 0.787 since t11 > 0.5 · tp, Q = Qmax Step 5: Determine prying force

( )f

ybbfypit p

FdWbFtF

⋅

⋅⋅Π+⋅+⋅⋅⋅=

4880.0285.0 312

lim

( )

32.2488863.017.380.0272.785.05047.0 32

⋅

⋅⋅Π+⋅+⋅⋅⋅=

= 7.85 k

kuseofFthus

kFf

85.7,4.20,85.7min

4.2027.402max

1 =

==

( )

( ) 44.1085.063.047.0682.3

085.0682.3

3

3

=−⋅=

−⋅= bp dta

2

1

12

21

34 ⎟

⎟⎠

⎞⎜⎜⎝

⎛

⋅⋅−⋅

⋅

⋅==

py

p

tWFF

atW

forcepryingQ

Calculations Manual 06/06 MBS, Inc. Page 4-20

k98.5

47.017.385.7350

44.1447.017.3 2

22

=

⎟⎠⎞

⎜⎝⎛

⋅⋅−⋅

⋅⋅

=

Step 6: Select bolt diameter

mmused

kforceBolt

b 16"63.0"617.044

3.262

3.2698.52

7.40

=∴=⋅Π⋅

=

=+=

B. Program Output: Bolted End Plate Design

=============================================================================== Calc_Manual Bolted-End-Plate Design 9/ 6/00 8:54am =============================================================================== Bolt Type = Gr8.8 Splice Member -SPLICE(mm)-- Tens Load(kN,kN-m) ------Bolt(mm)------- Id Typ Loc. Width Thick Loc. Id Shr Mom Row Diam Space Gage ------ ------ ----- ----- ---- -- --- ---- --- ----- ----- ----- 1 HFF 1- 2 164 12.0 Top: 13 -8 66 1 16.0 80.0 100 Bot: 2 8 83 2 16.0 80.0 100 2 -FF 2- 3 164 10.0 Top: 1 -34 22 1 12.0 80.0 100 Bot: 9 10 22 1 12.0 80.0 100 3 -FF 4- 5 164 10.0 Top: 1 34 22 1 12.0 80.0 100 Bot: 6 -10 22 1 12.0 80.0 100 4 HFF 5- 6 164 12.0 Top: 12 -8 66 1 16.0 80.0 100 Bot: 3 8 83 2 16.0 80.0 100 WELDS: ------ ------Top_Flange----- ----Bottom_Flange---- ---------Web--------- Splice Shear(kN/mm) Shear(kN/mm) Shear(kN/mm) Id Side Size Typ Calc Allow Size Typ Calc Allow Size Typ Calc Allow -- ---- ----- --- ----- ----- ----- --- ----- ----- ----- --- ----- ----- 1 L 6.0 F1 0.515 0.600 8.0 F1 0.653 0.800 3.0 F1 0.014 0.300 1 R 5.0 F1 0.447 0.500 8.0 F1 0.653 0.800 3.0 F1 0.014 0.300 2 L 3.0 F1 0.181 0.300 3.0 F1 0.218 0.300 3.0 F1 0.067 0.300 2 R 3.0 F1 0.189 0.300 3.0 F1 0.194 0.300 3.0 F1 0.067 0.300 3 L 3.0 F1 0.189 0.300 3.0 F1 0.194 0.300 3.0 F1 0.067 0.300 3 R 3.0 F1 0.182 0.300 3.0 F1 0.218 0.300 3.0 F1 0.067 0.300 4 L 6.0 F1 0.515 0.600 8.0 F1 0.653 0.800 3.0 F1 0.014 0.300 4 R 5.0 F1 0.447 0.500 8.0 F1 0.653 0.800 3.0 F1 0.014 0.300

Calculations Manual 06/06 MBS, Inc. Page 4-21

4.13 BOLTED END PLATE: FLANGE TO END PLATE WELD - Weld is to carry the force in the flange - Flange force is calculated from flange stress and flange area. - Consider the outside flange in the column to rafter splice.

- Flange stress = M / S = 3100

1000³76766

⎟⎠⎞

⎜⎝⎛⋅⋅

−m

cmkN

MNcm

mkN = 86.0 MN/m²

- Flange force = 86.0 · 0.164 m · 0.006 m · 1000 = 84.6 kN - Weld strength required = 84.6 / 164 = 0.516 kN/mm [0.515] - From DS_WELD file, weld capacities are: 5 mm = 0.50, 6 mm = 0.60, use 6 mm weld - See Section 4.12 for the bolted end plate design report which includes the welding

report. 4.14 STIFFENER AT COLUMN TO RAFTER SPLICE A. Calculations

a. Layout of Connection A stiffener is required if either

the tension or compression exceeds the capacity of the web.

tendplate = 12 mm = 0.47" tweb = 3 mm = 0.118" Mc = 66 kN-m = 48.6 ft-kip

Mt = 83 kN-m = 61.2 ft-kip Both moments include wind

load. b. Check for Tension Force Use a stiffener if the flange thickness, in this case bolted end plate thickness, is

less than

yc

bf

FP

⋅40.0 (K1-1)

where: 4/3 · flange force when loading includes wind =bfP

Calculations Manual 06/06 MBS, Inc. Page 4-22

column yield stress = 345 MN/m² = 50 ksi =ycF Flange force = (bending stress + axial stress) x area

kN1231000006.0164.01038

4.43767

10008.87=⋅⋅⋅⎟

⎠⎞

⎜⎝⎛ ⋅+

⋅=

kipkNPbf 8.3616412334

==⋅= [165]

mmtep 75.8"342.050

8.364.0 ==⋅=

since end plate thickness is > 8.8 mm, stiffener is not required for tension. c. Check for Compression Force

A pair of stiffeners are required opposite the compression flange when the column web depth is greater than:

bf

ycwcc P

Ftd

⋅⋅<

34100 (K1-8)

kNkipPbf 5.11245.43.2583

668.31=⋅=

⋅= [123.6]

mmdc 222"75.83.25

50197.04100 3

==⋅⋅

<

Column web depth is 600, > 48, use stiffener.

d. Size the Stiffeners - Available stiffeners come from the DS_RFPLT file. - Plate width is one half flange width, 164/2 = 82 - The first available stiffener is 6 mm x 70 mm. - Criteria for sizing the stiffener is in K1.8. - .7062 stiffenersmmbyTry − - 22 14657062525 mmArea =⋅⋅+⋅=

Calculations Manual 06/06 MBS, Inc. Page 4-23

- ( ) 43 312,524,11265270 mmI =⋅+⋅= - mmAIr 2.321465312,524,1 ===

- 9.132.3260075.0 =⋅=r

KL

- ²./3.1999.28 mMNksiFa ==

- kNMN

kNmm

mmmm

MNPallow 29210001000

²1465²

3.1992

=⋅⎟⎟⎠

⎞⎜⎜⎝

⎛⋅⋅= [292]

- Unity check on stiffeners = 123 / 213 = 0.58 [0.56]

B. Program Output: Stiffener Report

=============================================================================== Calc_Manual Stiffener Report 9/ 6/00 1:24pm =============================================================================== Stiff -Plate_Size- Web Load -----Force(kN)---- Location No. Width Thick Length Id Calc Allow UC ---------- --- ----- ----- ------ ---- ----- ----- ---- Left Col 1 70.0 6.0 600.0 13 165.3 292.3 0.57 Right Col 1 70.0 6.0 600.0 12 165.3 292.3 0.57 Int Col 1 2 70.0 6.0 655.2 1 52.9 291.0 0.18

4.15 STIFFENER ABOVE INTERIOR COLUMN - Rafter web: 5 x 660 mm - Rafter flange : 164 x 8 mm - Column compression force = 106 kN - Check web yielding:

( ) yw

FkNt

R⋅≤

⋅+⋅66.0

5 (K1-2)

where: R = reaction = 106 kN tw = web thickness = 5 mm = 0.197" N = length of bearing, 300 mm = cap plate length k = tflg + 5 mm = 8 + 5 = 13 mm

Calculations Manual 06/06 MBS, Inc. Page 4-24

( ) ( )

OkaymMNmMNm

mmkN

MNmm

kN

kNtR

w

∴=⋅<=

⎟⎠⎞

⎜⎝⎛⋅⋅=

⋅+⋅=

⋅+⋅

²/22834566.0²/56

10001000²

056.0

1353125106

52

- Check web crippling, use web stiffeners when R exceeds:

fw

yw

f

ww t

tF

tt

dNt ⋅⋅

⎥⎥

⎦

⎤

⎢⎢

⎣

⎡

⎟⎟⎠

⎞⎜⎜⎝

⎛⋅⎟⎠⎞

⎜⎝⎛⋅+⋅⋅

5.1

2 315.67 (K1-4)

where: d = member depth tf = flange thickness

5

85085

66031231197.05.67

5.12 ⋅

⋅⎥⎥⎦

⎤

⎢⎢⎣

⎡⎟⎠⎞

⎜⎝⎛⋅⋅+⋅⋅

= 39.8 k = 177.2 kN > 106 kN (column reaction) - Stiffeners are not required, however, they are always used to provide stability for the

connection. - Allowable load on the stiffener is calculated the same as that in Section 4.14. - See the stiffener report in Section 4.14.

4.16 INTERIOR COLUMN CONNECTION TO RAFTER UPLIFT (not in program) A. Flange Bending From Tension in Bolts

Calculations Manual 06/06 MBS, Inc. Page 4-25

- Layout Elevation Plan

Enlargement Around Bolt

- Check bending in flange due to bolt force.

mm

weldwebgagea

5.425252100

2 21

=−−=

−−=

mmb 42=

since a = b, one half of bolt force goes to the web and one half to the stiffener. Head flat distance = 1.0625" = 27 mm for 16 mm bolts Distance from head flat to weld = 42 - 27 / 2 = 28.5 mm Bending in plate; M (see enlargement around bolt)

mmkNM

kNforceboltF

FM

−=⋅=

=⋅==

⋅=⋅

8025.2865.5

65.521

42.45

"5.282

21

Plate width for bending = 27 + 2 · 42 = 111, maximum is ½ flange width, 164 / 2 = 82 mm.

Calculations Manual 06/06 MBS, Inc. Page 4-26

Calculate bending stress ²/5.911000

1000³6882

80 2

2 mMNkN

MNm

mmmmmmkN

=⋅⎟⎠⎞

⎜⎝⎛⋅

⋅−

=

B. Total Tension Stress In Flange

- As the rafter lifts up, it also has tension in the lower flange from bending in the rafter. - The 45.2 k uplift force is from loading 3. From the Actions and Stress Report for load 3, stress check point 20, the tension stress in the flange is 84 kN/m². - On a transverse section cut through the flange at the stiffeners, the tension stress caused by the bolts during uplift is added to the tension stress in the flange due to rafter bending. 4/3 · 91.5 + 84.0 = 206 kN/m² - Allow bending stress 3

475.0 ⋅⋅= yF (F2-1) OkaymkN ∴=⋅⋅= ²/34534575.0 3

4

4.17 DESIGN OF INTERIOR COLUMN CAP PLATE A. Calculations a. Plate Thickness For wide flange columns, the cap plate is designed the same as a base plate for uplift.

See Section 4.11. Column size : depth = 300 mm, flange width = 196 Uplift = 45.1 kN = 10.1 k (reduced by 0.75 for permitted stress increase)

fyp bF

gPt⋅⋅⋅⋅

=2

2 when fb⋅2 < d 1962 ⋅ = 277 < 300 Okay

mmt p 8.6"27.0196502

1001.102==

⋅⋅⋅⋅

=

use t = 10 mm, smallest available plate

b. Bolt Diameter Bolt = GR8.8 = A325, try 16 mm diameter Allowable tension stress = 44 ksi = 303 MN/m² Allowable load on 4 16 mm diameter bolts

( )

boltsdiausekN

kNMN

kNmm

MN

.1641.45

5.243100016.0²

3034

4 22

−∴>

=⋅⋅⋅Π⋅=

B. Program Output: Interior Column Cap Plate

Calculations Manual 06/06 MBS, Inc. Page 4-27

=============================================================================== Calc_Manual Interior Column Cap Plate 9/ 5/00 8:46pm =============================================================================== Bolt Type = Gr8.8 Col Cap -Plate(mm)-- ------Load(kN,kN-m)---- ------Bolt(mm)------- Id Type Width Thick Id Axial Shear Moment Row Diam Space Gage --- ---- ----- ----- -- ----- ----- ------ --- ----- ----- ----- 1 P- 196.0 10.0 3 -45.0 0.0 0.0 2 24.0 0.0 120.0

4.18 CHECK SIZE OF FLANGE BRACE A. Calculate Force in Flange Brace

- From flange brace report, the maximum flange brace force is near the peak of the building.

- Layout of flange brace is shown on the erection details. The slope of the flange brace is

633 mm horizontal to about 661 mm vertical. - Maximum compressive force in lower flange at building peak is from the DL + LL +

CL loading

kN

MNkNmm

mMN

areastressforce

1681000164.0008.0²

128=⋅⋅⋅=

⋅=

- The percent of the flange force required for stability to be provided by the flange brace

is set by the user as 2 percent. See rigid frame design parameter 44. - Diagonal force in brace

( ) kN84.4633

66163302.016822

=+

⋅⋅= [4.67]

B. Member Stress Check

a. Member section properties - Select the flange brace from the smallest available in the DS_FLGBR.SIZ file.

Try 50x50x4. - Flange braces are on one side only, hence the full force is carried by one angle in

compression. - Use the angle design procedure on page 3-55 of the AISC Manual. - Angle drawing

Calculations Manual 06/06 MBS, Inc. Page 4-28

Load Applied

- For a 50x50x4 angle ksimMNFy 0.34²/235 ==

mmcmAIr

cmIII

cmrAI

mmYcmImmrcmArea

w

zxw

zz

x

z

4.1994.1897.37.14

7.1482.326.922

82.399.0897.3

8.1326.990.9897.3

4

422

4

2

====

=−⋅=−⋅=

=⋅=⋅=

==

==

b. Check for local buckling

15.120.13

00447.034.1

0.133476,5.12450

=∴>

⋅⋅−=

===

s

ys

Q

FtbQ

tb

(A-B5-1)

Limiting flange bending yy FF ⋅=⋅⋅= 60.06.00.1 c. Calculate allowable axial stress - Allowable axial stress to follow code section (A-B5-11)

- Flange brace length between bolts mm915661633 22 =+=

Calculations Manual 06/06 MBS, Inc. Page 4-29

- zr

KL⎟⎠⎞

⎜⎝⎛ for minor principal axis 4.92

90.9915

==

- wr

KL⎟⎠⎞

⎜⎝⎛ for major principal axis 2.47

4.19915

==

- 7.129340.12900022 22

' =⋅⋅Π⋅

=⋅⋅Π⋅

=y

c FQEC

- a = 71.07.1294.92' ==⎟⎠⎞

⎜⎝⎛

cCr

KL

- 3

2

81

83

35

21

aa

FaQF

y

a

⋅−⋅+

⋅⎥⎦

⎤⎢⎣

⎡−⋅

= (A-B5-11)

- ( ) ²/1.9683.1

8.175

71.08171.0

83

35

235271.010.13

2

mMNFa ==⋅−⋅+

⋅−⋅=

d. Calculate moments in angle

- Mz = ez · P = 3.96 · 4.67 = 18.5 kN-mm ez (to mid thickness) = 3.96 mm - Mw = ew · P = 12.73 · 4.67 = 59.4 kN-mm ew (to mid thickness) = 12.73 mm

e. Calculate stress in angle

- mmBCI

CMf w

w

wwbw 4.35414.1502, ===

⋅=

= ²/3.147.14

4.354.59 mMN=⋅

- mmYBCI

CMf zz

zzbz 8.158.132

25022, =⋅−=⋅−=

⋅=

Calculations Manual 06/06 MBS, Inc. Page 4-30

= ²/65.782.3

8.155.18 mMN=⋅

f. Check combined axial + bending

- ,15.0040.096

897.367.4<==

a

a

Ff

Therefore,

,0.1≤−+b

bz

b

bw

a

a

Ff

Ff

Ff

,0.1195.023560.0

65.73.14040.0 <=⋅+

+ Okay [0.20]

C. Program Output: Flange Brace Report

=============================================================================== Calc_Manual Flange Brace Report 9/ 6/00 6:16am =============================================================================== Flange Brace Yield= 235 MN/m2 Flange Brace Bolt = 12.0 (Gr4.6) Surf No. Id Brace Flange_Braces ---- ----- ------------- 1 1 Loc : 4 Sides: 1 Part : L50X50X4 Force: 2.75 BrcUC: 0.11 ConUC: 0.35 2 6 Loc : 1 3 5 7 9 10 Sides: 1 1 1 1 1 1 Part : L50X50X4 L50X50X4 L50X50X4 L50X50X4 L50X50X4 L50X50X4 Force: 2.00 1.45 2.19 1.14 2.62 4.67 BrcUC: 0.08 0.06 0.09 0.05 0.11 0.20 ConUC: 0.26 0.19 0.28 0.15 0.34 0.60

4.19 CHECK FLANGE BRACE TO PURLIN CONNECTION - 12 mm GR4.6 bolts are used. - Allowable shear load : allowable shear stress = 10 ksi = 69 MN/m²

kN80.741269 2 =⋅Π⋅= (E3.4) - Allowable bearing 22.21 tDCFu ⋅⋅⋅= (E3.3)

Calculations Manual 06/06 MBS, Inc. Page 4-31

mmDwashersforC

FF yu

1200.31

3.1

==

⋅=

, purlinZmmt 1620060.1=

Allowable bearing 22.2161222.22353.1 ⋅⋅⋅⋅= = 7.93 kN - Both 7.80 and 7.93 are > 4.67 Okay - Unity check on connection = 4.67 / 7.80 = 0.60 [0.60]

4.20 WELD OF WEB TO FLANGE A. Calculations

- For each segment the maximum shear between web and flange is calculated from

V Q / I

where: V = shear force on member Q = flange area · distance from C.G. of flange to C.G. of member I = moment of inertia - At column base, load 4, V = 25.7 kN

( )

4

3

9711

8.1991646262400

cmI

cmQ

=

=⋅⋅+=

mmkNcmkNcm

cmkNV /053.0/529.09711

³8.1997.254 ==

⋅= [0.053]

B. Program Output: Web to Flange Weld

=============================================================================== Calc_Manual Weld Report: Web To Flange 9/ 6/00 6:16am =============================================================================== -Weld_Provided- ----Max_Weld_Shear----- One_Side_Of_Web Member Segment Section Load Shear Size Shear Id Id Id Id (kN/mm) (mm) (kN/mm) ------ ------- ------- ------ ------- ----- ------- 1 1 1 4 0.053 3.0 0.400 2 2 7 1 0.043 3.0 0.300

Calculations Manual 06/06 MBS, Inc. Page 4-32

4.21 CHECK WEB AT TOP OF SIDEWALL COLUMN A. Calculations

- The column web plate at the column to rafter connection is subject to the shear due to the rafter connection.

- AISC does not have a clear requirement for this. To activate the following requirement

from "Steel Structures" by Salmon and Johnson, set rigid frame design parameter 36 to a value greater than zero.

bmcolyweb ddF

Mt⋅⋅⋅

=63.2

,0.575.160.060.0²/345

8363.2<=

⋅⋅−⋅

= mmmmmMN

mkN Okay with 5 mm web

B. Program Output: Special Segment Report

=============================================================================== Calc_Manual Special Segment Report 9/ 6/00 6:16am =============================================================================== SEGMENT SIZE AT LEFT COLUMN: ----------------------------- Web Thick= 5.0 ( 5.0) Flange Width= 164.0 ( 164.0) Flange Thick= 6.0 ( 6.0)

4.22 CHECK FLANGE AT TOP OF SIDEWALL COLUMN - Set rigid frame design parameter 37 to have the program check the adequacy of the

flange at the top of the column to carry the force in the adjacent flange on the rafter. - In this case the two flanges are the same size and therefore Okay. - See Special Segment report in Section 4.20.

4.23 CHECK AREA REDUCTION IN TENSION FLANGE (Not in program) A. Calculations

- Where the interior column attaches to the rafter, bolt holes are placed in the rafter bottom flange.

- There are loading conditions where that rafter flange is in tension, hence the flange area reduction caused by the bolt holes needs to be investigated.

- AISC Section B10 provides criteria for determining the effective flange area when holes are placed in tension flanges.

Calculations Manual 06/06 MBS, Inc. Page 4-33

If: 0.5 · Fu · Afn < 0.6 · Fy · Afg where: Afn = net flange area, Afg = gross area, Fu = tensile strength, and Fy = yield strength. Then, the effective flange area, Afe is: Afe = 5 · Fu · Afn / (6 · Fy) - For a 164 x 8 flange with 2 16 mm bolts, Afg = 8 · 164 = 1312 mm² Afn = (164 - 2 · 18) · 8 = 1024 mm² Fu = 1.3 · 345 = 450 MN/m²

Fy = 345 MN/m²

0.50 · Fu · Afn = 0.5 · 450 · 1024 = 230400 0.60 · Fy · Afg = 0.6 · 345 · 1312 = 271584

Since 230 < 271, Afe = (5 · 450 · 1024) / (6 · 345) = 1113 mm² - Ratio of available flange area to total flange area is 1113 / 1312 = 0.848 - From the Actions and Stress Report, the maximum tension stress ratio is 0.28 for design

load 2. - Since the flange is loaded to 0.28 and 0.85 is available, the flange is adequate with the

two bolt holes.

B. Program Output: Influence of Holes in Tension Flange

4.24 CALCULATING THE LIVE LOAD DEFLECTION A. Calculations

- For load cases, DL + LL + CL, the mid span vertical deflection is 22.6 mm. - Rafter frame dead load is (439 + 112) · 9.81 / (7.5 · 15) = 0.049 kN/m² - Ratio of live load to total load

Calculations Manual 06/06 MBS, Inc. Page 4-34

= 0.60 / (0.60 + 0.12 + 0.10 + 0.049) = 0.69 - Live load deflection = 0.69 · 22.6 = 15.6 mm [16.5]

- Vertical deflection ratio 9095.16

15000== [908]

B. Program Output: Deflection Report

=============================================================================== Calc_Manual Design Summary Report 9/ 6/00 6:16am =============================================================================== DEFLECTIONS : (mm) Lateral Defl Vertical Defl Load @ Top Of Col @ Midspan Of Col Id Left Right LT-1 1-RT ---- ---- ----- ----- ----- 1 -0.2 0.1 -22.6 -22.6 2 71.0 71.0 5.4 20.3 Max Live Vertical = -16.5, Span/Deflection = 908 Max Horizontal Drift= 71.0, Eave Height/Drift= 109.

4.25 CALCULATING THE DRIFT RATIO

- The maximum horizontal deflection for the frame is 71.0 mm. - The horizontal deflection is reported at the top of the sidewall column along the rafter

surface. - For this building with 210 mm purlins and 210 mm sidewall offset, the height of the

corner of the column is:

780075015000

2102108000 =⋅+−

- Drift ratio = 9.10971

7800= [109]

The program reports the drift ratio as an integer. See Section 4.24.

Calculations Manual 06/06 MBS, Inc. Page 4-35

5. SIDEWALL DESIGN 5.1 Introduction.......................................................................................................... 5-1 5.2 Analysis Model .................................................................................................... 5-1 5.3 Moment of Inertia at Girt Laps ............................................................................ 5-1 5.4 Detailed Check on Girt 3, Span 2 ........................................................................ 5-2 A. Load, Shear, and Moment Diagrams ....................................................... 5-2 B. Program Output: Girt Design Report....................................................... 5-2 C. Check Reactions....................................................................................... 5-4 D. Check Moments from Area in Shear Diagram ........................................ 5-4 E. Member Stress Checks............................................................................. 5-4 F. Check Girt Deflection .............................................................................. 5-5 5.5 Check Right Door Jamb....................................................................................... 5-6 A. Program Output: Door Jamb/Header Report ........................................... 5-6 B. Load on Door Jamb.................................................................................. 5-7 C. Check Bending in Jamb ........................................................................... 5-7 D. Check Jamb Deflection ............................................................................ 5-7 5.6 Check Left Door Jamb ......................................................................................... 5-7 5.7 Check Door Header.............................................................................................. 5-7 5.8 Check Wall Panels ............................................................................................... 5-8

5. SIDEWALL DESIGN

5.1 INTRODUCTION

The front sidewall will be illustrated with the design calculations. See the drawing on Page 2-10 to view the framing. For ease of reference, portions of the input and output files are included with the calculations. Program output is enclosed in boxes to separate it from the calculations. The sidewall framing consists of wall girts, door jambs, and door headers. The wall girts are supported by the sidewall and endwall columns. The girts are also attached to the door jambs. The door jambs could either support the girt or place a load on the girt depending on the member deflection at the attachment point. Therefore, the girt/jamb analysis needs to consider the member deflection.

5.2 ANALYSIS MODEL

The jambs and girts are considered to be a grid with pin connected members supported by the floor, corner column, rigid frame sidewall column, and eave strut.

5.3 MOMENT OF INERTIA AT GIRT LAPS

- Member connections

Calculations Manual 06/06 MBS, Inc. Page 5-1

- Both members are attached to this support. At the lap point the members are bolted

together. - In the analysis of the members it is necessary to know the moment of inertia over the

full length of the member. - Over the lap, the moment of inertia is calculated from the wall design parameter (wall1)

times the sum of the moment of inertia of the girts on each side of the lap. - See Section 5.5.1 of the Design Manual.

5.4 DETAILED CHECK ON GIRT 3, SPAN 2

A. Load, shear, and moment diagrams This is the third girt up on the above drawing. The program output shear and moment diagrams are shown below.

B. Program Output: Girt Design Report

Calculations Manual 06/06 MBS, Inc. Page 5-2

============================================================================== SAMPLE Girt Design Report 4/06/00 8:15am ============================================================================== ------------------- GIRT # 3 ; SPAN # 2 ------------------- GIRT LAYOUT: Bay Girt Bay Lap Dist(ft) Girt Girt Id Size Width Left Right Location Weight --- -------- ----- ---- ----- -------- ------ 2 8.5Z16 11.13 2.17 12.0000 39.3 3 8.5Z16 25.00 2.17 12.0000 80.4 ------ 119.8 WIND PRESSURE : ---------------- GIRT ANALYSIS: ---------SHEAR(k )-------- --------------MOMENT(f-k )-------------- Bay Left Left Right Right Left Left Mid-Span Right Right Id Sup Lap Lap Sup Sup Lap Mom Loc Lap Sup --- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- 2 -0.11 -0.94 -1.15 0.00 2.06 5.56 4.73 6.99 3 1.44 1.24 -0.88 6.99 4.09 -4.18 15.51 0.00 STRESS/DEFLECTION: Span ------SHEAR(k )------ -----MOMENT(f-k )---- Mom+Shr DEFLECTION(in) Id Loc Calc Allow UC Loc Calc Allow UC Loc UC Calc Allow ---- --- ------ ----- ---- --- ------ ----- ---- --- ---- ------ ----- 2 RL -0.94 3.12 0.30 RL 4.73 5.39 0.88 RL 0.61 -0.37 3 LL 1.24 3.12 0.40 MS -4.18 6.59 0.64 LL 0.54 -0.97 2.50 UNBRACE LENGTHS --------------- Bay ------------Minor------------ Id Major LS LL MS RL RS --- ----- ----- ----- ----- ----- ----- 2 11.1 9.0 9.0 9.0 9.0 2.2 3 25.0 2.2 3.9 0.0 0.0 0.0 WIND SUCTION : ---------------- GIRT ANALYSIS: ---------SHEAR(k )-------- --------------MOMENT(f-k )-------------- Bay Left Left Right Right Left Left Mid-Span Right Right Id Sup Lap Lap Sup Sup Lap Mom Loc Lap Sup --- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- 2 0.12 1.03 1.26 0.00 -2.26 5.56 -5.18 -7.66 3 -1.58 -1.36 0.97 -7.66 -4.48 4.59 15.51 0.00 STRESS/DEFLECTION: Span ------SHEAR(k )------ -----MOMENT(f-k )---- Mom+Shr DEFLECTION(in) Id Loc Calc Allow UC Loc Calc Allow UC Loc UC Calc Allow ---- --- ------ ----- ---- --- ------ ----- ---- --- ---- ------ ----- 2 RL 1.03 3.12 0.33 RL -5.18 6.59 0.79 RL 0.73 0.40 3 LL -1.36 3.12 0.44 MS 4.59 4.61 1.00 LL 0.65 1.07 2.50 UNBRACE LENGTHS --------------- Bay ------------Minor------------ Id Major LS LL MS RL RS --- ----- ----- ----- ----- ----- ----- 2 11.1 0.0 0.0 0.0 0.0 0.0 3 25.0 0.0 0.0 19.0 19.0 19.0

Calculations Manual 06/06 MBS, Inc. Page 5-3

C. Check Reactions

Wind pressure loading, w = ( ) plf0.932

0.65.47.17 =+

⋅

Load sum = ( ) k36.3'0.25'1.110.93 =+⋅

Reactions = ,36.388.044.115.111.0 k=+++− okay

D. Check Moments from Area in Shear Diagram

( ) 99.62

1.1115.111.0=

⋅+

Positive moment = ( ) ,18.499.6246.92544.1 =−−⋅ okay

E. Member Stress Checks - The program checks each girt at 5 locations along each span: 2 supports, 2 lap points,

and at mid span (point of maximum moment). - At each point checks are made on shear, moment, and moment plus shear. - The results for that location with the highest unity check are reported. - In this example, 3 stress checks will be made, one at a lap, one at the support, and one at

mid span. a. Unity Check at Support with Lap - Moment in one member = 6.99 / 2 = 3.50 ft-k (since both are the same size) - Shear in one member = 1.44 / 2 = 0.72 k - Moment allow is based on an unbraced length of the bottom flange which is equal to

the lap. - Use the C_STRESS program to calculate the allowable values. kShearkftM allowallow 12.3,71.6 =−= - Unity checks Shear = 0.72 / 3.12 = 0.23 Moment = 3.50 / 6.71 = 0.52

Moment + Shear = 0.122

≤⎟⎟⎠

⎞⎜⎜⎝

⎛+⎟⎟

⎠

⎞⎜⎜⎝

⎛

aa VV

MM (C3.3.1-1)

= 0.23² + 0.52² = 0.32 [0.33]

Calculations Manual 06/06 MBS, Inc. Page 5-4