DCC 2012/2013 Annual Report

-

Upload

bm-analysts -

Category

Documents

-

view

240 -

download

0

description

Transcript of DCC 2012/2013 Annual Report

Contents

Key Facts and Numbers 2008 - 2013 ......................................................................................... 2

Report Scope .............................................................................................................................. 3

Brief Background to Cluster ....................................................................................................... 3

Letter from Chairman ................................................................................................................ 4

Letter from the Chief Facilitator ................................................................................................ 6

Chief FacilitatorLetter from the Deputy Mayor ......................................................................... 6

Profile of the local chemicals industry ....................................................................................... 8

Cluster Conceptual Model ....................................................................................................... 15

Executive Function ................................................................................................................... 16

DCC Strategic Priorities ............................................................................................................ 19

DCC 2012/13 Programme Activities ........................................................................................ 21

Highlights for the year 2012/13 ............................................................................................... 30

Annual Financial Statements ................................................................................................... 33

Notes ........................................................................................................................................ 42

Contact Information ................................................................................................................. 43

Key Facts and Numbers 2008 - 20132008 - 2013

Established in late 2008 and 5 years in existence with a membership of 28 firms

Membership represents approximately 28% of the chemicals manufacturing activity in

KwaZulu-Natal

5 successive years of unqualified financial audits

R2.25m annual budget

Approximately 25% of funding has been leveraged from private sector and sources other

than the eThekwini Municipality

245 people participated in workshop related activities between 2012 and 2013

91% average positive assessment for workshop related activities

Provided assistance to member firms to access R30 million for capital upgrading from MCEP

incentive

Report Scope

The Durban Chemicals Cluster (DCC) is a not for profit private public partnership between the

eThekwini Municipality and the Chemicals Industry in KwaZulu-Natal. This annual report represents a

review of the financial and operational performance of the cluster for the period July 2012 to June

2013.

Brief Background to Cluster

The DCC was established in 2008 with the primary purpose of developing the competitiveness of the

local chemicals manufacturing industry. The development of the cluster followed the successful

completion of a pilot phase nine months earlier. The DCC received its first tranche of funding from

the eThekwini Municipality and its member firms in March 2009. Thereafter the DCC became fully

operational as an industry body.

The Durban Chemicals Cluster aims to achieve and promote the competitiveness and development

of chemicals manufacturing firms through establishing mutually competitive advantages and helping

the industry overcome generic challenges. The DCC is governed by an Executive Committee which

comprises senior executives from member firms, as well as government officials. Five strategic focus

areas have been identified as central to the growth of this sector in consultation with various

stakeholders. These focus areas are as follows:

Value Chain Competitiveness;

Compliance;

Skills Development;

Transformation; and

Investment and Growth

Each of these strategic thrusts formulates a programme of the DCC

and has a dedicated Technical Steering Committee comprising of

industry officials which directs the activities of the programme. In this

way, the activities of the cluster are continuously changing in line with

the needs of industry and are for industry by industry.

Letter from the Chairman

On behalf of the Executive Committee of the

Durban Chemicals Cluster I am pleased to

deliver the Cluster’s 2012/13 Annual Report.

The aim of this Public-Private Partnership (PPP)

between the eThekwini Municipality and the

chemicals industry in Durban and surrounding

areas is to support the competitiveness and

development of the local chemicals

manufacturing industry – and in this regard the

Cluster continues to make good progress.

Since the Cluster’s inception late in 2008 a range of initiatives have been successfully implemented

as per the 2008 to 2012 business plan, with these initiatives reflecting the essence of clustering and

indicating that the Cluster has established a solid foundation for itself.

In 2011 the Cluster recognised that there was opportunity for it to play an even greater role in the

development of the local chemicals manufacturing sector and for this reason the Cluster

commissioned a study of the major chemicals manufacturing value chains in the eThekwini

Municipality. The purpose of this study was to create an improved understanding of the local

industry’s development requirements to enhance the Cluster’s ability to provide more beneficial and

relevant interventions.

The outcomes of this study informed a decision to re-align the strategic focus areas and hence

activities of the Cluster. The strategic focus areas, and associated activities, of the Cluster moving

forwards will therefore be as follows:

Investment and Growth - directed at promoting innovation, increasing local producer share of

the domestic market and export promotion.

Value Chain Competitiveness - incorporating operational competitiveness, supply chain

management and risk management.

Compliance - encompassing both enhancing adherence to best practices and representation in

respect of select compliance and regulatory matters.

Skills Development – based on first determining skill requirements and then establishing and

operationalising targeted skills programmes.

Transformation – directed at both promoting B-BBEE best practices amongst established

enterprises and developing SMEs.

I am also pleased to report that the cluster is in a healthy financial position. Income for 2013 totalled

R 2 252 695 while expenses totalled R 2 259 895. The cluster has a retained income of R 137 642.

The Section 21 Company remains compliant with all relevant legal and statutory requirements and

continues to receive unqualified, clean audits from PKF Auditors, the appointed auditing firm.

The Executive Committee firmly believes the new strategic direction of the Cluster positions it to

increase the value of activities to members while also supporting increased Cluster membership.

Accordingly, I think both industry and Government stakeholders can look forward to an exciting year

ahead.

Best Regards,

Robin Archer

Chairman

Letter from the Chief Facilitator

2012/13 proved to be a noteworthy year for the Durban

Chemicals Cluster for a number of reasons. In spite of being

challenged by moderate levels of funding uncertainty and new

compliance requirements, the Cluster managed to continue to

deliver effective support to member firms constantly challenged

by the effects of globalisation. I am therefore pleased to be able

to report that the Cluster has successfully overcome its funding

challenges and remains well positioned in respect of compliance

and governance requirements.

Importantly, the achievements of the Cluster would not have

been possible without the strategic direction and guidance of the

Executive Committee, which comprises member firm

representation. I would accordingly like to take this opportunity to thank the members of the

Executive Committee for their on-going commitment, support and leadership.

The Cluster’s funding of R2.25m for 2012/13 was employed as effectively as possible and, where

possible, used to leverage outcomes disproportional to the limited amount of funding available. In

this regard I am also pleased to report that collaborative partnerships continued to be expanded in

2012/13.

The Cluster took a significant step forward when it completed the value chain study of the local

chemicals manufacturing industry in 2012. This research identified the need for specific

interventions that would enhance industry growth prospects and the Cluster is consequently now

better positioned to support firms through its understanding of industry-wide issues, cluster-level

issues and value chain specific issues.

Lastly, I hope this report further affirms the fact that a solid foundation for the Cluster has been

successfully established and that the Cluster is well positioned to engage with its 2020 objective

through the implementation of its new business plan.

Kind Regards,

Douglas Comrie

Chief Facilitator

Letter from the Deputy Mayor

The Durban Chemicals Cluster is a Public-Private

Partnership (PPP) between the eThekwini

Municipality and the Durban-based chemicals

manufacturing sector. Since its inception in 2008,

the Cluster has achieved considerable success in

providing tangible interventions to facilitate the

economic development of the sector. The Cluster

has also facilitated the development of strategic

and international partnerships between

stakeholders and industry and has thereby been

able to leverage increased outputs for industry.

In 2012, the Cluster underwent a tender process for facilitation services. This process was deemed to

be transparent and fair and an exemplary example of good governance.

The Cluster has therefore created an effective platform for the delivery of industrial upgrading. The

eThekwini Municipality recognises the importance of supporting this sector and recognises its

significance as a key contributor to the local and national economy. Looking ahead, with the new

strategic direction of the Cluster, the Cluster has the ability to deepen its value addition to industry

even further. It is therefore crucial that the Cluster is provided with the necessary resources to

facilitate the delivery of these service offerings.

We, as eThekwini Municipality, view the partnership with industry through the Cluster as important

in providing for economic growth in this sector in the future.

Kind Regards,

Cllr Nomvuzo Shabalala

Deputy Mayor, eThekwini Municipality

Profile of the local chemicals industry

South African chemicals industry

The South African chemicals industry has achieved rapid sales growth in recent years, with a

compound annual growth rate (CAGR) of 8.2% between 2006 to 2010, and this is projected to rise to

9.4% over the 2010 to 2015 period (Datamonitor, 2011). Despite this, the chemicals manufacturing

value added has been sluggish over this period with a decline evident from 2007 to 2009, and a

slight recovery in 2010 (see Figure 1).

Figure 1: South African real value added (R million 2005 prices)

Source: Adapted from Quantec Database (2012)

Figure 2 below reflects the national export - output ratio for the period 2000 to 2010. The export -

output ratio indicates the proportion of output that is exported. Exports have been consistently

declining relative to output since the turn of the millennium, potentially indicating that domestic

manufacturers are either increasing their focus on capturing domestic market share or are

alternatively finding it increasingly difficult to compete successfully in export markets.

Figure 2: South African export - output ratio (at constant 2005 prices)

Source: Adapted from Quantec Database (2012)

The South African chemicals industry employs almost 150 000 people. Employment output has also

remained consistent in the face of a dramatic increase in salaries and wages (see figures 3 & 4). This

suggests that a trade-off has been made, with employment growth being sacrificed in order to

accommodate higher salaries and wages in an environment where there is limited growth in

production output.

Figure 3: South African gross salaries and wages (actual) by sub-sector

Source: Adapted from SARS (2010).

Figure 4: South African employment output ratio (including informal sector)

Source: Adapted from Quantec Database (2012)

The employment profile of the industry is increasingly orientated towards skilled and highly skilled

employment. Recent South African industrial policy has been increasingly aligned with harnessing

state procurement and incentivising capital investment and competitiveness upgrading. This

presents potential growth and competitiveness upgrading opportunities for existing enterprises as

well as opportunities for attracting green field investment. In particular, the IPAP2 and IPAP3 KAPs

present additional growth, investment and innovation related opportunities.

KwaZulu-Natal chemicals industry

Figure 5 presents the chemicals sector outputs for KwaZulu-Natal and eThekwini. Both the

associated contribution of eThekwini to the national sector’s output and the year on year growth of

the eThekwini sector are also represented. Between 2000 and 2010, KwaZulu-Natal’s output

increased by 39.4%, from R 42.0 billion to R 58.5 billion representing a CAGR of 3.4%. While by far

the majority of output from KwaZulu-Natal was produced within the eThekwini Municipality, output

from the eThekwini Municipality grew by 26.4% to R 37.0 billion over the corresponding period,

representing a CAGR of just 2.4%.

Figure 5: KwaZulu-Natal and eThekwini chemical output at basic prices (constant 2005 prices)

Source: Adapted from Quantec Database (2012)

The eThekwini chemicals manufacturing sector has been experiencing slower growth than that of

the sector at a provincial and national level. eThekwini therefore seems particularly weakly

positioned in relation to harnessing the opportunities associated with growth in domestic sales. This

should be raised as a concern given its ability to undermine employment creation prospects in an

increasingly globalised and competitive operating environment.

The eThekwini sector employed a total of 18 314 people in 2010, with a strong orientation towards

skilled and highly skilled employment. Pre-2009 employment levels have been comparatively

consistent, although there is a long term trend characterised by stable levels of skills and highly

skilled employment and reducing levels of semi-skilled and unskilled employment. Critically, then, it

is evident that the absence of output growth has reduced scope for employment growth and in

response to competitiveness pressures the sector seems to have reduced lower skilled employment

and increased its reliance on more skilled employment.

Profile of prominent value chains in eThekwini

The chemical sector largely comprises producer-driven value chains, based on high levels of

industrial capital investment. Firms that compete in producer driven chains develop core

competencies that lie in research and development as well as production capabilities. There are five

major value chains in eThekwini:

1. Coatings, inks, adhesives and dyes;

2. Resins and polymers;

3. Pulp and paper;

4. Water treatment; and

5. Petroleum and gas

The major demand side and supply side issues impacting on development of these five value chains

are summarised below. These findings emanate from the DCC Chemicals Value Chain Study (2012).

Table 1: Major coatings, inks, adhesives and dyes value chain development considerations

Demand side considerations Supply side considerations

Domestic demand likely to exceed GDP

growth due to historical trend as well as

interplay of industrial policy, social policy,

and Government expenditure.

Positive demand outlook in domestic

mining, food, petrochemicals and

automotive sectors.

Exports to other African economies present

opportunity for growth.

Reduced levels of protection and

differential operational compliance

requirements placed on local versus foreign

manufactures will diminish manufacturing

growth prospects.

Above inflation factor costs will inhibit

competitiveness challenges and adversely

affect employment growth.

Employment likely to be created in highly

skilled and skilled categories.

Investment in new capital equipment would

enhance competitiveness and support

improved economies of scale.

Investment in product and process

innovation would support improved

competitiveness.

Table 2: Major resin and polymer value chain development considerations

Demand side considerations Supply side considerations

Domestic consumer demand unlikely to

yield growth prospects above GDP growth

levels.

Positive demand outlook for sectors closely

aligned with Government expenditure.

Positive demand outlook for domestic

mining and automotive sectors.

Reduced tariff protection and differential

Investment in innovation would support

improved competitiveness, as well as

potentially new market opportunities

(particularly in green technologies).

Investment in new capital equipment would

enhance competitiveness and support

improved economies of scale.

Access to skilled and highly skilled persons

operational compliance requirements

placed on local versus foreign manufactures

will diminish manufacturing growth

prospects.

Exports to other African economies present

opportunity for growth.

required to support growth and innovation.

Table 3: Major pulp and paper value chain development considerations

Demand side considerations Supply side considerations

Uncertain if growth will exceed GDP

growth.

Positive demand outlook for sectors closely

aligned with Government expenditure.

Exports to other African economies present

opportunity for growth.

Chemical cellulose production presents

opportunities for growing exports and

establishing aligned downstream value

added manufacturing.

Duty circumvention and differential

operational compliance requirements

placed on local versus foreign manufactures

will diminish manufacturing growth

prospects.

Investment in new capital equipment would

enhance competitiveness and support

improved economies of scale.

Investment in innovation would support

improved competitiveness, as well as

potentially new market opportunities

(particularly in green technologies).

Access to skilled and highly persons required

to support growth and innovation.

Table 4: Major water treatment value chain development considerations

Demand side considerations Supply side considerations

Future growth likely to exceed GDP growth

due to interplay of social, environmental

and industrial policies.

Strong demand outlook in primary market

due to Government social expenditure &

local procurement

Water scarcity will intensify government

focus on treatment of waste water,

necessitating increased focus on process

innovation.

Investment in new capital equipment would

enhance competitiveness

A secondary, largely industrial, market to be

stimulated by water scarcity and related

Government environmental policies.

African economies present growth

opportunity.

Access to skilled and highly skilled persons

required to support growth and innovation.

Table 5: Major petroleum and gas value chain development considerations

Demand side considerations Supply side considerations

Primary long term consideration of

refineries will continue be demand for fuel

and legislative changes, not demand for by-

products.

Positive by-product demand outlook in

domestic mining, agriculture, food,

petrochemicals and automotive sectors.

By-product demand to be further bolstered

by competitiveness support, Government

local procurement, and efforts to bolster

industrial growth.

Export potential for HS 27, with specific

focus on Sub-Saharan African.

Installation of new, competing refining

capacity will reduce attractiveness of

refinery investment / upgrading and

introduce additional demand for scarce

skills.

Production of sulphur and benzene to

increase, introducing potential to affect

price and create new downstream

opportunities. Upgrade of all refineries

nationally will introduce additional

(temporary) demand for scarce skills.

Investment in new capital equipment would

enhance competitiveness

Biofuel technology will introduce new

sources of by-products.

Cluster Conceptual Model

The principle of clustering is in essence one of enhancing

the competitiveness of a regional industry through

collective interventions, which are more likely to be

successful than isolated efforts. Clustering efforts are

therefore based on undertaking rigorous research to

identify the major industrial challenges followed by the

facilitation of joint activities or interventions through

securing firm-level input into the specific opportunities

identified.

A successful and sustainable clustering model is dependent on a range of key principals, the most

fundamental of which are:

1. Partnership

A balance between private sector and public sector objectives and interests needs to be maintained,

with this principle applicable to goals, commitment, time, and funding.

2. Industry leadership and ownership

Industry leadership and ownership enables higher levels of commitment from industry and ensures

validity of cluster initiatives.

3. Trust relations

Clustering represents a partnership between the public and private sector that is enabled by cluster

facilitators. Transparency, reliability and accountability are important in the relationships that exist

between the various parties.

4. Reliability and consistency

A cluster’s credibility is enabled through reliable and consistent delivery, with this taking place within a

framework of defined objectives, transparent leadership and strong trust relations.

5. Flexibility

The ability to adapt to changing external factors is important and as such a cluster should be able to

adapt to emerging industry threats and opportunities while keeping within a framework that maintains

credibility and accountability.

Executive Function

Executive Committee

The DCC is an industry driven initiative and is overseen by an Executive Committee. The Executive

Committee is comprised of senior executives from members firms and government officials.

The Executive Committee’s responsibilities are primarily twofold:

1. Strategic direction and oversight of programme implementation

2. Corporate governance and compliance

The members of the Executive Committee for the year ending 30 June 2013 are listed below.

Name Position & Firm Role in Executive Committee

Robin Archer Purchasing and Materials Manager

Huntsman Tioxide

Chairperson & Transformation TSC Chair

Jay Udith Director

Sancryl Chemicals

Deputy Chairperson

Ravesha Govender HSE and Planning Manager

NCS Resins

Value Chain Competitiveness and

Compliance TSC Chair

Oswald Maluleka Operations Manager

Gold Reef Speciality Chemicals

Investment and Growth TSC Chair

Daniel Souchon Managing Director

Arkema

Nominated Industry Representative

Junai Maharaj Managing Director

Buckman Laboratories

Nominated Industry Representative

Mukesh Akoobhai Operations Manager

Hosaf

Nominated Industry Representative

Shunnon Tulsiram Head Economic Development

Department of Economic Development

eThekwini Municipality Representative

Douglas Comrie Managing Director

B&M Analysts

Non-Voting Chief Facilitator

Michele Arde Executive

B&M Analysts

Non-Voting Facilitator

Constitution

The activities of the DCC are governed by its Constitution. Within the constitution, rules and

regulations governing the DCC objectives, membership requirements, decision making processes and

the facilitation service providers are listed.

Compliance and Transformation

The Executive Committee pro-actively identifies and puts in place mechanisms to ensure that the

Cluster is compliant with relevant legislation.

Cluster Scorecard

The DCC is fully compliant with the following legislation:

Municipal Finance Management Act (MFMA)

Tax Administration Bill (TAB)

International Financial Reporting Standards (IFRS)

New Companies Act

Consumer Protection Act (CPA)

Competition Act

DCC is a Level 4 contributor.to the Broad-Based Black Economic Empowerment Act (B-BBEE)

Preferential Procurement Policy Framework Act (PPPFA)

Public Finance Management Act (PFMA)

Facilitation

Cluster facilitation services are provided by an independent team from Benchmarking &

Manufacturing Analysts SA (Pty) Ltd (B&M Analysts) appointed by the Executive Committee.

Founded in 1997, B&M Analysts provides high value specialised support services to drive sustainable

industrial development. Its primary areas of expertise and service provision include cluster

facilitation, competitiveness benchmarking, policy and strategy research, and training. These

services are provided to government, non-government organisations (NGOs), clusters, industry

associations and manufacturing companies. B&M Analysts is a verified ‘Level 2 contributor’, or what

the Codes define as being 125% B-BBEE compliant. For more information on B&M Analysts please

visit www.bmanalysts.com.

DCC Strategic Priorities

Based on the current positioning of the local chemicals sector, the DCC has developed the following

strategic priorities:

Compliance

Investment Attraction and Growth

Export Growth

Innovation

Value Chain Competitiveness

B-BBEE Transformation

Skills Development

The overall objective is that the development of the sector in these key priorities will enable the

chemicals sector in KZN to enhance its competitiveness and thereby grow its manufacturing value

added (see figure 6 below):

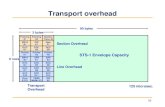

Figure 6: DCC Strategic Priorities

Each of these strategic priorities has dedicated programmes with activities designed to achieve the

programmes’ objectives. The programmes of the DCC are therefore as follows:

1. Compliance

2. Investment and Growth

3. Value Chain Competitiveness

4. B-BBEE Transformation

5. Skills Development

Each of these programmes is governed by a Technical Steering Committee (TSC) comprising industry

officials. The TSCs direct the activities of the programmes in line with industry’s needs. Each of these

programmes and their activities for 2012 are dealt with on the subsequent pages.

Figure 7: DCC Programme Organogram

DCC 2012/13 Programme Activities

Investment and Growth Programme

The chemical sector in South Africa is largely characterised by producer-

driven value chains, which are highly capital intensive in nature.

Unfortunately, this is also a sector in which there is a high level of machinery

which is outdated, and therefore firms are unable to take advantage of

economies of scale and the machines require high levels of maintenance. Therefore the aim of the

investment and growth programme is to facilitate investments in both capital equipment and

innovation to enhance the competitiveness of the firms and facilitate growth. During 2012, this

programme facilitated the following activities:

Investment Intervention Area

The Manufacturing Competitiveness

Enhancement Programme (MCEP) is a

Department of Trade and Industry (dti)

incentive programme of which the objective

is to promote enterprise competitiveness

and job retention within the manufacturing

industry. This incentive programme

comprises a number of components

including: Capital Investment; Green Technology and Resource Efficiency Improvement; Enterprise-

Level Competitiveness Improvement; Feasibility Studies; Cluster Competitiveness Improvement and

Industrial Financing Loan Facilities. The DCC has focussed on providing member firms with 1)

Detailed information on this programme and 2) With providing firm-level application assistance on

this programme. In August 2012, the Deputy Product Director for the MCEP programme from the dti

provided an information session for members on the MCEP programme. In 2012/13 the DCC

provided five member firms with assistance in submitting their MCEP applications.

The cluster is also staying abreast of the major government investment projects and conducting

information sharing sessions with member firms. This is important as it provides information on

projects which have important ramifications for our members. On 24 June, 2013, Transnet provided

information to cluster members on their national road and rail plans.

Business Retention and Expansion Support Desk

The Business Retention & Expansion (BRE) Cluster Support Desk initiative, started in 2011, is aimed

at assisting member firms with technical related problems that they are experiencing. During 2012,

the desk assisted member firms with issues related to EIA compliance, air quality monitoring,

environmental waste tyre management, storm water monitoring and air emission licensing. The DCC

in turn liaised with the relevant departments within the eThekwini municipality to assist cluster

members with their queries.

Trade Statistics

Trade statistics play a vital part in monitoring, analysis and projections of macroeconomic

developments. In order to enable DCC firms to stay abreast of these development trends the DCC

collects the latest import and export statistics for the five major value chains in the chemicals sector

and this data is shared with member firms in the bi-monthly DCC newsletter.

Duty Circumvention

One of the challenges in the chemicals sector is duty circumvention and differential operational

compliance requirements which are placed on local versus foreign manufactures. This diminishes the

local manufacturers’ competitiveness. In support to this, Santia Customs Consulting undertook a

customs presentation in June 2013. The presentation covered customs issues, including the global

trading environment, customer valuations and duties, the evasion of customs duties, customs duty

avoidance, tariff investigations, rebates as well as licensing and security issues.

Export Markets

Africa has become a major export market opportunity for domestic chemicals manufacturers.

Unilever export manager, Nhlanhla Mdlawuzo, presented on his experience with exporting into

Africa at a DCC workshop in August 2012. He gave an insightful presentation on possible models

which firms can use to engage in exporting. The DCC is now in the process of compiling an African

export market study. The objective of the study is to identify prioritised African export markets with

an overall aim of growing exports to select African markets. Further to this, the study endeavours to

identify key non-tariff and logistical barriers to African export markets.

Fast Track Investment Initiative

The KZN chemicals sector achieved sluggish growth in recent years. While the reasons for the poor

growth performance are varied, investors (and potential investors) commonly cite extreme

frustrations with the complexity and timelines associated with navigating and securing ‘regulatory’

approval. This in turn either defers or deters much needed investment associated with employment

growth. For this reason the DCC has developed a schedule of all the major investments which are

planned and being implemented by member firms. Going forward, the DCC will create a fast track

investment working group comprising various industry stakeholders to ensure that any blockages

and red tape for these investments are easily overcome. This will facilitate investment in the local

chemicals sector.

Compliance Programme

Safety, Health and Environment have all been identified as areas where firms

need to be able to comply with an increasingly complex set of requirements

in a cost effective manner. The objective of the compliance programme is to

support member firms with compliance to safety, health and environmental

requirements. Support is provided through the research and promotion of dialogue between

members and stakeholders on regulatory requirements for industry as well as the facilitation of

sessions to assist members with adherence to best practice. During 2012, this programme facilitated

the following activities:

Compliance Developments and Best Practice

The DCC hosted workshops which updated member firms with the latest developments in

compliance issues and best practices in safety, health and environment operations. The workshops

covered topics such as 1) The Air Quality Act and the application for Air Emission Licenses 2) Incident

reporting and inspection from Province in the

chemicals sector 3) Introduction to Globally

Harmonised Systems for the Classification and

Labelling of Chemicals (GHS). The cluster is staying

abreast of developments and best practice in

compliance and knowledge is shared with members,

as changes in legislation and compliance has a

significant impact on chemical firms.

.

Environmental Legal Register

The generic national environmental legal register is prepared annually for member firms and

highlights the environmental legislation that chemical firms are required to comply with. The register

provides member firms with a compilation of environmental legislation that relates to the chemical

industry, and includes the specific legal requirement for each firm. The firms are provided with the

implementation documents that are required for each legal requirement listed. Members are also

provided with a by-laws register that is specifically aimed at firms in the eThekwini region. The DCC

provides members with a hard copy of the register and an annual workshop to discuss updates of

the register.

Safety, Health and Environment Best Practice Tours

The cluster scheduled best practice tours for member

firms to identify best practices in safety, health and

environment as many firms are challenged with

continuous complex requirements. Member firms

were exposed to best practices within the food and

beverage industry, as many of these best practices can

be adopted within chemicals industries.

Best practice tours in 2012 included South African

Breweries (SAB) and Unilever both of which have world class systems in place. Member firms had

the opportunity to identify additional best practice procedures that are implemented by the firms

visited such as continuous improvement, 5S, visual management and ‘green’ initiatives.

Value Chain Competitiveness Programme

Understanding of the chemicals value chain linkages and challenges in the

chemicals industry, allows the DCC to identify interventions that aim to

enhance the competitiveness of member firms within their specific value

chain. Focus areas of the DCC’s Value Chain Competitiveness Programme

include local value chain linkages and associated opportunities as well as

infrastructure and logistics. The DCC supports firms with the understanding of value chains through

benchmarking and best practice tours. Member firms also participated in cleaner production

initiatives to enhance competitiveness in ever increasing environmental and legal restrictions.

During 2012, this programme facilitated the following activities:

Firm-Level Benchmarking

The DCC utilises benchmarking to outline the competitiveness of member firms and indicate the

strategic and operational priority competitiveness issues of firms. This in turn forms the basis for

consulting/coaching support that is provided to the firm by the DCC to enable it to make

improvements. During 2012, the DCC provided member firms with firm-level benchmarks as well as

customer benchmarks.

Supply Chain Management

Logistics costs contribute significantly to the overall cost of products supplied by local

manufacturers. Key port, rail and road infrastructure and services have consequently been identified

as priority areas. The cluster continuously stays abreast of key infrastructure projects and logistics

developments and conducts information sharing sessions with member firms. Updates have been

presented to the cluster on the Durban South Port and the Plan for the Intermodal Logistics Hub at

Cato Ridge.

In June 2013, the DCC hosted the launch of the 9th State of Logistics Survey which is an annual,

independent study presenting recommendations on South Africa’s logistics sector.

Carbon Footprint Assessments

In 2012, the South African Treasury released a proposed carbon tax policy paper. This tax is likely to

be implemented as soon as 2015, and firms will be taxed on their

greenhouse gas emissions. The cluster recognises that it is important for

firms to be aware of their current carbon emissions so that they are

equipped for the carbon tax. The DCC provided firms with carbon

footprint assessments, calculating greenhouse gas emissions and

supplying a report to each firm to indicate emissions and the possible

tax the firm will have to comply to. The cluster also provided an

information sharing session on carbon footprinting with an expert in the field. This expert, Mr Kevin

James from Global Carbon Exchange provided firms with an understanding of the carbon tax and the

effect this will have on the chemicals sector.

World Class Manufacturing: Best Practice Tours

The DCC initiated a World Class Manufacturing (WCM) study programme in 2012. The study

programme consisted of tours focused on lean methodologies such as 5S, continuous improvement

and visual management. Member firms visited various firms from different sectors, including food &

beverages, clothing & textiles and automotive.

Skills Development Programme

The chemicals industry requires access to a suitable quality and quantity of

skills that are central to enabling chemicals sector growth. The objective of

the skills development programme is to focus on attracting, developing and

retaining scarce skills in particular. During 2012, this programme facilitated

the following activities:

Skills Development

The DCC arranged student tours to member firms in 2012, exposing students to the chemicals

manufacturing environment. The cluster represented its member firms at career days at various

tertiary institutions where students were given an opportunity to gain additional knowledge on the

chemicals industry in KwaZulu-Natal and the opportunities that lie within them.

Wellness Programme

While many cluster members coordinate HIV/AIDS and Wellness initiatives of their own, the cluster

provides an opportunity to supplement these with additional interventions so as to enable each

participating company the opportunity to establish a more comprehensive HIV/AIDS and Wellness

programme at minimal cost. The programme currently comprises but is not limited to champion

training, peer educator training, condom distribution, awareness campaigns and HIV Counselling and

Testing (HCT). A highly successful Peer Educator training session was run for member firms in 2013

which resulted in firms gaining additional knowledge on employee wellness and managing their

peers in the workplace.

Transformation Programme

Empowerment and transformation is a challenge that affects all industries in

South Africa. It is vital that companies perform strongly in this area, as

Broad-Based Black Economic Empowerment (B-BBEE) has an impact in

decision making and strategies in the chemicals industry. Innovation and the

incubation of new enterprises present itself as an opportunity, as they provide the chemicals sector

with a growth opportunity. These opportunities may be aligned with a move into higher value

adding market segments and emerging industry trends such as green technology. During 2012, this

programme facilitated the following activities:

B-BBEE Best Practice Support

South African industries are required to be accredited B-BBEE firms. B-BBEE is a priority for member

firms as it impacts on their business strategy. The B-BBEE Act introduces the B-BBEE Balanced

Scorecard that sets indicators for measuring B-BBEE. Indicators are weighted to reflect relevant

importance placed on each component. The DCC hosts information sessions which consists of an

expert exploring B-BBEE components and assists firms with calculating and understanding the

scorecard. The B-BBEE Codes of good practice were amended, and released for public comment

towards the latter part of 2012. These amended codes will impact firms significantly as elements on

the scorecards are altered.

Small Medium Enterprise (SME) Development

Chemical SMEs in South Africa face a number of challenges, including high costs of capital, a difficult

regulatory environment, shortage of skills, difficult access to markets, an inflexible labour market

and increasing competition. All the above factors make it difficult for SMEs to be competitive and

hence grow in the chemical market in South Africa. There is an opportunity for chemical SMEs to be

the main driving force behind the growth of the industry, as seen in Europe. SMEs in South Africa

however face many difficulties in this industry. The DCC recognised this challenge within the

chemicals industry and embarked on a second SME Chemicals Manufacturer project in 2012 with the

Chemicals Industries Education and Training Authority (CHIETA). The aim of the project is to support

the competitiveness of struggling manufacturing SMEs so that they become sustainable

manufacturers in the long term. The sustainable development of SMEs will broaden the supply pool

of the existing chemicals sector and provide the sector with enhanced supply chain competitiveness

and value chain flexibility.

The SMEs all undergo a preliminary business viability study which outlines the competitiveness

position of each SME and thereby identifying critical focus areas to ensure sustainability of the

business, as well as to identify areas that need to be focused on in order to secure world class

manufacturing standards into the future. Each SME receives coaching support based on the

recommendations from the business viability study. The interventions include the revision of

business plans, production flow, 5S, financial management and various lean philosophies.

008 – June 2012

Highlights for the year 2012/13

Carbon Footprint Assessments

The SA Carbon Tax has been proposed to be implemented in January 2015 where industry will need

to embark on carbon reporting in order to identify their exposure to this tax. Carbon footprint

assessments will provide firms with this reporting and encourage firms to reduce their carbon

footprint and ultimately carbon tax. The DCC have been mandated by the Value Chain

Competitiveness and Compliance Technical Steering Committee to provide Carbon Footprint

Assessments to member firms. A total of eleven firms are participating in the Carbon Footprint

Assessments that are being conducted.

World Class Manufacturing Tours

The Cluster initiated a World Class Manufacturing (WCM) study programme in 2013. The study

programme hosted a tour on 5-S, which is a key pillar of WCM. 5-S is a workplace organisation,

continuous improvement system for efficiency and effectiveness by identifying and storing items

used, maintaining the area and items, and sustaining the order. The 5-S process involves sorting,

straightening, shining, standardising and sustaining items in a workplace area.

The DCC visited Dyefin Textiles as a best practice example of 5-S. The tour commenced with a

presentation which identified aspects of 5-S that the attendees could recognise in the plant. Twelve

representatives from the DCC attended the tour and learnt valuable lessons from visiting Dyefin

Textiles which they could take back to their individual companies.

9th State of Logistics Launch

The State of Logistics™ survey is an annual, independent study presenting directed research and

recommendations on South Africa’s logistics sector. It delivers a message of action and notes which

indicates that South Africa must make great strides in addressing critical issues relating to the road

freight sector, shifting freight from road to rail, addressing rampant skills shortages and

misalignment in the logistics sector. The State of Logistics™ survey was launched in KZN on 20 June

2013 at Makaranga Garden Lodge in Kloof. Nadia Viljoen (Scientific Editor: CSIR), and Prof. Jan

Havenga (Professor: University of Stellenbosch) introduced the survey to attendees and provided an

overview of the important findings that resulted from the survey.

This year’s edition relates to:

The cost of logistics in South Africa

Modal trends for inland freight flow

Regional connectivity in SADC

The impact of deteriorating road conditions on logistics costs

The state of transport infrastructure planning in South Africa

Critical skills shortages in the logistics and supply chain industry

SME Incubation Programme

The Durban Chemicals Cluster (DCC) recognised the challenges within the chemicals industry for

small firms and embarked on SME Chemicals Manufacturer projects with the Chemicals Industries

Education and Training Authority (CHIETA) and Engen Petroleum. The aim of the projects are to

support the development of new SMEs in the chemicals manufacturing sector and support the

competitiveness of struggling manufacturing SMEs so that they become sustainable manufacturers

in the long term. The sustainable development of SMEs will broaden the supply pool of the existing

chemicals sector and provide the sector with enhanced supply chain competitiveness and value

chain flexibility. Each project had the purpose of developing a group of black owned SMEs situated

in Durban and surrounding areas. The DCC achieved this by implementing a multi-phase programme

that commenced with a business viability study to identify the gaps and interventions that are

required. The SMEs received business plan training, which was required according to the

recommendations from the business viability assessments. The SMEs also received training on

business management and 5S. The DCC, with the support of CHIETA, have embarked on a second

SME Incubation programme which will be identifying an additional ten SMEs and provide support to

the SMEs with the ultimate aim to support their development within the chemicals manufacturing

sector and support the competitiveness of struggling chemicals manufacturing SMEs so that they

become sustainable manufacturers in the long term.

Wellness Programme

The DCC hosted Peer Educator training for cluster members in 2013 in order to better equip

organisations with the knowledge required to assist and communicate with their peers on all

Wellness and HIV/AIDS related issues. Peer Education is an approach to health promotion, in which

employees are supported to promote health-enhancing changes amongst their peers. Peer

Educators offer HIV-related education, counselling and support to other employees in the

workplace.” This comprehensive two day training session was modified to also include Tuberculosis

which has become one of the greatest health challenges facing South Africa.

MCEP Assistance

MCEP is a Department of Trade and Industry incentive programme of which the objective is to

promote enterprise competitiveness and job retention within the manufacturing industry. The DCC

is assisting member firms to benefit from the Capital Investment portion of the programme, which

falls under the Production Incentive. The primary objective of this particular incentive is to support

the investment in capital equipment upgrading and expansions within the manufacturing sector that

will support not only the retention of existing jobs but also lead to the creation of new jobs. During

2012, the DCC assisted member firms with their MCEP applications to the value of R30 million for

capital upgrading.

Annual Financial Statements

Report on the Annual Financial Statements (AFS)

We have audited the annual financial statement of the Durban Chemicals Manufacturing Cluster,

which comprise the statement of financial position as at 30 June 2013, and the statement of

comprehensive income, statement of changes in equity and the statement of cash flows for the year

then ended, and a summary of significant accounting policies and other explanatory notes, and the

director’s report, as set out on pages 5 to 15.

Directors’ Responsibility for the Annual Financial Statements

The directors are responsible for the preparation and fair presentation of these annual financial

statements in accordance with International Financial Reporting Standards, and the requirements of

the Companies Act of South Africa, and for such internal control as directors determine is necessary

to enable the preparation of annual financial statements that are free from material misstatements,

whether due to fraud or error.

Auditors’ Responsibility

Our responsibility is to express an opinion on these annual financial statements based on our audit.

We conducted our audit in accordance with International Standards on Auditing. Those standards

require that we comply with ethical requirements and plan and perform the audit to obtain

reasonable assurance whether the annual financial statements are free from material misstatement.

An audit involves performing procedures to obtain audit evidence about the amounts and

disclosures in the annual financial statements. The procedures selected depend on auditors’

judgement, including the assessment of risks of material misstatement of the annual financial

statements, whether due to fraud or error. In making those risks assessments, the auditors consider

internal control relevant to the entity’s preparation and fair presentation of the annual financial

statement in order to design audit procedures that are appropriate in the circumstances, but not for

the purpose of expressing an opinion on the effectiveness of the entity’s internal control. An audit

also includes evaluating the appropriateness of accounting policies used and the reasonableness of

accounting estimates made by the management, as well as evaluating the overall presentation of

the annual financial statements.

We believe that the audit evidence we have obtained is sufficient and appropriate to provide a basis

for our audit opinion.

Opinion

In our opinion, the annual financial statements present fairly, in all material respects, the financial

position of Durban Chemicals Manufacturing Cluster as at 30 June 2013, and financial performance

and cash flows for the year then ended in accordance with International Financial Reporting

Standards, and the requirements of the Companies Act of South Africa.

PKF Durban

Practice Number: 906352E

CHARTERED ACCOUNTANTS (SOUTH AFRICA)

REGISTERED AUDITORS

30 JUNE 2013

Directors’ Report

The directors present their report for the year ended 30th June 2013.

Review of Activities

Main Business

The company is engaged in the provision of cluster-based development support to the chemical

manufacturing sector in Durban and surrounding areas and operates principally in South Africa. The

operating results and state of affairs of the company are fully set out in the attached annual financial

statements and do not, in our opinion require further comment.

Events After Reporting Date

The directors are not aware of any matter or circumstance arising since the end of the financial year.

Directors

The directors of the company during the year and to the date of this report are as follows:

R. J. Archer

D. S. Comrie

R. Govender

O. T. Maluleka

Auditors

PFK Durban will continue in office in accordance with Section 90 (6) of the Companies Act.

Durban Chemicals Manufacturing Cluster

2013 Annual Report

STATEMENT OF FINANCIAL POSITION

Figures in Rand Notes 2013

R

2012

R

Assets

Current Assets

Trade and other receivables 2 369 874 483 783

Cash and cash equivalents 3 1 064 894 125 602

Total Assets 1 434 768 609 385

Equity And Liabilities

Equity

Retained income 137 642 144 842

Liabilities

Current Liabilities

Trade and other payables 4 598 505 313 660

Income received in advance 5 698 621 150 883

1 297 126 464 543

Total Equity and Liabilities 1 434 768 609 385

STATEMENT OF COMPREHENSIVE

Notes 2013

R

2012

R

Revenue 2 243 533 1 879 629

Operating expenses (2 259 895) (1 757 966)

Operating profit (16 362) 121 663

Investment revenue 9 162 288

Profit for the year -7 200 121 951

Other comprehensive income - -

Total comprehensive income -7 200 121 951

STATEMENT OF CHANGES IN EQUITY

Retained

income

R

Total equity

R

Balance at July 2011 22 891 22 891

Changes in equity

Total comprehensive income for the year 121 951 121 951

Balance at 01 July 2012 144 842 144 842

Changes in equity

Total comprehensive income for the year -7, 200 -

Balance at 30 June 2013 137 642 144 842

STATEMENT OF CASH FLOWS

Notes 2013

R

2012

R

Cash flows from operating activities

Cash used in operations 7 930 130 (225 858)

Interest income 9 162 288

Net cash from operating activities 939 292 (225 570)

Total cash movement for the year 939 292 (225 570)

Cash and cash equivalents at the beginning of the year 125 602 351 172

Total cash and cash equivalents at the end of the year 1 064 894 125 602

Member listing as of June 2013

Company name

Telephone

Facsimile

Website

Company name

Air Liquide

031 902 7807

031 902 8081

www.airliquide.co.za

Arkema Resins

Telephone 031 910 3500

Facsimile 031 902 9145

Website www.arkema.co.za

Company name

Telephone

Facsimile

Website

BASF

031 765 2249

031 765 8231

www.basf-cc.co.za

Company name Buckman Laboratories

Telephone 031 736 8800

Facsimile 031 736 1593

Website www.buckman.com

Company name

ChemSpec Paint

Telephone 032 541 8600

Facsimile 032 541 8616

Website www.chemspec.co.za

Company name Dow Advanced Materials

Telephone 031 716 5900

Facsimile 031 716 5965

Website www.dow.com

Company name Gold Reef Chemicals

Telephone 031 910 7500

Facsimile 031 910 7510

Website www.gold-reef.co.za

Company name H&R South Africa

Telephone 031 466 8700

Facsimile 031 466 87 16/7

Website www.hur.com

Company name Hosaf

Telephone 031 450 4169

Facsimile 031 468 4550

Website www.hosaf.co.za

Company name

Huntsman Tioxide

Telephone 031 910 3611

Facsimile 031 942 4191

Website www.huntsman.com

Company name

Isegen SA

Telephone 031 913 3200

Facsimile 031 902 5636

Website www.isegen.co.za

Company name

Telephone

Facsimile

Website

Company Name

Telephone

Improchem

031 949 8200

0861 064 654

www.improchem.co.za

Isncomo Trading Enterprise

073 222 5850

Company name KZN Oils

Telephone 031 570 0550

Facsimile 031 570 0522

Website

Company name

Telephone

www.kznoils.co.za

Lungelo General Dealers

084 283 3816

Company name

Telephone

Facsimile

Website

Company name

Melton Adhesives

031 500 5575

031 500 5576

http://www.melton.co.za

NCS Resins

Telephone 031 713 0600

Facsimile 031 705 8395

Website www.ncsresins.com

Company name Paperkem

Telephone 031 713 3200

Facsimile 031 713 3222

Website www.bimkemi.com

Company name Protea Chemicals

Telephone 031 468 5424

Facsimile 031 468 5429

Website

www.omnia.co.za

Company name Qolotha Cleaning and Manufacturing

Telephone 073 834 0522

Company name Sancryl Chemicals

Telephone 031 902 1422

Facsimile 031 902 1423

Website www.sunchem.co.za

Company name

Scott Bader

Telephone 031 736 8500

Facsimile 031 736 8511

Website www.scottbader.com

Company name SI Group

Telephone 031 910 7950

Facsimile 031 910 7960

Website www.siigroup.com

Company name SIKA South Africa

Telephone 031 792 6500

Facsimile 031 700 1718

Website www.sika.co.za

Company name

Synthomer

Telephone 031 480 8100

Facsimile 031 480 8298

Website www.synthomer.com

Company name

Telephone

Facsimile

Website

Company name

Steritech

031 702 7656

031 702 5576

www.steritech.co.za

Vopak Terminal Durban

Telephone 031 466 9200

Facsimile 031 466 9272

Website www.vopak.com

Notes

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

Contact Information

Durban Chemicals Cluster

Tel: +27 (0) 31 764 6100

Fax: +27 (0) 86 607 4510

Email: [email protected]

Unit 3 St Heliers Office Park

Valdean Rd

Gillitts

3610

South Africa

PostNet Suite 10139

Private Bag X7005

Hillcrest

3650

South Africa

www.durbanchemicalscluster.org.za