December 2011

-

Upload

mid-kansas-cooperative-association-mkc -

Category

Documents

-

view

214 -

download

1

description

Transcript of December 2011

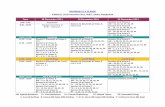

Board of Directors

David MillsSecretary

C J BlewChairman

Jason Gaeddert

Keith Becker Randy Ellwood

Myron VothVice Chairman

Cecil Wiebe

Matt Brack

Neal Beam

Associate

At Large

District 3

District 2

District 1

President & CEO . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Dave Christiansen

Vice President & CFO . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Danny Posch

Vice President & CMO . . . . . . . . . . . . . . . . . . . . . . . . . . . . .David Spears

Director of Energy Operations . . . . . . . . . . . . . . . . . . . . . . . .Jason Creed

Director of Southern Operations . . . . . . . . . . . . . . . . . . . . . . .Erik Lange

Director of Northern Operations . . . . . . . . . . . . . . . . . . . . .Steve Peterson

MKC Connections Managing Editor . . . . . . . . . . . . . . . . . . .Kerry Watson

Contents

Unique revenue programFirst-of-its-kind risk management program

mitigates risks for revenue and weather for

double crop soybeans . . . . . . . . . .Page 4

Community newsMKC donates to local emergency

management services; scholarship

information and other local

news . . . . . . . . . . . . . . . . . .Pages 8 & 9

Energy marketsDirector of Energy Operations, Jason

Creed, discusses factors driving

energy markets . . . . . . . . . . . . . .Page 5

MF Global BankruptcyTMA discusses affects of MF Global

bankruptcy . . . . . . . . . . . . . . . . .Page 10

Dixie Mattas (shown with her husband, Gary) is part of a growing trend of women in agriculture today.

Mid Kansas Coop AssociationP.O. Box D • Moundridge, KS 67107 • 620-345-6328

www.mkcoop.com

2

December, 2011

Duane Johnson

Living their dreamWomen make up approximately 26,800 of Kansas’ 70,000 farm operators and aneven smaller number are considered the principal operator of the farm. . . .Pages 6 & 7

3

Optimistic about our future By Dave Christiansen, President & CEO

I recently attendeda conferencewhere the speakerstated that pes-simism has itspleasures. He stat-

ed that while we’re right much of the time,we’re actually quite pleased even when weare wrong! I think he was joking but Ifound it interesting and I think we all knowpeople who revel in being “that person”.

I’m typically an optimist. While I generallytry to be a rational one, I am an optimist,none the less. I suppose it’s one of thosethings you grow up with or are conditionedto early in your life or career. Or maybeit’s simply innate. Whichever it is, it’s beenreinforced by observing firsthand what agroup of engaged individuals with a com-mon mission and purpose can accomplish.

At MKC we’re blessed to have a group thatworks together quite well and it all beginswith trust. We have each other’s backs andwe know it. And just so you know, wehave your back as well. We constantly strivefor a higher level of engagement and con-tinue to help all of our stakeholders, -whether they work at MKC or depend onthem daily - to understand just how criticaleach one of them is and how what they doon a daily basis is relevant to helping eachother be more successful.

The evidence of this collective effort is clearagain this year. Through the first eightmonths of our fiscal year we are on pacefor another year of record earnings. Whilethere are numerous events that can occur inthe next four months, I’m confident we willfinish the year very strong.

We all recognize that next year’s earningsmay not be another record simply due tothe shortfall of bushels across much ofKansas. We have had many discussions onour plans when dealing with a drought andthe likelihood of it being a one (or more)year event. In all of our discussions and inall the modeling we have done, the conver-sation still comes back to the fact that our

mission to renew our infrastructure with aslittle interruption as possible cannot waiver.We have contingency plans in place shouldthe drought turn out to be more than aone-year event.

Our projects continue to progress with themajority of them being on schedule. Theaddition of approximately one millionbushels of space and high speed receivingwas recently completed at Burns which wasa location that continued to be short onspace for fall harvest. Our crop productionand seed warehouse at Groveland includesstate-of-the-art crop nutrient loading and isvirtually complete. The new grain officeand scales worked well for fall harvestbased on the feedback we received. Bin liners are being installed in a number of our elevators. This is quite an expensiveundertaking but necessary in order to notonly maintain the elevators, but for some,to keep them usable. Additionally,FarmKan’s new warehouse was recentlycompleted and all of their operations havemoved to that location north of Halstead.

These improvements in our infrastructuredon’t account for the normal $3 millionworth of other items such as tip tanks forcrop nutrients, larger (1500 gallon) Nh3trailers, and assorted rolling stock.Additionally, something that at times fliesunder the radar for members is the$300,000 to $500,000 spent annually onregulatory, safety and environmental com-pliance. I can assure you we’re doing allwe can to minimize our environmentalimpact and to make sure our facilities areas safe as possible. Every new project isdesigned with both of these elements as pri-orities.

This past year saw another major undertak-ing with the recent implementation of anentire new software platform. Whileemployees and customers are both stillgoing through a learning curve, we will beinfinitely better when the dust all settles onthis particular project. The information ourcustomers and employees have immediateaccess to will make conducting business

and looking at history significantly easier.While the road can have a few bumps in it,we are certainly pleased with the manage-ment information we are receiving in orderto serve you better and faster. With thepace of change today, we need dashboardsthat provide quicker information.

Our grain project located between Cantonand Galva continues to move forward.

I hope by this time many of you haveenjoyed MKC’s efforts to travel down thesocial media path. Social media is not a fad that will go away if we drag our feetlong enough. It, or something like it, isgoing to be with us from here on. People want to connect with people.While we live in a world where face-to-facecommunication is becoming increasinglymore challenging for a whole host of rea-sons, we still feel that need to connect andbe part of something bigger than ourselves.

In the true cooperative spirit I will say, social media is right up our alley! Sincethe inception of the first cooperative, theneed to communicate our purpose to thosenot participating has always been a chal-lenge. Today, that challenge is bigger thanever before. If you’re not telling your story,someone else will.

Our effort today is to make sure we giveone more chance for your story to beheard. Feel free to participate in our effortand let us know how we can continue toimprove our effort by following us onTwitter, Facebook, LinkedIn and YouTube.

Communicatingthrough socialmedia By Dave Christiansen, President & CEO

Cont. on page 10

4

Traditionally producers in less than 10Kansas counties have had access to federal crop insurance for double cropsoybeans. No other program was available to the producer. Until thisyear. In keeping with their mission ofhelping farmers to be more successful,MKC management set out to find a riskmanagement tool that would mitigate therisks for revenue and weather for growing double crop soybeans.

Dave Spears, Vice President and ChiefMarketing Officer for MKC, has had anongoing relationship with Swiss Re forthe past ten years and had worked withthe company on other types of risk man-agement tools for production ag.

“We needed a company that had thefinancial strength to back stop the risk,”stated Spears. “Swiss Re has a historyof providing sound risk managementtools and is financially strong.”

In order for Swiss Re to be comfortablewith the amount of risk and commit tothe program, MKC needed to providethe appropriate data and analysis thatdemonstrated the need and justificationfor the program.

“Our field marketers and managers spenta great deal of time gathering productionhistory on double crop soybean yields,”stated Spears.

Spears commented that although condi-tions at wheat harvest were dry, SwissRe agreed to offer the program based onthe detailed analysis and prior produc-tion history that was submitted. “Ourdiligence paid off and Swiss Re agreedto provide a program that was a first ofits kind offered in the United States,”Spears stated.

While eleven counties were eligible toparticipate in the program, the droughtdid prevent some from being able to participate. Reno, Kingman andSumner counties were not eligible as thedrought had already set in and field con-ditions did not allow emergence of theplant. According to Spears, the othercounties were eligible as it was deemedthat crop conditions - even though deteri-orating - did warrant the planting givenclimate normal rainfall for the summer.

MKC received final approval from SwissRe to move forward with offering theprogram on June 17. With a final plant-ing date of June 30 to be eligible for the

program, MKC field marketers and man-agers had to work quickly to market theprogram. The result was close to 18,000acres enrolled in the program. New seedwas sold to approximately 10,000 ofthose acres.

The program offered producers twooptions. The first was $150 per acre thatwould cover all production costs includ-ing the option fees or the choice of $200per acre that essentially guaranteed aprofit per acre.

Unfortunately, the worst drought in sixyears persisted and we all know theresults. And even though MKC enteredinto the contract with the producer, allof the risk was passed on to Swiss Re.Producers who participated in the pro-gram will benefit greatly as Swiss Re willpay out approximately $3 million tothose who participated.

According to Spears, the drought hasn’tstopped Swiss Re from consideringanother program next year.

“Even with this year’s drought, Swiss Rewants to expand the program next year,” commented Spears. “Some aspects,however, may change or be adjusted.”

Producers benefit from unique revenue program By Kerry Watson

5

Fuel prices driven by various factors by Kerry Watson

The phrase, “remember when”, has com-monly been used all throughout history.As the speed of available informationincreases and the world continues tochange, it is probably safe to say that“remember when” used to mean 20, 30or 50 years ago. Today it can easily meana year or less.

Many of us remember when the price offuel changed a couple times a month (atmost). We also remember when achange of 10 cents over a month’s timewas a big deal. Back then we wouldhave been shocked to know that the mar-ket could fluctuate more than 10 cents ina single day.

So what is driving the change in price?According to Jason Creed, Director ofEnergy Operations for MKC, supply anddemand is still driving the change inprice just as it did years ago. Today, how-ever, it’s happening on a much largerscale.

“Prices used to be determined by whatthe supply and demand picture lookedlike locally,” stated Creed. “Today, it hasexpanded to include the global scene.”

While there are a number of thingsaffecting today’s energy markets, Creedbelieves supply source, market spreadsand diesel exports are making the biggestimpact.

SourceThe United States produces 5.5 millionbarrels of crude oil while it consumes14.7 million barrels per day resulting inthe need to import crude oil. Thisimbalance has caused the U.S. to relyheavily on foreign sources for crude oil.Most people would be surprised to learnthat OPEC is no longer the major sourceof oil for the U.S. but rather Canada,Mexico and Saudi Arabia are.

MarketsThe two most heavily traded crude oilmarkets are West Texas Intermediate(WTI) and Brent. While these two mar-kets typically trade close to the samevalue, the Libyan uprising and demandfrom China has caused Brent crude totrade at a substantial premium.

“Refineries on the east coast who importBrent crude are experiencing poor mar-gins or losses which has resulted in multi-

ple refinery closings,” stated Creed.“These closings are creating an imbal-ance in supply and demand and there-fore playing a role in prices.”

Product ExportsExporting refined products such as dieselis also playing a role in pricing. Thevalue of the dollar has allowed refinerson the gulf coast to export fuel to othercountries for a greater profit comparedto trading locally. According to Creed,exporting refined products has con-tributed to current inventory supplies ofdiesel to drop at a steady pace which inturn gives support to prices.

Will we ever see prices similar to thoseof 10 years ago? Probably not. Onething for certain, though, is the pace ofinformation and the complexity of theglobal economy will not slow down.

“We’ve entered a new age,” said Creed.“And some day in the near future we willprobably once again say, rememberwhen.”

6

Fall crops had been delivered to MidKansas Coop at Castleton when TinaCollins started cleaning machinery andbuilding fence in preparation for the cattleshe would be bringing home for winter onher Reno County farm.

At Dixie Mattas’ farm the routine isabout the same, down to the waxing ofthe combine. While Mattas farms withher husband Gary, just north ofLindsborg, in McPherson County, Collinsworks solo, having taken over her familyfarm four miles south of Pretty Prairie.

Collins and Mattas make up about 26,800female farmers out of Kansas’ nearly70,000 farm operators according to therecent Census of Agriculture. MeanwhileCollins is part of an even smaller groupof 7,943 women who are considered theprincipal operator of the farm.

Despite different farming operations, thetwo women share a passion for their workand an appreciation for MKC and howthe cooperative has enhanced their lives inseveral ways.

Both women were raised on farms, andhelping out was just always a part of theirchildhood.

“I loved it,” Mattas said of growing up onher parent’s farm near Bridgeport. Thegranddaughter of Swedish immigrantswho lived in a dugout near Bridgeport,she says her roots run deep in centralKansas.

Mattas was thrilled whenever she couldhelp out, running to the cooperative eleva-tor to pick up the feed or picking up theparts to repair the tractor in town.

She learned at an early age how integralthe cooperative was to the farming opera-tion. Her early memories were of herfather serving on the Lindsborg Co-opboard back when it was the Farmer’sUnion Elevator. That was the place whereher mother brought her eggs to sell andher dad butchered meat in the lockerplant.

Her father served as secretary of the Co-op board and she would hand-write the

minutes for him, because her family didn’town a typewriter.

Today she continues serving an integralpart of the farming operation with Gary.He considers her a huge asset with herrecord keeping skills and tenacity withbalancing the books. But, she also contin-ues working as she did growing up, help-ing where ever she is needed on the farm.However, Gary says her forte is managingthe operation.

He attributes the couple’s successful farm-ing operation to his wife’s excellent book-keeping skills.

“There’s a lot to know and she does allthe bookwork,” Gary Mattas said of theiroperation that includes 1,500 acres ofboth dryland and irrigated wheat, corn,beans, milo and alfalfa.

Every decision the couple makes is donejointly.

“The implement dealer knows he’s sellingthe equipment to both of us,” Mattassaid. “Gary looks at it from the perspec-tive of what the equipment will do; it’ssize and how fast. For me, it’s how muchwill it cost?”

Prior to retirement Dixie worked for 30years for General Motors AcceptanceCorporation. At one point she traveled toeight states for her work. Back then sheeven took vacation time to help Gary dur-ing harvest.

“I was always the truck driver,” she said.“Sometimes I wonder how I did it all. Idrove the truck, but I made sure that wehad a noon meal. Then I would stop bywith meals.”

Now, retired from GMAC, her full energygoes 100 percent into the couple’s farm.

For Mattas, the MKC webpage enhancesher farm work in a very positive way. She

Living their dream by Kathy Hanks, Freelance Writer

Dixie Mattas utilizes the customer access feature on MKC’s web site for proof ofyields and ledger sheets.

7

appreciates the fact that she can use itanytime. Even late at night, long after theelevator is closed; she can pull proof ofyields off the computer or downloadledger sheets for the landlords.

“I dot every ‘I’ and cross every ‘T,’” shesaid. “I can’t be off a penny. Everythingmust balance and be reconciled.”

She has been using a computer softwareprogram known as “Farmworks,” whichallows her to keep track of all the expens-es in each field.

“Even when we disk a field we can deter-mine the cost of disking per acre,” shesaid. At the end of every month she printsoff profit and loss records so Gary can goover them and know their profit and lossfor the month and year to date.”

Tina Collins shares Dixie’s passion forfarming. However, on her Reno Countyfarm she is a one-woman show except forduring harvest when an aunt comes todrive a grain cart and a neighbor lends ahand. She has taken over her parent’s, Jimand Trudy Heimerman’s, farm since herfather’s death in 2007. In 2009 she boughtequipment from her mother, and nowshe’s going it alone overseeing three irri-gated circles of corn and soybeans anddry land wheat.

“I’m really thankful that the landlordshave given me this opportunity,” she said.

Collins, who is raising her 6-year-olddaughter, Copper, admits she has justexperienced her toughest year because ofthe drought.

She recalls when she was about Copper’sage that she did everything with herfather.

“He was old school,” she said. He didn’tever make a big deal about Tina being afemale farmer. “I just did it,” she said.Even while she was a student at KansasState University she came home most

weekends to help her dad farm.

It’s not an easy life. She works hard everyday, from sun up until sundown. But, as asingle mother, she makes a point of takingtime for Copper. While Collins andCopper live in Pretty Prairie, Copperrides the school bus out to the farm everyafternoon. The first grader works on herhomework and tends to her 22 NewHampshire red chickens and kittens.

“There’s nothing I can’t do on the farm,”Collins said. “With dad you just got inand did it. I’m grateful they let me do it.”Now she’s planning for a future andknows that record keeping is just asimportant as the labor.

“I’d like to expand with more acres and

cattle and update the equipment, Collinssaid. “But, it will take a few years.”

She has never felt limited as a woman; shecan tear machinery apart with the best ofmechanics.

She appreciates MKC’s Castleton Elevatorwhich is just 10 miles from her fields.

“The employees at the elevator are help-ful,” she said. They treat her with therespect they treat any customer, and theyhandle all the spraying and fertilizing fromthe elevators at Castleton and Haven.

“I’m living my dream,” Collins said. “If Ihad to go to work in an office I couldn’tsurvive.”

Tina Collins takes time from her busy schedule on the farm to spend with her daughter, Copper.

8

MKC assists local EMSMid Kansas Cooperative recently donat-ed $500 to Moundridge EMS to helpoffset costs to purchase a SafeGuardChild Transport and a Pedi-Mate. Thetwo pieces of equipment will aid thedepartment in the transportation ofinjured infants and children.

According to the National Center forStatistics and Analysis (NCSA), themost common type of injury accidentsinvolving children are those that involvemotor vehicle collisions. MoundridgeEMS Director, Angie Vickery, com-mented that the department currentlytransports infants and young children intheir infant/car seat by using rolled

blankets and towels to stabilize and limittheir mobility.

“Not only did MKC’s contribution helpus meet our financial goal to purchasethe equipment that will provide a muchsafer means to transport the children, ithelped us exceed our goal,” statedVickery.

Vickery commented that extra moniesraised will be applied towards the purchase of a traction device used forstabilizing fractures.

The contribution was part of a matchingfunds program available through LandO’ Lakes Foundation.

Benisch to leadMKC’s PrecisionAg Services

Ross Benisch has accepted the position ofPrecision Ag Marketer and will be leading thecompany’s precision ag program. Benisch comesto MKC after spending two years in the cropconsulting business. He is originally fromQuinter, Kan and earned a degree in geographywith an emphasis in geographic information sys-tems from Fort Hays State University.

Dave Spears, Vice President and ChiefMarketing Officer for MKC, commented thatproducers will benefit from Benisch’s unique skillset and knowledge. “I am confident that Rosswill take our precision ag program to the nextlevel in terms of products and services offered tothe producer,” stated Spears.

MKC to improve recyclingprocessesRecycling has always been a matterof helping the environment and theprocess of recycling has been aroundfor thousands of years. In ancienttimes it was a common occurrence to melt down swords, pots and othermetal items that had served theirpurpose. After the meltingprocess, new items suchas coins, statues andother householditems were made.

Products werenot nearly asabundant inancient times asthey are now, soresources werehardly ever wasted.Folks from those timeswould likely cringe if they sawthe amount of recycled materials thegeneral public wastes today.

Recognizing a need to improve

upon the existing recycling programat MKC, members of the MKCWay Committee, a leadership pro-gram at MKC, have taken the initia-tive to do just that. Tires, scrapiron, paper, cans and bottles are justsome of the processes that will be

improved upon or put intoplace.

“We recognized thatwe didn’t have acoordinated effortwhen it came torecycling,” statedTara Struber, amember of the

committee. “Someof our locations have

processes in place andwe wanted to take their

programs and implement themthroughout the entire company. Our goal is to make recycling ahabit and join other leaders in ourcommunities who recycle.”

Brad Wedel, MKC Location Manager forMoundridge, presents $500 to AngieVickery, Moundridge EMS Director.

Community Newsby Kerry Watson

MKC launched their completelyredesigned and enhanced web site inearly October. With a totally freshappearance and format, MKC’s newweb site embodies the coop’s forward-thinking vision. “We believe the changesmade to the web site have resulted in asignificant improvement in the areas ofcontent, navigation and design,” statedKerry Watson, CommunicationsSpecialist for MKC.

Notable content changes include theaddition of on-line registration for MKC-hosted events, yield plot data, an on-lineapplication process for employmentopportunities and a completelyredesigned on-line customer account sys-tem. New sections added to the web siteinclude precision ag and input finance.

Also new to the web site is a “live help”button located at the top right of thehome page. The process is similar toinstant messaging and an MKC represen-tative is available to research and answercustomer questions through this serviceduring business hours.

According to Watson, the new web site,www.mkcoop.com, was the first step in asignificant shift in the coop’s approachto the company’s digital future includingsocial media. “We recognized the needto keep up with the latest trends in

technology when communicating to ourcustomers,” stated Watson. “UtilizingFacebook, Twitter, YouTube andLinkedIn will help us deliver time-sensi-tive information to our readers in a more efficient manner.”

9

MKC launches new web site; embraces social media

Mid Kansas CooperativeAssociation will once againaward nine scholarships valued at $500 each. Thescholarships, available to tohigh school seniors graduat-ing in the spring of 2012within MKC’s trade territo-ry, will be awarded based on academic achievement, activities and an essay about the value of the cooperative system.

“This is our opportunity to recognizeoutstanding students in our communities,” states Kerry Watson,Communications/AdministrativeSpecialist for MKC.

Seniors who plan to attend an accrediteduniversity or college including junior,community, vocational or technicalschools are eligible to apply. Applicationsare available online at www.mkcoop.comand are also available through area highschool guidance counselors’ offices.Application deadline is March 15, 2012.

Scholarships available to high school seniors

The agronomy sales and services pre-viously provided at MKC’s Conwayand Inman locations transitioned tothe new state-of-the-art agronomy cen-ter in Groveland on December 1.

The Conway facility will be operatedon a seasonal basis for grain andanhydrous services and Inman will beutilized as a maintenance facility forMKC’s equipment.

MKC service and sales professionalsat Groveland can be reached at 620-585-6649 or 888-993-2667.

Conway andInman agronomyservices moved

Community News (continued)by Kerry Watson

10

MF Global’s bankruptcy filing in lateOctober created quite a stir in the ag indus-try and caused some local producers towonder how it was affecting their coopera-tive. Team Marketing Alliance (TMA), anLLC wholly owned by four central Kansascooperatives, had used Man FinancialGroup, Inc., a subsidiary of MF Global, asa clearing firm and reports that the bank-ruptcy has not interfered with TMA’s dailybusiness.

Ted Schultz, Chief Operating Officer forTMA commented that although MFGIwas the clearing firm for their futures

transactions, TMA’s positions have beenmoved to a new futures commission mer-chant. “We are trading business as usual,”stated Schultz. “Only a small percentage ofour margin money was transferred with thepositions”.

According to Schultz the balance of themoney is tied up waiting on the bankruptcytrustee to release it to accounts like TMA.“The majority of the funds have beenaccounted for and awaiting distributionwith the exception of a small percentagethat is still being reconciled,” stated Schultz.

MF Global bankruptcy not interfering with TMA business By Kerry Watson

Separating ourselves from the competitionBy Devin Schierling

For years, the crop insurance industry hasbeen stuck in a status quo where applicationsare mailed to the producer, checks are writ-ten, and the policy is perpetually renewed.The lack of personal touch and communica-tion to producers who rely on federal cropinsurance for a revenue floor has exposed thestatus quo. While federal crop insurance is auniform offering to all individuals who ownor rent farm ground, what “separates themilk from the cream” in this industry are theservices and tools offered to the producer.

Service brought to the farm gateTeam Marketing Alliance (TMA) brings thepersonalized tools and service to the produc-er’s kitchen table. Every customer has a dif-ferent need and that is why TMA personallyreviews every policy with the customer eachseason. Keeping up with the constantchanges of crop insurance can seem daunt-ing. TMA’s agents are experts in their fieldand insurance is their primary responsibility.Our agents are focused on maximizing theproducer’s revenue potential and not on writ-ing loans or selling other types of insurance.

Understanding the complete revenuepictureThe increased volatility in today’s weatherand commodity markets has raised the level

of complexity in making the right crop insur-ance decision for your operation. TMA’sability to help producers manage the priceportion of their crop insurance revenue poli-cy through grain marketing contracts isanother tool that a traditional insuranceagent cannot provide. We can provide atotal revenue plan that cannot be duplicatedby offering additional risk management toolsdesigned to complement the producer’s cropinsurance policy.

Focusing on what we can controlTMA’s focus is to help producers improvetheir profitability by helping manage theircrop inputs, grain sales, and crop insurancedecisions. This focus allows us to holisticallylook at a producer’s option instead of focus-ing on the individual parts. For example, an85%

Revenue Assurance Policy that costs $25 peracre isn’t the wrong decision if it allows youto insure a guaranteed profit on your farmwhile providing more guaranteed bushels topotentially forward contract.

TMA’s ability to have Crop InsuranceSpecialists who can synthesize all the individ-ual decisions into whole- farm profitability iswhat separates us from our competition.

You don’t rush this type of financial invest-ment when most of it is in concrete andsteel. We have spent and are still spendingtime with designers, consultants and peoplewho have done it before us to make sureyour investment is done in the most pru-dent manner.

All of these investments are a wager on thefuture. For those who are insecure abouttheir future, it may appear as gambling.For those of us who believe it will take anextraordinary effort to make sure we are ina position to feed the ever-growing worldpopulation, there is no question in themerit of our endeavors. We have littlechoice. Just like any business, we have eco-nomic goals. The problem is they don’tprovide the passion to be the driver of ourefforts.

The thought of all our stakeholders joiningin an effort to ensure everyone in the worldhas access to a safe, dependable and rea-sonably priced food supply and that we canall participate in the spirit of shared successis an inspirationally driven vision.

Optimistic aboutour future Cont. from Page 3

.