Cupboard Plan

Transcript of Cupboard Plan

-

7/31/2019 Cupboard Plan

1/9

Plans NOWw w w . p l a n s n o w . c o m

THANKYOU!You have successfully downloaded your FREE PlansNOW.com woodworking plan.

Clear printer memory. If you are unable to print this document, turn off your printer for at least 15seconds and try again.

Get advanced printer help. VisitAdobe Support for instructions in troubleshooting commonprinter problems. www.adobe.com/support/techdocs/150d6.htm

Tips for Trouble-Free Printing

Craftsman Furniture PlansBuild the same distinctive fea-tures from the early1900s.

Bedroom Furniture PlansBeds, dressers, armoires, cribs,cradles, and more!

Workbench PlansSound woodworking starts with asolid workbench.

Shop Jig PlansGet the most from your tools witheasy-to-build shop jigs.

Go to Page 1

Gazebo & Arbor PlansMake outdoor living more enjoy-able this summer!

Outdoor Furniture PlansEasy-to-build projects using aminimum of power tools.

Playhouse & Shed PlansEverything you'll need for a kid'ssummer entertainment.

A Plan for Every Project! See more than 250 Plans at PlansNOW.com

Home Improvement PlansSave hundreds of dollars inremodeling when you DIY.

Visit us at www.PlansNOW.com

>

http://www.adobe.com/support/techdocs/150d6.htmhttp://www.adobe.com/support/techdocs/150d6.htmhttp://www.adobe.com/support/techdocs/150d6.htmhttp://store.yahoo.com/cgi-bin/clink?plansnow+c4DrTT+craftsman.htmlhttp://store.yahoo.com/cgi-bin/clink?plansnow+c4DrTT+craftsman.htmlhttp://store.yahoo.com/cgi-bin/clink?plansnow+c4DrTT+craftsman.htmlhttp://store.yahoo.com/cgi-bin/clink?plansnow+c4DrTT+bedroom.htmlhttp://store.yahoo.com/cgi-bin/clink?plansnow+c4DrTT+bedroom.htmlhttp://store.yahoo.com/cgi-bin/clink?plansnow+c4DrTT+bedroom.htmlhttp://store.yahoo.com/cgi-bin/clink?plansnow+c4DrTT+workbenchplans.htmlhttp://store.yahoo.com/cgi-bin/clink?plansnow+c4DrTT+workbenchplans.htmlhttp://store.yahoo.com/cgi-bin/clink?plansnow+c4DrTT+workbenchplans.htmlhttp://store.yahoo.com/cgi-bin/clink?plansnow+c4DrTT+shopjigs.htmlhttp://store.yahoo.com/cgi-bin/clink?plansnow+c4DrTT+shopjigs.htmlhttp://store.yahoo.com/cgi-bin/clink?plansnow+c4DrTT+shopjigs.htmlhttp://store.yahoo.com/cgi-bin/clink?plansnow+c4DrTT+gazeboarbor.htmlhttp://store.yahoo.com/cgi-bin/clink?plansnow+c4DrTT+gazeboarbor.htmlhttp://store.yahoo.com/cgi-bin/clink?plansnow+c4DrTT+gazeboarbor.htmlhttp://store.yahoo.com/cgi-bin/clink?plansnow+c4DrTT+patiodeck.htmlhttp://store.yahoo.com/cgi-bin/clink?plansnow+c4DrTT+patiodeck.htmlhttp://store.yahoo.com/cgi-bin/clink?plansnow+c4DrTT+patiodeck.htmlhttp://store.yahoo.com/cgi-bin/clink?plansnow+c4DrTT+shedsplayhouse.htmlhttp://store.yahoo.com/cgi-bin/clink?plansnow+c4DrTT+shedsplayhouse.htmlhttp://store.yahoo.com/cgi-bin/clink?plansnow+c4DrTT+shedsplayhouse.htmlhttp://store.yahoo.com/cgi-bin/clink?plansnow+c4DrTT+homeimprov.htmlhttp://store.yahoo.com/cgi-bin/clink?plansnow+c4DrTT+homeimprov.htmlhttp://store.yahoo.com/cgi-bin/clink?plansnow+c4DrTT+homeimprov.htmlhttp://store.yahoo.com/cgi-bin/clink?plansnow+c4DrTT+index.htmlhttp://store.yahoo.com/cgi-bin/clink?plansnow+c4DrTT+index.htmlhttp://store.yahoo.com/cgi-bin/clink?plansnow+c4DrTT+gazeboarbor.htmlhttp://store.yahoo.com/cgi-bin/clink?plansnow+c4DrTT+patiodeck.htmlhttp://store.yahoo.com/cgi-bin/clink?plansnow+c4DrTT+craftsman.htmlhttp://store.yahoo.com/cgi-bin/clink?plansnow+c4DrTT+bedroom.htmlhttp://store.yahoo.com/cgi-bin/clink?plansnow+c4DrTT+shedsplayhouse.htmlhttp://store.yahoo.com/cgi-bin/clink?plansnow+c4DrTT+homeimprov.htmlhttp://store.yahoo.com/cgi-bin/clink?plansnow+c4DrTT+shopjigs.htmlhttp://store.yahoo.com/cgi-bin/clink?plansnow+c4DrTT+workbenchplans.htmlhttp://www.adobe.com/support/techdocs/150d6.htm -

7/31/2019 Cupboard Plan

2/9

From Woodsmith MagazineAll rights reserved page 1 of 8 2004 August Home PublishinOne copy for personal use. Other copies prohibit

Plans NOWwww . p l a n s n ow . c om

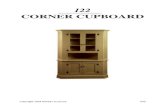

Every fall, my grandma made homemade jelly. Aftereach jar was sealed, it was set in a jelly cupboard

similar to this one to cool. I always liked the down-home look of that cabinet and tried to duplicate thatappearance with this version.

JOINERY.The shelves in this cupboard could havebeen mounted on adjustable shelf brackets. But I didsomething different this time. By gluing the shelves

into dadoes in the cupboard sides, the shelves are per-manently attached. This helps keep the cabinet fromracking. So the shelves are both functional and struc-tural. The door frame is assembled with half-lap jointsreinforced with dowel pins at the corners. This joint iseasily cut on the table saw or router table.

TIN PANELS.The door holds four tin panels. The pat-tern punched in each one is decorative, but it alsoserves a practical purpose. The holes allowed air to cir-culate so moisture from the jelly wouldnt build upinside the cabinet. Making the panels is easy. We usedfour sheets of tin (purchased at a local harware store)cut down to appoximately 10" x 14" each. Just use a

punch and follow a pattern that you've draw on a pieceof paper. The cupboard can also be built with woodraised panels instead of tin. The Designers Notebookon page 8 shows how to make this option.

BACK SLATS. Ordinarily I use plywood for a cabinetback, but for a country project like this, plywoodseemed out of place. So I used solid pine but not aglued-up panel. Instead, I cut rabbets on the slats for aship lap joint. This allows them to expand and con-tract without pushing on the cupboard sides.

FINISH.To avoid a blotchy finish, I used a pine sealerfirst. Then I stained it to get an "aged" look.

JELLYCUPBOARD

-

7/31/2019 Cupboard Plan

3/9

From Woodsmith MagazineAll rights reserved page 2 of 8 2004 August Home PublishinOne copy for personal use. Other copies prohibit

A

M

N

O

G

H

I

J

P

E

F

B

C

D

L

K

TOP

BACKSLAT

TOPFACINGSTRIP

KEEPERSTRIP

2" BUTTHINGE

LATCHROD

1MAPLEKNOB

!/4"DOOR

DIVIDER

DOORRAIL

DOORSTILE

DOORDOWEL

PIN

KICKBOARDDOWEL

PIN

BOTTOMFACINGSTRIP

KICKBOARD

SHELF

SIDEFACINGSTRIP SIDE

PUNCHEDTIN

PANEL

FLIPPER

HARVEST FRUIT GRANDMA'S PIE

HEARTS ON A BLANKET FRUIT BASKET

SPRING FLOWERS DAISY SWIRL

EXPLODED VIEW

OVERALL DIMENSIONS:

20W x 123/4D x 58H

CUTTING DIAGRAM

#/4 !/4x 7 - 60 (Four Boards @ 3.3 Bd. Ft. Each)

#/4 !/4x 11 - 60 (Two Boards @ 5 Bd. Ft. Each)

#/4 !/4x 11 - 96 (8 Bd. Ft.)

#/4 !/4x 11 - 96 (8 Bd. Ft.)

A

H

HC

B BB B B

I I FK K

M M MJJ

ED

NN

CASE

A Sides (2) 3/4 x 111/4 - 571/4B Shelves (5) 3/4 x 101/2 - 173/4C Side Facing Str. (2) 3/4 x 1 - 571/4D Top Facing Strip (1) 3/4 x 1 - 161/2E Bot. Facing Strip (1) 3/4 x 2 - 161/2F Kickboard (1) 3/4 x 51/2 - 181/2G Kickbd. Dwl. Pins (4)1/4 dowel - 21/4H Back Slats (4) 3/4 x 45/8 - 511/4I Top (1) 3/4 x 123/4 - 20DOOR

J Door Stiles (2) 3/4 x 21/2 - 495/8K Door Rails (2) 3/4 x 21/2 - 163/8L Door Dowel Pins (8) 1/4 dowel - 3/4M Door Dividers (3) 3/4 x 21/2 - 121/8N Keeper Strips (16) 1/4 x 1/4 - 13 roughO Latch Rod (1) 3/8 dowel - 15/8P Flipper (1) 1/8 x 1/2 - 111/16

HARDWARE SUPPLIES

(24) No. 8 x 11/2" Fh woodscrews(6) No. 8 x 13/4" Fh woodscrews(3) 2" x 19/16" butt hinges w/ screws(4 pieces) 10" x 14" tin (rough size)(40) 1/2" wire brads(1) 11/4"-dia. maple knob(20) 4d (11/2"-long) square cut finish nails(optional)

MATERIALS LIST

NOTE: PARTS G & L ARE CUT FROM

AN 18" LENGTH OF !/4"DOWEL.

KEEPER STRIPS (N) ARE CUT FROM

OVERSIZE BLANKS.

CUT LATCH ROD (O) FROM 3/8"

DOWEL.CUT FLIPPER (P) FROM SCRAP.

-

7/31/2019 Cupboard Plan

4/9

From Woodsmith MagazineAll rights reserved page 3 of 8 2004 August Home PublishinOne copy for personal use. Other copies prohibit

When cutting a dado ina large panel, using ahand-held router iseasier than wrestling alarge panel on my tablesaw or router table.

Since lumber is rarelythe exact same thicknessas the diameter of arouter bit, I use a smallerbit and make twopasses. First set up a

fence with a spacer stripthat determines theexact finished width ofthe dado. The width ofthe strip, plus the diam-eter of the router bit

should equal the finishedwidth of the dado (Fig.1a). After the first pass,remove the spacer. Asecond pass completesthe dado (Fig. 2).

TAPESPACER

STRIP TOFENCE

SPACER

ROUT INDIRECTIONOF ARROW

1 SPACER FIRSTPASS

SECONDPASS

REMOVE SPACERTO COMPLETE DADO

2

. . . . . . . . . . . . . . . .Routing Custom-Fit Dadoes

A

A

SIDE

TAPE SPACER TOSTRAIGHTEDGE

LAYOUTLINES FORDADOES

NOTE:TO ROUTDADOES,CLAMP SIDESTOGETHER WITHINSIDE FACES UP

11!/4

TOP ENDS

SIDE( -THICK STOCK,

57 LONG)#/4"

!/4"

12!/2

12!/2!/2

6

NOTE: DADOES ARE 12APART, MEASURED TOP EDGETO TOP EDGE.

!/2"

1

A

AUX.

FENCE

NOTE:SIDES AREMIRROR IMAGES

SIDE

FRONTEDGE

2

SIDES & SHELVES

Back when cupboards like this were acommon fixture in the kitchen or pantry,they would probably have been made ofknotty pine. So to make this jelly cup-board look authentic, I used No. 2common pine.

After letting the lumber dry out in the

shop for two weeks, I started work onthe sides of the cupboard.

CUT TO SIZE. In order to minimize thecupping that may occur with wideboards, I edge-glued each of the sidesfrom two narrower boards. When theglue dried, I cut the sides (A) to a fin-ished width of 111/4" and finished lengthof 571/4" (Fig. 1).

SHELF DADOES. Five shelves hold thesides of the cupboard together. Theshelves are held in dadoes spaced apartevenly(Fig. 1). But there are a coupletricks to routing the dadoes in the sides

and getting them to align after the cup-board is assembled.

First, I clamped both cupboard sidestogether with their top ends flush andthe inside faces up (Fig. 1). Then I laidout the positions of the dadoes by meas-uring down from the top end.

To follow the layout lines for thedadoes, I guided the router against astraightedge clamped to the workpiece.And because the pine for the shelves wasslightlyless than 3/4" thick, I used a1/2"straight bit in the router. I routed eachdado to the correct width in two passes

by using a removable spacer against thestraightedge (Fig. 1). (Refer to the ShopTip below for details.)

BACK RABBET.After routing the dadoesfor the shelves, a rabbet can be cut ineach cupboard side for installing theback slats (Figs. 2 and 2a).

Note:To make sure the rabbets arerouted along the correct edges (the sidesare mirror images), it helps to stand

the sides up first and mark the edges tobe rabbeted.

DECORATIVE CUTOUTS.The last cutsto make on the cupboard sides looksimply to be decorative but they alsoserve a purpose.

The semi-circular cutout at the bottomof each piece creates a pair of feet.(Fig. 3). This allows the cabinet tobridge uneven spots in the floor.

!/2"STRAIGHT

BIT

#/8

THICKNESSOF SHELVES

#/4

SEE SHOPTIP BELOW

FOR ROUTINGDADOES

a.

A

AUX.FENCE

RIPFENCE

THICKNESSOF BACK

#/4

#/8

a.

SPACER

STRAIGHTBIT

WIDTHOF DADO

a.

-

7/31/2019 Cupboard Plan

5/9

From Woodsmith MagazineAll rights reserved page 4 of 8 2004 August Home PublishinOne copy for personal use. Other copies prohibit

While dry-assembling thejelly cupboard, I ran intoa problem. When theshelves were clampedbetween the sides, thecenters of the sidepanels cupped out (Fig.

1). I came up with a fixthat uses opposingwedges. The wedgeswork against a clampingbar that straddles thesides (Fig. 2). It's simply a2x4 block with a 1/2"-

thick spacer glued oneach end. I stuck thespacers to the side of thecabinet using carpettape. Then I clamped thecupboard assemblytogether. To force the

WHEN USING CLAMPS ONLY,SIDES CAN CUP AWAY FROM SHELF

1WEDGES REMOVE

CUPPING!/2"-THICKSPACER

CLAMPINGBAR

2

. . . . . . . . . . . . . . . . . . . . Clamping With Wedges

A

RABBET

SIDE

BACKEDGE

FRONTEDGE

3 R!/4"

2 2#/4

6

3 BSHELF

CUT FIVE SHELVESFROM 1x12 STOCK

17#/410!/2

NOTE: IF 1x12 IS CUPPED, RIP SHELF INTO

THIRDS AND REGLUE WITH MIDDLE PIECEUPSIDE DOWN, THEN PLANE FLAT

4 18OVERALL

!/2"

CHECKFOR

SQUARE

WEDGECLAMP

(SEESHOP TIPBELOW)

NOTE:ALIGN SHELVESFLUSH WITH FRONTOF CASE SIDESAND SHOULDEROF RABBET

5

Square-cut nails are an authentic detail.To prevent splitting the wood, drill pilotholes before driving the nails. Then setthe heads just below the surface with a

punch before sanding the side.

Note:Although the feet start out dif-ferent widths, theyll end up the sameafter a facing strip is added to the front(refer to Fig. 6 on page 5).

After laying out the arcs, I used a jigsaw to cut just shy of the layout lines.Then I smoothed up to the line with adrum sander.

SHELVES. Next, I started on theshelves. I cut these from 1x12s. A singleboard this wide will often cup. If your

stock is cupped, one way to flatten it is torip each shelf blank into thirds. Thenglue the blank together with the middlepiece upside down. When the glue dries,plane the blank flat.

Now the shelves can be ripped towidth so theyre flush with the frontedges of the sides and also the shoul-ders of the rabbets for the back slats(Fig. 5). Then cut the shelves (B) to fin-ished length (Fig. 4). To determine thislength, measure between the bottomsof the dadoes on the case sides.

ASSEMBLY. Finally, the case can beassembled with the shelves glued intothe dadoes (Fig. 5). The Shop Tip belowshows one way to do this.

CLAMPINGBAR

SHELF

CLAMP

a.

center of the side paneltight against the shelf,tap opposing wedgesbetween the clampingbar and the sides untilthe shelf is completelyseated in the dado.

Note: Keep the shelves flush to thefront edges of the sides (A). If you donthave enough clamps, you can alsoassemble the case with square-cut nails.

-

7/31/2019 Cupboard Plan

6/9

From Woodsmith MagazineAll rights reserved page 5 of 8 2004 August Home PublishinOne copy for personal use. Other copies prohibit

E

C

C

D

TOPFACINGSTRIP

x 1" - 16#/4" !/2"

SIDEFACINGSTRIP

x 1" - 57#/4" !/4"

SIDEFACINGSTRIP

BOTTOMFACING STRIP

x 2" - 16#/4" !/2"

6

G

1!/4

1!/4

NOTE:ATTACH KICKBOARD

WITH GLUE ANDDOWEL PINS

#/8

KICKBOARDDOWEL PIN

-DIA. x2 LONG!/4"!/4"

8

F KICKBOARD

18!/2

5!/2

2!/2 2!/2

5#/4 5#/4

3 R!/4" 3 R!/4"

WASTE

7

FACING STRIPS

To create a frame that surrounds thedoor, facing strips are added next.

The facing strips are attached to thefront edges of the cabinet sides and to thetop and bottom shelves (Fig. 6).

RIP TO WIDTH. First, I ripped two sidefacing strips (C) and one top facing strip

(D) to a width of 1" (Fig. 6).SIDE STRIPS. Now cut the side strips to

the same length as the cupboard sides.Then glue these to the sides, flush withthe outside edges.

TOP AND BOTTOM STRIPS. Next, Iripped a 2"-wide piece for the bottomfacing strip (E) (Fig. 6).

Then the top and bottom facing strips(D, E) can be cut to length to fit snuglybetween the side strips.

ATTACH TO CASE. Before gluing on thetop and bottom strips, make marks onthe top and bottom shelves to indicate

where the strips should be glued on(Figs. 6a and 6b). By leaving 1/4" of eachshelf edge exposed, a lip is created atthe top and bottom of the door opening.These lips serve as stops for the door(attached later).

KICKBOARD

A kickboard at the bottom of the cup-board adds a decorative touch.

CUT TO SIZE.To make the kickboard(F), first rip a piece of3/4"-thick stock toa width of 51/2" (Fig. 7). Then cut it to

length to match the width of the case.ROUND OVER TOP EDGE. Next, to

soften the transition between the kick-board and the lower facing strip, rout a1/2" roundover along the top outside edgeof the kickboard (Fig. 7a).

TOE OPENING.To make a toe openingon the kickboard, I used my jig saw to cutout a profile along the bottom edge (Fig.7).

ATTACH TO CASE. Now the kickboardcan be attached to the case. But I didthis with dowel pins (G) (Fig. 8). First,clamp the kickboard to the case and drilltwo 1/4"-dia. holes that go through thekickboard and facing strip into the cup-board side (Fig. 8a).

Then cut four lengths of dowel to fitin the holes.

Note: Cut the dowels so they standproud of the kickboard when theyretapped into the holes (Fig. 8a). Thenthey can be trimmed and sanded flushafter theyre glued in place.

C

DTOP

FACINGSTRIP

1

1

!/4TOP

SHELF

SIDEFACINGSTRIP

NOTE:ALIGN TOPFACING STRIPWITH TOPS OFSIDE FACING STRIPS

a.

E

B

C

1

!/4

SIDEFACINGSTRIP

BOTTOMSHELF

2

BOTTOMFACINGSTRIP

b.

F

ROUTERTABLEFENCE

NOTE:ROUT TOP

OUTSIDE EDGEOF KICKBOARD

!/2" ROUND-OVER BIT

a.

G

E

F

B1"-WIDEREVEAL

1!/4

1!/4

TRIMPINSFLUSH

CROSSSECTION

DRILLHOLES

FOR PINS2" DEEP

a.

-

7/31/2019 Cupboard Plan

7/9

From Woodsmith MagazineAll rights reserved page 6 of 8 2004 August Home PublishinOne copy for personal use. Other copies prohibit

H

#8 x 1Fh WOOD-

SCREW

!/2"

4%/8

BACKSLAT

51!/4

NOTE:SLATS HAVEEQUAL GAPS

BETWEEN THEM

9

I

TOP

12#/4

20

CENTER TOPON WIDTHOF CASE

NOTE:MOUNT

TOP FLUSHWITH BACK

NOTE:

ROUTROUNDOVERON ALL EDGES,SANDRADIUS ONCORNERS

!/8"

!/8"

10

J

L

K

K

DOORSTILE

DOOR

STILE

49%/8

TOP/BOTTOMRAIL

TOP/BOTTOMRAIL

2!/2

2!/2

16#/8

11 NOTE:ROUT RABBETTO DEPTH IN

MULTIPLE PASSES(SEE DETAIL a)

SEEDETAIL b

OUTSIDEFACE

DOWNDIRECTIONOF ROUT

12

BACK & TOP

The back of the cupboard is made of indi-vidual slats to allow for plenty of expan-sion and contraction.

CUT TO SIZE.To make the back, startby ripping four back slats (H) from 3/4"-thick stock to the same width (Fig. 9).The finished width allows for a1/16" gap

between the installed slats (Fig. 9a).Next, cut the slats to finished length

so they extend from the top of the cab-inet sides to the bottom of the lower shelf(Fig. 9).

SHIP LAPS.The ship lap joint is reallyjust overlapping rabbets. The rabbetsare cut to a depth half the thickness ofthe pieces (3/8"), and to identical width.

Note: Cut rabbets on the oppositeedges of the middle slats, but on justoneedge of each outside slat(Fig. 9a).

ATTACH SLATS. Now the back slats canbe screwed to the cabinet, keeping the

gaps between them equal (Fig. 9a).TOP. The top (I) is an edge-glued

blank (Fig. 10). Cut it to finished size toallow for a3/4" overhang at the front andsides (Fig. 10a) butnot the back.

Next, rout 1/8" roundovers on theedges of the top, and sand a1/8" radius onthe corners. Now the top can be attachedusing woodscrews driven up from below(Fig. 10a).

DOOR FRAME

The door of the cupboard is a frame and

panel unit. Its construction is the samewhether you use tin or wood panels.

DOOR FRAME. To make the doorframe, start by ripping two door stiles

(J) and two door rails (K) to finishedwidth (Fig. 11).

Then, to determine the length of thepieces, measure between the facingstrips and subtract1/8" to allow for a1/16"gap all around the door. Cut the framepieces to finished length (Fig. 11).

END LAPS. Now cut the end lap jointshalf the thickness of each of the mating

pieces (Fig. 11a).After the lap joints are cut, the frame

can be glued and clamped together.

#8 x 1 "Fh WOODSCREW

!/2

4%/8

#/4EQUALGAPS

CROSS SECTION

#/8 #/8" x " LAPS

a.

A

I

B

CROSS SECTION

TOP

SIDE

SHELF

#/4

1!/2

#8 x 1 "

FhWOODSCREW

#/4

a.

L

NOTE:CENTERPINS ON

STILE

!/4"DOWEL

PIN

1!/4%/8

a.

#/8"RABBET

BIT

!/2

#/8

a.

SQUARE UPCORNERS WITH

CHISEL

b.

CORNER PINS. Next, I drilled two 1/4"-dia. holes through each corner of theframe for the dowel pins (L) (Fig. 11a).Then glue the pins into the holes andtrim them flush with the frame.

RABBET. When the frame is assem-bled, rout a rabbet around the perimeterof the door opening in the back side(Figs. 12 and 12a). This creates a lip for

the door panels.When the rabbet is cut, square up the

corners with a chisel (Fig. 12b).

-

7/31/2019 Cupboard Plan

8/9

From Woodsmith MagazineAll rights reserved page 7 of 8 2004 August Home PublishinOne copy for personal use. Other copies prohibit

30!!/16"

M

N

O

P

KEEPERSTRIP

TIN PANEL10" x 12"

DIVIDERx 2 - 12#/4" !/2" !/8"

NOTE:DIVIDERS AREINSTALLED ATEQUALINTERVALS

OUTSIDEFACE DOWN

1 -DIA.KNOB!/4"

LATCHROD

FLIPPER

CENTER -DIA.HOLE ON WIDTH

OF STILE

#/8"

13

M

MITERGAUGE

DIVIDER

AUX.FENCE

14

LAY OUTPOSITIONS

OF MORTISESFOR HINGES

NOTE:USE SPACERS

TO CENTERDOOR INOPENING

3

2

18

N

NOTE:USE PUSHSTICK

KEEPERSTRIP

17

RIPFENCE

!/4" ROUNDOVER16

O

P

DOOR LATCHASSEMBLY

1!!/16

THICKNESSOF FLIPPER

MATCHES SLOTIN DOWEL

!/2

19

FRONTFACE UP

CUT RABBETALONG EDGES

15

When the frame of the door is com-plete, the dividers (M) can be built. Thepurpose of the dividers is to separate and support the door panels.

CENTER DIVIDERS. Start by rippingthree blanks to finished width (Fig. 13).Then cut them to length to fit betweenthe rabbets in the door frame.

TONGUES. The dividers are held inplace by a short tongue on each end

(Fig. 13). I used a dado blade to cut therabbets that form the tongues (Fig. 14).

EDGE RABBETS. Now the dividers canfit flush down into the frame. But first, inorder to completely support the panels,two more rabbets are needed on theedges of each divider(Fig. 15a).

To cut these rabbets, I again used mydado blade (Fig. 15). Cut these with thefront of the divider facing up.

KEEPER STRIPS. Once the dividers areglued in place, work can begin on thekeeper strips.

The panels are held in place by small

quarter-round keeper strips (N) that arenailed to the door frame (Fig. 13a). Tomake these keeper strips, first rout1/4"roundovers on both edges of a blank(Fig. 16). Then set the rip fence 1/4" fromthe blade and cut a3/8"-deep kerf on eachedge. Finally, to separate a keeper stripfrom each edge, run the blank throughthe blade face down so the keeper stripfalls to the waste side (Fig. 17). This pre-vents kickback.

TIN PANELS.To make the tin panels,tape your pattern to the tin blank, thenfasten the blank to a hardboard backing

board. Punch the holes by striking anawl with a hammer. Use softer strikesfor smaller holes, heavier strikes forlarger holes. When each panel is fin-ished, trim it to size and secure it in thedoor(Fig. 13a).

MORTISES. After the panels are inplace, the door is attached to the case. Iused three 2"-long hinges and cut a

shallow mortise for each hinge in thedoor stile and the facing strip (Fig. 18aand the Exploded View on page 2).

DOOR KNOB. Next, I built a knob andlatch assembly. To start, drill a3/8"-dia.hole through the door stile (Fig. 13).Then drill a hole in the wooden knob toaccept a length of dowel (O) (Fig. 19a).

#/8

1%/8!/8

!/2

a.

N

CROSS SECTION

KEEPERSTRIP

!/2" WIREBRAD

PUNCHED TIN

a.

CUT RABBETON END

!/2

!/4#/8

a.

!/2

#/8

a.

!/4

!/4

a.

!/4

#/8

a.

A short flipper (P) fits in a slot inthe end of the dowel (Fig. 19). Whenthe knob is turned, the flipper will catchthe facing strip and prevent the doorfrom swinging open (see photo).

FINISH. Now the cupboard can bestained and finished. Since pine can stainunevenly, use a sealer first.

MORTISEDEPTH EQUALSTHICKNESS OF

HINGE LEAF

a.

Before gluing the latch together, makesure it will rotate. If it doesnt, lightlysand the dowel until it does.

-

7/31/2019 Cupboard Plan

9/9

From Woodsmith MagazineAll rights reserved page 8 of 8 2004 August Home PublishinOne copy for personal use. Other copies prohibit

CONSTRUCTION NOTES:

To make the wood panels (Q), glue upfour blanks from 3/4"-thick stock. Measure the rabbeted openings in theback of the door frame. Cut the panels1/8" less than these measurements toallow for a1/16" gap all around (Fig. 2).To steady the panels, fasten a tall aux-iliary fence to the table saw rip fence(Fig. 1).Then tilt the table saw blade10 and raise the blade to 13/8". Cut the bevels in two passes, movingthe rip fence slightly between passes.The first pass removes most of the waste.The second skim cut cleans up burn

marks or blade swirls and creates the1/16"-wide shoulder(Fig. 2).

Note: Before moving the rip fencefor the second pass, cut the bevels onall the edges of all your panels.

Cut across the end grain edges first.Then any chipout will be removed whenthe cut is made on the face grain edges.The tilted blade will slightly undercutthe shoulder. To square it up, make asanding block with a bevel on one edgethat matches the bevel on the panels.To make a tongue on the edge of thepanel, cut a3/4"-wide rabbet1/4" deep on

the back edges (Fig. 2).Now, fasten the panels in the door withkeeper strips (Fig. 2).

RAISEDPANELS

QKEEPERSTRIP

!/2" WIREBRAD

CROSSSECTION

#/4"WIDE

RABBET

SOLID WOOD

DOOR PANEL

!/4

#/4

1#/8

10BEVEL

!/16"SHOULDER

(SQUARE UPWITH

SANDING BLOCK)

2CUT PROFILEON ENDS

FIRST

TALLAUXILIARY

FENCE

RAISE BLADE1 ABOVE TABLE

AND TILT 10#/8"

1

If a panel shrinks, an unfinished edgemay be exposed. To prevent this, applyfinish before mounting it in the frame.

NEW PARTS

Q Door Panels (4) 3/4 x 97/8 - 12Note: Dont need tin panels

MATERIALS LIST

Change the look of the cupboard just by using solid wood panels instead of punched tin.These raised panels can be made entirely on the table saw.