Curva crecimento

-

Upload

maria-gonzalez -

Category

Documents

-

view

229 -

download

0

description

Transcript of Curva crecimento

-

Animal Sciencehttp://journals.cambridge.org/ASC

Additional services for Animal Science:

Email alerts: Click hereSubscriptions: Click hereCommercial reprints: Click hereTerms of use : Click here

The use of compositional growth curves for assessing theresponse to dietary lysine by high-lean growth gilts

K. G. Friesen, J. L. Nelssen, R. D. Goodband, M. D. Tokach, A. P. Schinckel and M. Einstein

Animal Science / Volume 62 / Issue 01 / February 1996, pp 159 - 169DOI: 10.1017/S1357729800014430, Published online: 02 September 2010

Link to this article: http://journals.cambridge.org/abstract_S1357729800014430

How to cite this article:K. G. Friesen, J. L. Nelssen, R. D. Goodband, M. D. Tokach, A. P. Schinckel and M. Einstein (1996). The useof compositional growth curves for assessing the response to dietary lysine by high-lean growth gilts. AnimalScience, 62, pp 159-169 doi:10.1017/S1357729800014430

Request Permissions : Click here

Downloaded from http://journals.cambridge.org/ASC, IP address: 128.210.126.199 on 30 Jul 2014

-

Animal Sriraiv 11%, 62: 159-169 1W6 British Society of Animal Science

1357-7298/96/45160159$20-00

The use of compositional growth curves for assessing the response todietary lysine by high-lean growth giltsK. G. Friesen1, J. L. Nelssen1, R. D. GoodbancTt, M. D. Tokach1, A. P. Schinckel2 and M. Einstein2

'Kansas State University, Manhattan, KS, USA:Purdue University, West Lafayette, IN, USA

AbstractGrowth modelling was used to characterize the response to digestible lysine in two experiments (114 gilts inexperiment 1 and 96 gilts in experiment 2) from 34 to 72-5 kg and 72-5 to 136 kg, respectively. Maize-soya-beanmeal diets were formulated to assure that lysine (5-4 to 10-4 and 5-4 to 9-4 g digestible lysine per kg for experiments1 and 2, respectively) was the first limiting amino acid. Analysis of variance was used to test linear and quadraticresponses in cumulative weight gain on test as digestible lysine increased. A time X digestible lysine interaction(linear, P < 0-001) was detected, indicating that a separate regression equation for each lysine level was necessary.In experiment 1, average daily gain (ADG) and carcass crude protein (CP) accretion were maximized for giltsgiven 10-4, 9-4 and 8-4 g digestible lysine per kg from 34 to 44 kg, 44 to 54 kg, and 54 to 72-5 kg, respectively. Lipidaccretion was minimized for gilts given 7-4 to 8-4 g digestible lysine per kg. In experiment 2, ADG was maximizedby feeding 8-4 g/kgfrom 72-5 to 92-5 kg and 7-4 g/kgfrom 92-5 to 136 kg. Carcass CP accretion was maximized byfeeding 9-4 g digestible lysine per kg, whereas lipid accretion was minimized for gilts given 8-4 g digestible lysineper kg from 72-5 to 136 kg. If feeding graded levels of digestible lysine resulted in parallel lines for protein accretion,mean values would result in accurate data evaluation. However, responses to digestible lysine changed over thefeeding period. Therefore, the use of body weight and compositional growth curves offers an approach to moreaccurately characterize the growing pig's response to increased digestible lysine.

Keywords: carcass composition, gilts, growth curve, lysine.

IntroductionCurrently, nutrient requirements for growing-finishing pigs are based on mean growthperformance or lean tissue deposition rates over agiven time period (Agricultural Research Council,1981; National Research Council (NRC), 1988). Thesestatic estimates of nutrient requirements limit theflexibility accurately to formulate diets for the dailychanges in nutrient needs as well as genotype,environment, and health status (Baker, 1986; Watt,DeShazer, Ewan, Harrold, Mahan and Schwab, 1987;Williams, Stahly and Zimmerman, 1994). Cook (1991)indicated that average daily gain (ADG) and foodefficiency (G/F) can overestimate the methioninerequirement for growing-finishing pigs comparedwith mathematical modelling techniques. Therefore,these data suggest a need for improved techniques todetermine nutrient requirements. The ideal protein

+ To whom correspondence should be addressed.

concept has attempted to increase the flexibility ofamino acid requirements for growing-finishing pigsby setting indispensable amino acids in a ratiorelative to lysine (Wang and Fuller, 1989). Thisconcept potentially could be limited to changes in theratio with maturity, efficiencies of amino acid use,and for maintenance v. growth (Benevenga, Gahl,Crenshaw and Finke, 1994). Furthermore, the idealprotein ratios are based upon nitrogen (N) retentionexperiments, which may proportionatelyoverestimate amino acid requirements by as much as0-05 (Baker, 1986). An approach for modelling bodyweight (BW) gain (Whittemore, Tullis and Emmans,1988; Schinckel, 1992) has been developed accuratelyto characterize total BW and tissue weight gain overtime. This modelling approach can conceptuallyimprove the estimates for nutrient requirements tomaximize lean tissue deposition. The objective of ourresearch was to use these mathematical techniques tocharacterize the changing response to digestiblelysine in high-lean growth gilts given food from 34 to72-5 kg and 72-5 to 136 kg.

159

-

160 Friesen, Nelssen, Goodband, Tokach, Schinckel and Einstein

Material and methodsAnimals and housingThe gilts and experimental procedures for theseexperiments have been described previously byFriesen, Nelsson, Goodband, Tokach, Unruh, Kropfand Kerr (1995a and b). Experiment 1 was conductedfrom August to November, 1992 and experiment 2was conducted from April to August 1993. Briefly,114 (experiment 1) or 96 (experiment 2) high-leangrowth gilts from a synthetic terminal sire line (PigImprovement Co., L326, Franklin, KY, USA) wereused in each of two experiments to determine thedigestible lysine requirement to maximize ADG andcarcass protein accretion from 34 to 72-5 kg(experiment 1) and from 72-5 to 136 kg (experiment2). The gilts in experiment 1 (30 kg BW) weredelivered to the Kansas State University SwineTeaching and Research Center and given a 9 g totallysine per g diet until they reached a mean weight of34 kg. In experiment 2 the gilts were given a 11-5 gtotal lysine per kg diet from 32 to 72-5 kg before theexperiment was initiated. Three gilts were housedper pen (4-6 m X 1-2 m pens with solid flooring) inan open-fronted building with six replicate pens pertreatment. Each pen contained a single whole feederand nipple waterer to provide ad libitum access tofood and water respectively.

Diet formulationDigestible lysine treatments were 5-4, 6-4, 7-4, 8-4, 9-4and 10-4 g/kg (7-5, 7-8, 9-6, 10-3, 11-7, 12-8 g totallysine per kg, respectively) for experiment 1 (Table 1)and 5-4, 6-4, 7-4, 8-4 and 9-4 g/kg (7-3, 8-7, 10-5, 10-7and 11-3 g total lysine per kg, respectively) forexperiment 2 (Table 2). The maize-soya-bean mealratio was adjusted to provide the desired digestiblelysine levels. Then, digestible tryptophan, threonine,methionine + cystine, and isoleucine concentrationswere set using an ideal amino acid ratio (Chung andBaker, 1992). Apparent ileal digestible amino acidcoefficients were taken as: maize = 0-64, soya-beanmeal = 0-85, and L-lysine-HCl = 0-93 (Knabe, LaRue,Gregg, Martinez and Tanksley, 1989). L-lysine-HClwas maintained at 0-5 g/kg complete diet. Thedietary metabolizable energy (ME) content wasincreased to 14-3 MJ/kg by adding 30 g soya-bean oilper kg. All other nutrients were formulated in excessof NRC (1988) estimates for the 20 to 50 kg and 50 to110 kg pig for experiments 1 and 2, respectively.

Carcass tissue accretion ratesSix gilts were selected randomly for slaughter at 34and 72-5 kg for experiments 1 and 2, respectively, andthe right side of each eviscerated carcass was groundto determine contents of moisture, crude protein (CP),

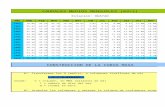

Table 1 Experiment 1 diet composition (as-fed basis)

Ingredient (g/kg)MaizeSoya-bean meal (485 g CP per kg)Soya-bean oilL-lysine HCIL-threonineDL-methionineL-tryptophanMonocalcium phosphate (210 g P per kg)LimestoneSaltTrace mineral pre-mixtVitamin pre-mix}:Chemical analyses (g/kg)Crude protein (CP)Total lysineCaPMJ/kg

5-4

796-2140-830-0

0-5

0-011609-53-51-52-0

14607-57-56-5

14-3

6-4

756-9180-930-00-50-10-01

15-39-33-51-52-0

153-47-87-56-5

14-3

Digestible lysine (g/kg)

7-4

717-1221-1

30-00-50-30-3

14-69-23-51-52-0

171-29-67-56-5

14-3

8-4

677-4261-230-0

0-50-30-7

13-8903-51-52-0

190-810-37-56-5

14-3

9-4

637-3301-4

30-00-50-71-1

1318-93-51-52-0

201-511-77-56-5

14-3

10-4

597-5341-5

30-00-51-01-4

12-48-73-51-520

208-612-87-56-5

14-3

t Provided the following per kg of complete diet: Mn, 100 mg; Fe, 100 mg; Zn, 100 mg; Cu, 10 mg; I, 3 mg; Co, 1 mg; Se, 3 mg.X Provided the following per kg of complete diet: retinol, 992 ng; cholecalciferol, 8-3 |ig; a-tocopherol; 8-7 mg; riboflavin, 3-3 mg;D-pantothenic acid, 8-3 mg; niacin, 18-2 mg; choline, 331 g; cyanocobalamin, 0-02 mg; menadione (menadione sodium bisulphatecomplex), 1-3 mg. Values from calculated analyses on as-fed basis.

-

Growth modelling in pigs 161

Table 2 Experiment 2 diet composition (as-fed basis)

Ingredient (g/kg)MaizeSoya-bean meal (485 g CP per kg)Soya-bean oilL-lysine HCIL-threonineDi.-methionineMonocalcium phosphate (210 g P per kg)LimestoneSaltTrace mineral pre-mixtVitamin pre-mix:):Chemical analyses (g/kg)Crude protein (CP)Total lysineCaPMJ/kg

54

788-3148-930-0

0-5

15-89-53-51-52-0

132-27-37-56-5

14-3

6-4

749-0189030-00-50-080-02

15-19-33-51-52-0

151-48-77-56-5

14-3

Digestible lysine (g/kg)

7-4

709-2229-1

30-00-50-30-36

14-49-23-51-52-0

160-710-57-56-5

14-3

8-4

669-3269-3

3000-50-520-72

13-79-03-51-52-0

174-310-77-56-5

14-3

9.4

629-2309-4

30-00-50-831-2

1308-93-51-52-0

189-611-37-56-5

14-3

See Table!.

lipid, and ash (Association of Official AnalyticalChemists (AOAC), 1990). When the mean weights ofgilts in a pen were approximately 54 and 72-5 kg(experiment 1) and 104 to 136 kg (experiment 2), onepig from each pen (six pigs per treatment) wasslaughtered for carcass analyses. The head, leaf fat,and viscera were removed at slaughter and were notincluded in determination of tissue accretion rate. At24 h post mortem, the right side of each carcass wasground once through a 15-mm plate and once througha 9-mm plate and homogenized for 3 min in a ribbon-paddle mixer. Proximate analyses (AOAC, 1990) wereconducted in triplicate on each carcass sample. Fromthe chemical analyses, the amounts (g/kg) of CP,lipid, ash and dry matter (DM) were determined foreach carcass based upon cold carcass weight. Moisturecontent was determined by subtracting the DM (g/kg)from 1000. Thus, initial composition, determined fromchemical composition of carcass weight, wassubtracted from chemical composition determined at55 and 72-5 kg (experiment 1) and 104 and 136 kg(experiment 2). Mean tissue accretion rates weredetermined from the difference between final andinitial compositions, divided by the days on test.These means then were used to test linear andquadratic effects of digestible lysine.

Statistical proceduresWeight interval performance analyses. Analysis ofvariance utilizing the GLM function of StatisticalAnalysis Systems Institute (1988) was used to obtainthe least-square means for ADG and carcass CP andlipid accretions from the periods of 34 to 72-5 kg and

72-5 to 136 kg. Linear and quadratic polynomials(Peterson, 1985) were used to evaluate the effect ofdigestible lysine. Break-point analysis (Walker andCarmer, 1967) was used to determine the inflexionpoint when the quadratic function was significant. Itprovided for a 0-95 lower confidence limit whichassured that the optimal dose exceeded the lowerlimit. The inflexion point for a lysine requirementwas determined for carcass protein and lipidaccretions from 34 to 72-5 kg. From 72-5 to 136 kg, theinflexion point was not estimated for ADG andcarcass protein and lipid accretion rates because nosignificant quadratic response was observed.

Body component growth curves for the treatment periods.The procedures for body component growth curveshave been described previously by Whittemore et al.(1988) and Schinckel (1992). Two functions, onerelating live weight to time and one relating the bodycomponent mass to live weight, were used toestablish the body component accretion rates at eachage or weight. To determine the relationshipbetween live-weight gain and days on test regressionanalysis was used first in the following equation tosolve for regression coefficients:

live weight = ba + b-1 (day) + b2 (day2).An allometric equation then was used to determinethe coefficients of carcass CP and lipid accretionrelative to live weight:

Y = aXh

-

162 Friesen, Nelssen, Goodband, Tokach, Schinckel and Einstein

where Y = carcass CP or lipid, a = scale constant, X =body weight, and b = relative growth coefficient. Theequation was linearized as log Y = log a + b log X toutilize least-squares regression analyses. Component(carcass CP or lipid) gain then was related to live-weight gain by multiplying the derivative of liveweight over time by the derivative of componentweight over live weight:

dComponent/dTime = dLive weight/dTimeX dComponent/dLive weight.

The derivative of live weight over time (daily gain ateach day) is equal to bx + 2b2 (day). The derivatives ofthe carcass CP and lipid components on live weightare equal to abXbA. The interactions betweendigestible lysine and the change in BW over timewere tested. The significance of the analysesindicated that separate regression equations wereneeded for each digestible lysine treatment.

Overall body component growth curves. Total liveweight and carcass CP and lipid functions werefitted from 34 to 136 kg. Gilts (three gilts per pen, sixpens per treatment) that were given 9-4 g/kgdigestible lysine in experiment 1 (34 to 72-5 kg) andexperiment 2 (72-5 to 136 kg) were used to developthese models. Pig weights were collected weekly,and carcass composition was determined (six giltsper slaughter weight) at 34, 54, 72-5, 104 and 136 kg.The function: M, = wtm (l-e""1'3) where Wti = weightgain (kg) from birth (1-5 kg); e = mathematicalconstant; m = exponential growth delay function; t =days of age; a = kinetic order constant; wtm = weightat maturity - birth weight; was used to fit dailyweight gain (Bridges, Turner, Smith, Stahly and

Loewer, 1986; Schinckel, 1992). This function wasfitted for two reasons over other three parameternon-linear functions. It results in a better fit to pigdata based on residual standard deviations andDurbin Watson statistics. Also, Monte Carlosimulation results of a two-step solution procedureindicated that the function was flexible yet stable,consistently resulting in unbiased estimates of WTM,m and a (Sun, Schinckel, Einstein, Yuan and Randin,1993) in small data sets (no. = 16 or 24 pigs). Thefollowing equation gives the relationship of liveweight to age of the pig:

live weight = 209-3 kg X (1 - EXP (-0-0000395X(age126))) + l-5.

Carcass CP and lipid mass data from pigs at 34, 54,72-5, 104, and 136 g were fitted to allometricequations. The functions developed were:

carcass CP = (10") X (weight1 03);carcass lipid = (10") X (weight1 536).

These curves were used to estimate maximum ADCand carcass CP and lipid accretion.

ResultsADG, and CP and lipid accretion rates of gilts from32 to 72-5 and 72-5 to 136 kg are presented in Table 3.The carcass CP and lipid contents for gilts inexperiment 1 and 2 are presented in Table 4. Thesevalues were used for determining their appropriatecompositional curve. The initial weights (b0) weresimilar for all digestible lysine levels at 34(experiment 1) and 72-5 kg (experiment 2; Table 5).

Table 3 The influence of digestible lysine in high-lean growth gilts on end point average daily gain (ADG) and carcass crude protein (CP)and lipid accretion (means calculated from six observations per treatment at each body weight)

34 to 72-5 kgADG (kg)tCP accretion (g)t^:Lipid accretion (g)||

72-5 to 136 kgADG (kg)CP accretion (g)1Lipid accretion (g)

5-4

0-6883

107

0-8487

172

6-4

0-759099

0-8692

193

7-4

0-7411179

0-9292

167

Digestible lysine (g/kg)

8-4

0-83113

73

0-9199

143

9.4

0-8712380

0-85103164

10-4

0-8211084

s.e.

0-036-0

10-0

0-038-5

21-2

t Linear effect of digestible lysine (P < 0-01).t Quadratic effect of digestible lysine (P < 0-05). Linear effect of digestible lysine (P < 0-05).|| Quadratic effect of digestible lysine (P < 0-10).1 Linear effect of digestible lysine (P < 0-10).

-

Growth modelling in pigs 163

Table 4 Carcass chemical composition (g/kg) of gilts slaughtered at 34, 54, 72.5, 104 and 136 kgi

34 kg 54 kg 72-5 kg 104 kg

Digestible lysine (g/kg)

136 kg

CP

179-0

Lipid

107-0

CP

171-5176-7184-0179-5178-9178-7

Lipid}:

146-2126-3113-0117-0113-098-4

cpt

1671169-9187-6183-7171-01810

Lipid*11

162-3146-8124-5115-3114-0123-7

CP

167-9165-7166-3163-1166-3

Lipid

174-3160-2185-2174-9185-0

CP

148-0144-2151-2155-8158-5

Lipid

201-0207-5194-9173-7187-6

Initial5-46-47-48-49-4

10-4

+ Means calculated from six pigs per treatment at each body weight. The head, leaf fat, and viscera were removed atslaughter and not included in carcass chemical composition or determination of tissue accretion rate.X Linear effect of digestible lysine (P < 001). Quadratic effect of digestible lysine (P < 0-05).|| Quadratic effect of digestible lysine (P < 0-01).

The linear (frj) and quadratic (b2) terms were different(P< 0-001) for each digestible lysine level in bothexperiments 1 and 2. The b^ terms increased asdigestible lysine level increased from 5-4 to 10-4g/kg, resulting in greater ADG for gilts givenincreased digestible lysine (Figure 1). The b2 valueswere positive for gilts given 5-4, 7-4 and 8-4 g/kg,indicating increased ADG as BW or time increased.The negative b2 terms for gilts given 6-4, 9-4 and10-4 g/kg suggest reduced ADG as BW increased.For experiment 2, the bA and b2 terms were different(P < 0-001) for each digestible lysine level. The b-jterm increased as digestible lysine increased from 5-4to 9-4 g/kg, resulting in greater ADG (P < 0-001).ADG (Figure 2) was reduced as BW increased, asreflected by the negative b2 terms for each digestiblelysine level. These b2 terms were influenced(P < 0-001) by digestible lysine for gilts given 6-4, 8-4and 9-4 g/kg digestible lysine.

The intercepts (a) developed for the carcass CPallometric functions from 34 to 72-5 kg decreased

(P < 0-001) as digestible lysine increased (Table 6).The allometric growth coefficients (b) were greater(P < 0-001) as digestible lysine increased from 5-4 to10-4 g/kg and peaked at 7-4 g/kg. The intercepts forcarcass lipid accretion were influenced (P < 0-001) bydigestible lysine (Table 6). Carcass lipid growthcoefficients (b) were reduced (P < 0-001) as a result ofincreased digestible lysine. Similarly, carcass CP andlipid intercepts were influenced (P < 0-001) asdigestible lysine increased in experiment 2 (72-5 to136 kg; Table 7). The allometric growth coefficientsfor carcass CP increased (P < 0-001), whereas carcasslipid coefficients decreased (P < 0-001) as digestiblelysine increased from 5-4 to 9-4 g/kg at 72-5 to136 kg.

The data in Table 3 and Figure 1 represent weightinterval performance analyses and the correspondingregression analyses for ADG and carcass CP andlipid accretions from 34 to 72-5 kg. Weight intervalperformance analyses for ADG (Table 3) indicatedgreater (linear, P < 0-01) gains as a result of increased

Table 5 Live weight growth parameters for high-lean growth gilts fed from 34 to 72-5 kg and 72-5 to 136 kg where live weight gain on test= b0 + b/dni/s) + b1(days)1i

Digestible lysine (g/kg)

5-46-47-48-49-4

10-4

bo

34-30633-77534-30634-33233-82834-306

34 to 72-5 kg

0-592 (0-037)***0-760 (0-039)***0-632 (0-039)***0-710 (0-046)***0-852 (0-046)***0-995 (0-043)***

b2

0-0009 (0-0009)-0-00118 (0-0009)

0-00136 (0-0009)0-00227 (0-0014)

-0-00090 (0-0014)-0-00635 (0-0009)***

bo

73-70272-56871-83871-41172-142

72-5 to 134 kg

bx

0-900 (0-032)***0-957 (0-032)***0-935 (0-032)***0-998 (0-031)***0-963 (0-031)**"

b2

-0-0009 (0-0005)-0-0018 (0-0005)**-0-0009 (00005)-0-0023 (0-0005)***-0-0018 (0-0005)**

+ b0 is the initial mean weight for the treatment at the beginning of the experiment.Probability levels are for deviations of coefficients from 0.

-

164

1-00

0-40

u

Friesen, Nelssen, Goodband, Tokach, Schinckel and Einstein

1-05

150

^ 1 3 0

-

Growth modelling in pigs 165

Table 6 Weight of carcass crude protein and lipid components using the relationship o/Y = aXb, where Y is the component and X the liveweight (kg), for high-lean growth gilts fed from 34 to 72-5 kgf

Digestible lysine (g/kg)

5-46-47-48-49-4

10-4

+ Probability levels are for deviations of coefficients from 1-00.

a

0-09380-08200-05400-06000-06100-0643

Carcass crude protein

b

1-052(0-039)1-089(0-041)1-209(0-059)**1-178(0-042)***1-177(0-046)***1-157(0-056)**

R2

0-980-980-960-980-970-96

a

0-00490-01040-01820-02860-02680-0275

Carcass lipid

b

1-742(0-178)***1-526(0-156)**1-364(0-129)**1-240 (0-154)1-263 (0-138)1-240(0-140)

R2

0-870-870-870-790-830-82

54 kg, and 54 to 72-5 kg respectively. The analysis ofCP accretion would result in lysine estimates(digestible and total) to those from the ADG analysis.Carcass lipid accretion decreased (quadratic,P < 0-10) as digestible lysine increased (Table 3). Theinflexion point for minimum carcass lipid gain wascalculated at 7-1 g digestible lysine per kg (13 g/day)(8-4 g/kg or 15 g total lysine per day). The regressionof carcass lipid accretion over BW indicated a linearincrease (P < 0-001) in lipid gain for all dietarytreatments except in gilts given 10-4 g/kg (Figure 3c).

Weight interval peformance analyses from 72-5 to136 kg indicated that digestible lysine did notinfluence significantly (P > 010) ADG (Table 3).Numerically, ADG appeared to be maximized forgilts given 7-4 g/kg (22 g digestible lysine per day) or8-8 g total lysine per kg (27 g/day). Regressionanalyses of BW gain over time (Figure 2a) indicatedmaximum (P < 0-001) ADG for gilts given 8-4 and7-4 g digestible lysine per kg from 72-5 to 92-5 kg and92-5 to 136 kg, respectively. These estimates wouldprovide 25 and 22 g digestible lysine per day intake).Carcass CP accretion (Table 3) was greater (linear,P < 0-10) as digestible lysine increased. This increasein CP accretion would require 9-4 g digestible lysineper kg (28 g/day) or 11-2 g total lysine per kg(33 g/day). Regression analyses showed that carcass

CP accretion over BW (Figure 3b) was maximum(P < 0-001) for gilts given 9-4 g digestible lysine perkg (28 g/day) or 11-2 g total lysine per kg (33 g/day).However, as BW increased, carcass CP accretioncontinually decreased (P < 0-001). Carcass lipidaccretion (Table 3) was not influenced (P < 0-10) bydigestible lysine in high-lean growth gilts fed from72-5 to 136 kg. The regression analyses of carcasslipid accretion (Figure 3c) indicated increased lipidaccretion for gilts given all diets except that with8-4 g digestible lysine per kg.

ADG (Figure 3a) and carcass CP accretion (Figure 3b)increased at a decreasing rate from 38 kg to about 98and 100 kg, respectively. ADG (0-85 kg/day) andcarcass CP accretion (107 g/day) were maximized at948 kg body weight. Carcass lipid accretion (Figure3c) increased linearly (P < 0-001) as BW increased.The rate of carcass CP and lipid accretion decreasedas BW increased.

DiscussionWhittemore et al. (1988) indicated that fitting live-weight gain on test to a Gompertz function andallometric equations was the most accurate way todetermine the rate of protein deposition. Unbiasedcomparisons of carcass tissue growth using

Table 7 Weight of carcass crude protein and lipid components using the relationship ofY = aXb, where Y is the component and X the liveweight (kg), for high-lean growth gilts fed from 72-5 to 136 kgf

Digestible lysine (g/kg)

5-46-47-48-49-4

a

0-44100-32180-35890-28280-2378

Carcass crude protein

b

0-718 (0-058)***0-788 (0-064)**0-763 (0-047)***0-817(0-091)0-857 (0-050)**

R2

0-910-900-940-850-95

a

0-0021**0-0010**0-0024**0-0061**"0-0024**"

Carcass lipid

b

1-876 (0-178)***2-030 (0-152)***1-843(0-198)***1-622(0-179)**1-836(0-179)***

R2

0-870-910-850-840-87

t Probability levels of deviations of coefficients from 1 -00.

-

166 Friesen, Nelssen, Goodband, Tokach, Schinckel and Einstein

0-88

78Body weight (kg)

U

58 78 98Body weight (kg)

118 136

Figure 3 The predicted change in (a) average daily gain(ADG); (b), carcass crude protein (CP) accretion rate; (c)carcas lipid accretion rate for high-lean growth gilts fed94 g/kg digestible lysine from 34 to 136 kg.

allometric equations were conducted by Gu,Schinckel and Martin 1992) for five differentgenotypes. The data in our experiment (34 to 72-5 kgand 72-5 to 136 kg) could not be fitted to a sigmoid-shaped function, because only short weight periodswere analysed instead of the entire growth curve.The entire growth curve is needed to use thesigmoid-shape growth equation so that an inflexionpoint is clearly defined (Schinckel, 1992 and 1994).Live-weight gain on test in our experiment wasdetermined by polynomial regression, because two

portions of the curve were completed by eachexperiment. Two experiments were conducted toavoid confounding the data set from 72-5 to 136 kgby feeding deficient diets from 34 to 72-5 kg.

Fitting a non-linear (age and live-weightrelationship) function (Bridges et al., 1986) results inshapes of the total BW and carcass CP accretioncurves that are slightly different compared withthose derived from the use of the polynomial (linearand quadratic) functions fitted for each individualexperiment. The predicted CP accretion over time ishighly sensitive to the function being fitted(Schinckel, 1994). The sigmoidal (non-linear) growthfunction fits a line assuming that live-weight gainincreases to an inflexion point, reaches a plateau, andthen decreases. However, the function is fittedunder the assumption that maximum growthperformance is achieved throughout the entiregrowth period (Whittemore, 1986; Whittemore et al.,1988). However, the performance recently describedin segregated early weaned pigs indicates thatperformance is not maximized in traditional 21- or28-day weaning (Dritz, Nelssen, Goodband, andTokach, 1994). This type of function could not befitted to the individual experiments, because weightintervals of 38 and 61 kg for experiments 1 and 2,respectively, were analysed instead of the entiregrowth period. Thus, the polynomial functions willgive a different representation of the data, which ismore accurate because it does not assume thesigmoidal shape as does the age-dependent function(Bridges et al, 1986).

The ADG and carcass CP gain data from 34 to72-5 kg are in agreement with the linear-plateauportion of the growth curve proposed byWhittemore (1986). Weight interval performanceanalyses fit a linear response to increased digestiblelysine. These data are similar to the linear-plateaurelationship for protein deposition in the growingboar (Campbell and King, 1982; Campbell, Tavernerand Curie, 1984) and castrated male (Oyeleke,Balogun, Fetuga and Babatunde, 1988). Campbell,Taverner and Curie (1988) suggested that the dietaryprotein content could be decreased in both gilts andboars as end-point weight increased from 50 to 90 kg.However, these end-point analyses and simpleregression models do not characterize the changingresponse to dietary lysine as BW increases. The non-linear regression models developed in ourexperiment indicate that the response to digestiblelysine changed as BW increased from 34 to 72-5 kg.

At 34 kg, food intake (i.e. lysine intake) was limitedby reduced appetite in the growing pig (Rao andMcCracken, 1992) Thus, each incremental increase indigestible lysine resulted in greater total weight and

-

Growth modelling in pigs 167

carcass CP gain. Lipid accretion, on the other hand,decreased as a result of greater lysine intake. Thisshift in the composition of gain to greater CPaccretion suggests that digestible lysine was thelimiting factor for CP deposition (Campbell et al.,1988). Campbell et al. (1984) observed a lineardecrease in empty body protein gain as proteinintake was increased from 95 to 186 g/kg for boarsfed from 45 to 90 kg. However, these authorsproposed that protein retention is dependent on levelof feeding (energy intake) and not on protein intakeduring the linear portion of the protein depositioncurve. These concepts are further supported by theresults of Rao and McCracken (1992) in growingboars (33 to 90 kg), which indicated greater ADG,empty body protein gain, and efficiency of gain asenergy intake increased from 14-8 to 15-2 MJ ME perkg. In our experiment, the dietary ME was heldconstant at 14-3 MJ/kg. Thus, the resulting increasein carcass protein gain was dependent on increasedlysine intake.

The regression data for carcass CP accretion suggestthat gilts given 6-4 g digestible lysine per kgexhibited proportionately only 0-65 of the maximalprotein with gilts given 10-4 g digestible lysine perkg. The difference in the regression modelsrepresents the influence of digestible lysine on BWwhere peak protein gain was attained. De Greef andVerstegen (1993) suggested that previous nutrientintake will influence the shape of compositionalcurves, offering the potential for compensatoryprotein gain (Critser, Miller, Lewis and Wolverton,1993; Whang and Easter, 1994). Our data suggest thatthe 7-4 g digestible lysine per kg diet given prior tothe first experiment limited protein deposition. Thus,feeding greater levels of digestible lysine resulted inlarger increases in protein gain, potentially ascompensatory gain as well as meeting the lysineneed for maximum carcass CP gain.

Gilts given 10-4 g digestible lysine per kg hadmaximum protein gain at the onset of theexperiment. However, the rapid reduction in CP gainfor those gilts is rather alarming. Potentially, CP gaincould be decreased by increased amino acidcatabolism, resulting in a reduction in the net energyfor gain (Holmes, Carr and Pearson, 1980; Campbelland King, 1982). However, the formation of ureafrom the catabolism of excess amino acids results inonly a two-ATP depletion per molecule of aminoacid (Stryer, 1988). A second rationale iscompensatory protein gain for the gilts given 7-4, 8-4,and 9-4 g digestible lysine per kg (Whang and Easter,1994). Maximum protein gain was attained atdifferent BWs for gilts receiving various levels ofdigestible lysine. Thus, reduced digestible lysine(104 i'. 8-4 g/kg) resulted in heavier BWs for

attaining maximum protein gain. These dataillustrate two important concepts. First, the influenceof under-feeding lysine during the growing phase,i.e. in reduced carcass protein gain. This concept wascharacterized by Stahly, Cromwell and Terhune(1988), who reported the dramatic reduction in leangrowth for high-lean growth barrows when givenlysine-limiting diets from 50 to 110 kg. Secondly, theregression analysis emphasizes the importance ofphase feeding throughout the linear portion of thegrowth curve (34 to 72-5 kg).

Lipid accretion from 34 to 72-5 kg increased as BWincreased. Similarly, Shields, Mahan and Graham(1983) suggested a linear increase in lipid gain as aresult of increased BW. Lipid accretion increased to alesser extent for gilts given 8-4 to 9-4 g digestiblelysine per kg than for gilts given a deficient diet (5-4to 6-4 g digestible lysine per kg). The resultingincrease in amino acid intake is equated with greaterCP gain rather than lipid gain (de Greef andVerstegen, 1993). Thus, carcass lipid gain isminimized when CP gain is maximum in high-leangrowth gilts. In the grower phase, lysine will be usedpreferentially for protein synthesis (Finkelstein,1990). However, not all protein synthesis isassociated with lean tissue gain (Etherton,Wangsness, Hammers and Ziegler, 1974). The highimpetus muscles of the ham and loin will respond toincreased lysine intake to a greater extent in thegrower period (34 to 72-5 kg) than in the finishingperiod (72-5 to 136 kg). But the increase in lipid gainis consistent with protein gain for the adipose tissuematrix, and minimal lipid is needed for bodymaintenance (Whittemore, 1986).

The gilts in experiment 2 (72-5 to 136 kg) did notexhibit the magnitude of response to digestible lysineseen in experiment 1. Generally, the ADG andcarcass CP gain decreased linearly, whereas carcasslipid gain increased linearly as a result of greaterBW. These results are consistent with previousreports of Shields et al. (1983). The decreasing rate oftotal body and carcass CP gain indicated that thegilts in this experiment were beyond the inflexionpoint for maximum weight gain (Whittemore andFawcett, 1976). Similarly, Shoup (1991) and Gu et al.(1992) indicated a linear reduction in lean tissue gainas BW increased from 60 to 130 kg. The resultingincrease in food intake with increased BW wasattributed to greater lipid deposition. These resultsare similar to the increased lipid gain with increasedenergy intake in growing boars from 30 to 90 kg byCampbell and Taverner (1988). The efficiency oflysine utilization appears to be reduced for heaviergilts. The total lysine intake in finisher gilts was5g/day greater to support carcass CP depositionrates that were 20 to 30 g/day less than those of

-

168 Friesen, Nelssen, Goodband, Tokach, Schinckel and Einstein

grower gilts. This was apparent in reduced foodefficiencies as BW increased (Shields et ah, 1983). Thepoorer efficiencies for lysine use can be attributedfurther to increase lipid deposition that resulted fromthe greater food intake and excess nutrient intake(Campbell et ah, 1984).

Thus, performance and carcass lean depositionapparently are reduced as a result of increased BW.Our data suggest that greater digestible lysine intakeincreased CP gain and decreased lipid gain.However, the efficiency of lysine utilization inexperiment 2 was reduced compared with that ofgilts in experiment 1. This reduction was evident bythe decreased slope of carcass CP on lysine intake.These data are in agreement with de Greef andVerstegen (1993), who reported increased carcassleanness with increasing energy intake combinedwith sufficient amino acid intakes. However, theincreased protein gain was proportionally greaterthan the non-lean tissue gain (i.e. lipid gain), whichis evident in our data. Although carcass CP gain isgreater with increased digestible lysine the cost ofachieving maximum protein gain is not economicallyfeasible (Crenshaw, Gahl and Benevenga, 1994).Therefore, economics will determine the level oflysine that can be offered for maximum profit.

In conclusion, the growth and composition modelsdescribed in this experiment indicate the importanceof regression modelling to describe accuratelynutrient requirements in growing-finishing pigs. Inthe growing period (34 to 72-5 kg), the modelsaccurately estimated digestible lysine requirementfor maximum carcass protein gain as BW increased.Although digestible lysine caused less of a responsein the finishing period (72-5 to 136 kg), the modelscharacterized the diminishing response to digestiblelysine as BW increased. Thus, these models providebasic information that can be incorporated witheconomic considerations to maximize profit.

AcknowledgementsContribution no. 95-63-J from the Kansas AgricultureExperiment Station, Manhattan, 66506.

ReferencesAssociation of Official Analytical Chemists. 1990. Officialmethods of analysis. 15th ed. Association of OfficialAnalytical Chemists, Arlington, Va.Agricultural Research Council. 1981. The nutrientrequirements of pigs. Commonwealth Agricultural Bureaux,Slough.Baker, D. H. 1986. Critical review: problems and pitfalls inanimal experiments designed to establish dietaryrequirements for essential nutrients, journal of Nutrition 116:2339.

Benevenga, N. J., Gahl, M. J., Crenshaw, T. D. and Finke,M. D. 1994. Protein and amino acid requirements formaintenance and amino acid requirements for growth oflaboratory rats. Journal of Nutrition 124: 451.Bridges, T. C, Turner, U. W., Smith, E. M., Stahly, T. S.and Loewer, O. J. 1986. A mathematical procedure forestimating animal growth and body composition.Transactions of the Society for Agricultural Engineering 29:1342-1347.Campbell, R. G. and King, R. H. 1982. The influence ofdietary protein and level of feeding on the growthperformance and carcass characteristics of entire andcastrated male pigs. Animal Production 35: 172-184.Campbell, R. G. and Taverner, M. R. 1988. Genotype andsex effects on the relationship between energy intake andprotein deposition in growing pigs, journal of Animal Science66: 676-686.Campbell, R. G., Taverner, M. R. and Curie, D. M. 1984.Effect of feeding level and dietary protein content on thegrowth, body composition and rate of protein deposition inpigs growing from 45 to 90 kg. Animal Production 38:233-240.Campbell, R. G., Taverner, M. R. and Curie, D. M. 1988.The effects of sex and live weight on the growing pigs'response to dietary protein. Animal Production 46:123-130.Chung, T. K. and Baker, D. H. 1992. Ideal amino acidpattern for 10-kilogram pigs, journal of Animal Science 70:3102.Cook, D. A. 1991. The conceptual analysis of a dynamicmathematical model for the estimation of the amino acidrequirements for pigs from weaning to maturity. Ph. D.dissertation, University of Illinois, Urbana-Champaign.Crenshaw, T. D., Gahl, M. J. and Benevenga, N. J. 1994.The impact of diminishing returns on performance and feedcosts for growing and finishing pigs, journal of AnimalScience 72: sttppl. I, p. 59 (abstr.).Critser, D. J., Miller, P. S., Lewis, A. J. and Wolverton,C. K. 1993. The effects of dietary protein concentrationduring realimentation on compensatory growth in barrowsand gilts, journal of Animal Science 71: suppl. 1, p. 178(abstr.).Dritz, S. S., Nelssen, J. L., Goodband, R. D. and Tokach,M. D. 1994. Application of segregated early weaningtechnology in the commercial swine industry. Compendiumon Continuing Education for the Practicing Veterinarian 16: 677.Etherton, T. D., Wangsness, P. J., Hammers, V. M. andZiegler, J. H. 1974. Effect of dietary restriction on carcasscomposition and adipocyte cellularity of swine withdifferent propensities for obesity. Journal of Nutrition 112:2314.Finkelstein, J. D. 1990. Methionine metabolism inmammals, journal of Nutritional Biochemistry 1: 228.Friesen, K. G., Nelssen, J. L., Goodband, R. D., Tokach,M. D., Unruh, J. A., Kropf, D. H. and Kerr, B. J. 1995a.Influence of dietary lysine on growth and carcasscomposition of high-lean growth gilts fed from 34 to 72kilograms, journal of Animal Science. 72: 1761.Friesen, K. G., Nelssen, J. L., Goodband, R. D., Tokach,M. D., Unruh, J. A., Kropf, D. H. and Kerr, B. J. 1995b. Theeffect of dietary lysine on growth and carcass composition

-

Growth modelling in pigs 169

in high-lean growth gilts fed from 72 to 136 kilograms.journal of Animal Science. In press.Greef, K. H. de and Verstegen, M. W. A. 1993. Partitioningof protein and lipid deposition in the body of growing pigs.Livestock Production Science 35: 317.Gu, Y., Schinckel, A. P. and Martin, T. G. 1992. Growth,development, and carcass composition in five genotypes ofswine. Journal of Animal Science 70:1719.Holmes, C. W., Carr, J. R. and Pearson, G. 1980. Someaspects of the energy and nitrogen metabolism of boars,gilts and barrows given diets containing differentconcentrations of protein. Animal Production 31: 279-289.Knabe, D. A., LaRue, D. C, Gregg, E. J., Martinez, G. M.and Tanksley, T. D. 1989. Apparent digestiblity of nitrogenand amino acids in protein feedstuffs by growing pigs.Journal of Animal Science 67: 441.National Research Council. 1988. Nutrient requirements ofswine. 9th ed. National Academy Press, Washington, DC.Oyeleke, M. O., Balogun, O. O., Fetuga, B. L. andBabatunde, G. M. 1988. Influence of dietary protein levelson rate of tissue deposition and individual muscledevelopment of growing European pigs in a tropicalenvironment. Journal of Agricultural Science, Cambridge 110:377.Peterson, R. G. 1985. Design and analysis of experiments.Marcel Dekker, New York.Rao, D. S. and McCracken, K. J. 1992. Energy:proteininteractions in growing boars of high genetic potential forlean growth. 1. Effects on growth, carcass characteristicsand organ weights. Animal Production 54: 75-82.Schinckel, A. P. 1992. Concepts of lean growth modelingand methods of describing genetic differences forapplication to lean growth models. Proceedings of theNational Pork Producers Council lean-growth modelingsymposium, Dcs Moines, IA, pp. 53-73.Schinckel, A. P. 1994. Nutrient requirements of modern piggenotypes. In Recent advances in animal nutrition (ed. P. C.Garnsworthy and D. J. A. Cole). Nottingham Press,Loughborough.Shields, R. G., Mahan, D. C. and Graham, P. L. 1983.Changes in swine body composition from birth to 145 kg.Journal of Animal Science 57: 43.Shoup, M. A. 1991. The effects of recombinant porcinesomatotropin (pST), slaughter weight and genotype on

postweaning growth and carcass merit and thecharacterization of three genotypes of swine. M. S. thesis,Purdue University, West Lafayette, IN.Stahly, T. S., Cromwell, G. L. and Terhune, D. 1988.Response of pigs from high and low growth genotypes todietary lysine levels. Journal of Animal Science 66: suppl. 1,p. 137 (abstr.).Statistical Analysis Systems Institute. 1988. SAS/STATuser's guide. Release 6.03. Statistical Analysis SystemsInstitute Inc., Cary, NC.Stryer, L. 1988. Biochemistry. 3rd ed. Freeman, New York.Sun, F., Schinckel, A., Einstein, M., Yuan, L. and Randin,R. 1993. Solution and testing of three parameter live weightgrowth curve in a two stage procedure. Proceedings of thecooperative lean growth update, Purdue University.Walker, W. M. and Carmer, S. G. 1967. Determination ofinput levels for a selected probability of response in acurvilinear regression function. Agronomy Journal 59:161.Wang, T. C. and Fuller, M. F. 1989. The optimum dietaryamino acid pattern for growing pigs. British Journal ofNutrition 62: 77.Watt, D. L., DeShazer, J. A., Ewan, R. C, Harrold, R. L.,Mahan, D. D. and Schwab, G. D. 1987. NCCISWINE:Housing, nutrition, and growth simulation model. AppliedAgricultural Research 2: 218.Whang, K. E. and Easter, R. A. 1994. Effect of starterfeeding program on growth performance and protein gainfrom weaning to market weight in barrows and gilts.Journal of Animal Science 72: suppl. 1, p. 65 (abstr.).Whittemore, C. T. 1986. An approach to pig growthmodeling. Journal of Animal Science 63: 615.Whittemore, C. T. and Fawcett, R. H. 1976. Theoreticalaspects of a flexible model to simulate protein and lipidgrowth in pigs. Animal Production 22: 87-96.Whittemore, C. T., Tullis, J. B. and Emmans, G. C. 1988.Protein growth in pigs. Animal Production 46: 437-445.Williams, N. H., Stahly, T. S. and Zimmerman, D. R. 1994.Impact of immune system activation on growth and aminoacid needs of pigs from 6 to 114 kg body weight. Journal ofAnimal Science 72: suppl. I, p. 57 (abstr.).

(Received 24 July 1995Accepted 25 August 1995)