Defects in Solids 0-D or point defects –vacancies, interstitials, etc. –control mass diffusion...

-

Upload

ophelia-weaver -

Category

Documents

-

view

212 -

download

0

Transcript of Defects in Solids 0-D or point defects –vacancies, interstitials, etc. –control mass diffusion...

Defects in Solids• 0-D or point defects

– vacancies, interstitials, etc.

– control mass diffusion

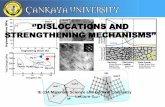

• 1-D or linear defects– dislocations

– control deformation processes

• 2-D or planar defects– grain boundaries, surfaces, interfaces,

– heterophase boundaries

• 3-D or volume defects– voids, secondary components (phases)

(mechanical properties – yield, metals)

(mechanical props – fracture, ceramics)

Volume Defects / Heterophase Boundaries

• Composites– Two or more distinct types of materials, “phases”– Boundary between them is a heterophase interface

A

B

• At grain boundaries– Second phase concentrated at triple

contacts of host grain boundaries– Typical when liquid phase forms at

high temperature

liquid / amorphous

grain 1grain 3

grain 2

Balance of forces

interphase boundary

SS

LS LS

SS = 2SLcos(/2)

• Pores– 2nd phase is a void– increases scattering– thermal insulation– white, not transparent

Volume Defects and Mechanics• A secondary (different) material: “phase”

– in metals: secondary phases tend to pin dislocations

• Pores– in ceramics: tend to be source of failure

= F/A

= L/L

ceramic

metal

Mechanical Behavior

y

frac

Y

Y

Y – from chemical bonds

y – due to dislocation glide

y (obs) << y (theo)

frac – due to volume defects

frac (obs) << frac (theo)

F

F

L

x

“graceful” failure

“catastrophic” failure

Evaluate frac(theoretical)

F = dE/dR

attr

activ

ere

puls

ive

F

RR0

ER (interatomic distance)

E0

R0

bond energy curve

bond force curve

= F/A

theofrac

approximate as sinusoidal

x

th

2πsinth

x

R0 ~ a0

0

xY

a

linear region: Y

2π~ th

x 0

xY

a

02πth

Y

a

fracture plane

F

F

???

/2

x = 0

simultaneous failure

0

RY

R

Evaluate frac(theoretical)

02πth

Y

a

1. ~ ao 2πth

Y

2. Obtain by equating mechanical energy (work) of creating two surfaces to their surface energy

a0

th

/2

x = 0

x

E Fdx /E area dx2

0

2π/ sinth

xwork area dx

πth

surface energy / area of fracture = 22 π

th

2 π

2πtho th

Y

a

12

tho

Y

a

Griffith’s equation If some plastic deformation occurs:

eff = surf + plastic

Evaluate frac(observed)1

2

0

~obs thfrac frac

Y

a

Stress concentration at crack tips

12

2tip app

c

1122

2 appo

c Y

a

Why??

2c only this region of the material supports the load

can show:radius of curvature

take fracture to occur when:th

tip frac

12

4appo

Y

a c

obsfrac ao

12

4obsfrac

Y

c

in general:½obs

frac c

measured fracture stress is not an “inherent” material property

= F/A

inte

rnal

forc

e lin

es

atomically sharp crack tip

Evaluate frac(observed)

Alternative derivation: again, consider energy balance

0( )E c E

+ surface energy

take fracture to occur when: c > c*obsfrac

122

πobsfrac

Y

c

as before:½obs

frac c

measured fracture stress is not an “inherent” material property

= initial energy

- released strain energy

22π0 4

E c

c Y

E(c)

c

energy per unit thickness

crack length

crack energy

c*

2 2π c

Y

4c

2c

Mechanical Properties• Elastic properties

– depend on chemical bonding, not so sensitive to slight variations in composition, processing

• Yield stress (metals)– depends on details of processing– fairly reproducible

• Fracture stress (ceramics)– an almost meaningless property– depends on details of crack/pore distribution– achieving reproducibility is a major effort

Fracture Behavior• In general:

@ failure:

custom:

not @ failure:

K, KC units: pressure (length)½

in practice, need to specify geometry of the experiment

shear vs. tension, etc. geometric constant

characterization: put in a crack of known length and defined geometry

½,geometrytip app appf c kc

½frac fractip app kc

½

theofracobs

frac kc

½ ½(π ) (π )

theofracobs C

frac

K

k c c

fracture toughness

stress intensity factor

critical stress intensity

indep. of geometry depends on crack length

depends on geometry

theofrac

k

To strengthen ceramics, pay attention to cracks

½)π( cK appl

½(π )obsC fracK c

molten potassium

salt

Strengthening of Ceramics• Process to eliminate cracks (internal)• Polish to eliminate surface cracks• Blunt crack tip• Anneal (heat treat) to eliminate randomly

distributed internal stresses• Quench (a silicate glass) to induce

compressive stress on surface• Ion exchange to induce surface compressive

stress

tension

compression

tension

compression

NaO*SiO2

K

Na

once crack penetrates compressive region, material shatters explosively

Strengthening of Ceramics• Transformation toughening

• Cool ZrO2: cubic tetragonal monoclinic

• Modify with CaO: cubic tetragonal monoclinic + cubic

• Rapid cooling: tetragonal monoclinic is slowobtain tetragonal + cubic

cubic

tetragonal

crack catalyzes tetragonal monoclinic transition

increase in volume upon transition

V places compressive stress on crack (closes it)

![arXiv:1810.04078v1 [cond-mat.soft] 9 Oct 2018century to describe incompatibility resulting from material defects, such as disclinations, dislocations, and point{defects [23{27]. Building](https://static.fdocuments.in/doc/165x107/5f4b42632ae71836c80a0e49/arxiv181004078v1-cond-matsoft-9-oct-2018-century-to-describe-incompatibility.jpg)

![Computer Search for Defects in a D = 3 Heisenberg Spin Glass · Some of my approach was inspired by work on dislocations in metallic glasses [8]. Looking for topological defects in](https://static.fdocuments.in/doc/165x107/5f2accc66bc30d732c46da2c/computer-search-for-defects-in-a-d-3-heisenberg-spin-some-of-my-approach-was-inspired.jpg)