Cycloconverters and Machines

-

Upload

muscalualina -

Category

Documents

-

view

125 -

download

11

description

Transcript of Cycloconverters and Machines

-

C

o

p

y

r

i

g

h

t

y

e

a

r

A

B

B

.

A

l

l

r

i

g

h

t

s

r

e

s

e

r

v

e

d

.

-

1

-

3

0

/

0

1

/

2

0

0

4

Insert image here

Machines andACS6000c Cycloconverter

Training Indexesto

Material

Phase

current

-

C

o

p

y

r

i

g

h

t

2

0

0

3

A

B

B

-

2

-

Links to machines/cyclo training material

Machines Cyclo principle System description

-

B

A

A

T

E

M

T

r

a

i

n

i

n

g

-

1

A

f

t

e

r

S

a

l

e

s

.

p

p

t

2

0

0

3

-

0

4

-

1

7

Marine AMG & AMZ Training

Ilpo Vrel

-

B

A

A

T

E

M

T

r

a

i

n

i

n

g

-

2

A

f

t

e

r

S

a

l

e

s

.

p

p

t

Introduction to Synchronous Machines

-

B

A

A

T

E

M

T

r

a

i

n

i

n

g

-

3

A

f

t

e

r

S

a

l

e

s

.

p

p

t

AMG 0710MM06

ABB Industry Synchronous Machine

G = generator

Z = motor

Standard shaft height in millimeters

Designation letter for frame length

Designation letter for core length

Number of poles

Type Designation Code

-

B

A

A

T

E

M

T

r

a

i

n

i

n

g

-

4

A

f

t

e

r

S

a

l

e

s

.

p

p

t

Training subjects Presentation Generator design Propulsion motor design Bearings & lubrication units Accessories Test reports Windings AVR Maintenance Hands-on

-

B

A

A

T

E

M

T

r

a

i

n

i

n

g

-

5

A

f

t

e

r

S

a

l

e

s

.

p

p

t

Main Components AMG

Exciter

D-end Bearing

Diode Bridge

End Shield

Rotor Poles

Transformers Line Terminals

Shaft

Stator Core

Fan

Stator Windings

Neutral Point

Air Filters

Rotor Windings

-

B

A

A

T

E

M

T

r

a

i

n

i

n

g

-

6

A

f

t

e

r

S

a

l

e

s

.

p

p

t

Main Components AMZ

Exciter D-end Bearing

Diode Bridge

D-end

Rotor Poles

Line Terminals

Shaft

N-end

Stator Core

Stator Windings

Neutral Point

N-end Bearing

-

B

A

A

T

E

M

T

r

a

i

n

i

n

g

-

7

A

f

t

e

r

S

a

l

e

s

.

p

p

t

Stator Core and Frame

Frame and end shields are made of fabricated steel

-

B

A

A

T

E

M

T

r

a

i

n

i

n

g

-

8

A

f

t

e

r

S

a

l

e

s

.

p

p

t

Stator Core Stator core is made of punched, stacked, high-grade, low-loss

silicon steel sheets. Sheet thickness is 0.5 mm and it is insulated on both sides

Radial cooling ducts in the stator core ensure uniform and effective cooling of the stator

Complete VPI for the stator as a single unit making it virtuallymaintenance free

Radial Air Duct

Core

Support Bar

Fixing Plate

Pressure Plate

-

B

A

A

T

E

M

T

r

a

i

n

i

n

g

-

9

A

f

t

e

r

S

a

l

e

s

.

p

p

t

Rotor Rotor is designed to withstand the vibration and stresses appearing up to

120 % of rated speed Critical rotational speed is at least 1.5 times the nominal speed Shaft is made of forged steel and salient poles are bolted to the rotor hub Poles are constructed of punched and stacked steel plates and provided

with damper winding. Cooling and supporting of windings by aluminum profiles

-

B

A

A

T

E

M

T

r

a

i

n

i

n

g

-

1

0

A

f

t

e

r

S

a

l

e

s

.

p

p

t

Excitation

Generators and propulsion motors are with brushless excitation

Exciter rotor windings are wound with enameled wire, impregnated and shrink fitted to the shaft. Securing with a key

Mounting inside the motor frame with removable inspection covers

Mind tightening torques when inspecting or replacing semiconductors and rectifier bridge components

Diode bridge is mounted on the exciter rotor hub that is shrink fitted on to the shaft

-

B

A

A

T

E

M

T

r

a

i

n

i

n

g

-

1

1

A

f

t

e

r

S

a

l

e

s

.

p

p

t

Windings and Insulation

MICADUR-Compact Industry (MCI) Insulation System based on Vacuum-Pressure Impregnation (VPI) and has been used 20 years and it is well known for its high reliability.

Winding insulation exceeds Class F requirements (temperature limit 155C).

The complete winding and its supporting structures are vacuum pressure impregnated with epoxy resin which ensures a very robust, solid and moisture resistant insulation.

Insulation voltage level is matched to converter voltage waveform

VPI is used for all stators and rotors

-

B

A

A

T

E

M

T

r

a

i

n

i

n

g

-

1

2

A

f

t

e

r

S

a

l

e

s

.

p

p

t

Terminals The stator line terminals and neutral terminals are situated in the top box

on the top of the generator Excitation transformers are installed in the terminal box The terminals for excitation and control equipment are in auxiliary terminal

box

Differential Protection Transformers

Main Terminals Voltage Transformer Neutral Point

Short Circuit Current Transformers

Current Transformer for Parallel Operation

-

B

A

A

T

E

M

T

r

a

i

n

i

n

g

-

1

3

A

f

t

e

r

S

a

l

e

s

.

p

p

t

Cooling

For propulsion motors the internal cooling air flow is symmetrical and separate fan motors are used

For generators the internal cooling air flow is asymmetrical and fan is mounted to the rotor shaft

-

B

A

A

T

E

M

T

r

a

i

n

i

n

g

-

1

4

A

f

t

e

r

S

a

l

e

s

.

p

p

t

Balancing and Vibration Dynamic balancing on two planes Balancing is carried out with a half key Balancing grade G6.3 Vibration level of a fully assembled generator

mounted on rigid foundation is below 2.8 mm/s (RMS) with nominal speed and excitation

Max.allowed vibration level is 20 mm/s (RMS) according to ISO 8528-9 (DIN 6280 Teil 11)

Reference measurement is always taken in three directions on the bearings (vertical, transversal and longitudinal)

-

B

A

A

T

E

M

T

r

a

i

n

i

n

g

-

1

5

A

f

t

e

r

S

a

l

e

s

.

p

p

t

Bearings and Lubrication

The generator is provided with split-type sleeve bearings as standard Non-drive end bearing is insulated Bearings are spherically seated to facilitate assembling and maintenance The D-end bearing is designed to carry the loads produced by a coupling

misalignment and the rotor weight

-

B

A

A

T

E

M

T

r

a

i

n

i

n

g

-

1

6

A

f

t

e

r

S

a

l

e

s

.

p

p

t

Accessories

Winding temperature pt-100 sensors Cooling air temperature pt-100 sensors Space heaters Leakage water indicators Lubrication units (motors only)

oil flow filter indicatotors jack-up pressure

-

B

A

A

T

E

M

T

r

a

i

n

i

n

g

-

1

7

A

f

t

e

r

S

a

l

e

s

.

p

p

t

Testing Routine test performed on every motor Type test performed on one of a series of identical motors Special tests performed as required

Routine tests1. Visual inspection2. Air gap measurement and clearance check of sleeve bearings3. Insulation resistance measurement in cold condition4. Winding resistance measurement5. Checking of temperature detectors and space heaters6. Terminal markings and direction of rotation7. Axial play for unlocked bearing8. Bearing run9. Vibration measurement 10. No load point11. Short circuit point12. High voltage tests13. Overspeed test for generator14. Tests of excitation cubicle15. Insulation resistance measurement in hot condition

Type tests16. Moment of inertia17. No load curve18. Short circuit curve19. Heat run test (temperature rise test) / IEC 34-1 + IEEE 11520. Zero power factor test22. Losses and efficiency

Special tests1. Sound level measurement at no load / ISO 37442. Sudden short circuit test / IEC 34-4 + IEEE 1153. Measurement of the shaft voltage4. Wave form measurement / IEC 34-1 + IEEE 1155. Load switching on / off test6. Starting of the synchronous motor (locked rotor test)7. Polarization index / IEEE 43

-

B

A

A

T

E

M

T

r

a

i

n

i

n

g

-

1

8

A

f

t

e

r

S

a

l

e

s

.

p

p

t

Recommended spares for AMG/AMZ machine 1. Safety Parts

Excitation system Rectifier bridge semiconductors Temperature sensors Bearing parts Oil lubrication unit Brushes and brush holders Tachometers and encoders

2. Maintenance Parts Protection units Water cooler element Cooling air motor & fan Slip rings Voltage and current transformers Space heater

3. Capital Parts Exciter rotor and stator Rectifier bridge Rotor pole Rotor complete Stator (wound core) Stator with frame

-

B

A

A

T

E

M

T

r

a

i

n

i

n

g

-

1

9

A

f

t

e

r

S

a

l

e

s

.

p

p

t

Site Service

Inspection Installation Commission Maintenance On site testing

Condition monitoring

Trouble shooting

Upgrading and modification

Recondition

-

B

A

A

T

E

M

T

r

a

i

n

i

n

g

-

2

0

A

f

t

e

r

S

a

l

e

s

.

p

p

t

Technical Support Documentation Drawings FAT On site testing protocols Recondition instructions Insulation laboratory Redesign Recalculation

-

C

o

p

y

r

i

g

h

t

y

e

a

r

A

B

B

.

A

l

l

r

i

g

h

t

s

r

e

s

e

r

v

e

d

.

-

1

-

3

0

/

0

1

/

2

0

0

4

ACS6000ccycloconverter

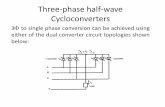

Cycloconverter principle

Phase

current

-

P

r

o

d

u

c

t

s

e

r

v

i

c

e

-

2

7

.

2

.

2

0

0

3

Cycloconverter

Low speed and high power frequency converter

Runs always synchronous motor (AC motor with DC excitation)

Power up to 27MW Motor nominal voltage 1350V...

1570V Maximum continuous current up

to 4500A(water cooled) Nominal speed of delivered

motors 30220rpm Maximum speed 720rpm

-

P

r

o

d

u

c

t

s

e

r

v

i

c

e

-

3

7

.

2

.

2

0

0

3

Cycloconverter in metalsRolling mills Nominal power 0,5...15 MW Max. load 115...300 % High torques >1000 kNm Roughing mills for steel and aluminium Z-mills for stainless steel Tandem Cold rolling mills Cold mills for aluminium and copper Performance and availability are most important

-

P

r

o

d

u

c

t

s

e

r

v

i

c

e

-

4

7

.

2

.

2

0

0

3

Cycloconverter in Marine with AzipodMain propeller Nominal power up to 20 MW Speed 100..300rpm In cruise vessel normally 2 or 3 main propellers Safety and redundancy are really important

-

P

r

o

d

u

c

t

s

e

r

v

i

c

e

-

5

7

.

2

.

2

0

0

3

Operation of synchronous motor

The magnetic field of the stator attracts the rotor magnet

The rotor rotates until the rotor N-pole meets the S-pole of stator

Continuous rotation is not possible with permanent magnet

N

S

-

P

r

o

d

u

c

t

s

e

r

v

i

c

e

-

6

7

.

2

.

2

0

0

3

Operation of synchronous motorStator magnetic field

Battery voltage makes current Current induce field Attracts rotor magnet

Battery voltage polarity reversing Stator magnetic polarity swap Rotor turns 180

Right timing of U swaps Continuous rotor rotation is possible

thought starting may be difficult from certain positions

Jumpy torque

+

_

S

N

N

S

_

+

-

P

r

o

d

u

c

t

s

e

r

v

i

c

e

-

7

7

.

2

.

2

0

0

3

Operation of synchronous motorStator

In order to allow starting in any position a stator with 3 phase winding is used

A phase winding is divided in two parts opposite side of stator

Excitation Rotor permanent magnet is also

replaced with winding

-

P

r

o

d

u

c

t

s

e

r

v

i

c

e

-

8

7

.

2

.

2

0

0

3

Operation of synchronous motor

DC pulse control(simple method) Torque is not smooth Step operation(stepper motor)

AC sinusoidal supply Smooth torque If frequency and voltage can be

controlled also motor speed can be controlled

-

P

r

o

d

u

c

t

s

e

r

v

i

c

e

-

9

7

.

2

.

2

0

0

3

SM frequency vs. speed

-

P

r

o

d

u

c

t

s

e

r

v

i

c

e

-

1

0

7

.

2

.

2

0

0

3

Motor power supply

Main requirements for the power supply of motor Sinusoidal phase currents Variable frequency and voltage Low losses (cyclo efficiency is >99,5 % at rated load) Can be easily connected to utilitys power network Fast control of currents for fast torque control

-

P

r

o

d

u

c

t

s

e

r

v

i

c

e

-

1

1

7

.

2

.

2

0

0

3

Cycloconverter

VARIABLE FREQUENCY0...20 / 24 HZ

CONSTANT FREQUENCY ACNETWORK 50 / 60 HZ 3 -PHASE

M

Input frequency 50 or 60 Hz + 5 % Input voltage 1000V(1000V or 1200V in marine) Output voltage controllable 01500V(01570 in marine) Output frequency controllable 0...20 / 24 Hz Auxiliary voltage 220..690VAC

-

P

r

o

d

u

c

t

s

e

r

v

i

c

e

-

1

2

7

.

2

.

2

0

0

3

Supply network

timeu r

u s

u t

Three phase constant frequency (50 Hz or 60 Hz) constant voltage system

20 ms (for 50 Hz) 16.7 ms (for 60 Hz)

1 second = 1000 milliseconds = 1000 ms

-

P

r

o

d

u

c

t

s

e

r

v

i

c

e

-

1

3

7

.

2

.

2

0

0

3

SCR thyristor

CathodeAnode

A KGGate

Semiconductor switch Switches in the rectifiers have to be fast, in 50 Hz network they have to close and

open 50 times every second Thus mechanical switches are unsuitable and a semiconductor switch is used

instead A high power thyristor is a 0.5 mm thick and 50 - 150 mm diameter disk of silicon

packed in a housing made of metal and ceramics A thyristor can withstand a voltage of over 5000 volts and conduct a current of

several thousand amperes(4200 or 5200 Volts SCRs used in cycloconverter) Thyristor is controlled by a short gate current pulse of few amperes (the firing

pulse)

-

P

r

o

d

u

c

t

s

e

r

v

i

c

e

-

1

4

7

.

2

.

2

0

0

3

timeu r

u s

u t

u + Average voltage

= 0 0

Output voltage can be controller by controlling firing angle

Motor current can be controlled by controlling drive output voltage

U output

Controlled bridgeg

-

P

r

o

d

u

c

t

s

e

r

v

i

c

e

-

1

5

7

.

2

.

2

0

0

3

Firing angle

-

P

r

o

d

u

c

t

s

e

r

v

i

c

e

-

1

6

7

.

2

.

2

0

0

3

Sinusoidal outputSupply voltage

U output

I output

-

P

r

o

d

u

c

t

s

e

r

v

i

c

e

-

1

7

7

.

2

.

2

0

0

3

Positive and negative thyristor bridge

-1

-0,5

0

0,5

1

0 90 180 270 360I

Thyristor bridge change time

-

P

r

o

d

u

c

t

s

e

r

v

i

c

e

-

1

8

7

.

2

.

2

0

0

3

Phase currentsPhase currents of a rolling mill cycloconverter drive, f = 8 Hz (simulation)

-1.5

-1

-0.5

0

0.5

1

1.5

600 620 640 660 680 700 720 740 760 780 800

p

e

r

u

n

i

t

Time (ms)

Phase a current Phase b current Phase c current

-

P

r

o

d

u

c

t

s

e

r

v

i

c

e

-

1

9

7

.

2

.

2

0

0

3

Phase voltagesPhase voltages of a rolling mill cycloconverter drive, f = 8 Hz (simulation)

-1.5

-1

-0.5

0

0.5

1

1.5

600 620 640 660 680 700 720 740 760 780 800

p

e

r

u

n

i

t

Time (ms)

Phase a voltage Phase b voltage Phase c voltage

-

P

r

o

d

u

c

t

s

e

r

v

i

c

e

-

2

0

7

.

2

.

2

0

0

3

Cycloconverter drivePhase

current

Excitation current (DC current)

Positive bridge Negative bridge

-

P

r

o

d

u

c

t

s

e

r

v

i

c

e

-

2

1

7

.

2

.

2

0

0

3

Operation curves, VOLTAGE and FLUX

0 Base speed Speed

Flux

Voltage

All electrical motors have a so called base speed or nominal speed. On AC motors it is related to frequency.

at this speed the motor voltage is nominal(100%) below this speed excitation current is kept constant if speed is increased above this speed motor flux has to be reduced to prevent motor over voltage .

Stator voltage formula is Us = * = flux, controlled by excitation current = speedThis means that faster the motor is running the higher is the voltage provided that flux is kept constant

At zero speed flux is nominal 100% and speed 0%, thus Us=100% * 0% = 0%

At nominal speed both flux and speed are nominal, thenUs=100% * 100% =100%=Nominal voltage

If speed is increased over the base speed then flux(i.e.. excitation current) has to be reduced. For example 2 * base speed.Us= * = 50% * 200% = 100%

Nominalflux

Nominalvoltage

Constant flux/torque range Field weakening/constant power range

-

P

r

o

d

u

c

t

s

e

r

v

i

c

e

-

2

2

7

.

2

.

2

0

0

3

Operation curves, TORQUE

Motor torque is the product of flux and torque.

Motor torque formula is T = * Is = flux, controlled by excitation currentIs = stator current

Normally all drives can produce full current through the whole speed range. Same applies also to cycloconverter.

Because flux is reduced in field weakening area the absolute torque(Nm) is reduced.

Torque

Flux

Stator current

Constant flux/torque range Field weakening/constant power range

0 Base speed Speed

-

P

r

o

d

u

c

t

s

e

r

v

i

c

e

-

2

3

7

.

2

.

2

0

0

3

Operation curves, POWER

Motor shaft power is product of torque and speed.

Motor power formula is P = T * T = Torque = motor speedThis means that full power could be reached only at base speed.

Torque

Power

Speed

Constant flux/torque range Field weakening/constant power range

Flux

Power

0 Base speed Speed

-

P

r

o

d

u

c

t

s

e

r

v

i

c

e

-

2

4

7

.

2

.

2

0

0

3

Operation curves, propeller and fan

0 125rpm Speed

145rpm

Motor torque

Maximum power

Power

Propeller load curve

Constant flux/torque range Field weakeningconstant power range

Load curve of propeller or fan is quadratic.

For example in cruise liner main propulsion field weakening point could be 125rpm and maximum speed 145rpm.

-

P

r

o

d

u

c

t

s

e

r

v

i

c

e

-

2

5

7

.

2

.

2

0

0

3

Operation curves, rolling mill

Torque

Power

1

2 3

45

Constant flux/torque range Field weakeningconstant power range

Rolling mills and extrudes are constant load machines. The load depends on the rolling schedule and material. In Extruder load depends mainly on material.

On the example there are roughing mill passes 15. First passes are at low speed and high torque

0 125rpm Speed

To start page

cover: cover_03: