D r a in a g e in v e s t m e n t - williammorfoot.co.uk · S o il p u s h e d b a c k o v e r th e...

Transcript of D r a in a g e in v e s t m e n t - williammorfoot.co.uk · S o il p u s h e d b a c k o v e r th e...

Tillage Summer 2017 14 www.tillagemagazine.net

One look at an outfall into aditch makes it clear why a20ha (50-acre) block of

land on the Penllyn Estate inSouth Wales was in dire need ofa new drainage scheme.

Four weeks after being laid inearly March, water is flowing outof the 80mm pipe at a fair rate ofknots – and has been from withinan hour of being put in theground as part of a herringbonepattern scheme installed bycontractor William Morfoot.

Damien Burnell, who looksafter day-to-day management ofthe arable enterprise on theestate near Cowbridge in theVale of Glamorgan, says the newdrainage scheme will make a bigdifference to the workability andprofit potential of the block.

“It gets terribly wet, causingpoor crop establishment andmaking it difficult to get on theland when you need to,” he says.“We have other land with acutedrainage problems and the planis to tackle another 40ha (100acres) over the next two years.”

Arable crops account for justover half of the 1000ha (2478acres) of mostly in-hand landfarmed on the estate, with wheatsupplying two south Wales feedmills accounting for 50% of arotation that also includes feedbarley and some malting springbarley, which is partly grown forits strategic value in blackgrasscontrol.

Spring beans and spring oatsare also part of the mix, and witha climate that brings few fleabeetle problems, winter oilseedrape remains a popular crop.

“In fact, it’s our biggestearner,” says fellow managerAndrew Shackell, whose mainfocus is the estate’s numerousdiversification enterprises. “Wedon’t suffer from dryness downhere, so as long as we keep ontop of the slugs, we can growgood crops of oilseed rape.”

1000mm annual rainfallWith a long-term average in

excess of 1000mm a year, notsuffering from dryness issomething of an understatement.And on soils that arepredominantly clay loams andsilty loams, with the heavierground lying over limestone,timely cultivations and drilling are essential.

“The larger arable block on theestate is free-draining but partslying in a historic flood plain arenot as naturally free-draining,”notes Damien. “For the past threeyears we’ve been introducing

Soil pushed back over the trench will belevelled with a rotary tiller once settled.

Penllyn Estate managers Andrew Shackell (left) and Damien Burnell, with digital contourand drainage scheme layout maps.

Waterlogged land has poor soil structure, delays field operations and prevents crops performing to their potential.

Drainageinvestmentpays off

Bringing land back into productive cropping is the aim of a land drainagescheme recently completed on a south Wales farming estate. Peter Hill reports.

www.tillagemagazine.net 15 Tillage Summer 2017

PracticalPractical

cover crops such as deep-rooting radish to help improve the soils.”

Min till establishment approach At present, the farming

operation is committed to alargely minimum tillage approachto crop establishment, using a6m version of Vaderstad’s Carrierdisc cultivator. This has two rowsof flexible tines up front to bashslugs when working on stubblesand the levelling board tines forploughed ground.

A 7.5m Claydon stubble rakeis also available to spread chaffand disrupt slugs, and the estatehas toyed with direct drilling tothe extent of calling in a localcontractor’s Mzuri Pro-Til tinedrill to put spring beans intocover crops, accompanied by100kg of TSP.

But for the most part, a 6mRapid A-600S trailed disc seederis the lead drill, while oilseedrape, and stubble turnips andforage rape for the sheepenterprise are sown in one passfrom a BioDrill on the back of a4m TopDown progressive depthtine cultivator.

In addition to surfacecultivation, the TopDown’slongest tines provide the

subsoiling action required tobreak through compaction fordrainage and to encourage thecrop in its deep-rooting habit.

“Elsewhere in the rotation,subsoiling is carried out only ifinvestigation with a spade showsthat it’s needed,” says Damien.“We also use the spade beforeany cultivation because we don’tlike cultivating deeper than weneed to.”

Organic matter dilemma At present, the majority of straw

is chopped on the combine butin a dry season Andrew andDamien could be tempted toleave some in the swath forbaling given keen demand forsupplies from the stock farms ontheir doorstep.

“As ever, it’s a question ofbalance,” says Andrew. “The landis in good heart as far as organicmatter is concerned because wehave a 30,000 tonne gardenwaste composting operation onthe estate and only recentlypacked in a 1200-head beef unit.

“We already see someherbicide lock-up because of thehigh organic content, so the soilwouldn’t miss the straw,” he adds.“But then we have to consider theimpact of soil compaction frombaling, collecting and hauling thestraw off fields.”

While that is a decision for adry year, the currentpreoccupation is with gettingland that lies wet into moreserviceable condition.

Selling a block of land fordevelopment on the edge of thelocal town has provided thecapital to invest in drainage inthree tranches across 60ha (150acres) of the estate so faridentified as being in most need.

Fields deteriorated over timeTim Sisson of drainage

contractor William Morfoot takesup the story: “The estate had

identified multiple fieldsexperiencing acute drainageissues, with poor cropestablishment and evidence ofsoils being at saturation point atground level, resulting in fieldsbeing unable to achieve theiryield potential and ultimatelyreducing the bottom line earningcapacity of the ground.”

Although there was little or novisual evidence of it, a linen mapdiscovered in the estate officerevealed an extensive complex ofclay tile drains installed some 50years ago when generous grants

were available for such landimprovement works.

Andrew Shackell remembersvegetable crops being grown onthe site in the 1970s andharvesting fodder beet beingmanageable in the 1980s.

“But since then, conditionshave deteriorated as drains failedand the ground becamewaterlogged and pretty muchdied,” he says.

Investigations on the groundhad shown that many of thepipes were failing and there hadbeen no gravel backfill used on

www.tillagemagazine.net 17 Tillage Summer 2017Tillage Summer 2017 16 www.tillagemagazine.net

Damien Burnell points out the barelyvisible trace of the tracked gravel cart.

Marker post highlights the location of aninspection chamber for jetting access.

Draining through the rape when it wasmuch smaller in early March has costlittle through losses compared with thebenefits anticipated, says Damien Burnell.

The next generation TopDown

BioDrill

Double SteelRunner

Single SteelRunner

TopDown is now entering a new generation. Extensive updates, together with the new packer option double SteelRunner, means that the unmatched performance of this combination cultivator is further expanded.

Double SoilRunner

www.vaderstad.com

Water has been gushing from the mains since an hour or so after they were laid.

PracticalPractical

Practical

Tillage Summer 2017 18 www.tillagemagazine.net

Practical

www.tillagemagazine.net 19 Tillage Summer 2017

the older pipes, despite beinglaid in heavy subsoils.

Drainage issues investigatedWilliam Morfoot was engaged

to further investigate the issuesand undertake a detailed surveyearly this year. The firm’s quadbike GPS survey provided adigital topographical map whilestudying old paper farm mapsrevealed how water flows weremanaged around former fieldboundaries – the first block of20ha (50 acres), for example,was once eight individualpaddocks.

“We also identified the need forsome improvements to ditchsystems and, in particular, for a new ditch to manage waterflowing into the area fromsurrounding higher ground,”notes Tim Sisson.

The ditch will be dug using theestate’s own Takeuchi 360-degree excavator as aninterceptor for water coming offthe narrow field to the west of therecently drained site and thewooded area beyond, takingcare to avoid a pipe running tothe farm buildings from a nearbyborehole.

Andrew recalls his concernthat this had been breachedwhen the main drains wereinstalled: “I was convinced they’dcut into the pipe when the mainsstarted running with a largevolume of water – but it wassimply coming out of theground.”

Scheme gets in placeThe natural contours of the

land and overall shape of thefields called for a herringbone

layout, using 80mm and 100mmperforated plastic pipe for thelaterals at 20m spacing feedinginto a pair of 160mm main drainsrunning down the slope to anexisting ditch.

Gravel backfill was added toan average depth of 450mm as itis considered a key factor inassisting rapid infiltration ofsurface water into the pipednetwork.

“Gravel speeds the rate atwhich excess water is able todrain away, which allows the fieldto recover more quickly afterheavy or prolonged rainfall,” saysTim Sisson. “Mole drainage wasconsidered at the survey stagebut we felt that the subsoilspresent were not conducive toholding mole channels openeffectively in the long term.”

There is also the added

dynamic of the significant annualrainfall – more than 1000mm ayear, remember – which limits thewindow for carrying out moledrainage operations.

With everything agreed, notime was lost in getting thescheme underway, with Morfoot’sMastenbroek tracked trencherguided by GPS steering andgradient control working its waythrough oilseed rape in thewestern side of the site andpoorly established winter wheaton the eastern portion.

As Damien Burnell points out,only a third of the intended winterwheat area was sown in the fieldlast autumn because of theground conditions.

“We knew what the crops wedid get in wouldn’t performparticularly well so there was nopoint waiting until harvest to havethe work done,” he says. “Bypressing on, we thought we’d

Let’s talk profitable farming.

Now that’s something to talk about.

High leg clearance for unrivalled trash flow Band placement of fertiliser ensures early

nutrient accessibility Accurate seed depth control Press wheel reconsolidation provides excellent seed

to soil contact A choice of row spacing for optimum light interception

Mzuri’s unique one-pass system significantly reduces crop establishment costs, improves soil structure and increases yields, meaning farmers can enjoy profits – both today and tomorrow.

T: +44(0)1905 841123 E: [email protected] www.mzuri.eu

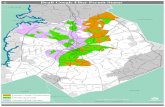

An aerial view of the first 20ha (50 acre) block to be drained; fields at the far end and bottom right are also due to be drained during the next three years.

Contractor William Morfoot’s trencher and backfill wagon work in tandem.

www.tillagemagazine.net 21 Tillage Summer 2017

probably get more benefit fromthe drainage than any lossescaused by draining through thestanding crop.”

To start putting that right, amotley hedge running from oneend of the site to the other wascleared with half an eye tocombining the land on either sideinto one field. As it is,conservation scheme rulesrequire that it be re-instated,which is why pre-cast concreteinspection chambers set into thetwo mains to facilitate flushing ifneeded in future coincide with itslocation.

In the meantime, the old hedgeline and tramlines provided auseful access route for the self-propelled gravel cart, whichdespite a fully laden all-up weightof 33 tonnes left barely visibletrack marks where it had to crossvirgin ground.

“We were hugely impressedwith the way Morfoots went about

the job, from the site inspectionand surveying to the work on-site,” says Andrew Shackell. “The operators were veryconscious about minimising theamount of travel off previouslytracked ground and they evenmanaged to get the mains intothe ditch without disturbing thestock fence – perfect!

“Over the seven or eight daysthe crew was here, they alwayscleaned the yard and anymachines of ours they used, suchas our small excavator, andthey’ve been in constantcommunication, ensuring weknew what to expect and withgood follow-up.”

In addition to a drainagescheme that should workwonders for future cropping onthat block of land, the estate nowhas a detailed map of thescheme available digitally as wellas on paper.

And also a low-tech, high-tech

combination of marker posts andGPS co-ordinates now enteredinto the estate’s Gatekeeperfarm records as a permanentrecord of the location of the newoutfalls, which continue to run asa huge volume of water shifts outof the soil.

Tillage Summer 2017 20 www.tillagemagazine.net

Practical Practical

“YOU CAN HEAR MY HEART BEATING IN EVERY MACHINE.“

www.horsch.com

MICHAEL HORSCHManaging Director and founder

Visit our website, your local HORSCH dealer or call 01778 426987.

VERSATILE OPERATIONS FOR STUBBLE AND CULTIVATED LAND

JOKER

The contractorDrainage contractor William

Morfoot Ltd is based nearThetford, Norfolk but operatesnationally, having drained landthroughout Britain for almosthalf a century.

“There are few costsassociated with farming thatproduce a comparable andconsistent level of return tothat of investing in fielddrainage,” says Tim Sisson. “A professionally designedand installed land drainagesystem will last for 20 years ormore on stronger soil types,and that’s what we aim toprovide with our latest-technology surveying andmapping systems, and

drainage installationequipment.”

In addition to land drainage,the firm works in theenvironmental sector creatingwetland habitats and createsand refurbishes wetlandscrapes as well as lakes,ponds and reservoirs. It alsohandles the installation ofwater management, utility andrenewables infrastructure, andconstructs sports fields andhorse arenas.

The company is accreditedby the Land DrainageContractors Association(LDCA) and is Achilles UVDBverified and approved forutility works.

Tim Sisson, managing director atdrainage contractor William Morfoot.

Getting excess water away will help timeliness of operations such as drilling and spraying

!"#$%#&$'()(*+%#$,-$"#./$'(0#$/1#2+3+-%$4(1'+%)$&-105• Practical• Independent• Authoritative

678321+8#$%-&$(,www.precisemag.net9(..$:;<=$>=?$?@?>

Tillage Spring 2017

24

www.tillagemagazine.net

ractical

Practical

A tablet in the cab

Using a tablet com

puter in the tract

or cab has becom

e a realistic altern

ative

or complement t

o an ISOBUS disp

lay terminal.

Trimble s newly-introduced

MMX-070 terminal uses Androidas its operating platform and has

an ISOBUS task controller —

although Trimble does not

participate in AEF conformance

testing — that will provide

automatic rate adjustment and

working width section control.

The 7in colour touch-screeen,

and built-in WiFi and Bluetooth,

can be used in the cab to also

provide visual steering

guidance; in the field for

scouting and mapping; and in

the farm office for planning and

data analysis.

Various Trimble and approved

third-party Apps for other

functions are also available for

the device and it can access

Trimble s Connected Farm

records for decision making

based on real-time data.

Trimble s newly-introduced MMX-070 terminal

V derstad s E-Control also

uses an Apple iPad

for remote machine control,

monitoring and data transfer

functions, while bringing the

tablet computer s proven

abilities as a computer for

Internet access and professional

apps into the tractor cab.

E-Control can operate with the

Tempo precision planter and

Rapid seed drills (but not the

Spirit as yet) for calibration, in-

work monitoring, settings

adjustments and collected data

transfer.The iPad is set into a moulded

case that incorporates a side

grip and buttons that are easier

to use when the tractor is in

motion than tapping the touch-

screen. But there are no

electrical connections between

these two components to be

affected by dust or moisture

because they communicate via

WiFi and the iPad communicates

in the same way with the

Gateway job computer on the

planter or drill.

The lack of hard wiring means

the tablet can be used out of the

cab — so, for example, an

operator can stand alongside a

Tempo planter while running

through the calibration process

for individual seeding units.

V derstad s E-Control also uses an Apple iPad

Claas favours using an Apple

iPad running iOS8 or later as a

control terminal; an ISO UT

applications maps the ISOBUS

system of an implement so it can

be operated through the tablet

computer s touch screen.

Being ISOBUS compatible,

the Claas EASY on board app

can be used with any machine

that conforms to the standard

and certain implement functions

can be assigned to the F keys

on a Claas tractor s control

joystick.Communication between the

implement and the iPad takes

place over a wireless connection

via an adapter connected to the

in-cab ISOBUS socket of the

tractor.

Claas favours using an Apple iPad running iOS8 or later

WiFi is also used by Danish

fertiliser spreader manufacturer

Bogballe for communications

between an Android tablet

computer, a wireless

communication module and the

company s Calibrator Zurf

spreader controller.

Harnessing the typical ease of

use and display quality of a

tablet computer provides a

means of setting and operating

the spreader regardless of the

GPS and tractor brand, says the

company. It also gives access to

functions such as test features

that are not possible with an

ISOBUS virtual terminal.

Apps downloaded to the

tablet provide various functions,

including touch-screen spreader

operation and auto stop/start

and straight or curved A-B

line guidance.

Headland section control,

which includes a split-screen

display showing the area treated

alongside spreader settings, is

also available along with the

newly-introduced variable rate

application.

Position data can be received

from an existing GPS antenna or

non-GPS variable-rate devices

such as the Yara N-Sensor and

Claas Isaria crop sensing

systems, and to external

variable-rate treatment units

including the Soyl Opti, iSoyl and

Patchwork devices.

WiFi is also used by Danish fertiliser spreader manufacturer

www.tillagemagazine.net

25

Tillage Spring 2017

Farm Smarter

Summer 2017

!"#$%&'()*!"#$%&''&()#*+,,-**

!"#$%&'()*./0#/%#1//'2#13-#,4*-#5/%#$%/(-*

+",-./%01$2-#-3.%4"15-./%631,

&01-./

7-/%0-2'(1$.3-#,4*-#5/%#6.781"2'-2"98'+)#4($#9'40#&*#3-%-#1/#*140

:.#-/;':+1%&-(1*2#$/#&1#%&)31!"#$%&#'()"%*+'

,-.''''''''''''''''''''''''''

''''''''''''''''''''''''''''''''''

''''''''''''',/'''''''''''''''''

''''''''''''''''''''''''''''''''''

'''''''''0001)"#$%

+1*#4

![^^D , >d, WZKs/ Z >/^d/E' r &/E E / > ^^/^d E D ] o ' } µ Z …...^^D , >d, WZKs/ Z >/^d/E' r &/E E / > ^^/^d E](https://static.fdocuments.in/doc/165x107/5eae9b3147042534de5dc81c/d-d-wzks-z-de-r-e-e-d-e-d-o-z-d.jpg)

![d Æ d R y B .F GR ANT WM e r f d U S P i n e o r o e d T ... · k!] 9! 9! 9! 9! 7 I s l a n d R d G l a d e s R d H e a r n ' s u R d R e i d s R d U n i o n R C h a p e l R d G](https://static.fdocuments.in/doc/165x107/5e6f7dd3a89b897c3463f640/d-d-r-y-b-f-gr-ant-wm-e-r-f-d-u-s-p-i-n-e-o-r-o-e-d-t-k-9-9-9-9-7.jpg)

![D e s e r t e r - D&D Eberron 5E€¦ · D e s e r t e r 7KH/DVW:DUPRELOL]HGKXJHQXPEHUVRIVROGLHUV ZKLFKWKH QDWLRQVKXUOHGDJDLQVWHDFKRWKHULQVHHPLQJO\HQGOHVV ... 13 I keep my weapons](https://static.fdocuments.in/doc/165x107/5b770fbb7f8b9ad3338c5581/d-e-s-e-r-t-e-r-dd-eberron-5e-d-e-s-e-r-t-e-r-7khdvwduprelolhgkxjhqxpehuvrivroglhuv.jpg)