Decrease By the Secondary · 2018-07-31 · NTH-TR 01 FLORIDA POWER & LIGHT COMPANY THERMAL...

Transcript of Decrease By the Secondary · 2018-07-31 · NTH-TR 01 FLORIDA POWER & LIGHT COMPANY THERMAL...

FPL

NTH-T8-01

Decrease in Heat Removal

By the Secondary System

Issued By:Fuel Resources

Date: July 1989

89i0060230 891002PDR AD(ICK 05000250P PDC

NTH-TR 01

FLORIDA POWER & LIGHT COMPANY

THERMAL HYDRAULIC MODEL QUALIFICATION

DECREASE IN HEAT REMOVAL BY THE SECONDARY SYSTEM EVENTS

JULY 1989

Jorge ArpaWilliam BryanRandolph DeckerJoel HandschuhOlga HanekSundershan MathavanStavroula MihalakeaJayaram PolavarapuJose Ramos

APPROVED BYC

J. A. HandschuhSupervisor of ThermalHydraulic.cs and Safety

APPROVED BY! o

D. C. PoteralskiManager of Nuclear Fuel

e

DISCLAIMER OF RESPONSXBXLITY

This document was prepared by the Fuel Resources Department ofFlorida Power & Light, Company. The material therein is believedto be true and accurate to the best of our knowledge andinformation. However, ~ it is authorized and intended for use andapplication only by Florida Power & Light Company.

FLORIDA POWER & LIGHT COMPANY~ ITS OFFXCERS ~ DXRECTORS, AGENTAND EMPLOYEES SHALL NOT BE RESPONSIBLE OR LIABLE FOR ANY CLAIMS,LOSSES, DAMAGES OR LIABILITIES, WHETHER OR NOT DUE TO OR CAUSEDBY THE NEGLIGENCE OF FLORXDA POWER & LIGHT COMPANY, RESULTINGFROM THE USE OR MISUSE OF THXS DOCUMENT OR ANY INFORMATIONCONTAXNED HEREIN

ACKNOWLEDGEMENTB

The authors would like to thank A. Mirza for has dedicatede orff ts in the development of the graphics used in the topical.The assistance of M. Varela in the typing and preparat'\ ation of thisreport is gratefully acknowledged.

The authors would also like to acknowledge the many3n ivld'viduals who have contributed to previous RETRAN applicationsat FPL. This report would not have been possible withefforts.

ty TABLE OF CONTENTS

PAGE

Acknowledgements

List of Tables

List of Figures

List of Acronyms

1.0 INTRODUCTION

1.1 Background1.2 FPL RETRAN Models

v3.

vi1i

1.2.1 Steam By-pass Contgol Systems1.2.2 Multi-node Steam Generator Models1.2.3 Modelling Approaches

1.2 ~ 3 ~ 11 ' '.21 ' ' '1 2 ' '1.2 ' '

Pressurizer ModellingNodalizationSafety Valve ModellingSteam Generator Tube PluggingControl Systems

2 ~ 0 T&UCEY POINT LOSS OF INVERTER EVENT 15

2.1 Summary of Events2.2 Analysis2.3 Results

2.3.1 RETRAN Analysis

2.3.1.1 Secondary System Response2.3.1.2 Primary System Response

151619

1921

2.4

2.3.2 RETRAN Comparison to Plant Data

Sensitivity Studies with RETRAN Models

22

25

2.5 Conclusions 27

3.0 ST. LUCIE UNIT 1 PARTIAL LOSS OF FEEDWATER 35

3 ~ 13.2

Summary of EventsAnalysis

3535

~ 1

0

TABLE OF CONTENTS (Cont9.nuect)

PAGE

3.3 Results

3.3.1 RETRAN Analysis

3.3.1.1 Secondary System Response3.3.1.2 Primary System Response

3.3.2 RETRAN Comparison to Plant Data

3.4 Conclusions

38

38

3841

41

43

4.0 SAFETY ANALYSIS METHODS

4.1 Introduction4.1.1 RETRAN Modelling

54

54

56

4.1 ~ 1.14.1.1.24 ~ 1 ~ 1.34.1.1.4

Safety ValvesPressurizer ModelTemperature Transport DelayMulti-node Steam Generator Model

56565757

4.2 Limiting Transient Determination

4.2.1 St. Lucie Unit 1

60

60

4.2.1.1 Loss of External Load4.2.1.2 Turbine Trip4.2.1.3 Loss of Condenser Vacuum

4.2.1.3.1 Limiting Event Development4.2.1.3.2 Results

606162

6265

4.2 1.44.2 ' 54.2 '.64.2 1.74.2. 1.8

.Main Steam Isolation Valve ClosureSteam Pressure Regulator Failure .

Loss of Non-emergency AC Powerto the Station AuxiliariesLoss of Normal FeedwaterFeedwater Line Break

737374

7576

0

TABLE OF CONTENTS (Continued)

4.2.2 St. Lucie Unit 2

PAGE

77

4.2.2.1 Loss of External Load4.2.2.2 Turbine Trip4.2.2.3 Loss of Condenser Vacuum

4.2.2.3.1 Limiting Event Development4.2.2.3.2 Results

777879

7982

4.2.2.44.2.2.54.2.2.6

4.2.2.74.2.2.8

Main Steam Isolation Valve ClosureSteam Pressure Regulator FailureLoss of Non-emergency AC Powerto the Station AuxiliariesLoss of Normal FeedwaterFeedwater Line Break

909091

9293

i4.2.2.8.1 Limiting Event Development4.2.2.8.2 Results

4.2.3 Turkey Point Units 3 and 4

4.2.3.1 Loss of External Load4.2.3.2 Turbine Trip4.2.3.3 Loss of Condenser Vacuum

9396

105

105106107

4.2.3.3.1 Limiting Event Development 1074.2.3.3.2 Results 110

4.2.3.44.2.3.54.2.3.6

Main Steam Isolation Valve ClosureSteam Pressure Regulator FailureLoss of Non-emergency AC Powerto the Station Auxiliaries

118118119

4.2.3.6.1 Limiting Event, Development4.2.3.6.2 Results

119122

4.2.3.7 Loss of Normal Feedwater4.2.3.8 Feedwater Line Break

129129

5.0 Conclusions 130

6.0 References 131

LIST OF TABLES

TABIE TITLE PAGE

1 '-12 ~ 2 1

FPL RETRAN Base Models Summary

Initial Conditions forLoss of Inverter Event

2 ~ 3 1 Sequence of Events, RETRAN AnalysisLoss of Inverter Event

20

2 ~ 3 ~ 2 1 Sequence of Events, RETRAN Comparisonto Plant Data

24

2.4-1 RETRAN Sensitivity Studies, Loss ofInverter Event

28

3 ~ 2 1 Initial Conditions for PartialLoss of Feedwater Event

37

3 ~ 3 ~ 1 1 Sequence of Events, RETRAN AnalysisPartial Loss of Feedwater Event,

39

3 ' '-1~ ~ Sequence of Events, RETRAN Comparisonto Plant Data

4 '-14.1-2

4.2.1.3-1

Standard Review Plan Events

FPL RETRAN Methodology

Key Parameters Assumed for the Loss ofCondenser Vacuum Event, St. Lucie Unit 1

55

58

64

4.2.1 ~ 3-2 Sequence of Events, Loss of CondenserVacuum for St. Lucie Unit 1

66

4 ' '.3-1 Key Parameter Assumed for the Loss ofCondenser Vacuum Event, St. Lucie Unit 2

81

4 '.2.3-2 Sequence of Events, Loss of CondenserVacuum for St. Lucie Unit 2

83

4 '.2.8-1

4 ~ 2. 2. 8-2

Key Parameters Assumed for the FeedwaterLine Break Event, St. Lucie Unit 2

Sequence of Events, Feedwater LineBreak for St. Lucie Unit 2

95

97

la'

LIST OF TABLES (Continued)

TABLE TITLE PAGE

4.2.3.3-1 Key Parameters Assumed for the Loss ofCondenser Vacuum Event, Turkey PointUnits 3 & 4

109

4.2.3.3-2

4.2.3.6-1

Sequence of Events, Loss of CondenserVacuum for Turkey Point Units 3 & 4

Key Parameters Assumed for the Loss ofNon-emergency AC Power, Turkey PointUnits 3 & 4

111

121

4.2. 3. 6-2 Sequence of Events, Loss of Non-emergencyAC Power, Turkey Point Units 3 & 4

123

gV

LIST OF FIGURES

F1GURE

1 ~ 2 1

1 ~ 2 2

1 % 2 3

1.2-4

1.2-5

TITLE

St. Lucie Unit 1 RETRAN Model

St. Lucie Unit 2 RETRAN Model

Turkey Point Units 3 & 4 RETRAN Model

St. Lucie Multi-node SG Model

Turkey Point Multi-node SG Model

PAGE

10

12

13

14

2 ~ 3 1 Steam Generator Pressure "B" and "C",Turkey Point Loss of Inverter Event

2%32

2%3 3

Steam Generator "A" Pressure,Turkey Point, Loss of Inverter Event

RCS Average Temperature,Turkey Point Loss of Inverter Event

30

2.3-4

E.E-E

2. 3-6

Reactor Power,Turkey Point Loss of Inverter Event

Pressurizer Pressure,Turkey Point Loss of Inverter Event

Pressurizer Level,Turkey Point Loss of Inverter Event

32

33

3 ~ 3 1 Steam Generator "B" LeveliSt. Lucie 1 Partial Loss of Feedwater

3 ~ 3 2 Steam Generator "B" PressureiSt. Lucie 1 Partial Loss of Feedwater

45

3 ~ 3 3 Steam Generator "A" Pressure,St. Lucie 1 Partial Loss of Feedwater

3. 3-4 Steam Generator "A" Level/St. Lucie 1 Partial Loss of Feedwater

47

3.3-5 Pressurizer Pressure,St. Lucie 1 Partial Loss of Feedwater

48

3.3-6 Pressurizer Level,St. Lucie 1 Partial Loss of Feedwater

E.E-7 Loop "A" Average Temperature/St. Lucie 1 Partial Loss of Feedwater

50

LIST OF FIGURES (Continued)

FIGURE TITLE PAGE

3.3-8 Loop "B" Average Temperature,St. Lucie 1 Partial Loss of Feedwater

51

3 '-9 Steam Generator "B" Pressure, MSSV FlowSensitivity, St. Lucie 1 Partial Loss ofFeedwater

52

3.3-10 Steam Generator "A" Pressure, MSSV FlowSensitivity, St. Lucie 1 Partial Loss. ofFeedwater

53

4-1

4.2.1.3-1

Primary and Secondary Safety ValveModels, RETRAN Licensing Methodology

Reactor Power, St. Lucie Unit 1Loss of Condenser Vacuum

59

67

4.2 '.3-2 Heat Flux, St. Lucie Unit 1Loss of Condenser Vacuum

68

4.2.1.3-3

4.2.1.3-4

RCS Pressure, St. Lucie Unit 1Loss of Condenser Vacuum

RCS Temperatures, St. Lucie Unit 1Loss of Condenser Vacuum

69

70

4.2.1.3-5 SG Pressure, St.'ucie Unit 1Loss of Condenser Vacuum

71

4.2. 1. 3-6 Pressurizer Level, St. Lucie Unit 1Loss of Condenser Vacuum

72

4.2.2 '-1 Reactor Power, St. Lucie Unit 2Loss of Condenser Vacuum

84

4.2.2.3-2 Heat Flux, St. Lucie Unit 2Loss of Condenser Vacuum

85

4.2.2.3-3 RCS Pressure, St. Lucie Unit 2Loss of Condenser Vacuum

86

4.2.2.3-4 RCS Temperatures, St. Lucie Unit 2Loss of Condenser Vacuum

87

4.2.2.3-5 SG Pressure, St. Lucie Unit 2Loss of Condenser Vacuum

88

~~ ~ ~4.2.2.3-6 Pressurizer Level, St. Lucie Unit 2

Loss of Condenser Vacuum89

4I IL

LXST OF FIGURES (Continued)

FIGURE TITLE PAGE

4.2.2.8-1

4.2.2.8-2

Pressurizer Pressure, St. LucieUnit 2 Feedwater Line Break

RCS Average Temperature, St. LucieUnit 2 Feedwater Line Break

98

99

4.2.2.8-3 Reactor Power, St. Lucie Unit 2Feedwater Line Break

100

4.2.2.8-4 Pressurizer Level, St. Lucie Unit 2Feedwater Line Break

101

4.2.2.8-5 Unaffected Loop Temperatures,St. Lucie Unit 2, Feedwater Line Break

102

4.2.2.8-6

4.2.2.8-7

Affected Loop Temperatures,St. Lucie Unit 2, Feedwater Line Break

Steam Generator Pressure, St. LucieUnit 2 Feedwater Line Break

103

104

4.2.3.3-1~ ~ ~ Reactor Power, Turkey Point Units 3 & 4Loss of Condenser Vacuum

112

4.2.3.3-2 Heat Flux, Turkey Point Units 3 & 4Loss of Condenser Vacuum

113

4 '.3.3-3 RCS Pressure, Turkey Point Units 3 & 4Loss of Condenser Vacuum

114

4.2.3.3-4 RCS Temperatures, Turkey PointUnits 3 & 4 Loss of Condenser Vacuum

115

4.2.3.3-5 SG Pressure, Turkey Point Units 3 & 4Loss of Condenser Vacuum

116

4 '.3.3-6 Pressurizer Level, Turkey PointUnits 3 & 4 Loss of Condenser Vacuum

117

4.2.3 '-1

4.2.3.6-2

4 ' ' '-3

Reactor Power, Turkey Point Units 3 & 4Loss of Non-emergency AC Power

Heat Flux, Turkey Point Units 3 & 4Loss of Non-emergency AC Power

Pressurizer Pressure, Turkey Point Units3 & 4 Loss of Non-emergency AC Power

124

125

126

LIST OF FIGURES (Continued)

F1GURE TITLE PAGE

4 '.3.6-4

4.2.3.6-5

Pressurizer Level, Turkey Point Units 3& 4 Loss of Non-emergency AC Power

RCS Temperatures, Turkey Point Units 3& 4 Loss of Non-emergency AC Power

127

128

LIST OF ACRONYMS

AFAS

CE

CEA

CEDM

DEH

DNBR

EPRI

FLB

FPL

FRV

IHTC

LOAC

Auxiliary Feedwater Automatic Signal

Auxiliary Feedwater

Combustion Engineering

Control Element Assembly

Control Element Drive Mechanism

Digital Electronic Hydraulic

Departure from Nucleate Boiling Ratio

Electric Power Research InstituteFeedwater Line Break

Florida Power & Light Company

Feedwater Regulating Valve

Final Safety Analysis Report

Gallons Per Minute

Interface Heat Transfer Coefficient

Loss of Non-Emergency Power to the StationAuxiliaries

MFRV

MSIV

Loss of Forced Coolant Flow

Main Feedwater Regulating Valve

Main Feedwater4

Main Steam Isolation Valve

NSSS

PORV

RCP

RCS

Megawatt

Nuclear Regulatory Commission

Nuclear Steam Supply System

Power Operated Relief Valve

Reactor Coolant Pump

Reactor Coolant System

X3.3.

I

LIST OF ACRONYHS (Continued)

RPS

SER

SDBS

SG

SI

SLB

TBS

TBV

TSV

Reactor Protective System

Safety Evaluation Report

Steam Dump and By-pass System

Steam Generator

Safety InjectionSteam Line Break

Turbine By-pass System

Turbine By-pass Valve

Turbine Stop Valve

Westinghouse

>3,

V

l4

1

1.0 Introduction

In 1986, Florida Power and Light Company (FPL) submitted atopical report to the NRC (Reference 1) which provided RETRANanalyses ranging over a broad spectrum of transients. FPL's goalwith this submittal was to meet the requirements of the NRC asdelineated in Generic Letter 83-11 (Reference 2) to demonstratestaff technical proficiency. This was a first step in the processof obtaining qualification of FPL to perform safety analyses usingthe RETRAN code to support licensing actions.

In 1988, the NRC safety evaluation (Reference 3) was obtainedon the RETRAN topical report. The conclusion of this evaluationwas that "...the topical report does demonstrate that FPL has thecapability to use RETRAN computer code to perform systems transientcalculations for the Turkey Point and St. Lucie plants and,therefore, fulfillsthe requirements of Generic Letter 83-11." TheNRC safety evaluation also stated, "However, additional comparisonsbetween the RETRAN computed results and plant operating datatogether with appropriate nodalization, sensitivity studies andlicensing assumptions will be necessary in future reports beforethese models are acceptable for licensing submittals." The purposeof this document is to provide the additional information requiredby the NRC in one specific class of transient events, Decrease inHeat Removal by the Secondary System and obtain NRC approval forthe use of RETRAN in licensing actions associated with transientswithin this category.

The sections that follow address the NRC requirement foradditional information. Basic information related to the RETRANmodels currently used at FPL will be discussed in Section 1.1.Models for St. Lucie Unit 1 and Unit 2 as well as that for TurkeyPoint Units 3 & 4 are provided.

Section 2.0 is a detailed description of a reactor transientat Turkey Point which produced a reduction in heat removal of thesecondary side because of a turbine runback. The mismatch betweenprimary power and secondary heat removal resulted in a reactorscram on high pressure. This section also provides sensitivitystudies which will provide justification for the RETRAN modellingused in transients within .the Decrease in Heat Removal by theSecondary System category. Prediction of this transientdemonstrates the accuracy of two key RETRAN models, i.e.,calculation of primary to secondary heat transfer and thepressurizer model, which are needed for the analysis of this classof event.

I

0

n

V

Section 3.0 presents a benchmark analysis for a partial lossof feedwater event that occurred at St. Lucie Unit 1. The RETRANmodel used in this analysis is consistent with the Turkey Pointmodel discussed in Section 2.0 with the exception of geometric andsystems differences representative of Westinghouse versusCombustion Engineering Nuclear Steam Supply Systems (NSSS). Thiscalculation demonstrates the use of the multi-node steam generatormodel and presents qualification of this model for futureapplications when accurate tracking of the steam generator levelis important.

Section 4.0 willpresent the assumptions that willbe utilizedin the future for licensing actions within the category of Decreasein Heat Removal by the Secondary System events. A discussion ofeach event within this category will be provided along with thedetermination of the limiting event within the category throughcomparison of the key physical phenomena that impact thetransients. The limiting transients are executed and presented inSection 4.0 using input parameters chosen to produce boundingresults for those transients in RETRAN. Section 4.0. also includesthe RETRAN modelling assumptions which will be used in the futurefor licensing actions. The modelling used is derived from theresults of sensitivities performed in Section 2.0 using the basicplant models which will be discussed in Section 1.2.

1.2 FPL RETRAN Models

All the analyses presented in this report have been performedwith RETRAN02 MOD004 (Reference 4). Approval of this code for usein licensing applications was obtained from the NRC in October 1988(Reference 5).

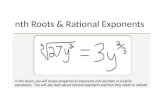

The noding diagrams for the St. Lucie Unit 1, Unit 2 and theTurkey Point Units 3 & 4 RETRAN base models are shown in Figures1.2-1, 1.2-2 and 1.2-3, respectively. A general description ofthese models is provided in Reference 1. A more detaileddescription of the Steam Bypass Control Systems and the Multi-nodeSteam Generator Models available for use in the respective basedecks is provided in Sections 1.2.1 and 1.2.2. These two componentmodels are described here because of their important roles in theprediction of several of the transients presented in this report.A summary matrix of the models used in the respective plant basedecks is shown on Table 1.2-1. A discussion on the modellingapproaches followed in the development of the plant base models ispresented in Subsection 1.2.3.

I

~)

li

1.2.1 Steam B ass Control S stems~ ~

The discharge flows of the respective Steam Dump BypassSystems (SDBS) for the St. Lucie Units and the Turbine By-passSystem (TBS) for the Turkey Point Units are represented with filltables o'f flow versus demand. Except for the cases where thedemand is a function of pressure, allowance for pressuredependence of the discharge flow is ignored. The demand iscomputed by the respective Steam Bypass Control Systems (SBCS).

ST. LUCIE STEAM DUMP BYPASS SYSTEM

The SDBS and their associated SBCS at both St. Lucie Unitsare identical. The total steam bypass flow capacity of theSDBS is 454 of the nominal steam flow that corresponds to2560 Mwth (original plant rating). The system consists ofthree sequentially operated valve groups with one 5%, one104 and three 104 capacity valves respectively. The systemutilizes two modes of operation, the modulation and theQuick Opening (QO) modes. During. load reductions and othertransients, all groups are modulated to maintain steamheader pressure at 910 psia. If a reactor trip occurs,valve groups 2 and 3 (40% total capacity) are switched frompressure to temperature modulation to reduce primary coolantaverage temperature to a value of 535.1 Degree F while valvegroup 1 continues to modulate based on the steam generatorheader pressure.

The pressure control mode of operation is accomplished bymeans of a proportional-plus-integral-plus-derivative (PID)controller operating on the difference between the steamheader pressure and a constant setpoint of 910 psia. Thismode of operation regulates the valves at a relatively lowspeed, which limits the maximum load changes that can beaccommodated by this type of control alone.

For large load reductions and for unit trips from high powerlevels, the energy accumulated in the system would typicallybe large enough that the secondary safety valves would berequired to relief secondary system pressure before thebypass valves would reach a fully open position under thepressure control mode of operation. To avoid this, the QO

control mode is actuated in these situations to open allvalves at a much faster rate. A QO signal is generated whena load reduction rate is greater than a given rate or if,after reactor trip, the primary coolant average temperatureexceeds a preset threshold.

I

l~

1

I4 '

— TlJRKEY POINT TURBINE BY-PASS SYSTEM

At the Turkey Point Units, the relief capacity of theTBS is 40% of nominal steam flow. The system consists oftwo valve groups with two valves each and a total dischargecapacity of 20% per group. The TBS at Turkey Point differsfrom that at St. Lucie in the manner in which the bypassflow is controlled. At Turkey Point, the only automaticcontrol variable is primary coolant average temperature.The magnitude of the flow is based on the difference betweenactual coolant average temperature and a referencetemperature. The reference temperature can be based eitheron a load reduction program or a temperature setpoint of 547F. The first, is used for transients not involving turbinetrip and the second for situations where turbine trip hasoccurred. A QO logic is also available to open the valvesat a faster rate than during temperature control. Itsopening logic varies depending on whether or not a turbinetrip has occurred.

1.2.2 Multi-node Steam Generator Models

Detailed steam generator models are available for caseswhere predictions of level, or inventory are important. The

~~ ~ ~

~

~

~

~

~

~

~

models for St. Lucie Units and Turkey Point are shown in Figures1.2-4 and 1.2-5 respectively. Both models use the Non-Equilibrium code option to better represent the phenomena in theupper downcomer (outside the separators) region. The separatorsare represented with the RETRAN bubble rise model. Modelparameters such as mixture levels and enthalpy of the liquidregion in the non-equilibrium volumes are adjusted to yielddesign liquid mass inventories and good predictions of planttransient level responses.

1.2.3 Modellin A roaches

1.2.3.1 Pressurizer Modellin

The primary system pressure response in a PWR is largelydetermined by the pressurizer insurge or outsurge flows, theprocesses that take place within the pressurizer and by theresponse of the pressure control systems. It is important thatall these effects be correctly modelled to ensure that the systempressure response is calculated adequately.

For heatup type transients, the pressurization or insurgephase of the transient is crucial because it affects pressurepeak magnitude and timing and hence the time of the reactorprotection system actuation.

I

I

The modelling approach for the pressurizer in the FPL RETRANmodels has the following features:

SINGLE NODE, NON-EQUILIBRIUMVOLUME

The non-equilibrium option is used to model the pressurizervolume in the FPL RETRAN models. This option allows thevapor and liquid regions in the pressurizer to havedifferent temperatures while at the same pressure. This isa needed feature to model the phenomena taking place in thepressurizer especially during insurges. When an insurgeoccurs, the liquid region in the pressurizer becomessubcooled with the addition of cooler fluid from the hot. legwhile the vapor region, compressed by the addition of newfluid into the pressurizer, becomes superheated.

Another important process taking place in the pressurizer isthermal stratification within the liquid region. Duringfluid insurges into the pressurizer thermal stratificationtends to delay the cooling of the vapor region and thereforeresults in higher pressurization rates. During outsurges,thermal stratification causes the upper layers of hotterliquid to stay hotter for a longer time thus causing thepressure to decrease less rapidly than in the cases whereperfect mixing is allowed. The effects of the perfectmixing assumption used in the one node pressurizer model canbe balanced with the use of a very low inter-region heattransfer coefficient (IHTC) value to better approximate theeffects of thermal stratification. This is the approachtaken in the FPL RETRAN base models.

INTER-REGION HEAT TRANSFER COEFFICIENT

The IHTC has been shown to have little effect on thepressure response unless high values in the order of 30,000to 50~000 Btu / hr-ft -F are used. A low value of 50 Btu /hr-ft -F is used in the FPL RETRAN models to compensate forthe instantaneous mixing assumption in the liquid region.

BUBBLE RISE AND RAINOUT VELOCITIES

These two velocities are important in de-pressurizationsituations where the saturation temperature in thepressurizer decreases. As the temperature decreases,liquid droplets start forming in the superheated vaporregion and vapor bubbles form in the subcooled liquidregion. The water droplets fall onto the interface at acertain velocity called rainout velocity. Vapor bubbles in

Cy

the liquid rise to the surface or interface between theliquid and the vapor at a certain velocity called the bubblerise velocity.The rainout velocity is specified by the user and is keptconstant by the code throughout the calculation. Typically,values between 1 and 5 ft/sec are recommended. Thisparameter has no impact during insurges into thepressurizer. The value of 5 ft/sec is used in the FPLRETRAN models.

The user has several options for the bubble rise model. Inaddition to the bubble velocity, the user can also select abubble gradient to represent the increase in bubbleconcentration with elevation . in the mixture region. Therange of gradients is between 0 and 1 where 0 corresponds tothe case with a homogeneous distribution of bubbles in themixture. Bubble velocity and gradient define how quicklyvapor in the liquid region moves into the vapor region. Forregions that require the existence of a steam dome (e.g.,pressurizer and steam generators) and well defined phaseseparation in the mixture region, values of 0.8 and 3.0ft/sec for the gradient and initial bubble velocity arerecommended (Reference 4) and have been incorporated intothe RETRAN models.

HEAT TRANSFER TO AND FROM PRESSURIZER WALL

During insurge transients, the colder metal in . thepressurizer wall tends to absorb some of the heat from thesuperheated vapor region thus reducing the pressurizationrate from the values that could be observed if wall heattransfer did not occur. Similarly during outsurges thepresence of heat transfer from the hotter wall tends todecrease the de-pressurization rate.

Heat transfer to or from the pressurizer wall is notmodelled in the FPL RETRAN models. In this case, it wasdetermined that the conservatism in not modelling theeffects of the pressurizer wall 'heat transfer (both forinsurge and outsurge events) would be the appropriate choicefor the base models.

— SPRAY OPTION

The RETRAN code offers two options to model the spray fluidinto the pressurizer, one de-superheats the vapor regionwhile the other does not. The second option tends to yieldhigher peak pressures on insurge transients and has beenselected for the FPL RETRAN models.

gH

H—»'~ ~

OVERALL NODALIZATXON

The nodalization approach for the three FFL RETRAN basemodels is shown in Figures 1.2-1, 1.2-2 and 1.2-3. The threemodels are very similar in nodalization with the onlydifferences being due to the geometric differences betweenCE and W NSSS. The nodalization for these models isdiscussed in some detail in Reference 1.

For analysis of transients within the Decrease in HeatRemoval by the Secondary System category, the nodalizationdetail in regions such as the vessel and hot and cold legsis not important. The level of detail found in the threeFPL RETRAN base models is more explicit than required forthe analysis of Decrease in Heat Removal by the SecondarySystem events presented in this report. Simplified basemodels with combined volumes in the reactor vessel and otherparts of the system could have been used with practicallythe same results. For consistency reasons, however, a singlenodalization approach that can be expanded to include amulti-node steam generator when needed has been preferredfor the three FPL RETRAN base models.

- STEAM GENERATOR NODALXZATXON

The most important consideration in the modelling of thesteam generators is whether or not a single node approach isadequate in the simulation of certain events. Based onindustry experience with this issue, . FPL has resolved toretain the single node approach for its base models. Thisapproach is valid for most applications of the models whereprediction of steam generator level response is not crucial.For situations where level is important (e.g., situationswhere reactor trip is on low level), the multi-node modelsfor'ach plant (Figures 1.2 4 and 1.2-5) will be attached totheir respective RETRAN base models.

1.2.3.3 Safet Valve Modellin

The safety valves in the existing RETRAN base decks are.modelled in two parts: a fill junction to model the dischargeflow and a valve to ensure initiation and termination of the fillflow at the selected setpoints. The discharge flow is entered asa table of pressure dependent values based on the Moody criticalflow correlation. Design flow is assumed at the opening setpointpressure and it is allowed to= increase if the system pressureincreases. Accumulation and hysteresis are not assumed. In theTurkey point model one-second ramps are used to model the openingand closing of the pressurizer safety valve at the respective

f

4

%1/

I

setpoints and half-second ramps are used for the secondarysafeties. In the St. Lucie base models the opening and closingof all safety valves is, assumed instantaneous at the respectivesetpoints.

1.2.3.4 Steam Generator Tube Plu inCurrent plant levels for steam generator tube plugging have

been approximately incorporated into the respective RETRAN basemodels. Values of 04 for Turkey Point and 54 for the St. LucieUnits, are used for the SG tube plugging in the base models.

1.2.3.5 Control S stems

Control systems are modeled in all the base models torepresent as closely as possible the operation of thecorresponding plant systems. Table 1.2-1 summarizes the controlsystems available in the respective FPL RETRAN models. The mostelaborate controller in the base decks is that of the Steam DumpBypass System developed for both the St. Lucie and the TurkeyPoint models. These systems have been described in detail inSection 1.2.1. A less complex system is the Feedwater ControlSystem which currently is only available for the Turkey PointRETRAN model. Such a system facilitates the analyses of planttransients and will be developed for the St. Lucie models in thefuture.

In addition to that of the the feedwater controller, twoadditional differences can be noted between the control systemsused in the different FPL RETRAN base models. One is in themodelling of the PORVs which at Turkey Point require the actionof a controller to simulate the operation of one of the twoavailable PORVs to generate an anticipatory opening signalearlier than at the pressure setpoint. The other difference isin the need for a controller for the Atmospheric Dump Valves atTurkey Point." Neither the PORV's or the ADV's operate in amanner which requires a control system at the St. Lucie Units.

TABLE 1 ~ 2-1

FPL RETRAN BASE MODELS SUMMARY

TURKEY POINT ST LUCIE 1 ST LUCIE 2

PRESSURIZER

-Non-Equilibrium Volume YES YES YES

-Metal Heat

-Spray Option

NO

YES

NO

YES

NO

YES

ENTHALPY TRANSPORT YES YES YES

TEMPERATURE TRANSPORT NO NO NO

STEAM GENERATOR

-Multi-node

-Tube Plugging

NO

NO

NO

YES

NO

YES

CONTROL SYSTEMS

-Pressurizer Heaters

-PORV Opening

YES

YES(1 out of 2)

YES

NO

YES

NO

-Feedwater Flow YES NO NO

-Steam Bypass YES YES YES

-Atmospheric Steam Dump YES NO NO

fl

Setety85 Votree Sd

CONTAINMENT(SINKVOLUME)

99To Torbtoe

Sotety88 Votreo by

Q)

Qss

Hoor)or

94Qs)

91yteyet SetetyVotoee Veloce

Steeo)ON)V)11 01st

Steer)ISypeso

I5'4)

Qs)

98 105 97

QH

Oo

bt 89MFVy

Heetere

Q»

3dQ»

oo

3 Qs

Q»

22Qe II 0

~ IO

po10

100 103

» o)o

p.

26

25

OI Charb)oy

101 tde

21 A1

Qo

1PP

19

22

O voLVMZS 105

Letdown

OI

A2(n)

1PP

I)SAT CONOUCTOR

WIIOttSFIGURE 1.2-1

St. Luoie 1 RETRAN Base Model

-lQss

Cvh CONTAINMENTISINKVOLUME)

99To Turbine

Qss

Sar cry88Valeea 8y

Qs<

91Aeoel SalaryValsee Valrree

SsennDump(1oss)

SSennDumpfXss)

Sse am

Bypaaa15'%)

Qsl 0$ 2

41 89

3s

s

.35sots

Qs

Loop8

~ess

Qn

ss n 2213

a" nsasa

sa sr

Qs

2PPa

10

I Ctwyty

100 103

nn sa Qn

—~Oas Charoln9

2$ 10'I S 0l

Al0»

1PP

19

O VCL~

HEAT CNNUCTOR~ JUSICTlOSSS

FIGURE 1.2-2St. Lucie 2 RETRAN Base Model

2e

1PP23

s lsrsl

~ ~ ~ ~ ~ ~ ~ ~

0

P

E

'r

91 92k

051

151 152

132

141

12

012 l

142112

FW 61

221 211 4 212 222

16

10 7 Q5 Q4 5(y 9 9 Q1

17

214 15 215

e Qe Q3 4(y 8 Q1 Q1 O116

18

T14

21B

'OOP B LOOP A

PIGURE 1.2-4St. Lucie Multi-node Steam Generator Model

-13-

0

Ill

42

241 141 131

112

12

12

14

110 15

10Gj) Cm)

25 31

16

10

TWO LOOP

(LOOP A&G)

SNGLE LOOP(LOOP B)

FIGURE 1.2-5Turkey Point Multi-node Steam Generator Model

-14-

1

g

2 ' Turke Point Unit 4 Loss of Inverter

2.1 Summa of Events

On June 20, 1985, Turkey Point Unit 4 experienced a reactortrip from 1004 power. The initiating event was the tripping ofthe 4C inverter which was supplying power to the 120 volt vitalinstrument panel 4P06. The loss of the inverter initiated aturbine runback due to the loss of power to a 'nucleari'nstrumentation system channel. Xn addition, Loss of 4P06 de-energized the pressurizer level and spray valve controller s(causing the spray valve to remain at its last demand position).De-energizing of the level controller caused a false indicationof low pressurizer level (less than 144) which in turn de-energized the pressurizer heaters {control and backup) andinitiated letdown isolation.

Loss of the 4C inverter also resulted in the loss ofautomatic operation of one of the two Power Operated ReliefValves {PORV), the other PORV was available but had its blockvalve closed due to leakage problems. These conditions resultedin the reactor coolant system pressure increasing until itreached the pressurizer high pressure reactor trip setpoint of2385 psia which initiated an automatic reactor trip. Zt shouldbe noted that the Technical Specification setpoint is 2385 psigfor the high pressure trip. Plant procedures provide a 15 psiauncertainty allowance for instrument. drift, therefore thesetpoint applicable for this event is 2385 psia.

Pressurizer pressure decreased after the trip and continuedto decrease because of the de-energized pressurizer spray valvecontrollers which maintained spray flow even as the pressuredecreased.

Loss of the 4P06 panel also caused the "A" Steam Generator(SG) feedwater level controller to transfer from automatic tomanual. Feedwater to SG "A" remained at the 100% power flowrate during the early stages of the transient. Loss of automaticlevel control along with continuous supply of 1004 feedwater flowresulted in the "A" SG level increasing until it reached the Hi-Hi level setpoint {804). Both SG feedwater pumps are tripped dueto reaching the high SG level setpoint about one minute after thereactor trip. This resulted in a feedwater isolation signal andan automatic start of the auxiliary feedwater pumps.

A varxe y o ot f countermeasures were taken by the operators tobout't' th ooldown caused by the feedwater trans'.ent. At a ou

seventeen minutes into the event, power to the 4P06 panel wasrestored and the lost instrumentation on Unit 4 was regained.

-15-

'E y,t~l

2

I

-fl

2.2 A~nal sisAnalysis of plant events can be performed in order to

validate the ability of the simulation model being used toaccurately represent actual plant performance. The plant eventdescribed above in Section 2.1 has been chosen as a benchmark dueto the many characteristics which are similar to the licensingtype transients found in the Decrease in Secondary Heat Removalby the Secondary System category of events.

Specifically, this plant event demonstrates a primary tosecondary heat generation/removal mismatch sufficient to resultin a primary pressurization to the reactor trip setpoint.Another similarity was that the PORVs were not, available tomitigate the primary pressurization, as in most. licensingtransients. Even though the over-filling of SG "A" and thepossibility of operator action are not consistent with alicensing transient, this plant event, within the first 60seconds, clearly offers a valid means to compare the predictivecapability of the component models within RETRAN to the actualplant response to a decrease in the secondary system heatremoval.

The plant event was analyzed with the initial conditionssummarized in Table 2.2-1. A discussion of the assumptions andinitial conditions used in the RETRAN analysis follows. Thebasis for this information is found in References 6-8.

1) Simulation Time

Only the first 60 seconds of the event are provided forcomparison of the plant data to the RETRAN simulation.After the initial 60 seconds, possible operator actionsto try to reduce the cooldown and de-pressurizationcaused by the excess feedwater flow and the continuedspray flow are not well documented.

2) Feedwater and Auxilia Feedwater Flows

Feedwater flow to the "A" SG switches to manual at theinitiation of the event and the MFRV to SG "A" remainsat the 100% power position throughout the first 100seconds. Feedwater flow to SG's "B" and "C" remainedin automatic for the duration of the event. Flow tothe "B" SG was the only feedwater flow recorded on theSystem Parameter Display System (SPDS) and thatinformation is provided at 10 second intervals.

-16-

V

For the RETRAN analysis, flow to the "C" SG is assumedto be the same as that to the "B» SG and is used as aboundary condition for the analysis. The flow'or the"A" SG is kept constant at the initial value. Afterreactor trip, feedwater temperature is reduced based onthe available measured data. These feedwater flowanalysis assumptions have some uncertainty since noinformation is available for SG "A" and "C" feedwaterflow and the potential exists for the operator to havetaken action to reduce feedwater flow in order tomitigate the primary cooldown that was occurring duringthe event.

One auxiliary feedwater pump was undergoing routinetesting at the time of the event. The total pump flowof 375 gpm. as indicated in the Test Procedure, isdivided into 125 gpm per SG and kept constant for theduration of the RETRAN simulation.

Pressurizer S ra and Heaters

All pressurizer heaters were on at the time of theevent initiation trying to compensate a faultypressurizer low level indication. The pressurizerspray valve was 10$ open to compensate for the heaters.At initiation of the simulation the heaters are lostwhile the spray valve is kept at the 10% open position.

Pressurizer PORVs

Of the two PORVs available at the plant, one wasisolated for leakage problems at the time of the event,while the other was lost with the inverter failure. Enthe RETRAN simulation the two PORVs have been assumedunavailable.

Turbine Runback

As a result of the loss of inverter, the 'turbineexperienced a runback to 70% power. This is modeled inRETRAN by decreasing the steam flow at the designrunback rate of 200% /minute.

-17-

TABLE 2.2-1

KJRKEY POINT UNXT 4

XNXTIAL CONDITXONS FOR LOSS OF XNVERTER W/ENT

PLANT CONDITIONS VALUE

POWER LEVEL (4 OF NOMINAL)

TIME IN CYCLE 11

PRESSURIZER PRESSURE (PSIA)

PRESSURIZER LEVEL (0 NR)

COLD LEG TEMPERATURE (DEG.F)

PRIMARY COOLANT AVERAGE TEMPERATURE (DEG.F)

CHARGING FLOW (GPM)

STEAM GENERATOR PRESSURE (PSIA)

STEAM GENERATOR LEVEL (4 NR)

FEEDWATER TEMPERATURE (DEG.F)

AUXILIARYFEEDWATER FLOW / SG (GPM)

100

MOC

2255

51.7

553

572

72

825

60.6

427

125

1

6) Plant Initial Conditions

Initial Pressurizer and SG pressures, cold . leg andaverage temperatures, pressurizer level and chargingflow for the .RETRAN model have been obtained fromReference 6 and are shown in Table 2.2-1.

7) Turbine B -Pass

With the loss of the inverter, automatic operation ofthe Turbine By-Pass system is not available until afterthe reactor trip occurs.

2.3 Results

The results of the RETRAN analysis are presented in alisting of the Sequence of Events shown in Table 2.3-1. Adetailed discussion of the RETRAN results is found in Section2.3.1. Section 2.3.2 provides a discussion of the maindifferences between the results predicted by RETRAN and the plantresponse. Section 2.4 describes the results of a variety ofparametric studies performed with RETRAN to better understand thecode capabilities and limitations in modelling these type ofevents.

2.3.1 ETRAN Anal sis

2.3.1.1 Seconda S stem Res onse

Following the loss of the 4C inverter, at the initiation ofthe event, the turbine admission valve closes to reduce steamflow from 1004 to 704 in 9 seconds (turbine runback). Turbinerunback is occurring since the loss of the inverter initiatesactions as if there was a control rod drop event. The turbinerunback is designed to reduce secondary heat removal in order tobetter match the reduced core power expected due to the insertionof a control rod. Since no control rod action actually happened,this produced a mismatch between the power generated by the coreand the power removed by the secondary system which results in aheatup of the secondary system with 'the subsequent heatup of theprimary. Figure 2.3-1. shows the ensuing secondary pressureresponse for Sois »B» and »C»

-19-

!

~ I

'TABLE 2-3-1

SEQUENCE OP EVENTS

RETRAN ANALYSIS LOSS OF INVERTER EVENT

EVENT TIME seconds SETPOINT OR VALUE

Loss of Inverter 0.0

Turbine Runback 0.1

High Pressurizer Trip 17 ' 2385 psia

Rods Begin to Drop 19.7

Peak Pressurizer Pressure 20. 6 2428 psia

Turbine By-pass Actuates 20.8

Turbine Stop Valves Closed 21.2

Rods Fully Inserted 22.1

Peak SG Pressure 28 ' 982 psia

-20-

0

I

4 '~

The secondary pressure response in RETRAN shows a smooth rateof increase until the reactor/turbine trip. After the turbine stopvalves are fully closed, 21.2 seconds after the initiation of theevent, the secondary pressurization increases more rapidly untilthe Turbine By-pass system reaches full flow at 24 seconds. TheTurbine By-pass system monitors the difference between primarytemperature and the reference No-Load temperature. As primarytemperature decreases after the reactor trip, the Turbine By-passvalves close (prior to the actual attainment of the No-Load Tavgdue to the anticipatory action of the control system), with bothg or ups fully closed at approximately 45 seconds into the transient.With the closure of the Turbine By-pass system, the raterate ofsecondary system pressure decrease is reduced as shown on Figure2.3-1 at 45 seconds.

The secondary pressure decrease seen from about 50 seconds to60 seconds reflects the analysis assumptions made relating to themain ee wa er af d t ddition to SG "A" and the reduction of feedwater

to SG "A"temperature over time. Maintaining 100% feedwater flow in oat a reduced temperature along with normal main feedwater flow toSG's "B" and "C" is more than sufficient to remove decay heat fromthe primary without pressurizing the secondary system. Thisexpected behavior of the secondary system pressure is shown onFigure 2.3-1- .

The secondary system pressure response for SG "A" is shown on2 3-2. No plant data is available for comparison with the

RETRAN prediction of the SG "A" behavior. During the ini 'Figure . - . o

of the transient, the SG response is very similar to that shown onFigure 2.3-1. This is as expected since no real deviation betweenthe three SG's was acknowledged at the plant and the RETRANanalysis assumes no differences until after the reactor trip whenlow to SG "A" is assumed to be maintained at 1004 flow. In fact,

SG pressure response for the three SG's is basically the same untilthe Turbine By-pass valves close. At that point, the addition ofmain feedwater to SG "A" produces a faster de-pressurization of theSG. At the 60 second end point for this comparison, there iscalculated to be a 12 psia reduction in pressure in SG "A" relativeto that shown in Figure 2.3-1.

2.3.1.2 Prima S stem Res onse

As the secondary temperature and pressure increases, theprimary coo an el t temperature also increases as shown in Figure 2.3-3. At approximately 23 seconds the primary hea upt d b th reactor trip on high pressurizer pressure of 2385sia and the action of the Turbine By-pass system. The RETRANRAN data

shown in Figure 2.3-3 includes a time delay corresponding to theeffect found in the Resistance Temperature Detectors (RTD's)

th 1 t. The reactor trip causes the turbine to tripe the enerand the Turbine By-pass system to open and relieve e gy

accumulated in the system. The Turbine Bypass valves operate basedon the difference between actual primary temperature and areference No-Load temperature.

-2l-

~ ~

1

F

,'El%

0,

As shown on Figure 2.3-3, the primary temperature decreasessmoothly until the Turbine By-pass system closes. It can be seenthat the rate of temperature decrease changes after the TurbineBy-pass system closes. Primary temperature continues todecrease, however, due to the combination of continued additionof 100% feed flow into SG "A" and continued addition of chargingwith letdown isolation.

The primary system power is shown in Figure 2.3-4. Theinitial response to the decrease in heat removal by the secondarysystem is a slight power decrease due to the action of thenegative moderator temperature coefficient. Power decreasesrapidly after the reactor scram as the rods begin to be insertedat 19.7 seconds after the initiation of the event.

i

The pressurizer pressure as calculated by RETRAN is shown inFigure 2.3-5. As shown, the primary system heatup caused by thedecrease in secondary system heat removal results in an insurgeinto the pressurizer. The pressurizer pressure increases andreaches a maximum of 2428 psia at 20.6 seconds into the event.Pressurizer pressure after that point decreases steadilythroughout the rest of the simulation as primary temperaturedecreases and as the pressurizer sprays continue to operate atapproximately 10% of full capacity.

The pressurizer level response calculated by RETRAN is shownin Figure 2.3-6. As the heatup progresses, the level increasesdue to the insurge into the pressurizer. A maximum level isreached at 20.8 seconds into the simulation. Similar to thepressurizer pressure, level thereafter decreases throughout thesimulation. A change in slope of the decrease in pressurizerlevel occurs at 26.6 seconds. This change in slope in the leveldecrease corresponds to a reduction in the rate of de-pressurization calculated by RETRAN as shown in Figure 2.3-5.

2.3.2 RETRAN Com arison to Plant Data

The data calculated by RETRAN for the Loss of Inverter eventhas been described in Section 2.3. The sequence of events ascalculated by RETRAN and measured at the plant is compared inTable 2.3-2. As previously mentioned, the plant data was onlyavailable at 10 second intervals in most cases. Therefore datapresented as maximum only represents the maximum data pointrecorded.

In general, the RETRAN calculations show responses similarto the measured plant data. Specific comparisons show that theRETRAN model reacts slightly slower to the event than the actualplant. This can be observed most clearly by examining theresponse of SG "B" and "C".

)f„', Oi

As shown in Figure 2.3-1, the SG model in our base RETRANcalculation shows a slower pressurization during the period ofturbine runback (0 - 21 se'conds). Aftex turbine trip however,the SG pressurization in RETRAN is faster and results in a higherpeak SG pressure. The model then starts to de-pressurize due tothe action of the =Turbine By-pass system and the action of thefeedwater, both the reduction in feedwater tempexature as well asthe continuation of full feedwater flow to SG "A".

The plant data demonstrates a de-pressurization afterturbine by-pass system operation, however, the plant data after40 seconds fox SG "B" shows a stabilization of pressure not seenin RETRAN. The effect of a reduced feedwater temperature in theRETRAN calculation appears to be the cause of the difference.Instantaneous mixing of the fluid within the single node SGresults in an overprediction of the impact the colder feedwaterhas in reducing secondary temperature and pressure.

Comparisons between the other key parameters and the RETRANresults show that RETRAN predicts the same general trends as theplant data. The RETRAN primary pressuxization is larger andtakes longer to be reduced than the plant data. This differencemay be due to the fact that the RETRAN model ignores pressurizerwall heat transfer.

!

Primary temperature differences between RETRAN and the plantdata show that the RCS temperature trends are very'imilar.RETRAN predicts a peak temperature somewhat later than the plantdata, however the cooldown rate after the peak matches wellbetween the plant and RETRAN with a relatively constantdifference after 38 seconds.

Pressurizer level comparisons show a slightly larger levelincrease at the plant during the turbine runback with the longterm level response showing almost exact agreement after about 38seconds.

One key conclusion that can be drawn from these comparisonsis that the single node SG 'model produces peak primary andsecondary pressures which are conservative relative to the plantdata. This is a key item when considering modelling applicationsfor the licensing events.

-23-

TABLE 2 3.2-1

SEQUENCE OF EVENTS

TUEUG"Y POINT UNIT 4 LOSS OF INVERTER EVENT

RETRAN COMPARISON TO PLANT DATA

EVENT Plant DatTIME (seconds)

gETRAN

Loss of Inverter 0.0 0.0

Turbine Runback 0.1 0.1

High Pressurizer Trip

Rods Begin to Drop 19 '

17.7

19.7

Peak Pressurizer Pressure 20 ' 20.6

Turbine By-pass Actuates 20.8

Turbine Stop Valves Closed 21.2

Rods Fully Inserted 21 8 22. 1

Peak SG Pressure 28.7 28.5

-24-

Jt„

~

~

I

l4+

E

2.4 SENSITIVITY STUDIES WITH RETRAN MODELS

The Loss of Inverter Event at Turkey Point has been selectedto assess the impact of various RETRAN modelling techniques andoptions on the prediction of heatup events. These effectsalthough investigated with the Turkey Point RETRAN model are alsoapplicable to the St. Lucie models in the analysis of heatupevents. Since, as described in Section 1.2, the three FPL RETRANbase models have a very similar nodalization approach and thephysical phenomena involved in heatup events is the same, it isreasonable to expect applicability of relative effects from onemodel to the others. This is confirmed by the similarity of theresults of the Loss of Condenser Vacuum analyses performed withthe three FPL RETRAN models (see Section 4.0).

The relative impact of the modelling techniques and codeoptions has been evaluated against the two following criteria:

— Fidelity of the RETRAN prediction to the plant data.

Conservatism of the RETRAN prediction with respect toplant data.

The results of these sensitivity studies support the choicesin modeling techniques made for the licensing methodology toanalyze Decreases in Heat Removal by the Secondary Systempresented in Section 4.0.

The various sensitivity studies performed with the Loss ofInverter analysis are described below. A summary of thesestudies is presented in Table 2.4-1.

Pressurizer Inter-Re ion Heat Transfer Coefficient

The Inter-Region Heat Transfer Coefficient (IHTC) waschanged from the value of 50. Btu/hr-ft -F used in the basemodel to a value of 20,000. Btu/hr-ft -F with no noticeableeffect in the predicted peak pressure or its timing.Therefore it can be concluded that changes in the IHTCwithin the above range of values do not impact the keyparameters of this event and that the value of 50. Btu/hr-ft -F used in the FPL RETRAN base models is adequate inpreventing the two regions in the pressurizer from reachingequal temperatures.

S ra 0 tionThe effects of having the spray option activated wereinvestigated and found to cause an increase in predictedpeak primary pressure as expected. The option, however, wasnot kept for the base case analysis of the Loss of Inverterevent on the basis of fidelity to plant data. The effects

-25-

I

I

'g ~

i

of the spray option are not applicable for analysis oflicensing events involving Decrease in Heat Removal by theSecondary System because no credit for the use of the spraysystem is taken in such methodology.

H draulic Resistance

Higher hydraulic resistances in the surge line or at thepressurizer inlet will tend to yield higher peak pressuresin insurge transients. This is because less cold fluid fromthe surge line can flow into the pressurizer. The impact ofthis effect has been investigated with the Loss of InverterEvent. The results show a very small sensitivity withhydraulic xesistances. The increase of the hydraulicresistance at the entrance of the pressurizer from a valueof 0 to a value of 10 resulted only in an increase of 0.9.psia in peak pressure. Based on this, it was determinedthat the FPL RETRAN models will use the nominal hydraulicresistances for both best estimate and licensingcalculations.'em

erature Trans ort Dela

The temperature transport delay model is intended tosimulate the displacement of a temperature front through achannel with little mixing such as in straight pipes. Theeffects of this option have been investigated with the Lossof Inverter Event by subdividing the hot and cold legs inthe RETM model into 10 sections to more accuratelyrepresent the temperature variation throughout the system.The effects on predicted peak pressure and time of the peakare negligible. Therefore this option will not be utilized.

Courant LimitThe version of the code (MOD004) used in this report has adefault value of 0.3 fox the Courant time step controlcoefficient in the iterative numerics solution. This value.can be changed by the user to try to improve running timesas long as the accuracy ox stability of the solution is notaffected. Sensitivity studies have been performed bychanging the base case value of 0.3 to 0.6 and 1.0. Table2.4-1 shows that the results are insensitive to reasonablechanges in the value of the Courant coefficient. Values ofthe coefficient above 1.0 are not considered realistic andcould result in unstable solutions or convergence errors.

-26-

2.5 Conclusions~~

The Loss of Inverter Event has been analyzed with RETRANusing the known plant inital conditions and equipmentactuations during the transient as boundary conditions. Theresults of the comparison shows the same trends for theparameters and general agreement in timing and magnitude.The key parameter for this type of event, primary systempressure, was calculated conservatively relative to theavailable data.

The sensitivity studies have reviewed the impact of varyinginputs and the conclusions derived will be used indevelopment of the licensing methodology discussed inSection 4.0

-27-

Oi

TABLE 2-4-1

RETRAN SENSITIVITY STUDIES

TURKEY POINT LOSS OF INVERTER EVENT

REACTORTRIPTIME

PEAKPRIMARYPRESSURE TIME

PEAKSECONDARYPRESSURE TIME

Base Case 17. 7 2428 20.6 981 28.5

IHTC Variation 17.720,000 BTU/hr-ft -F

2428 20.6 981 28 ~ 5

PressurizerSpray Option

16.3 2430 19-1 975 27.0

Surge LineHydraulic Resistance:

K~= 0.0

K)= 10.0

17 '

17 '

2428

2429

20.6

20.6

981

982

28.5

28.5

TemperatureTransport Delay

17 F 7 2428 20.6 982 28 '

CourantCoefficient (C4)

C~=O ~ 6

C( = 1.0

17 '

17 '

2428

2429

20 '20.6

981

981

28 '

28.5

-28-

Oi

FIGURE 2.3-1

1100

4

Turkey Point Loss of InverterRETRAN Benchmark Analysis

STEAM GENERATOR PRESSURE "B"AND "C" vs. TIME

1080

1060

1040

1020

1000

980

960

940

920

900

880

860

840

820

800

40

RETRAN Data

TlME (SECONDS)

Plant Data

FIGURE 2.3-2

1100

Turkey Point Loss of InverterRETRAN Benchinark AnalysisSTEAM GENERATOR "A"PRESSURE vs. TIME

1080

1060

1040

1020

980

960

940

920

900

880

860

840

820

40

71MB (SECONDS)

-30-

0

FIGURE 2.3-3

590

Turkey Point Loss of InverterRETRAN Benchmark Analysis

RCS TEMPERATURE vs. TIME

580

560

SS0

540

530

40

REIRAN Data

llME{SECONDS)

Hant Data

-31-

FIG&&2.3-4

1.2

Turkey Point Loss of InverterRETRAN Benchmark Analysis

REACTOR POWER vs. TIME

0.9

0.8

0.7

0.6

0.5

0.4

0.3

0.2

0.1

40

TIME (SECONDS)

-32-

~,

FIGURE 2.3-5

Turkey Point Loss of InverterRETRAN Benchmark Analysis

PRESSURIZER PRESSURE vs. TIME

R

fomI 2100

1900

1800

40

RETRAN Data

TIME (SECONDS)

Plant Data

-33-

0

FIGURE 2.3-6

Turkey Point Loss of InverterRETRAN Benchmark Analysis

PRESSURIZER LEVEL vs. TIME

50

40

30

10

40

RETRAN Data

TIME(SECONDS)

Plant Data

-34-

3.0 St. Lucie Unit 1 Partial Loss of Feedwater Flow~~ ~

3.1 Summa of Events

On September 20, 1988 a plant trip occurred at St. Lucie Unit1. The initiating event was a loss of power to the "B" Main FeedRegulating Valve (MFRV) controller. The loss of power caused the"B" MFRV to shut and a loss of feedwater to the "B" Steam Generatorto occur. The loss of feedwater resulted in a reactor trip due toreaching the low SG level setpoint, set at the plant atapproximately 39.25% of narrow range. Following the trip, anAuxiliary Feedwater Actuation Signal (AFAS) was generated.

In this transient, the primary pressure did not. reach thePower Operated Relief Valve (PORV) setpoint of 2400 psia. The MainSteam Saf ety Valves (MSSV) opened to relieve secondary systempressure in conjunction with the operation of the Steam Dump andBypass System (SDBS). After reset of the MSSV's, decay heat isremoved through action of the SDBS. No unusual actuations oroperator actions occurred.

3.2 '~nal sis~~

The RETRAN analysis of a plant transient can be performed tovalidate the ability of the model to accurately predict actualplant performance. The key RETRAN component model which is beingexamined with this transient is the multi-node model used fortracking the behavior of the water level in the steam generators.A noding diagram for the multi-node steam generator model is shownin Section 1.2. This transient was chosen since it demonstratesa loss of secondary system heat removal which results in a lowsteam generator trip rather that a high pressurizer pressure trip.The characteristics of the Loss of Normal Feedwater or Loss of ACtype events within the category of Decrease in Heat Removal by theSecondary System are similar to the event that occurred at St.Lucie Unit 1.

One of the difficulties in examining the comparison of RETRANto the plant results in this case is the lack of data from theplant instrumentation. Most of the parameters'f interest wereonly recorded every 10 seconds. The data available is plotted aspoints on the comparison graphs rather than as lines since linearinterpolation over such a large time interval is not representativeof the way the plant responded.

-35-

leap

T'i,

WI 0

This plant event was analysed using the initial conditions~ ~ ~

~

~

~

~ ~

~ ~~

~ ~ ~

~

~

summarized in Table 3.2-1. A discussion of the assumptions andinitial conditions follows. The basis for the plant data is foundin References 9 and 10.

Simulation Time

Only the first 100 seconds of the event are provided forcomparison of plant data to the RETRAN simulation. Thisevent is an uncomplicated reactor trip on low level anddata beyond 100 seconds provides no insights on theability of the calculational models to accurately predictplant response during the time period important tolicensing analysis.

2) Feedwater Assum tionsThe main feedwater flow to SG "B" is ramped to zero in10 seconds after initiation of the event. Main feedwaterto SG "A" is assumed to be in automatic mode of control.After the reactor trip signal, main feedwater to SG "A"was also lost with flow being reduced to zero in 10seconds. While data on feedwater flow to SG "A" wasavailable for each second of the event, data for SG "B"was not available and the assumption of a linear rampdownwas chosen.

3) Pressurizer Pressure Control S stem

The pressurizer pressure control system is assumed to bein automatic mode and is available when needed.

4) Plant Initial Conditions

Plant initial conditions are shown in Table 3.2-1. Theinitial conditions for the key parameters of interest inthis event, i.e., initial SG pressure and level, wereavailable from the plant data.

5) eactor Protection Dela Times

The time delays associated with the action of the ReactorProtection System (RPS) is taken from the plant sequenceof events recorder. The time delays recorded for openingreactor trip breakers and closing of the turbine stopvalves are significantly shorter than the valuestypically assumed. For purposes of evaluating thisevent, the time delays as recorded at the plant will beassumed in the RETRAN calculation.

-36-

TABLE 3.2-1

,ST. LUCIE UNIT 1

INITIALCONDITIONS FOR PARTIAL LOSS OF FEEDWATER EVENT

PLANT CONDITIONS VALUE

POWER LEVEL (4 OF NOMINAL)

TIME IN CYCLE 9

PRESSURIZER PRESSURE (PSIA)

SG "A" LEVEL (4'R)SG "B" LEVEL (4 NR)

SG PRESSURE (PSIA)

COLD LEG TEMPERATURE (DEG. F)

RCS AVERAGE TEMPERATURE (DEG. F)

FEEDWATER TEMPERATURE (DEG. F)

100

BOC

2250

65.9

69.9

888

549

574

434

-37-

0

3.3 Results

The results of the RETRAN analysis are provided in Section3.3.1. Section 3.3.1 discusses the RETRAN analysis resultsrelative to the analysis assumptions and RETRAN modelling used forthis event. Section 3.3.2 provides a discussion of the maindifferences between the results predicted by RETRAN and the plantdata.

3.3.1 RETRAN Anal sisA sequence of events as calculated by RETRAN is provided in

Table 3.3-1. As shown, the key actions during this transient arefound in the secondary system, which is discussed in Section3.3.1.1. The response of the secondary system is described overtwo time intervals due to the different actions occurring. beforeand after reactor/turbine trip.

3.3.1.1 Seconda S stem Res onse

1) Time Interval 0 to 21 seconds

Following the loss of power to MFRV "B", main feedwater to SG"B" is assumed to ramp down to zero flow in 10 seconds. Asthe feedwater flow is reduced, the SG level for SG "B", Figure3.3-1, shows a gradual reduction. When all feedwater isisolated, the level begins to reduce much more rapidly withthe low level signal occurring at 21.6 seconds after theinitiation of the event. The SG "B" pressure response isshown in Figure 3.3-2. The use of the multi-node SG modelprovides a much more sensitive response to small steam flowvariations which are occurring between the two SG's than theuse of a single node model. As shown in Figure 3.3-2, the SG

pressure. increases after feedwater flow has stopped. Thepressure increases until action of the SDBS at 20 secondsbegins to mitigate any further pressurization.

SG "A" behavior is shown in Figures 3.3-3 and Figures 3.3-4.For the first 21 seconds of the event, RETRAN calculates onlya small increase in SG level. This increase is due to aslightly increased MFW flow to SG "A" that occurs when the"B" MFRV closes as both MFW pumps continue to operate. Thedrop in pressure that begins at approximately 20 seconds isdue to the opening of the SDBS which has reacted to thepressurization of SG "B".

-38-

0„

TABLE 3.3.1-1

SEQUENCE OF EVENTS

RETRAN ANALYSIS PARTIAL LOSS OF FEEDWATER

ST. LUCIE UNIT 1

EVENT TIME seconds SETPOINT OR VALUE

Loss of Power to MFRV

MFRV SG "B" Fully Closed

SDBS Begins to Open

Low SG "B" Level TripReactor Trip Breakers Open

Turbine Stop Valves Closed

SDBS Full Capacity

Rampdown of Feedwater to SG "A"

CEA's Fully Inserted

SG "B" MSSV's Open

SG "A" MSSV's Open

SDBS Begins to Modulate Flow

MSSV's Close

0.0

10.0

20.0

21.63

21.67

22 '723.0

25.0

25.1

25.5

26.0

41. 0

44.0

39.25 4 NR

AFAS Signal

1000 psia

1000 psia

920 psia

-39-

~ 1

h

~ I

2) Time Interval 21 to 100 seconds

After the reactor trip and turbine trip, RETRAN calculates aswift increase in secondary pressure until the MSSV firstbank setpoint is reached at 25.5 seconds for SG "B". Theaction of the MSSV's and the SDBS reduce the pressure untilthe MSSV's close. Plant data showed that the pressure forfully closing the MSSV's was at 920 psia. After the closureof the MSSV's, RETRAN predicts a slight re-pressurizationwhich is turned around by the continued action of the SDBS.The changes in de-pressurization rates seen at 32.0 and 37.0seconds are related to the sensitivity of the multi-nodemodel. The changes in de-pressurization rates are tieddirectly to observed steam flow changes as both SG's competeto provide flow to the SDBS and the MSSV's. The increase in"B" SG level starting at approximately 27 secondscorresponds to the initiation of the secondary systempressure turnaround through action of the MSSV's and SDBS.This represents only a short term- effect since there is acontinuation of steam flow with no feedwater additionthroughout this time interval. The level decrease is slowedwhen the MSSV's close and the SDBS begins to modulate andshows only a small rate of decrease until the end of thesimulation.

The response of SG "A" is very similar in this time frame toSG "B" discussed above. The changes in SG "A" pressureafter the turbine trip are associated with the changes inthe steam flow. The SDBS acts as a constant demand in theRETRAN model which combined with the higher and earlierpressurization of SG "B" results in the behavior seen onFigure 3.3-3. In addition, the MSSV model used in theevaluation of this event is the simple flow versus pressuremodel discussed in . Section 1.1. This model calculatesoscillatory flows, that is, when pressure increases the flowwill increase which in turn reduces the pressure whichreduces the flow and so on. This results in the pressurespike behavior seen in the time interval of 23 to 30seconds.

The level response shown in Figure 3.3-4 shows a decrease inlevel which occurs when the feedwater flow is lost to SG "A"and the pressure increases due to the turbine trip. Thechange in slope in the level decrease which is seen atapproximately 32 seconds is related to the reduction inpressure and correspond to the changes in slope shown inFigure 3.3-3.

-40-

l

0

'\h '

3.3.1.2 Prima S stem Res onse

The primary system response as calculated by RETRAN followsthe effects seen in the secondary system. As the feedwater to SG"B" ramps to zero, RETRAN calculates a small insurge to thepressurizer and a consequent increase in primary system pressure.This behavior is shown in Figure 3.3-5. After the reactor trip,the steam relief from the SDBS and the MSSV's are sufficient toproduce a de-pressurization. The rate of de-pressurization isslowed when the MSSV's close at 44 seconds into the event.

The pressurizer level is shown in Figure 3.3-6. Thebehavior of the level is consistent with that calculated for thepressurizer pressure.

The responses calculated by RETRAN for Tavg for loops "A"and "B" are shown in Figures 3.3-7 and 3.3-7 respectively. Afterthe reactor trip, Tavg is calculated to decrease through theaction of the MSSV's and the SDBS. A RTD delay time of 3.0seconds is included in the values plotted for the RETRANsimulation.

3.3.2 RETRAN Com arison to Plant Data

'A sequence of events comparing the RETRAN simulationdescribed in Section 3.3.1 to the plant data is shown in Table3.3.2-1. As shown the calculated time for reactor trip isearlier than the time inferred from the plant data. The basictrends of the data show excellent agreement. In particular, asshown on Figures 3.3-1 and 3.3-4, the SG level response ascalculated by the multi-node SG model in RETRAN shows a closeagreement to the plant data.

8

One source of the differences between RETRAN and the plantcomparisons that was investigated was the short delay timesmeasured by the plant and used in the RETRAN simulation. Theresponse of the primary system indicates that the use of a longerdelay time between reactor trip signal and rod motion wouldimprove the timing of the primary system responses considerably.That is, the delay of the reactor scram would result in theprimary cooldown being delayed in the RETRAN simulation andtherefore the comparison would be better to the plant data. TheTechnical Specifications for low SG trip signal delay time is1.15 seconds. Plant sequence of events recorder show completionof the low level trip logic and reactor trip breaker opening totake only 0.04 seconds. Discussion with Plant Staff after thisbenchmark was completed indicates that some additional timeshould have been credited for sensor delay times, however, thisadditional time would add only about 0.1 seconds to the, reactortrip delay. This small additionally delay would not make asignificant difference in the RETRAN results and the comparisonto plant data.

-41-

a ~I

TABLE 3. 3 2-1

SEQUENCE OF EVENTS

ST. LUCIE UNIT 1 PARTIAL LOSS OF FEEDWATER

RETRAN COMPARISON TO PLANT DATA

VENTTIME (seconds)

Plant Data RETRAN

Loss of Power to MFRV

"B" MFRV .Fully Closed

SDBS Begins to Open

Low SG "B" Level TripReactor Trip Breakers Open

Turbine Stop Valves Closed

SDBS Full Capacity

Reduction Feedwater SG "A"

CEA's Fully Inserted

SG "B" MSSV's Open

SG "A" MSSV's Open

SDBS Begins to Modulate

MSSV's Close

0.0

25.4

25.44

25.94

28.7

29 '

29.0

53.0

0.0

10.0

20.0

21.63

21.67

22.17

23.0

25.0

25 '

25.5

26. 0 ~

41. 0

44.0

-42-

~

~ I

As shown, it is clear that RETRAN is calculating a faster de-pressurization than the plant data indicates. Steam flow was notavailable in enough detail to determine the root cause of thedifferences, however, one possibility is the MSSV model used inthe RETRAN simulation. The noding used in RETRAN places all theMSSV's in the same volume which is then represented by onecomposite valve for each of the two banks. Therefore, our RETRANmodel opens all of the four MSSV's/SG that compose the first bankwhen the pressure setpoint is reached. This modelling would notbe expected to simulate exactly the actual behavior at the plantsince the valves are sure to have differences in opening setpointsas well as being physically separated. Xn addition, it would notbe expected that. all the MSSV's would close at the same setpointas assumed in the RETRAN analysis.

Calculations, therefore, were made which varied the flowcapacity allowed through the MSSV's in RETRAN. The secondarysystem response was closest to the plant data when it, was assumedthat only 75% of the MSSV capacity operated, i.e., only three ofthe four valves operated per SG. The results of that calculationare shown for SG pressure response in Figures 3.3-9 and 3.3-10.These results demonstrate a closer match to the measured datathroughout the event for this parameter.

3.4 Conclusions

A partial Loss of Feedwater Flow event has been examined usingthe FPL RETRAN model. The results of the comparisons to plant datashows good agreement in trends and demonstrates the ability of theSG multi-node model to accurately predict level response.

-43-

~ I

0

FIGURE 3.3-1

St. Lucie 1 Partial Loss ofFeedwaterRETRAN Benchmark Analysis

STEAM GENERATOR "B"LEVEL vs. TIME

80

70

40

30

10

40 80

RETRAN Data

TIME(SECONDS)

Plant Data

-44

FIGUIM3.3-2

1040

1030

1020

1010

1000

990

980

970

960

950

940

St. Lucie 1 Partial Loss of FeedwaterRETRAN Benchmark AnalysisSTEAM GENERATOR "B"PRESSURE vs. TIME

920

910

900

890

880

870

860

850

840

80

TIME(SECONDS)

Plant Data

-45-

~ I

FIGURE 3.3-3

1040

1030

1020

1010

1000

St. Lucie 1 Partial Loss of FeedrvaterRETRAN Benchmark AnalysisSTEAM GENERATOR "A"PRESSURE vs. TIME

980

970

960

950

g 930

920

910

880

870

850

840

80 100

REIRAN Data

YlME(SECONDS)

Plant Data

-46-

0

5„

FIGURE 3.3-4

St. Lucie 1 Partial Loss of FeedpumpRETRAN Benchmark Analysis

STEAM GENERATOR "A"LEVEL vs. TIME

80

70

40

10

80 I00

RETRAN Data

TIME(SECONDS)

Plant Data

-47-

0

FIGURE 3.3-5

St. Lucie 1 Partial Loss ofFeedwaterRETRAN Benchmark Analysis

PRESSURIZER PRESSURE vs. TIME

N2100

CA

M

1900

1800

40 80 100

TIME (SECONDS)

RElRAN Data Plant Data

-48-

0

Oi

FIGURE 3.3-6

80

St. Lucie 1 Partial Loss ofFeedwaterRETRAN Benchmark Analysis

PRESSURIZER LEVEL vs. TIME

70

50

40

80 100

REIRAN Data

TlME (SECONDS)

Plant Data

-49-

FIGUfM3.3-7

590

St. Lucie 1 Partial Loss ofFeedwaterRETRAN Benchmark AnalysisLOOP A AVERAGETEMPERATUI&vs. TIME

580

570

560

550

540

530

80 100

TIME(SECONDS)

RIHRANData PIant Data

-50-

FIG&&3.3-8

590

St. Lucie I Partial Loss ofFeedwaterRETRAN Benchmark AnalysisLOOP 8 AVERAGETEMPERATURE vs. TIME

580

570

560

550

540

530

80 IOO

TIME(SECONDS)

RE1RAN Data Plant Data

-51-

FIGUIM3.3-9

1040

1030

1020

1010

1000

990

980

970

960

950

940

930

920

910

St. Lucie 1 Partial Loss ofFeedwaterMSSV Reduced Flow Sensitivity

STEAM GENERATOR "B"PRESSURE vs. TME

890

880

870

860

850

840

80 100

'IIME(SECONDS)

REIRAN Data Plant Data

-52-

k"

0

FIGURE 3.3-10

1040

1030

1020

1010

St. Lucie 1 Partial Loss ofFeedwaterMSSV Reduced Flow Sensitivity

STEAM GEMS TOR "A"PRESSURE vs. TIME

990

980

970

960

v) ~ 950

940

I 930

920

910

890

880

870

850

840

80 100

TIME(SECONDS)

REIRAN Data Plant Data

-53-

4.0 Safet Anal sis Methods

4.1 IntroductionThe events within the Decrease in Heat Removal from the

Secondary System category are discussed in Standard 'Review Plan(SRP) Section 15.2 (Reference 11). Events in this category arelisted in Table 4.1-1 with the numerical designation found in theSRP. The events in this category typically produce a reductionin secondary side heat removal which causes a heatup andpressurization of the primary side. The event and the associatedpressurization is eventually terminated by a reactor trip.=

The first task in developing the safety analysis methodologyto be used with this category of events is to discuss each eventand determine the limiting transients for each of FPL's plants.After the limiting transients have been identified, the key inputparameters that will be used in the licensing analysis of theevent will be discussed and justified. The analysis of the eventwill then be performed to provide the results of the limitingtransient. This process is repeated for all three units in orderto provide full and complete information in a format designed tofacilitate FSAR updates when the FPL methods are utilized in thefuture. This approach has generated sections which are verysimilar from unit to unit since the parameters which impact theresults of the events are in general the same, irrespective ofthe vendor;