Denim Position Paper - Lectra · can shrink fabric after assembly, ... denim, and lingerie...

Transcript of Denim Position Paper - Lectra · can shrink fabric after assembly, ... denim, and lingerie...

lectra.comWhere fashion and technology meet

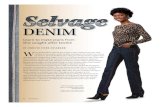

Skinny jeans, boyfriend jeans, yoga jeans, designer jeans…

Denim has come a long way from its humble beginnings as the five-

pocket uniform of the working class. Jeans are now a wardrobe staple—but the growing

popularity of “athleisure” clothing has been eating away at this category’s market share. Sportswear

as daywear has become fashionable and lifestyles more active, creating a generation of consumers

that demand comfort and performance in their clothing as much as they do style. In response,

denim brands are racing to tempt fickle consumers with high-performance,

body-shaping fabrics, new cuts and trendy washes.

Denim

lectra.comWhere fashion and technology meet

Overview

Specific Challenges

Position Paper

In today’s global marketplace, denim brands need to keep a

bigger range of body shapes and sizes in mind when they design their

collections. Stretchy new fabrics can behave in unpredictable ways and finishing treatments

can shrink fabric after assembly, making the product development process tricky. To complicate matters, brands are also racing to keep up with the pace of fast

fashion, designing and delivering new, on-trend styles to market quickly, while dealing with added

expenses linked to rising cotton prices and labor costs, as well as increasing public

pressure to use environmentally responsible production methods.

Lectra in Denim

A Question of Style and Fit

TechnologySolutions for Denim

www.lectrafashionblog.com@LectraFashion

LectraFashionNetworkwww.facebook.com/LectraOfficial

+4%GROWTH IN WOMEN’S JEANS WORLDWIDE IN 2014DOWN FROM 6% GROWTH IN 2013.

With 40 years of fashion industry expertise, Lectra helps the world’s biggest denim brands overcome their design, development and manufacturing challenges. Lectra’s fashion-dedicated solutions help them master fit, style and comfort, speed up the development process, maximize profit margins and reduce time to market. With Lectra, denim manufacturers can ensure they maintain product quality while keeping their offer fresh and relevant

to consumers in the face of increasing competition from sportswear

brands.

Lectra in FashionWith 40 years’ experience in fashion and apparel, Lectra’s mission is to provide a complete spectrum of design, development, and production solutions to confront 21st-century challenges. From first creative spark to final product, our professional services address an end-to-end process. We support the day-to-day operations of our customers in over 100 countries for around-the-clock process optimization. From fast fashion to luxury to ready-to-wear, Lectra’s 23,000 customers in markets as diverse as casual, sports, outdoor, denim, and lingerie represent every development and sourcing model imaginable. Beyond suppliers and manufacturers, they are the brands you love and the stores where you shop.

If there was such a thing as the Holy Grail of denim, it would be the elusive “perfect fit”. One pair of jeans can have as many as 24 different measurements from waist to ankle; determining what those should be and how to translate them into other sizes, can be a mammoth task.

Meanwhile, the growing demand for denim in China and other international markets is posing new challenges as companies adapt their styles and sizing to accommodate a wider range of morphologies across different regions.

Being able to predict how denim will look and behave after being washed, chemically treated or mechanically distressed is key to making good design and development decisions, but doing this can be tricky, as denimwear is more affected by shrinkage than any other clothing category. Add stretchy new high-tech fabrics into the mix and multiple trials to decide which finishing treatments to use, and the product development process becomes time-consuming, labor-intensive and expensive.

An efficient supply chain has never been more crucial here: design elements and finishing treatments need to be decided upon and modified quickly, and production needs to be fast and precise, if that stylish, perfect-

fitting pair of jeans is going to make it onto store shelves in time to capitalize on

market trends.

Combined technologies such as 3D and product lifecycle management can speed up and improve the development process by connecting design and technical teams, so they can work together to create fashionable products that look good, fit well and stay on budget.

Development teams can use 3D technology to adjust measurements virtually until fit is just right, or adapt designs to suit different body shapes and sizes, reducing the lengthy prototyping process. Cutting down on the number of physical samples required means less fabric waste and fewer fittings, shipments and tests, for a faster, more cost-efficient development process with reduced environmental impact.

Technology in production takes things one step further by maximizing efficiency in the cutting room. Smart production planning solutions that communicate with each other help brands get the most out of fabric or decide on the best way to mobilize available resources. Heavy-duty cutters designed with denim in mind can handle thick stacks of heavyweight or stretchy material with speed and precision. Add to this a lean production process that minimizes errors and shortens time to market and the end result is a better-quality product,

bigger profit margins and a more streamlined, effective supply chain from

beginning to end.