CTM Bro.Qxd (Page 1)ctmsystemsinc.com/pdfs/CTM_Venturi_Brochure.pdf · CTM Systems,Inc. is...

Transcript of CTM Bro.Qxd (Page 1)ctmsystemsinc.com/pdfs/CTM_Venturi_Brochure.pdf · CTM Systems,Inc. is...

Custom Trim Management

COST-EFFECTIVE SOLUTIONS

for Material Waste Handling Problems

Venturis — An economical optionGenerally, the lowest first cost of all systems, the Venturi providescustomers with a cost effective option for removing trim and/or waste.Venturis can be a stand-alone system or a component in a larger system.

Venturis tend to be maintenance free because there are no moving parts inthe flow path. The only moving part is the system driving fan, which doesnot come in contact with the material being pulled. The Venturi systemdesign is excellent for adhesive matrices because the matrix passes throughpipe only, leaving all rotating items out of the material stream.

Unlike other systems, vacuum is created by inducing flow inside the Venturi, which enables the Venturi to move a wide variety of materials efficiently. Venturis systems have built-in flexibility and can be designed for mobility, enabling the system to be moved from machine to machine within your production facility.

CTM Systems,Inc. is continually researching new technology and the latestequipment in order to better serve our customers in this ever-evolving industry.

Our design engineers have the experience and technical expertise to design Trimand Waste Removal Systems that are compact, highly efficient, cost effective

and provide trouble free installation and operation.

Venturis Features:� Venturis are standard products and

are usually available off the shelf.

� Systems are generally compact and requireminimal horsepower to operate.

� System volumes are available to handle many size applications.

� System Fan is out of the material flow stream.

� Flexible blower location. The fan can be located indoors or outdoors and up to fifty (50) feet from the Venturi.

� Requires minimal air separation.

� For adhesive matrix applications coating canbe applied, as well as oil mist systems.

� Options include silencing and air separationequipment.

SYSTEM DESIGN � EQUIPMENT � EXPANSIONS & UPGRADES � INSTALLATIONS � TROUBLESHOOTINGTOLL FREE: 877-493-5800 � www.ctmsystemsinc.com � EMAIL: [email protected]

Locally Represented By:

VENTURI ADVANTAGES

� Low First Cost and Maintenance Free

� Fast and Easy Installation

� Flexible Blower Location, Up To 50 Feet Away

� Conveys Material Up To 30 Inches Wide

� Material Conveyed At Speeds Up To 3,000 Feet Per Minute

� Edge Trim Up To 4 Inches Wide

� System Sizes From 400 cfm To 4,000 cfm

VENTURI SYSTEM INCLUDES

� Venturi

� Venturi Fan

� Material Pick Up Nozzles

� Wye

� Short or Long Run Flex Hose

VENTURI OPTIONS INCLUDE

� Air Separators (Relief Heads)

� Sound Attenuation Devices

� Control Panel

� Nonstick Coatings

� Oil Mist Systems

� Casters for Mobility

� And More

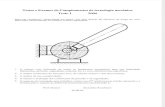

PRODUCTTECH N ICAL SP ECI F ICATIONS

3369 Gun Club Rd., Nazareth, PA 18064484 285-0211 / TOLL FREE: 877-493-5800 / FAX: 484 285-0214email: [email protected] / www.ctmsystemsinc.com

Locally Represented By:

Custom Trim Management

MODEL #

2535346354746856106812

A

2-1/23

3-1/2456

B

344668

C

56781012

D

35-3/43846

52-5/863-1/2

76

NOTE: All dimensions in inches.