De-brief on F-35 machining, fabrication, assembly and ...

Transcript of De-brief on F-35 machining, fabrication, assembly and ...

© May 2017

Michael W McLean FAICD, FIMC-CMC, FAOQ, JM

Goal Professional Services Pty Ltd

website: www.goalgroup.com.au

De-brief on

Lockheed-Martin Joint Strike Fighter – F-35 machining, fabrication,

assembly and testing facility tour conducted on 2 May 2017, Dallas

Forth-Worth Texas, USA by Michael McLean and Mike Anleitner

(Lennox, USA) courtesy of Victor Ugarte, Varley Group.

26 May 2017

© May 2017AiG Hunter Lean Cluster Meeting 26 May - MWMcLean Goal Group Page 2 of 302017/1

https://www.f35.com/about/life-cycle/production

© May 2017AiG Hunter Lean Cluster Meeting 26 May - MWMcLean Goal Group2017/1

2 Feb 2017.

• The Government is preparing to spend $17 billion on 72 F-35A Lightening II aircraft

• Howard government decided to join JSF program at the US' invitation

• Now President Trump blasted project tweeting F-35 cost blowouts were "out of control“

Page 3 of 30

© May 2017AiG Hunter Lean Cluster Meeting 26 May - MWMcLean Goal Group2017/1

“Although it would be

unrealistic to expect first

production to be issue

free, our contractor

assessments indicate that

greater emphasis on

quality assurance,

requirement flow down,

and process discipline is

necessary, if the

Government is to attain

lower program costs.”

Source: US DoD IG.

Page 4 of 30

© May 2017AiG Hunter Lean Cluster Meeting 26 May - MWMcLean Goal Group2017/1

Senator Payne said she looked forward to the

outcome of the Trump Administration's review of the

controversial program.

"The US Government negotiates on behalf of all

partner nations, so Australia will share in any realised

cost reductions," she said. “All 72 aircraft are expected

to be fully operational by 2023

The F-35A is being purchased by Capability Acquisition and Sustainment Group under

project AIR 6000.

Page 5 of 30

© May 2017AiG Hunter Lean Cluster Meeting 26 May - MWMcLean Goal Group2017/1

The JSF program comprises Australia,

Denmark, Israel, Italy, Korea, the

Netherlands, Norway, Turkey, the UK

and the United States..

http://mobile.abc.net.au/news/2017-02-07/joint-strike-fighter-f35-to-visit-australia-avalon-

air-show/8248194?pfmredir=sm

Page 6 of 30

© May 2017AiG Hunter Lean Cluster Meeting 26 May - MWMcLean Goal Group2017/1

http://www.defenseone.com/business/2016/05/f-35-production-set-quadruple-massive-

factory-retools/128120/

Page 7 of 30

© May 2017AiG Hunter Lean Cluster Meeting 26 May - MWMcLean Goal Group Page 8 of 302017/1

Michael Anleitner, Sr. Principal Quality Engineer, Lennox Industries

University of Michigan - Stephen M. Ross School of Business, Addison,

Texas. USA

“The plant operates on a three-shift basis. At this point in time, they are still in ramp-up mode, having shipped more than 200 aircraft thus far (out of a total projected run of just less than 2,500 aircraft). By 2019, line speed will reach 1 aircraft per day, a rapid pace for anything this large and complex.

Wing Build. Unlike wing builds for commercial airliners, the F35 wings are rotated into a

vertical position. (Commercial jetliner wings are too large to do this.)

All drilling is done with massive (2-3 story high) vertical CNC drilling machines, almost no

drilling (a very common requirement given wing designs) is done by hand. While remaining in

a vertical orientation, wings are rotated and/or raised/lowered to provide comfortable work-

height access for all line personnel.

https://www.slideshare.net/Anleitner/lts-2009-dfmea

© May 2017AiG Hunter Lean Cluster Meeting 26 May - MWMcLean Goal Group Page 9 of 302017/1

https://www.f35conference.co.uk/

© May 2017AiG Hunter Lean Cluster Meeting 26 May - MWMcLean Goal Group Page 11 of 302017/1

https://www.youtube.com/watch?v=lJdzFPnku2U

© May 2017AiG Hunter Lean Cluster Meeting 26 May - MWMcLean Goal Group Page 17 of 302017/1

© May 2017AiG Hunter Lean Cluster Meeting 26 May - MWMcLean Goal Group Page 18 of 302017/1

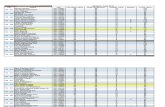

Visual

Production

Deployment

and Progress

Board

Wings – fuel

(Yellow) – aids

stealth

Wings –

electronics

in turquoise

(Visual) Process Control Plan

/ SOP + BOM

Moveable

Kanban

Consumable

Racks

© May 2017AiG Hunter Lean Cluster Meeting 26 May - MWMcLean Goal Group Page 19 of 302017/1

https://youtu.be/MNeq-Snpnb0?t=1

© May 2017

• As a programme partner, Australian

businesses have the opportunity to

supply components for the entire F-35

fleet, not just Australian aircraft.

• More than 50 Australian companies are

contributing to the development and

production of the F-35, and to date,

these companies have been awarded

more than $800 million AUD in

contracts, providing high-tech

manufacturing jobs for Australian

industry.

https://f35.com/global/participation/Australia

Chief of air force, Air

Marshal Geoff Brown, RAAF

AiG Hunter Lean Cluster Meeting 26 May - MWMcLean Goal Group Page 20 of 302017/1

© May 2017AiG Hunter Lean Cluster Meeting 26 May - MWMcLean Goal Group Page 21 of 302017/1

“4.0 Content of the Deliverable Quality Plan

4.1 General

The content of the Deliverable Quality Plan

must be adequately precise and detailed enough

to reflect the ongoing supplier activities

specific for a contract.

The Deliverable Quality Plan shall refer to

and/or include all procedures, plans and other

documents applicable to the contract.

The Deliverable Quality Plan shall specify the

activities (managerial and technical) to be

implemented, either directly or by reference to

appropriate procedures and documents.”

© May 2017

“5. Deliverable

Quality Plan”

“1. ISO 9001

Certification”

“2. AS9100

Certification”

“3. ISO 10007

Configuration

Management”

“4. ISO 10005

Quality Plan”

AiG Hunter Lean Cluster Meeting 26 May - MWMcLean Goal Group Page 26 of 302017/1

© May 2017AiG Hunter Lean Cluster Meeting 26 May - MWMcLean Goal Group Page 27 of 302017/1

All Suppliers ISO 9001 Cert’n + meet these Backward Integration requirements for each Tier 1

“KPC” and Process Control

– derived from Process

Control Plan – IATF

16949:2016 Core Tools

“Statistical Process

Control” also from IATF

16949:2016 Core Tools

Reaction Plan for U/LCL in

Control Charts shown in

Process Control Plan

Post Control Chart showing

Stability, THEN conduct

Process Capability

+ Process Control drawn

from Lean Tools, Industrial

Engineering, Work

Simplification and Study

© May 2017AiG Hunter Lean Cluster Meeting 26 May - MWMcLean Goal Group Page 28 of 302017/1

ISO (Draft) 31010:2017 - Risk management

– Risk assessment techniques.

“Goldilocks Techniques” – New Zealandhttps://www.riskmgmt.co.nz/fileadmin/documents/Risk_techniques_working_paper.pdf

“Process description: Inputs, Process

Activities, Outputs

“Failure Mode and Effects Analysis

(FMEA) and Criticality Analysis

(FMECA):

• Identify potential failure modes for a

product or process

• Assess the risk associated with those

failure modes

• Ranks the important issues

• Carry out corrective actions on most

serious concerns.”

“B.2.4.3 Inputs include performance specifications of

the design; or hardware can include gb

For non-hardware related HAZOP (‘Hazard and

Operability Studies) inputs can be any document that

describes functions and elements of the system to ID

potential deviations from the design intent, and

examining their possible causes and consequences

IEC 60812, Analysis techniques for system reliability –

Procedures for failure mode and effect analysis

(FMEA).

© May 2017

USAF's Bogdan Gives Final F-35

Lightning II Progress Report as JSF

Program Executive Officer for the F-

35 Lighting II Fighter, provides a

status report on the F-35 Joint Strike

Fighter (JSF) Program in an

exclusive interview with Defense &

Aerospace Report Editor Vago

Muradian.

The interview was conducted on

May 11, 2017 at the program's

offices in Arlington, Virginia, USA.

https://www.youtube.com/watch?v=Li0PTiSzvXw

LIEUTENANT GENERAL CHRISTOPHER C. BOGDAN

Retiring effective July 01,2017

http://www.af.mil/About-

Us/Biographies/Display/Article/108398/lieutenant-

general-christopher-c-bogdan/

2017/1 Page 29 of 30AiG Hunter Lean Cluster Meeting 26 May - MWMcLean Goal Group

© May 2017

Thank you and the Hunter Lean Cluster for

your time today.

L-M Supplier Requirements can be obtained from

Michael W McLean FAICD, FIMC-CMC, FAOQ, JM

Goal Professional Services Pty Ltd

website: www.goalgroup.com.au

Quality Digest ‘Live’ interview in Chico, CA, USA with Mike McLean, ISO Convener

for the Task Force to revise the ISO ‘Integrated Use of Management System Standard’

Handbook with over 25 nations

https://www.youtube.com/watch?v=qDv63X4PE1s

Mike is also on the ISO Working Group and expert on ISO 10005 Quality Plans

revision in 2016/2017 and represents AiG Members on ISO 9000 / 9001:2015 and

AS/NZS ISO 9001:2016; ISO 9004:2017

2017/1 Page 30 of 30AiG Hunter Lean Cluster Meeting 26 May - MWMcLean Goal Group