David Johnson

description

Transcript of David Johnson

11David Johnson

Challenges Associated with 8 GeV H- Transport and Injection for Fermilab Project-X

David JohnsonAccelerator Physics Center

Fermilab

22David Johnson

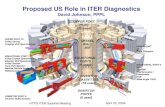

Project X IntroductionProject X Introduction

Project X is a high intensity proton facility conceived to support a world-Project X is a high intensity proton facility conceived to support a world-leading program in neutrino and flavor physics over the next two leading program in neutrino and flavor physics over the next two decades at Fermilab. Project X is an integral part of the Fermilab decades at Fermilab. Project X is an integral part of the Fermilab Roadmap as described in the Fermilab Steering Group Report *Roadmap as described in the Fermilab Steering Group Report *

http://www.fnal.gov/pub/directorate/steering/index.shtml

*From Project X R&D plan

325 Mhz front end1.3 Ghz linac8GeV H- transport 8GeV H- injectionRecycler (re)configRecycler extractionMI upgradesCivil ConstructionUtilities & Controls

360 kW @ 8 GeVUpgradeable 2 MW @ 8 GeV

33David Johnson

Project X Layout

8 GeV Linac

1 km Transfer line

MI / RecyclerTevatron

RR-10 Injection

44David Johnson

Project X Components

The base line specifications call for an 8 GeV H- linac capable of running at 5 Hz The base line specifications call for an 8 GeV H- linac capable of running at 5 Hz with a pulse length of 1 ms and an average beam current of 9 mA -> leads to a beam with a pulse length of 1 ms and an average beam current of 9 mA -> leads to a beam power of 360 kW out of the linac with 200 kW available for 8 GeV Physics program.power of 360 kW out of the linac with 200 kW available for 8 GeV Physics program.

delivers 5.6E13/pulse at 72 kJoules/pulse -> 2.8E14/sec for 360 kWdelivers 5.6E13/pulse at 72 kJoules/pulse -> 2.8E14/sec for 360 kW A transport line to A transport line to cleanlycleanly transport the H- and prepare for injection into the transport the H- and prepare for injection into the RecyclerRecycler

Average activation level on beam pipe < 20 mrem/hr (i.e. 0.05 w/meter)Average activation level on beam pipe < 20 mrem/hr (i.e. 0.05 w/meter)Transport efficiency > 99.99%Transport efficiency > 99.99%

Modification of the Recycler lattice to permit multi-turn injection and accumulation Modification of the Recycler lattice to permit multi-turn injection and accumulation over multiple linac cycles. over multiple linac cycles.

For neutrino program: MI cycle of 1.4 sec -> 3 linac pulses ->1.7E14 for 154 kW For neutrino program: MI cycle of 1.4 sec -> 3 linac pulses ->1.7E14 for 154 kW at 8 GeV and 2.3MW at 120 GeV (4 linac pulses left over i.e. 200 kW @ 8 GeV)at 8 GeV and 2.3MW at 120 GeV (4 linac pulses left over i.e. 200 kW @ 8 GeV)

Single turn Transfer to the Main InjectorSingle turn Transfer to the Main InjectorExtraction from the Recycler for an 8 GeV experimental programExtraction from the Recycler for an 8 GeV experimental programModifications to Main Injector for high intensity accelerationModifications to Main Injector for high intensity accelerationUpgrade path for 2 MW beam power at 8 GeV (linac current, pulse length, rep rate) Upgrade path for 2 MW beam power at 8 GeV (linac current, pulse length, rep rate) Although this is not in the base line design…. Although this is not in the base line design….

55David Johnson

Uncertainties

•With the recent comments from the Fermilab Accelerator With the recent comments from the Fermilab Accelerator Advisory Committee*, a renewed interest in increased linac Advisory Committee*, a renewed interest in increased linac current and variations in SC linac cavity and cryo-module current and variations in SC linac cavity and cryo-module design have arisen. The impact of this is an uncertainty of design have arisen. The impact of this is an uncertainty of which accelerator will be used for injection: directly into the MI which accelerator will be used for injection: directly into the MI or use the Recycler as an accumulator. This has a direct or use the Recycler as an accumulator. This has a direct impact on the design of collimation systems, injection impact on the design of collimation systems, injection systems, the injection absorber, and ring modifications. systems, the injection absorber, and ring modifications.

* “Synergy with ILC needs to be re-evaluated. There are limitations due to ILC adoption – may be detrimental if needed for a neutrino/muon facility later on --- that must be articulated: peak current, repetition rate, pulse length,…..”• This uncertainty requires us to approach the design as an This uncertainty requires us to approach the design as an

exercise of risk analysis on the design choices of linac cavity exercise of risk analysis on the design choices of linac cavity design / Recycler vs MI injection. design / Recycler vs MI injection.

66David Johnson

Transport /Injection Design ChallengesTransport /Injection Design Challenges

• The number one challenge control and mitigation of The number one challenge control and mitigation of uncontrolled beam loss due to:uncontrolled beam loss due to:– Single particle loss mechanisms in the transport line:Single particle loss mechanisms in the transport line:

• Photodetachment of H- due to interaction with Black-body photonsPhotodetachment of H- due to interaction with Black-body photons• Lorentz stripping of weakly bound electronLorentz stripping of weakly bound electron• H- stripping by the residual gas in the beam pipeH- stripping by the residual gas in the beam pipe

– Multi-particle beam loss Multi-particle beam loss • Controlled (Controlled (halohalo & momentum collimation) & momentum collimation)• Un-controlled (alignment, aperture, orbit and lattice control)Un-controlled (alignment, aperture, orbit and lattice control)

• The other number one challenge are injection (foil) issuesThe other number one challenge are injection (foil) issues– Uncontrolled losses in the injection regionUncontrolled losses in the injection region due injected and due injected and

circulating ion interaction with the stripping foilcirculating ion interaction with the stripping foil– Stripping EfficiencyStripping Efficiency– Collection & Collection & disposal of waste beamdisposal of waste beam (neutrals & H- missing foil) (neutrals & H- missing foil) – Foil LifetimeFoil Lifetime

• Engineering Design issuesEngineering Design issues– Absorbers, ring chicane & painting magnets (& ps), foil changer & Absorbers, ring chicane & painting magnets (& ps), foil changer &

e-catcher, cryo-shield, etc.e-catcher, cryo-shield, etc.

77David Johnson

Current FY08 R & D PlanCurrent FY08 R & D Plan

A Project X R&D plan* was established last January although no funds A Project X R&D plan* was established last January although no funds were available for significant implementation. were available for significant implementation. With 2008 budget cuts restores and a private donation, activity on the With 2008 budget cuts restores and a private donation, activity on the R&D plan has resumed and CD0 planning has (re)started.R&D plan has resumed and CD0 planning has (re)started.Although we’ve been down this road before, we can/will build upon Although we’ve been down this road before, we can/will build upon previous work done at other facilities (c.f. SNS, BNL, JPARC, TRIUMPH, previous work done at other facilities (c.f. SNS, BNL, JPARC, TRIUMPH, LANL, etc.) as well as FNAL. LANL, etc.) as well as FNAL.

* Available on Project X web site: http://projectx.fnal.gov/

Create a viable Recycler injection straight section and transport line interface to the injection straight section and injection absorber. Integrate solutions with the new Recycler ring lattice. Initialize simulations for transverse phase space painting.Revise Proton Driver Injection absorber design for Project X beam parameters.Evaluate the stripping efficiency, losses, impact on circulating beam, and technological feasibility of carbon foil stripping and laser stripping techniques for 98% to 99% stripping efficiency utilizing Project X beam parameters.Begin Conceptual Design of transverse collimation absorbers

88David Johnson

Black Body Stripping Black Body Stripping

The issue of potential photodetachment of HThe issue of potential photodetachment of H-- due to black body radiation was due to black body radiation was raised prior to 2004 Mini-workshop on H- transport and injection by C. Hill and H. raised prior to 2004 Mini-workshop on H- transport and injection by C. Hill and H. Bryant and further discussed at the workshop (with potential mitigation options).Bryant and further discussed at the workshop (with potential mitigation options).Interior of the beam pipe emits blackbody radiation with a spectral energy density Interior of the beam pipe emits blackbody radiation with a spectral energy density of thermal photons per unit volumeof thermal photons per unit volume

Black Body Spectrum and H- Photodetachment Cross Section

0.0

0.5

1.0

1.5

2.0

2.5

3.0

3.5

4.0

0 0.5 1 1.5 2 2.5 3 3.5 4 4.5 5

Photon Energy [eV]

Sp

ectr

al D

ensi

ty

0.0

1.0

2.0

3.0

4.0

5.0

6.0

7.0

8.0

Ph

oto

det

ach

me

nt

cro

ss s

ecti

on

300K in lab frame

300K 1 GeV H-

300K 4 GeV H-

300K 8 GeV H-

H- Photodetachment Cross Section

When this Doppler When this Doppler shifted spectrum of shifted spectrum of thermal photons thermal photons overlaps the overlaps the photodetachment photodetachment cross section of cross section of moving H- ions, the moving H- ions, the photodetachment rate photodetachment rate becomes non-becomes non-negligible.negligible.

99David Johnson

Black Body Stripping

Loss Rate vs Beam Pipe Temperature

1.00E-13

1.00E-12

1.00E-11

1.00E-10

1.00E-09

1.00E-08

1.00E-07

1.00E-06

1.00E-05

0 100 200 300 400 500 600

Beam pipe Temperature [K]

Fra

cti

on

al b

ea

m lo

ss

[p

er

me

ter]

8 GeV Prj X

4 GeV (PS2)

1 GeV SNS

• Loss rate is 7.8x10Loss rate is 7.8x10-7-7/meter /meter which is which is 0.288 Watts/m0.288 Watts/m•Loss rate is 2.6x10Loss rate is 2.6x10-7-7/meter /meter •Reducing the internal beam Reducing the internal beam pipe temperature to 77pipe temperature to 77ooK with a K with a beam shield lowers the loss beam shield lowers the loss rate at 8 GeV to 1.9x10rate at 8 GeV to 1.9x10-10-10/meter /meter or or 7x107x10-5 -5 Watts/m Watts/m ! !

Calculations of the photodetachment rate and fractional beam loss Calculations of the photodetachment rate and fractional beam loss have been reported by Chris Hill (Fermilab) and H.C. Bryant (UNM) and have been reported by Chris Hill (Fermilab) and H.C. Bryant (UNM) and replicated by J.-P. Carneiro for implementation in the beam dynamics replicated by J.-P. Carneiro for implementation in the beam dynamics code TRACK.code TRACK.

1010David Johnson

Lorentz StrippingLorentz Stripping

A relativistic H- ion moving through a transverse magnetic field is subject to a rest A relativistic H- ion moving through a transverse magnetic field is subject to a rest frame electric field given by E= frame electric field given by E= c) B. c) B. Lifetime in the rest frame* is a function of the electric field and can be espressed Lifetime in the rest frame* is a function of the electric field and can be espressed by by = (A/E) exp(B/E). The loss = (A/E) exp(B/E). The loss raterate [per meter] is then 1/ [per meter] is then 1/((c)c) *Scherk (1978)*Scherk (1978)

The coefficients A and B The coefficients A and B are fctn of electron affinity*are fctn of electron affinity*Used the parameters for A Used the parameters for A and B obtained from fitting and B obtained from fitting P1 parameterization of P1 parameterization of Keating (i.e.)Keating (i.e.)

A= 3.073x10A= 3.073x10-6-6 s V/m s V/mB=4.414x10B=4.414x1099 V/m V/m

By selecting dipole fields By selecting dipole fields ~480G for main dipoles the ~480G for main dipoles the loss rate is negligible.loss rate is negligible.

Loss rate per meter at 8 GeV1.E-16

1.E-14

1.E-12

1.E-10

1.E-08

1.E-06

1.E-04

1.E-02

1.E+00

1.E+02

0.50 1.50 2.50 3.50 4.50 5.50 6.50

Electric Field [MV/cm]

Lo

ss

Ra

te p

er

me

ter 480 Gauss Dipole Field

measurements reported by Keating

580 G

1111David Johnson

Residual Gas Stripping Loss Summary

• The loss rate [per meter] of the H- by residual gas molecules is proportional to the molecular density and the ionization cross section dmi for i molecules.•The cross section decreases with energy proportional to -2 •Vacuum levels are expected to by ~ 1E-8 in transport line leading to loss rate of a few E-8…

An average residual dose rate < 20 mrem/hr on beam pipe requires a beam loss rate of < 0.05 watt/meter*

X2 > X28< X1.7<

loss mechanism

360 kW 360 kW with shield 2.1 MW with shield

[m-1] [w/m] [m-1] [w/m] [m-1] [w/m]

Black body (@300K) 8.00E-07 1.06E-01 1.90E-10 2.51E-05 1.90E-10 4.10E-04

Residual Gas (A150 10-8 torr) 1.30E-08 1.72E-03 1.30E-08 1.72E-03 1.30E-08 2.81E-02

Magnetic (500 G) 1.30E-10 1.72E-05 1.30E-10 1.72E-05 1.30E-10 2.81E-04

Total 8.13E-07 1.07E-01 1.33E-08 1.76E-03 1.33E-08 2.88E-02

1212David Johnson

Challenges for transverse collimation are:Challenges for transverse collimation are: to design a system safely remove large amplitude halo (depend on linac to design a system safely remove large amplitude halo (depend on linac current)current) to design a movable foil and absorber capable of safely accepting a 1% to design a movable foil and absorber capable of safely accepting a 1% beam loss on beam loss on eacheach foil/absorber assembly (baseline 3.6kW ultimate 20 foil/absorber assembly (baseline 3.6kW ultimate 20 kW)kW)Accurately predict beam phase space including halo at exit of linacAccurately predict beam phase space including halo at exit of linacAnticipate fast transverse steering feedback system to keep beam Anticipate fast transverse steering feedback system to keep beam position fixed at foil locations (if necessary)- position fixed at foil locations (if necessary)- SNS experience position SNS experience position move within macro pulsemove within macro pulse

Similar to SNS: 2 step process-> foil in front of quad strips halo, Similar to SNS: 2 step process-> foil in front of quad strips halo, quad defocuses resultant protons which drift to a movable jaw quad defocuses resultant protons which drift to a movable jaw absorberabsorberSimulation using TRACK which tracks H-,H+,H0Simulation using TRACK which tracks H-,H+,H0 simultaneously simultaneously through multiple collimation systems (see example for 1 vertical through multiple collimation systems (see example for 1 vertical location only)location only)

Just before absorber

TTransverse Collimation SchemeTransverse Collimation Scheme

foils

Just after foil Just after quad

1313David Johnson

First turn H- missing foilFirst turn H- missing foilGoal of less than 2 percent Goal of less than 2 percent determined by foil dimensions & depth of transverse collimationdetermined by foil dimensions & depth of transverse collimation

First turn H0 excited states stripping and falling outside the acceptance of the ringFirst turn H0 excited states stripping and falling outside the acceptance of the ringMinimized by chicane designMinimized by chicane design

Multiple scattering in foilMultiple scattering in foilDetermined by foil thicknessDetermined by foil thickness

Energy straggling in foilEnergy straggling in foilContribute to longitudinal emittance dilutionContribute to longitudinal emittance dilution

Nuclear interaction with foil producing hadronic showerNuclear interaction with foil producing hadronic showerInitial estimates ~6E9 particles/secInitial estimates ~6E9 particles/secReduce parasitic hits and foil thicknessReduce parasitic hits and foil thickness

Stripped electronsStripped electrons at 2.8E14 H-/sec contribute ~360 watts at 2.8E14 H-/sec contribute ~360 watts

Circulating protons interacting with foilCirculating protons interacting with foilMinimize injection time, foil orientation & cross section, and paintingMinimize injection time, foil orientation & cross section, and painting

Single large angle Coulomb scatteringSingle large angle Coulomb scatteringEstimate loss rate at 4E-4 or ~150 wattsEstimate loss rate at 4E-4 or ~150 watts

Many of these processes are included in the simulation code STRUCT (routines from Many of these processes are included in the simulation code STRUCT (routines from MARS) and ORBIT. Those that are not will be added…MARS) and ORBIT. Those that are not will be added…

Injection Losses

1414David Johnson

•Challenge is to design a painting system spanning multiple linac cycles which:Challenge is to design a painting system spanning multiple linac cycles which:• creates a uniform distributioncreates a uniform distribution• minimize interactions of circulating protons with foilminimize interactions of circulating protons with foil

• Recycler used as an accumulator requires 3 linac cycles at 5 Hz with 5.6E13 injected per Recycler used as an accumulator requires 3 linac cycles at 5 Hz with 5.6E13 injected per cycle (1 ms beam pulse). cycle (1 ms beam pulse). •Painting algorithms and foil geometries will be investigated using simulations performed with Painting algorithms and foil geometries will be investigated using simulations performed with STRUCT and ORBIT.STRUCT and ORBIT.

Design of Painting System

Painting Waveforms

0

0.2

0.4

0.6

0.8

1

1.2

0 50 100 150 200 250 300 350

Injection Turns

Rel

ativ

e A

mp

litu

de

Horizontal PaintingVertical PaintingHorizontal Removal

pulse 1 (1ms) pulse 2 (1ms) pulse 3 (1ms)

remove from foil (200 ms)

End 1st injection

End 2nd injection

End 3rd injection

Foil (injected beam)

Closed orbit movement

Move off foil

Start injection Stripping foil

Closed orbit

for Recycler Injection

1515David Johnson

We need to be able to predict the efficiency of converting HWe need to be able to predict the efficiency of converting H-- into protons and H into protons and H00 excited states for incident 8 GeV Hexcited states for incident 8 GeV H-- ions. ions. The efficiency of converting HThe efficiency of converting H-- into protons and H into protons and H00 excited states have been excited states have been measured at energies up 800 MeV [Stinsen (69), Webber (79), Mohagheghi (91) , measured at energies up 800 MeV [Stinsen (69), Webber (79), Mohagheghi (91) , Gulley (96), and Keating (98)]Gulley (96), and Keating (98)] Scale the 800 MeV cross sections for HScale the 800 MeV cross sections for H--HH++,H,H-- H H00, and H, and H00 H H++, by 1/, by 1/22.. [W.Chou, et.al. NIM A 590 (2008) 1-12][W.Chou, et.al. NIM A 590 (2008) 1-12] Capture to circulating beam ->Capture to circulating beam -> H+ & H0(n>3) from chicane designH+ & H0(n>3) from chicane design Only H0(n=1,2) are sent to absorber Only H0(n=1,2) are sent to absorber (dependent on Chicane 3 field)(dependent on Chicane 3 field) Foil Stripping cross sections to Foil Stripping cross sections to be implemented in TRACK whichbe implemented in TRACK which will produce injection phase will produce injection phase at foil of Hat foil of H++,H,H00,H,H-- which can track each which can track each species through the injection region species through the injection region and to absorber.and to absorber. Will also be used as input to ORBIT.Will also be used as input to ORBIT.

Foil StrippingStripping Efficiency

Carbon Stripping Foil Yield at 800 MeV and 8GeV

0.00E+00

1.00E-01

2.00E-01

3.00E-01

4.00E-01

5.00E-01

6.00E-01

7.00E-01

8.00E-01

9.00E-01

1.00E+00

0 100 200 300 400 500 600Carbon foil thickness [ug/cm2]

Rel

ativ

e yi

eld

H- (800Mev :Gulley)

H0 (800MeV: Gulley)

H+ (800MeV: Gulley)

H0 (8GeV scaled)

H- (8GeV; scaled)

H+ (8GeV:scaled)

H0(n=1 only)

800Mev data: Gulley

425 g/cm2 98% 507 g/cm2 99%

1616David Johnson

Must cleanly transport both H- and H0 excited states to injection Must cleanly transport both H- and H0 excited states to injection absorberabsorberAbsorber must handle both routine and accident conditionsAbsorber must handle both routine and accident conditions

Routine 10% of 360 kWRoutine 10% of 360 kWAccident 360 kW for x number of pulses)Accident 360 kW for x number of pulses)

Shielding must meet all radiological standardsShielding must meet all radiological standardsMust be instrumented for hardware protectionMust be instrumented for hardware protectionInternal vs External (a risk analysis)Internal vs External (a risk analysis)

Currently utilizing MARS and ANSYS to investigate absorber core Currently utilizing MARS and ANSYS to investigate absorber core geometries and thermal capacitiesgeometries and thermal capacities

Waste Beam Disposal

INTERNAL EXTRENAL

simple optics complicate opticsno civil civil const

$$ absorber <$ absorberresidual shielding separate enc

elevation of absorber (RR or MI)

1717David Johnson

•Foil lifetimes are associated with Foil lifetimes are associated with peak peak temperaturetemperature and and thermal and thermal and mechanical stressmechanical stress due to periodic due to periodic heating. heating. •There has been much progress with the There has been much progress with the manufacture and testing of new foils manufacture and testing of new foils capable of withstanding the brutal capable of withstanding the brutal punishment of high intensity/fast rep rate punishment of high intensity/fast rep rate associated H- injection( c.f. SNS, associated H- injection( c.f. SNS, JPARC, LANL)JPARC, LANL)

Stripping Foil Lifetime Issues

•Calculations done for Proton Driver Calculations done for Proton Driver by C.J Liaw and J. Beebe-Wang (BNL)by C.J Liaw and J. Beebe-Wang (BNL)•Project X intensity down by factor of Project X intensity down by factor of 3 (i.e.5.6E13/1 ms pulse) 3 (i.e.5.6E13/1 ms pulse) •Spot size will determine foil size and Spot size will determine foil size and trade-off on the number of secondary trade-off on the number of secondary hits.hits.

1.5E14/3ms @ 1.5s9 secondary hits3 beam sizes

Peak Temperature determined primarily by injected beam

1mm sigma <9 hits>

1818David Johnson

Contributions from…Contributions from…

Howard Bryant (UNM) [Black Body]Howard Bryant (UNM) [Black Body]Jean-Paul Carnerio [TRACK]Jean-Paul Carnerio [TRACK]Alex Chen [ANSYS – Absorber]Alex Chen [ANSYS – Absorber]Wieren Chou Wieren Chou Alexander Drozhdin [STRUCT painting]Alexander Drozhdin [STRUCT painting]Chris Hill [Black Body]Chris Hill [Black Body]Steve Hays [Power Supplies]Steve Hays [Power Supplies]Dave Harding [Magnets/Technical]Dave Harding [Magnets/Technical]Jim Lackey [Foil issues]Jim Lackey [Foil issues]C.-J. Liaw (BNL) [CDR/Foil issues]C.-J. Liaw (BNL) [CDR/Foil issues]Nikolai Mokhov [MARS]Nikolai Mokhov [MARS]Tom Nichol [Cryo beam shield]Tom Nichol [Cryo beam shield]Petr Ostroumov [TRACK]Petr Ostroumov [TRACK]Tony Parker [Drafting support]Tony Parker [Drafting support]

Igor Rakhno [MARS absorber/coll]Igor Rakhno [MARS absorber/coll]Deepak Raparia [PD CDR / injection]Deepak Raparia [PD CDR / injection]Zhijing Tang [ANSYS – absorber/coll]Zhijing Tang [ANSYS – absorber/coll]Kamran Vaziri [Shielding Requirements]Kamran Vaziri [Shielding Requirements]Leonid Vorobiev [ORBIT painting]Leonid Vorobiev [ORBIT painting]Joanne Beebe-Wang (BNL) [PD CDR Joanne Beebe-Wang (BNL) [PD CDR Foil /painting issues]Foil /painting issues]J. Wei (BNL) [PD CDR]J. Wei (BNL) [PD CDR]Meiqin Xiao [Recycler lattice]Meiqin Xiao [Recycler lattice]Bob Zwaska [Laser stripping]Bob Zwaska [Laser stripping]Others….Others….

Plus:Plus: Participants in Proton Driver Studies I and II (inside & outside Participants in Proton Driver Studies I and II (inside & outside FNAL)FNAL) Participants in 2004 Mini-Workshop on H- Transport and InjectionParticipants in 2004 Mini-Workshop on H- Transport and Injection The many staff from labs and universities world wide who have The many staff from labs and universities world wide who have contributed to the advancement of HB beam technologies…. contributed to the advancement of HB beam technologies….

1919David Johnson

Summary

•The design choice of beam parameters (linac current, pulse length, and rep rate) and potential upgrade paths will determine which accelerator will be used for the injection of H-, hence the direction of future efforts.

•Simulation software TRACK,STRUCT,ORBIT,MAD, OPERA, etc. exists for transport, collimation, injection painting, waste disposal, injection losses, energy deposition, field maps, etc. Future modifications and optimizations are expected.

•Selection of transport line fields, vacuum, and beam shield mitigates issues for single particle loss.

•Continue foil development and testing.

•Continue investigation of Laser stripping

•Continue R&D effort to determine initial configuration

2020David Johnson

Project X Design Parameters

Baseline LinacBaseline Linac running @ 5Hz and 9mA avg. current 1ms pulse running @ 5Hz and 9mA avg. current 1ms pulse lengthlength

delivers 5.6E13/pulse at 72 kJoules/pulse -> 2.8E14/sec for 360 kWdelivers 5.6E13/pulse at 72 kJoules/pulse -> 2.8E14/sec for 360 kW

For neutrino program: MI cycle of 1.4 sec -> 3 linac pulses ->1.7E14 For neutrino program: MI cycle of 1.4 sec -> 3 linac pulses ->1.7E14 for 154 kW at 8 GeV and 2.3MW at 120 GeV (4 linac pulses left over for 154 kW at 8 GeV and 2.3MW at 120 GeV (4 linac pulses left over i.e. 200 kW @ 8 GeVi.e. 200 kW @ 8 GeVUpgrade paths Upgrade paths

–increase linac pulse length 1ms -> 3 msincrease linac pulse length 1ms -> 3 ms–linac average current 9 mA -> 27 mA linac average current 9 mA -> 27 mA –linac rep rate 5 Hz, 10Hz, 15 Hz ???linac rep rate 5 Hz, 10Hz, 15 Hz ???

Req. No. Req. Unit1.0 General1.1 120 GeV Beam Power 2.3 MW1.2 8 GeV Beam Power 360 kW1.3 8 GeV Slow Spill Beam Power 200 kW1.4 8 GeV Slow Spill Duty Factor 55 %1.5 120 GeV Availability 75 %1.6 8 GeV Availability 80 %

1.7Upgradeable 8 GeV Beam Power for Civil, RF, & Cryo Systems

2 MW

Description

->1.5E15 protons/sec

->2.8E14 protons/sec

(back up slide)

2121David Johnson

Transport Line Requirements

Req. No. Req. Unit4.0 8 GeV Transfer Line4.1 Injection Stripping effi ciency 98 %4.2 Length (approx.) 1000 meters4.3 Maximum average activation level 20 mrem/hr4.4 Availability 98 % 1.64.5 Momentum Aperture +/- 0.8 % 3.104.6 Minimum Transverse Aperture 25 p-mm-mrad 3.13 4.34.7 Maximum Dipole Field 0.05 T 4.1 4.34.8 Transfer Effi ciency 99.99 % 4.34.9 Final Energy Variation +/- 0.11 % 5.104.10 Energy 8 GeV 5.1

Description Reference Requirements

Req. No. Req. Unit5.0 Recycler5.1 Energy 8 GeV5.2 Storage Effi ciency 99.5 %5.3 Average Recycler Beam Current 0.6 A 1.25.4 Availability 95 % 1.65.5 Injection Rate 5 Hz 2.35.6 Maximum Space Charge Tune Shift 0.05 5.25.7 95% normalized transverse emittance 25 p-mm-mrad 5.65.8 r.m.s. normalized transverse emittance 13 p-mm-mrad 5.65.9 Bunching factor 2 5.65.10 Longitudinal emittance per Bunch 0.5 eV-Sec 5.6 5.125.11 Cycle Time 1.4 S 6.15.12 RF Frequency 53 MHz 6.25.13 Abort Gap Length 700 nS 6.35.14 Peak Recycler Beam Current 2.4 A 6.5

Description Reference Requirements

(back up slide)

2222David Johnson

Transport line

•The

(back up slide)

•The upstream end of the transport line remains unchanged. The new vertical The upstream end of the transport line remains unchanged. The new vertical bend section moves transport line further under MI-65 (needs to be verified) bend section moves transport line further under MI-65 (needs to be verified) •Option II is to change elevation of entire beam line and linacOption II is to change elevation of entire beam line and linac•Option III is to move dog leg elsewhereOption III is to move dog leg elsewhere•Solution will be greatly influenced by civil construction issues.Solution will be greatly influenced by civil construction issues.

collimation New section

injection

Defines beam size on foil, hence specifications for injection foil

~achromatic

2323David Johnson

(back up slide)Initial Recycler Lattice ModificationsInitial Recycler Lattice Modifications

Qx=25.445

Qy=24.134

x~70

y ~30

~25m

No tuning !

Issue:• use phase trombone for tune control• add distributed quads for tune control

Next slide

Dispersion “free”

2424David Johnson

Recycler Injection(back up slide)

•Layout used for Proton Driver injection into Main InjectorLayout used for Proton Driver injection into Main Injector•150 mm offset dictated by MI geometrical constraints and missing 150 mm offset dictated by MI geometrical constraints and missing MI magnetsMI magnets•The DC chicane could become ramped bumpThe DC chicane could become ramped bump

•Start paint•End paint

•DC orbit (Chicane)

•Removal from foil

•Next slide

2525David Johnson

Injection Layout

•The

(back up slide)

Layout used for Proton Driver injection into Main Layout used for Proton Driver injection into Main InjectorInjector

HBC1 HBC2 HBC3 HBC4

75 to 100 mm

8.941 m 0.606 m 1.068 m

Stripping foilH-

H0

H+ to inj. absorber

Thick foil H0->H+

Circulating protons

foilMagnetMagnet Length Length [m][m]

Strength Strength [kG][kG]

Theta [mr]Theta [mr] H & V Aperture [in]H & V Aperture [in]

HBC1HBC1 0.70.7 +3.5669+3.5669 +8.4211+8.4211 6 x 26 x 2

HBC2HBC2 6.06.0 -0.4656-0.4656 -9.4211-9.4211 12 x 2 or 3?12 x 2 or 3?

HBC3HBC3 2.02.0 -5.5620-5.5620 -37.5179-37.5179 12 x 3 (?)12 x 3 (?)

HBC4HBC4 1.01.0 +11.4206+11.4206 +38.5179+38.5179 12 x 3 (?)12 x 3 (?)

2626David Johnson

Injection Painting(back up slide)

Current scheme is anti-correlated horizontal painting and vertical Current scheme is anti-correlated horizontal painting and vertical steering. steering.

Suggested by KEK and implemented into STRUCTSuggested by KEK and implemented into STRUCT

MI CL 0 mm 100 mm

33(inj)

150mm

Chicane (DC Bump)

Start Paint150 mm

Removal

Offset

Painting

33(cir)

11(inj)11(cir)

Total

H- Injection Orbit

B0 = maximum kickN = Number turns to paintn = turn numberP = Painting displacementR = Removal displacementT = Total displacement

Foil support

Foil

2

0

21

N

n

N

n

T

P

T

RBB

2

4444

2)('

N

nN

N

nNy injcir

Maximum kick, BMaximum kick, B00 [kG] [kG] 10.9810.98

Painting Displacement, P [mm]Painting Displacement, P [mm] 10.4510.45

Removal Displacement, R [mm]Removal Displacement, R [mm] 39.5439.54

Offset [mm]Offset [mm] 33.0533.05

2727David Johnson

Transport /Injection Design Challenges

• The control and mitigation of uncontrolled beam loss due The control and mitigation of uncontrolled beam loss due to single particle loss mechanisms in the transport line:to single particle loss mechanisms in the transport line:– Photodetachment of H- due to interaction with Black-body Photodetachment of H- due to interaction with Black-body

photonsphotons– Lorentz stripping of weakly bound electronLorentz stripping of weakly bound electron– H- stripping by the residual gas in the beam pipeH- stripping by the residual gas in the beam pipe

• Leads to activation of accelerator components Leads to activation of accelerator components • Performance degradation Performance degradation • Will form the basis for many design considerationsWill form the basis for many design considerations

• Multi-particle beam loss Multi-particle beam loss – Controlled (Controlled (halohalo & momentum collimation) & momentum collimation)– Un-controlled (alignment, aperture, orbit and lattice control)Un-controlled (alignment, aperture, orbit and lattice control)

• Uncontrolled losses in the injection region due injected Uncontrolled losses in the injection region due injected and circulating ion interaction with the stripping foiland circulating ion interaction with the stripping foil– Impact on downstream componentsImpact on downstream components– Collection & Collection & disposal of waste beamdisposal of waste beam (neutrals & H- missing foil) (neutrals & H- missing foil)

2828David Johnson

•Design of injection system•Physics Design

•Optical design of injection straight section including chicane magnetic fields and transport line matching•Stripping efficiency and lifetime of injection foil*•Stripping efficiency of a laser stripping injection system•Design of injection foil system •Design of painting system•Beam absorbers/collimators

•Engineering Design •Collimation systems and beam absorbers•Ring chicane magnets and their power supplies•Foil changing system ( including electron catcher)•Painting magnets and their power supplies

• GOAL: produce an accurate end-to-end simulations* taking into account all fields and loss mechanisms. * currently working with (MAD, TRACK, STRUCT, and ORBIT)

Transport /Injection Design Challenges

2929David Johnson

Transport /Injection Design ChallengesTransport /Injection Design Challenges

• TheThe