CTM Brochure 4 2011 Inside -...

Transcript of CTM Brochure 4 2011 Inside -...

��Heavy Duty Compression Strapping System��One to Four Strapping Heads��Strap Centers Spaced to Minimize Hits and Maximize Throughput

CTMC o m p r e s s i o n U n i t i z e r

I n n o v a t i v e S t r a p p i n g S y s t e m s©2011 EAM-Mosca Corporation All Specifi cations Subject to Change Without Notice. 04-2011

S t a n d a r d S p e c i f i c a t i o n s Te c h n i c a l D a t a

CTM

Power Requirements: Electrical: 230/460 VAC, 3 Ph, 60 Hz. (Alternative Voltage

Strapping:

Strap Tension: Infinitely adjustable from 50 - 250 Lbs. Strap Seal: Friction weldConveyor:

Bed dimensions of 89” l x 108” w x 12” h. Heavy duty

2 3/8” diameter steel rollers on 3.25” centers. Half-width roller

design, independently driven. Standard speed set at 60 ft./min.

O.E.M. Controls: Allen-Bradley SLC-5/03.

Options:��Internal Turntable: Hydraulic twin arm, cross style turntable in-tegrated into internal conveyor. Load rotation continuous in either direction or reciprocating on request. 2,500# or 4,500# load capacity.�� Lances (PVFA): Feeds strap through pallet voids. Unique soft docking, soft start/stop with “clear path” sens-ing and safety clutches for system protection. �� Spare Strapping Head and/or Test Stand: Easy head mounting with quick disconnects; casters for portability. Features complete track for strap feed and take-up; electrical controls included for head operation. ��Crane Kit for fast, safe sealing head removal.��Manual Control Station

The CTM Unitizer from EAM-Mosca features a number of unique features. Additionally, we have a strong history of proven performance. Our press drive, conveyor and strapping head have a 1� year history with hundreds of successful installations in the Americas.

While there are several good unitizers on the market, we suggest you consider the high throughput of the CTM. Be wary of published throughput rates. Actual throughput depends on more than just a fast machine cycle. It also requires an optimum num-ber of heads correctly spaced to enable the platen to compress and strap in a “single hit” the wide variety of units that are typical in most box plant’s production schedules. With up to four strap-ping heads with spacings of 13.25”, 16.5” and 24”, our throughput claims are achievable, day in and day out.

Unit load quality. While box makers are rightly focused on the box as their key quality measure, your customers are also going to judge the appearance of incoming units. The EAM-Mosca CTM provides superior units in several ways. Our compression system applies continuous pressure throughout the strap cycle. This means that we achieve consistent load densities for both dense and highly compressible units. Our encoded platen position for cross strapping ensures that cross straps are tensioned properly to support the primary straps, neither too tight which loosens primary straps, nor too loose which fails to add needed support to the load. You will be proud of your unit loads strapped with a CTM.

The CTM also features a number of safety features for operator protection. A special overspeed valve, and an external mechanical lockout device help ensure safe conditions - just a few of the precautions we have taken to make your workplace safer.

EAM-Mosca provides qualified system installation supervi-sion, operator and maintenance personnel training; and follow-up visits to provide additional training and system performance checks. We have field service technicians for preventive mainte-nance and emergency calls. We also outfit each unitizer with a remote service interface built in to the control package.

The System Focus. EAM-Mosca is committed to providing complete strapping systems, a key component of which is our plastic strapping. New, state-of-the-art strap manufacturing lines in our Hazle������� plant help to ensure the production of high-quality and competitively priced strapping products. Our polypropylene and polyester strapping materials are specifically designed to optimize our equipment performance. Starting with prime virgin resins and carrying through to the manufacturing process specifications, system performance is the controlling factor. Let us show how our system focus can work for you.

Call us or visit our web site at www.eammosca.com for more information.

W h y C h o o s e M o s c a ? S y s t e m H i g h l i g h t s

CTM-602 CTM-703 CTM-804

129"147.5"

19.25"

50.5"

133.25"

120"

163.25"

16.5”

12"

18"

12"

18"

90" MAX. OPENING

89"24"

12"

18"

72" Stroke 72" Stroke 72" Stroke

89"24"

89"

24"16.5” 13.25”

133"

CTM Brochure 11_21_05.indd 1 1/4/2006 12:09:25 AM

Load Sizes

Length 30” Minimum - 82” Maximum

Width 20” Minimum - 98” Maximum; 110” Optional

Diagonal 100” Standard; 112” Optional

LoadHeight

Standard 18” Minimum - 84” Maximum

Low 11” Minimum - 77” Maximum

Extra Low1, 7” Minimum - 73” Maximum

High 30” Minimum - 96” Maximum

Rated Production Speeds (Loads/Hour)3

2 X 0 PatternWithout Lances 180

With Lances 130

2 X 2 PatternWithout Lances 90

With Lances 75

1 Not available with Lances (PVFA)2 Optional3 Assumes 48” x 48” x 48” Load. Throughput speeds can vary depending on conveyor speed, load size, compressibility, turning devices, and use of pallet void feeders. Consider all variables.

CTM Series

Model 600 700 800

Strapping Heads 1 or 2 2 or 3 2, 3, or 4

Head Spacing 24” 24” & 16.5”16.5”, 24” &

13.25”

Conveyor Width 108” Standard; 120” Optional

Conveyor Length 89” Standard

Conveyor Height 12” Standard

Conveyor Speed 45 or 60 Feet Per Minute

Compression Type Hydraulic

Compression Range 10,000+ Lbs..

Internal Turntable2

Model 600 700 800

Arm Length 52” 52” 48”

Power Hydraulic Lift/Rotate

Capacity 2,500# Capacity; Optional 4,500#

2

2

2

Available. Please Inquire.)

9mm, (3/8”), 11mm, (7/16’) 12mm (1/2”) machine grade PET; or 12mm (1/2”) PP

EAM-Mosca Corporation In Canada, call or write675 Jaycee Drive EAM-Mosca (Canada) Ltd.Hazle Township, PA 18202 170 William Smith Driveph: 800.456.3420 Whitby, Ontario LIN9N3 570.459.3426 ph: 905.665.8225fx: 570.455.2442 fx: 905.665.8188www: [email protected] www.eammosca.com

Soft Docking Pallet Lances• Electrically powered chain-driven pallet lance for feed-ing through the pallet void. Features high-speed travel with ‘clear path’ sensing, positive docking and soft start/stop to extend equipment life.

OEM Controls• System controls are designed to interface with customer’s con-veyors and controls with hard-wired connectivity or optional electronic interfacing. Complete internal wiring with motor con-trollers and Allen-Bradley PLC is standard. Push-button panel for manual operation is optional.

Technical Support• Each system is shipped with a modem that with a customer supplied phone line, can be used to connect an EAM-Mosca technician to the system 24/7 to assist in-plant personnel with troubleshooting. When field service is required, our technicians through-out the Americas are available on an emergency or preventive maintenance basis.

Internal Turntable• Hydraulically powered Internal Turntable lifts, turns and lowers in five seconds. Turntable lift, conservatively rated at 2,500 Lbs., and rotate functions are powered from the unitizer hydraulic package. The turn-table grid is designed to expose the minimum un-driven area

beneath loads centered on the grid in order to reliably re-start strapped loads. Rolls in the grid area are coated with a bonded abrasive grit to further insure reliable re-starts.

Simplified Shipping and Installation• Manufacturing methods permit the CTM to be dismantled after final assembly and testing into manage-able, more easily shipped components. System fits into standard trailer and through existing plant entrances. Easy on-site erection.

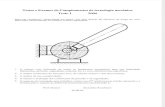

Exclusive Sealer Technology• The Mosca KSR-2 friction-seal strapping head provides a fast cy-cle and consistently high-strength welds. Adjustable strap tension range of 50-250 pounds provides the proper tension for every load. The compact, hinged gas-spring, counter-balanced strapping head is easily lifted for routine, on-platen maintenance. An optional hoist system makes head removal from the platen safe and easy.

High ‘Single Hit’ Capability• Unique head spacings of 13.25”, 16.5” and 24” facilitates greater single hit capability to ensure uniform load height, strap tension and increased through-put.

Safety Controls• Platen mounted strapping head controls allow strap threading and jam clearing to be done from the floor without climbing on the conveyor or platen.

• Special over-speed valve stops the platen instantly when unwanted move-ment or an over-speed condition is detected. External mechanical lockout is electrically interlocked to disable the platen drive to ensure safe condition when working around or under the press.

Low Resistance Dispenser• Mechanical strap dispenser provides low-resistance strap feed-ing which minimizes strapping head wear and tear; fast take-up response maintains good strap control throughout the strapping cycle. No need for strap accumulators on platen.

Independently Driven Conveyor• The conveyor frame is integrated into the unitizer press frame weldment for extra stability. Half-width 2 3/8” diameter rolls on 3.25” centers are independently driven via 50# Duplex chain by a one HP helical gear brake motor. Spring mount absorbs start/stop impacts for long motor life. The center supports prevent roller damage during compression. Tangential chain drive keeps chain tight for accurate load positioning. Rollers easily lift out for maintenance without chain removal.

Structurally Sound• Heavy duty 12” C-Channel uprights with bolted cross member and a rack and pinion equalizer system provides strong struc-tural support for the 60”, 73” or 84” deep hydraulically powered compression platen. Platen travel allows for load heights of 84” down to 18”. Optional Low Platen can strap loads as low as 11”; Extra Low Platen, 7”. The system features touch to 10,000 Lbs. of compression.

Reliable Strap Feeding• The strap track assembly is manu-factured with ultra-low friction UHMW plastic providing minimum resistance for fast and reliable strap feeding. Gates are made of long-life, low-wear stainless steel.

Better Cross-Strapped Loads• Direct force compression measurement with load height memory provides superior compression control on soft loads and maintains uniform strap tension when cross-strapping.

C T M S y s t e m F e a t u r e s

Systems featured on front: (2) CTM-703-10’s (Special Paint)Above: CTM-703-10 (Special Paint)

CTM Brochure 11_21_05.indd 2 1/4/2006 12:09:38 AM

��Heavy Duty Compression Strapping System��One to Four Strapping Heads��Strap Centers Spaced to Minimize Hits and Maximize Throughput

CTMC o m p r e s s i o n U n i t i z e r

I n n o v a t i v e S t r a p p i n g S y s t e m s©2011 EAM-Mosca Corporation All Specifi cations Subject to Change Without Notice. 04-2011

S t a n d a r d S p e c i f i c a t i o n s Te c h n i c a l D a t a

CTM

Power Requirements: Electrical: 230/460 VAC, 3 Ph, 60 Hz. (Alternative Voltage

Strapping:

Strap Tension: Infinitely adjustable from 50 - 250 Lbs. Strap Seal: Friction weldConveyor:

Bed dimensions of 89” l x 108” w x 12” h. Heavy duty

2 3/8” diameter steel rollers on 3.25” centers. Half-width roller

design, independently driven. Standard speed set at 60 ft./min.

O.E.M. Controls: Allen-Bradley SLC-5/03.

Options:��Internal Turntable: Hydraulic twin arm, cross style turntable in-tegrated into internal conveyor. Load rotation continuous in either direction or reciprocating on request. 2,500# or 4,500# load capacity.�� Lances (PVFA): Feeds strap through pallet voids. Unique soft docking, soft start/stop with “clear path” sens-ing and safety clutches for system protection. �� Spare Strapping Head and/or Test Stand: Easy head mounting with quick disconnects; casters for portability. Features complete track for strap feed and take-up; electrical controls included for head operation. ��Crane Kit for fast, safe sealing head removal.��Manual Control Station

The CTM Unitizer from EAM-Mosca features a number of unique features. Additionally, we have a strong history of proven performance. Our press drive, conveyor and strapping head have a 1� year history with hundreds of successful installations in the Americas.

While there are several good unitizers on the market, we suggest you consider the high throughput of the CTM. Be wary of published throughput rates. Actual throughput depends on more than just a fast machine cycle. It also requires an optimum num-ber of heads correctly spaced to enable the platen to compress and strap in a “single hit” the wide variety of units that are typical in most box plant’s production schedules. With up to four strap-ping heads with spacings of 13.25”, 16.5” and 24”, our throughput claims are achievable, day in and day out.

Unit load quality. While box makers are rightly focused on the box as their key quality measure, your customers are also going to judge the appearance of incoming units. The EAM-Mosca CTM provides superior units in several ways. Our compression system applies continuous pressure throughout the strap cycle. This means that we achieve consistent load densities for both dense and highly compressible units. Our encoded platen position for cross strapping ensures that cross straps are tensioned properly to support the primary straps, neither too tight which loosens primary straps, nor too loose which fails to add needed support to the load. You will be proud of your unit loads strapped with a CTM.

The CTM also features a number of safety features for operator protection. A special overspeed valve, and an external mechanical lockout device help ensure safe conditions - just a few of the precautions we have taken to make your workplace safer.

EAM-Mosca provides qualified system installation supervi-sion, operator and maintenance personnel training; and follow-up visits to provide additional training and system performance checks. We have field service technicians for preventive mainte-nance and emergency calls. We also outfit each unitizer with a remote service interface built in to the control package.

The System Focus. EAM-Mosca is committed to providing complete strapping systems, a key component of which is our plastic strapping. New, state-of-the-art strap manufacturing lines in our Hazle������� plant help to ensure the production of high-quality and competitively priced strapping products. Our polypropylene and polyester strapping materials are specifically designed to optimize our equipment performance. Starting with prime virgin resins and carrying through to the manufacturing process specifications, system performance is the controlling factor. Let us show how our system focus can work for you.

Call us or visit our web site at www.eammosca.com for more information.

W h y C h o o s e M o s c a ? S y s t e m H i g h l i g h t s

CTM-602 CTM-703 CTM-804

129"147.5"

19.25"

50.5"

133.25"

120"

163.25"

16.5”

12"

18"

12"

18"

90" MAX. OPENING

89"24"

12"

18"

72" Stroke 72" Stroke 72" Stroke

89"24"

89"

24"16.5” 13.25”

133"

CTM Brochure 11_21_05.indd 1 1/4/2006 12:09:25 AM

Load Sizes

Length 30” Minimum - 82” Maximum

Width 20” Minimum - 98” Maximum; 110” Optional

Diagonal 100” Standard; 112” Optional

LoadHeight

Standard 18” Minimum - 84” Maximum

Low 11” Minimum - 77” Maximum

Extra Low1, 7” Minimum - 73” Maximum

High 30” Minimum - 96” Maximum

Rated Production Speeds (Loads/Hour)3

2 X 0 PatternWithout Lances 180

With Lances 130

2 X 2 PatternWithout Lances 90

With Lances 75

1 Not available with Lances (PVFA)2 Optional3 Assumes 48” x 48” x 48” Load. Throughput speeds can vary depending on conveyor speed, load size, compressibility, turning devices, and use of pallet void feeders. Consider all variables.

CTM Series

Model 600 700 800

Strapping Heads 1 or 2 2 or 3 2, 3, or 4

Head Spacing 24” 24” & 16.5”16.5”, 24” &

13.25”

Conveyor Width 108” Standard; 120” Optional

Conveyor Length 89” Standard

Conveyor Height 12” Standard

Conveyor Speed 45 or 60 Feet Per Minute

Compression Type Hydraulic

Compression Range 10,000+ Lbs..

Internal Turntable2

Model 600 700 800

Arm Length 52” 52” 48”

Power Hydraulic Lift/Rotate

Capacity 2,500# Capacity; Optional 4,500#

2

2

2

Available. Please Inquire.)

9mm, (3/8”), 11mm, (7/16’) 12mm (1/2”) machine grade PET; or 12mm (1/2”) PP

EAM-Mosca Corporation In Canada, call or write675 Jaycee Drive EAM-Mosca (Canada) Ltd.Hazle Township, PA 18202 170 William Smith Driveph: 800.456.3420 Whitby, Ontario LIN9N3 570.459.3426 ph: 905.665.8225fx: 570.455.2442 fx: 905.665.8188www: [email protected] www.eammosca.com

��Heavy Duty Compression Strapping System��One to Four Strapping Heads��Strap Centers Spaced to Minimize Hits and Maximize Throughput

CTMC o m p r e s s i o n U n i t i z e r

I n n o v a t i v e S t r a p p i n g S y s t e m s©2011 EAM-Mosca Corporation All Specifi cations Subject to Change Without Notice. 04-2011

S t a n d a r d S p e c i f i c a t i o n s Te c h n i c a l D a t a

CTM

Power Requirements: Electrical: 230/460 VAC, 3 Ph, 60 Hz. (Alternative Voltage

Strapping:

Strap Tension: Infinitely adjustable from 50 - 250 Lbs. Strap Seal: Friction weldConveyor:

Bed dimensions of 89” l x 108” w x 12” h. Heavy duty

2 3/8” diameter steel rollers on 3.25” centers. Half-width roller

design, independently driven. Standard speed set at 60 ft./min.

O.E.M. Controls: Allen-Bradley SLC-5/03.

Options:��Internal Turntable: Hydraulic twin arm, cross style turntable in-tegrated into internal conveyor. Load rotation continuous in either direction or reciprocating on request. 2,500# or 4,500# load capacity.�� Lances (PVFA): Feeds strap through pallet voids. Unique soft docking, soft start/stop with “clear path” sens-ing and safety clutches for system protection. �� Spare Strapping Head and/or Test Stand: Easy head mounting with quick disconnects; casters for portability. Features complete track for strap feed and take-up; electrical controls included for head operation. ��Crane Kit for fast, safe sealing head removal.��Manual Control Station

The CTM Unitizer from EAM-Mosca features a number of unique features. Additionally, we have a strong history of proven performance. Our press drive, conveyor and strapping head have a 1� year history with hundreds of successful installations in the Americas.

While there are several good unitizers on the market, we suggest you consider the high throughput of the CTM. Be wary of published throughput rates. Actual throughput depends on more than just a fast machine cycle. It also requires an optimum num-ber of heads correctly spaced to enable the platen to compress and strap in a “single hit” the wide variety of units that are typical in most box plant’s production schedules. With up to four strap-ping heads with spacings of 13.25”, 16.5” and 24”, our throughput claims are achievable, day in and day out.

Unit load quality. While box makers are rightly focused on the box as their key quality measure, your customers are also going to judge the appearance of incoming units. The EAM-Mosca CTM provides superior units in several ways. Our compression system applies continuous pressure throughout the strap cycle. This means that we achieve consistent load densities for both dense and highly compressible units. Our encoded platen position for cross strapping ensures that cross straps are tensioned properly to support the primary straps, neither too tight which loosens primary straps, nor too loose which fails to add needed support to the load. You will be proud of your unit loads strapped with a CTM.

The CTM also features a number of safety features for operator protection. A special overspeed valve, and an external mechanical lockout device help ensure safe conditions - just a few of the precautions we have taken to make your workplace safer.

EAM-Mosca provides qualified system installation supervi-sion, operator and maintenance personnel training; and follow-up visits to provide additional training and system performance checks. We have field service technicians for preventive mainte-nance and emergency calls. We also outfit each unitizer with a remote service interface built in to the control package.

The System Focus. EAM-Mosca is committed to providing complete strapping systems, a key component of which is our plastic strapping. New, state-of-the-art strap manufacturing lines in our Hazle������� plant help to ensure the production of high-quality and competitively priced strapping products. Our polypropylene and polyester strapping materials are specifically designed to optimize our equipment performance. Starting with prime virgin resins and carrying through to the manufacturing process specifications, system performance is the controlling factor. Let us show how our system focus can work for you.

Call us or visit our web site at www.eammosca.com for more information.

W h y C h o o s e M o s c a ? S y s t e m H i g h l i g h t s

CTM-602 CTM-703 CTM-804

129"147.5"

19.25"

50.5"

133.25"

120"

163.25"

16.5”

12"

18"

12"

18"

90" MAX. OPENING

89"24"

12"

18"

72" Stroke 72" Stroke 72" Stroke

89"24"

89"

24"16.5” 13.25”

133"

CTM Brochure 11_21_05.indd 1 1/4/2006 12:09:25 AM

Load Sizes

Length 30” Minimum - 82” Maximum

Width 20” Minimum - 98” Maximum; 110” Optional

Diagonal 100” Standard; 112” Optional

LoadHeight

Standard 18” Minimum - 84” Maximum

Low 11” Minimum - 77” Maximum

Extra Low1, 7” Minimum - 73” Maximum

High 30” Minimum - 96” Maximum

Rated Production Speeds (Loads/Hour)3

2 X 0 PatternWithout Lances 180

With Lances 130

2 X 2 PatternWithout Lances 90

With Lances 75

1 Not available with Lances (PVFA)2 Optional3 Assumes 48” x 48” x 48” Load. Throughput speeds can vary depending on conveyor speed, load size, compressibility, turning devices, and use of pallet void feeders. Consider all variables.

CTM Series

Model 600 700 800

Strapping Heads 1 or 2 2 or 3 2, 3, or 4

Head Spacing 24” 24” & 16.5”16.5”, 24” &

13.25”

Conveyor Width 108” Standard; 120” Optional

Conveyor Length 89” Standard

Conveyor Height 12” Standard

Conveyor Speed 45 or 60 Feet Per Minute

Compression Type Hydraulic

Compression Range 10,000+ Lbs..

Internal Turntable2

Model 600 700 800

Arm Length 52” 52” 48”

Power Hydraulic Lift/Rotate

Capacity 2,500# Capacity; Optional 4,500#

2

2

2

Available. Please Inquire.)

9mm, (3/8”), 11mm, (7/16’) 12mm (1/2”) machine grade PET; or 12mm (1/2”) PP

EAM-Mosca Corporation In Canada, call or write675 Jaycee Drive EAM-Mosca (Canada) Ltd.Hazle Township, PA 18202 170 William Smith Driveph: 800.456.3420 Whitby, Ontario LIN9N3 570.459.3426 ph: 905.665.8225fx: 570.455.2442 fx: 905.665.8188www: [email protected] www.eammosca.com