DAVIT ARM - Sayfa...6 or an tecncal eres lease call or ace lne on 0845 241 9102 AVIATOR DAVIT ARM...

Transcript of DAVIT ARM - Sayfa...6 or an tecncal eres lease call or ace lne on 0845 241 9102 AVIATOR DAVIT ARM...

REVISION NO: 002PRODUCT DATA SHEET REPORT NO: 024

PRODUCT CODE: DA300

DAVIT ARM

024

For any technical queries please call our advice line on 0845 241 9102 3

AVIATOR DAVIT ARM

024

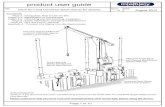

PRODUCT DESCRIPTION:The Aviator Davit Arm is designed to beremovable and to be used together with thepermanent Davit base plates. They are designedfor lifting and lowering personnel and materials. The hook on the end of the arm allows abseil and lifting ropes to extend over the roof edge or balustrading. The Davit base can also be used to anchor a personal fall arrest system when the user is being lifted and lowered. It is essential when designing rope access to ensure at least 2 abseil rope connection points (one for working line and the other for safety line) are available to connect to at any one time. Davit arms, up to 1m, are manufactured in aluminium section to ensure they are light weight and easily transportable. The davit arm is designed to fold to facilitate storage and transport.

In use

The Standard DA300 davit arm can be manufactured up to a height of 1500mm with a maximum reach of 850mm. It weighs approximately 15Kg. The arm can be locked into 2 positions – 135 degrees and 90 degrees off the vertical arm. The locking pin and clip are permanently fixed to the Davit arm to prevent them being mislaid.

Folded not in use

Removable

1.25m

0.8m

For any technical queries please call our advice line on 0845 241 91024

AVIATOR DAVIT ARM

024

900

SWL136Kg

For personnel

1350 SWL272Kg

For materials

only

Pulley

Handwinch

The DA300 Davit arm has a maximum safe working load of 136kg. This is a greater than 10:1 safety factor for personnel use and a greater than 5:1 safety factor for materials (272Kg). In the event of an emergency or for rescue situations 2 persons can use the Davit arm. The Davit arm can be supplied with a hand winch and pulley for material lifting. The Aviator Davit arms are designed and manufactured to fit into the Aviator Davit base plates. Never use the Aviator arm on any other make or model of Davit base or the system warranty will be invalidated

For any technical queries please call our advice line on 0845 241 9102 5

AVIATOR DAVIT ARM

024

MATERIAL SPECIFICATION:

Yield 275 N/mm² C 0.15 – 0.26; Si < 0.35; Mn < 1.5; P < 0.035;

S < 0.040; Mo 0.4 – 0.6.

Young’s Modulus of Elasticity 200 x 103 MPa at 20 °C

Density 7.87 g/cm3 at 20 °C

Coefficient of Thermal Expansion Low-Carbon/HSLAS: 12.4 μm/m/°C in 20 °C to 100 °C range

I-F Steel: 12.9 μm/m/°C in 20 °C to 100 °C range

Thermal Conductivity Low-Carbon/HSLAS: 89 W/m°C at 20°C I-F Steel: 93 W/m°C

at 20°C

Specific Heat 481 J/kg/°C in 50 °C to 100 °C range

Electrical Resistivity 0.142 μΩ•m at 20 °C

Davit armAluminium 0.50 - 0.75 Si, Max 0.35, Fe 0.40 - 0.70 MgTensile strength 186MPa Yield strength 110MPa

Component parts and fixingsStainless Steel - Grade 304 (UNS S30400)Fe, <0.08% C, 17.5-20% Cr, 8-11% Ni, <2% Mn, <1% Si, <0.045% P, <0.03% Stainless Steel

Brackets - galvanised steel

Galvanised hand winch

Folding joint

Stainless steel rope guides

Stainless steel fixings

Aluminium arm

Aluminium locating spiggot

For any technical queries please call our advice line on 0845 241 91026

AVIATOR DAVIT ARM

024

Maintenance to be in accordance with SIMS standards. (details available on request)

Maintenance to be carried out at time of yearly inspection.

Contact Sayfa Systems to arrange system maintenance.

TRAINING REQUIREMENTS:All personnel who use the Aviator system should have attended a Sayfa Systems Ltd, Aviator users course.

Courses are available from Sayfa Systems UK Ltd.

Courses cover the use of all Aviator and Payload products, the legal and practical side of the Working at Height legislation - 2005 and how to use and carry out safety checks on harnesses and all necessary PPE equipment.

INSPECTION/MAINTENANCE/TRAINING

INSPECTION ROUTINE:All systems to be inspected at least every 12 months from date of installation.

In harsh environments all systems to be inspected at least every 3 months.

Inspections must be carried out by approved Aviator engineers.

Inspections must be approved to SIMS (Safety Inspection and Maintenance Service) standards.

All inspections to be carried out to EN795:2012 and BS 7883:2005 and WAHSA (inspection of eyebolts) requirements for safety line and anchor points.

All inspections to be carried out to EN364 requirements for personal protective equipment.

Contact Sayfa Systems to arrange inspections.

MAINTENANCE SCHEDULE:All maintenance to be carried out by approved Aviator engineers. Maintenance to be in accordance with Sayfa Systems UK (manufacturer) guidelines and recommendations.

In harsh environments all systems to be inspected at least every 3 months.

12 Months

From date of installation

3Months

in harsh environments

d

12 Months

From date of installation

6Months

in harsh environments

d

CERTIFICATEOF

OPERATIVE INSTRUCTIONAL TECHNIQUES AND

WORKING AT HEIGHT SAFETY

In recognition of successful completion of training for the installation and assembly, use, handling and safety checks of:-

Aviator Safety Line Systems nAviator Mobile Anchors

Payload Access Ladder Systems

Payload Handrail Systems

Aviator PPE n

To:

........................................................................

Location of Training:

............................................................................0......................................................................

Certificate Number:

........................................................................

Name of trainee: ...................................................... Signed by trainee: .............................................

Inductor’s name: Adrian Stutterheim .................. Signed: Adrian Stutterheim ................................

Date of Training: 00 January 1900 .......................

For any technical queries please call our advice line on 0845 241 9102 7

AVIATOR DAVIT ARM

024

OPERATING AND DESIGN STANDARDS:Eurocodes are designated by EN

British standards are designated by BS• BS/EN 795• Steel – EN10 113 and EN 10 025• BS 7985: 2013 Code of Practice for Rope Access

Methods for industrial purposes• The lifting operations and lifting equipment

regulations 1998• LOLER REG. 5(1) (a and b) for design• LOLER REG. 7(a, d and e) for marking• LOLER REG. 9 (1, 2 , 3 a and b) for examination• ISO 9001:2008, ISO14001:2004, BS OHSAS

18001:2007• Management of health and safety at work

regulations 1999 (MHSWR) ref.2• Work at height regulations 2005 (Ref 7)• Work at height (amended) regulations 2007 (Ref.8)

WAHR• BS ISO 22846 - 2 2012 Personal Equipment for

protection against falls code of practice• BS ISO 22846 - 1 : 2003 Personal Equipment for

protection against falls Fundamental principles for a system of work

• Provision and use of work equipment regulations 1999 PUWER 98 (Ref.5)

• The work at height safety association WAHSA- guidance on inspecting eyebolts for personal fall protection purposes

✔

BS ENISO

Standards

The company operates to the following standards

Typical connection loads (Maximum SWL 136kg for single user with a factor of safety greater than 10:1 with maximum davit arm cantilever of 0.8m)

Note: For guidelines only to be checked by Chief Engineer

Table of bracket moments

12kN for 800mm arm

15kN for 1000mm arm

18kN for 1200mm arm

22.5kN for 1500mm arm

In Use

ULS15kN

For any technical queries please call our advice line on 0845 241 91028

AVIATOR DAVIT ARM

024

COMPONENT PART DETAILS:Davit arm personnel use DA300 BIM No: SpecEquip_RfSftySymDvtArm_SayfaSystems_DA300_

M3_G2

Davit arm materials lifting DA400 BIM No: SpecEquip_RfSftySymDvtArm_SayfaSystems_DA400_

M3_G2

Winch Bracket DAWB01BIM No: SpecEquip_RfSftySymDvtArmWnchBkt_SayfaSystems_

DAWB01_M3_G2

Material Lifting Folding Aluminium Davit Arm DA500

1

1

2

2

3

3

4

4

5

5

6

6

A A

B B

C C

D D

Folding Davit Arm

DA500

Mark.S CS 13/04/2017

D

Designed by Checked by Approved by Date

1 / 7 Edition Sheet

Date

DA500Material Lifting Folding Aluminium

Davit Arm

Portable

Folded

135 Degrees

90 Degrees

R T

1

1

2

2

3

3

4

4

5

5

6

6

A A

B B

C C

D D

Folding Davit Arm

DA300

Mark.S MW 10/06/2015

B

Designed by Checked by Approved by Date

1 / 4 Edition Sheet

Date

DA300Single User Folding Aluminium

Davit Arm

Portable

Folded

135 Degrees

90 Degrees

R T

1

1

2

2

3

3

4

4

5

5

6

6

A A

B B

C C

D D

Folding Davit Arm

DA300

Mark.S MW 10/06/2015

B

Designed by Checked by Approved by Date

1 / 4 Edition Sheet

Date

DA300Single User Folding Aluminium

Davit Arm

Portab

le

Fold

ed

135

Degr

ees

90 D

egre

es

R

T

1 1

2 2

3 3

4 4

5 5

6 6

AA

BB

CC

DD

Fold

ing

Davit

Arm

DA30

0

Mar

k.S

MW

10/0

6/20

15

B

Desig

ned

byCh

ecke

d by

Appr

oved

by

Date

1 / 4

Ed

ition

Shee

t

Date

DA3

00Si

ngle

Use

r Fol

ding

Alu

min

ium

D

avit

Arm 135 Degrees

Portable

90 Degrees

Folded

1

1

2

2

3

3

4

4

5

5

6

6

A A

B B

C C

D D

Folding Davit Arm

DA400

Mark.S MW 10/06/2015

C

Designed by Checked by Approved by Date

1 / 7 Edition Sheet

Date

DA400Material Lifting Folding Aluminium

Davit Arm

135 Degrees

Portable

90 Degrees

Folded

1

1

2

2

3

3

4

4

5

5

6

6

A A

B B

C C

D D

Folding Davit Arm

DA400

Mark.S MW 10/06/2015

C

Designed by Checked by Approved by Date

1 / 7 Edition Sheet

Date

DA400Material Lifting Folding Aluminium

Davit Arm

135 Degrees

Portable

90 Degrees

Folded

1

1

2

2

3

3

4

4

5

5

6

6

A A

B B

C C

D D

Folding Davit Arm

DA400

Mark.S MW 10/06/2015

C

Designed by Checked by Approved by Date

1 / 7 Edition Sheet

Date

DA400Material Lifting Folding Aluminium

Davit Arm

135

Deg

rees

Portable

90 D

egre

es

Fold

ed

1 1

2 2

3 3

4 4

5 5

6 6

AA

BB

CC

DD

Fold

ing

Dav

it Ar

m

DA4

00

Mar

k.S

MW

10/0

6/20

15

C

Des

igne

d by

Chec

ked

byAp

prov

ed b

yD

ate

1 /

7 Ed

ition

Shee

t

Dat

e

DA

400

Mat

eria

l Lif

ting

Fol

ding

Alu

min

ium

D

avit

Arm

Portable

Folded

135 Degrees

90 Degrees

R T

1

1

2

2

3

3

4

4

5

5

6

6

A A

B B

C C

D D

Folding Davit Arm

DA300

Mark.S MW 10/06/2015

B

Designed by Checked by Approved by Date

1 / 4 Edition Sheet

Date

DA300Single User Folding Aluminium

Davit Arm

Portable

Folded

135 Degrees

90 Degrees

R T

1

1

2

2

3

3

4

4

5

5

6

6

A A

B B

C C

D D

Folding Davit Arm

DA300

Mark.S MW 10/06/2015

B

Designed by Checked by Approved by Date

1 / 4 Edition Sheet

Date

DA300Single User Folding Aluminium

Davit Arm

1

1

2

2

3

3

4

4

5

5

6

6

A A

B B

C C

D D

Folding Davit Arm

DA500

Mark.S CS 13/04/2017

D

Designed by Checked by Approved by Date

1 / 7 Edition Sheet

Date

DA500Material Lifting Folding Aluminium

Davit Arm

For any technical queries please call our advice line on 0845 241 9102 9

AVIATOR DAVIT ARM

024

Aviator™ Da300/Da400 Fixed To Cast Concrete Slab With Parapet Wall

MOUNTING HOLESTO SECURE DAVIT ARMTO DAVIT BASE WITH 8M16 BOLTS

8NR M16 BOLTS RESIN FIXEDINTO CONCRETE SLAB

PITCH POCKET WEATHERING(RECOMMENDED) BY ROOFINGCONTRACTOR

DB400GALVANIZED STEELBRACKET 150-350mm

DA300/400ALUMINUM FOLDING ARMWEIGHT 35kg Approximately

DAWDAVIT ARM WINCHONLY SUITABLE FOR USEWITH DA400 - MATERIALSLIFTING DAVIT ARM

· Bases to be located as indicated on theroof plan.

· Arm primarily used to gain access toexposed facades.

· Incorporates Aviator™ units and allSayfa Systems components required.

· Fixing details for Aviator™ units asindicated within layout.

· Structural Engineer to confirmsubstructure can wistand LSD12-15kN. SLD 4-6kN of post/davit.

System Details

Jubilee House

ShepshedLeicestershireLE12 9NHT:01509 502 155F:0845 130 4520www.sayfasystems.com

Unit 3, Gelders Hall Road

UNDER THE CDM REGULATIONS 2015, IF ANY ALTERATIONS ARE MADE TO THIS DRAWING THEN THE PERSON UNDERTAKING THESE CHANGES ASSUME THE ROLE OF THE DESIGNER, THEREFORE TAKING FULL CDM RESPONSIBILITY.

Drawing Symbols

THIS DRAWING IS PROTECTED BY COPYRIGHT AND THE INFORMATION HEREIN IS CONFIDENTIAL. THE DRAWING MAY NOT BE COPIED AND THE INFORMATION HEREIN MAY NOT BE USED OR DISCLOSED EXCEPT WITH THE WRITTEN PERMISSION OF SAYFA SYSTEMS ©

THIS DRAWING WAS CREATED INCONJUNCTION WITH N/A

DRAWING NO. N/A

DRAWING REVISIONS

REV BY DATE COMMENTS

A M.W 07/09/2015 Issued forinternal review

B C.S 26/06/2018 Part No.s added

Client:

Contract:

Project Title:

SAYFA SYSTEMS UKLIMITED

FIXING DETAILS

AVIATOR™ DA300/DA400FIXED TO CAST CONCRETESLAB WITH PARAPET WALL

Revision:

Drawn By:

Scale:

Date:

Checked By:

Job No:

DWG No:

Status:

Released By:

N/A

N/A

B

C.S

FOR DESIGN

1:12 @ A3

26/06/2018

M.S

For any technical queries please call our advice line on 0845 241 910210

AVIATOR DAVIT ARM

024

Aviator™ Da500 Davit Arm Fixed To Cast Concrete Slab With Parapet Wall

MOUNTING HOLESTO SECURE DAVIT ARMTO DAVIT BASE WITH 8M16 BOLTS

8NR M16 BOLTS RESIN FIXEDINTO CONCRETE SLAB

PITCH POCKET WEATHERING(RECOMMENDED) BY ROOFINGCONTRACTOR

DB400GALVANIZED STEELBRACKET 150-350mm

DA500ALUMINUM FOLDING ARMWEIGHT

DAWDAVIT ARM WINCH(OPTIONAL)

· Bases to be located as indicated on theroof plan.

· Arm primarily used to gain access toexposed facades.

· Incorporates Aviator™ units and allSayfa Systems components required.

· Fixing details for Aviator™ units asindicated within layout.

· Structural Engineer to confirmsubstructure can wistand LSD12-15kN. SLD 4-6kN of post/davit.

System Details

Jubilee House

ShepshedLeicestershireLE12 9NHT:01509 502 155F:0845 130 4520www.sayfasystems.com

Unit 3, Gelders Hall Road

UNDER THE CDM REGULATIONS 2015, IF ANY ALTERATIONS ARE MADE TO THIS DRAWING THEN THE PERSON UNDERTAKING THESE CHANGES ASSUME THE ROLE OF THE DESIGNER, THEREFORE TAKING FULL CDM RESPONSIBILITY.

Drawing Symbols

THIS DRAWING IS PROTECTED BY COPYRIGHT AND THE INFORMATION HEREIN IS CONFIDENTIAL. THE DRAWING MAY NOT BE COPIED AND THE INFORMATION HEREIN MAY NOT BE USED OR DISCLOSED EXCEPT WITH THE WRITTEN PERMISSION OF SAYFA SYSTEMS ©

THIS DRAWING WAS CREATED INCONJUNCTION WITH N/A

DRAWING NO. N/A

DRAWING REVISIONS

REV BY DATE COMMENTS

A C.S 26/06/2018 Issued forinformation

Client:

Contract:

Project Title:

SAYFA SYSTEMS UKLIMITED

FIXING DETAILS

AVIATOR™ DA500 DAVIT ARMFIXED TO CAST CONCRETESLAB WITH PARAPET WALL

Revision:

Drawn By:

Scale:

Date:

Checked By:

Job No:

DWG No:

Status:

Released By:

N/A

N/A

A

C.S

FOR DESIGN

1:12 @ A3

26/06/2018

M.S

Sayfa Systems UK LtdJubilee HouseNo. 3 Gelders Hall RoadShepshed, LoughboroughLeicestershire LE12 9NH

T: 0845 241 9102F: 0845 130 4520email: [email protected]

Ref: 125/024-11/18