culture - John Deere Dealer | Farm Equipment WA · in John Deere’s long history. Deere built...

Transcript of culture - John Deere Dealer | Farm Equipment WA · in John Deere’s long history. Deere built...

quickly and efficiently,” Pollock said. All model year 2020 sprayers now also come standard with an expanded Precision Ag technology package. In addition to the existing integration of Generation 4 CommandCenter displays, AutoTrac and documentation, customers will now receive JDLink with five years of connected service as standard. Deere has incorporated this into the base offering for R4045 & R4060 sprayers due to its proven value and the technology becoming an expected feature with customers. Model year 2020 John Deere self-propelled sprayers are now available to order. For more information, contact your local AFGRI branch today.

ExactApply the next step in spraying smarter with technology

ENHANCED: John Deere 4-Series sprayers will also come with five years of JDLink as standard.

culture June 2019

Pleasetake one!

AFGRIculture June 2019

After the successful introduction of the John Deere R4060 sprayer to the WA market, a range of exciting new enhancements have been incorporated into John Deere’s range of model year 2020 4-series sprayers. In new model year 2020 machines, which includes the R4045 and R4060, the sprayers will come standard with the new CommandDrive powertrain. CommandDrive is a new hydrostatic all-wheel-drive powertrain that allows operators to spray more hectares with less stress and lower operating cost by staying in the cab longer. The intelligent powertrain uses a single hydrostatic pump to power all four variable-displacement wheel motors. If one or more wheels lose traction, the system adjusts to slow the slipping wheels and direct more flow to the other wheels with traction to power the sprayer over the terrain. It also helps the sprayer handle hills, soft soil and other conditions where additional traction is needed more easily. In addition, CommandDrive works in tandem with the engine and entire sprayer system to automatically increase RPMs when more

power is needed and to maintain proper spraying. With the powertrain’s Auto Mode setting, operators can maintain selected ground speed and application rate at lower engine RPMs, while the Auto Idle setting reduces the engine’s RPM to 900 when the machine is stopped. Both functions help to reduce fuel/DEF consumption and provide a quieter cab experience. John Deere product manager for sprayers Lindsey Pollock said the powertrain is a well-suited addition to the sprayers, which were designed for large, broad-acre cropping systems and high-volume applications. “This new powertrain will help farmers and ag service providers cover more acres

CommandDrive among additions to MY20 John Deere sprayers

Increasing spray efficacy and efficiency is continuing to drive machinery manufacturers towards further automation of sprayer technology, including John Deere. Smarter machinery can ultimately lead to increases in machine automation, leading to the operator doing less and having less risk from inside the cab. John Deere product specialist for crop care Anton Kowalenko said global positioning systems have fundamentally lead improvements in sprayer technology over the last two decades. “The ability to AutoTrac a sprayer and turn the boom on and off was the start of our machines becoming smarter.” The incorporation of ExactApply into John Deere’s sprayer

technology is an example of the next step in spraying smarter. Kowalenko said the technology had made a significant impact on the market, in part due to its flexibility. “Our system can spray both conventionally, as a pressure-based system reliant on speed, or with a Pulse Width Modulation (PWM) system that operates on 30 hertz,” he said. “With PWM, the amount you pulse, or your duty cycle, goes up and down as you change speed, this means you can maintain a constant spray pressure and constant spray quality despite your speed.” PWM can also reduce spray drift and improve spray coverage, as the operator can set their desired spray droplet size, suited to their conditions and

the machine would maintain that quality throughout the spray. Kowalenko said the ExactApply system also features turn-control, which prevented under or over application when turning. “When you are using PWM and go around a corner, the outside of the boom speeds up while the inside slows down,” he said. “We can change the duty cycle, or the nozzle output across the boom. “By doing that, we have an even application rate.” Section control technology will automatically turn boom sections on and off when the machine crosses boundaries, also saving wastage of spray. For more information on John Deere’s sprayer technology, contact your local AFGRI branch today.

AFGRIculture June 2019

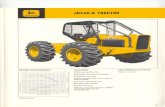

With the advancements in today’s modern tractors, it’s important to look back and reflect on the earlier models that helped make John Deere the household name it is today. When it comes to tractors, there aren’t many more iconic than John Deere’s Model A tractor. The tractor is classed by many as the first true row-crop tractor and is one of the most beloved tractors in John Deere’s long history. Deere built approximately 300,000 Model A tractors between 1934-1952, but among the thousands, are hundreds of different configurations, design changes and early experimental models. In 1931, John Deere company President Charles Deere Wiman formed a committee to create a versatile tractor specifically for row-crop farming, building on the principles of the Model GP Wide Tread tractor, which was only built in small numbers. During the Great Depression in 1931, John Deere’s expenses exceeded sales for the first time in 20 years. Nevertheless, Deere continued to develop the Model A due to popular demand from customers yearning for a true row-crop tractor. Deere, however, decided to abandon the four-cylinder engine concept and focus just on the two-cylinder engine, avoiding adding increases to the purchase price of the tractor. The first working prototype, the FX, was completed in December 1931, followed by the GX and other additional prototypes in 1932 and 1933. In early 1933, Deere built ten pre-production prototypes under the

Model A tractor a model example of Deere’s customer commitment

designation of AA, with either four-speed transmission, the AA-1 or three-speed transmission, the AA-3. One of each model was kept by Deere for factory testing, while the other eight were sold to customers for field testing. The revamped Model A tractor was shipped on July 14, 1934 and included 50-inch skeleton rear wheels, in place of regular steel rear wheels. The tractor was the first to have adjustable wheel treads, which gave it a wider range

AFGRI Wagin had the pleasure of sponsoring Lake View Golf Club’s annual stroke competition in Dumbleyung on

AFGRI Wagin proud to support Dumbleyung golf with great start to season

READY FOR GOLF: The day’s golfers at Lake View Golf Club with AFGRI’s Matt Hitchcock-Jose.

IMPRESSIVE: A John Deere Model A tractor after a full restoration returned it to its former glory.

May 25. The competition was the club’s first stroke event of the season. The day involved both a men’s and women’s

of utility and adaptability than other models on the market at the time. It gave the operator more control, making the tractor easier to steer. After various modifications and different variations throughout the following years, production of the John Deere Model A came to an end, marking an almost 20-year manufacturing lifetime. The tractors are now often collected and restored, rather than used showcasing their revered status with John Deere enthusiasts.

competition with the fairways running fast. Marc Ball was the winner of the men’s competition with a brilliant 65 net score/83 gross score while runner up was club President Eric Gossage with 68 net score/82 gross score. Overall gross for the men’s competition went to Dave Wall. Making it three years running, Elizabeth Dare won the women’s competition with a score of 75 net score/113 gross score with runner up going to Ronnie Ball. Overall gross for the women’s competition went to Tamara Bartram. AFGRI Wagin’s Matt Hitchcock-Jose, who also played in the competition said the day, as always, was very well received. “It’s fantastic to attend events like these and fly the AFGRI flag high,” Matt said. “It’s always a great event. “It’s a really good opportunity to reach out to the local community and see everyone in a more social setting.” AFGRI Equipment look forward to sponsoring the event again next year.