CSD TWO INTERCONNECTED MIDDLE SCHOOLS PROJECT...

Transcript of CSD TWO INTERCONNECTED MIDDLE SCHOOLS PROJECT...

-

Page 1 of 24

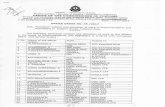

Date: January 22, 2021

Re: CSD TWO INTERCONNECTED MIDDLE SCHOOLS

Dover, Delaware

2019180.00

ADDENDUM THREE

The addendum forms a part of the contract documents and modifies the original bidding documents dated December 18,

2020 as noted below.

PROJECT MANUAL VOLUME 1

1. See attached RYJ Addendum No. 3, which also confirms the BID DATE is February 3, 2021 at 3:30 pm.

PROJECT MANUAL VOLUMES 2

1. ADD attached Section 055113- METAL PAN STAIRS.

2. Section 057300 – Decorative Metal Railings

a. DELETE 2.5A. 2. and REPLACE with “2.5A.2. Pattern: 3/8” square holes on 1/2” straight centers.”

3. Section 075323 - ETHYLENE-PROPYLENE-DIENE-MONOMER (EPDM) ROOFING

a. Under 2.6, ADD the following:

D. Cover Board: ASTM C 1177/C 1177M, glass-mat, water-resistant gypsum substrate, ½

inch thick, factory primed.

1. Products: Subject t compliance with requirements, provide one of the following:

a. Georgia-Pacific Gypsum LLC; Dens Deck Prime.

b. National Gypsum Company; Gold Bond Exp Extended Exposure Sheathing.

c. USG Corporation; Securock Glass Mat Roof Board.

4. Section 076200 - Sheet Metal Flashing and Trim

a. Under 2.2B.1.a, DELETE “Three-Coat Fluoropolymer” and REPLACE with Two-Coat

Fluoropolymer.”

5. Section 077200- Roof Accessories

a. DELETE 2.4 Roof Hatch in its entirety.

6. Section 093013 – Ceramic Tiling

a. Under 2.3A.6., ADD “a. WT-1 color must match custom pantone color – 2126C.

7. Section 098414 – Linear Acoustical Panels

a. Under 2.2D., ADD “10. Pattern 1.”

8. Section 101100 – Visual Display Boards

a. Under 2.5C.3., DELETE “and easel pad clamps.”

9. Section 101400 – Signage

a. DELETE 2.6 Numerical Signs in its entirety.

-

Page 2 of 24

10. Section 102641 – Bullet Resistant Panels

a. Under 2.3B1, CHANGE requirement for Level 4 to Level 3.

11. Section 105113 – Metal Lockers

a. Under 2.3.N., DELETE item 1 and replace with “1. Color shall match PT-8 as specified in Finish

Legend.”

12. Section 122413 – Roller Window Shades

a. Under 2.2 E.1., DELETE “b. Opaque: At windows at Nurse A16.”

b. Under 3.6 A.2., CHANGE “Pull Out D115” to “Pull Out C115.”

13. Section 313116 – Termite Control

a. Under 3.4A.2., ADD “Extend coverage a minimum of 12” from foundation.”

14. DELETE Section 27420 - 0 IP Video Distribution in its entirety.

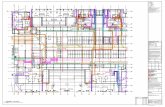

DRAWING VOLUMES 1

1. A003 – construction types – floors, ceilings, railings, ladders

a. Railing type 5

2. A005 – Construction Types Interior Walls

a. REVISE wall type 5A to level III ballistic wall panel

b. REVISE wall type 5B notes

c. REMOVE dimension chain

d. REVISE wall type 5C

e. ADD wall type 5D

3. A100 – Foundation Plan

a. ADD sheet.

4. A101A –

a. REVISE changing table B124A.

5. A101B

a. ADD door tag B0/1.

6. A101C

a. ADD note “Coord. chase height with Mech Duct”

b. REVISE note to say “Knee Wall w/ Stained WD Cap”

c. ADD note.

d. ADD slope to slab

7. A101D

a. ADD storefront tag.

b. ADD storefront tag.

c. ADD Curtain Wall tag.

8. A101G

a. REVISE changing table C124A.

-

Page 3 of 24

9. A101H

a. ADD curtain wall tag.

10. A102B

a. ADD storefront tag.

11. A102G

a. REVISE changing table C221A

12. A102H

a. ADD Curtain Wall tag.

13. A104A – First Floor Reflected Ceiling Plan – Area A

a. REVISE ceiling height in Stair B1

14. A104B – First Floor Reflected Ceiling Plan – Area B

a. REVISE ceiling height in Stair B2

15. A104F – First Floor Reflected Ceiling Plan – Area F

a. REVISE ceiling height in Stair C2

16. A104G – First Floor Reflected Ceiling Plan – Area G

a. REVISE ceiling height in Stair C1

17. A105B

a. REVISE ceiling.

18. A105F

a. REVISE ceiling.

19. A106A

a. REVISE room finish tag for monumental Stair B3B: WOOD to WD-3 and RT-4 to WD-3

20. A106G

a. ADD room finish tags to Monumental Stair C3B and Alcove C3D

21. A302 – Building Sections

a. Detail 1:

i. Update slab slope

b. Detail 1A:

i. Update slab slope

22. A312 – Wall Sections – Classroom Wings

a. Detail 4:

i. REVISE note.

ii. REVISE ceiling.

iii. REVISE foundation detail.

-

Page 4 of 24

23. A401 – Enlarged Toilet Plan

a. Plumbing Fixture Types: REVISE SH-1 to SH-1A

b. Plumbing Fixture Types: REVISE title to “SH-2/ SH-2A”

c. Detail 1: REVISE SH-1 to SH-1A in Toilet D109A and Toilet D112A

d. Detail 10: REVISE changing table

i. ADD note.

24. A403 – Enlarged Stair Plans and Sections

a. Detail 3: REMOVE second railing

:REVISE ceiling height at landing

: REVISE note to say, “GWB on Stud at underside of Stair, Typ. Coord. Height at Landing

with Sprinkler Piping”

b. Detail 4: REVISE ceiling height at landing

: REVISE note to say, “GWB on Stud at underside of Stair, Typ. Coord. Height at Landing

with Sprinkler Piping”

25. A404 – Enlarged Stair Plans and Sections

a. Detail 3:REVISE ceiling height at landing

: REVISE note to say, “GWB on Stud at underside of Stair, Typ. Coord. Height at Landing

with Sprinkler Piping”

b. Detail 4: REVISE ceiling height at landing

: REVISE note to say, “GWB on Stud at underside of Stair, Typ. Coord. Height at Landing with

Sprinkler Piping”

26. A409 – Enlarged Auditorium Details

a. Detail 2:

i. REVISE railing.

ii. ADD T.O.M notes.

iii. REVISE height of masonry

27. A410 – Enlarged Reception Desk, Elevations and Details

a. Reissuing Sheet.

28. A430 – Field House Plans, Elevations, and Sections

a. Detail 1: REVISE wall types

b. Detail 1: ADD FE to Concessions F2, Header Room F5, and Weight Room F8.

c. Detail 8: REVISE T.O.M. to 10’-8”

d. Detail 9: REVISE T.O.M. to 10’-8”

e. ADD: Code Study Notes

29. A511 – Section Details

a. Detail 9: REVISE blocking in wall to match structural details.

30. A512 – Section Details

a. Detail 1: ADD note “Refer to finish schedule for floor finish”

31. A546 – Typical Oko Skin Details

a. REVISE details on sheet.

-

Page 5 of 24

32. A601

a. REVISE room finish schedule for Monumental Stair B3B, Alcove B3D, Monumental Stair C3B, and

Alcove C3D

b. ADD detail 3 to sheet depicting elevation sketch of Schluter Jolly, mitered at corner to show how it

would transition form bottom edge of tile to vertical edge of tile.

33. A608- Window Types – Storefront

a. Revised Storefront SF-B4, SF-B4A, SF-B4B

34. A705 – Interior Elevation – Auditorium & Dressing Rooms

a. Detail 1:

i. ADD note

b. Detail 2:

i. REVISE railing type.

c. Detail 3:

i. ADD note.

d. Detail 11: REVISE dimension to 3”

e. Detail 15:

i. REVISED note.

35. A709 – Interior Elevation – Corridors

a. Details 5:

i. ADD note.

b. Detail 6:

i. ADD note.

BIDDER’S RFI’s

RFI 39

1. Will the bid be getting extended?

a. Answer: The Bid Date was extended to February 3rd in Addendum 2.

2. Carpentry scope M says that contract owns all expansion joints other than roof. Drywall scope I says to

provide expansion joints 2 drywall. Is this referring to 093 control joint? Which contract owns the actual

expansion joint covers in drywall systems? Further clarification is required.

a. Answer: Contract 5 Carpentry & General Work provides expansion joint covers.

3. Is there a construction schedule for this project?

a. Answer: Construction will start March 2021 and project completion is June 2023. A more detailed construction schedule will be provided once construction starts.

4. Has there been any addendums issued to date?

a. Answer: This is Addendum 3. Addendum 1 was available 1/8/21; Addendum 2 was available 1/15/21.

Addendums are posted on RYJ’s website and on the States mymarketplace website.

RFI 40

1. Please reference drawing A601 detail 1. Can you please provide more detail on the Schluter L-trim above the

integral resinous cove base? We are looking for a product line and finish.

a. Answer: The Schluter L-Trim above the integral resinous cove base is to be the SCHIENE profile in

-

Page 6 of 24

stainless steel finish.

2 Please reference drawing A601 detail 1 and 2. We note that the specified Schluter Jolly Trim does not make a dedicated outside corner cap. Because of this, the outside corner trim is left exposed, giving an unfinished

look from top view at all outside corners. We recommend switching the Schluter Systems Jolly finish to

Schluter Systems Rondec. Rondec is available in a Stainless-Steel finish while providing an outside corner

piece. Please clarify how we are to proceed.

a. Answer: Schluter Systems Jolly is to be used. Miter outside corners. Rondec does not meet desired aesthetic.

3. In single toilet rooms with showers, can you please confirm whether or not we are to tile showers? If so please

confirm that elevation 1 on sheet A601 is the wall tile pattern?

a. Answer: The walls at shower locations in single toilet rooms will not be tiled.

4. Please reference drawing A601 detail 1. Can you please clarify what is considered a wet wall in single toilet

rooms?

a. Answer: The wet wall within a single toilet room is any wall that hosts a plumbing fixture including the

toilet and sink, but excluding the shower (which has an integral enclosure).

5. Please clarify the wall tile pattern for WT-4. Is it to be installed Full height?

a. Answer 5.WT-4 is a custom gradient blend to be installed full height.

RFI 41

1. Detail pages A613-A616 are missing from the Architectural Drawings.

a. Answer: These will be issued by Addendum Four.

2. Contract #8 Alum & Glass, scope of work line item "H" says to provide pre-fab canopies. Canopies are not

often provided by the glass contractor and we are not familiar with them. Please verify if this can be supplied

and installed by another contract (possibly carpentry or metal panels). If not, please advise what spec to

reference for them as we do not see a spec section referenced in Contract #8 Alum & Glass for these.

a. Answer: There are no prefab canopies.

3. Contract #8 Alum & Glass, scope of work line item "L" says to provide walkway covers. We have never seen

this item in the alum & glass scope before and have never done these. Please verify if this can be supplied and

installed by another contract.

a. Answer: Section 107326 Walkway Coverings is to be provided by Contract 8 Aluminum

Storefront/Windows/Glass & Glazing

RFI 42

1. Corner guard spec calls for corner guards on ALL outside corners from base to finished ceiling. Please

confirm this is for ALL drywall Outside corners only.

a. Answer: Per Section 102600, item 3.3B, “Install outside Corner Guards at all drywall corners.

RFI 43

1 The 088000 glazing spec lists glass types that cannot be located on the storefront / curtain wall openings (IG- 4, IG-5, IG-6, IG-7). Also, spandrel glass type IG-2 on the drawings, is listed as IG-2A & IG-2B in the spec.

Please verify locations for these glass types

a. Answer: Will be issued in Addendum 4.

-

Page 7 of 24

2 Contract #8 Alum & Glass, scope of work line item "B" lists "translucent wall assemblies, kalwall". I do not see any kalwall on the project and do not see a spec for it. I just want to verify there is none on this project.

a. Answer: There is no Kalwall in the project. See revisions to Summary of Work in this addendum.

RFI 44

Will be answered in Addendum 4.

RFI 45

1. Please if confirm Section 271000 – Structured Cabling and Section 270500 Common Work Results for

Communications are to be bid separately.

a. If the answer is no and both Sections 271000 and 270500 are to be bid together… then disregard the below

question b.

b. Drawing T000 #2 Technology General Notes #4 reads “Structured cabling contractor shall provide and

install a compete data network infrastructure including all cabling, termination equipment UPS EQUIPMENT

and associated components” Then under Section 270500 Common Work Results for Communications page

270500-7 paragraph K. UPS Equipment lists the required UPS’s. Which Section is required to provide the

UPS’s for the racks?

a. Answer: Both Specifications are in Contract 19 Structured Cabling

2. Drawing T001 #7 Concession Remote Equipment rack diagram & #8 Maintenance Remote Equipment both

shows no UPS. Please confirm this is accurate. If a UPS is required, please confirm the Tripplite

SU2200RTXLCDN should be used for both racks.

a. Answer: A smaller UPS should be provided. A 1500 VAC unit is acceptable. The UPS should either fit

in the equipment enclosure of be wall-mounted adjacent to the cabinet.

3. All rack diagrams shown on Drawings T500, T501 and T502 all show a 3 RU 2200 VAC UPS, but the

numbered notes below list 3000 VAC UPS. Then on drawing T512 #3 Video Surveillance Line Diagram show

a 3000 VAC UPS (Tripplite SMART3000RM2UN). Please confirm which UPS should be installed in each

rack.

a. Answer: The 2200 VAC UPS is acceptable.

4. All rack diagrams shown on Drawings T500, T501 and T502 all show a 1 RU 10 Port Power. Then Section

270500 Common Work Results for Communications page 270500-5 #7 reads “Provide (1) 8-port transient

surge protection strip for each TR and per rack/cabinet in the TER and TRs. Please confirm which port count

is correct 8 or 10?

a. Answer: The 8 port unit is acceptable.

5. Drawing T000 #4 Technology Grounding Diagram shows the grounding and bonding requirements. All rack

diagrams shown on Drawings T500, T501 and T502 all show a Ground Bar. Please confirm if all grounding

and bonding for the racks will be completed by the electrical contractor, Structured Cabling contractor or

Common Work Result for Communications contractor.

a. Answer: Contract 17 Electrical provides grounding and bonding per Item W in their scope of work.

6. Drawing T000 #3 Technology Scope Notes Full Scope - #1 reads “Electrical contractor shall supply and

install all low voltage pathways including, but not limited to conduits, boxes, junction boxes, SLEEVES,

chasers, raceways, cable trays and J-Hooks to properly support the low voltage infrastructure. Then Section

270500 – Common Work Results for Communications page 270500-8 paragraph E. 1. Reads “the

telecommunications contractor shall provide sleeves through all walls and floors to protect cabling and or

raceways installed as part of the telecommunications system. All sleeves shall extend through the respective

-

Page 8 of 24

wall or partition and finish with a connector protective bushing. Does the Electrical Contractor or the

Common Work Result for Communications contractor provide and install the Sleeves?

a. Answer: Contract 17 Electrical provides.

7. Drawing T500 #9 Labeling Scheme note #5 reads “Wireless cablings shall be green with green jacks and

green patch cords” Please confirm the wording of “Wireless Cable” are for the Wireless Access Points

(WAP) with CAT6A cabling.

a. Answer: Correct. Wireless Cables are Cat 6A and green.

8. Section 28200 Video Surveillance System – page 28200-6 paragraph E. Video Surveillance NVR’s 1. Exacq

6408144T-R4Z. This is an ExacqVision Z-series NVR with 144 terabytes. Do we have to provide this

specific recorder part number multiple times to support the IP video surveillance system or can an

ExacqVision Z-Series NVR be provide with more terabytes to reduce the overall number of NVR’s required?.

a. Answer: As long as the recording parameters are met, then other Exacq NVRs are acceptable.

9. Please confirm if the following part numbers are also required for each ExacqVision Z-Series NVR

9a. Professional or Enterprise camera licenses?

a. Answer: Enterprise camera license required.

9b. Windows or Linus OS?

a. Answer: Confirm with owner but ESP’s understanding is Windows.

9c. Part # 5000-20070 ExacqVision Rackmount sliding rail kit?

a. Answer: Yes, required.

9d. Part # 5000-40141 Quad NIC Option (2 additional, 4 total)?

a. Answer: Quad NIC not required on all NVRs

9e. Part # 5000-40223 Microsoft Windows Server 2019? f. Part # 5000-40393 Z-Series CPU & Memory

Upgrade?

a. Answer: Yes, required.

9f. Are there any other add-on parts required for these ExacqVision NVR’s?.

a. Answer: Standard configuration is acceptable.

9g. Part # 5000-65003 Field Repair Kit for Z-Series Includes redundant power supply and fans.?

a. Answer: 1 field repair kit should be provided.

9h. Are there any other add-on parts required for these ExacqVision NVR’s?.

a. Answer: No.

10. Drawings T000 #1 lists the following icons

a. Sound enhancement ceiling speakers

b. Sound enhancement wall speakers

c. Line Level and Bluetooth Outlet

d. Touch Pad Controller

e. HDMI, VGA and 3.5 Audio

f. Neutrik Mic Jack

g. Monitor Jack

h. Auxiliary Sound Speaker

i. Auxiliary Sound Pendant Speaker

-

Page 9 of 24

. Please confirm the above cabling will be provided by Section 274100 Audio-Video Systems and/or Section

274116 Small AV Systems awarded vendor.

a. Answer: Equipment is divided per spec section. Spec sections should be followed for providing and

installing equipment.

11. Please confirm Section 271000 Structured Cabling - regarding field / workstation patch cables from the

faceplate:

11a. Does the Structured Cabling awarded vendor need to provide any field / workstation patch cables?

a. Answer: Yes. Patch cables should be provided for both ends of the cable.

11b. If yes, does the Structured Cabling awarded vendor need to provide a patch cable for each field /

workstation faceplate port?

a. Answer: Yes.

11 c. If yes, what length of patch cord needs to be provided for each device?

a. Answer: Provide in varying lengths: 3 ft. – 33%, 7 ft. – 33%, and 10 ft. 33%.

12. Drawing T500 #4 Backbone Riser Diagram and #7 Data & Telephone Horizontal Structured Cabling

Diagram both list single mode fiber. Section 282000 on page 282000-5 C.2.a reads 50 Micron OM4

Multimode Fiber Optic Strands. Which is required single mode or multimode?

a. Answer: Singlemode should be provided.

RFI 46

1. Is this a widened 12" Footing Below For wall?

a. Answer: See detail 14/S201 which will be issued by this addendum.

RFI 47

1. Requesting sections cuts for wall foundation RW2 size and reinforcing

a. Answer: See details 14, 15 & 16/S201 which will be issued by this addendum.

2 Section cuts thru stepped area that detail 15/S301 doesn’t show. a. Answer: See details 14, 15 & 16/S201 which will be issued by this addendum.

3. Top of wall elevations for cast in place concrete wall in auditorium?

a. Answer: Change wall to CMU. Refer to A409 for heights of walls.

4. Do the masonry walls that wrap around the three stepped seating areas in back of auditorium require

waterproofing?

a. Answer: No.

5. Will the above- mentioned masonry walls need to be shored/braced during backfilling process?

a. Answer: Yes, the masonry walls need to be shored during backfilling.

RFI 48

1. SOW L in concrete scope of work states concrete contractor owns slab work to exterior face of enclosed

building. Site contractor will pick it up at that point. SOW U under site contract Basically says the same thing.

-

Page 10 of 24

SOW LL in concrete scope states we own loading dock pad and trench drain….please advise. If concrete

contractor does own it (Loading dock pad), is the loading dock pad based on “loading Area concrete Pad

detail” on C-305..? Also Concrete SOW LL states we own trench drain… does this mean supplying and

setting trench drain..? Plumbers usually do this.

a. Answer: Yes, Contract 2 Concrete contractor to provide per C-305. Trench drain to be supplied and

set by concrete contractor. Trench drain hook up to storm water system is to be provided by Site Work

contractor.

2 SOW I concrete scope of work states we own all foundations outside of building footprint. In addendum #1 RFI #3 1a states Contract A-5 owns foundations for the storage building and that concrete contract A-2 owns

the slab on grade…just making sure this is correct

a. Answer: Correct, storage building is wood post frame type construction and foundation is done with

setting of poles.

RFI 49

1. In looking through the geotechnical reports, I don’t see any boring that goes deeper than 40’ deep, leaving

between 40’ to 404’ of geological conditions unknown. Is there a geothermal test bore report from a

geothermal test bore was that drilled?

a. Answer: Yes, See Project Manual Section 009300.

RFI 50

1. Could you please provide some clarification as to which products/manufactures are to represent the Resilient

Athletic Flooring on this project?

a. Answer: See Section 096566, article 2.1.

RFI 51

1. Can elevations of this area ( west and south elevations of metal panels at Auditorium/Stage) be shown

on SheetA206?

a. Answer: See 1A/A304 for west elevation and 1B/A306for south elevation.

RFI 52

Will be answered in Addendum 4.

RFI 53

1. Schneider is an approved manufacture for a BAS system. Section #230900-39: 2.12 Heat Pump Controller,

Section A. item 1. “Heat pump controllers for listed manufactures subject to compliance with requirements

shall be as follows:” • Schneider is not listed. Is this an oversite? • Can it be added as an approved

manufacture?

a. Answer: Schneider Electric will be added as an acceptable Manufacturer by this addendum.

RFI 54

1. Specification Section 075323 EPDM Roofing – Paragraph 2.2. A. 3. States Exposed Face Color: White, but

with a minimum R-value of 30 polyisocyanurate insulation to be installed there will be no loss or gain in

Energy efficiency with a white or black membrane face color. The white EPDM is considerably more

expensive than black and will have no overall benefit to the building. Can black EPDM be used in lieu of

white EPDM?

-

Page 11 of 24

a. Answer: No.

2. Specifications Section 076200 Sheet Metal Flashing and Trim - Paragraph 2.2 B. 1. A. states Three Coat

Fluoropolymer finish, but the Standing Seam and Soffit Sections state 2-coat finishes, is a 2-coat

fluoropolymer finish acceptable?

a. Answer: Yes, a two-coat is acceptable. Clarification will be issued by this addendum.

3. Contract 6 Roofing – SOW Items J and L, state to provide all metal soffits. It makes sense for the Roofing

Contractor to provide and install the soffit panels at the Standing Seam Roof area, but the soffit areas on the

main building tie into and would most likely be installed in conjunction with the Metal Wall Panel system.

Can the exterior metal soffits on the Main Building be included in Contract 18 – Wall Panel Systems, please

advise?

a. Answer: Contract 6 Roofing is to provide all metal soffits.

4. Contract 6 Roofing – SOW Item B. states nail board insulation, but Contract 9 SOW Item B, states Provide

structural nailable insulated sheathing and parapet sheathing. What nailable insulation does the Roofing

Contract own or is it all by Contract 9?

a. Answer: Contract 6 Roofing is to provide only if shown on roof area, not on walls

5. Contract 6 Roofing – SOW Item B. states Provide cement board on roof. Please clarify what type and where

this material is to be installed?

a. Answer: See revisions to Summary of Work in this addendum.

6. Contract 6 Roofing – SOW Item B. states dens deck cover-board, but Section 075323 paragraph 2.5 C. states

Composite Polyisocyanurate Board Insulation with High-density polyisocyanurate … ½” thick coverboard. Is

the Composite material in the EPDM spec the correct coverboard material or is dens deck to be used, please

clarify?

a. Answer: Cover Board is glass-mat, water-resistant gypsum substrate and will be added by this

addendum.

7. Specification Section 077200 paragraph 2.4 Roof Hatch, is a roof hatch needed for the project as it appears the

roof access is through the Penthouses, please advise if a roof hatch is required?

a. Answer: The requirement for a roof hatch will be deleted by this addendum.

RFI 55

1. Can you elaborate on what specifically will be required under section 015000 Temporary Facilities and

Controls for the carpentry/general trades contract? Reading this section there could be a substantial amount of

work Such as temporary building enclosures, temporary entrance doors, safety items such as railings,

barricades, protection at holes, recesses, trash chute, snow removal with the building etc. This is largely a

guess on what may be needed. can an allowance be made for this section of work?

a. Answer: No allowance will be added; these items are typical necessary items on all projects for

General contracting.

RFI 56

1. RFI 15 Q #1 Spec section 126613 is not in Revised A5 SOW as stated

a. Answer: See Revisions to Summary of Work this addendum.

2. RFI #15 Q #2 SOW DDD what office equipment is included as literature racks are deleted?

a. Answer: See Revisions to Summary of Work this addendum.

-

Page 12 of 24

3. RFI #17 Q #3 Answer is incomplete as louvers, and louvered rooftop equipment screens are not the same

item.

a. Answer: See Revisions to Summary of Work this addendum.

RFI 57

1. Why is Earthmoving referenced in both contracts?

a. Answer: If any trenching is required to complete your work, perform in accordance with specification 312000 Earthmoving..

2. Section 274118 Auditorium Audio & Video Systems should be its own contract (21?) since this is a

specialized trade not related to the other two sections.

a. Answer: See Revisions to Summary of Work this addendum.

3. Sections 274100 and 274116 should be together under their own contract (20?) since both sections are

related.

a. Answer: See Revisions to Summary of Work this addendum.

RFI 58

1. Are the exterior compressed expansion joint in the masonry by the masonry contractor or carpentry contract

under the expansion joint spec?

a. Answer: Masonry contract provides. Expansion joint covers only provided by Carpentry contract.

RFI 59

1. Can we get more details on the stairs. 7’-0” clearance between stringers is quite a big span. Especially with no

column support in the center? I have not seen any mention of the stringer sizes. I can guess it would be HSS

12x2x1/4. But that would be a guess.

a. Answer: Drawing clarification is issued by this addendum.

RFI 60

1. Please reference spec section 011100-29. Spec section 011100-29, line-item Q references preparation of all

floors and walls to receive new wall and floor tile. However, we note that there is no floor tile on this project.

Can this line item be revised to only mention wall tile?

a. Answer: See revision to Summary of Work this addendum.

2. Please reference spec section 011100-29. Spec section 011100-29, line-item R references quarry tile.

However, we note that this project has no quarry tile. Can this line item be revised to remove quarry tile?

a. Answer: See revision to Summary of Work this addendum.

3. Please reference spec section 011100-29. Spec section 011100-29, line-item Q references stair tread tile.

However, we don’t see any stairs that are to revive tile. Can this line item be revised to remove stair tread tile?

a. Answer: Yes.

4. Is there any finish schedule for the field house shown on A430? Is there any ceramic tile in Women’s and

Men’s toilet rooms? Resinous floor? Etc.?

a. Answer: See A601.

-

Page 13 of 24

5. How are we to cap outside corners at corridors and in the cafeteria where wall tile is present? Is Schluter

required? If so, please provide a product and finish? We recommend Schluter Systems Rondec.

a. Answer: Basis-of-Design Product will be issued by Addendum 4.

6. Are we required to cap the top row of tile at corridors and cafeteria? If so, what Schluter product is required?

We are looking for product and finish. We recommend Schluter Systems Rondec.

a. Answer: Basis-of-Design Product will be issued by Addendum 4.

7. Are any details available on shower wall tile and the shower pan in locker rooms and restrooms?

a. Answer: Clarification will be issued by addendum 4.

RFI 61

1. Sheet A430 - Note 1 states all ceilings in the fieldhouse shall have mold & moisture resistant GWB. The RCP

plan on same pages shows GWB in toilet rooms & Jan/storage only. Please clarify which is correct.

a. Answer: RCP is correct. Note 1 will be revised by this addendum.

2. Please clarify which Contract is responsible for the soffit & siding on the field house?

a. Answer: Soffit is provided by Contract 6 Roofing. Siding is MWP provided by Contract 18 Wall Panels.

3. Please provide details for interface/attachment between coated chainlink fencing at the softball dugouts and

the wood framing. Please confirm that this system is to be provided by Contract A-5, complete.

a. Answer: Correct; provided by Contract 5.

4. Confirm softball fence detail C-906 should detail 6' & 8' high fencing (currently details 4’ & 6’) as indicated

for the “competition softball field layout”.

a. Answer: Sheet C-906 with revised details and a new 8’ fence detail will be issued by this addendum.

5. Are temporary fire extinguishers to be provided and maintained during construction? If so, please confirm

which Contract scope will carry this scope and confirm the quantity required?

a. Answer: See section 015000 Item 3.20B; CM will provide temporary fire extinguishers.

6. Section 101400 Signage, Part 2.6.D.1 Numerical Signs required at climbing wall panels in Gymnasium A133.

There are no climbing wall panels or Gymnasium A133 indicated on the drawings. Please clarify

requirements. Contract No. 5, Paragraph QQ, clarify the required locations and elevation drawings for exterior

wall logos, and cast letters.

a. Answer: 2.6 Numerical Signs will be deleted by this addendum.

7. Contract #5, scope paragraph QQ indicates to "provide vinyl graphics and lettering", which conflicts with

Contract #12 paragraphs L & P related to vinyl graphics and lettering. Please clarify the delineation in scope

responsibility.

a. Answer: See revisions to Summary of Work this addendum.

8. Section 101419—Dimensional Letter Signage located at Sheet A201 South exterior elevation. Please confirm

any additional required locations for dimensional lettering.

a. Answer: There are no locations other than the letters on 1A/A201 and the logo on 1B/A201.

9. Are fire extinguishers required at IDF rooms, MDF rooms, or in the fieldhouse?

a. Answer: Not in IDF or MDF room, but they will be added to the fieldhouse by this addendum.

-

Page 14 of 24

10. Section 105613 Metal Storage Shelving MS-1 is specified 48” wide. Sheet A430 Fieldhouse, Janitor/Storage

F7 shelving scales to 36” width. Please confirm width of these units.

a. Answer: 48”.

11. Clarify the storage requirements for Storage D132B

a. Answer: Casework storage units in this room will be relocated from another Dover school by the

Contractor and installed by the Contractor.

12. Section 101100 Visual display panel assembly MB2 locations cannot be found on the drawings. If required,

provide all locations and elevation drawings.

a. Answer: See 14/A701.

13. Section 101100 Visual Display Boards, Part 2.5.C.3 clarify requirements for easel pad clamp accessory for

SD1 Sliding Visual Display Units. Manufacturers require additional information to provide pricing.

a. Answer: Requirement for easel pad clamps will be deleted by this addendum.

14. Are hand dryers or paper towel dispensers required at handicap toilet stalls on enlarged plans 3/A402 and

4/A402?

a. Answer: Hand dryers. Clarification will be issued by this addendum.

15. Are hand dryers or paper towel dispensers required at single ADA toilet rooms on enlarged plans 3/A402 and

4/A402?

a. Answer: Paper towel dispensers. Clarification will be issued by this addendum.

16. Provide specification for CH Baby Changing Station.

a. Answer: Basis-of Design is model R8478 by Pressalit Care. Clarification on drawings will be issued

by Addendum 4.

17. Which Contract is responsible for providing SH-1, SH-1A, SH-2, SH-2A shower enclosures and all related

accessories?

a. Answer: Contract 15 Mechanical is to provide shower enclosures and all related accessories.

18. Clarify a mirror is not required at Sheet A401 Plumbing Fixture Detail for Type LAV-1A that states “No

Accessory G (framed mirror) above lavatory".

a. Answer: Correct. Lav-1A does not require “Type G” Framed Mirror (intent is to minimize site lines.)

19. Specification Section 116623: a. Part 2.3 confirm the project total required quantities for Volleyball Systems

and Sleeves. b. Part 2.3.K Post Standard Transporter, confirm total quantity required. c. Section 116623,

Part 2.3.L Storage Cart, confirm total quantity required. d. Section 116623, Part 2.3.J Referee stand, confirm

total quantity required. e. Section 116623, Part 2.4 Safety wall pads basis-of-design model number is

standard 6’- 0” high (as is the industry standard). Wall pads on elevation drawings scale to 7’-0”. Are

standard 6’-0” high wall pads acceptable?

a. Answer: Total of 6 volleyball sleeves(See Gymnasium D101). One Post Standard Transporter

required. One Storage Cart required. One Referee Stand for each of system (Total equals three).

Standard 6’ high safety pads are acceptable.

20. Section 105113 Metal Lockers, provide specifications for Locker Types ML-2 and ML-3.

a. Answer: Basis-of-Design is Republic’s Athletic All Welded Ventilated.. See A513 for sizes.

21. Section 116613 specified dance barre manufacturer supplies only 4’, 6’, 8, 10’ and 14’ lengths, with no

custom lengths available. At Elevation 9/A704, a single adjustable wall-mounted barre will not fit due to the

configuration and widths of frameless mirrors. Please clarify design intent.

-

Page 15 of 24

a. Answer: The intent is to extend across entire length of wall as much as possible. Coordination with

mirror spacing will be required.

22. Please clarify which Contract that owns projection scissor lifts. Scope of work for Contract 5, Paragraph X,

indicates Contract 5 is to provide. Sheet EP101E Keynote #22 indicates that the scissor lifts are “furnished

under Division 27” (Contract #20).

a. Answer: See revisions to Summary of Work this addendum. Contract 20 Classroom A/V Systems is to

provide scissor lift.

23. Projection scissor lift Draper SXL as indicated on Sheet T101E has several different models, SLX10,

SLX14, SLX17, SLX21, SLX24, and SLX28 - which corresponds to overall lift length and significantly

impacts cost. Specify the complete model number for each lift location so bids are comparable.

a. Answer: Will be answered in Addendum 4.

24. Section 122413, part 3.6.A.2 Pull Out D115 does not exist on the drawings, confirm this should read Pull Out

C115?

a. Answer: Confirmed. This will be corrected by this addendum.

25. Section 122413, part 2.2.E.1.b specified Nurse A16 could not be found on the drawings

a. Answer: 2.2E.1.b. will be deleted by this addendum.

26. Please provide the storefront system tag for Multi-Purpose D104 on sheet A101D.

a. Answer: SF-9 and SF-10. Tags will be added by this addendum.

27. Please provide the storefront system tag for Conference/Study B223 on Sheet A102B

a. Answer: See floor plan for SF-1. tag.

28. Sheet A609, CW-6 indicates a head section tag 12/A511 SIM. CW-6 is located at Corridors B5 and C5,

Section 122413, Part 3.6 specifies roller shades are not required in corridors. Please confirm roller shades are

not required at CW-6 units.

a. Answer: Roller shades are not required at CW-6 units (corridors) bur are required in CW-6B units

(teaching space).

29. Are Section 102600 corner guards required at the following locations: a. Walls adjacent to the water

fountains located at the ganged toilet room entrances? b. Walls on either side of corridor locker runs? c.

Walls adjacent to cabinet runs. Reference classroom plans.

a. Answer: Corner guards are not required at water fountain alcoves. Corner guards are not required at interior side of locker alcoves. Where face of cabinet is more than 4”

from drywall corner, install a corner guard. Typically classroom casework runs are nearly flush with

drywall end wall. There are unique instances where outside corner is 4” or more beyond the face of

casework.

30. Section 105113 Metal Lockers, Part 2.3.N.1 Color: Match Pantone PT-8. Pantone Corporation has advised

PT-8 is an invalid number. Provide the complete number (i.e. 1815C, 2303C, etc.).

a. Answer: Reference to “Pantone” will be deleted by this addendum. Color shall match PT-8 as

specified in finish legend on sheet A602.

31. Metal locker manufacturers are recommending to supply lockers in their standard color selections, due to the

significant cost increase associated with a custom finish selection. Please confirm a custom color is desired

as specified.

a. Answer: Yes, lockers shall be color matched to PT-8.

-

Page 16 of 24

32. Confirm which contract is responsible for providing the 2.6" nailable insulated sheathing shown in typical

parapet roof details and if this is a manufactured composite insulation panel. The architectural details are not

clear on the extent of materials.

a. Answer: Contract 9 Drywall/Metal Stud provides.

33. Addendum #2 indicates that the wood stair risers and treads are to be provided from "reclaimed oak". Will

further requirements be provided in order to ensure a level bidding field?

a. Answer: See Section 064023-Interiot Architectural Woodwork, article 2.2A.

RFI 62

1. Am I to assume that the MV specification section 260513 paragraph 3.8 D, E, & F are all factory tests or

Independent Testing?

a. Answer: Yes, specification section 260513, paragraphs 3.8.D, 3.8.E, and 3.8.F are factory tests.

RFI 63

1. Specification section 230900-47 3.4 A “All line voltage wiring, all wiring exposed, and all wiring in

equipment rooms shall be installed in conduit in accordance to the electrical specifications.” Please confirm

exposed plenum rated cable acceptable for 24V and below wiring in concealed areas, inside walls, above

ceilings, and in plenum spaces is acceptable.

a. Answer: Free-run cabling is only permitted where concealed above accessible ceilings. Please refer to

260533-3.3.L.

2. Please confirm Kitchen Make-up Air Units described on 230000-25 to be fully controlled by the Building

Automation system controls and ATC contractor to furnish and field install equipment controller.

a. Answer: Confirmed.

3. Current Sensors- are depicted throughout the ‘M’ Series drawing set for monitoring of Fan Motors. Fan Motor

Current Switches such as the Senva C-2300 are generally more economical and still provide positive

indication of current and status. Please confirm these will be an acceptable form of Fan status indication.

a. Answer: Current Sensors shall be as specified.

4. Drawing M403 ATC Control Point List shows VFD Amperage and Speed. Please confirm this is meant to

indicate the Current sensor status and 0-10V speed command signal.

a. Answer: Confirmed.

5. Drawing M503 details Dryer Booster Fans DBF1-3. Please confirm if Dryer Booster Fans are to be controlled

or monitored by Building Management System.

a. Answer: Control of Booster Fan is packaged. No control or monitoring by BAS is needed.

6. Drawing M503 details Kiln Vent Hood HD-1. Please confirm if Kiln Vent Hood will be controlled or

monitored by Building Management System.

a. Answer: Control of Kiln is packaged. No control or monitoring by BAS is needed.

7. Are combination space sensors (temperature/humidity or temperature/CO2) by Automated Logic acceptable?

Combination sensors require less wiring and are typically more visually pleasing to the architect and occupant,

since one sensor is mounted on the wall, not 2. See cutsheet attached.

a. Answer: No, combination sensors shall not be used.

8. Addendum 2 Pg. 12 of 14 Item 2 describes packaged unit with included BACnet. Drawing M404 describes

-

Page 17 of 24

Sequence of Operation for Packaged Single Zone VAV units. On this page’s schematic there is a rectangle

that depicts controls located integral to the unit. Please confirm controls located within this rectangular area

are to be provided and factory installed by manufacturer of unit, and all devices outside of this rectangle are to

be furnished and wired by ATC contractor.

a. Answer: No, the rectangle only represents the outline of the unit. BAS Contractor will need to provide and install any and all devices not factory furnished by the unit manufacturer.

9. Specification document 230900-1 Item 1.1 E and 230900-5 Item 1.7A both list Automated Logic as an

acceptable ATC and CCMS manufacturer. These terms are used interchangeably with Building Management

system. Specification 230900-40 does not list Automated logic as an acceptable vendor for software. Please

confirm Automated Logic as an acceptable software vendor as described throughout the other portions of the

specification.

a. Answer: Automated Logic is acceptable for software. This will be changed in the next Addendum.

10. Specification section 230900-7 Item C requires minimum 4 License Seats for the Building Management

Software. Automated Logic provides software that allows for unlimited users of the ATC system. Please

confirm this is truly the customer’s minimum number of users, as in our experience, 4 is generally

insufficient for a project and building of this size and scope.

a. Answer: Minimum of 4 seat licenses are to be provided.

11. Drawing M409 Electric Unit Heater schematic describes factory packaged controls for Electric Unit Heaters.

230900-2 K. 26 describes Electric Unit Heaters as being controlled by ATC system. Please confirm ATC

system to monitor and control Electric Unit Heaters.

a. Answer: Referenced unit heaters shall be packaged controls. No control of monitoring by BAS is

needed.

12. Drawing M408, Controls Schematic for Split System units states these units will be provided with a

thermostat. Shall the BAS manufacturer provide an additional thermostat in rooms served by Ductless Splits

to be monitored for alarming purposes?

a. Answer: Yes. Please reference Diagram #1 on Drawing M410.

13. Drawing M409 describes exterior lighting controls and references Electrical Drawings. Drawing E408

Describes Lighting Control System to be connected to Building Management System. Please confirm

Lighting Control System to be BACnet, Modbus, or Lon capable.

a. Answer Basis of design lighting control system BMS interface is nLight Eclypse, which can have BACnet MS/TP or Modbus RTU 1 x RS-485 communications port. Successful bidder to coordinate with

actual lighting control system communication type.:

14. Drawing M409 also describes interior lighting to be “mapped over” to Building Management System. Please

confirm interior lighting control system shall also be BACnet, Modbus, or Lon capable.

a. Answer: Interior lighting and exterior lighting controls are on same nLight system with Eclypse BMS

interfaced described in response to #13.

15. Please provide ATC point list of networked lighting control system if possible.

a. Answer Intent is for BMS system to be capable of scheduling/controlling exterior lighting plus interior lighting in corridors. Refer to lighting control panel scheduled on Contract Drawings E506, E507,

E522, and E523 for relay quantity. Refer to Contract Drawings E403 and E408 for intended sequences

of operation.:

-

Page 18 of 24

RFI 64

1. Can the EOR please confirm there is no concern with us engineering bolted connections for the T1 and T2

truss web members using the allowable loads shown on Sheet S401? The conceptual details diagrammatically

show welds, but the truss notes indicate the details are shown for concept only and these connections are delegated

and to be designed by a licensed engineer. Additionally, can the EOR please confirm if we are able to engineer a

bolted splice in the T1 truss chords using the allowable loads provided that is off center? There is concern with

controlling the camber specified using a welded splice.

a. Answer: Bolted connections are acceptable.

RFI 65

1. There are no specifications regarding the stairs.

a. Answer: Stair Specification will be added by Addendum 4.

2. Stairs show Tube steel. But does not call it out anywhere. If I were to guess I would go with HSS 12x2x1/4?

7’6” is a very wide stair. What material does the EOR recommend for stair pans.

a. Answer: Clarification is issued by this addendum.

3. Even if the stairs will be Delegated Design it will be difficult to get an accurate estimate without first

consulting an engineer

a. Answer: Stair Specification will be added by Addendum 4.

4. What fills the gap between the stringer and the underside of the tread of the monumental stairs? The design

intent of the stairs is a bit confusing. Please provide more details.

a. Answer: Clarification is issued by this addendum.

5. The stairs stringers regardless of pan design are called out to be steel. However the Tube and Pipe Railing

Spec section only discusses aluminum Railings. Are the Railings at the stairs to be steel or aluminum? o

Aluminum rails at stairs are less common because the two materials cannot be welded. Making fabrication and

assembly more difficult and time consuming ($$$)

a. Answer: Aluminum. Decorative Metal Railings refer to interior railings at, monumental stairs and

auditorium.

6. The decorative railings Spec section states that Welded Railing will not Be accepted. And all decorative

railing should be by Hollander Manufacturing. Please clarify what is meant by decorative railings? Would

the stair Railings with Panel infill be considered Decorative? Where should Decorative Railings be located

under which conditions? Again only Aluminum material is discussed.

a. Answer: Decorative Metal Railings refer to interior railings at Monumental Stairs and Auditorium..

7. Which spec section should be consulted for the railings around the auditorium? Loading Docs and other utility

railings?

a. Answer: Section 057300 for the auditorium and section 055213 for utility railings.

8. What does the Architect have in mind for the Panel Infill? Is the infill to be woven or welded? o How thick

is the material? o What size gaps are required?

a. Answer: See Section 057300 – Decorative Metal Railings, article 2.5 Infill for Railings, as revised by

this addendum.

9. Does detail 3/A403 accurately show two sets of cane railings?

a. Answer: No. Clarification will be issued by this addendum.

-

Page 19 of 24

10. Should the alternating tread ladders be aluminum or steel?

a. Answer: Steel. See Section 055000-Metal Fabrications.

RFI 66

Will be answered in Addendum 4.

RFI 67

1. On Drawing A-002 where it calls out the slab types it refers you to drawing A-100 for details and extent of

each slab type. There is no drawing A-100. I need more info on where these slab types are located and what each

slab type is. The slabs in the gym and auditorium call for sheet waterproofing to go under the slab but there are no

details for the water proofing. Can you get me more info please.

a. Answer: A100 is issued by this addendum.

RFI 68

1. There is a conflict between the Concrete SOW and the Site SOW. In the concrete SOW item L it calls out for

the concrete contractor to own the loading dock walls, steps, ramp and slab for a complete package. In the site

work SOW item U & V it says the site contractor owns the loading dock walls, steps, ramps, and slabs for a

complete package. We need to know who is responsible for what. These SOW’s contradict each other. Can

you give me some clarification please.

a. Answer: See answer to RFI 48 Question 1.

RFI 69

1. Item D states concrete sub is responsible for perimeter insulation however the insulation is only shown on

the exterior face of the block foundation walls. Knowing that shouldn’t the masonry subcontractor install the

vertical insulation? Who is responsible for supplying and installing the vertical insulation as shown on the

various architectural wall sections?

a. Answer: Contract 2 Concrete Work provides perimeter insulation.

2. Also there is no horizontal insulation shown on the plans so please confirm there is no below slab horizontal

insulation being installed along any of the exterior walls.

a. Answer: Refer to drawings for location of slab-on-grade insulation. Typically, insulation is provided in masonry cavity.

3. Item U states all concrete testing and soil compaction inspections is the concrete subcontractor’s

responsibility however it is standard practice that the GC or CM usually picks up these costs. Please confirm

who is responsible for footing soil compaction testing and concrete test samples.

a. Answer: The prime contractor per scope of work of contract you are bidding.

4. Where is the self-adhering waterproofing and composite waterproofing to be installed? Are you referring to

the below slab on grade areas within the auditorium area?

a. Answer: Yes, and at the elevator pits.

5. How far beyond building footprint is the termite control to be spayed?

a. Answer: 12” of soil directly adjacent to the foundation.

6. Item W requests trash enclosure footers, but the only area showing a trash compactor is within the loading

-

Page 20 of 24

area. What footing dimensions should I use given there is no dumpster enclosure noted on the plan? Are

trash enclosure footings still to be included within the concrete scope of work?

a. Answer: Yes, Contract 2 Concrete Work provides all footings.

7. Item LL states to include the loading dock pad and trench drain. Is that pad to include the loading area pad

plan view as shown on sheet C-305 (proposed total area 15593 sf)?

a. Answer: Yes, Contract 2 Concrete Work provides..

RFI 70

1. RFI 12 requested information on the geothermal test bore. The RFI referenced Specification 009399 and the

Geotechnical Boring Logs. I only found shallow bore logs. We are looking for a test bore for the entire 404-

foot geothermal borehole. Does the full-length test bore exist?

a. Answer: No.

2. For the Geothermal Field, which Prime Contractor has responsibility for Top Soil Removal, Top Soil Pile

Construction, Top Soil Erosion Control and Top Soil Replacement ; Bore Field Spoils including Spoils Pile

and Spoils Disposal; Returning the Borefield to Rough Grade; and Landscaping the Borefield after return to

Rough Grade

a. Answer: Contract 15 Mechanical all listed items except for Landscaping of the area. Contract 1 Site

Work provides landscaping.

3. Please provide a schedule duration for geothermal borefield and piping into the building. We estimate a

duration of about one year.

a. Answer: Schedule duration for geothermal borefield is to be determined by contractor bidding.

4. For the geothermal pipe bedding, can the sand native sand from the geothermal filed be used?

a. Answer: Pipe Bedding shall be as specified in Section 232113.33 Article 2.5..

5. Will Electric Service be available for the geothermal field?

a. Answer: Temporary service will be provided. See electrical scope for details..

RFI 71

1. The angled rising walls at the vomitory walkway leading into the auditorium from the vestibule labeled 5B are

showing DCMU on both sides, is this the intention? The BOD manufacturer cannot make these units double

sided.

a. Answer: Drawing clarification will be issued by this addendum..

2. The wall details and spec sections show differing material dimensions on the DCMU, which should we

follow?

a. Answer: Specification. Clarification will be issued by this addendum.

3. Could we please have a drawing of the plan East and West elevations in the D136 Auditorium?

a. Answer: Additional elevations will be provided by this addendum.

RFI 72

1. Contract No. 20 – Classroom A/V Systems – The contract summary for this identifies section 274000. That

specification does not exist in Spec Volume 4 or any other of the contract documents… Please advise what

spec sections in volume 4 are to be included in Contract No. 20 – Classroom A/V Systems.

a. Answer: There is no specification 274000 listed; see Specification Section Summary of Work page

-

Page 21 of 24

011100-46 Item A for specifications provided by Contract 20. .

2. Contract No. 21 – Specialized A/V Systems The contract summary for this identifies section 274100. Please

specify if there are any other Division 27 specifications to be included with Contract No. 21 – Specialized A/V

Systems.

a. Answer: See revisions to Summary of Work this addendum for Contract 21.

3. Specification Sections seen in Division 27 that we want to have clarified as to which Contract No. they are to

be provided under: SECTION 27 41 00 – AUDIO-VIDEO SYSTEMS SECTION 27 41 16 - SMALL AV

SYSTEMS SECTION 27 41 18 AUDITORIUM AUDIO & VIDEO SYSTEM SECTION 27 42 00 – IP

VIDEO DISTRIBUTION SYSTEM

a. Answer: Contract 20 is to include specifications 274100 & 274116, Contract 21 is to include

specification 274118. Section 274200 IP Video Distribution will be removed by this addendum (and bid

under a separate contract at a later date.)

4. In Alternate 2 it listed the removal of 274100, Section 2.2, subheading F. There is not 2.2 F. There is

however a 2.3 F. is the section we are to omit?

a. Answer: We believe the alternate language is not necessary. .

5. 5a. Listed speaker part # JBL CT1000 is this supposed to be CBT1000?

a. Answer: Yes, speaker should be CBT1000..

5b. Listed Extron plate DTP T HWP 4K D. this is not a valid part. There is an option to use the DTP T DWP

4k D and use a display to HDMI adapter or cable from the plate to the device as needed.

a. Answer: Part # should be Extron DTP T HWP 4K 331 D.

5c. What is the manufacturer and model number of the 55” LED TVs for the classrooms?

a. Answer: Classrooms do not get 55” LED TVs. Classrooms receive 75” Interactive displays.

See Section 274116 for classroom display model.

5d. What is the manufacturer and model number of the 80” interactive display for the classrooms?

a. Answer: Replace 80” displays with the 75” display listed in 274116.

5e. Is the contractor providing the “Audio Enhancement” hardware or the client?

a. Answer: Contractor shall provide classroom sound reinforcement equipment.

5f. In the two Cafeterias, what size screens? 16:10 will these also be 16’x10’?

a. Answer: 16:10 screen size is 14’-8” X 9’-2”.

5g. What is a Lowell LE193, if it is supposed to be a 1RU blank panel, can I sub in a Middle Atlantic EB1?

a. Answer: Yes, blank panel, substitutes are allowable.

5h. Shure ULXD124/58 is not available, can we sub in SLXd124/85 or QLXD124/85?

a. Answer: Yes.

5i. Tascam SS-R200 is discontinued, can we use SS-R250N?

a. Answer: Yes, the Tascam SS-R250N is acceptable.

5j. Shure SLXD124/58, is that supposed to be SLXD124/85?

a. Answer: Yes, Sure SLXD124/85.

5k. Cafeteria parts list, Letter D, Line 30. Is this 60-1621-01 HD 4K 101 Plus? How many?

-

Page 22 of 24

a. Answer: Yes, but may include additional equipment from Extron for proper signal transmission.

5l. AV system section E. Conference AV Equipment What is conference room number? How many

conference rooms?

a. Answer: Conference Rooms are labeled on the plans. L1-M1 outlet configuration also all get this equipment.

5m. Section F: There are three rooms called Study, there I see only a 65” interactive board in each, but it is

not totaled at the bottom of the list. Is this providing the panels and mounting hardware only?

a. Answer: Study rooms should include Displays, mounts, and cables infrastructure..

.

5n. Are we to use Lightspeed or Audio Enhancement hardware?

a. Answer: Section 274116 is the basis of design for classroom sound reinforcement. Substitutes meeting the performance are allowable. .

RFI 73

1. Drawing T-000, Detail 1, Technology Symbols: The last symbol in this detail is a CCTV camera. It does not

indicate any cable for this device. Is the Contract 19 installer to provide any cable for this device? If so

please specify.

a. Answer: Contract 19 Structural Cabling provides. Sheet T512 shows cable types for site cameras.

2. Drawing T-000, Detail 3, Technology Scope Notes full: This not advises the electrical contractor (Contract

17) to provide install cable tray and other listed items… Is the electrical contractor providing and installing

cable tray in corridors only or corridors and within the MDF & IDFs? Or is contract 19 to provide tray within

the MDF/IDFs only?

a. Answer: Contract 17 Electrical provides within corridors and MDF & IDF.

3. Drawing T-001 – Site Drawing: Pole mounted CCTV cameras are shown on this drawing: Is contract 19 to

provide any cabling to these locations? If yes please specify what cabling.

a. Answer: Contract 19 Structural Cabling provides. Sheet T512 shows cable types for site cameras.

4. Drawing T-504 Please confirm that all A/V cabling shown between L&M outlets and the L1&M1 outlets is to

be provided and installed by contracts other than contract 19. Contract 19 only to provide faceplates for A/V

openings at combined outlets etc.

a. Answer :Confirmed.

RFI 74

1. SOW L states tread grips ; Please provide a manufacture and model number for these.

a. Answer: Tread Grip Basis-of-Design will be issued by Addendum 4.

2. Can we get a cut through these display cabinets to see what needs to be built?

a. Answer: See Basis-of-Design in Specification..

3. Detail 4/A705 shows stage front as wood Detail 15/A705 shows stage front as metal panel Please advise

which is to be used.

a. Answer: Note on Detail 15/A705 will be revised front metal wall panel to wood by this addendum.

4. In addendum 2, RFI 32, line item 4 leads me to believe that the Mineral Wool Board that shows to occur

behind metal wall panels, cementitious panels, and rain screen panels are now being furnished and installed by

-

Page 23 of 24

Contract 18. Is this the case? I did not see the Mineral Wool Board “deleted” from Contract 9 in addendum 2.

Please clarify.

a. Answer: Contract 9 provide fire safing mineral wool insulation where no metal panels are installed.

5. Detail 4/A312 shows a drywall ceiling at VEST D0 however the RCP for A104E shows an exposed painted

deck. Please clarify. There is no 2nd floor RCP for area E. There appears to be no drywall ceiling in detail 1A/

A306.

a. Answer: The Reflected Ceiling Plan is correct. Detail 4/A312 will be corrected by this addendum. See A104E FOR Second Floor RCP for area E.

6. Is there a specification and dimension for the wood treads at the monumental stairs along with a spec on the

inlaid aluminum tread grip? Don’t see any spec that would cover this.

a. Answer: See Section-064023-Interior Architectural Woodwork, 2.2A for wood at monumental stairs.

See 1/A406 and 2 & 3/A407 for tread dimensions. Tread Grip Basis-of-Design will be issued by

Addendum 4.

RFI 75

1. The standard storefront frame shown/specified for fire rated glazing (A608) will not meet any fire rating. An

aluminum “Fire Rated Frame/Door” must be used in conjunction with the fire rated glass to meet the fire

rating specified.

a. Answer: Specification will be issued by Addendum 4.

RFI 76

1. Drawing T511 is the Culinary/Kitchen AV, Where is this room located within the building?

a. Answer: . T511 is incorrectly labeled and should read Family and Consumer Science C127 found on Sheet T101F.

2. In the Gym diagram says, 8 speakers and 1 Subwoofer. On the Print it shows 9 speakers and 1 Subwoofer. 9

makes since. Is it 8+ sub or 9+ sub?

a. Answer: .9 Speakers plus 1 subwoofer for a total of 10.

RFI 77

1. The specification is calling for 72" door and panel height. The description sounds like our Hiny Hider system.

On the drawing is a detail for what might look like our ARIA system. Our ARIA system can have a 1"

clearance for the 79" door with 0" standard for the panels. It has a headrail just beneath the ceiling and is

available in heights from 86" to 110" . Can you please clarify product type? I have attached an ARIA form if

ARIA is required.

a. Answer: Clarification will be issued by Addendum 4.

RFI 78

Will be answered by Addendum 4.

RFI 79

Will be answered by Addendum 4.

-

Page 24 of 24

END OF ADDENDUM NO. THREE

Attachments: Bid Form

Specification Sections 051100, 052200, 061753

Becker Morgan Group, Inc. drawings C906, A003, A005, A100, A101A, A101B, A101C, A101D,

A101G, A101H, A102B, A102G, A102H, A104A, A104B, A104F, A104G, A105B, A105F, A106A,

A106G, A302, A312, A401, A403, A404, A409, A410, A430, A511, A512, A546, A601, A608,

A705, A709

Baker, Ingram & Associates drawings S101C, S103E, S202, S205, S402, S403, S430

Baker, Ingram & Associates Addendum No. 3, dated 01/22/2021.

Richard Y. Johnson & Son, Inc Addendum No. 3, dated 01/22/2021.

201918000_Addendum3.doc

-

CSD TWO INTERCONNECTED MIDDLE SCHOOLS 2019180.00

STRUCTURAL STEEL FRAMING 05 12 00 - 1

SECTION 05 12 00 - STRUCTURAL STEEL FRAMING

PART 1 - GENERAL

1.1 RELATED DOCUMENTS

A. Drawings and general provisions of the Contract, including General and Supplementary Conditions and Division 01 Specification Sections, apply to this Section.

1.2 SUMMARY

A. Section Includes:

1. Structural steel. 2. Shear stud connectors. 3. Shrinkage-resistant grout.

B. Related Requirements:

1. Section 053100 "Steel Decking" for field installation of shear stud connectors through deck.

2. Section 055000 "Metal Fabrications" for steel lintels and shelf angles not attached to structural-steel frame, miscellaneous steel fabrications, and other steel items not defined

as structural steel.

3. Section 099113 "Exterior Painting" and Section 099123 "Interior Painting" [and] [Section 099600 "High-Performance Coatings"] for painting requirements.

1.3 DEFINITIONS

A. Structural Steel: Elements of the structural frame indicated on Drawings and as described in ANSI/AISC 303.

B. Heavy Sections: Rolled and built-up sections as follows:

1. Shapes included in ASTM A6/A6M with flanges thicker than 1-1/2 inches (38 mm). 2. Welded built-up members with plates thicker than 2 inches (50 mm). 3. Column base plates thicker than 2 inches (50 mm).

1.4 COORDINATION

A. Coordinate selection of shop primers with topcoats to be applied over them. Comply with paint and coating manufacturers' written recommendations to ensure that shop primers and topcoats

are compatible with one another.

-

CSD TWO INTERCONNECTED MIDDLE SCHOOLS 2019180.00

STRUCTURAL STEEL FRAMING 05 12 00 - 2

B. Coordinate installation of anchorage items to be embedded in or attached to other construction without delaying the Work. Provide setting diagrams, sheet metal templates, instructions, and

directions for installation.

1.5 PREINSTALLATION MEETINGS

A. Preinstallation Conference: Conduct conference at Project site.

1.6 ACTION SUBMITTALS

A. Product Data:

1. Structural-steel materials. 2. High-strength, bolt-nut-washer assemblies. 3. Shear stud connectors. 4. Anchor rods. 5. Threaded rods. 6. Forged-steel hardware. 7. Shop primer. 8. Galvanized-steel primer. 9. Galvanized repair paint. 10. Shrinkage-resistant grout.

B. Shop Drawings: Show fabrication of structural-steel components.

1. Include details of cuts, connections, splices, camber, holes, and other pertinent data. 2. Include embedment Drawings. 3. Indicate welds by standard AWS symbols, distinguishing between shop and field welds,

and show size, length, and type of each weld. Show backing bars that are to be removed

and supplemental fillet welds where backing bars are to remain.

4. Indicate type, size, and length of bolts, distinguishing between shop and field bolts. Identify pretensioned and slip-critical, high-strength bolted connections.

5. Identify members and connections of the seismic-load-resisting system. 6. Indicate locations and dimensions of protected zones. 7. Identify demand-critical welds. 8. Identify members not to be shop primed.

C. Welding Procedure Specifications (WPSs) and Procedure Qualification Records (PQRs): Provide in accordance with AWS D1.1/D1.1M for each welded joint whether prequalified or

qualified by testing, including the following:

1. Power source (constant current or constant voltage). 2. Electrode manufacturer and trade name, for demand-critical welds.

D. Delegated-Design Submittal: For structural-steel connections indicated on Drawings to comply with design loads, include analysis data signed and sealed by the qualified professional engineer

responsible for their preparation.

-

CSD TWO INTERCONNECTED MIDDLE SCHOOLS 2019180.00

STRUCTURAL STEEL FRAMING 05 12 00 - 3

1.7 INFORMATIONAL SUBMITTALS

A. Qualification Data: For Installer, and fabricator.

B. Welding certificates.

C. Paint Compatibility Certificates: From manufacturers of topcoats applied over shop primers, certifying that shop primers are compatible with topcoats.

D. Mill test reports for structural-steel materials, including chemical and physical properties.

E. Product Test Reports: For the following:

1. Bolts, nuts, and washers, including mechanical properties and chemical analysis. 2. Direct-tension indicators. 3. Tension-control, high-strength, bolt-nut-washer assemblies. 4. Shear stud connectors.

F. Survey of existing conditions at the time of steel erection including anchor bolt locations.

G. Source quality-control reports.

H. Field quality-control reports.

1.8 QUALITY ASSURANCE

A. Fabricator Qualifications: Engage a firm experienced in fabricating structural steel similar to that indicated for this Project and with a record of successful in-service performance, as

well as sufficient production capacity to fabricate structural steel without delaying the

Work.

B. Installer Qualifications: Engage an experienced Installer who has completed structural steel work similar in material, design and extent to that indicated for this Project and with a

record of successful in-service performance.

C. Shop-Painting Applicators: Qualified in accordance with AISC's Sophisticated Paint Endorsement P1 or to SSPC-QP 3.

D. Welding Qualifications: Qualify procedures and personnel in accordance with AWS D1.1/D1.1M.

1. Welders and welding operators performing work on bottom-flange, demand-critical welds shall pass the supplemental welder qualification testing, as required by

AWS D1.8/D1.8M. FCAW-S and FCAW-G shall be considered separate processes for

welding personnel qualification.

-

CSD TWO INTERCONNECTED MIDDLE SCHOOLS 2019180.00

STRUCTURAL STEEL FRAMING 05 12 00 - 4

1.9 DELIVERY, STORAGE, AND HANDLING

A. Store materials to permit easy access for inspection and identification. Keep steel members off ground and spaced by using pallets, dunnage, or other supports and spacers. Protect steel

members and packaged materials from corrosion and deterioration.

1. Do not store materials on structure in a manner that might cause distortion, damage, or overload to members or supporting structures. Repair or replace damaged materials or

structures as directed.

B. Store fasteners in a protected place in sealed containers with manufacturer's labels intact.

1. Fasteners may be repackaged provided Owner's testing and inspecting agency observes repackaging and seals containers.

2. Clean and relubricate bolts and nuts that become dry or rusty before use. 3. Comply with manufacturers' written recommendations for cleaning and lubricating

ASTM F3125/F3125M, Grade F1852 bolt assemblies and for retesting bolt assemblies

after lubrication.

PART 2 - PRODUCTS

2.1 PERFORMANCE REQUIREMENTS

A. Comply with applicable provisions of the following specifications and documents:

1. ANSI/AISC 303. 2. ANSI/AISC 341. 3. ANSI/AISC 360. 4. RCSC's "Specification for Structural Joints Using High-Strength Bolts."

B. Connection Design Information:

1. Design connections and final configuration of member reinforcement at connections in accordance with ANSI/AISC 303 by fabricator's qualified professional engineer.

a. Use Allowable Stress Design; data are given at service-load level.

C. Moment Connections: Type PR, partially restrained.

D. Construction: Combined system of moment frame and braced frame.

2.2 STRUCTURAL-STEEL MATERIALS

A. W-Shapes: ASTM A992/A992M.

B. Channels, Angles: ASTM A36/A36M.

C. Plate and Bar: ASTM A36/A36M and ASTM A572/A572M, Grade 50 (345), ASTM A529/A529M, Grade 50 (345).

-

CSD TWO INTERCONNECTED MIDDLE SCHOOLS 2019180.00

STRUCTURAL STEEL FRAMING 05 12 00 - 5

D. Cold-Formed Hollow Structural Sections: ASTM A500/A500M, Grade B structural tubing.

E. Steel Pipe: ASTM A53/A53M, Type E or Type S, Grade B.

1. Weight Class: As indicated. 2. Finish: Black except where indicated to be galvanized.

F. Steel Castings: ASTM A216/A216M, Grade WCB, with supplementary requirement S11.

G. Steel Forgings: ASTM A668/A668M.

H. Welding Electrodes: Comply with AWS requirements.

2.3 BOLTS AND CONNECTORS

A. High-Strength A325 Bolts, Nuts, and Washers: ASTM F3125/F3125M, Grade A325 (Grade A325M), Type 1, heavy-hex steel structural bolts; ASTM A563, Grade DH

(ASTM A563M, Class 10S), heavy-hex carbon-steel nuts; and ASTM F436/F436M, Type 1,

hardened carbon-steel washers; all with plain finish.

1. Direct-Tension Indicators: ASTM F959/F959M, Type 325-1 (Type 8.8-1), compressible-washer type with plain finish.

B. Shear Stud Connectors: ASTM A108, AISI C-1015 through C-1020, headed-stud type, cold-finished carbon steel; AWS D1.1/D1.1M, Type B.

2.4 RODS

A. Unheaded Anchor Rods: ASTM F1554, Grade 36.

1. Configuration: Straight threaded. 2. Nuts: ASTM A563 (ASTM A563M) heavy-hex carbon steel. 3. Plate Washers: ASTM A36/A36M carbon steel. 4. Washers: ASTM F436 (ASTM F436M), Type 1, hardened carbon steel. 5. Finish: Plain unless noted otherwise.

B. Threaded Rods: ASTM A36/A36M.

1. Nuts: ASTM A63 (ASTM A563M) heavy-hex carbon steel. 2. Washers: ASTM A36/A36M carbon steel. 3. Finish: Plain unless noted otherwise.

2.5 FORGED-STEEL STRUCTURAL HARDWARE

A. Clevises and Turnbuckles: Made from cold-finished carbon-steel bars, ASTM A108, AISI C-1035.

B. Eye Bolts and Nuts: Made from cold-finished carbon-steel bars, ASTM A108, AISI C-1030.

-

CSD TWO INTERCONNECTED MIDDLE SCHOOLS 2019180.00

STRUCTURAL STEEL FRAMING 05 12 00 - 6

C. Sleeve Nuts: Made from cold-finished carbon-steel bars, ASTM A108, AISI C-1018.

2.6 PRIMER

A. Steel Primer:

1. Comply with Section 099113 "Exterior Painting" and Section 099123 "Interior Painting." for exposed steel to be painted. [Section 099600 "High-Performance

Coatings."] [Section 099113 "Exterior Painting," Section 099123 "Interior

Painting," and Section 099600 "High-Performance Coatings."]

2. SSPC-Paint 23, latex primer. 3. Fabricator's standard lead- and chromate-free, nonasphaltic, rust-inhibiting primer

complying with MPI#79 and compatible with topcoat.

B. Galvanized-Steel Primer: [MPI#26] [MPI#80,] MPI#134.

1. Etching Cleaner: MPI#25, for galvanized steel. 2. Galvanizing Repair Paint: MPI#18, MPI#19, or SSPC-Paint 20 [ASTM A780/A780M].

2.7 SHRINKAGE-RESISTANT GROUT

A. Nonmetallic, Shrinkage-Resistant Grout: ASTM C1107/C1107M, factory-packaged, nonmetallic aggregate grout, noncorrosive and nonstaining, mixed with water to consistency

suitable for application and a 30-minute working time.

2.8 FABRICATION

A. Structural Steel: Fabricate and assemble in shop to greatest extent possible. Fabricate in accordance with ANSI/AISC 303 and to ANSI/AISC 360.

1. Camber structural-steel members where indicated. 2. Fabricate beams with rolling camber up. 3. Identify high-strength structural steel in accordance with ASTM A6/A6M and maintain

markings until structural-steel framing has been erected.

4. Mark and match-mark materials for field assembly. 5. Complete structural-steel assemblies, including welding of units, before starting shop-

priming operations.

B. Thermal Cutting: Perform thermal cutting by machine to greatest extent possible.

1. Plane thermally cut edges to be welded to comply with requirements in AWS D1.1/D1.1M.

C. Bolt Holes: Cut, drill, or punch standard bolt holes perpendicular to metal surfaces.

D. Finishing: Accurately finish ends of columns and other members transmitting bearing loads.

E. Cleaning: Clean and prepare steel surfaces that are to remain unpainted in accordance with SSPC-SP 1, SSPC-SP 2, or SSPC-SP 3.

-

CSD TWO INTERCONNECTED MIDDLE SCHOOLS 2019180.00

STRUCTURAL STEEL FRAMING 05 12 00 - 7

F. Shear Stud Connectors: Prepare steel surfaces as recommended by manufacturer of shear connectors. Weld using automatic end welding of headed-stud shear connectors in accordance

with AWS D1.1/D1.1M and manufacturer's written instructions.

G. Holes: Provide holes