CSP0000703 01 Maintenance

Transcript of CSP0000703 01 Maintenance

-

7/30/2019 CSP0000703 01 Maintenance

1/42

Rev. 5

1-2010MCN2010-0009

MAINTENANCE AND OPERATION

WARNINGS

01A20

50

For confidential use only, not for circulation, distribution or reproduction without prior

permission in writing by FLSmidth. All Rights Reserved.

SAFETY STATEMENT

No personnel, authorized or unauthorized, should depend wholly on safety devices to prevent

accidents. Safety features and devices are meant only to supplement proper, careful, and safepractices on the part of the individual.

WARNING: If the safety procedures given in this manual are compromised

or ignored, severe personal injury or death may occur. Safetypractices accepted by the industry, as well as those dictated by

the responsible regulatory agencies must be followed.

PERSONNEL SAFETY WARNINGS

WARNING: Use extreme care when working around rotating or othermoving parts, to prevent injuries to yourself or others. Also,

anyone entering the area of this equipment must be wearing

adequate safety equipment such as safety glasses, safety shoes,hard hat, etc. Loose fitting clothing, uncovered long hair, or

jewelry must not be worn when working around rotating or

moving equipment.

WARNING: Keep foreign objects, hands, etc. away from moving parts. Do

not operate this equipment if guards have been removed, or aredamaged. All guards and safety devices must be properly

installed and functional before operating this equipment.

WARNING: Lock-out power from electrical equipment using a manualbreaker or disconnect switch before starting any work or

maintenance on the equipment. Lock and tag disconnect switch

so it cannot be closed.

-

7/30/2019 CSP0000703 01 Maintenance

2/42

Rev. 5

1-2010MCN2010-0009

MAINTENANCE AND OPERATION

WARNINGS

01A20

51

For confidential use only, not for circulation, distribution or reproduction without prior

permission in writing by FLSmidth. All Rights Reserved.

WARNING: Experience with and understanding of this equipment isessential for the safe disassembly and repair of the equipment.

Therefore, in case of a question on how to safely proceed,contact your FLSmidth representative immediately.

WARNING: The fumes given off during welding and cutting can be

injurious to the operator's health. Some fumes, such as thoseproduced when working with Zinc; Cadmium and painted

surfaces can be toxic.

HEARING PROTECTION

WARNING: Use hearing protection anytime there is exposure to noise.

Noise is a deceptive hazard. Workers can be exposed to considerable amounts of noise and notbe aware that they may have suffered permanent injury. Noise intensity exceeding an average

of 90 decibels over an 8-hour period can cause hearing loss. This intensity exists in most

industrial and processing plants. Noise also increases a workers fatigue and stress level. It

presents additional hazards when the worker is unable to clearly hear instructions or warningsignals.

The selection and wearing (properly) of adequate hearing protection should be taken seriouslyby personnel operating and maintaining this equipment.

1. Know the types of hearing protection required in your work area. The two basic typesof hearing protection are earplugs and ear muffs. In extreme noise-exposure areas, both

earplugs and ear muffs are recommended. Always use hearing protection in areas

where it is specifically required by plant procedures.

2. Select the hearing protection that is most effective.

3. Always follow the manufacturers instructions for cleaning and storage of reusable earprotection.

Before Operation, Maintenance or Repair of this Equipment:

Read and understand the instructions in this manual.

-

7/30/2019 CSP0000703 01 Maintenance

3/42

Rev. 5

1-2010MCN2010-0009

MAINTENANCE AND OPERATION

WARNINGS

01A20

52

For confidential use only, not for circulation, distribution or reproduction without prior

permission in writing by FLSmidth. All Rights Reserved.

As with any other mechanical equipment, there are safety concerns associated with the

operation and maintenance of FLSmidth supplied equipment. It is absolutely essential,therefore, that operators, maintenance personnel, and supervisors be instructed in safe working

practices

Only personnel who have been trained in safety procedures for this equipment should beallowed around or in the area of the FLSmidth equipment or its auxiliaries. Training can be

done by your own safety personnel or it can be conducted by an FLSmidth representative at

your request.

Contact: FLSmidth, Midvale, Utah. Refer to the Offices page listed on the Table of

Contents.

-

7/30/2019 CSP0000703 01 Maintenance

4/42

Rev. 1

9-2012MCN2012-0306

GENERAL MAINTENANCE

01A25

CSP0000704-01I53

For confidential use only, not for circulation, distribution or reproduction without prior

permission in writing by FLSmidth. All Rights Reserved.

1. Keep the area around the filter clean and free of oil, debris and tools.

2. Make sure all guards are in place and functional.

WARNING: Do not operate this equipment if guards have been removed,

or are damaged. All guards and safety devices must be

properly installed and functional before operating thisequipment.

3. Lubricate the filter components, referring to the Filter Lubrication instructions.

4. Lubricate and maintain all accessory equipment provided by FLSmidth, referring to the

manufacturers instructions in the Accessory Equipment section of this manual.

5. Periodically turn on the sluice pipe water and inspect the nozzles to be sure they are

clear and positioned correctly and also check for leakage at all connections. Remove

and clean all line strainers. Refer to the Operating Instructions.

6. Check all piping connections and flexible connectors on a regular basis to be sure they

are in good condition and are not leaking. Adjust or repair, as necessary.

7. Drain, inspect and clean the filter tank, as required based on operating conditions, to

remove any accumulated material.

8. Check drive belts for tension weekly and adjust, as necessary. Replace worn ordamaged belts, as required.

9. Check monthly for loose bolts and nuts and tighten, as required.

10. Paint, as required.

-

7/30/2019 CSP0000703 01 Maintenance

5/42

Rev. 3

2-2012

MCN2012-0037FILTER DRIVE PARTS REPLACEMENT

04B24

54

For confidential use only, not for circulation, distribution or reproduction without prior

permission in writing by FLSmidth. All Rights Reserved.

DISASSEMBLY

1. Disconnect the power to the drive motor. Then disconnect the drive coupling and

remove the motor drive if necessary for working space.

2. Drain the oil from the drive housing.

3. Remove the packing retainer (18) and packing.

4. Remove the drive cover (1), referring to Figure 13.

Figure 13

1- Drive Cover 12- Gear Lock

2- Blind Seal Plate 13- Set Screw

3- Shims 14- Gear

4- Seal (See Figure 17) 15- Key

5- Bearing Housing Assembly 16- Key

6- Worm Shaft 17- V-Ring Seal

7- Worm 18- Packing Retainer

8- Bearings 19- Drive End

10- Thrust Spacer 20- Drive End (Optional)

19

4

6

17

5

14

1

1815

3 16710

2

20

8

13

12

3

-

7/30/2019 CSP0000703 01 Maintenance

6/42

Rev. 3

2-2012

MCN2012-0037FILTER DRIVE PARTS REPLACEMENT

04B24

55

For confidential use only, not for circulation, distribution or reproduction without prior

permission in writing by FLSmidth. All Rights Reserved.

5. Remove the blind seal plate (2) and bearing housing assembly from the non-drive end of

the drive housing. Refer to Figure 13.

Note: As the bearing housing (2) is removed, note and carefully mark the location of

any shims (3). Retain the shims for reuse.

6. Remove the V-ring seal (17) from the worm shaft (6). Then, remove the bearing

housing assembly (5) from the drive end. This will also remove the oil seal (4).

7. Remove the worm shaft (6) and worm (7) (through the non-drive end), turning the shaft

to disengage the worm from the gear and pulling as necessary.

8. Remove the bearings (8) from the worm shaft using a puller, if necessary: then remove

the thrust spacers (10).

9. Remove the worm (7) from the worm shaft (6) using a puller or brass driver asnecessary.

10. Remove the gear locks (12) and setscrews (13).

Figure 14

25

24

23

22

21

14

-

7/30/2019 CSP0000703 01 Maintenance

7/42

Rev. 3

2-2012

MCN2012-0037FILTER DRIVE PARTS REPLACEMENT

04B24

56

For confidential use only, not for circulation, distribution or reproduction without prior

permission in writing by FLSmidth. All Rights Reserved.

14- Gear 23- Adjust Nuts To Pull Evenly On Gear

21- Trunnion 24- Hook Of Puller Rod On Rib Of Gear

22- Hydraulic Jack 25- Puller Plate

11. Remove the gear (14) using a puller as shown in Figure 14.

Note: Before removing the gear the trunnion should be rotated until the keyway is

located on top.

PARTS INSPECTION

Carefully inspect all parts for wear and damage and replace as necessary. Refer to the followinginstructions:

1. Check the gear teeth for the following:

a. ABRASIVE WEAR: This will show at random spacing across the teeth. It is

normally caused by dirt or other foreign material in the lube oil.

b. SCORING: This will show up as vertical scratches and/or grooves running from

the base of the tooth to the top of the tooth. It results from improper lubrication.

c. PITTING: It is evident in large or numerous pits in the gear teeth. Note that

small pits may occur during run-in of a new gear, but these will smooth out as

the gear wears in. This is caused by over-load on the gear or poor lubrication.

d. GALLING: This condition appears on the gear teeth as numerous deep grooves.

It's caused by overload of the gear, incorrect lubricant used or misalignment.

2. Check the worm shaft and bushing (bearing housing) for scoring and wear.

3. Check the bearings for pitting, roughness of rotation and scoring.

4. Since oil seals are subject to deterioration, they should be replaced with new seals.

Note: All parts and housing must be kept clean. Dirt, metal clips, etc. left in thehousings or other parts will cause wear and other damage.

REASSEMBLY

Note: All parts should be thoroughly washed in solvent then coated with a light oil or greasebefore reassembly. The oil seal should be replaced with a new seal.

-

7/30/2019 CSP0000703 01 Maintenance

8/42

Rev. 3

2-2012

MCN2012-0037FILTER DRIVE PARTS REPLACEMENT

04B24

57

For confidential use only, not for circulation, distribution or reproduction without prior

permission in writing by FLSmidth. All Rights Reserved.

1. Set the key (15) in place in the trunnion. Then set the gear (14) on the trunnion in line

with the key. Press the gear on the trunnion using a press as shown in Figure 15. The

gear hub must contact the drive housing.

Note: It will assist installation to expand the gear hub by heating with a rose bud tip.

-

7/30/2019 CSP0000703 01 Maintenance

9/42

Rev. 3

2-2012

MCN2012-0037FILTER DRIVE PARTS REPLACEMENT

04B24

58

For confidential use only, not for circulation, distribution or reproduction without prior

permission in writing by FLSmidth. All Rights Reserved.

CHECK for clearance between the gear and top of the key. If clearance is more than .050

inch, then the gear must be pulled back and shims set under the key to reduce clearance.

Reinstall the gear.

Figure 15

7- Worm 29- Tank

14- Gear 30- Small Plates To Prevent Damage To Gear

25- Puller Plate 31- Nut (Welded To Puller Plate)

26- Drive Housing 32- Jack Screw

27- Trunnion Shoulder 33- Bolts To Secure Puller Trunnion

28- Key 34- Gear Must Contact The Drive Housing

7

14

34

25

33

32

31

30

28

29

27

26

-

7/30/2019 CSP0000703 01 Maintenance

10/42

Rev. 3

2-2012

MCN2012-0037FILTER DRIVE PARTS REPLACEMENT

04B24

59

For confidential use only, not for circulation, distribution or reproduction without prior

permission in writing by FLSmidth. All Rights Reserved.

2. Install the gear locks (12) and setscrews (13).

3. Set the key (16) in place in the worm shaft keyway. Line up the worm (7) with the key

(16) then drive the worm into place using a brass driver or a press. DO NOT drivedirectly on the worm, use a wood or brass driver.

Note: If necessary shim under the key for a tight fit between the key and worm.

4. Install the thrust spacers (10) using a tubular brass driver, if necessary. The spacers mustfit flush against the worm.

5. Mount the thrust bearing (8) to the worm shaft (6) using a brass bearing driver as

necessary. The thrust bearings must fit flush against the thrust spacers.

Figure 16

2- Bushing Housing 35- 1/4" Dia. Drill Oil Hole

5- Bushing Housing 36- Press Bushing Flush With This Surface

11- Bushing 37- Recess In Bushing

6. Replace the bushings (11) within the bearing (bushing) housings (2) and (5) if necessary:

2

37

36

3511

or 5

-

7/30/2019 CSP0000703 01 Maintenance

11/42

Rev. 3

2-2012

MCN2012-0037FILTER DRIVE PARTS REPLACEMENT

04B24

60

For confidential use only, not for circulation, distribution or reproduction without prior

permission in writing by FLSmidth. All Rights Reserved.

a. Using a brass driver, remove the existing bushing.

b. Drive the new bushing in place so the recess in the bushing will be in line withthe oil hole in the bearing housing.

c. The bushings must fit flush with the inside surface of the bearing housing as

shown in Figure 16.

d. Field drill a " diameter hole through the bushing using the hole in the bearing

housing as a pilot.

7. Coat the drive end bearing housing mounting flange with Permatex #2. Include anyshims. Then install the drive end bearing housing (5). Do not install the oil seal (4).

8. Install the worm assembly, through the non-drive end of the drive housing, running thedrive end of the shaft into place in the drive end bearing housing. The thrust bearing

must seat against the drive end bearing housing.

9. Install the non-drive end bearing housing with blind plate (2). Include any shims and

apply Permatex #2 to the mounting flange.

10. CHECK the worm for end play:

a. Pull the worm shaft to the drive end bearing housing until the thrust bearing is in

contact with the drive end bearing housing (5).

b. Using a feeler gauge, measure the clearance between the non-drive end thrust

bearing and the thrust spacer. This clearance must be between .020" and .050".

11. Adjust the worm shaft for end play as follows:

a. To increase end play, shim (3) between the non-drive end bearing housing (2) and

drive housing.

b. To decrease end play remove shims (3) from between the bearing housing (2) andthe drive housing.

Note: Only full contact shims, as furnished by FLSmidth, should be used. Refer to theparts list for shim part number.

-

7/30/2019 CSP0000703 01 Maintenance

12/42

Rev. 3

2-2012

MCN2012-0037FILTER DRIVE PARTS REPLACEMENT

04B24

61

For confidential use only, not for circulation, distribution or reproduction without prior

permission in writing by FLSmidth. All Rights Reserved.

12. After end play is correct, install the oil seal (4):

a. Check the worm shaft surface to be sure it is free of corrosion, sharp edges, etc.

Correct as necessary.

b. Coat the outer sealing lip of the seal with non-hardening Permatex (not byFLSmidth) and coat the worm shaft with a light oil (not by FLSmidth).

c. Cover the keyway of the worm shaft with tape to protect the seal lip against cuts.

d. Install the seal (4) using a tubular driver or seal installation tool. The seal must be

installed with the lip facing out as shown in Figure 17.

e. Install the V-ring seal (17) as shown on the Filter Drive Housing Assemblydrawing and in Figure 17.

Figure 17

4- Seal 38- Bearing Housing

17- V-Ring Seal 39- Worm Shaft

13. Apply a coat of non-hardening Permatex No. 2 (not by FLSmidth), or substitute, to the

gasket face of the drive housing. Mount the cover and secure.

39

17

4

38

-

7/30/2019 CSP0000703 01 Maintenance

13/42

Rev. 3

2-2012

MCN2012-0037FILTER DRIVE PARTS REPLACEMENT

04B24

62

For confidential use only, not for circulation, distribution or reproduction without prior

permission in writing by FLSmidth. All Rights Reserved.

14. Install the cover seal packing and packing retainer. Cut the ends of the packing at a 45o

angle and make sure the ends butt squarely. Do not stretch or twist the packing during

installation.

15. Fill the drive housing up to the oil level plug or midway in the sight glass with new oil.Refer to the Lubrication instruction section of this manual

16. Connect the drive coupling. If the drive was shifted or removed, see the motormanufacturer's instructions in the Accessory Equipment section of this manual.

17. Test the filter drive and look for leakage at the oil seal, blind seal plate and front worm

shaft bearing.

18. Check the filter drive for alignment referring to the Filter Drive Alignment instructions inthe Erection and Installation section of this manual.

-

7/30/2019 CSP0000703 01 Maintenance

14/42

Rev. 1

9-2012MCN2012-0306

TRUNNION BEARING MAINTENANCE

04B28

CSP0000703-01J63

For confidential use only, not for circulation, distribution or reproduction without prior

permission in writing by FLSmidth. All Rights Reserved.

1. Remove the Cake Wash Frame from the tank. Be sure to properly disconnect all

connections prior to lifting of the frame.

2. Remove the upper bearing halves from the filter drive and non-drive bearing and removethe drum. Refer to the instructions for lifting and temporary support of the drum on a

following page.

Note: A filter drum can be lifted off the trunnions for bearing maintenance, by

"floating" the drum. After the upper bearing halves have been removed, close offall tank outlets. Then fill the tank with water until the drum is lifted off the

bearings.

3. Remove the lower bearing liners when the drum is removed. Do not disturb the drivehousing, otherwise it will require realignment.

4. Remove the grease fittings from the bearings. Then thoroughly clean the bearings withsolvent and clean out all grease passages by working a wire through them.

5. Installing one complete bearing liner at a time (top and bottom) place a liner in positionon the lower bearing half and line up the liner flush with the thrust face of the bearing

(side facing the drum).

6. Referring to Figure 18, place the retainer plates on the recessed surfaces of the bearing.Next, insert the upper liner in the upper bearing half, then place the bearing half over the

roll pins and in position on the lower bearing. Install the capscrews, but do not tighten.

Note: The retainer must be set back of the inside diameter (wearing face) of the liner by

1/16". Trim (grind) the inner end of the retainer, if necessary, to obtain this

clearance.

Also, make sure the liner is flush with the thrust face of the bearing.

7. Draw up the capscrews hand tight and evenly until the liner is tight against the bearing.

Make sure the liner is in complete contact with the bearing by tapping along the full

length of the liner, using a rawhide or wooden mallet and listening for a metallic ring,

which means the liner is contacting the bearing. A dull hollow sound indicates the lineris not in contact with the bearing.

Tighten the capscrews to 440-ft. lbs. (lubricated).

8. Drill the grease holes through the liners from the outside (grease fitting side) of thebearing.

-

7/30/2019 CSP0000703 01 Maintenance

15/42

Rev. 1

9-2012MCN2012-0306

TRUNNION BEARING MAINTENANCE

04B28

CSP0000703-01J64

For confidential use only, not for circulation, distribution or reproduction without prior

permission in writing by FLSmidth. All Rights Reserved.

9. Remove the capscrews and remove the upper bearing housing. Run wires through the

grease passages to make sure they are clean.

10. Install the grease fittings and prime the lube passages.

11. Coat the new liners thoroughly with the lubricant recommended for the trunnionbearings, referring to the lubrication instructions.

12. Reinstall the drum.

13. Install the upper bearing housing, using the capscrews and lock washers specified.

Note: Tighten the capscrews to 440-ft. lbs. (lubricated).

Figure 18

6

5

4

3

2

1

-

7/30/2019 CSP0000703 01 Maintenance

16/42

Rev. 1

9-2012MCN2012-0306

TRUNNION BEARING MAINTENANCE

04B28

CSP0000703-01J65

For confidential use only, not for circulation, distribution or reproduction without prior

permission in writing by FLSmidth. All Rights Reserved.

1- Bearing upper half 4- Retainer plate

2- Capscrew with lock washer 5- Bearing liner half

3- Bearing liner half 6- Bearing lower half

Drum Lifting Instructions

CAUTION: Check the weight of the drum as given in the certified general

arrangement drawing to be sure the hoist equipment and rigginghave the capacity to support the load.

1. Make up skids or supporting devices on which to set the drum. Cover the trunnion anddrive end shaft surface of the device with rubber belting to prevent damage to the bearing

contact surfaces of the trunnion and drive end shaft.

WARNING: Make sure the drum supporting devices are located on flat

solid ground and will support the weight of the drum. Donot allow the drum deck to contact the ground.

2. A crawl beam is recommended, as shown in Figure 19. With this arrangement, the cablespull vertically, thus preventing them from pressing against and damaging the end rings.

It also assists in balancing the drum and allows adjustments to be made relatively easy to

accomplish this.

-

7/30/2019 CSP0000703 01 Maintenance

17/42

Rev. 1

9-2012MCN2012-0306

TRUNNION BEARING MAINTENANCE

04B28

CSP0000703-01J66

For confidential use only, not for circulation, distribution or reproduction without prior

permission in writing by FLSmidth. All Rights Reserved.

Figure 19

1 Wood blocks to protect drum heads 3 Rubber belting to protect trunnion 4 Crawl beam

2 Locate cables as close to drum as possible

Note: The angle of the suspension cables (above the crawl beam) must not exceed 40o

from the vertical centerline.

3. First, apply tension to the cables, but do not lift the drum. If the cables contact the drumheads, place blocks of wood between the cables and the upper rims of the drum to

prevent damage to the end rings.

4

3

2

1

-

7/30/2019 CSP0000703 01 Maintenance

18/42

Rev. 1

9-2012MCN2012-0306

FILTER VALVE MAINTENANCE

05B16

CSP0000703-01K67

For confidential use only, not for circulation, distribution or reproduction without prior

permission in writing by FLSmidth. All Rights Reserved.

The filter valve assembly is comprised of two basic parts: (1) the stationary valve itself and (2) a

rotating, replaceable wear plate. See Valve Assembly drawing.

The wear plate, which bolts to the end of the drum trunnion, has a projecting valve stem thatsupports and centers the valve. The valve is held in position against the wear plate by spring

loaded take-up studs.

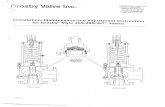

Figure 20

1- Grease Fitting Or Lube Cup 4- Valve Stem

2- Customer Piping 5- Valve Body Assembly

3- Take Up Spring Assembly 6- Wear Plate Assembly

MAINTENANCE

Inspect the valve daily during operation, checking for excessive leakage between the valve andwear plate. Some valve leakage normally occurs when the vacuum is OFF and the drum is being

washed or rotated in liquid. This leakage is acceptable and should not be confused with that

which might occur during operation.

1

2

4

3

5

6

5

3

-

7/30/2019 CSP0000703 01 Maintenance

19/42

Rev. 1

9-2012MCN2012-0306

FILTER VALVE MAINTENANCE

05B16

CSP0000703-01K68

For confidential use only, not for circulation, distribution or reproduction without prior

permission in writing by FLSmidth. All Rights Reserved.

Inspect the multiflex connectors periodically, but at least once a week, for signs of leakage or

deterioration. Replace as necessary. Also check for leakage or deterioration. Replace as

necessary. Also check for leakage at the ends of the connectors as occurs with loose hose

clamps.

Make sure the connectors are properly aligned and not stretched or bent from their natural form.

REPLACEMENT VALVE

Check the valve to make certain the bridge setting is identical to the setting of the valve being

replaced or identical with the drawing of a new bridge setting specifically requested. See

"Adjusting" procedures below.

The valve automatically controls the entire filtering cycle, simultaneously regulating the

functions of pick-up, dewatering and shutting off vacuum for discharge.

The control of these functions is accomplished by the division of the valve into sections or

compartments, while the exact timing and duration of the functions are regulated by the location

and size of bridge blocks within the circular opening of the valve's inner face.

The blocks are located over and in contact with the various compartment division ribs and fitted

into a bridge ring drainage channel machined into the inner face of the valve. The bridges are

installed at the factory for the prescribed functions of the filter.

Due to varying conditions occurring from one application to another, sometimes it is necessary to

alter the timing and/or duration of one or more functions in the filtering cycle. These alterationscan be made either by changing the position of the valve or by changing the bridge setting, as

covered below:

ADJUSTING THE VALVE POSITION

The timing of the filtering cycle may be advanced or retarded slightly by altering the position ofthe valve head. This is done by loosening the spring loaded take-up studs, then using the valve

adjusting rod to rotate the valve. See Valve Installation drawing and Figure 20.

ADJUSTING THE BRIDGE SETTING

When it is necessary to change the duration as well as the timing of the various functions of the

filtering cycle, bridge blocks can be removed, added or moved. Although no recommendationsare made for specific bridge settings, the following instructions cover the procedure for changing

the blocks:

-

7/30/2019 CSP0000703 01 Maintenance

20/42

Rev. 1

9-2012MCN2012-0306

FILTER VALVE MAINTENANCE

05B16

CSP0000703-01K69

For confidential use only, not for circulation, distribution or reproduction without prior

permission in writing by FLSmidth. All Rights Reserved.

The bridges are adjusted as follows (see Valve Body and Bridge Setting Assembly drawing and

Figure 21).

1. Follow the reverse procedure of the valve installation instructions to remove the valvefrom the filter.

2. Place the valve on a clean flat surface with its inner face up. Mark the surface of the

valve lightly in pencil to show the revised location of the bridge blocks.

3. Loosen the setscrews holding the blocks which are to be removed or moved.

4. When a block is moved, tap it on a flat side - never an edge - until the block has been

shifted in its bridge ring groove to the new position.

Use a wooden or plastic mallet. Never use a metal hammer or tool in this operation, as itcan damage the face of the valve or bridge block, preventing a proper seat against thewear plate during operation.

After positioning the bridge, tap it lightly on top to make sure its face is flush with the face of thevalve and it is fully seated against the cast rib of the valve.

-

7/30/2019 CSP0000703 01 Maintenance

21/42

Rev. 1

9-2012MCN2012-0306

FILTER VALVE MAINTENANCE

05B16

CSP0000703-01K70

For confidential use only, not for circulation, distribution or reproduction without prior

permission in writing by FLSmidth. All Rights Reserved.

Figure 21

1- Valve Body 2- Bridge Block (TYP)

2

1

-

7/30/2019 CSP0000703 01 Maintenance

22/42

Rev. 1

9-2012MCN2012-0306

FILTER VALVE MAINTENANCE

05B16

CSP0000703-01K71

For confidential use only, not for circulation, distribution or reproduction without prior

permission in writing by FLSmidth. All Rights Reserved.

Figure 22

1- Valve Body 2- Set Screws

5. If the bridges are shifted or new ones added so that no setscrews are found opposite the

bridges, it will be necessary to drill and tap the valve head for setscrews. Remove theblock before tapping.

6. When a new bridge block is installed, it will be necessary to grind its surface so that it fits

perfectly flush with the surface of the valve. See the procedures for grinding the filter

valve surface

7. Tighten all setscrews holding blocks in position. All setscrews, whether in use or not,

must be left in the valve body in order to prevent leakage.

8. Clean the valve and wear plate thoroughly as described in the valve installation

instructions. Be sure there are no chips or pieces of foreign material on the wearing faces

which might score the surfaces. Then grease both surfaces liberally just prior to

installation.

9. Install the valve according to the installation instructions.

IMPORTANT: Replacement valves should be checked to make sure the bridge setting is

identical to the setting of the valve being replaced or identical with the drawing

of a new bridge setting specifically requested.

2

1

-

7/30/2019 CSP0000703 01 Maintenance

23/42

Rev. 1

9-2012MCN2012-0306

FILTER VALVE MAINTENANCE

05B16

CSP0000703-01K72

For confidential use only, not for circulation, distribution or reproduction without prior

permission in writing by FLSmidth. All Rights Reserved.

VALVE LEAKAGE

If leakage occurring between the valve head and wear plate cannot be stopped by adjusting the

valve take-up springs, it usually indicates that both the valve head and wear plate requirerefacing. This work can be performed by grinding or with a lathe, depending on the extent of

wear or scoring.

If, after close examination, it appears that grinding will correct the difficulty, grind the surfaces

using No. 60 Emery mixed with oil. Grind both faces together until they seat perfectly, thendeburr the edges with a fine grade emery cloth.

If the surfaces are badly scored or damaged, first take a light cut off each surface with a lathe,

then grind them together as described in the procedure above. Remove all burrs, as instructedabove.

Note: Do not remove the bridge blocks.

Once a perfect seat has been achieved, thoroughly clean the valve and wear plate as directed in

the installation instructions. Then double check the bridge setting to be sure it was not changedduring the refacing. See the bridge setting drawing to be sure.

Before the wear plate is installed on the trunnion, thoroughly clean the face of the trunnion (pipe

plate) to remove old sealant. Install the wear plate and valve as directed in the installationinstructions.

If there are any questions regarding these instructions, contact FLSmidth before proceeding withthe refacing.

-

7/30/2019 CSP0000703 01 Maintenance

24/42

Rev. 1

9-2012MCN2012-0306

AGITATOR ASSEMBLY MAINTENANCE

06D29

CSP0000703-01L73

For confidential use only, not for circulation, distribution or reproduction without prior

permission in writing by FLSmidth. All Rights Reserved.

Refer to Tank and Agitator Assembly drawings.

INSPECTION

1. Periodically inspect the agitator mechanism for smoothness of operation. Watch for

clearance of the connecting rods.

2. Inspect the agitator drive referring to the manufacturer's instructions in the Accessory

Equipment section of this manual.

3. Periodically check drive v-belt tension and adjust, as required.

CONNECTING ROD BEARING REPLACEMENT

1. Remove the connecting rod by loosening the setscrews and pulling the connecting rodbearings off the wrist pins.

2. Remove the pin and unscrew the bearing assembly.

Note: Entire bearing assembly must be replaced.

3. Screw new bearings onto the connecting rods. Secure grease fitting with spring and

retainer locking plunger. Set the connecting rod to the length shown on the ConnectingRod Assembly drawing.

Note: The grease fitting in each connecting rod bearing serves not only as a means forlubrication, but also it helps secure a locking plunger that prevents rotation of the

bearing outer race. This locking feature is shown in Figure 23. The grease fitting

locks the hollow pin against the bearing outer race.

When the original grease fitting is replaced, make sure the threaded end of the fitting is

exactly the same size and length as the original fitting. This is important since the fittingsecures the locking plunger. Also be sure the plunger is in place before the fitting is

installed.

4. Drill a " hole through the new bearing hub and install the pin.

5. Grind smooth any burrs and the projection of the pin.

6. Reinstall the connecting rod and lubricate the bearing. Check alignment.

-

7/30/2019 CSP0000703 01 Maintenance

25/42

Rev. 1

9-2012MCN2012-0306

AGITATOR ASSEMBLY MAINTENANCE

06D29

CSP0000703-01L74

For confidential use only, not for circulation, distribution or reproduction without prior

permission in writing by FLSmidth. All Rights Reserved.

Figure 23

1- Bearing 4- Spring

2- Grease Fitting 5- Plunger

3- External Tooth Lock washer

CRANKSHAFT BEARING REPLACEMENT

1. Release belt tension and remove the drive v-belt.

2. Loosen the capscrews securing the crank throws to the crankshaft and remove the crankthrows.

3. Remove the bolts and nuts holding the crankshaft bearings.

4. Pull the crankshaft until it clears either the reducer furnished or the end of the tank, then

tilt the crankshaft away from the tank and remove it.

5. Thoroughly clean and check each bearing for roughness and side play. Replace defective

bearings.

3

4

5

1

2

-

7/30/2019 CSP0000703 01 Maintenance

26/42

Rev. 1

9-2012MCN2012-0306

AGITATOR ASSEMBLY MAINTENANCE

06D29

CSP0000703-01L75

For confidential use only, not for circulation, distribution or reproduction without prior

permission in writing by FLSmidth. All Rights Reserved.

6. Install the crankshaft following the reverse procedure above.

7. Align crankshaft. The crankshaft must be parallel with the drum. Measure at both endsof the filter from the trunnion bearing to the crankshaft. These measurements must be the

same if the crankshaft is in alignment. Adjust the crankshaft bearings to correctalignment.

8. Mount the connecting rod to the crank throw.

9. Check connecting rod and crankshaft alignment by slowly turning the agitator drive byhand through one complete cycle of the rake. If the mechanism operates smoothly with

no binding, alignment will not be necessary.

10. If a connecting rod binds, it is probably bent. Remove the rod by loosening the setscrewsin the bearings and pulling the connecting rod bearings off the wrist pins. Remove the

bearings before straightening the rod. Be sure to secure the setscrews on installation.

AGITATOR PIVOT BEARING REPLACEMENT

Reference Drawing: Tank and Agitator Assembly

1. A come-along placed on top of the trunnion should be used to support the agitator during

the replacement.

The come-along cable must be passed under the agitator hub and back up to connect with

the hook on the come-along.

Note: If a come-along is not available, remove the tank cleanout covers. Place blocks

through the cleanout holes and under the agitator rakes to support the agitator.

2. Disconnect the agitator drive connecting rod at the agitator end. This will release any

tension on the pivot bearing.

3. Loosen the bearing setscrew and remove the bearing hardware, and bearing. It may be

necessary to pry the bearing loose. Examine the bearing for roughness of rotation anddiscard, if necessary.

4. Inspect the pivot shaft bearing surface. If scoring or other damage exists, remove with

emery cloth or replace the shaft.

-

7/30/2019 CSP0000703 01 Maintenance

27/42

Rev. 1

9-2012MCN2012-0306

AGITATOR ASSEMBLY MAINTENANCE

06D29

CSP0000703-01L76

For confidential use only, not for circulation, distribution or reproduction without prior

permission in writing by FLSmidth. All Rights Reserved.

5. If removed, install the cover plate seal and cover plate. Then slide the bearing on the

shaft. Work the bearing by hand as required to seat it against the cover plate and secure.

6. Attach the connecting rods to the agitator, then remove the come-along cable fromaround the drum trunnion and agitator. If blocking was used under the agitator rakes for

bracing, remove the blocking and replace the cleanout covers.

7. Lubricate, referring to the lubrication instructions.

-

7/30/2019 CSP0000703 01 Maintenance

28/42

Rev. 1

9-2012MCN2012-0306

AGITATOR ASSEMBLY MAINTENANCE

06D29

CSP0000703-01L77

For confidential use only, not for circulation, distribution or reproduction without prior

permission in writing by FLSmidth. All Rights Reserved.

Figure 24

1- Agitator 2- Tank

3- Pivot shaft 4- Bearing

5- Cover plate 6- Cover plate seal

2

3

4

5

6

1

-

7/30/2019 CSP0000703 01 Maintenance

29/42

Rev. 1

9-2004MCN2004-0434

AGITATOR REDUCER MAINTENANCE

INSTRUCTIONS

06D30

78

For confidential use only, not for circulation, distribution or reproduction without prior

permission in writing by FLSmidth. All Rights Reserved.

Refer to the Agitator Drive Reducer Assembly drawing. Loaded seals are provided at each end of

the gear shaft and at the worm drive shaft. The bearings and gears are oil bath lubricated.

CARE OF STORED REDUCER

Although the reducer is run with special lubricant at the factory, if it will be stored more than amonth it should be lubricated and run about five minutes once each month to protect against rust

and maintain operating condition.

REPLACEMENT OF SEALS

The seals will not require replacement under normal conditions, but in the event of leakage they

should be replaced as follows:

REMOVAL:

1. Remove the sheave or dismount the reducer, whichever is necessary to replace the seal.

Drain the oil when replacing the worm seal.

2. Remove the seal with a seal puller, using care to prevent damage to the shaft.

Installation:

1. Check the shaft to be sure the surface over which the new seal will pass is smooth and

free of corrosion. Correct as necessary.

2. Apply light oil to the shaft and sealing lip of the seal, then coat the outer surface of the

seal with a non-hardening sealing compound.

3. Cover the keyway with tape or shim stock to protect the seal against cuts. Then install

the seal with the lip facing inside, using a tubular driver. Note that the spring element is

also facing inside.

4. Lubricate as required and remount the sheave or reducer. Then start the reducer and

check for leakage.

PARTS REPLACEMENT

Should it ever become necessary to disassemble the reducer for parts replacement, refer to theAgitator Drive Reducer Assembly drawing. Proceed as follows:

-

7/30/2019 CSP0000703 01 Maintenance

30/42

Rev. 1

9-2004MCN2004-0434

AGITATOR REDUCER MAINTENANCE

INSTRUCTIONS

06D30

79

For confidential use only, not for circulation, distribution or reproduction without prior

permission in writing by FLSmidth. All Rights Reserved.

Disassembly:

1. Drain the oil and remove the reducer from the filter, using eye bolts where the installation

permits.

2. Remove the sheave from the worm shaft.

3. Remove the capscrews from the gear end caps, remove the caps and gear from the

housing. If the caps cannot be removed easily, it may be necessary to tap the gear endwith a soft brass or rawhide hammer in order to force the bearing out of the reducer

housing. Carefully remove the worm gear from the unit being sure to proceed cautiously

to avoid damage to the gear teeth.

Care should be taken to avoid the damage to the seals when sliding the bearing caps off

the shaft. Keep the shims with the bearing caps so that they may be used uponreassembly of the unit.

Examine the seals and, if their replacement is deemed necessary, remove from the caps.

4. Check the worm gear bearings for roughness of rotation or excessive side movement.

Remove the bearings only if there is indication of these conditions, using a puller.

5. Inspect the worm gear teeth for wear that may have destroyed the original tooth shapeand for chips or other damage. Replace if necessary. With damaged or worn bronze

gears, remove the worm gear rim.

6. Remove the worm shaft bearing end caps. Keep the shims with the caps. Use caution in

removing the open end bearing cap to avoid damage to the seal.

7. Remove the worm and bearing assembly. To free the worm from the housing, it may be

necessary to strike the end of the worm with a brass hammer. Then pull the worm from

the housing.

8. If it is determined that the worm shaft seal requires replacement, remove the seal from the

open end cap.

9. Inspect the worm bearings for roughness of rotation or excessive side movement and

remove only the ones requiring replacement, depending on whether the worm will be

replaced.

10. Examine the worm for wear that may have destroyed the original shape. Replace ifnecessary.

-

7/30/2019 CSP0000703 01 Maintenance

31/42

Rev. 1

9-2004MCN2004-0434

AGITATOR REDUCER MAINTENANCE

INSTRUCTIONS

06D30

80

For confidential use only, not for circulation, distribution or reproduction without prior

permission in writing by FLSmidth. All Rights Reserved.

11. Remove the worm bearing in a press or by using a puller.

Cleaning and Inspection:

1. Thoroughly clean all parts with solvent or similar cleaner. Remove and clean the vent

plug, then flush out the housing. Blow all parts dry with compressed air, except thebearings. Never dry bearings with air.

2. Oil the bearings and recheck for roughness and side play. Reinspect the worm and gearfor wear and damage. Replace if necessary.

3. Examine all other parts for wear or damage.

4. Inspect all seals for cuts or indications of deterioration and replace, if necessary.

Reassembly:

1. When installing new bearings, coat the mating surfaces with white lead and use the

proper size installation sleeve and press to seat the bearing. Heat the bearings if specifiedby the manufacturer. Generally, bearings are heated to 300

oF in an oil bath. Be sure to

install the bearings with the thick side of the outer race facing outside.

2. Press the bearings onto the worm gear and worm shafts as necessary.

3. The worm may be installed from either end of the reducer housing.

4. Using one shim as a gasket install and tighten the open end worm plate. Then adjust the

closed end worm plate by providing the necessary amount of shims until the bearings are

just clamped and the worm shaft turns freely.

5. Position the worm gear assembly in the reducer housing using caution to avoid damage to

the gear and worm teeth.

Install and adjust gear end caps by providing shims under each cap until the bearings are

just clamped and the gear turns freely.

6. Gear tooth contact should be checked after reassembly of the unit to guarantee against

premature wear of the parts.

Remove one worm gear end cap and coat the worm with Prussian blue. Reinstall the

worm gear end cap, then turn the worm by hand and check the position of tooth contactby once again removing a worm gear end cap.

-

7/30/2019 CSP0000703 01 Maintenance

32/42

Rev. 1

9-2004MCN2004-0434

AGITATOR REDUCER MAINTENANCE

INSTRUCTIONS

06D30

81

For confidential use only, not for circulation, distribution or reproduction without prior

permission in writing by FLSmidth. All Rights Reserved.

It will be necessary to transfer shims from one worm gear end cap to the other until the

gear is adjusted centrally with the worm. Under no load, both faces of gear tooth should

have a leaving side contact in relation to the corresponding direction of rotation of the

worm.

7. Install the seals referring to "Replacement of Seals" on a previous page. Install the ventand drain plugs.

8. Mount the reducer to the filter and complete all installations. Lubricate referring to theLubrication instructions.

Note: If the worm and gear were replaced, run-in the reducer four to five hours with the tank

empty, then one to two additional hours with the tank filled with water up to drum level.

-

7/30/2019 CSP0000703 01 Maintenance

33/42

Rev. 1

11-2004MCN2004-0563

FILTER MEDIA MAINTENANCE

07D16

82

For confidential use only, not for circulation, distribution or reproduction without prior

permission in writing by FLSmidth. All Rights Reserved.

INSPECTION

Periodically, wash the filter media (cloth) clean of all foreign material and check for damage or

wear. If the cloth is badly worn, it must be replaced. Repair holes in the filter cloth referring tothe instructions below.

CLOTH REPAIRS

When a tear or hole first appears in the cloth, it should be repaired as quickly as possible or, ifdamage is excessive, the cloth should be replaced.

Hand sew or tie up the loose ends surrounding the hole, then cut a patch of cloth a size large

enough to extend at least one inch beyond the hole and hand stitch it to the cover. Since somecloths shrink during operation, and particularly when they dry, these repairs may be difficult and

should be made when the cloth is wet.

-

7/30/2019 CSP0000703 01 Maintenance

34/42

Rev. 1

9-2012

MCN2012-0306

ADJUSTABLE DISCHARGE SCRAPER

MAINTENANCE

09D22

CSP0000703-01M

83

For confidential use only, not for circulation, distribution or reproduction without prior

permission in writing by FLSmidth. All Rights Reserved.

1. Lubricate the scraper bearings according to the Filter Lubrication instructions.

2. Check the cloth and scraper blade periodically for damage and, if necessary, adjust the

scraper stops for maximum inward movement of the blade.

3. Inspect the blade periodically for wear and replace it as required. Never allow the blade

to wear down to the apron.

Figure 25

1- Drum 5- Scraper apron 9- Capscrew w/ nut & washer 13- Adjusting lever

2- Scraper blade 6- Scraper stops 10- Locking screw 14- Regular hex nut

3- Machine Screw 7- Bearing 11- Spacer

4- Nut with washer 8- Cap screw 12- Locking lever

4. Check the scraper occasionally to be sure it turns freely in its bearings and replace the

bearings, if necessary.

8

13

14

1

2

3

4

5

6

7

9

10

11

12

5

7

8

9

-

7/30/2019 CSP0000703 01 Maintenance

35/42

Rev. 1

9-2012MCN2012-0306

FILTER DRUM MAINTENANCE

SO

CSP0000703-01N84

For confidential use only, not for circulation, distribution or reproduction without prior

permission in writing by FLSmidth. All Rights Reserved.

DRUM INSPECTION

Fill the tank with water to about 20% submergence. Cover all tank outlets with blind flanges, if

necessary. Since the drum piping will pick up some water, mount a blind flange to the trunnionpipe plate if the valve is not installed.

Revolve the drum slowly for about 5 to 10 minutes, remove a manhole cover, and check the

drum, piping and around manholes for leakage. Pinpoint any leakage and mark for repair. Be

sure to replace the gasket under the manhole cover.

Contact your FLSmidth Representative before making repairs.

DRUM WELDING

When welding inside or outside a drum, always remove a manhole on each side of the drum andmake a gas test for safety. Also, remove the plastic drainage grids in the vicinity of the welding.

Connect the ground lead for arc welding to the drum heads. Never connect to the tank since this

will damage the trunnion bearings due to electrical circuit contact.

BAILER PIPE (LEAK DETECTOR)

CAUTION: Do not cap, cover or connect to this pipe.

This pipe, located on the drive end trunnion, serves as the air vent to the inside of the drum. It

must be kept clear and periodically inspected to be sure it has not become plugged; clean asnecessary.

WARNING: Do not attempt to clean the bailer pipe when the filter is

operating. Shut down the filter drive before attempting any

hands-on maintenance.

The bailer also connects to a scoop device inside the drum. If the drum should leak internally,this device will scoop up the water and discharge it through the pipe, giving warning to the

operator.

Since this bailer will also pick up moisture or condensation caused by changes in temperature,

some discharge of water is normal. Do not mistake that for excessive discharge caused by a leak.

-

7/30/2019 CSP0000703 01 Maintenance

36/42

Rev. 1

9-2012MCN2012-0306

FILTER DRUM MAINTENANCE

SO

CSP0000703-01N85

For confidential use only, not for circulation, distribution or reproduction without prior

permission in writing by FLSmidth. All Rights Reserved.

In case of leakage, check the manhole covers to be sure they are tight and have gaskets. Also

check the piping, connections, and drum shell.

Consult your FLSmidth Representative before making repairs.

-

7/30/2019 CSP0000703 01 Maintenance

37/42

Rev. 2

3-2007

MCN2007-0135GRID INSTALLATION

12D11

86

For confidential use only, not for circulation, distribution or reproduction without prior

permission in writing by FLSmidth. All Rights Reserved.

These instructions cover the installation of PPW-6 grids on drum decks, which have wing type

division strips. They describe the sizing and cutting of the grids to provide necessary clearances,

along with a proven method of grid installation.

Although the instructions deal with complete grid replacement, they should be generally

followed, with special attention to clearances, for the replacement of individual grids.

EIMCO grids are furnished in full mold size to allow for exact measuring and fitting in thefield. Any wood or metal saw of the circular, band or jig type can be used for cutting. Refer to

the Cutting Instructions drawing for PPW-6 Grids drawing.

Note: When individual grids are replaced for reasons of breakage or wear, shiftthe existing grids in position in order to locate the new grids over the

vacuum ports.

1. Thoroughly clean the drum deck and division strips of scale or other material, especiallyunder the division strips where the grids must fit.

2. Layout the grids along one section of the drum on a trial basis, as shown in Figure 27 and

3. Arrange the grids as follows:

a. Each drum deck vacuum port must be bridged or covered by a single grid. Neverallow the grid to intersect over a vacuum port.

b. All adjoining grids must interlock, as shown, with 1/16 inch clearance separatingthem.

c. Grids adjacent to the end rings should be arranged with the feet as close to the ringsas possible, while allowing 1/16 inch clearance. Because these grids must be

trimmed to fit, make sure they interlock properly before cutting.

3. Refer to Figure 26. Determine the measured grid dimension that is the specified length ofthe grid between the division strips. This dimension must be determined for each drum

section before the grids are trimmed and notched; since, the spacing of the division strips

may not be exactly uniform from centerline to centerline.

Note: The measured dimension must provide 1/16 inch clearance between the

grid and each division strip, as shown. Or, the measured dimension mustprovide a total clearance of 1/8 inch between the grid and strips.

-

7/30/2019 CSP0000703 01 Maintenance

38/42

Rev. 2

3-2007

MCN2007-0135GRID INSTALLATION

12D11

87

For confidential use only, not for circulation, distribution or reproduction without prior

permission in writing by FLSmidth. All Rights Reserved.

Figure 26

1 Measured grid dimension 3 Wing type division strip 4 1/162 Drum shell

Figure 27

1 Division strip 2 1/16 3 Grid

1

4 4

3

2

4

1

3

2

2

-

7/30/2019 CSP0000703 01 Maintenance

39/42

Rev. 2

3-2007

MCN2007-0135GRID INSTALLATION

12D11

88

For confidential use only, not for circulation, distribution or reproduction without prior

permission in writing by FLSmidth. All Rights Reserved.

Figure 28

1 Width of division strip plus .010 to .015 2 1/16 3 Drum shell

4. Cut the grids to the measured grid dimension. Keep in mind the clearances requiredbetween each grid and the division strip.

Note: Make sure the grids interlock before cutting.

5. Notch the ends of the grids where they fit under the division strips as follows. Refer

to Figure 29.

a. Set the cutting length of the saw blade for the width of the notch. Make sure to

include 1/16 inch for clearance.

b. Adjust the saw guide for the required depth of cut on the grid. This cuttingdimension includes the width of the division strip wing plus .010 to .015 inch forclearance.

c. Notch the grids and bevel the notched end.

12

3

2

-

7/30/2019 CSP0000703 01 Maintenance

40/42

Rev. 2

3-2007

MCN2007-0135GRID INSTALLATION

12D11

89

For confidential use only, not for circulation, distribution or reproduction without prior

permission in writing by FLSmidth. All Rights Reserved.

6. Starting at one end of the drum, install the grids as they were arranged in Step #2.

a. Place the grid under the wing of the bottom division strip.

Figure 29

1 Width of division strip wing plus .010 to

.015

3 Saw guide 5 Saw blade

2 Depth of notch to fit grid under division

strip

4 Saw table

b. Insert the grid tool hooks in the center of the grid. Pull up gradually on the bottomhandle of the grid tool, while pressing on the top handle, and bend the grid just

enough to clear the top division strip. Do not bend the grid more than necessary to

slip it under the wing of the strip.

c. Gradually release the tension on the bottom tool handle to allow the grid to slide

into position under the strip.

1

2

3

4

5

-

7/30/2019 CSP0000703 01 Maintenance

41/42

Rev. 2

3-2007

MCN2007-0135GRID INSTALLATION

12D11

90

For confidential use only, not for circulation, distribution or reproduction without prior

permission in writing by FLSmidth. All Rights Reserved.

7. CHECK the first grid to make sure that proper clearance has been allowed between the

division strips and end ring. Install the remaining grids along the drum section according

to the required clearances.

8. Install the remaining sections of grids. Use the previous section as a reference and

carefully CHECK the measured grid dimension and clearances.

-

7/30/2019 CSP0000703 01 Maintenance

42/42

Rev. 1

9-2012

MCN2012-0306WASH AND SLUICE PIPE MAINTENANCE

12D19

CSP0000703-01O

91

Filter Wash Assembly

1. The spray pipes are installed so that the nozzle locations of any one pipe will be midwaybetween the nozzle locations of the adjacent pipes. The U-bolts and clamps allow for the

adjusting of the pipes along the arc of the wash frame panels.

2. Regulated water pressure of approximately 7-10 p.s.i. is recommended for the wash.

3. Check all pipes and hoses individually to make sure they are clean. Also inspect each

nozzle for spray pattern.

Maintenance of Wash Assembly

1. Check periodically for leaks. Keep hose clamps tight.

2. Check regularly for clogged nozzles.

3. Remove the water strainer screen periodically. Clean the screen and flush out thesediment in the strainer.

Maintenance of Sluice Pipe Assembly

Refer to the Sluice Pipe Assembly drawing.

1. Check periodically for leaks. Keep hose clamps tight.

2. Check regularly for clogged nozzles.

3. If a water strainer (not by FLSmidth) is used, periodically remove the screen, clean the

screen and flush out the sediment in the strainer.