DENSIMAT ALCOMAT 2 - Gibertini Elettronica s.r.l....Tutte le informazioni riportate in questo...

Transcript of DENSIMAT ALCOMAT 2 - Gibertini Elettronica s.r.l....Tutte le informazioni riportate in questo...

INSTRUCTION MANUAL

INSTRUCTION MANUAL

INSTRUCTION MANUAL

INSTRUCTION MANUAL

INSTRUCTION MANUAL

INSTRUCTION MANUAL

INSTRUCTION MANUAL

INSTRUCTION MANUAL

INSTRUCTION MANUAL

INSTRUCTION MANUAL

INSTRUCTION MANUAL

INSTRUCTION MANUAL

60.5

0.3

71 -

Ed

. 10 –

09/2

015

INSTRUCTION MANUAL

INSTRUCTION MANUAL

INSTRUCTION MANUAL

INSTRUCTION MANUAL

INSTRUCTION MANUAL

INSTRUCTION MANUAL

INSTRUCTION MANUAL

INSTRUCTION MANUAL

INSTRUCTION MANUAL

INSTRUCTION MANUAL

INSTRUCTION MANUAL

INSTRUCTION MANUAL

INSTRUCTION MANUAL

DENSIMAT

&

ALCOMAT 2

INSTRUCTION MANUAL

INSTRUCTION MANUAL

INSTRUCTION MANUAL

INSTRUCTION MANUAL

INSTRUCTION MANUAL

INSTRUCTION MANUAL

INSTRUCTION MANUAL

INSTRUCTION MANUAL

INSTRUCTION MANUAL

INSTRUCTION MANUAL

INSTRUCTION MANUAL

INSTRUCTION MANUAL

Tutte le informazioni riportate in questo manuale sono quelle disponibili al momento della stampa. Il costruttore si riserva il diritto di apportare modifiche al prodotto in qualsiasi momento senza preavviso.

Si consiglia di verificare eventuali aggiornamenti.

All the information given in this manual is what available at the time of printing. The manufacturer reserves the right to make changes to the product at any time without notice.

It is advisable to verify if there are any updates.

Tutti i diritti riservati. E’ vietata qualsiasi forma di stampa, duplicazione, riproduzione o pubblicazione di questo manuale,

o parte di esso, senza l’autorizzazione scritta da parte della GIBERTINI ELETTRONICA Srl.

All rights reserved. Forbidden any form of print, duplication, reproduction and publication of this instruction manual, or

part of it, without the written agreement of GIBERTINI ELETTRONICA Srl

INDICE - INDEX

1. GENERAL SPECIFICATIONS OF DENSIMAT ............................................................................................ 2

2. DESCRIPTION .............................................................................................................................................. 3

2.1 INSTALLATION OF DENSIMAT.................................................................................................................... 3

2.2 PROCEDURE FOR DENSIMAT INSTALLATION ........................................................................................ 4

2.3 DENSIMAT KEYBOARD ............................................................................................................................... 5

3. MEASUREMENTS WITH DENSIMAT .......................................................................................................... 5

3.1 DETERMINATION OF SPECIFIC GRAVITY D20

/20 OF A LIQUID ................................................................. 6

3.2 DETERMINATION OF THE DENSITY OF A LIQUID AT 20°C ...................................................................... 7

3.3 COMPENSATION OF FLOATER IN USE ..................................................................................................... 7

4. BEHAVIOUR OF THE INSTRUMENT WHEN SWITCHING ON AND CONDITIONS FOR OPTIMAL MEASUREMENTS ........................................................................................................................................ 9

5. APPENDIX A: LIST OF PRINCIPAL MESSAGES DISPLAYED BY DENSIMAT ....................................... 10

6. APPENDIX B: POSSIBLE OPTIONS FROM DENSIMAT KEYBOARD ..................................................... 11

7. APPENDIX C: USE OF THE CYLINDER FOR MEASUREMENTS IN CONTINUOUS ............................. 12

7.1 INSTALLATION ........................................................................................................................................... 12

7.2 OPERATING INSTRUCTION ...................................................................................................................... 13

8. APPENDIX D: REFERENCE TO LEGAL METROLOGY ........................................................................... 14

8.1 METROLOGICAL CHECKING OF DENSIMAT ........................................................................................... 14

8.1.1 Procedure of the metrological control of Densimat ..................................................................................... 14

8.1.2 SIT Calibration ............................................................................................................................................. 15

8.2 LEGAL METROLOGICAL APPROVAL OF THE DENSIMAT ...................................................................... 15

9. GENERAL CHARACTERISTICS OF ALCOMAT 2..................................................................................... 16

10. ALCOMAT 2 DESCRIPTION ..................................................................................................................... 17

10.1 PROCEDURE OF ALCOMAT 2 INSTALLATION ........................................................................................ 17

10.2 ALCOMAT 2 KEYBOARD ........................................................................................................................... 17

11. MEASUREMENTS WITH DENSIMAT - ALCOMAT 2 ................................................................................ 18

11.1 SPECIFIC GRAVITY AT 20 °C OF A DISTILLATE AND ASV (ALCOHOLIC STRENGTH BY VOLUME) ... 19

11.1.1 Specific gravity of a liquid ............................................................................................................................ 20

11.1.2 Correction of floater or compensation ......................................................................................................... 21

11.1.3 Print of the value of TAV or specific gravity ................................................................................................ 23

11.1.4 Zeroing balance ........................................................................................................................................... 23

11.2 TOTAL DRY EXTRACT ............................................................................................................................... 24

11.2.1 Print of the value of TOTAL DRY EXTRACT .............................................................................................. 26

11.3 EVALUATION OF MUSTS .......................................................................................................................... 27

11.3.1 Print of the value of the degrees Baumé, Babo, Brix and Oechsle of a must ............................................. 28

11.4 ALCOMAT 2 SETTINGS ............................................................................................................................. 28

11.4.1 Modification of the progressive label ........................................................................................................... 28

11.4.2 Set date ....................................................................................................................................................... 28

11.4.3 Set hour ....................................................................................................................................................... 29

11.4.4 Regulation of contrast of the ALCOMAT 2 display...................................................................................... 29

11.4.5 Language..................................................................................................................................................... 29

11.5 SERVICES (SUPPLEMENTARY CALIBRATION) ...................................................................................... 30

12. BEHAVIOR OF MODULE ALCOMAT 2 TO THE SWITCHING ON, CONNECTED TO THE DENSIMAT AS SOON AS INSTALLED, AND OPTIMAL CONDITIONS OF MEASUREMENT .................................... 31

12.1 CONDITIONS OF USE OF THE DENSIMAT-ALCOMAT 2 SYSTEM ......................................................... 32

13. DISPOSAL – INFORMATION FOR USERS ............................................................................................... 33

ENGLISH DENSIMAT & ALCOMAT-2

2

1. GENERAL SPECIFICATIONS OF DENSIMAT

- Power consumption: 10 VA - Power source: 220 V - 15% / + 10 % ; optional: 110 V - Operating temperature range: 15 - 30 °C HYDROSTATIC BALANCE SECTION - Relative density measuring range: 0.5 - 2.25 - Readability: 0.00005 - Repeatability : +/- 0.00005 - Auto-calibration with internal mass - Time of answer: 6 sec

THERMOMETER SECTION - Temperature measuring range: 8 - 32 °C - Sensitivity: 0.025 °C - Repeatability : +/- 0.05 °C (range 10 –30 °C) - Readability: 0.1 °C - Thermometric probe: Pt 100 1/3 DIN Standard accessory kit

- 2 floaters (plungers) calibrated for weight (50 g) and volume (20 ml) - 2 double wall 70 ml cylinders - 1 power supply Accessories available on request - cylinder for measurements in continuous - Pan for metrological control - Certificated masses - Certificated floaters FLOATERS INTERCHANGEABLE IN MASS AND VOLUME Particular care must be paid in the construction and calibration of floaters. They are all interchangeable in mass and in volume in order to facilitate utilization; for example to determine the specific gravity of a must or a given wine and the relative ASV, 2 separate floaters can be used without problem to avoid contamination (preliminary check of the compensation factor; see paragraphs 3.3 and/or 11.1.2). To obtain the above both the suspension1 wire and the surface of the glass have been subject of many studies in order to resolve the problems caused by surface tension, from the volume of wire and from electrostatic charges. The wire is made with an antimagnetic material, inoxidable and a diameter lower or equal of to 0,20 mm. The volume of floaters, on request, can be certified by the competent European Institutes such as the L.N.E. of Paris, the I.M.G.C. of Turin, the PTB in Germany etc.

1 Realized with an antimagnetic material, inoxidizable and a diameter lower or equal of 0,20 mm

DENSIMAT & ALCOMAT-2 ENGLISH

3

2. DESCRIPTION

The instrument consists of an electronic hydrostatic balance DENSIMAT, with a sensitivity of fifth decimal points, which can be connected to an ALCOMAT 2 module that receives and processes the data.

2.1 INSTALLATION OF DENSIMAT

Densimat was designed and made to resist and to function even under difficult conditions. However, it is advisable to install Densimat:

a. on a rigid support without vibrations b. in a stable room temperature and without excessive ventilation c. utilizing a separate electrical supply

NOTE: if the Densimat stops working because of an incorrect operation on the keyboard, the plug must be removed and connected again to the socket while pressing the “+” key. When the instrument is switched on again the following message appears

Pnor

which indicates the return to use of the parameters of standard functioning.

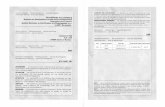

Figure 1

1 – Floater knob 7 – Knob to adjust the cylinder-balance 2 – Cylinder and floater 8 – Centring plate 3 – Rubber mat 9 – Knob for blocking balance (to transport) 4 – Keyboard 10 – Thermo probe 5 – Transformer 11 – Supports to level regulation 6 – Plug

ENGLISH DENSIMAT & ALCOMAT-2

4

2.2 PROCEDURE FOR DENSIMAT INSTALLATION

• Level the balance by adjusting the back supports in order to centre the air bubble in the middle of the circle.

• unlock the balance by rotating the knob in an anticlockwise direction and when it stops it comes to rest on the right side of the instrument (Figure 1 n. 9 and Figure 2).

UNLOCKED LOCKED ( Only to transport )

Figure 2

• Insert the connector of the thermo probe in the place indicated in figure 1 (10), keeping the locking pin in an upright position and pushing it till its complete insertion: the connector is in the correct position if, trying to pull it out, it does not come. To pull it out press the locking pin.

• Connect (figure 3) the circular socket of the transformer indicated in figure 3 with (6) to the connector of Densimat indicated with (3) keeping the flat side of pin upwards. Connect the transformer to the socket (fig. 3 n. 5) of the electric mains.

Figure 3 - Rear view of DENSIMAT

1- Connection Alcomat 2 2- Serial number 3- Transformer socket 4- Adjustable supports 5- Mains plug 6- Transformer plug

DENSIMAT & ALCOMAT-2 ENGLISH

5

2.3 DENSIMAT KEYBOARD

The Densimat keyboard (fig. 1 n. 4) has two displays and three keys. On the left display it appears the temperature read by thermo probe; on the right display it appears:

a. specific gravity, with the parameters of standard functioning; b. messages for user (see Appendix A: List of principal messages visualised by Densimat); c. this is selectable by means of three keys “Mode”, “+” and “-“. The activated functions through

these keys are described in Appendix B: Selecting options from the Densimat keyboard.

3. MEASUREMENTS WITH DENSIMAT

DENSIMAT allows to determine: directly:

• the specific gravity d20/20 of a liquid

• the density of a liquid at 20°C (by a simple calculation) indirectly, through the tables2:

• the degree Baumé, degree Babo, degree Brix and the degree Oechsle of a must;

• the ASV (Alcoholic Strength by Volume) of wines, musts and spirit drinks;

• the total dry extract of a must/wine. The measurements must be carried out at exactly 20°C N.B. Indications on the best conditions to carry out the measurements with Densimat are indicated in

paragraph 4. The behaviour of the instrument when switching it on and the conditions for optimal measurement.

2 See R. Bechetti, “Methods of analysis of wines and spirit drinks”, 1999 pub. Gibertini Elettronica

ENGLISH DENSIMAT & ALCOMAT-2

6

3.1 DETERMINATION OF SPECIFIC GRAVITY D20/20 OF A LIQUID

The determination of the specific gravity is carried out at 20°C exactly. It follows that the product to examined is brought in advance3 to a temperature near to 20°C. In this case a thermostatic bath (manufactured by Gibertini Elettronica) is useful. It is operated as follows: 1. degas if necessary the samples rich a CO2 by agitation or vacuum filtration or through filter paper; 2. fill the double coated cylinder with the liquid, whose density is to be measured, up to the level (about

70 ml); 3. immerse the thermal probe into the liquid; 4. immerse the clean and dry floaters carefully;

Figure 4

Thermostatic bath Gibertini Elettronica

5. slowly move the floater for a few seconds, with a circular movement, into the cylinder, in order to obtain a uniform temperature of the liquid (be carefully not to create air bubbles which might falsify the measurement);

6. once 20°C has been reached (left display) the reading is carried out: e.g. 0.98480 Figure 5 1– Knob to adjust the cylinder position 2 – Centring plate

3 For this scope a thermostatic bath (manufactured by Gibertini Elettronica), where the vessel containing the

liquid under examination is be put, is useful.

DENSIMAT & ALCOMAT-2 ENGLISH

7

a. push the cylinder against of centering plate (figure 1 n.8 or figure 5 n. 2); b. wait that the instrument has brought itself to zero (if this should not occur it carry out a zeroing

manual operation by pressing the key “ - “ of keyboard): on the right display appears

000

c. hang the floater in suspension (figure 6 n.1) and verify that it not touch the internal walls of the

cylinder or the thermoprobe. If necessary, correct the position of the centering plate loosening its fastening knobs and repositioning it carefully (fig.5 – n. 1).

d. read the specific gravity d20/20 of the liquid on the right display;

0.98480

N.B.- At the end of the determination, always replace the floater in use, clean and dry, on the appropriate hooks (figure 6 n.2). Figure 6 1 – Suspension 2 – Hooks to replace the floaters not in use

3.2 DETERMINATION OF THE DENSITY OF A LIQUID AT 20°C

To calculate the density of a liquid at 20 °C multiply its specific gravity d20/20 read by the Densimat by the density of the water at 20 °C, that is: d20/20 liq x 0,998203

3.3 COMPENSATION OF FLOATER IN USE

By means of the procedure of " Compensation of floater " it does not modify either mass or the volume of floater in use. "Compensate", instead, the behaviour of every floater in such way that all floaters show the same in the same standard conditions. Such conditions are the determination of the specific gravity d20/20 of the distilled water and/or a water-alcohol solution with a known titre, furnished on request by our company. "Compensation" occurs by modifying from the keyboard the answer of the Densimat in standard conditions controlling the correspondence between read value and theoretical value. Regular checks of this correspondence is advisable.

ENGLISH DENSIMAT & ALCOMAT-2

8

It is operated as follow:

• determine the specific gravity d20/20 of the distilled water or a water-alcohol solution with a known titre (procedure mentioned in the precedent paragraph);

• if the read value is 1,00000 (theoretical d20/20 H2O) or coincides with the d20/20 indicated on the bottle label of the water-alcohol solution then we are in conditions of ideal reading: the measurements can be carried out;

• if the read value is various(different) from 1.00000 or from the theoretical value d20/20 on the bottle label then it actives the procedure of " Compensation of floater" since in this situation the readings are not reliable.

Procedure of "Compensation of the floater"

� free the suspension, used with the floater;

� operate always at a temperature of 20 ± 0.1 °C; � press the key MODE until the message “CorrP” appears on the right display of DENSIMAT; � confirm with the key " + ", on the display reappears:

000

� hang floater in the suspension, read the value of specific gravity d20/20 of the distilled water or of the

water-alcohol solution with a known titre, on the display appears as for example:

0.99990. the point on the right of the display shows that the CorrP option is active; � the keys " + " and " - " increase and decrease respectively the value of density read to 5 units at a

time: press the keys until making to coincide the value read on the display with the theoretical value d20/20 of the distilled water or of the water-alcohol solution used like reference;

� the compensation remains memorized even when the instrument is switched off; � remove the suspension and exit from the procedure " Compensation of floater ": press the key

MODE: “CorrP "appears on the display; press the key " - ". N.B.- When the water-alcohol solution with a known titre is used, it is advisable, in order to stabilize the value, to wait a few seconds more before reading the specific gravity.

DENSIMAT & ALCOMAT-2 ENGLISH

9

4. BEHAVIOUR OF THE INSTRUMENT WHEN SWITCHING ON AND CONDITIONS FOR OPTIMAL MEASUREMENTS

At the moment when Densimat is switched on, the following message appears on the right display:

dx-xx

where x-xx are the numerical values that indicate the installed release on instrument, giving therefore an useful indication for technical service if it is necessary. After around two seconds the following message appears:

HELLO

and immediately after this all segments of both displays for the test are switched on and flashing for a few seconds. In this case the following message appears:

rECAL

successively flashing for a few seconds, to indicate that it is carrying out the first phase of a calibration. The appearance of the following messages on the display

LOAd e CALC

indicates the passage to the second phase of calibration. At the end of calibration and in the conditions of rest, the right display shows:

000

to indicate that the instrument is in zero condition, or

- 000 e + 000

to indicate that it is near zero. At the same time on the left display it appears firstly the message “HI”, and after this the value of temperature (in °C) recorded by thermo probe. The instrument automatically, after approximately 10 minutes of rest, starts the calibration procedure: on the display of right appears that as already described previously. During the calibration cannot be use the instrument. At the moment of switching on of the Densimat a period of ten minutes of thermal stabilization is needed4 during which the instrument carries out automatically a calibration each minute and, even if possible, it is not advisable to carry out measurements. After this period of thermal stabilization Densimat it is in the better conditions to work.

Other periods for thermal stabilization are not requested until the instrument remains connected to the mains/electricity, also in the case when module ALCOMAT 2 is switched off. It is advised therefore to maintain the Densimat always electrically connected.

ATTENTION:

• carry out always the measurements in the zero condition of the instrument;

• for eventual anomalies found during the installation of the instrument (as for example on display appear the flashing messages "- HI -" or "UnLd" or "Lo") consult the Appendix A: List of the principal messages showed by Densimat.

4 The necessary time for the thermal stabilization varies in function of the difference of temperatures between

Densimat and the ambience

ENGLISH DENSIMAT & ALCOMAT-2

10

5. APPENDIX A: LIST OF PRINCIPAL MESSAGES DISPLAYED BY DENSIMAT

The fixed messages warn the operator that some process is in progress. No intervention is needed. The flashing messages warn of an anomalous condition or they ask for an intervention of the operator.

RIGHT DISPLAY

INFORMATION MESSAGE ON THE STATE OF THE HYDROSTATIC BALANCE

Dx-xx Release or revision level of the internal program (Firmware). The letters " x " are replaced by the current values

- - - - Zero setting phase. It is activated by pressing the key " - ".

000 Zero of the balance

Er18

Weight not stable during the zero setting phase. Press the key " - " to cancel. The previous zero value is valid.

If it occurs at the switching on of the instrument, it is not possible to cancel it. Switch off for some second and switch on again; if it appears again, the instrument is broken or exists an excessive ventilation.

Er19 Weight not stable during a calibration phase. Press the key " - " to cancel. The previous calibration value is valid. The cause can be an excessive ventilation.

ErrC Calibration error. Press the key " - " to cancel. The previous calibration value is valid.

- HI -

Suspension overloaded. Remove the cause to cancel.

If the suspension is engaged during the 2 phases: rECAL and LOAd (see below) the display shows - HI -. Remove the floater. in the end shows ErrC.

- Lo - The instrument is locked or incorrectly installed. Remove the cause to cancel.

UnLd Indicates the phase during which the internal calibration mass is unloaded.

It can indicates an overload on the suspension; remove the cause to continue.

RECAL Zero setting phase during a calibration. Flashing message and subsequently fixed for a few seconds.

LOAd Indicates the phase during which the internal calibration mass is loaded.

CALC Indicates the phase during which the internal calibration mass is weighed and the calibration factor is being calculated. After this, appears " 2,49995 " follow from “000” or the ErrC message (see above).

Fuori SCALA

The internal diagnostic of the instrument detects an anomaly that could impair its accuracy. It is advisable to do a careful check. Press the key " - " to continue.

Pnor This is appeared when the instrument is switched on again holding(keeping) pressed the key " + " to indicate the return to use of the parameters of standard functioning, as previously explained.

DENSIMAT & ALCOMAT-2 ENGLISH

11

6. APPENDIX B: POSSIBLE OPTIONS FROM DENSIMAT KEYBOARD Pressing the key MODE it enters in following options:

OFF CorrP CorrC PAr CAL LuLd and that it shows in order pressing repeatedly the key MODE. To activate one of them press the key “+". To return to operative mode press the key " - ".

OPTION CHARACTERISTIC OF OPTION

OFF It switches off the display of the instrument leaving it connected to the mains/electricity in order to conserve its thermal condition. In this situation the instrument is not active: to bring back into use the operative condition press the key ”+” .

CorrP It allows the compensation of the floater by means of distilled water, or a water-alcohol solution with a known titre, at a temperature of 20 °C +/- 0.1 °C. See the paragraph 3.3 Compensation of floater in use.

CorrC

It allows the compensation of the temperature indication.

The thermometer division is calibrated in the factory to comply with a centesimal sample thermometer : although it is advisable to activate this procedure only in the case of proved necessity and however having a thermometer of an adequate precision. It is activated by pressing the key MODE till the message CorrC appears on the display and confirming with the key “+” .

It is possible to carry out only one compensation for each activation: pressing the key “+” or the key ” –“ , it increases or decreases of 0.025°C the temperature indication. To obtain a variation of 0.1 °C it may be necessary to repeat three or four times the operation pressing the key MODE (till the message CorrC appears on the display), then the key “+” therefore the key “+” or the key “-“

If the option is activated but it does not want to carry out any compensation or it is carried out the compensation and it want to exit from CorrC, press again the key MODE till the CorrC appears on the display and then the key “-“ .

PAr

It introduces a menu of the options of the functioning of the instrument. The values of parameters (P0 – P6) are memorized in the testing phase of the instrument. In the case of a particular necessity our technical service can be contact. To deactivate the option “PAr” press the key MODE till the message PAr appears on the display and then the key - .

CAL It allows the execution of a supplementary calibration. It activates pressing the key MODE till the message CAL appears on the display and confirming with key “+” .

LuLd It consists of a service function and it must be never be activated by the user. If it enters because of an error in this option, press the key MODE to deactivate it till the message LuLd appears on the display and then key “-“ .

NOTE: if the Densimat stops working because of an incorrect manoeuvre on the keyboards, remove the plug and connect it again in the socket keeping pressed the key “+”. As soon as the instrument is switched on again the following message appears:

Pnor

that indicates the return to use of the parameters of standard functioning.

ENGLISH DENSIMAT & ALCOMAT-2

12

7. APPENDIX C: USE OF THE CYLINDER FOR MEASUREMENTS IN CONTINUOUS

7.1 INSTALLATION

• Put in place the second centre-cylinder over the one already existent and fix it with the relative knobs.

• Fix the support of floater with the two screws (Figure 8). The function of support is to hold the floater when it is not used, allowing therefore the Densimat to carry out the automatic calibration.

1 – Floater support 2 – Cylinder for measurements in continuo 3 – Spring for cylinder fixing 4 – Overflow tube 5 – Tap 6 – Overflow 7 – “Y” pipe connector

Figure 7

• Fix the cylinder on the Densimat with the spring as shown in figure 7.

• Connect the tubes to the cylinder for measurements in continuo.

• Insert into the inside of the cylinder the appropriate "net to break bubbles", pushing it to the bottom. The "net to break bubbles", as the name suggests, has the function to avoid the formation of bubbles.

• Insert the tail pipe (Figure 7 n.6) in an appropriate container.

• Verify that the floater moves easily in the centre of the cylinder.

DENSIMAT & ALCOMAT-2 ENGLISH

13

Figure 8

7.2 OPERATING INSTRUCTION

• Put the floater in place, to the inside of the cylinder for measurements in continuous, on the "support for floater".

• Close the tap (Figure 7 n. 5)

• Fill up the cylinder pouring the liquid into the funnel. The excess liquid is eliminated through the “overflow” tube (Figure 7 n. 4)

• The liquids under examination must have the same temperature as the floater. Being careful not to create air bubbles adhering to the floater or to the wire of the floater which might falsify the measurement.

• Hang the floater in suspension and read the specific gravity on the display.

• At the end of the measurement replace the floater on the support for floater (Figure 7 n.1) and open the tap to empty the cylinder.

ENGLISH DENSIMAT & ALCOMAT-2

14

8. APPENDIX D: REFERENCE TO LEGAL METROLOGY

8.1 METROLOGICAL CHECKING OF DENSIMAT

The Densimat hydrostatic balance can be checked at anytime by using certified masses from the authorized agencies ( such as the I.M.G.C. of Turin, the BIPM to Paris, the PTB in Germany, Namas in UK, etc). Also the thermo probe is verifiable by using a calibrated and certified thermometer from recognized agencies. 8.1.1 Procedure of the metrological control of Densimat

• The check must be carried out at least 1 hour after the switching on of the instrument using certified masses in E2 class.

• Press the key MODE on Densimat until the display shows "PAr" and confirm with the key " + "; the display shows "P0=00".

• Press again MODE until the display shows "P4=00".

• By the key " + " increase the value from "P4=00" to "P4=06".

• Confirm pressing the key " - ": the display will indicate the value in grams 0.000.

• The key " - " can be used to reset the reading value.

• To carry out the check with the certified masses it is recommended to use the appropriate pan shown in figure 9.

Figure 9

• The weight of the pan (10 g) must be zeroset: in this case the available capacity is 50 g.

• Carry out the measurements at 10, 20, 30, 40 and 50 g (maximum tolerance ± 1 mg).

• To read again the density on display: � press MODE until the display shows "PAr" and confirm with key " + "; on the display appears

"P4=06" � press the key " + ": on the display appears " P4=00 ". � press the key " - "; on the display appears " 000 ".

IMPORTANT ! - When on the Densimat display the value in grams is visualized, the instrument does not carry out the automatic calibration that therefore must be carried out by the keyboard. For that purpose press the key MODE until the display shows " CAL " and confirm with the key "+".

DENSIMAT & ALCOMAT-2 ENGLISH

15

8.1.2 SIT Calibration

The Gibertini Electronica is SIT CENTER n. 94 (law 273/91) accredited for the characterization of electronic balances with capacity till 30 kg. The certifications issued have an official value: they are documents that, according to the law, can be used for all the procedures of certification, homologations and accreditation of products, services and systems of business quality. The Gibertini, therefore, can emit the calibration certificate which guarantees:

• the maintenance of the referral of apparatus used by the Centre with national samples of unity of the International System of Unities (S.I.);

• the metrological correctness of the measuring procedure adopted by the Centre.

8.2 LEGAL METROLOGICAL APPROVAL OF THE DENSIMAT

The use of the Densimat hydrostatic balance, to determine the Alcoholic Strength by Volume (alcoholic strength), is included. in the utilizations of the "weighing instruments " that involve the obligation of CE seal (art. 2 subsection 2 letter a) of the EEC 90/384 Directive acknowledged with the Legislative Decree 517/92). The mod. Densimat hydrostatic balances are sealed " CE ": the Metric Central Office of Rome has issued an approval certificate CE of the type n. the 96-011, in virtue of this the Gibertini company provides the affixing of the nameplate " CE " with the Lead Seal of the Metric Office ("seal") on the balance. The balance must be verified periodically by the Metric Office of the competent local Chamber of Commerce .

ENGLISH DENSIMAT & ALCOMAT-2

16

9. GENERAL CHARACTERISTICS OF ALCOMAT 2

• Absorbed power: 10 VA

• Mains voltage: 220 V -15% +10%; on request: 110 V

• Ambience temperature of use: 15 ÷ 30 °C

• Fuse: 160 mA T

• Alphanumeric display of liquid crystals

• Visualization of messages in different languages (I, D, F, E, GB)

• Printer output

• Menu functions shown on display ALCOHOLIC STRENGTH BY VOLUME

• Interval of reading: 0.13 ÷ 99,98 % vol

• Readability: 0,01 % vol

• Precision and repeatability of reading: ± 0,03 % vol (between 15 and 25 °C) TOTAL DRY EXTRACT

• Interval of values: 0,0 ÷ 505,8 g/l of saccharose

• Precision and repeatability of reading: ± 0,3 g/l MUSTS EVALUATION

• Interval of specific gravity d20/20 : 1,04 ÷ 1,16 Additional equipment

• 1 serial cable

• 1 Alcomat 2 mains cable

• Supplementary output RS232 Optional accessories

• Printer

DENSIMAT & ALCOMAT-2 ENGLISH

17

10. ALCOMAT 2 DESCRIPTION

The ALCOMAT 2 module receives and processes the data of the Densimat to which it is connected; in this case it is not necessary to work exactly at 20 °C to measure the ASV or the specific gravity d20/20 of a wine and/or must. Moreover ALCOMAT 2 allows the automatic determination of the total dry extract of a wine or the evaluation of a must.

10.1 PROCEDURE OF ALCOMAT 2 INSTALLATION

Connect the module ALCOMAT 2 with the Densimat inserting the plugs of the serial cable found in equipment respectively in the connector on ALCOMAT 2 indicated with 2 in figure 10 and in the connector on Densimat indicated with 1 in figure 3. Screw to the bottom the screws.

Figure 10 - Rear view of ALCOMAT 2

1 - Printer and RS232 connector 4 - Electric socket 2 - Densimat connector 3 – Serial number

Connect ALCOMAT2 to the mains introducing the cable of the transformer into the place indicated with 4 (figure 10); switch on the instrument with the switch (Fig. 10 n.6). The cable for the printer must be connected to the connector indicated with 1 in figure 10. Make sure that the screws are screwed to the bottom.

10.2 ALCOMAT 2 KEYBOARD

ALCOMAT 2 keyboard has 6 keys where its functions have a different meaning according to the menu which appears on the display. The active keys are those found on the lower part and on the right side of the display and each of them corresponds to an indication on the display. The key must be pressed till it emits an acoustic signal that indicates the acceptance of the command by the instrument. N.B.- After some minutes, in which ALCOMAT 2 must not be used, the display is switched off automatically. Pressing [ ON ] the display is switched on again. Figure 11 - Front view of ALCOMAT 2 1- Alphanumeric display of liquid

crystals 2- Waterproof Keyboard with 6 keys

function

1

2

4 3

ENGLISH DENSIMAT & ALCOMAT-2

18

11. MEASUREMENTS WITH DENSIMAT - ALCOMAT 2

When the Densimat-ALCOMAT 2 system is ready to carry out the measurements PRINCIPAL MENU appears on the display of ALCOMAT 2 (see figure n° 8). The PRINCIPAL MENU indicates the various functions that can be carried out with a module ALCOMAT 2 - Densimat. Pressing one of the keys places on the lower part or on the right side of the display, which corresponds to the same display [ 1 ] or [ 2 ] or [ 3 ] or [ 4 ] or [ 5 ], it switches on to the desired corresponding function. The single functions then are shown from the indications on the display.

Figure 12 - PRINCIPAL MENU

N.B.- For ease of writing, in the text that follows, we use the generic function key corresponding to a determined text present on the display with the corresponding text; as for example on the PRINCIPAL MENU the key corresponding to [ 1 ] is indicated with [ 1 ]. ALCOMAT 2 with Densimat allows:

� with the function [ 1 ]: ALC. STR. VOL.(Alcoholic Strength by Volume or ASV)

• to carry out the measurements of specific gravity d20/20 of distillate;

• to visualize in 6 seconds and in a completely automatic way the Alcoholic Strength by Volume of distillate, from 0,05 to 99,98 % vol, according to the official tables (the EEC Regulations 2676/90 and 2870/00 according to the “international alcoholometric Tables” published in the International Recommendation N° 22 of O.I.M.L. in 1972).

� with the function [ 2 ]: TOTAL DRY EXTRACT

• to determine the value of total dry extract of a wine or a must for specific gravity comprised between 0,99 and 1,16;

� with the function [ 3 ]: MUSTS EVALUATION

• to estimate the musts calculating the value of the degrees Baumè, Babo, Brix and Oechsle for d20/20 comprised between 1,04 and 1,16;

operating to a temperature also different from 20 °C, provided that it is in the interval between 15 and 25 °C.

DENSIMAT & ALCOMAT-2 ENGLISH

19

11.1 SPECIFIC GRAVITY AT 20 °C OF A DISTILLATE AND ASV (ALCOHOLIC STRENGTH BY VOLUME)

It is operated as follows:

• press the key [ 1 ] to select “Alcoholic Strength by Volume”. On the display of ALCOMAT 2 appears: It indicates that Densimat is in “zero condition”; it

appears at the end of the calibration and/or in conditions of rest. Preceded by a “+” or a “-” it indicates that the hydrostatic balance is near zero.

Temperature read from thermo probe of Densimat

Figure 13 – Zero condition of the hydrostatic

• fill up the double coated cylinder (see figure 4) with distillate or the water-alcohol solution, to carry out the measurements of specific gravity at 20 °C and the ASV, until reaching the mark (70 ml);

• place(put) the cylinder on the Densimat;

• immerse the thermo probe into the liquid;

• immerse carefully the floater clean and dry;

• agitate (for a few second) floater into the liquid (figure 5), slowly, with circular movement, in order to uniform the temperature (being careful not to create air bubbles adhering to the floater or the wire of floater which might falsify the measurement);

• carry out the reading: a. push the cylinder against the appropriate centre-cylinders (figure 1 n.8 or figure 5 n.2); b. attend that display of ALCOMAT 2 shows the “zero condition” or the “zero” of the hydrostatic

balance (figure 13); if this should not occur (+000 or -000) carry out a manual operation of zeroing: � press the key [ zero ] (figure 13); � on the display appears “zero” therefore it is returned to the precedent view

c. hang the floater in suspension (figure 6 n.1) and verify that it not touch the internal walls of the cylinder or the thermo probe. Correct the position of the centre-cylinders, if it is necessary, loosening the knobs that blocks it(7 figure 1n.7 or figure 5 n. 1) and put in place it again in an appropriate mode;

d. read the ASV value on display (figure 14): � The ASV and the specific gravity at 20 °C appear subsequently on the display to the read

specific gravity; the figures(numbers) change until when the data not reach the stability.

ENGLISH DENSIMAT & ALCOMAT-2

20

Temperature of distillate. Indication of temperature to the values lower than 15 °C or higher than 25 °C is visualized in a square with contrasting colour. Specific gravity of the distillate at 19.4 °C measured by Densimat

TAV del distillato a 20°C [%vol]

Specific gravity at 20 °C (d20/20) of distillate

Figure 14 – ASV and d20/20 of a distillate

� At the moment when the data reaches stability, the value of ASV is visualized with contrasting characters compared to the background and the instrument emits a short acoustic signal. The data remains fixed on display until the removal of floater from suspension.

� The read specific gravity is corrected at 20°C in accordance with the tables given by the official method contained in the EEC Regulation n. 2676/90 and n. 2870/00). The correction is reliable only for the water-alcohol mixtures and in a temperature interval of the liquid under examination comprising between 15 and 25 °C. Outside the mentioned interval the results may have variations.

• At the end of the determination, always replace the floater in use on the appropriate hook (figure 6

n.2). 11.1.1 Specific gravity of a liquid

If the value of specific gravity of the liquid under examination is not included in the field of values that corresponds to an Alcoholic Strength by Volume, only the specific gravity and temperature of the liquid appear on the display (figure 15): For d20/20 < 0.79000 e d20/20 > 0.99995 it is not possible to get a water-alcohol mixture: ASV does not appear Temperature of liquid Specific gravity of liquid at 19.4°C; operating at 20 °C the READ SPEC:GRAV. is the d20/20 of liquid

Figure 15 – Specific gravity of a liquid

DENSIMAT & ALCOMAT-2 ENGLISH

21

11.1.2 Correction of floater or compensation

By means of the procedure of “Correction of floater” it does not modify either the mass or the volume of floater that it is being used. It modifies, instead, the so-called “factor of correction” of the floater, in such way that all floaters give the same answer in the same standard conditions. Such conditions are the determination of the specific gravity of distilled water and the determination of the ASV or alcoholic strength of a water –alcohol solution at a known titre, supplied on request by our company. These two possibilities are selectable from keyboard pressing respectively [ H2O ] or [ ALCOHOL ]. On the display appears the current value of the compensation factor that can be increased or decreased to five units at a time pressing the key + and – and it remains memorized even when the instrument is switched off. It is advisable to check such factors with regularity. 11.1.2.1 Correction of floater with the water-alcohol solution

It is operated as follows:

• fill the cylinder with 70 ml of water-alcohol solution with a known titre in a temperature comprises between 15 and 25°C, immerse the thermo probe, the floater and agitate;

• from principal Menu, by pressing (1) (figure 12), select “Alcoholic Strength by Volume”, and with the corresponding key enter in option “Correction” (figure 13);

• wait the “zero” of the balance and hang the floater on the suspension;

• the values of the factor of current correction, specific gravity of the water-alcohol solution, the specific gravity of the same one at 20°C and the alcoholic strength appear on the display (figure 16);

• if the value of alcoholic strength read on display correspond(coincide) to that declared on the label of water-alcohol solution used as reference, then the instrument is in condition of ideal reading; in the opposite case it is necessary to change(vary) the factor of correction of floater. Press the keys + and – taking in consideration that key + increase the read alcoholic strength and the key – decrease it. Taking into consideration that between the variations of compensation factor and those of alcoholic strength there does not exist a precise correspondence, and that such variations come very slowly: therefore it is necessary to proceed waiting a few seconds before read the results and stopping at the value nearest this reference.

• At the end of the determination, always replace the floater in use on the appropriate hook (figure 6 n.2).

Must coincide the ASV measured with Densimat and the value on label of confection of the water-alcohol solution

Decrease ASV

Increase ASV

ASV or alcoholic strength calculated from the read specific gravity Specific gravity of water-alcoholic mixture read with Densima

Previous reading

Compensation of floater in water”

Consent manual zeroing, before the reading

Figure 16 – Correction of floater with water-alcohol solution

ENGLISH DENSIMAT & ALCOMAT-2

22

11.1.2.2 Correction of floater with distilled water

It is operated as follows:

• fill the cylinder with 70 ml of distilled water in a temperature comprises between 15 and 25°C, immerse the thermo probe, the floater and agitate;

• from principal Menu, by pressing (1) (figure 12), select “Alcoholic Strength by Volume”, then press CORREC to enter in option “Correction”, press(H2O) (figure 16);

• wait the “zero” of the balance and hang the floater on the suspension;

• the values of the factor of current correction, the specific gravity that the water should have at the temperature measured by thermo probe and the specific gravity of the water measured effectively by the instrument appear on the display (figure 17);

• if these two values are equal then the instrument is in condition of ideal reading; in the opposite case it is necessary to change(vary) the factor of correction of floater.

Press the keys [+] and [–] taking in consideration that key [+] increase the value of specific gravity

read and the key[–] decrease it.

• At the end of the determination, always replace the floater in use on the appropriate hook (figure 6 n.2).

Make the two specific gravities

coincide

[+]increases the specific gravity of 5 units

Specific gravity of water measured with Densimat at 19.5°C Specific gravity of water at 19.5 °C from table

tI returns to reading for ASV

“Compensation of floater in alcohol”

Consent manual zeroing, before the reading of specific gravity

[-] decreases the specific gravity of 5 units

Figure 17 – Correction of floater with distilled water

DENSIMAT & ALCOMAT-2 ENGLISH

23

11.1.3 Print of the value of TAV or specific gravity

To have a print of the value of ASV of distillate or specific gravity of the liquid under examination it is enough to press [ PRINT ]; at the moment of determination the option appears on the display . If printer is not connected, the following flashing message appears on the display:

PRINTING LABEL PLEASES WAIT

PRINTER ERROR PRESS ANY KEY TO CONTINUE

During the printing, the following flashing message appears on the ALCOMAT 2 display:

PRINTING LABEL PLEASES WAIT

PRINTING OK

The print is as follows in the two possible cases:

Date: 06-03-2001 Hour : 16:07 Pr. 012 Alcoholic .strength. [%VOL] : 13.24 Temp. of distillate : 23.7 °C Spec. gravity at 20 °C : 0.98270 Spec. gravity of distillate : 0.98170

Date: 06-03-2001 Hour : 15:20 Pr. 001 Temp. of liquid : 24.5 °C Spec. gravity of liquid : 1.10510

N.B. - On the printed label appears an identification number indicated with “Pr”, that is “progressive label”. When the instrument is switched on, the numbering starts from 1. Every time a label is printed, the numbering is automatically increased. It is possible to modify the numbering ; for more details see paragraph 11.4.1 Modification of the progressive label. 11.1.4 Zeroing balance

Although the instrument automatically maintains the zero, the operator may carry out a manual zeroing operation, if it is necessary:

• make sure that the suspension is free, that is that floater is hung on one of the hooks (figure 6 - n. 2)

• press the key [ zero ]; on the display appears ”zero” following then from the initial reading;

• if the suspension is engaged, on the display appears:

ZEROSET IMPOSSIBLE

ENGLISH DENSIMAT & ALCOMAT-2

24

11.2 TOTAL DRY EXTRACT

Total dry extract includes all the substances which, in specific physical conditions, do not volatize. The official European method is densimetric (EEC Regulation N. 2676/90 Annex 4: Total dry extract) The total dry extract is calculated indirectly according to the value of specific gravity of the dealcoholized wine/must, that is from which alcohol has been eliminated and brought to its initial volume with distilled water. The dry extract is expressed by the concentration in g/l of a saccharose solution that has the same specific gravity of the “dealcoholized must/wine”. The utilization of Alcomat 2 with a Densimat allows one to determine the value of the total dry extract of a wine or a must for specific gravity including values from 0.990 and 1.160, in a temperature range of 15 °C and 25 °C. Under 15 °C and over 25 °C the results are not completely reliable. Proceed as follows:

• by pressing [2] (figure 12), select TOTAL DRY EXTRACT from the page of Principal Menu. The instrument awaits the measurement of specific gravity of a given wine/must(valid sample with a specific gravity comprised between 0.99 e 1.16) with a flashing message:

Figure 18

• wait the “zero” of balance or press [ZERO] to a manual zeroing operation, hang then the floater on suspension;

• on the display appear: temperature, specific gravity read, specific gravity corrected at 20°C and the density at 20°C of the sample of must/wine under examination (figure 19).

Density of a given wine/must

Recall the sample of wine/must

Memorize the sample of wine/must

Pass directly to the calculation of DRY EXTRACT

Figure 19

DENSIMAT & ALCOMAT-2 ENGLISH

25

ALCOMAT 2 provides automatically to bring the specific gravity read to the corresponding value at 20°C. On reaching the stable value, the value of corrected specific gravity at 20°C (expressed to a fourth decimal point ) appears on the display with black characters on a white ground and with a short acoustic signal. The value of density is obtained by multiplying the value of corrected specific gravity at 20 °C with 0.998203 g/ml (density of water at 20 °C).

• At this point it is possible to memorize until 99 samples of wine/must.

� Press [MEMORIZ.] (figure 19),

� by means of keys [+], [-], [+10], [-10] assign to each an identification number,

� confirm the value with [SAVE] (only if the value of specific gravity at 20°C is stable this operation is consented) and pass in the measurement of an another sample of wine/must freeing the suspension.

� This function allows us to carry out first of all the measurements of samples of wine/must in order then recalling them, later on, at the moment of the measurement of the specific gravity of the corresponding distillates. Use another floater to avoid the contamination of the sample (having checked the correction factor; see paragraph 11.1.2).

To recall a sample:

� Press [ RECALL. ] or [ RECALLS ], � by means of keys [ + ], [ - ], [ +10 ], [ - 10 ] select the identification number of sample to recall, � confirm the choice pressing [ RECALL. ] and pass to the determination of the dry extract pressing

[ CALCULATION ].

• To pass to the determination of the dry extract directly, press [ CALCULATION ]. The instrument remains on hold to read the specific gravity of the distillate obtained from the wine/must under examination (the valid sample with specific gravity d20/20 between 0.79000 and 0.99995), with a flashing message (figure 20):

Specific gravity of wine/must as soon as read, otherwise “000” appears

Wait for the “zero” or make manual zeroing before the reading of distillate

Figure 20 wait the "000" of the balance, hang therefore floater on the suspension; on the display appear: temperature, read specific gravity and Alcoholic Strength by Volume of the distillate together with the value of total dry extract in g/l of saccharose (figure 21). ALCOMAT 2 automatically shows the ASV of the distillate, using the valid algorithm of correction for water-alcohol mixtures, and subsequently the same specific gravity d20/20. ALCOMAT 2 applies the formula of Tabarié to determine the specific gravity d20/20 of the dealcoholized wine/must, then it gives the corresponding tabular value5 of total dry extract.

5 For further information see R. Becchetti, “Method of analysis of wine and spirit drinks”, 1999 pub. Gibertini

elettronica

ENGLISH DENSIMAT & ALCOMAT-2

26

On reaching the stable value, the value of total dry extract appears on the display with black characters on a white ground and with a short acoustic signal.

Figure 21

• Once the value of total dry extract is calculated it is possible to print the relative label (see the following paragraph) and/or to cancel from the memory the sample of wine/ must as soon as examined by pressing [ CANCEL. ].

• To exit from the function of total dry extract press [ EXIT ] until the PRINCIPAL MENU appears on the display.

• At the end of the determination, always replace the floater in use on the appropriate hook (figure 6 n.2).

11.2.1 Print of the value of TOTAL DRY EXTRACT

To have the printed value of TOTAL DRY EXTRACT of the wine/must under examination it is enough to press [ PRINT ]; at the moment of determination the option is present on the display. During the printing the following flashing message appears on the display of ALCOMAT 2 :

PRINT OF LABEL WAIT

PRINT OK

the label is therefore composed:

Date: 09-03-2001 Hour : 10:24 Sample N. : 29 ------------------------------------------------------ Dry extract [ g/l ] : 129.2 Alcoholic str. [%VOL] : 3.95 Spec. gravity wine/must at 20°C: 1.044 ------------------------------------------------

The identification number of sample is chosen in the memorization phase (see the previous paragraph). “Sample N.” NON is increased by 1 unit every time that it is printed and is the last value selected in [MEMORIZ.].

If the printer is not connected, the following flashing message appears on display :

PRINTING LABEL PLEASES WAIT

PRINTER ERROR PRESS ANY KEY TO CONTINUE

If the printer is connected but the stable value of dry extract is not reached the following message appears on display:

UNSTABLE DATA: ZERO NOT ALLOWED

DENSIMAT & ALCOMAT-2 ENGLISH

27

11.3 EVALUATION OF MUSTS

The degrees Baumé, Babo, Brix and Oechsle are in relation to the specific gravity d20/20 of a must. The use of ALCOMAT 2 with Densimat allows the automatic determination of the density and the value of the degrees Baumé, Babo, Brix and Oechsle of a must, for specific gravity d20/20 comprised between 1.04 and 1,16, in a range of temperature comprised between 15 °C and 25 °C. Under 15 °C and over the 25 °C the results are not completely reliable. It operates as follows:

• In the case when the must is not limpid, filtration is necessary.

• Select MUSTS EVALUATION from the PRINCIPAL MENU pressing [ 3 ] (figure 12). Wait for the " zero " of the balance and then hang the floater in suspension. On the display appears: temperature, read specific gravity, corrected specific gravity at 20 °C (with four figures) and density at 20 °C of the sample of must under examination (valid sample for d20/20 comprised between 1.04 and 1.16, figure 22).

• After a few seconds, on reaching the stable value of the specific gravity, the numerical values corresponding to the degrees Baumé, Babo, Brix and Oechsle of must appear on the display, preceded by a short acoustic signal.

Figure 22

ALCOMAT 2 determines the specific gravity d20/20 of a must under examination. The density of a must is obtained by multiplying the value of the corrected specific gravity at 20 °C by 0,998203 g/ml (density of the water at 20 °C). In correspondence to the corrected specific gravity at 20°C ALCOMAT 26 � for the values of specific gravity present in the tables it gives the corresponding degrees Babo,

Brix, etc. ; � for the values of specific gravity not present in the tables an interpolation is offered .

• It is possible to number until 99 samples of must: � press [ NUMBER ], � by means of keys [ + ], [ - ], [ +10 ], [ - 10 ] it assigns to each an identification number and press

[ EXIT ]. � The given numerical value is indicated on the display and on the print. � It is increased automatically every time that is printed. It is therefore possible to identify the

sample under examination through the function [ NUMBER ] or by means of the automatic increase of 1 unit of the sample numbering.

• At the end of the determination, always replace the floater in use on the appropriate hook (figure 6 n.2).

• Press [ EXIT ] to return to PRINCIPAL MENU.

6 For further information see R. Becchetti, “Method of analysis of wine and spirit drinks”, 1999 pub. Gibertini

elettronica

ENGLISH DENSIMAT & ALCOMAT-2

28

11.3.1 Print of the value of the degrees Baumé, Babo, Brix and Oechsle of a must

For having a relative print to the evaluation of a must enough to press [ PRINT ]; at the moment of determination the option appears on the display. During the print the following flashing message appears on the ALCOMAT 2 display:

PRINT OF LABEL WAIT

PRINT OK

The label is therefore composed:

Date: 10-03-2001 Hour : 10:38 Musts evaluation Must Sample N. : 16 Temperature of must : 24.6 °C Spec.grav. of must at20°C : 1.1060 Degr. Baumé : 13.93 Degr. Babo : 21.35 Degr. Brix : 24.9 Degr. Oechsle :106.0

Number automatically by increased 1 unit every time that it is printed or value given by [NUMBER].

If the printer is not connected , the flashing message appears on the display:

PRINTING LABEL PLEASES WAIT

PRINTER ERROR PRESS ANY KEY TO CONTINUE

If the printer is connected but the stable value of specific gravity is not reached the following message appears on display :

UNSTABLE DATA: OPERAT. IMPOSSIBLE

11.4 ALCOMAT 2 SETTINGS

To modify some settings the options menu indicates different possibilities as described below. 11.4.1 Modification of the progressive label

When the ASV of distillate or the specific gravity of a liquid is determined it is possible to identify the sample under examination through a number to bring back in the printing phase. This number is represented by the " Progressive label " that, as already said, increases by 1 unit every time that it is printed and the value of ASV or specific gravity is various from the previous. To modify the " Progressive label " select from the PRINCIPAL MENU " settings " by pressing [ 4 ] (figure 12), then select " Progressive label " pressing [ 2 ]. By means of keys [ + ] and [ - ] such progressive number is varied by 1 unit, while with [ +10 ], [ +100 ] the tens and the hundreds are selected. The maximum value possible of labels is equal to 999. The labels that are printed only with the value of specific gravity and temperature have a numbering which cannot be changed by the user. 11.4.2 Set date

To set the date select from the PRINCIPAL MENU "Settings " by pressing [ 4 ] (figure 12), then select "set date" by pressing [ 3 ]. Day, month and year are brought up to date by pressing respectively [DAY] or [MONTH] or [YEAR]. At this point the value is modified by pressing [ + ] or [ - ] taking into consideration that the two keys increase and decrease it respectively by one unit.

DENSIMAT & ALCOMAT-2 ENGLISH

29

11.4.3 Set hour

To set the hour select from the Principal MENU "Settings" by pressing [ 4 ] (figure 12), then select "Set hour" pressing again [ 4 ]. Hours, minutes or seconds are updated by pressing respectively [ HOURS ] or [MINUTES ] or [ SEC ]. At this point the value is modified by pressing [ + ] or [ - ] taking into consideration that the two keys increases and decreases it respectively by one unit. 11.4.4 Regulation of contrast of the ALCOMAT 2 display

To regulate the contrast of the ALCOMAT 2 display select from the PRINCIPAL MENU "Settings" by pressing [ 4 ] (figure 12), then select "Display contrast" pressing [ 5 ]. The key [ REVERSE ] (figure 23) allows to invert the contrast: the writing becomes white on a black background, while [ Normal ] brings it back to the initial contrast: black writing on white background. By pressing [ + ] the background of display becomes darker, while [ - ] renders it more light.

Figure 23

11.4.5 Language

To change the language with which all the messages that appear on the display are visualized, select " Settings" from the PRINCIPAL MENU by pressing [ 4 ] (figure 12), then select "Language" pressing [ 6 ]. It then selects the desired language (figure 24) from Italian, English, French, Spanish and German by pressing the corresponding key. Press [ 1 ] to exit.

Figure 24

All the messages appeared on the display will be visualized in this new language. The language selection will be maintained even when the instrument is switched off.

ENGLISH DENSIMAT & ALCOMAT-2

30

11.5 SERVICES (SUPPLEMENTARY CALIBRATION)

As already mentioned the instrument automatically, after about 10 minutes of rest, starts the calibration procedure. This self-calibration is not active, if the suspension is occupied by the floater. If the operator wants to, he can activate a supplementary calibration, on condition that the suspension is free from floater. Select "Services" from the PRINCIPAL MENU by pressing [ 5 ] (figure 12), then select "Calibration" pressing [ 2 ]. On the display of ALCOMAT 2 it appears:

CALIBRATION PROCEDURE ACTIVATED

PLS. WAIT

therefore the flashing message

SELF- CALIBRATION ACTIVATED

(PHASE 1) PLS. WAIT

followed by

INSTRUMENT IN SELF - CALIBRATION

(PHASE 2) PLS. WAIT

During the first and second phases of calibration the instrument cannot be used.

DENSIMAT & ALCOMAT-2 ENGLISH

31

12. BEHAVIOR OF MODULE ALCOMAT 2 TO THE SWITCHING ON, CONNECTED TO THE DENSIMAT AS SOON AS INSTALLED, AND OPTIMAL CONDITIONS OF MEASUREMENT

At the switching on of the module connected to the Densimat as soon as installed, the number of release of the software appears on the ALCOMAT 2 display(figure 25), preceded with an acoustic signal and from the name of the factory.

Figure 25

After about two seconds the PRINCIPAL MENU it appears

Pressing the keys function [ 4 ] or [ 5 ] it is possible to enter to "Settings" or "Services" (see paragraphs 11.4 and 11.5), by pressing instead the keys function [ 1 ] or [ 2 ] or [ 3 ] the following flashing message appears on the display:

Figure 26

At this situation any key pressed (figure 26) brought to the PRINCIPAL MENU, that is that ALCOMAT 2 connected to a balance in phase of thermal stabilization cannot be used to carry out the measurements, while the Densimat keyboard remains active.

ENGLISH DENSIMAT & ALCOMAT-2

32

If the keyboard is not touched, the flashing message remains on the display until the Densimat is in phase of thermal stabilization (about 10 minutes). At the end of this phase(thermal stabilization) the following flashing message appears on the ALCOMAT 2 display

SELF- CALIBRATION ACTIVATED

(PHASE 1) PLS. WAIT

followed by

SELF- CALIBRATION ACTIVATED

(PHASE 2) PLS. WAIT

while the Densimat shows

rECAL flashing successively for some seconds

followed by LOAd and CALC

At this point the display of ALCOMAT 2 is switched off, while the keyboard of Densimat continues to remain active. Pressing 3 times the first key on the left of the ALCOMAT 2 keyboard, the displays and the keys of the Densimat become deactivated and all the functions of the instrument can be carried out only by the keyboard of ALCOMAT 2. The PRINCIPAL MENU appears on the display of ALCOMAT 2. Now the DENSIMAT-ALCOMAT 2 system is ready to carry out the measurements.

12.1 CONDITIONS OF USE OF THE DENSIMAT-ALCOMAT 2 SYSTEM

When the Densimat establishes the connection with ALCOMAT 2, the Densimat keyboard MUST be deactivated. In the previous paragraph the procedure to carry out at the moment of the installation is explained. If, subsequent to the installation of ALCOMAT 2 module, both the keyboards become active (e.g. when the current to Densimat is switched off leaving ALCOMAT 2 connected and switched on) the ALCOMAT 2 switches off and switches on again through the general switch (figure 10 n. 6), then press once the first key on the left. In order to work only with the Densimat, to reactivate the displays and keyboard it is necessary to switch off and to switch on again the instrument keeping ALCOMAT 2 switched off. N.B. - If the Densimat at the switching on shows the flashing message "Fuori SCALA", press the key "-" on the Densimat to continue. ALCOMAT 2, connected with it, shows the flashing message "Balance in phase of thermal stabilization. Wait". At the end of thermal stabilization ALCOMAT 2 with Densimat it is operating. In case that the message for thermal stabilization persists for beyond 15 minutes press again the key " - " and have the DensiAlcomat 2 checked by a technician.

DENSIMAT & ALCOMAT-2 ENGLISH

33

13. DISPOSAL – INFORMATION FOR USERS

According to the 2002/95/CE, 2002/96/CE and 2003/108/CE Directives, concerning the reduction in the use of hazardous substances in electrical and electronic apparatus, as well as the disposal of waste materials.

The symbol of a crossed box applied on the apparatus or on the packaging indicates that the product must be collected separately from other waste materials at the end of its useful life. The separate waste collection of the apparatus which has reached the end of its useful life is organised and managed by the producer. The user who desires to get rid of present apparatus must therefore contact the seller and follow the given instructions. Suitable separate waste collection for future sending of the disused apparatus for recycling, treatment and environmentally friendly disposal, contributes towards preventing any possible negative effects on the environment and on health and encourages the reuse and recycling of the materials the apparatus is made of. Unauthorised disposal of the product by the user will lead to payment of the administrative sanctions in force in the country were it is put on the market.