D ATA M ONITORING in both reactors L IQUID M EDIA : pH, Dissolved Oxygen (DO) H EADSPACE G ASES : O...

-

Upload

ellen-mcdonald -

Category

Documents

-

view

215 -

download

1

Transcript of D ATA M ONITORING in both reactors L IQUID M EDIA : pH, Dissolved Oxygen (DO) H EADSPACE G ASES : O...

DATA MONITORINGin both reactors

LIQUID MEDIA: pH, Dissolved Oxygen (DO)HEADSPACE GASES: O2 , CO2 , Methane (CH4)

ALGAL REACTOR MASS BALANCE MODEL

A2M: Experimental and Modeling Approaches to Optimize an Algae-to-Methane Coupled Bioreactor SystemRuby An1,2,*, Joseph J. Vallino2, Zoe G. Cardon2

1The University of Chicago, Chicago, IL; 2Marine Biological Laboratory, Woods Hole, MA; *[email protected]

Why A2M?Electricity generated by solar and wind power depends on available sunlight or sufficient wind and currently cannot be stored efficiently. Algae-to-methane (A2M) has potential as an efficient and practical strategy to provide reliable renewable energy around the clock and on demand.• Algal biomass is a renewable resource that requires minimal land and

water usage.

• Methane can be efficiently stored and effectively transported using existing infrastructure.

• Coupled bioreactors incorporate nutrient recycling which removes the need for expensive fertilizer inputs.

In our A2M setup, these components create a closed system that uses the biological processes of photosynthesis and methanogenesis to generate usable energy solely from light and air.

AcknowledgementsNorsk Institutt for Vannforskning (NIVA) algal culture collection

Falmouth Wastewater Treatment Plant & Foreman LabZeiss Microscopy Staff & Huber Lab

Suzanne ThomasAnonymous Donor & Jeff Metcalf Internship

Specific Aims

1. Experimental Develop a closed system with

100% nutrient recycling Maximize methane production

2. Modeling Develop accurate description of

A2M system Use model predictions to improve

system performance & achieve experimental objectives

http://dryas.mbl.edu/A2M/Exp1/Exp1.html

Experimental Results

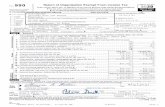

Modeling ResultsModels were built and numerically solved using the R package deSolve.

STATE VARIABLES : 1.cA – concentration of Algae2.cDIC – concentration of Dissolved Inorganic Carbon3.cO2(aq) – concentration of Dissolved Oxygen4.pCO2(g) – pressure of Carbon Dioxide gas5.pO2(g) – pressure of Oxygen gas

ALGAL GROWTH RATE EQUATION :

OUR ALGAE:Chlamydomonas reinhardtii CW15, a green algae mutant lacking a cell wall – making them easier to digest hence facilitating both methane production and nutrient recycling (left).

OUR MICROBES:We first inoculated with anaerobic groundwater from a sampling well near Little Pond (middle left). Although this established a microbial community, it did not perform methanogenesis. Subsequently, we inoculated again with wastewater sediments from the Falmouth Wastewater Treatment plant (bottom left).

Methods

25 μm

12 h

r Die

l Lig

ht C

ycle

Temperature: 25 °C

anaerobicMICROBIAL DIGESTER

aerobicALGAL REACTOR

A clump of algae being attacked by microbes

(right)

The A2M system in real life: microbial digester on left with top of cover removed (for photo visibility) & the algal reactor on the right (above left). Both reactors contain part liquid media (18L in digester, 4L in algal reactor) and part gaseous headspace. The monitoring & control rack measures liquid and gas data (above right).

Summary Optimized experimental system

conditions for high algal growth Accurately modeled algal reactor

dynamics

Next Steps Optimize experimental

conditions to establish & maximize methane production

Develop full coupled bioreactor model to simulate methanogenesis

Day 90

Day 1

KEY ASPECTS OF DATA• Diel Cycling (24 hr period)• Strong CO2 limitation with input at atmospheric level

– photosynthesis does not occur through full day• We stimulated high algal growth (see photos on right)

by elevating CO2 input levels to 2% in air.

Dou

bled

ligh

t lev

els

Elev

ated

CO

2 Inp

ut

Inst

alle

d ai

r spa

rger

sto

incr

ease

inpu

t airfl

ow

Bioreactors Coupled

pH c

rash

Bioreactors Decoupled

Atm

osph

eric

CO

2

•Days 30-33 : Atm. Input•Days 57-60 : Elevated

Platt equation for light limitationMonod CO2 Limitation

PARAMETERS :This model contains 35 parameters. Parameter values were determined both from system measurements and standard literature values; however, the following 5 parameters represented unknown system characteristics. These parameters were used to fit the model to experimental data from days 57-60: α, β, κL

O2A, rA, KCO2

MODEL FIT TO EXPERIMENTAL DATA DATA COMPARISON TO MODEL PREDICTIONS

MODEL DESCRIPTION OF EXPERIMENTAL DATA:We were able to attain a decent fit of model output to experimental data under elevated CO2 conditions by adjusting the variable parameters (bottom left). We then tested the model predictions for atmospheric CO2

input and compared this to earlier experimental data from days 30-33 (bottom right). The model reasonably reproduces the CO2 limitation dynamics of the system.

DataModel

DataModel