186880494 mother-dairy-vs-its-competitors-in-ice-cream-business

Dairy Products Technology (Dairy Technology) · 2017-03-16 · Dairy Products Technology (Dairy...

Transcript of Dairy Products Technology (Dairy Technology) · 2017-03-16 · Dairy Products Technology (Dairy...

Dairy Products Technology 1

Dairy Products Technology(Dairy Technology)

Student Handbook

for

Class XII

Central Board of SeCondary eduCation, delhiShiksha Kendra, 2 Community Centre, Preet Vihar, delhi-110092 india

2 Dairy Products Technology

Fluid Milk Processing Student’s Handbook for Class XI

Price :rs. 285.00

Firstedition2013cBse, india

coPies : 1,000

“This Book or part thereof may not be reproduced by any person or agency in any manner.”

PuBlISHeD By : thesecretary,central Boardofsecondary education,shiksha Kendra, 2,communitycentre,PreetVihar, delhi-110092

DeSIgn, layouT : deeKay Printers, 5/37Kirtinagar,newdelhi-110015 Phone : 25414260

PrInTeD By : shree BalajiPrinters,B-266, iind Floor,VivekVihar, Phase-i, delhi-110095

Dairy Products Technology 3

PrefaceAt present india is the world leader in milk production with an annualproduction of 127 million tonnes. About 50 percent of the milk is handledby the organized sector. domestic market for value added products likebutter, ice cream, cheese, dairy whiteners and spreads is growing at 8-10percent per year. despite the large infrastructure available for processing ofmilk, only 27% of the total milk produced is at present converted into valueadded products. consumption of large quantities of liquid milk at the site ofproduction and poor post-harvest handling and processing are among thereasonsfor lowvalueadditionofmilk.WiththelaunchofthenationaldairyPlan,milkproductioninindiaislikelytoincreaseover4to5percentannuallyin the next two decades.the increasing demands and the accompanyingvalue addition present a great opportunity for the dairy industry to take upthe production and marketing of various dairy products especially traditionalproducts on an industrial scale. Accordingly the demand for professionalswith formal education in dairy technology would be increasing.

theattemptofcBse, to introducedairytechnologycourses forclassXii is to encourage young minds to begin their career in dairying. in thepresent book, the composition, standards, methods and equipment used formanufacturingdifferent dairy products viz. traditional indian dairy products,westerndairyproductsanddairybyproductshasbeenincluded.theobjectiveofthisbookistomakeunderstandthestudentsthediversityofdairyproducts,theirprinciplesofmanufacturingand legalstandardsprevalent in thecountrythat governmarketingof theseproducts.

Vineet Joshi, IaSchairman,cBse

4 Dairy Products Technology

Acknowledgements

l Dr. rameshwar Singh, Projectdirector(dKMA),directorateofKnowledge,ManagementinAgriculture,5th Floor,KrishiAnusandhan Bhawan - i,Pusa,newdelhi-110002

l Dr. a.K. Srivastava, director,nationaldairyresearch institute (ndri),Karnal- 132001,Haryana

l Dr. P. narender raju,scientist,dairy,technologydivision,ndri,Karnal-132001

l Dr. Pradip Behare,scientist,dairyMicrobiologydivision,ndri,Karnal-132001

l Mr. Devraja,scientist, dairytechnologydivision,ndri,Karnal-132001

l Mr. yogesh Khetra,scientist, dairytechnologydivision,ndri,Karnal-132001

l Dr. Kaushik Kharui, seniorscientist,dairytechnologydivision,ndri,Karnal-132001

l Mr. Shaik abdul Hussain,scientist,dairytechnologydivision,ndri,Karnal

l Dr. Biswajit Saha, Programmeofficer,Vocationaleducation,cBse,delhi

l Shri Dharampal Singh,Formerdirector,edUsAt&Vocationaleducation,andconsultant(Agriculture),cBse,delhi

l Mrs Pragya gaur, consultant (science),cBse,delhi

SPeCIal aCKnowleDgeMenT

auTHor grouP

editingAndcoordinAtion

l Dr. S. ayyappan, secretary, dAre & director general, icAr, Krishi Bhavan, new delhi-110001

l Sh. Vineet Joshi, iAs,chairman,cBse,delhi

aDVISorS

l Dr. P. narender raju,scientist,technicaleditor,technologydivision,ndri,Karnal-132001

l Dr. Pradip Behare,scientist,technicalco-editor,ndri,Karnal-132001

TeCHnICal grouP

Dairy Products Technology 7

Contents

chapter 1composition,standards,Manufacturing -Process andequipmentsand defects duringManufacturingandstorageofcream,Butter,ghee,Khoa, channa,Paneer 1

chapter 2composition,standards,Manufacturing -Process andequipmentsand defects duringManufacturingandstorageofcurd/dahi,Yoghurt,chakka, shrikhand,cheese 38

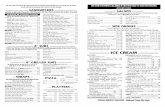

chapter 3composition,standards,Manufacturing -Process andequipmentsand defects duringManufacturingandstorageofsofty, icecream,Kulfi 58

chapter 4composition,standards,Manufacturing -Process andequipmentsand defects duringManufacturingandstorageofdriedandcondensedMilk Products (MilkPowder-skimMilk,WholeMilk,Whitner,condensedMilk) 74

chapter 5composition,standards,Manufacturing -Process andequipmentsand defects duringManufacturingandstorageofdairyByproducts (skimMilk, casein,caseinate,Whey-concentrate,Powder, Lactose,gheeresidue) 100

chapter 6sensoryevaluation ofMilk andMilkProducts 126

8 Dairy Products Technology

Dairy Products TechnologyTheory

(Time 120 hrs)

S. no. Chapter Hours weightege (Marks)

1. Chapter 1 25 12.5

2. Chapter 2 20 10

3. Chapter 3 20 10

4. Chapter 4 25 12.5

5. Chapter 5 20 10

6. Chapter 6 10 5

Dairy Products Technology 1

Chapter-1Composition, Standards, Manufacturing – Process and Equipment and Defects during Manufacturing and Storage of Cream, Butter, Ghee, Khoa, Chhana and Paneer

Creamobjective

to learn the Production, Processing andstorage ofcream

Introduction

in the indian dietary regimen, milk fat in the form of cream, butter and ghee contributessignificantly towardsnourishmentofpeopleofalmostallagegroups.theseproductsaregood sources of fat soluble vitamins A, d, e and K. in the ancient vedic literature it ismentionedthatgheederivedfromcowmilkhasgotexcellentnutritionalandtonicqualitiesspeciallybeneficialtopersonsconvalescingafterchronicillnessandbonefracture.creamisa fat richcomponentandhasbeenknownfromtime immemorialas thefatty layer thatrisestothetopportionofthemilkwhenleftundisturbed.creamissoldinmanyvarieties.Although used for several purposes, it is primarily something of a luxury because of itsexcellent flavor, body and texture.

Definition

cream may be defined as that portion of milk which is rich in milk fat or that portion ofmilk into which fat has been gathered and which contains a large portion of milk fat, orwhen milk fat is concentrated into a fractionof theoriginal milk.

According to the Fssr rules (2011), cream excluding sterilized cream is the product ofcow or buffalo milk or a combination there of which conations not less than 25 per centmilk fat (table 1.1). Cream is rich in energy giving fat and fat-soluble vitamins A, d, e,and K, the contents of whichdependson the fat level in cream.

2 Dairy Products Technology

Classification

creamisnotadefinitespecificsubstance.itcontainsallthemilkconstituentsbutinvaryingproportions. cream for sale to consumers is produced with different fat contents.creamof lower fat content, 10 – 18%, is often referred to as half cream or coffee cream, it isincreasingly used for desserts and in cooking. cream with a higher fat content, typically35 – 40 %, is usually considerably thicker. it can be whipped into a thick froth and istherefore referred to as “whipping cream”.the milk fat in cream may vary from 10 to 75per cent.

crammaybeclassifiedbroadlyas:(a)marketcream,whichisusedfordirectconsumptions,and (b)manufacturing cream,which is used for themanufacturingof dairy products.

the various types of creamare:

1. table cream

2. Light cream

3. coffee cream

4. Whipping cream

5. Heavy cream

6. Plastic cream

Table 1.1: Chemical composition of cream

Constituents Percentage

Water 45.45-68.2%

Fat 25-60%

Protein 1.69-2.54%

Lactose 2.47-3.71%

Ash 0.37-0.56%

totalsolids 31.8-54.55%

solidsnotfat 4.55-6.80%

Production of Cream: the basic principle of cream separation, whether by gravity orcentrifugalmethod, isbasedon the fact thatmilk fat is lighter than theskimmilkportion.

Dairy Products Technology 3

At 160c the average density of milk fat is 0.93 and skin milk 1.036. Hence when milk,whichmaybeconsidered tobeamixtureof fat (ascream)andskinmilk, is subjected toeither gravity or a centrifugal force (Fig. 1.1), the two components, viz. cream and skinmilk, by virtueof their differing densities stratify fromoneanother.

centrifugalmethodisusedcommerciallytoseparatecreamfrommilk.Whenmilkenterstherapidly revolvingbowlof thecreamseparator, it is immediately subjected toacentrifugalforce,which is3000 to1600 timesgreater thangravitational force.Whileboth the fatandskimmilkaresubjectedtothecentrifugalforce,thedifferenceindensityaffectstheheavieri.e.portionskimmilkmoreintentlyandforcedtotheperipherywhilethefatportionmovestowards the centre.

the skim milk and cream both form vertical walls within the and are separated by ledthrough separate outlets

Fig. 1.1: Flow Diagram for the production of cream

Milk

Filtration

Preheating (650c)

creamseparation

skimmilkcream

standardization (typeof cream required)

Pasteurization (710c/20minor 95-1000c/15sec)

Packaging (Laminatedpouch, Plastic containers,tin cans)

storage (40c)

4 Dairy Products Technology

Cream neutralization (for butter- making)

neutralizationofsourcreamforbuttermakingrefertoapartialreductioninacidity.creamis neutralized to avoid excise fat loss in buttermilk that result from churning highly acidpasteurizedcream, toguardagainst theproductionofanundesirableoff-flavor incream(which may result when high acid cream is pasteurized), to improve the keeping qualityof butter made from high acid cream. salted acid butter develops a fishy flavor duringcommercial storage at – 230c to -290c. neutralizers commercially used are Sodium bi carbonate and Calcium hydroxide.

(a - b)XQuantity of creamAmount of neutralizer to beadded= 100Xneutralization factor

a- %Acidity of the cream

b- % desired acidity of the cream

neutralization factor is asbelow

sodium bi carbonate 1.1

ca(Ho)2 2.45+20%ofneutralizer

Standardization of Cream

thisreferstotheadjustmentofthefatlevelincreamtothedesiredpercentage,confirmingtostandardrequirements.the fatpercentage incream isadjusted to theprescribed levelby the addition of skim milk or cream. desired level of fat in cream for butter making is33 to40percent.standardization tobothhigherand lower level leads tohigher fat lossin butter milk. reduction of fat by adding water should be avoided as it interferes withripening of creamand also results in butterwith‘flat’ or‘washedoff’ flavour.

Pasteurization of Cream

cream ispasteurizedat710c for20min inabatchprocessand95 to1000c for15secin a Htst pasteurizer. Pasteurization is done mainly to destroy the pathoges, inactivateenzymes, eliminate gaseous tainting substances, and remove volatile off flavors.

Packaging and Storage

tablecreamispackagedinretailpacksinglassbottle,laminatedpouches,plasticcontainersetc. and stored at 4-70cand distributed asearly aspossible.

Dairy Products Technology 5

activity

take100mlmilk inaglassandkeep inundisturbedcondition for2honuniformplatformand observe for fat layer separation.

review Questions

1. Write the importance of creamstandardization

2. Write the importance of neutralization of cream

3. standardize the cream having 60% fat to 45% fat using skim milk testing 0.8% fat.calculate theamountofskimmilk requiredandfinalquantityofstandardizedcreamproduced.

Butterobjective

to learn the Manufacturing and PackagingofButter

Introduction

Butter isa fat richdairyproduct,generallymade fromcreambychurningandworking. itcontains80% fat,which ispartlycrystallized.Buttermaking isoneof theoldest formsofpreserving the fat componentofmilk. itsmanufacturedatesback tosomeof theearliesthistoricalrecords,andreferencehasbeenmadetotheuseofbutterinsacrificialworship,for medicinal and cosmetic purposes, and as a human food long before the christianera. Butter can be produced from the milk of cow, buffalo, camel, goat, ewe and mares.Fat is separated from milk in the form of cream using cream separator.the cream canbe either purchased from a fluid milk dairy or separated from whole milk by the buttermanufacturer.thecreamshouldbesweet (pHgreater than6.6),not rancid,notoxidized,and free from off flavors.the cream is pasteurized at a temperature of 80°c or more todestroy enzymesand micro-organisms.

Composition of Butter

Butter is principally composed of milk fat, moisture, salt and curd. it also contains smallamount of lactose, acids, phospholipids, air, microorganisms, enzymes and vitamins.the proportion of principal constituents in butter is largely controlled by the method ofmanufacture and this inturn is chiefly regulated to conform to the standards of butter

6 Dairy Products Technology

prescribed by regulatory authorities such as codex and FssAi. general composition ofbutter is given in table below (table1.2).

Table 1.2: Composition of butter

Constituents Quantity (% w/w)

Fat 80-83

Moisture 15.5-16.0

salt *0-3

curd 1-1.5

*0 percent salt indicates that butter is unsaltedand it is not intended for direct consumption

Definition of Butter as per FSSr, 2011

Butter can be defined as the fatty product derived exclusively from milk of cow and/orbuffalo or its products principally in the form of an emulsion of the type water-in-oil.theproductmaybewithorwithoutaddedcommonsaltandstarterculturesofharmlesslacticacid and / or flavour producing bacteria.table butter shall be obtained from pasteurisedmilkand/orothermilkproductswhichhaveundergoneadequateheattreatmenttoensuremicrobialsafety. itshallbefreefromanimalbodyfat,vegetableoil,mineraloilandaddedflavour. it shall have pleasant taste and flavour free from off flavour and rancidity. it maycontainfoodadditivespermittedintheseregulationsasgivenintable1.3.itshallconformto themicrobiological requirementsprescribed intable1.4.Provided thatwherebutter issoldor offered for salewithout any indicationas towhether it is tableor desi butter, thestandards of table butter shall apply.

Table 1.3: Food additives allowed in Butter

Sl. no. Food additive Permissible limit

1 curcumin 100ppm

2 Betacarotene 100ppm

3 carotene(naturalextract) 100ppm

4 AnnattoextractonBixin/norbixinbasis(50:50ratio) 20ppm

5 Betaapo-8carotenal 35ppm

6 MethylesterofBetaapo-8carotenoicacid 35ppm

7 sodiumandcalciumhydroxide 2000ppm

8 sodiumphosphate gMP

Dairy Products Technology 7

Table 1.4: Microbiological standards of Butter

1 totalPlatecountMax 50,000/g

2 coliformcount 50/g

3 e.coli Absent/g

4 salmonella Absent/25g

5 staphaureus 50/g

6 Yeastandmoldcount 50/g

7 ListeriaMonocytogenes Absent/g

8 samplingguidelines 100gsampleand-18°corlowerstorage

temperature

Production of Butter

Preparation of Cream

commercialbuttercanbeproducedfrombothsweetaswellasculturedcream.However,butter from sweet cream is most preferred as it results in sweet butter milk which hasbettereconomicvaluethansourbuttermilkthatresultswhensour/culturedcreamischurned(Fig. 1.2). cream should be neutralized to 0.06% lactic acid to produce butter for longstorageand to0.3% lactic acid toproducebutter for early consumption.thenadjust thefat percentage of cream to 35 to 40% fat. Heat the neutralized and standardized creamto 95°c for 15 secand cool it to 9°c.

ripening: ripeningreferstotheprocessoffermentationofcreamwiththehelpofsuitablestarter culture. this step can be eliminated if sweet-cream butter is desired. the mainobject of cream ripening is to produce butter with higher diacetyl content. starter cultureconsistingofamixtureofbothacidproducing(Streptococcus lactis, S.cremories)andflavourproducing(S.diacetylactis, Leuconostoccitrovorum and/or Leuc. dextranicum)organismsisadded.Amountof starteraddeddependsonseveral factorsandusually rangesbetween0.5-2.0 percent of the weight of the cream. After being thoroughly mixed, the cream isincubatedat about 21oc till desiredanacidity is reached.cream is subsequently cooledto 5-100c to arrest further acid development.

Dairy Products Technology 9

Cream Processing

aging: cream is held at cool temperatures to crystallize the butterfat globules, ensuringproper churning and texture of the butter. in the aging tank, the cream is subjected to aprogram of controlled cooling designed to give the fat the required crystalline structure.As a rule, aging takes 12 - 15 hours. From the aging tank, the cream is pumped to thechurnorcontinuousbuttermakingmachineviaaplateheatexchangerwhichbrings it tothe requisite temperature.

Churning: cream is agitated, and eventually butter granules form, grow larger, andcoalesce. in theend, therearetwophases left:asemisolidmassofbutter,andthe liquidleft over, which is the buttermilk.

Draining and washing: in traditional churning, themachinestopswhen thegrainshavereached a certain size, whereupon the buttermilk is drained off. With the continuousbuttermaker thedrainingof thebuttermilk isalsocontinuous.Afterdraining, thebutter isworked to a continuous fat phase containing a finely dispersed water phase. it used tobe common practice to wash the butter after churning to remove any residual buttermilkand milk solids but this is rarely done today.this washing process would ensure that allthe butter milk is washed out of the butter. otherwise the butter would not have goodshelf life and go rancid.

Salting: salt isused to improve theflavorand theshelf-life,as it actsasapreservative.Further,thebutterisworkedtoimproveitsconsistency.saltusedshouldbe99.5to99.8%sodium chloride and microbial count should be less than 10/g. salt is added at the rateof 2 to 2.5%.

working: theobjectiveofworkingbutteristoincorporatemoistureanduniformlydistributeadded moisture and salt in butter. during this process remaining fat globules also breakup and form a continuous phase, and moisture is finally distributed to retard bacterialgrowth in butter. it is safer to slightly over-work butter than to under-work. Under-workedbutter may be leaky in body with large visible water droplets and may develop ‘mottles’on standing.

Packing and storage: thebutter isfinallypatted intoshapeandthenwrapped inwaxedpaperandthenstored inacoolplace.As itcools, thebutterfatcrystallizesandthebutterbecomes firm. Whipped butter, made by whipping air or nitrogen gas into soft butter, isintended tospreadmoreeasilyat refrigeration temperatures.normallybutter isstoredat-230c to -290c.

Classification of Butter

Butter may be classified based on treatment given to cream, salt content, method ofmanufacturing and end use.

10 Dairy Products Technology

I. Classification based on acidity of cream used for butter making

1. Sweet cream butter: sweet cream butter (made from non-acidified cream; thisincludes butter in which no bacterial culture have been added to enhance diacetylcontent) having pHof 6.4 (acidity of the churned creamdoesnot exceed0.2%).

2. Mildly acidified butter (madefrompartiallyacidifiedsweetcream)havingpHin therange of 5.2 to 6.3

3. Sour cream butter (made from ripened cream which has more than 0.2% acidity)havingpH5.1.

II. Classification based on salt content

1. Salted butter: Butter to which salt has been added. it is added to improve flavourand keepingquality of butter.

2. unsalted butter: this type of butter contains no salt. it is usually prepared formanufacturing other products suchasgheeandbutteroil.

III. Classification based on end use (as followed by BIS)

1. Table Butter:theproductmadefrompasteurizedcreamobtainedfromcoworbuffalomilkoracombination thereofwithorwithout ripeningwith theuseofstandard lacticculture,additionofcommonsalt,annattoorcaroteneascolouringmatteranddiacetylas flavouring agent.

2. white Butter:theproductmadefrompasteurizedcreamobtainedfromcoworbuffalomilkoracombinationthereofwithoutripeningandwithoutadditionofanypreservativeincluding common salt, anyadded colouringmatter or anyadded flavouringagent.

IV. Classification based on the manufacturing practice (as followed by FSSaI)

1. Pasteurized cream butter/ Pasteurized Table butter: this is made usually frompasteurized sweet cream. such butter usually has a milder flavour than that madefromsimilar creamnot pasteurized.

2. Desi butter:thebutterobtainedby traditionalprocessof churningdahiormalaiaspracticedat domestic levels.

activity

Prepare butter from dahi at your home.take 1 kg milk, boil it for 3min and then cool itto 32°c.Adda spoon of previous daydahi and keep it undisturbed for 8-10h.

Dairy Products Technology 11

review Questions

1. give theFssr2011 standards for butter

2. Write the importance of salting

3. Whyworking is an important step in butter preparation?

Gheeobjective

l to learn the Manufacturingtechniques,Packaging andstorage ofgheel to learnabout thedifferentstandards andgrades ofghee

Introduction

since time immemorial,gheehasbeenused in indiandietas themost importantsourceof fat. ghee, the indian name for clarified butterfat, is obtained by heat clarification anddesiccationofsourcream,creamorbutter.Becauseofitscharacteristicsflavorandpleasantaroma,besidesbeingasourceoffat-solublevitamins,gheeoccupiespredominantpositionamongst milk products in india.

ghee means the pure heat clarified fat derived solely from milk or curd or from desi(cooking) butter or from cream to which no colouring matter or preservative has beenadded.ghee essentially consists of 99 to 99.5%milk fat (table1.5).

Table 1.5: Chemical composition of ghee

Constituents Cow Buffalo

Fat(%) 99-99.5 99-99.5

Moisture <0.5 <0.5

carotene(mg/g) 3.2-7.4

Vitamin(iU/g) 19-34 17-38

cholesterol(mg/100g) 302-363 209-312

tocopherol(mg/g 26-48 18-31

FreeFattyAcid 2.8 2.8

12 Dairy Products Technology

Methods of Preparation

the principle involved in ghee preparation includes concentration of milk fat in the formofcreamorbutter, followedbyheatclarificationof fat richmilkportionand thus reducingtheamountofwatertolessthan0.5%.thebrowncoloredresidue(curd)isthenremovedas ghee residue fromclarified fat.

there are fivemethods of ghee making:

i. desi or indigenous Method

ii. directcreamMethod

iii. creameryButter Method

iv. Pre-stratificationMethod

v. continuous Method

Most of the indian ghee is produced through butter route and there are only a fewinstallations where the cream is concentrated to 85% fat and above and converted toghee by conventional boiling. Pre-stratification of molten butter to save energy in finalboiling is now an integral part of ghee process design. Melting of butter is mostly donein conventional butter melting vats. Few installations exist with on-line butter melting.theconversionofbutterblock intomoltenbutterandseparationofmoisture frommoltenbutter aimed at minimizing the quantity of moisture for evaporation in ghee manufacture.centrifugal clarification of ghee is becoming more popular in recent times. the gheeproducedbycentrifugalclarificationhasgotbetteropticalclarity.continuousgheemakingprocesshasbeenreportedlydeveloped, itscommercialadoption isstillawaitedby indiandairy industry.

Desi Method

thiswasthepracticefromage-olddaysinruralareaswhereexcessivemilkwillbeculturedandkeptforovernightforfermentation.theresultantcurdwaschurnedusinghanddrivenwooden beaters to separate the milk fat in the form of desi butter. some follow slightlydifferent method wherein milk is heated continuously to about 800c, the malai (creamylayer) that forms over the surface was collected manually.this malai is then churned togetthedesibutter.Aftercollectionofdesibutteroveraperiodoftime,thisbutterismeltedin a metal pan or earthenware vessel on an open fire. extent of frothing is an index tojudgewhentoterminateheating.Heatingmustbestoppedwhensuddenfoamingappearsand leave thecontentsundisturbedafterheating.curdparticlesstartssettlingdownoveraperiodof timeanddecant theclear fatcarefully. in thismethod it ispossible toachieveonly 75 – 85% fat recovery.

Dairy Products Technology 13

Creamery Butter Method

Production of ghee fromcreamerybuttermethod is depicted in fig. 1.3.

Fig. 1.3: Flow digram for production of ghee from creamary butter method

this is the standardmethodadopted inmost of theorganizeddairies.Unsaltedorwhitebutter is used as raw material. Butter mass or butter blocks are melted at 60°c to 80°cin butter melter. Molten butter is pumped into the ghee boiler, where final heating willbe done using steam as heating medium. increase the steam pressure to raise the

14 Dairy Products Technology

temperature.scumwhich is formingon the topof the surfaceof theproduct is removedfrom time to time with the help of perforated ladle. At the moment of disappearance ofeffervescence and appearance of finer air bubbles on the surface of the fat along withbrowning of the curd particles indicates the end point. At this stage typical ghee aromais produced. Final heating temperature is adjusted to about 114±2°c.to get the cookedflavour, heating beyond this temperature is also being in practice. ghee is filtered via oilfilter into the settling tank.

agMarK ghee Specifications (gradedesignation marks for ghee)

thegradedesignationmarkshallconsistofalabelspecifyingthenameofthecommodity,gradedesignationandbearingadesignconsistingofanoutlinemapofindiawiththeword“AgMArK” and the figure of rising sun with the words produce of india and resemblingthe design as set out as follows.

Design of label

1.specialgrade 2.generalgrade 3.standardgrade

grade Colour of letter and Circular border

special red

general green

standard chocolate

l the labelsshallbeprintedon thewatermarkpaperof thegovernmentof indiaandshallhaveamicro tintbackgroundbearing thewords“governmentof india” inolivegreen color

l each label shall have printed thereon a serial number along with a letter or lettersdenoting the series, e.g.A054987.

l eachlabelshallhaveprintedthereontheapproximateweightcontentofthepackageon which it is affixed.

the word ‘regional’ shall be printed on each label used on a package of the ghee notconforming to the normal physical and chemical constants specified in table 1.6&1.7.

Dairy Products Technology 15

Table 1.6: Physical & chemical constant for ghee

Parameters Special grade general grade Standard grade

Baudouintest negative negative negative

Butyro-refractomerreadingat400c

40.0–43.0 40.0–43.0 40.0–43.0

reichertMeisslvalue notlessthan28.0 notlessthan28.0 notlessthan28.0

Polenskevalue 1.0–2.0 1.0–2.0 1.0–2.0

Moisturecontent notmorethan0.3% notmorethan0.3% notmorethan0.3%

PercentageofFreeFattyAcid(asoleicacid)

not more than 1.4 not more than 2.5 not more than 3.0

For cotton tracts areas such as part of saurashtra region and Madya Pradesh followingstandards areapplicable.

Table 1.7: Physical & Chemical constant for ghree in cotton tract areas

ParametersSpecial grade

winter Summer

Baudouintest negative negative

Butyro-refractomerreadingat400c 41.5–44.0 42.5–45.0

reichertMeisslvalue notlessthan23.0 notlessthan21.0#

Polenskevalue 0.5–1.2 0.5–1.0

Moisturecontent notmorethan0.3% notmorethan0.3%

PercentageofFreeFattyAcid(asoleicacid)

notmorethan1.4 notmorethan2.5

general and standard grade have percentage of free fatty acids (as % oleic acid) notexceeding 2.5 and 3.0, respectively. According to the law it is not compulsory for everytrader and manufacturer, to get his produce certified under AgMArK symbol. Presentlyit is only a voluntary schemeof thegovernment.

activityBuy 200g table butter from the retail shop and try to produce ghee as mentioned in thecreamerybuttermethod

review Questions1. What is ghee?

2. Write the flowdiagram for themanufactureof gheeby creamery buttermethod

3. Write theAgMArKstandards for ghee

16 Dairy Products Technology

Khoaobjective

to learn the Meaning,Varieties andstandards andProductionofKhoa

Introduction

Among the indigenous milk products, khoa occupies first position as it form a base fornumber of sweet delicacies. Khoa is a popular product throughout india and is called bydifferent names in different regions likeKhoya, Mawa, Kova, Palghova etc.

Definition ofKhoa

Khoa is a concentrated whole milk product obtained by open pan condensing of milkunder atmospheric pressure.

According toFood Safety and Standard regulations 2011,KHoYAbywhatever varietyof names it is sold such as Pindi, danedar, dhap, Mawa or Kava means the productobtainedfromcoworbuffaloorgoatorsheepmilkormilksolidsoracombinationthereofby rapid drying.the milk fat content shall not be less than 30% on dry weight basis offinished product. it may contain citric acid not more than 0.1 per cent by weight. it shallbe free fromadded starch, added sugar andadded colouringmatter.

Chemical Quality of Khoa

Wide variationsexist in chemical quality of cowandbuffalomilkkhoa (table1.8).

Table 1.8: Chemical Composition of Khoa

Constituent % Cow Khoa Buffalo Khoa

Moisture 30.93 22.34

totalsolids 69.07 77.66

Fat 22.00 32.20

Proteins 19.10 17.70

Lactose 24.10 23.70

Ash 3.72 3.71

themarketsamplesofkhoashowwidevariationsinchemicalcomposition.certaintimes,the market samples fail to meet the minimum legal standards.to provide minimum legalstandards in khoa, the minimum fat content of 4.4% in cow’s milk and 5.5% in buffalomilk should be maintained.

Dairy Products Technology 17

Varieties of Khoa

therearethreedistinctvarietiesofkhoa.theydifferintheircomposition,bodyandtexturalcharacteristics and end use (table1.9).

Pindi

this variety is identified as a circular ball of hemispherical pat with compact mass,homogenous and smooth texture. it shall not show any sign of fat leakage or presenceof free water. it possesses pleasant cooked flavour and devoid of objectionable tasteslike burnt, acidic etc.this variety of khoa is used in the manufacture of burfi, peda andother similar varieties of sweets.

Dhap

it is a raw (katcha) khoa characterized by loose but smooth texture and soft grains andsticky body. dhap variety carries highest percentage of moisture over other varieties ofkhoa.thishighmoistureisnecessarytoprovideadequatefreewaterforsoakingofmaidaand semolina (vermicelli) and for homogenous distribution of other ingredients in thepreparationofsmoothgulabjamoonballs.thisvarietyofkhoa isused in themanufactureof gulabjamoon, kalajamoon, pantooa, carrot halwa, etc.

Danedar

thisischaracterizedbythegranulartexturewithhardgrainsofdifferentsizesandshapesembedded in viscous serum. slightly sour milk is preferred in the manufacture of thisvariety as it yields granular texture. this variety of khoa is used in the manufacture ofkalakand, milk cake, etc.

Table 1.9: BIS standards of khoa

Characteristics Pindi Danedar Dhap

totalsolids%bymass(min) 65.0 60.0 55.0

Fat%bymass(ondrymatterbasis)min 37.0 37.0 37.0

totalash(%ondrymatterbasis) 6.0 6.0 6.0

titratableacidity%(max) 0.8 0.9 0.6

coliformcount/g(max) 90 90 90

Yeastandmouldcount/g(max) 50 50 50

18 Dairy Products Technology

Preparation of Khoa

Khoa is prepared by different methods depending on the location, quantity etc. Khoa ismanufacturedby the following fourbasicmethodsviz. traditionalmethod, improvedbatchmethod, mechanized method and useofmembrane technology.

Traditional Method

generally buffalo milk is preferred for manufacture of khoa as it results in higher yield,smooth texture and soft body with sweet taste.Where buffalo milk is not available, cowmilk is used for khoa making but it results in pasty body and slightly saltish taste in theproduct.

Filtered milk is taken in a thick wide mouth iron pan (karahi) and boiled on a brisknon – smoky fire. An iron scraper (kunti) is used for stirring the milk during boiling andalso to scrape the milk films forming on the surface during boiling. A rapid stirring andscrapping is carried out throughout boiling to facilitate quick and rapid evaporation ofwater frommilkandalso toprevent scorchingofmilk filmonsurface.due to continuousevaporation of water, the milk progressively thickens. some researchers observed thatat 2.8 fold concentration of cow milk and 2.5 fold concentration of buffalo milk, heatdenaturation of milk proteins take place and the proteins will not go into solution again.As the concentration is progressing the product slowly tends to leave the sides of thepanandstartsaccumulatingat thebottomandat this stage thepanhas tobe removedfrom the fire.the contents are worked up and allowed to cool and the residual heat intheproducthelps in furtherevaporationofmoisture.At thisstage,stirringandscraping isincreased to obtain good quality product. if the milk is subjected to high heat treatmentwith less stirring and scraping at this stage results in dark colored khoa that does notfetchgoodmarket valueas thatofwhiteor creamcoloredkhoawhich ismorepreferredfor sweets making.

Production of Three Varieties of Khoa

Dhap

For preparing dhap variety of khoa the heating should be stopped at rabri stage (thickmass)andleavingtheproductwithoutmuchworkingresults indhapvarietyofkhoawhichcarry soft grainsand highmoisture content.

Dairy Products Technology 19

Pindi

For production of pindi variety of khoa, heating is continued after rabri stage and withthehelpofawooden ladle thesoft grainsarecrushedand themass isworkedout toasmooth texturedproduct.Aftercooling, thekhoa ismoulded in tohemisphericalmolds togive its shape.

Danedar

sour milk is preferred for production of khoa.generally the milk that is left over after thepreparationofothervarietiesofkhoaisconvertedintodanedarvarietyofkhoa.sometimescitric acid (0.05 to 0.1%) or sour whey is added to milk at boiling stage to get granulartexture.

Improved Batch Method

A stainless steel double jacketed, steam heated pan or kettle is used to provide greatercontrolontheheatingprocessandtoensureanonsmokyheating.Fivelitersofstandardizedcowmilkwith4.5%fatorfourlitersofstandardizedbuffalomilkwith5.5%fatistakenperbatchandmilk isbrought toboil in thekettle.duringboiling,bottomand thesurfacesofthe kettle are scraped and milk is stirred vigorously by a stainless steel stirrer to avoidburning of milk solids. About 2 kg/cm2 pressure is used for boiling milk. When the milkattainsa rabri stage,slowheating isnecessaryat thisstage topreventburningofsolidson the surface, discoloration of the product, development of burnt flavour and hard bodyand coarse texture.the rate of stirring should be increased during last stages to obtaingood quality product. As soon as the product shows signs of leaving the sides of thekettleandaccumulating in thecentre inapat form,heating isstopped. it takesabout15-20 minutes to prepare abatch ofkhoa (1 kgapprox) by thismethod.

Assteamwillnotbeavailableatvillageleveltheabovemethodhasitsapplicationonlyindairieshavingsteamproductionlines.Howeveravillagelevelkhoapanwasdevelopedtoovercome theaboveproblem.thesetupconsistsofhemisphericalmildsteelpan joinedto a cylindrical jacket.Water is taken in the jacket and heated by placing the whole unitoverachulla.steamisgeneratedinthejacketandthepressureis indicatedbyagauge.the milk is taken in the steel pan and heated by the steam and after loosing the latentheat, returns towaterphase.Water in liquidandvapour formexists inphaseequilibriumat adjusted pressure because of the closed system. good quality khoa can be preparedin the pan from2.5 litersmilk in 8minutes.

20 Dairy Products Technology

Mechanized Processes for Khoa Production

use of roller Driers

Arollerdryingprocesswasadoptedinthepreparationofkhoa.Processvariablessuchassteam pressure, flow rate and distance between rollers and scrappers were adjusted toget thedesirableproduct.Vacuumconcentratedmilkwith 50%t.s.washeated to 74 ºcfor10minutes todevelopcookedflavour inkhoa.steamatapressureof25 -30psiandrollerspeedof17-19rpmgivesgoodresults. itwasconcluded thatsatisfactorykhoacanbe prepared on drum driers using 50%t.s. vacuum concentrated milk.the concentrateis preheated to 101 to 103 ºc for 10-12 minutes to develop cooked flavour and drumswith steam pressureof 0.7 to 1 kg/cm2anda roller speedof 10 rpm.

use of Scrapped Surface Heat exchangers

Attempts have been made to use scrapped surface heat exchangers in the preparationof khoa. A mechanized scraped surface heat exchanger with a conical vat process isdeveloped for theproductionofkhoa. Forty kg concentratedor 80 kgwholemilk canbetakenperbatchwhichtakesabout14minutes&50minutesrespectively.steampressureused is 1.5 kg/cm2.Product lossesarehigh in thismachine.

a Continuous Khoa Making Machine

Acontinuouskhoamakingmachinewasdevelopedwhichconsistsofapreheatingcylinderand two cascading pans. the preheater is a steam jacketed cylinder containing rotaryscrapers which rotate at 120 rpm. the cascading pans are open steam jacketed pansprovidedwithspringloadedreciprocatingtypescrapperknivesoperatingat30strokesperminute.the milk is taken into the preheater and heated by steam at 3 kg/cm2 pressure.Here the milk is concentrated to about 30 to 35 per cent of total solids within 10 to 12minutes time. From the preheater, the milk enters the first cascading pan. Here the milkis further concentrated toabout 50 to55per cent total solidswithin7 to8minutes.theproduct thenmoves to thesecondcascadingpanwhere itsconcentration is raised to thedesired level i.e., 70-75 per cent in 6 to 7 minutes.the steam pressures maintained inthetwopansare2kg/cm2and1.5kg/cm2respectively.50 litersofmilkcanbeconvertedinto khoa within an hour time in this machine.the steam requirement is 50 kg per hourand electric power requirement is 4KWper hour.

use of Horizontal Heat exchanger

Ahorizontal heat exchanger forkhoamakingwasdevelopedwhich consists of ahopper

Dairy Products Technology 21

toaccommodate thefoamandprovidemilkconcentrationunderatmosphericpressure. inthismodelthesteamjacketissubdividedintothreepartstoreducetheamountofheatingas theproductmoves.thescraper speed is40 rpmand thesteampressuremaintainedis 3 kg/cm2in the first compartmentwhich is stepwise reduced to1.5 kg/cm2 in the lastcompartment.themachinecanconvert50kgofmilk intokhoaperhourperbatch.Latera continuous khoa making machine with three stage concentration was developed. themachine has three jacketed cylinders placed in a cascade arrangement. this facilitateseasytransferofmilkfromonecylinderintotheother.thescrapperspeedsare40,55and69 rpm for the first, 2nd& 3rd stage respectively.the operating steam pressures used are2.0&1.7&1.5kg/cm2 in respectivestages.one roller isused in the laststage inplaceof scraper blade which kneads the khoa to improve its body and texture.the first stageraises the milk solids level from initial 15 to 25 percent, the second stage to 50 percentandthethirdstageto70percent.themachineconverts50kgofmilk intokhoaperhourattheoperatingpressures,specified.However,thecapacitydependsonthemilkflowrate,steampressure,totalsolidconcentrationoffeedandfinalmoisturerequiredintheproduct.it is claimed that useof concentrated milk improves the capacity of themachine.

use of Inclined Scraped Surface Heat exchanger

An inclined scraped surface heat exchange for continuous khoa making was developed.theyusedascraperassemblywhichcombines the functionsof scrapingandconveying.the ssHe has 3 jackets which operate at 1.0, 1.5 and 1.0 kg/cm3 respectively. Milk ispre-concentrated to 40 - 55% t.s and fed at the rate 60-80 lts/hr. Feed temperaturesbetween10–80°ccanbeemployed.rotorspeedusedis40to80rpm.theadvantagesclaimed by this unit are:

l increased solids content in feed improves the colour of khoa because of reducedresidence times. it also improves the capacity of themachine.

l increase in feed temperature enhances the capacity of theplant.

l By increasing rotor speed there will be significant increase in the heat transferrate.

l Variation in steam pressure in separate sections of steam jacket results in changeof heat transfer rate, colour and texture of khoa due to change in the temperatureto which the milk constituents are subjected to different stagesofkhoamaking.

l the manpower requirementsare less.

22 Dairy Products Technology

Contherm – Convap System

Attemptsweremadetopreparekhoaoncontherm-convapsystemwhichwasdevelopedbyAlfa-Laval.thisunitconsistsoftwoparts,aconthermforheatingthefeedtoabout95ºcandconvap(assHe) forconcentratingmilk todesiredmilksolids level.concentratedmilkwith35-40%t.s.at the rateof300-350kgperhourcanbe fed to themachine.thesteam pressures employed are3 kg /cm2 in contherm and4 kg/cm2 in convap.

Factors affecting Quality of Khoa

Higheramountoffreefat(>60%)willbereleasedinbuffalomilkkhoathancowmilkkhoa.Higher free fat content contributes to soft body and oily or greasy appearance to buffalomilkkhoa.the quality ofkhoa dependson:

type ofmilk used inkhoa preparation

chemical quality ofmilk

Methodof preparation

degree of heat treatment

Manner of handling the product

Packagingemployed

duration, temperatureand humidity of storage.

due tocompositionaldifferences incowandbuffalomilks, thephysicalattributesofkhoawill vary.

activity

Prepare Khoa at homeusing1kgmilk

review Questions

1. Write theFssr 2011 standards forKhoa

2. Write thedifference betweenPindi anddanedarkhoa

3. Write the floe diagram for themanufactureof khoa

4. List the factors affecting quality of khoa

Dairy Products Technology 23

Chhana

objective

to learn the Product description, Methods of Manufacture, Packaging and storage ofchhana

Introduction

Chhana isanacidcoagulatedproductobtainedwhenmilkcoagulatedwith thepermittedacidsatnearlyboilingtemperature.solidcurdobtainedafterfiltrationofcoagulumiscalled chhana. it looks off-white, tastes mildly acidic, and has characteristic spongy texture.Chhana ismainlyprepared fromcowmilkandused forpreparationof veritiesofBengalisweets.ProductionofchhanaisconfinedtomostlyineasternregionofthecountrynotablyWest Bengal, Bihar, orrisa. About 4 to 4.5% of the total milk produced in india is usedfor chhana making.Chhana is usedasabase for thepreparationof a variety of sweetslikesandesh, rasogolla, chamcham, rasmalai, pantoa, channamurki etc.

Food Safety and Standards regulation, 2011 definition

Chhanaasaproductobtainedfromcoworbuffalomilkorcombinationthereofbyprecipitationwithsourmilk,lacticacidorcitricacid.itshouldnotcontainmorethan70%moisture,andits milk fat content should not be less than 50% on the dry matter basis. if skim milk isused, moisture should not exceed 70%milk fat shouldnot exceed13%of dry matter.

Methods of Manufacturing

Traditional Method of Manufacture

Chhanahasbeenpreparedbyboilingabout20-40ltsofcowmilkinanironKarahi.Acidicwhey (previous day whey) added to boiling hot milk serve as coagulant with continuousstirring till the completion of coagulation. contents then poured over a muslin cloth heldover another vessel, whey will be collected in that vessel. Muslin cloth containing curdmass is hung to further drain out thewhey.

24 Dairy Products Technology

Fig. 1.4: Flow diagram for Industrial production of chhana from cow milk

Method is similar to paneer making except pressing. ss vats and plate heat exchangeror steam jacketed kettle have been used for heating of milk and for storage of liquidmilk at industrial production. other process controls like temperatures of heating of milk,coagulationand coagulant are verypreciselymaintainedas shown in flowdiagram.Alsoss strainers with cloth liningareused to filter thewheyout of coagulum.

Dairy Products Technology 25

Mechanized System for Chhana Making

Aprototypemachinewithacapacitytoproduce40kgsofchhana/hourhasbeendevelopedatndri, Karnal.the production of chhana of commercial level is depicted inFig. 1.4.

thestandardizedcowmilkispumpedfromthebalancetank@of250litresofmilk/hrtoan injectionchamberwhereculinary livesteam(at1kgs/cm2pressureandat therateof65kgs/hr) is directly injected into the milk.the steam gets completely condensed in milkand the temperature is raised to 90-95°c.thereafter the milk is brought in contact withsour whey, the quantity of which is regulated in proportion to the rate of milk flow.themixture of whey and milk is circulated through a holding coil (8m X 10mm) to facilitatecompletecoagulationofmilk.thecoagulatedproductalongwithwheyisthenpumpedintoadouble jacketedcooling tank,where it is cooleddown to room temperature.Finally theproduct is taken to mechanical strainer, a double jacketed mechanical strainer, a doublejacketed inclined sieve, where it is drained thoroughly. Chhana with 55-65% moisture isdischarged through theoutlet and collected in the container.drainedwhey is transferredto a holding tank for souring for subsequent use.

Preparation of Chhana from Buffalo Milk

Introduction

in india about 53% of the total milk produced is from buffaloes. dairy plants prefer tobuy buffalo milk as it contains higher proportion of fat andt.s. (1.5 to 2.0) times morefat thancowmilk.Becauseofmany inherentdifferences inPhysico-chemicalmakeupofcowandbuffalomilkseveralproblemsareencounteredduringprocessingofbuffalomilk.calcium content has direct correlation with hardness.the high calcium and casein (cowmilk2.42-2.7%caseinandbuffalomilk2.6-3.38%casein)contentinbuffalomilktenderit unfit for preparation of most chhana based sweets. Few attempts have been made toproduce chhana frombuffalo milk

Amixtureofbuffalomilkandcowmilkintheratioof1:3yieldschhanawithsoftbodyandsmooth texture with features suitable for rasogolla andsandesh preparation.

Additionofmixtureofsodiumdiphosphate(75gper100lit.)anddisodiumphosphate(58gper100lit.) followedbystoring thehotmilk forsome timebeforeprecipitationproducesasoft chhana. sodium citrate converts some of the insoluble calcium into soluble salts inthe BM and this helps in production of softerchhana.

dilution of buffalo milk (standardized to 4% fat) with notable water @ 30% of milk afterboiling and coagulating at 70°c using 0.5% citric solution produces chhana good forsandesh making.

26 Dairy Products Technology

Factors Influencing Quality of Chhana

Type of Milk

cowmilkproduceschhanawithmoistsurface,lightyellowcolour,softbody,smoothtextureandmildlyacidic flavourwhich ismore suitable for sweetspreparations thanbuffalomilkchhana. Buffalo milk gives hard body and coarse texture, white in colour and greasysurface. sweets prepared from buffalo milk chhana are hard, coarse and less spongy.colostrum milk produces too pasty Chhana with deeper yellow colour and unsuitable forrossogolla.

Quality of Milk

Fat level

Minimum 3.5 to 4% fat in cow and 5% fat in buffalo milk gives a satisfactory body andtextureinchhana.Lowerthan3.5%fatleadstohardbodyandcoarsetexturewhilehigherfat level results in greasy surface

Acidity

Acidicmilkproduceschhanawithsoursmellandbittertastehenceunfitforsweetmaking.Additionof neutralizer to slightly acidicmilk helps in gettingchhana suitable forsandeshand not for rasogolla. Milk with 0.25-0.28% LA can be used by adding 0.2% sodiumcitrate followed by thorough washingof the coagulum.

Type, Strength and Quantity of Coagulant

Type

organicacids, likecitricacid, lacticacidor theirsalts(calciumlactate), tartaricacid,sourwhey are normally used. Lactic acid produces granular chhana suitable for rasogollamaking. citric acid gives pasty texture suitable for sandesh making. However citric acidcanalsobeusedformakingchhanasuitableforrasogolla.sourwheywith(0.9%LA)canalso be used for producing good quality chhana. calcium lactate produces chhana withbrightwhitecolour, softbodyandsmooth textureandpleasant flavourandmost suitablefor sandeshmaking.

Strength

Lowacidstrength(0.5%)resultsinverysoftbodyandsmoothtexturesuitableforrasogollabutunsuitableforsandeshmaking.theoptimumstrengthofcoagulantshouldbebetween

Dairy Products Technology 27

1 to 2% citric or lactic acid to produce good quality chhana suitable for making bothrasogollaandsandesh.However,calciumlactateof4%solutionproducesmostsatisfactoryquality chhana.

Quantity

the quantity of coagulant required is dependent on the type of milk. generally, 2 to 2.5g of citric acid per kg of fresh milk and 2.5 to 3.9 gm of lactic acid and 6 to 12 gm ofcalcium lactate per kgare required individually for complete coagulation.

Temperature of pH Coagulation

As the coagulation temperature decreases the moisture content of chhana increasesresulting softer bodyandsmooth texture, stickychhanawith slowwheydrainage.Highercoagulationtemperatureimpartsgraininessandhardnesstochhana.optimumcoagulationtemperature of cow milk is 80 to 850c and pH is 5.4 and that of buffalo milk is 70 to800cand pH is 5.7.

Speed of Stirring during Coagulation

Higher speedof stirringduring coagulation reduces themoisture content onchhana andincreases its hardness, whereas lower speed the reverse hold true (optimum speed is40-50 rpm).

Method of Straining

delayed straining produces a soft and smooth texture chhana than immediate straining.delayedstraininggivesahigherproportionofmoisture,yield, recoveryofmilksolidsandlower hardness.delayed straining is recommended for buffalomilk.

yield of Chhana

Yield and quality of chhana depends on the type of milk, heat treatment given to milkprior to acidification, coagulation temperature, acidity of milk strength of coagulant andresidence time of the coagulated chhana-whey mixture before separation of milk solidsfromwhey.

totalsolidspresent inmilkespecially fatandcasein influence largelyonyieldofchhana.the yield of chhana from cow milk is 15 to 17% and from buffalo milk yield will be 21to 23 %.

28 Dairy Products Technology

Shelf life of Chhana

Chhana isanextremelyperishablefoodproductduetoitshighmoisturecontent.Atroomtemperatureitdoesnotkeepgoodlongerthanaday.Underrefrigerationtheshelflifecanbe extended up to six days. since fresh chhana is preferred for making sweets of goodquality much research efforts have not beenmade in extending the shelf life.

Packaging of Chhana

Mostof thechhanawill beused formakingchhana basedsweets,nospecialpackagingmaterials were prescribed, as most of the time chhana will be sold in bulk. Polyethylenebags are widely used to pack the chhana. However, vegetable parchment paper, tincans, cellulose film, LdPe, aluminum foil /LdPe laminates could also be used to packthe chhana.

Defects in Chhana

the various defeets occurs in chhanaarebreifly explained in table 1.10, 1.11&1.12.

Table 1.10: Flavour defects

Defect Causes Prevention

smokyUse of smoky fire for boiling andsimmeringofmilk

Usenonsmokyfireforboiling&simmeringofmilk

sourUseofexcessiveaciditymilk.Useexcessiveamountofcoagulatingacid/sour-whey

Useoptimumaciditymilk, (preferably freshmilk)Useproperamountofcoagulatingacid/sourwhey

rancidFat hydrolysis due to lipase actionduringstorage(atroomtemperatureorabove)

storechhanaatlowtemp(4to60c)

staleexcessively long period of storage ofchhanaatlowtemp.(5-100c)

earlyutilization.

Dairy Products Technology 29

Table 1.11: Body & texture defects

HardBody

inadequatefatcontentinmilkusedforchhanaproduction.inadequatemoisturecontentinchhanaduetofaultyproduction

Useoptimumfatcontentinmilk

Maintain proper moisture content ofchhanabyadaptingcorrectproductiontechnique

coursetexture

Useofexcessiveaciditymilk.

inadequatefatcontentinmilk

too-hightemp.ofcoagulationtoo-lowpH.ofcoagulation

Useoptimumaciditymilk,(freshmilk)Keepoptimumfatcontentinmilkcoagulateatoptimum.temp.coagulateatoptimumpH

Table 1.12: Colour & appearance defects

Mouldysurface

Longstorageofchhana,especiallyinhumidatmosphereexcessivemoisturecontentinchhana

PacktheproductimmediatelyandreducetheexposuretoairMaintainpropermoisturecontentofchhana

Visibledirt/foreignmatter

incorrectornoclarification/filtrationofmilkimpropercleaningofutensils/equipmentsdirty/windysurroundingsduringmanufacturetransportofunpackedchhana

Followtheclarification/filtrationwithsuitablefilterscleantheutensils/equipmentsproperlyManufacturechhanainhygienicplacePackthechhanainairtightcontainersandthentransport

activity

take1kgmilk,heatitneartoboilingtemperature,coolitto70°c.Addthejuiceoffreshlycut lemonwhilemixingverygentlytillcleargreenishcoloredwheyseparatesout.takeoutthe curdmass in a thin cloth and hang it to drain the remainingwhey.

review Questions

1. definechhana asperFssr2011 standards

2. Brieflyexplain the factors affectingquality ofchhana

3. List thedefect ofchhana

30 Dairy Products Technology

Paneerobjective

to learn the product description, standardsandmethodsofmanufactureofPaneer

Introduction

Paneer is an acid coagulated product obtained when standardized milk coagulated withthepermittedacidsatspecifiedtemperature,resultantcoagulumisfilteredandpressedtoget the solid curdmass.Paneer has firm, close, cohesiveand spongybodyand smoothtexture.Paneerismainlypreparedfrombuffalomilkandusedforlargenumberofculinarydishes.though originally it was localized in north Western part of india but now it hastraveled almost all parts of the country. Paneer is generally sold as blocks or slices, italso refer as indian fresh cheese. itwas reported that, 5%of themilk produced in indiaisconverted intopaneer,around4500Mtwaspaneermade in2003-04,andgrowth rateof paneer production is 13%annually.

Standards

FSSr, 2011 Standards

Paneermeanstheproductobtainedfromthecoworbuffalomilkoracombinationthereofbyprecipitationwithsourmilk,lacticacid,orcitricacid.itshallnotcontainmorethan70%moistureandmilkfatcontentshallnotbelessthan50%ofthedrymatter.Milksolidsmayalsobeused in thepreparationof thisproduct (table1.13).Low fatpaneer shall containnot more than 70%moistureand notmore than15%milk fat ondry matter basis

Table 1.13: Chemical & microbiological limit for paneer

characteristics Bis(is:10484-1983,reaffirmed1999)

Moisture %Max 60

Milk fat %bymass (drymatter basis)min. 50

titratable acidity(as lactic acid),%bymass,max, 0.5

total Platecount nMt50,000/g

coliformcount, per g,Max 90

Dairy Products Technology 31

Yeast and Mould count per g,Max 250

totalPlatecount nMt50,000/g

coliforms nMt90/g

e.coli Absentin1g

salmonella Absentin25g

shigella Absentin25g

staphylococcusaureus nMt100/g

YeastandMoldcount nMt250/g

Anaerobicsporecount Absentin1g

Listeriamonocytogens Absentin1g

nMt=notmore than

Physico-Chemical Changes during Manufacturing

the phenomenon of coagulation involves formation of large structural aggregates andnetwork of protein in which milk fat get embedded. Acid and heat treatment causes thephysicalandchemicalchangesincasein.Heatingcausestheinteractionofß-lactoglobulinwith 8-casein and complex formed between ß-lactoglobulin and /-lactalbumininteract with8-casein. Acidification initiates the progressive removal of tri-calcium phosphate from thesurfaceofthecaseinanditgetsconvertedintomono-calciumphosphate.Furthercalciumis progressively removed from calcium hydrogen caseinateto form soluble calcium saltand casein. colloidal dispersion of discrete casein micelles changes into large structuralaggregatesofcasein.Undersuchcircumstancedispersionisnolongerstable,caseingetsprecipitated and forms coagulum.Fat will beembedded in the caseinnetwork.

32 Dairy Products Technology

Method of Manufacture

Fig. 1.5: Traditional method of paneer manufacture

Buffalomilkisboiledinasuitableironvesselandasmallportionofthisisthentransferredtoasmallervessel (Fig.1.5).thecoagulant (usuallysourwhey) isadded to thehotmilkandstirredwithaladletillcoagulationiscompleted.thecontentsofthevesselareemptiedover a piece of coarse cloth to drain off whey.the whole process is repeated till all themilk is converted into paneer.the curd is collected after draining the whey and pressedto remove more whey.Finally, product is thenwashedwith cold tapwater.

34 Dairy Products Technology

ForcommercialmanufactureofpaneerBuffalomilkisstandardizedto5.8%fathaving9.5%snF (standardize the buffalo milk to a fat: snF ratio of 1:1.65) (Fig. 1.6). Milk is heatedto 90°c without holding (or 82°cn with 5 minutes holding) in a jacketed vat and cooleddown to 70°c. coagulation is done at about 70°c by slowly adding 1% hot (70°c) citricacidsolutionwithconstantstirring tillacleanwhey isseparatedat (pH5.30 to5.35)andcoagulumisallowedtosettlefor5minutesthenwheyisdrainedoff.thecurdsoobtainedis filled into hoops lined with cloth. Pressure is applied on top of the hoop at a rate of0.5to1kg/cm2.thepressedblocksofpaneerareremovedfromthehoopsandimmersedin chilled water for 2-3 hrs.the chilled paneer is then removed from water to drain out.Finallypaneerblocksarewrapped inparchmentpaper /polyethylenebagsandplaced incold room at about 5 to 10°c. (indiandairyscience 1992, 6review6K.V.s.s.rao)

Paneer form Cow Milk

cowmilkyieldsaninferiorproductintermsofbodyandtexture.itiscriticizedtobetoosoft,weakand fragileandunsuitable for fryingandcooling.Buffalomilkcontainsconsiderablyhigher levelofcaseinandmineralsparticularlycalciumandphosphorous,which tends toproducehardand rubberybodywhilecowmilkproducessoftandmellowcharacteristics.By replacingone thirdof buffalomilkwith cowmilkagoodqualitypaneer canbemade.Buffalo milk paneer retains higher fat, protein and ash content and lactose as comparedtocowmilkpaneer.tomakepaneerexclusivelyfromcowmilkcertainmodificationsintheconventionalprocedurehave tobemade.Additionofcalciumchlorideat the rateof0.08to0.1% tomilkhelps ingettingacompactsliceable,firmandcohesivebodyandcloselyknittexture.Ahighertemperatureofcoagulation(85°-90°c)withoptimumpHofcoagulationof 5.20 to 5.25 keeps in producing good quality paneer from cow milk. However, at thispHof coagulation, moisture, yield and solids recoveryare less.

recent Developments in Paneer Manufacturing

use of ultra Filtration in Paneer Manufacturing

Ultrafiltration(UF)canbeused for themanufactureofpaneerwhichofferadvantages likeaccesstomechanization,uniformquality,improvedshelflifeincreaseyieldandnutritionallybetter product. in this process milk after standardization and heating is passed throughUFmembranewhere lactose,water and someminerals are removedaspermeate.

the concentrated mass which has about 40% total solids is cold acidified to getthe desired pH.Upto this point the product is flowable and can be easily dispersed intocontainerswithautomaticdispersingmachines.thefilledcontainerscanthenbesubjected

Dairy Products Technology 35

to texturization by passing through microwave tunnels.the resulting product has typicalcharacteristicsofnormalpaneer.theyields increasesbyabout25%which isdue to theretentionofgoodqualitywheyproteinsandslightlyincreaseinmoisturecontent(moistureabout 70%) yield is about 25%.

In-package long life Paneer like Product

A fully mechanized process has been developed which yields a long shelf life paneerlike product. in this process standardized buffalo milk is concentrated partly by vacuumconcentration process and partly by UF to a t.s. content of 30%. Acidified using gdL– gluco delta Lactone. After packaging in metallized polyester pouches, the product isformedby texturizingprocessat115°c for5minwhichpermits concomitant sterilization.the yieldofpaneer ismoredue to retentionofwhey solidsand the shelf life is 110, 80&47 days at 25, 35 and 45°c respectively.

Continuous Manufacture of Paneer

A continuous paneer-making system was developed at ndri, Karnal by Agrawala et al.(2001).inthissystem,theunitoperationsinvolvedinpaneermakinghavebeenmechanized.thecontinuouspaneermakingmachineisdesignedtomanufacture80kgpaneerperhourby employing twin-flanged apron conveyor cum filtering system for obtaining the desiredmoisture content and texture attributes

yield

theyieldofpaneer isdependenton the fatandsolidnot fatcontentof thestartingmilk,aswellas themoisture, fatandprotein retained in thepaneer.coprecipitationofcaseinand whey proteins is the simplest way of recovering whey proteins and thus increasingthe yield of paneer. Heat treatment of milk to 90°c is necessary to achieve good yield.generally a yield of 20-22 kgsof paneer frombuffalomilk and16-18 kg fromcowmilk

Factors affecting Quality and yield of Paneer

Type of Milk

Paneerpreparedfrombuffalomilkwillhavedesirablefryingproperties,bodyandtextureascomparedtocowmilk.thecowmilkpaneeristoosoft,weakandfragileandduringcookingit tend to disintegrate. However cow milk and buffalo milk at 50:50 yields better productthan cow milk.Paneer made fromskimmilk has chewy, rubbery andhardbody.

36 Dairy Products Technology

Quality of Milk

toobtainpaneerofgoodquality, themilkmustbefreshandfreefromoff falvour.growthof psychotrophic organisms should be minimized to restrict the off-flavour development.Acidic milk having a titratable acidity of more than 0.20% lactic acid yields a product ofinferiorquality.themilkwithcoBpositiveandlowacidity(sweetcurdling)isnotsuitableforpaneermaking.Paneermadefromsuchmilkhasweakbodyandtexture,moremoisture,acidic smell and not safe for humanconsumption.

Type, Strength and Temperature of Coagulant

Productyieldandmoistureretentionaredirectly influencedbythetypeandconcentrationoftheacidandthemodeofdeliveryandblendingintothehotmilk.citricacidisgenerallyused as a coagulant. Lemon or lime juice or vinegar imparts a typical flavour to theproduct. 1% solution of citric acid yields good quality of paneer. sufficient acid is addedgentlybutquicklyblendedwiththemilk(within1minute)toreachidealphofcoagulation.normally 1.8 to 2.0 kg citric acid is required for 1000L of milk coagulation High acidconcentrationimpartsacidflavour,hardnessandcausesgreatersolidsloss.Wheyculturedwith Lactobacillus acidophilus at a level of 2% and incubated overnight at 37°c can beused as a substitute for citric acid.

Heat Treatment of Milk

thisisoneofthetechnologicalrequirementsoftheprocesswhichaffectthesensoryandmicrobiological quality ofpaneer.theobjectiveof heating themilk is toprepare themilkfor rapid iso-electric precipitation, control the moisture content, develop typical body andtexture,createconditionsconducive to thedestructionofpathogenicandothermicroflorapresent in milk and ensure safety as well as keeping quality of the final product. themilk is heated to 90°c without holding or 82°c for 5 minutes in order to maximize thetotal solids recovery. Whey proteins especially ß-lactoglobulin and a-lactalbumin form acomplexwith Қ-caseinandretainwith thecurd thus increasetheyieldof theproduct.thehighheat treatment impartsdesirablecookedflavourbycontrolled liberationofsulphydrylcompounds.

Coagulation Temperature

it influences the moisture content of the paneer, an increase in temperature from 600cto860cdecreases themoisture inpaneer from59 to49%.At700c,paneerhas thebestorganoleptic and fryingquality in termsof shape retention, softnessand integrity.

Dairy Products Technology 37

pH of Coagulation

the optimum pH of coagulation of milk at 70°c is 5.30-5.35 for better product qualityandmaximum recoveryof solidswhenmade frombuffalomilk.themoisture retention inpaneer decreases with the fall in pH and consequently the yield also decreases. At pHmore than5.35 thepaneer isverysoftwith fragileandcrumblybody.optimumpHwhencow milk is used forpaneer preparation is 5.2.

Packaging and Shelf life

Polyethylene pouches, cryovac films, co-extruded laminates, retort pouches, are beingused for paneer packing. Vacuum packaging of paneer in laminated pouches increasestheshelflifetoabout30daysat6°c.Paneerpackagedinlaminate(eVA/eVA/PVdc/eVA)under vacuum and heat treated at 90°c for one minute increases the shelf life of up to90 days under refrigeration. Paneer packed in tins along with water/ brine and sterilizedin an autoclave at 15 Psi for 15 minutes lasts for 4 months.the product can be storedunder frozen conditions (below 18°c) for more than one year without any deteriorationin its quality. Paneer dipped in 5% brine solution lasts for about 22 days at 8-10°c.thesaltingat the timeof dipping into chilledwater canbeused inextending the shelf lifeofpaneer.dipping inbenzoicacid (1200ppm) increases theshelf lifeofpaneer to40daysat refrigerated temperature and 20 days at 37°c. By adding sorbic acid to milk (0.15%)and subsequent wrapping of paneer in sorbic acid coated waxed paper the shelf life ofpaneer can be increased to 36daysat room temperature.

activity

Prepare paneer asper the flowdiagramgiven in the chapter using1kg cowmilk

review Questions

1. definepaneer

2. Write the technical flowdiagram for thepreparationof paneer

3. give thegross composition of paneer

4. List thedefect of paneer

38 Dairy Products Technology

Chapter-2Composition, Standards, Manufacturing – Process and Equipment and Defects during Manufacturing and Storage of curd/dahi, yoghurt, chakka, shrikhand and cheese

Dahiobjective

to learn the Production, Packaging,storage anddefects ofdahi

Introduction

dahiisafermenteddairyproduct,producedbyfermentationprocessbydeliberatelyaddinglive,harmless, lacticacidproducingbacteria intheformofbacterialculturetomilk.Lacticacidbacteriaadded in the formofstarterculturemultiplyandgrow,produces lacticacid,acetic acid and carbon dioxide by utilizing lactose present in the milk. some bacteriause the citric acidofmilk to produce certain volatile organic compoundsmainly diacetyl,which is mainly responsible for flavor of dahi. Judicious combination of acid producingandflavourproducingmicroorganismsinthestarterhelpsintheproductionofdahiwithafirmbodyandgoodflavour.Fermentationgivesanacid taste tomilkwhich isparticularlyrefreshing inhot climateandalsopossess certain therapeutic valuesoriginally absent inmilk. Hence fermented dairy products are playing a very important role in human diet inmany regions of the world. Fermentation leads to partial breakdown of milk constituentsparticularly lactose and proteins and increases thedigestibility of culturedmilk products.

inVedicliteraturesalsowecouldfindmanyreferencesaboutfermentedmilkproducts,someof thepopular indian fermentedmilkproductsaredahi,Lassi,shrikhandMishtidoiandraita.

Food safety and standards regulation (FSSr, 2011) defines:dahi or curdmeans theproduct obtained from pasteurised or boiled milk by souring, natural or otherwise, by

Dairy Products Technology 39

a harmless lactic acid culture or other harmless bacterial culture may also be used inconjunction with lactic acid bacteria cultures for souring. dahi may contain added canesugar. dahi shall have the same minimum percentage of milk fat and milk solids-not-fatas the milk fromwhich it is prepared (table2.1).

Table 2.1: Chemical Composition of Dahi

componentsWholemilkdahi skimmilkdahi

%

Water 85-88 90-91

Fat 5-8 0.05-0.1

protein 3.2-3.4 3.3-3.5

Lactose 4.6-5.2 4.7-5.3

Lacticacid 0.5-1.1 0.5-1.1

Ash 0.7-0.75 0.7-0.75

Wheredahiorcurd issoldoroffered forsalewithoutany indicationofclassofmilk,the standards prescribed for dahi prepared from buffalo milk shall apply. Milk solids mayalso be used in preparation of this product.

Method of Preparation

Traditional Method

in traditional method of dahi preparation, milk is heated intensively to boil for 5 to 10min and then it is cooled to room temperature. thus boiled and cooled milk is addedwithpreviousday’scurdorbuttermilk, stirredandallowedundisturbed, toset,usually forovernight.

At halwai’s shop the milk is considerably concentrated before being inoculated withstarterculture.so that the totalsolidcontentofmilk is increased,particularly increase inthe protein content of milk results in custard like consistency of the dahi and keep theproduct fromwheying off.

Industrial Method of Making Dahi

the commercialmethod for productionof dahi is given in fig. 2.1.

Selection of raw Material

Productionofcultured/fermentedmilkdemandshighquality rawmaterialswith respect tophysical, chemical and microbial standards.

40 Dairy Products Technology

Filtration/Clarification

Fresh raw milk is heated to 35 to 40°c to aid clarification or filtration process then it isfiltered to ensure the milk is free fromextraneousmatter.

Standardization

FatisstandardizedbasedontypeofproductrangingfromfatfreetofullfatandsnFlevelis increasedbymin. 2% than thatofmilk. it is common toboost thesnFcontentof themilk to about 12%with the additionof skimmilk powder or condensed skimmilk.

increasedsnFinturnincreasestheprotein,calciumandothernutrientsandresultedwithimprovedbodyandtexture,custardlikeconsistency.Highermilksolidspreventwheyingoff of the product during storage.

Fig. 2.1: Flowchart for preparation of dahi at dairy industries

receivingofmilk

Preheating (35–40°c)

Filtration/clarification

standardization– (Fat: 0 – 5%,snF: 11–13%)

Preheating (60°c)

Homogenization (175Kg/cm2 )

Pasteurization (95°c/15min)

cooling to 30°c)

Addition ofstarter cultures (1 – 1.5%)

Dairy Products Technology 41

Packaging

incubation (300 - 35°c/8-10hrs)

dahi

coolingand storage<5°c

Homogenization

thestandardizedmilk issubjected tohomogenizationafterheating it to60°cto increasetheefficiency.Homogenizationreducesthecreamlayerformationduringincubation,singlestage homogenization with 175kg/cm2pressurewouldbe sufficient.

Heat Treatment

Milk intendedfordahioranyother fermentedmilkproduct isgivensevereheat treatmenti.e. 95°c for 15minor 85°c for 30min. followingare thebenefits of highheat treatment

– denatures and coagulates milk albumin and globulins which enhance the viscosityand produce custard like consistency

– Kills contaminating and competitivemicrobes

– development of relatively sterilemedium

– removal of air form the medium – more conducive for the growth of culturebacteria

– effectivethermalbreakdownofproteinreleasingpeptonesandsulfhydrylgroups,thisinturn providenutrients to starter bacteria

Packaging and Fermentation

theheattreatedproductmixiscooledto37°canditisinoculatedwithspecificdahicultureat the rate of 1 to 1.5%. starter culture is the most crucial component in the productionof high quality fermented milks. For the production of dahi mixed mesophilic cultures ofLactococcus lactis subsp lactis, Lc. Lactis subsp. cremoris, Lc. Lactis subspdiacetylactis,along with Leuconostoc species are grown together. Proper selection of culture strainsdecides thegoodqualityproduct.dairyculturesareavailable invarious forms like freeze

42 Dairy Products Technology

dried, liquidand frozen forms. in india freezedriedculturesaregenerallyused.After theproduct mix is inoculated with dahi culture it is thoroughly mixed and filled into plasticcups,sealedproperlytoavoidanycontaminationandspillageoftheproduct.thuspackedproduct is arranged in cases or crates and transferred to incubation room maintained at37°c.theproductmix is incubated till thepHof theproduct reaches4.4 to4.5and thenit is cooled rapidly to less than 5°c by exposing the cups to high velocity cold air or bycirculating chilled water.

Storage

dahi isnormallystoredat4–5°c.storageareashouldbemaintainedcleanand tidy toavoid any sort contamination.

Packaging of Dahi

dahi is packed in food grade polystyrene and polypropylene cups in 100g, 200g and400gpacksizes.Variouspackagingmachinesofupto400cups/minspeedareavailabletopackageculturaldairyproducts indifferentsizes.thepackagedproductshouldbestoredat 1-4°c for extended shelf life.

Table 2.2: Defects in dahi

slno

defect Probablecause remedy

1 insufficientFlavour

Lowcitrate level inmilk,Lowdiacetyl content

Add0.02–0.05%sodiumcitrateprior to themixcool rapidly after culturing

2 oxidized flavor copper contaminationexposure to fluorescent lightexposure to sunlight

Avoidusageof copper utensilsProtect product fromdirect exposuretosunlight/UV light

3 Yeast/cheesy contaminating yeast growth sanitation check

4 rancid flavor Lipolytic activity donotmix pasteurized andrawdairy ingredients prior tohomogenization

5 Weakbody insufficient heat treatment tothemixtoo lowmilksnFsever agitationafterfermentation

Heat treatment should be less than850c/30minHomogenize thedahi mix prior tohomogenizationincrease theMsnFcontent to 11%byaddingskim milk powder

6 grainy texture Highacidityimproper dispersion ofskimmilk powder

rapidly cool theproduct to<5°cafter attainingoptimumacidityUse in line screen/filter

Dairy Products Technology 43

Common Quality Problems in Dahi

several defects, that occurs in dahi due to various factors are shown in table 2.2.

activity

take1kgmilk,heat it near toboiling temperature,andcool it to32°c.Addaspoon fullof previous day’s dahi and keep it undisturbed for 8-10h. observe for flavor, texture andtaste.

review Questions

1. give the chemical compositionof dahi

2. List thedefects and preventing measures in dahi

3. Write the technical flowdiagram for themanufactureof dahi

Chakkaobjective

to learn Productdescription and Methods ofManufactureofchakka

Product Description

chakka is a fermented, intermediate dairy product obtained during the production ofshrikhand.scientificallychakkacanbedescribedasstraineddahi,inotherwordsitisthecurdmassobtainedafterremovingwheyfromdahi,eitherbymuslinclothorbasketcentrifuge.chakka is thebase material for theproduction of shrikhand and shrikhandwadi.

FSSr, 2011 Definition for Chakka

Meansawhite topaleyellowsemi-solidproductofgood textureanduniformconsistencyobtainedbydrainingoff thewhey from theYoghurtobtainedby the lactic fermentationofcow’s milk, buffalo’s milk, skimmed milk and recombined or standardised milk which hasbeen subjected to minimum heat treatment equivalent to that of pasteurisation. it shallhavepleasantYoghurt/dahi likeflavour. it shall not containany ingredient foreign tomilk.it shall be free from mouldness and free from signs of fat or water seepage or both. itshall be smooth and it shall not appear dry. it shall not contain extraneous colour andflavours. it shall conform to the requirements, given in table 2.3

44 Dairy Products Technology

Table 2.3: Chemical standards for chakka

Sl. no. Components

FSSr, 2011

ChakkaSkimmed

Milk ChakkaFull cream

Chakka

1 totalssolids(%Min)ondM 30.0 20 28.0

2 MilkFat%ondM 33.0(Min) 5.0(Max) 38.0(Min)

3 MilkProtein%(Min)ondM 30 60 30.0

4 titratableAcidity(%LA)Max 2.5 2.5 2.5

5 totalAshondM(%Max) 3.5 5.0 3.5

chakka when soldwithout any indication shall conform to the standards ofchakka.

Traditional Method of Making Chakka

in traditional method, cow milk or buffalo milk or mixed milk is boiled thoroughly andcooled to room temperature (30°c) Fig. 2.2. Previous day curd is added to this milk attherateof1to1.5%.Milk is leftundisturbedovernightatroomtemperaturetosetfirmly.it is then stirred and hung in a muslin cloth for 10 to 12 hrs to drain off whey.the curdmassobtained after removal of whey is calledas chakka.

Fig. 2.2: Flow diagram for traditional method of making chakka

Wholemilk

Boiling

cooling to 30°c

Additionof [email protected] to 1.5%

Keptundisturbedovernight

dahi (0.7 to 0.8%acidity)

Whey stirredandHung inmuslin cloth for 10–12hrs

chakka

Dairy Products Technology 45

Industrial Production of Chakka

skim milk is normally used in the commercial scale production of chakka (Fig. 2.3). Useof skimmilk hasgot three fold advantages theyare:

1. Low fat loss through whey

2. Faster moisture expulsion

3. Less moisture retention in the final product.

Fresh, good quality skim milk is received and heated to 85°c for 30min. High heattreatmentkills thecompetitivemicrobesandcreatecongenialenvironment for theculturebacteria.Heattreatedmilk iscooledto30°candinoculatedwithLF-40culturecontainingLactococcuslactissubsp.lactisandLactococcusLactisvar. diacetilactisattherateof1.0–1.5%.Milkaddedwithculturebacteriaisincubatedat30°cfor10-12hrs.Aftertherequiredacidityof0.8to0.9%lacticacidisreached,thecurdistakenintobasketcentrifugeorquargseparatortoremovewheyfromthecurd.Quargseparatorisaspecialtypeofseparatorcommonlyusedduringthe production of quargcheese to removewheyfrom the curd. Use of quargseperator forremovalofwheyfromcurdisarecent innovation, ithas increasedthechakkaproductionto8 tonnes/day.thusobtainedcurd mass/chakkaisready for furtherprocessing i.e. productionof shrikhand.

Fig. 2.3: Flow diagram for traditional method of making chakka

skimmilk

Heat treatment (85°c/30min)

cooling to 30°c

inoculation with LF-40 [email protected] to 1.5%

(Lactococcuslactis subsp. lactisandLactococcusLactisvar. diacetilactis)

incubation (10–12hr)

dahi (0.8 to 0.9% lactic acid)

Whey Basket centrifuge/quarg separator

chakka

46 Dairy Products Technology

review Questions

1. chakka is the intermediateproduct obtained during theproduction of

a) chhana

b) Paneer

c) shrikhand

d) rasogolla

2. skimmilk is preferred in caseof industrial productionof chakkabecause

a) reduction in fat loss through whey,

b) Fastermoisture expulsion

c) Less moisture retention in the final product

d) All the above

3. As perBis standards the fat content ofwholemilk chakka is

a) Min. 25%

b) Max. 30%ondrymatter basis

c) Min. 35%

d) Min. 33%ondrymatter basis

4. As perPFA standards yeast andmold count of skimmilk chakka

a) Max10 cfu/g

b) Max20 cfu/g

c) Max 30 fcu/g

d) Max 40 cfu/g

5. Acidity of chakka

a) 0.5% lactic acid

b) 0.8% lactic acid

c) 1.5% lactic acid

d) 2.5% lactic acid

AnsWers

1.(c) 2.(d) 3.(d) 4.(a) 5.(d)

Dairy Products Technology 47