D E MOL #4 Newsletter of Dispuut Geo-Engineering De ...

Transcript of D E MOL #4 Newsletter of Dispuut Geo-Engineering De ...

Main sponsor of “De Ondergrondse”:

DE MOL #4December 2015

Newsletter of Dispuut Geo-Engineering “De Ondergrondse”

2

De Ondergrondse has been working together with the Dutch engineering association “KIVI Geotechniek” for quite some time now. In order to make this cooperation even better, KIVI Geotechniek is offering the stu-dents of the Geo-Engineering section the possibility to join the activities hosted by KIVI Geotechniek. These activities vary from excursions to conferences and more, for most activities you need to be a member of KIVI Geotechniek and most are organized in Dutch language. In order to become a member students pay a re-duced fee, however KIVI geotechniek offers students of the Geo section a special offer: the first 10 registra-tion don’t have to pay any fee! If you would like to become a member of KIVI Geotechniek, send an email to

Furthermore I would like to inform you about the best graduate price, this price is handed to the best graduate every year, students can also nominate each other by sending an email to [email protected] or you can contact us for more information.

Upcoming KIVI activities can be found in the agenda of this Mol and even more at https://afdelingen.kiviniria.net/geotechniek/

3

Ta

ble

of co

nte

nts

Table of contents

From The Board

Recent activities

Article TEC-tunnel: Santos Harbour Channel Crossing

Article Fugro: Statische en Seismische Analyse (Dutch)

Msc Thesis: Yask Kulshreshtha

Upcoming activities

4

5

9

12

16

19

ColophonContact

“De Ondergrondse”p/a Stevinweg 1, kamer 0.0.432628 CN Delft

T | 015-278 2778E | [email protected] | www.ondergrondse.nl

ColophonCirculation: 300Editor: Loys Vermeijden

CoverEl Salvador Landslide, www.usgs.gov

BackRock Formation, www.geologyin.com

Next editionDeadline: 29th of January 2016

4

Fro

m t

he

Bo

ard

by Loys Vermeijden

From the board

The new academic year started quite hectic for all new master students with a lot of laboratory tests and reports to deliver. Where the second year students took different paths. Some stayed at the university to follow courses while others did an in-ternship at different companies. The year was start-ed with a barbeque where the new students could meet the second year students and the staff. Now everybody is settled in Delft and also the new stu-dents found De Ondergrondse. All showing up at the activities organized in the first and second pe-riod.

Throughout the period there were different Geodrinks and excursions organized which many members joined. In October the board changed and although it is still December a new year has already started for De Ondergrondse. At the gen-eral members assembly we pointed out our priori-ties for this year of which you can read more in this Mol. We have a lot more planned coming year and we hope you will all join the activities with us. Not to forget this year the Ondergrondse celebrates its

second Lustrum so don’t miss out.

Attached to this Mol you also find our constitu-tion card, introducing this years board.

Last but not least I would like to say: Merry Christmas and a Happy New Year! I hope to see you all in 2016 still having ten fingers and joining our New Years Dinner the 5th of January. Enjoy reading the Mol and enjoy your holidays.

Just before the holidays the last ‘Mol’ reached you. This edition is full with all the activities that were or-ganized in the first and second period and some interesting articles from Fugro, TEC and Yask that will get you through your Christmas holidays. Enjoy.

5

Re

cem

t activ

ities

by Kjell Dedecker

by Gustav Andrag

by Jorrit Molendijk

Already three weeks into the 1st period, all newcomers to the Geo-Engineering Master Program were settled and could almost remember a quarter of their fellow students’ names! This made the second Geod-rink of the year a bit more relaxed with many a lecturer showing face. We had a few cold beers and good conversations. As usual, board members struggled to dissipate the remaining participants at closing time. •

On the 31st of August a new academic year started. About 50 new students couldn’t wait to start the geo-engineering master track. After a short introduction about the courses, De Ondergrondse offered the students a first touch with a geo-engineering project. The whole group visited the Spoorzone Delft site dur-ing the afternoon. After a short introduction, a presentation about the construction of the Spoorzone was given. Next the theory was put into practice by a visit to the construction site and one of the tunnels. The day was finished with the first geodrink of the year, accompanied with a tasty barbeque. While the board roast-ed the meat, the first year students took their chance to get to know the other students and staff members while enjoying a nice, cold beer. It is clear that the excursion and geodrink with barbeque were a perfect start of the new year, both for the students as for De Ondergrondse! •

At the start of October the Ondergrondse was warmly welcomed by our main sponsor Fugro at their headquarters in Leidschendam. The afternoon was opened with a luxurious lunch and some informal con-versation with the staff of Fugro that arranged the Company Day. Huub Schellekens explained about the history of the company Fugro, their vision, mission and key drivers.

A recent geo topic in the Netherlands concerns the earthquakes in the Northern region: Groningen. Fugro helps conducting research on understanding the man-induced earthquake phenomena and predicting dam-ages caused by these earthquakes to the buildings in the area. Since it is a relatively new field in the Nether-lands a lot of research is done, numerical and physical modelling can help us understand these earthquakes and maybe provide a basis for preventive measures. Following the nice introductory talk and the lecture about Dutch earthquakes, two sections of Fugro were visited: the DRIVE-MAP system and the laboratory of Fugro, where the soil investigation is done.

The DRIVE-MAP system of Fugro is a mobile laser scanner system which maps the environment and can provide very precise topographic information. The system can be used on driving cars and trains and there-fore provides a fast solution for precise environment mapping.

Recent activities

Company day Fugro

Geodrink September 24th

First day excursion and BBQ

6

Re

cen

t A

ctiv

itie

s

On the 7th of October, the yearly Projects marathon was held. This initiative by the COB and KIVI TTOW was joined by six of our master’s students. We had a nice inside look into places where we normally are not allowed to go, visiting three projects around Amsterdam. We gathered at 07:15 already to travel by train to Amsterdam Central station where we left for the trip.

First, we went to the Velser tunnel, one of the oldest tunnels in The Netherlands, which the consortium HYACINT is renovating. After an interesting presentation about how they were going to get the job done, we had a look inside the tunnel to all the installations. The project is especially difficult because the replace-ment of the installations in the tunnel and the enlarging of the tunnel height had to be done within a very tight schedule.

After this visit, we went back to Amsterdam to the VU where we had lunch and then visited the construc-tion site of the new VU building. The new VU building needed a three layers deep parking garage which meant constructing an 11 meter deep building pit using an underwater concrete floor.

This all had to happen with the existing VU buildings lying within 5 m of the building pit meaning settle-ments of the surrounding where not acceptable. To make things even more complicated, vibrations also were not allowed hence the sheet piles had to be pushed into the ground. The last project of the day, was the Spaarndammertunnel, situated between the Spaarndammer neighborhood in Amsterdam and the IJ. This two-way, two lane tunnel was constructed by Max Bögl and is going to be 800 m long to help the congestion problems in Amsterdam. After the projects, the whole group went out for dinner to end the day.

A small movie was shown where the visual result of the mapping was provided.

All geo-engineering students perform some standard laboratory testing during the first period of their first year with the course Site Characterisation, Testing and Physical Modelling. At the Fugro laboratory the head of the laboratory showed us how these test were performed and used in professional practice. A very nice link between our master’s programme and practice!

The afternoon was finished with a nice drink and some more informal conversation with the Fugro staff about the presentations and tours. All students were able to get a good overview of the company and the possibilities of internships, theses and starting a career at Fugro. On behalf of the Ondergrondse board I would like to thank Fugro, the students and the previous board members for the pleasant and interesting afternoon. •

Excursion KIVI TTOWby Tom Laumen

7

Re

cem

t activ

ities

It was a nice opportunity to see how the big underground projects in the Netherlands are put into prac-tice, often within very tight schedules and very limited space. Again we would like to express our thanks to the COB and KIVI TTOW for being able to join this nice event. •

ISGSR 2015by Edwin Kester

From Tuesday October 13th until October 16th, the fifth International Symposium on Geotechnical Safety and Risk (ISGSR2015) was held. De Ondergrondse was involved in the organization of this conference. The task of De Ondergrondse was to organize students that were willing to help during the conference. During the conference speakers from different countries all over the world gave lectures about their research and findings on geotechnical safety and risk. The speakers were divided over different sessions with each their own theme. Some different themes were: spatial variability, slope stability, risk management, observational method, offshore and reliability analysis.

During the conference the students that subscribed for the event of De Ondergrondse entered the con-ference for free, in return they had to assist with some minor actions during the different sessions. The conference was very interesting!

De Ondergrondse thanks her members: Ceren, Marilou, Manuel, Sharief, Raghav, Tom Laumen, Tom Maatkamp, Jip, Robbin, Gerrit and Edwin for their commitment! •

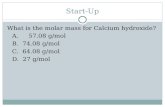

General Members Assemblyby Gustav Andrag

The board change occurred at the General Members Assembly on the 22nd of October. The evening con-sisted of feedback from the previous board on events and current position of the society, the introduction of the new board and an informal Geodrink to congratulate them, afterwards.

David, Christian and Edwin officially handed over their roles to the new board that will represent De Onder-grondse for the 2015-2016 term. The new board comprises of Loys Vermeijden as Chairman, Gustav Andrag

8

Re

cen

t A

ctiv

itie

staking over the role as Secretary, Jorrit Molendijk taking care of the finances, Kjell Dedecker in the posi-

tion of Commissioner of Activities and Tom Laumen remaining in the position of Commissioner of Education.

At the assembly the precedence was set for the Newcomers and Loys presented the priorities for the coming term. Effort will be focussed on the integration of international students, contact between members and companies, getting new companies on board and Lustrum activities during the tenth year existence of the more recently established society.

About half of the students following the Master Program are from outside of the borders of the Nether-lands. For this reason, the first international board member, Gustav Andrag, was introduced into the board. One of the main purposes of De Ondergrondse is, not only to establish contact between members, but also to introduce members to future employers. Company contact was thus placed on the priority list of the new board. To create the best experience for members, a search for new main supporting companies was also launched.

An inauguration dinner for old and new board members ensured a smooth transition into the new term. •

Geodrink November 12thby Kjell Dedecker

After a demanding first quarter for the students, it was good to start the second one a with some relaxa-tion. And what better way there is than a geodrink. A big crowd showed up to enjoy some drinks and crisps. Students and lecturers discussed the past exams and the upcoming courses or had some nice chats about non-school related things. After the geodrink a group even continued the night with a visit to a local bar. This geodrink was exactly what the students needed to start the second period fresh and full of courage! •

Kivi Excursionby Loys Vermeijden

On the 23th of November 17 students visited the dike reinforcement project by Waterschap Rivierenland. This excursion was made possible with the help of Kivi-Geotechniek. At 08.00 in the morning we drove all the way to Groot-Ammers. After some coffee and cake, Max Slimmens gave an introduction of the project. Eleven kilometres of dike along the river Lek was tested unsafe. The upward water pressures on the inside of the dike were higher than the weight of the clay soil, causing the dike to be unstable. In order to solve this, three different measurements where applied. First they auger concrete piles into the soil to prevent the soil from sliding. The piles had a diameter of 1 meter. The piles were build with some space in between to let water be able to flow. The second solution was building a new dike in the polder creating a soft shoulder. The last solution was building a new dike on the outside of the river. Building this new dike causes the riverbed to be smaller. This is not a preferable solution and was only applied when there was no other option. After a little break Sander Kapinga followed with a presentation about CSSM (Critical state soil mechanics) and how the used it for this project.

After the presentations we drove by bus over the dike. We stopped at three different points to see the work in progress and get some more information about the project. Around 13.00 we were back at the uni-versity, thinking about a very successful excursion. Again thanks to Waterschap Rivierenland and KIVI-Geo-techniek for making this excursion possible. •

9

Article

TE

C

Santos Harbour Channel CrossingbyTEC-tunnel

The Santos Harbour Channel Crossing project is located in the Port of Santos in the state of São Paulo, in Brazil, some 80 km south west of the city of São Paulo. The cities of Santos and Guarujá are separated by an approximately 500 m wide entrance channel to the busiest port of Brazil. The connection between the cities is currently operated by ferry boats, but there is a desperate need for a fixed link to accommodate the increasing transport volume and foreseen extension of the harbour as a consequence of economic growth. The current travel distance on the road between the two cities will be reduced from approximately 45 km to less than 1 km.

An immersed tunnel was selected as the most viable option for this crossing. The option, the first of its kind in Brazil, combines a safe and secure connection with minimal impact on city life and port development against a reasonable investment. The immersed tunnel will consist of six 145 meter long tunnel elements consisting of 7 segments each. The total length of the covered section of the tunnel will be about 2,600m, including the Cut & Cover sections on both sides, and is part of a broader upgrade of the surrounding road network. A channel depth of 21 meters must be guaranteed to allow for deeper draft vessels to enter the port area. The tunnel will consist of 2x3 lanes for road traffic and a separate tube for pedestrians and cyclists.

The tunnel elements will be constructed in the approach ramp on the Guarujá side of the river, which will serve as a dry dock for 2 sets of 3 ele-ments. The dry dock is made up of diaphragm walls and a combi-wall at the river-side. After the first 3 elements are constructed, the dry dock will be flooded, the combi-wall removed and the elements moored nearby. The combi-wall will be placed in its original location in order for the next series of elements to be constructed.

Due to the poor soil conditions, the T-shaped diaphragm walls will reach up to 55 meters deep to a rock layer. A jet-grout layer will work as a strut below the excavation level, while drainage will relieve water pressure underneath it. A trench will be dredged in the channel in which the elements are placed. The last element will remain in the dry dock and a closure joint is constructed in-situ between this element and the approach structure.

The foundation of the immersed tunnel will be realized by way of sand flow through pipes that lead under-neath the tunnel element. A smooth transition in the foundation between the jet-grout in the construction dock and the soft soils in the channel will be realized by a gradually decreasing number of jet-grout columns under the tunnel elements nearest to the river banks.

Tunnel Engineering Consultants (TEC) is a permanent partnership between Royal HaskoningDHV and Witteveen+Bos. TEC’s role in this project consists of knowledge transfer, design review, design manage-ment, and expertise. The project is currently at the end of the detailed design stage. •

For more info: www.TEC-tunnel.com, [email protected]

10

11

12

Art

icle

Fu

gro

Statische en seismische analyse LNG in Maleisië

by Krisitna Reinders, Fugro Geoservices B.V.

In Pengerang, het zuidelijke punt van het Maleisische schiereiland, wordt aan de kust van het Singapore Straits een LNG-terminal gebouwd. De projectlocatie bevindt zich aan de kust in zee. Om de tanks te kun-nen bouwen moest er eerst landaanwinning plaatsvinden. Dit is gebeurd door middel van ophoging van de zeebodem. Bovendien moet er rekening mee worden gehouden dat de locatie in een aardbevingsgevoe-lig gebied ligt. Voordat de landaanwinning is uitgevoerd is er een oriënterend grondonderzoek gedaan, bestaande uit boringen met SPT’s en sonderingen tot in de rots. Nadat de landaanwinning was uitgevoerd is er opnieuw grondonderzoek uitgevoerd. Beide onderzoeken zijn gebruikt voor de geotechnische adviezen.

Op de LNG-terminal zullen in eerste instantie zes LNG-tanks worden aangelegd met een diameter van 86 m en een hoogte van 36 m. LNG-tanks zijn verticale, cilindrische opslagtanks bestaande uit een stalen binnenschil en een dikke betonnen buitenschil en basisplaat. De vervormingseisen voor dit type tanks zijn zeer streng. LNG-tankconstructies mogen nauwelijks zettingsverschillen hebben en/of scheefzakken.

AdviezenDoor Fugro zijn diverse adviezen uitgevoerd voorafgaande aan en na de landaanwinning. De adviezen

betroffen onder andere:- Zettingsberekeningen voor de landaanwinning;- Evaluatie van de gemeten zettingen nadat een deel van de landaanwinning was gerealiseerd;- Zettingsberekeningen na de landaanwinning;- Funderingsberekening voor een fundering voor de tanks op staal;- Funderingsberekening voor een fundering voor de tanks op palen;- Adviezen voor de toepassing van grindkolommen te behoeve van een reductie van zettingen;- Stabiliteitsberekeningen voor de onderwatertaluds;- Seismische analyses, bestaande uit probabilistische, seismische risicoanalyses voor een fundering

op staal en een fundering op palen.

BodemgesteldheidDe bodem van de zee in de omgeving van de projectlocatie bevindt zich ongeveer op 1 m beneden gem-

iddeld zeeniveau. Uit grondonderzoek dat voorafgaand aan de landaanwinning is uitgevoerd, bleek dat de ondergrond bestaat uit 5 tot 25 m slappe normaal geconsolideerde klei met daaronder een laag vaste klei of leem. Op circa 13 m tot 30 m beneden gemiddeld zeeniveau bevindt zich een rotsformatie bestaande uit graniet. Lokaal is deze formatie niet aangetroffen en bevindt er zich een zeer vaste, harde leemlaag. Van-wege de grote variatie in de dikte van de kleilaag is voor de analyses in eerste instantie uitgegaan van twee grondprofielen: één met dikke top-kleilaag van 25 m (slechtste situatie) en één van 5 m (beste situatie).

Analyses voorafgaande aan de landaanwinningDe toekomstige hoogte van de projectlocatie zal circa 5 m boven gemiddeld zeeniveau liggen. Er zijn drie

varianten bekeken voor het aanbrengen van de ophoging van het terrein en het funderen van de tanks.

Variant 1: Ophogen met zand. Vervolgens verticale drains installeren, een grote extra overhoogte als voorbelasting aanbrengen, waarbij voldoende tijd wordt genomen om zettingen te forceren. Voorbelasting van het zand weer afgraven en tank funderen op staal.

Variant 2: Ophogen met zand. Vervolgens verticale drains en grindkolommen installeren, een grote extra overhoogte aanbrengen, en laten consolideren. Overtollig zand weer afgraven en tank funderen op staal. De grindkolommen dienen in dit geval als grondverbetering en zettingsreducerende maatregel.

Variant 3: Ophogen met zand. Vervolgens verticale drains en overhoogte aanbrengen, en laten consoli-deren. Overtollig zand weer afgraven en tank funderen op palen.

13

Article

Fu

gro

Uit de berekeningen bleek dat optie 1 niet haalbaar is. Voor de bodemprofielen met een beperkte kleilaag-dikte voldoet deze optie, maar ter plaatse van bodemprofielen met een dikke kleilaag zijn de restvervormin-gen van de tanks te groot. Optie 2 en 3 zijn wel haalbaar. Met het installeren van grindkolommen in de slappe kleilaag worden de sterkte en stijfheid van de klei verhoogd. Daarnaast zorgen deze kolommen voor extra drainage en dus voor een snellere consolidatie van de kleilaag. Met grindkolommen kan een zodanige zettingsreductie worden gerealiseerd dat wordt voldaan aan alle vervormingseisen voor de tanks en kunnen de tanks op staal worden gefundeerd. Bij een fundering op palen zijn de zettingen niet maatgevend, maar moet er rekening worden gehouden met grote verschillen in paallengtes. De langste palen moeten circa 44 m lang zijn en tot 1 m in het graniet worden aangebracht.

Analyses na de landaanwinningNadat er circa 10 à 11 m zand (circa 5 m overhoogte) was aangebracht is er aanvullend grond- en labora-

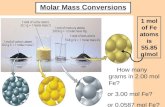

toriumonderzoek uitgevoerd, bestaande uit sonderingen, boringen en samendrukkingsproeven. Voor elke tank zijn er vier sonderingen op de omtrek en één sondering en een boring in het midden van de tank uit-gevoerd. Aan de hand van het grondonderzoek en de samendrukkingsproeven zijn gedetailleerde grond-profielen opgesteld en nieuwe zettingsberekeningen uitgevoerd met de uit de samendrukkingsproeven be-paalde zettingsparameters. Daarnaast zijn er twee zakbaken per tank geplaatst. De zakbaken zijn geplaatst nadat er 5 m zand was aangebracht. In figuur 1 is het grondprofiel ter plaatse van tank 2 gegeven. Hier is het grondprofiel redelijk uniform. Dit is echter zeker niet het geval voor alle tanks.

Figuur 1: Grondprofiel ter plaatse van tank 2

Aan de hand van de nieuwe grondprofielen en zettingsparameters zijn opnieuw zettingsberekeningen ge-maakt. De zettingsberekeningen zijn vergeleken met de zakbaakmetingen. Voor zakbaak 421 is de vergelijk gegeven in figuur 2.

Figuur 2: Zakbaakmeting en zettingsberekening t.p.v zakbaak 421, tank 2

14

Art

icle

Fu

gro

Uit alle zakbaakmetingen en zettingsberekeningen blijkt dat de berekeningen een hogere zetting geven dan de metingen. De verklaring is dat de parameters waarschijnlijk te ongunstig waren ingeschat. De mon-sters in een samendrukkingsproef zijn relatief klein van hoogte ten opzichte van de laagdikte in werkeli-jkheid en vaak wordt het meest samendrukbare deel van het ongeroerde monster geselecteerd. Het bep-roefde stuk van het ongeroerde monster zal niet altijd representatief zijn voor de hele laag. Daarom zijn de parameters aangepast. Om de berekende zettingen aan te laten sluiten op de waargenomen zettingen zijn zettingsparameters aangepast door deze met 0,75 te vermenigvuldigen. Hierdoor ontstaat een betere ‘fit’ tussen de metingen en de voorspellingen. Een onnauwkeurigheid van deze orde is overigens gebruikelijk in de praktijk.

Vervolgens is met de aangepaste parameters een betere voorspelling gedaan voor de te verwachten zet-tingen voor de optie met grindkolommen, waarbij de tank op staal wordt gefundeerd en de optie zonder grindkolommen waarbij de tank op palen wordt gefundeerd. In figuur 3 zijn de berekende zettingen voor de optie met grindkolommen gegeven voor tank 2, ter plaatse van zakbaak 421. In figuur 4 zijn de restzettingen in 30 jaar gegeven voor de optie met grindkolommen voor tank 2.

Figuur 3: Voorspelling eindzetting voor tank 2, met grindkolommen

Figuur 4: Restzettingen in 30 jaar voor tank 2, met grindpalen

Voor tank 2 zijn de zettingen en zet-tingsverschillen klein en wordt er aan de zettingseisen voldaan. Voor een aantal andere tanks zijn de zettingsverschillen echter groter.

Seismische analysesAangezien het gebied in een seismisch

actieve zone ligt moest hiermee in het ontwerp rekening worden gehouden. Als eerste is door Fugro een probabilistische seismische risicoanalyse (PSHA) uitgevo-erd. Op basis van topografische gegevens en bevingen in het verleden, is een kaart met seismische activiteit gemaakt, waarin een overzicht is gegeven van alle aardbev-ingsbronnen met de locatie en de zwaarte. Van deze bronnen is de locatie, het type breuk, de kans van optreden van een beving, het type vervorming en de maxi-male aardbevingsmagnitude vastgesteld. Vervolgens is een deterministischeseismische risicostudie (DSHA) uitgevoerd om een model te maken van de grondbewegingen op het niveau van de harde granietlaag. Er zijn twee seismische aardbevingssterkten gesimuleerd waarmee de te verwa-chten piekversnellingen (PGA) op de diepte van de harde granietlaag konden worden bepaald. In tabel 1 zijn de piekversnellingen weergegeven voor een herhalingsperiode van 500 jaar en 5000 jaar.

15

Article

Fu

gro

In een vervolgfase is een respons-analyse uitgevoerd voor deze locatie. Hierbij is de invloed van de slappe grondlagen bovenop de harde granietlaag bekeken en zijn piekversnellingen (PGA) en grondbewegingen op maaiveld bepaald. Dit bepaalt de seismische belastingen voor de constructie.

Tot slot is een 3D-eindige-elementenmodel opgesteld voor zowel een fundering op staal als een funder-ing op palen. Hierbij zijn de tankconstuctie, de statische belastingen, de palen, de grindkolommen, de grond en de seismische belastingen ingevoerd in één berekeningsmodel. Met dit totale constructie-grond-inter-actiemodel is de invloed van de vastgestelde aardbevingen op de constructie en de palen geanalyseerd. Uit de analyses blijkt dat een fundering op palen en een fundering op staal toelaatbaar zijn. Echter de buigende momenten in de bovenste 7 m van de palen zijn erg hoog, zodat ter plaatse extra wapening benodigd is.

Figuur 5: Verplaatsingen palen bij een aardbeving

Tabel 1: Piekversnellingen

ConclusiesOp basis van bovenstaande studies is samen met de opdrachtgever een afweging gemaakt voor de toe-

passing van een fundering voor de LNG-tanks op staal of op palen. Uit de statische analyse blijkt bij een fun-dering op staal het risico op verschilzettingen groot te zijn door de grote verschillen in dikte van de slappe kleilaag, waardoor de voorkeur uitgaat naar een fundering op palen. Vanuit de seismische studie blijkt juist een fundering op staal aantrekkelijker, vanwege de optredende hoge buigende momenten in de paalkop-pen. Het risico voor verschilzettingen is maatgevend gebleken en uiteindelijk is geadviseerd de tanks op palen te bouwen, waarbij extra wapening in de paalkop moet worden aangebracht om het moment in de seismische situatie te kunnen opnemen. •

16

MSc

Th

esi

s

MSc ThesisCoRncrete: A bio-based construction material

by Yask Kulshreshtha

“There is no secret ingredient, To make something special you just have to believe it’s special”. These lines from Kung Fu Panda movie has been an inspiration throughout my master thesis. Looking back, In my first year I was not yet sure about my interests. By the end of first year, I developed a passion for material and I wanted to combine it with my knowledge in Geo-Engineering for a master thesis. I was enthusiastic about writing my own proposal. As a cartoon enthusiast, I decided one day that I want to create a Sandman, a ficti-tious character that appeared in the movie Spiderman 3. It might sound as a crazy idea but I was too serious about it. Sandman can be considered as a smart Geo-material that has a potential to change its shape and stiffness based on his wish. To create such a material, a smart binder was required. So, I added corn starch and water (work as a glue) to sand in order to form a material which in fact change its stiffness on impact loading. However, this material no definite shape and strength. One day I decided to microwave it in order to give it some strength. When I took out this material out of microwave, it was hard. Although, not revers-ible in strength and stiffness, it was fairly strong. I named this material CoRncrete and decided to explore it further as a master thesis topic.

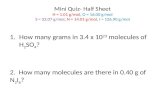

Introduction Corn starch is a common food ingredient that is

used to thicken soup and sauces. The renewability and bio-degradability of corn starch has made it an interesting material for many industrial appli-cations such as the production of bio-plastic and bio-ethanol. This study introduces the application of corn starch as a binder in a novel construction material, named CoRncrete. CoRncrete is prepared by mixing corn starch with water and sand, and heating the mix in a microwave or oven.

process results in the formation of a hardened CoRncrete whose compressive strength is compa-rable to fired clay brick. Fig. 1 show the process of formation of CoRncrete. An introductory video on preparation of CoRncrete can also be seen on You-Tube [1]. The main objective of this research work was to understand and study mechanical property of CoRncrete, with focus on factor affecting com-pressive strength; durability and its environmental performance.

Figure 1: Preparation of hardened CoRncrete by heating fresh CoRncrete (filled in a silicone mould) inmicrowave or convection oven.

How does CoRncrete gain its strength? The heat induced transformation of CoRncrete is caused by the physical modification of corn starch. This modification is a result of gelatinization pro-cess. Heating of corn starch in the presence of water results in the formation of a gel that binds with sand grains and hardens. Gelatinization of corn starch depends on amount of water and heat-ing temperature. The gelatinization temperatures

(temperature at which gelatinization occurs) of CoRncrete was determined by Differential Scan-ning calorimetry (DSC) test. It was found that a minimum temperature of about 70°C is required to transformation fresh (unhardened) CoRncrete into a hardened CoRncrete, provided no water is lost during the heating process.

17

MSc T

he

sisTo understand the microstructure of CoRncrete, ESEM (Environmental Scanning Electron Micro-scope) test was carried out. ESEM test indicated the effect of water content, heating method (mi-crowave, oven) and duration of heating on the gelatinization of corn starch and its influence on bonding with sand grains, therefore on microstruc-ture of CoRncrete.

Phase change in fresh CoRncreteIn fresh (unhardened) CoRncrete, corn starch changes phase from solid particles (with some ad-sorbed water) to particles in suspension of water, at a specific water content. This water content was determined by cone penetrometer test and proctor test. In cone penetrometer test, a dynamic pene-tration was observed from 16.62% to 20.23% water content, indicating the range of water content at phase change of corn starch in fresh CoRncrete. To capture the precise water content at phase change, proctor test was performed. Proctor tests showed a sharp increase in density close to the optimum wa-ter content. The optimum water content for CoRn-crete compacted at 22.1 KJ/m3 (150gm rammer) and 51.5 KJ/m3 (350gm rammer) energy was found to be 16.64% and 17.94% respectively (Fig. 2). The change of phase was observed at optimum water content where material start flowing like a viscous liquid.

Factors affecting strength of hardened CoRn-creteFresh CoRncrete was heated in microwave or oven to form hardened CoRncrete. In this research, the heating duration adopted for microwave and oven are 5min and 24h (at 105°C) respectively. The strength of CoRncrete has been shown to be af-fected by water content, grain size of the sand and the heating procedure. Compressive strength upto 26.67 MPa was achieved in the case of microwave heating whereas, it was limited to 13.70 MPa in oven heating method (fig 4). At similar water con-

tent, the extent of gelatinization achieved in mi-crowave heating is higher than oven heating. Thus, the specimens heated in microwave are stronger in compression. Figure 4 and 5 show the image of hardened CoRncrete at different water content.

Irrespective of the source of heating, with an in-crease in sand grain size, compressive strength decreases. With increase in duration of heating, the compressive strength increases until the water content in specimen reduce significantly. With fur-ther heating, compressive strength reduces due to burning of corn starch.

Degradation in water and environmental impactWhen submerged in water, CoRncrete specimen show complete to partial degradation in a day to a week. The specimen with 15% and 16.66% water content heated in a microwave and oven respec-tively degrades completely in 1 day [2]. Whereas, CoRncrete heated in microwave with 16.66% water content shows a partial but significant degradation (based on Equotip hardness value) in 7 days. The water content and method of heating influences the gelatinization process which affect the degra-dation rate of CoRncrete.

Figure 2: Plot of dry density versus water content of fresh CoRncrete.

Figure 3: Compressive strength of hardened CoRn-crete with varying water content.

Figure 4: CoRncrete specimen heated in convection oven with water content (a) 10%, (b) 13.33%, (c) 16.66% and (d) 20%.

Figure 5: CoRncrete specimen heated in microwave with water content (a) 10%, (b) 15%, (c) 16.66% and (d) 20%.

18

MSc

Th

esi

sThe life cycle assessment (LCA) of CoRncrete over its partial life cycle (cradle to gate) indicated that the CoRncrete has a higher environmental impact as compared to red clay brick and Portland cement concrete. The higher eco-cost of CoRncrete is main-ly due to the use of fertilizer that results in higher eco-toxicity and affect human health adversely. If this aspects can be eliminated, CoRncrete may of-fer potential reductions in environmental impact.

Application of CoRncreteCoRncrete is a bio-based material that achieve its final strength in few minutes as compared to sev-eral days required to manufacture traditional build-ing materials. Moreover, CoRncrete (1552 kg/m3) is 19% and 34% lighter than red clay brick (1920kg/m3) and Portland cement concrete (2357 kg/m3). These advantages combining with its derivation from renewable source make it an interesting ma-terial. CoRncrete can be used as a structural block, similar to the brick, in dry environment which is usually available in arid regions and indoors of a building. The durability of CoRncrete in wet envi-ronment can be improved by use of a hydrophobic additive or coating. The use of corn starch also af-fects the environmental performance of CoRncrete. In recent years, use of corn starch in industrial ap-

plications has raised debate over competition with food industry. Utilization of biomass or feedstock from maize crops in the production of starch can be an alternative to manufacture green CoRncrete. The gain in strength upon heating at relatively low temperature and flow properties of CoRncrete also makes it an interesting material for 3D printing of buildings.

References and video link[1] How to make CoRncete by Yask Kulshreshtha https://www.youtube.com/watch?v=b7dYcJa-COMU[2] Degradation of CoRncete in water by Yask Kul-shreshtha https://www.youtube.com/watch?v=h-vnxkZBCsA4.[3] Donavan, J.W. (1979), Phase transition of the starch–water system, Biopolymers, Volume 18, Pages 263–275.[4] Liu,H., Yu,Long, Xie,f. and Chen,L. (2006), Gelat-inization of cornstarch with different amylose/am-ylopectin content, Carbohydrate Polymers, Volume 65, Issue 3, Pages 357-363.[5] Kulshreshtha,Y., CoRncrete: A bio-based con-struction material, MSc Thesis, http://repository.tudelft.nl/view/ir/uuid%3A0919b058-4499-493f-b024-88c948ade7ff/

19

Up

com

ing

activ

ities

December 15Lunch lecture van Hattum en Blankenvoort

January 5New Years Dinner

February 11Geodrink

Upcoming activities