Cryoprotectants for freeze drying of drug nano-suspensions: Effect of freezing rate

-

Upload

min-kyung-lee -

Category

Documents

-

view

223 -

download

2

Transcript of Cryoprotectants for freeze drying of drug nano-suspensions: Effect of freezing rate

Cryoprotectants for Freeze Drying of DrugNano-Suspensions: Effect of Freezing Rate

MIN KYUNG LEE, MIN YOUNG KIM, SUJUNG KIM, JONGHWI LEE

Department of Chemical Engineering and Materials Science, Chung-Ang University, 221, Heukseok-dong, Dongjak-gu,Seoul 156-756, South Korea

Received 12 November 2008; revised 8 February 2009; accepted 2 March 2009

Published online 27 May 2009 in Wiley InterScience (www.interscience.wiley.com). DOI 10.1002/jps.21786

Corresponde5269; Fax: 82-2

Journal of Pharm

� 2009 Wiley-Liss

4808 JOURN

ABSTRACT: Drug nanoparticles are often prepared in a liquid medium, and a dryingmethod such as freeze drying is used to convert them to an oral solid dosage form. Whenthe dried form is reconstituted in an aqueous system, it may be redispersed to achieve itsoriginal particle size. The redispersibility of dried nanoparticles depends on the para-meters of the freeze drying process. In this study, an apparatus with a freezing rategradient was used to systematically investigate the effect of cryoprotectants on theredispersibility of nanoparticles as a function of freezing rate. Sucrose, lactose, mannitol,and polyethylene glycol were used as cryoprotectants for a naproxen nano-suspension.A fast freezing rate and a high cryoprotectant concentration were generally favored.However, under certain conditions, a slower freezing rate resulted in better redisper-sibility. This is probably because slow freezing can produce a more cryo-concentratedliquid phase, and the concentrated cryoprotectant in the liquid phase can more effec-tively protect the nanoparticles. An irreversible aggregation map was constructed asa function of the freezing rate and the cryoprotectant concentration, and shows boththe favorable and unfavorable effects of cryoprotectants. � 2009 Wiley-Liss, Inc. and the

American Pharmacists Association J Pharm Sci 98:4808–4817, 2009

Keywords: drying; nanoparticles; na

notechnology; freeze drying/lyophilization;freeze-drying; milling; particle size; suspensionsINTRODUCTION

The use of drug nanoparticles has widened theapplicability of drug delivery systems by improv-ing the bioavailability and stability of drugs,sustaining drug effects in target tissues, andenhancing intracellular uptake.1–18 The prepara-tion and subsequent processing technology of drugnanoparticles has been developing rapidly.19,20

However, the unit operation dealing with nano-particles (drying, granulation, compaction, etc.)

nce to: Jonghwi Lee (Telephone: 82-2-820--824-3495; E-mail: [email protected])

aceutical Sciences, Vol. 98, 4808–4817 (2009)

, Inc. and the American Pharmacists Association

AL OF PHARMACEUTICAL SCIENCES, VOL. 98, NO. 12, DE

is still a challenging task in the pharmaceuticalindustry.

A decrease in particle size leads to an increasein Gibbs free energy by increasing the extra‘‘subdivision potential’’ term,1,21 which is mainlyrelated to the increase in surface energy. Deter-mining how to compensate for this term is thekey to both the preparation and subsequent unitoperations of nanoparticles. Various methods toprepare drug nanoparticles such as liquid-basedmethods (e.g., nano-emulsions, nano-precipitation),nano-comminution, impinging jetting, and super-critical fluid methods use surface stabilizingmaterials and an external energy source to compen-sate for the extra Gibbs energy related to particlesize reduction. For example, nano-comminution

CEMBER 2009

FREEZING RATE EFFECT 4809

uses mechanical energy with the aid of one ormore stabilizers.

Nanoparticles are usually prepared in a liquidmedium that can offer a favorable environment tostabilize the high surface energy of nanoparti-cles.21–26 The nano-comminution of drug particles,a commercially successful method used to produceRapamune1, Emend1, Tricor1, and Megace1 ES,uses water as a dispersion medium.1–5 However,for the final drug delivery form, oral solid dosageforms are preferred, mainly due to patientcompliance. Furthermore, the improved long-term stability of nanoparticles has increased thepopularity of solid dosage forms. Therefore, theconversion of drug nanoparticle suspensions andemulsions into solid powders is important.27,28

A commonly used process for drying drug nano-suspensions is freeze drying.29–36 Freeze dryingremoves water from a frozen sample throughsublimation.37–40 The first step is freezing, fol-lowed by primary drying (ice sublimation) andsecondary drying (desorption of unfrozen water).Various stresses are generated during the processsuch as freezing and desiccation stresses. Toprotect nanoparticles from stresses and sub-sequent aggregation, a cryoprotectant or lyopro-tectant is generally used. As a rule, a higherconcentration of cryoprotectant and a fasterfreezing rate result in a better redispersibility ofnanoparticles.33,36 Here, when dried powders arereconstituted in an aqueous system, the ability ofthe nanoparticles to go back to their originalparticle size is defined as ‘‘redispersibility.’’

The selection of a proper cryoprotectant is notstraightforward. In fact, some previous resultsshow that a typical cryoprotectant such as sucrosemay even destabilize nanoparticles.41 As the con-centration of a cryoprotectant increases, theaggregation of nanoparticles may either decreaseor increase depending on the system of nanopar-ticles and the freeze drying conditions.28 Thiscomplex process has been developed only bytrial and error. Furthermore, the freezing rate,an important parameter in the first step offreeze drying, has seldom been systematicallyinvestigated.30

The primary concern associated with freezedrying of drug nanoparticles is the redispersibilityof the final product. Nanoparticles are stabilizedby a stabilizer or a combination of stabilizers inan aqueous system; however, freezing inducesthe irreversible aggregation of nanoparticles. Thisis mainly because a steric stabilizer becomesinactive during freezing.1,30

DOI 10.1002/jps JOURNA

Recently, we developed a simple apparatus thatprovides a freezing rate gradient, and we reportedthe existence of a critical freezing rate for thepreparation of redispersable nanoparticles.30 Inthat study, we used suspensions of naproxennanoparticles stabilized by hydroxypropyl cellu-lose (HPC) without using a cryoprotectant. Theirreversible aggregation of nanoparticles startedbelow the critical freezing rate. In contrast withother comparison studies using different freezingmethods,28 our study on freezing rate provided asystematic quantitative view. However, powderscontaining no excipients are rarely used in actualpharmaceutical processes. Here, we used thesame experimental technique to investigate theeffect of cryoprotectants on redispersibility as afunction of freezing rate. Additionally, this studyaimed to clarify controversial results regardingthe effect of cryoprotectants.

MATERIALS AND METHODS

Materials

Naproxen, a relatively insoluble crystalline drugcompound (Mw¼ 452.8 g/mol, purity> 95%,Aldrich, St. Louis, MO) was used as a modeldrug. Hydroxypropyl cellulose (HPC, Mw¼ 60 kg/mol, surface energy¼ 45 mN/m, FMC) was used asa steric stabilizer for wet comminution. Lactose,sucrose, mannitol and polyethylene glycol (PEG,Mw¼ 2000 g/mol) were obtained from Aldrichand used as a cryoprotectant. HPLC-gradewater from Aldrich and yttria-stabilized zirconiabeads (Performance Ceramics, Peninsula, OH,1 mm diameter) were used without any furtherpurification.

Preparation of Nanocrystal Dispersion

Low energy comminution was used to producenanocrystal dispersions using 1 mm zirconiabeads (50 mL) as grinding media.1–3 API wasmixed with hydroxypropyl cellulose (HPC,Mw¼ 60 kg/mol, surface energy¼ 45 mN/m) pre-viously dissolved in water in a 100 mL glass bottle,and the beads and additional water were put intothe bottle. The total weight of slurry (APIþstabilizerþwater) was 3.75 g, and the concentra-tion of API in water was 11.5 wt%. The weightratio of HPC/drug was kept 1/6. The comminutionspeed and time were 125 rpm and 5 days. Aftercomminution, the media beads were filtered out,and the suspension was stored at 58C. Before

L OF PHARMACEUTICAL SCIENCES, VOL. 98, NO. 12, DECEMBER 2009

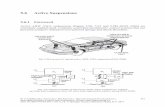

Figure 1. Schematic illustration of an experimental setup to freeze nanocrystaldispersion at various freezing rates. Sampling was performed after freeze drying formore than 24 h.

4810 LEE ET AL.

freeze drying, the aqueous solutions of cryopro-tectants such as lactose, sucrose, mannitol, andPEG were mixed for 24 h with the nanosuspensionprepared by wet comminution. The solutionconcentration of cryoprotectant was changed from5 to 40 wt%.

Nano-suspensions were frozen using a custom-made apparatus (Fig. 1).30 Freezing rate varied asa function of the distance from a liquid nitrogenreservoir in a sample reflecting changes intemperature gradient. As shown in Figure 1,nano-suspensions were first put into a long tubecontainer, and the container was placed in contactwith a liquid nitrogen reservoir. After the contact,freezing started from the region near the liquidnitrogen reservoir. For fast heat transfer, both thecontainer and the reservoir were made of stainlesssteel. In addition to the heat transfer throughstainless steel, cold nitrogen gas flow helped thepropagation of freezing front. Because the frozenparts of suspension had different turbidity(refractive index) compared to liquid parts, thefreezing interface between frozen and liquid partswas distinct. Freezing rates could be calculatedby monitoring the distance (at every 10 mm)and the time (s) that the freezing front moves.The distance and time raw data were carefullycompared with the results of the previousreport.30 To obtain reproducible results, all otherexperimental factors, such as the amount of liquidnitrogen, were carefully kept constant.30 Frozensuspension was vacuum dried using a bench topfreeze-dryer FD-1000 (EYELA, Tokyo, Japan,trap chilling temperature �458C, 5.6 Pa) for 24 h.

JOURNAL OF PHARMACEUTICAL SCIENCES, VOL. 98, NO. 12, DECEMBER 200

Characterization

Particle size was measured in 150 mL water usinga Horiba LA 910 laser light scattering analyzer(632.8 nm He–Ne laser). A relative refractiveindex of 1.2� 0.00i and 1 min sonication of 40 Wand 39 kHz were employed. After freeze drying,disk-shape powder samples of 5.1 mm diametertaken at different locations along the long tubecontainer were used with carefully adjusting itsscattering intensity (Fig. 1). The volume averageparticle sizes of powders were used in this study.The morphologies of freeze dried powders werecharacterized by Hitachi S-4300E scanning elec-tron microscope (3–4 kV, 3 nm platinum coating).The crystal structure of the dried powder wasanalyzed by D/Max-2500/PC powder X-ray dif-fraction pattern using an accelerating voltage of40 kV (1 degree/min).

RESULTS

The freezing rate was controlled by the sameapparatus that proved the existence of criticalfreezing rate in the freeze drying of drug nano-suspensions without a cryoprotectant (Fig. 1).30

The reproducibility and accuracy of freezing ratevalues were confirmed by plotting the time for thefreezing front to arrive at position x versusdistance from liquid nitrogen reservoir (x), asreported previously.30 In short, nano-suspensionfreezing was controlled by heat transfer to theliquid nitrogen reservoir through stainless steel

9 DOI 10.1002/jps

FREEZING RATE EFFECT 4811

and cold nitrogen gas flow from the reservoir.Nano-suspensions closer to the reservoir werefrozen faster. The range of freezing rates thatcould be obtained by the apparatus was limited byseveral experimental difficulties such as evapora-tion of liquid nitrogen and too fast or too slowmovement of the freezing front. Measuring theposition of the freezing front was more difficult inthese experiments than our previous experimentsusing drug nano-suspensions with no cryoprotec-tant.30 Although we used the same apparatus,different nano-suspensions resulted in differencesin the range of attainable freezing rates due todifferent thermal conductivity and measurabilityof movement of the freezing front. However,despite these experimental difficulties, we werestill able to draw important conclusions.

Figure 2 shows the volume-averaged meanparticle sizes of drug particles after redispersingfreeze dried powder. Compared to the meanparticle size before freeze drying (140 nm, sameas that in Ref. 30), the 10 wt% sucrose and the10 wt% lactose results show significant aggrega-tion. The size decreased slightly with an increasein freezing rate, which agrees with previousresults.28 However, the existence of a criticalfreezing rate is unclear within the ranges ofexperimental variables. In the case of 20 wt%

Figure 2. Effect of freezing rate on the volume-aver-age mean particle size of drug nanoparticles freezedried in presence of lactose or sucrose as a cryoprotec-tant. The dashed line is the result of nano-suspensionwithout a cryoprotectant redrawn from Ref. 30 forcomparison.

DOI 10.1002/jps JOURNA

sucrose, a critical freezing rate appears to exist ator near 100 mm/s. A faster freezing rate seemsto be generally beneficial in the preparation ofredispersible nanoparticles (Fig. 2).

Interestingly, the critical freezing rate value(100 mm/s) for treatment with 20 wt% sucrose issimilar to what we observed in our previous reportusing the same nano-suspension without usinga cryoprotectant (Fig. 2), indicating that 20 wt%sucrose does not significantly help the redis-persibility of nanoparticles. Furthermore, theaddition of 10 wt% sucrose actually promotesaggregation of nanoparticles. These results sug-gest that the addition of a cryoprotectant such assucrose is not always helpful in the preparation ofredispersable drug nanoparticles.

Low-molecular weight water-soluble polymerscan also be used as cryoprotectants. In oneexperiment, PEG was evaluated as a cryoprotec-tant with consistent results (Fig. 3). Whensuspensions were treated with 5–15 wt% PEG,the mean particle size increased as the freezingrate increased, indicating more significant aggre-gation of drug nanoparticles. When the concen-tration of PEG was increased further to 25 or40 wt%, an increase in particle size was notobserved, and all the nano-suspensions werefreeze-dried into redispersable powders. In other

Figure 3. Effect of freezing rate on the volume-aver-age mean particle size of drug nanoparticles freezedried in presence of PEG as a cryoprotectant. Thedashed line is the result of nano-suspension withouta cryoprotectant redrawn from Ref. 30 for comparison.

L OF PHARMACEUTICAL SCIENCES, VOL. 98, NO. 12, DECEMBER 2009

4812 LEE ET AL.

words, above 15 wt%, PEG successfully performedas a cryoprotectant regardless of freezing rate.However, below 15 wt%, PEG performed as anaggregation promoter at a freezing rate between80 and 180 mm/s.

The same counteracting effect was observed formannitol (Fig. 4): As the concentration of manni-tol increased, the mean particle size of drugnanoparticles decreased, indicating that mannitolacts as a successful cryoprotectant. However,particle size unexpectedly increased with anincrease in freezing rate similar to PEG. Acomparison of nano-suspensions with or withoutcryoprotectants30 revealed that the addition ofa cryoprotectant was not always beneficial. Thecommon generalization that a faster freezing rateor the addition of cryoprotectant is helpful for thepreparation of redispersible drug nanoparticlesshould therefore be reconsidered.

Although we obtained unexpected resultswhen we added cryoprotectants, our results forthe redispersibility of nanoparticles frozen byliquid nitrogen were as expected: nanoparticlesfrozen at an extremely fast freezing rate alwaysshowed good redispersibility. When nanoparticleswere frozen by directly dropping the suspensioninto liquid nitrogen, the volume average meanparticle sizes of powders were all approximately

Figure 4. Effect of freezing rate on the volume-aver-age mean particle size of drug nanoparticles freeze driedin presence of mannitol as a cryoprotectant. The dashedline is the result of nano-suspension without a cryopro-tectant redrawn from Ref. 30 for comparison.

JOURNAL OF PHARMACEUTICAL SCIENCES, VOL. 98, NO. 12, DECEMBER 200

130–150 nm, similar to the original particle size ofthe naproxen nanoparticles (data not shown).

The mean particle sizes were confirmed furtherby SEM (Fig. 5). The SEM micrographs showprimary particles of 100–200 nm in all cases. Themean particle sizes (plotted in Figs. 2–4) do notexactly match the sizes of the primary particles.Therefore, the primary particles (Fig. 5) are madeduring the nano-comminution process, and theirsubsequent aggregation leads to an increase inmean particle sizes. However, because it wasnot possible to distinguish naproxen, mannitol, orlactose phases, the nature of aggregation remainsunclear.

In a nano-suspension after comminution, drugnanoparticles largely retain their crystallinenature, and cryoprotectants can crystallize duringfreeze drying.1–5,28 To investigate the influence ofcrystallinity upon aggregation, XRD patterns offreeze-dried powders were investigated (Fig. 6).As references, the XRD patterns of naproxenand a cryoprotectant were compared. While thecrystalline diffraction patterns of naproxen werefound in the powders, mannitol diffraction pat-terns were hard to find. For example, the peak of23.58 in the mannitol as received was not clearlyobserved in the freeze-dried powders. The differ-ences in the relative peak intensity of naproxenand freeze-dried powders are shown in Figure 6.These results indicate that mannitol mightundergo phase separation during freezing possi-bly without significant crystallization. Similarlyfor lactose, sucrose, and PEG, no significantcrystalline peaks of cryoprotectants were observed(data not shown) suggesting that the effect offreezing rate cannot be explained solely bydifferences in the crystallinity of cryoprotectantsas reported previously.28,36

DISCUSSION

Freezing is a critical step in the freeze-dryingof nano-suspensions.28,30 When a cryoprotectantis present, water freezes into ice crystals whileexcluding solutes and particles into a cryo-concentrated liquid phase. At equilibrium, theconcentration of the liquid phase can follow theequilibrium phase boundary (equilibrium freezingcurve).28 The liquid phase eventually passesthrough the glass transition temperature ofmaximally cryo-concentrated solution. For exam-ple, in the case of sucrose, the maximumconcentration is 80%.28 Some cryoprotectants

9 DOI 10.1002/jps

Figure 5. SEM micrographs of freeze-dried drug nanoparticles in presence of differ-ent cryoprotectants at a different freezing rate. The scale bar is 500 nm, and freezing rateis in the parenthesis.

FREEZING RATE EFFECT 4813

such as mannitol, but not sucrose, can precipitateinto their own phase (crystalline or amorphous)during this step.28

A cryoprotectant vitrifies at a specific tempera-ture, and the glassy matrix of cryoprotectant canprotect nanoparticles from the mechanical stressof ice. In most studies on cryoprotectants, thehigher the concentration of cryoprotectant, thebetter the stability of the nanoparticles (lessaggregation).

A fast freezing rate is beneficial for a largevariety of nano-suspensions and emulsions. Theeffect of freezing rate has been studied usingdifferent freezing methods.28 Fast freezing resultsin smaller ice crystals and a larger specific surfacearea of ice42 resulting in a decrease in mechanicalstress upon particles. However, conflicting resultshave also been reported, namely, that fastfreezing has no effect in cases using a cryopro-tectant,41,43–45 similar to our results. We showedthat, overall, a higher concentration of cryopro-tectant and a faster freezing rate is better forthe redispersibility of nanoparticles. However, the

DOI 10.1002/jps JOURNA

trend is reversed in some cases. In the previousreports,41,43–45 when an unusual effect of freezingrate and concentration was found, specific inter-actions among cryoprotectants, solvents, andparticles were used as an explanation. In othercases, the temperature dependence of solubility orcrystallization behavior of the cryoprotectantswere employed as a possible rationale. Whilethese studies used only certain freezing rates, weused a range of freezing rates, and, surprisingly,the unusual effects of cryoprotectants were foundin all three cryoprotectant cases. Therefore, amore general explanation appears to be war-ranted.

All the data points from the PEG cases wereplotted as a map according to the redispersibilityof nanoparticles (Fig. 7). The size criterion wasarbitrarily chosen to be 300 nm (2� originalparticle size) above which redispersibility wasconsidered to be poor (closed circles). Twoboundaries are shown: one at a relatively highfreezing rates (lower dashed line) and the otherat a lower freezing rate (upper dashed line).

L OF PHARMACEUTICAL SCIENCES, VOL. 98, NO. 12, DECEMBER 2009

Figure 6. XRD patterns of freeze-dried naproxen/mannitol particles: (a) mannitol as received, (b)naproxen as received, (c) naproxen/mannitol(15 wt%)[freezing rate¼ 50 mm/s], (d) naproxen/mannitol(15 wt%) [freezing rate¼ 161 mm/s].

Figure 7. Aggregation map as a function of cryopro-tectant concentration and freezing rate in freeze dryingnaproxen nanoparticles in presence of PEG. The closedcircles indicate significant aggregation cases (volumeaverage mean particle size> 300 nm), and the opencircles are well dispersed cases. The dashed boundariesare also arbitrarily defined following the arbitrary cri-teria of average size> 300 nm. The data of 0 wt% caseswere taken from Ref. 30.

JOURNAL OF PHARMACEUTICAL SCIENCES, VOL. 98, NO. 12, DECEMBER 200

4814 LEE ET AL.

Depending on the size criterion, the exact loca-tions of boundaries could be varied, but theirgeneral behavior remains the same. The highfreezing rate data follow the general trend: Thefaster freezing rate is better for redispersibility.Faster freezing results in the formation of smallerice crystals and subsequent better redispersibil-ity. However, the results when using a lowfreezing rate were rather unexpected.

What can cause an increase in the aggregationof nanoparticles with an increase in freezing ratenear the low freezing rate boundaries? As afreezing front moves in, ice crystals and cryo-concentrated solution phases form. The nanopar-ticles aggregate in the cryo-concentrated liquidphase mainly through the chain entanglement ofpolymers (HPC) physically adsorbed on the sur-face of nanoparticles. This aggregation canhappen during freezing and also subsequentdrying steps. When the freezing rate is relativelyslow, cryoprotectants such as PEG can migratefully into the cryo-concentrated liquid phase. As aresult, the local concentration of cryoprotectantin the liquid phase is relatively high and theaggregation prevention effect can be enhanced. Infact, when the concentration of PEG was 40 wt%(Fig. 7), no significant aggregation was found,regardless of freezing rate. Therefore, the con-centrations of excipients (cryoprotectants) in thecryo-concentrated liquid phase might be deter-mined by a competition between the diffusionrate of the excipient molecules and the freezingrate.

When a fast freezing rate (>100 mm/s, Fig. 7) isused and the concentration of cryoprotectant isvaried, the presence of the cryoprotectant below acertain concentration seems to be unfavorable forachieving good redispersibility. The cryoprotec-tant molecules cannot migrate fully into the cryo-concentrated liquid phase under these conditions.The existence of the cryoprotectant in the icecrystal phase seems to increase the freezingstresses, resulting in poor redispersibility. How-ever, this adverse effect will disappear whenenough cryoprotectant is added to exist in thecryo-concentrated liquid phase. This explanationcan tie in with previously proposed mechanismsto explain the adverse effects of cryoprotectantsthat are based on the specific interactions,solubilities, and crystallization behaviors of cryo-protectants.41,43–45 However, because the pre-vious studies did not systematically control thefreezing rate, their explanations are more fromthe point of view of materials.

9 DOI 10.1002/jps

FREEZING RATE EFFECT 4815

In our previous study of naproxen nano-suspensions without a cryoprotectant, a criticalfreezing rate showing a sharp change in the meanparticle size of redispersibility was detected.30 Incontrast, the same critical changes were not foundin this study, although we used the same drugnano-suspensions, indicating that the existence ofa single critical freezing rate cannot always bedefined.

The meaning of a freezing rate could be inter-preted as actual freeze drying operation para-meters.30 If freezing rate is 130 mm/s, this meansa suspension of 50 mL should be frozen within2.9 min (if it is a round drop).30 Once we know theheat transfer coefficients of medium and containermaterials, we can predict the temperature gra-dient necessary to freeze the suspension at therate. If we use the simplest heat transfer equation,

h ¼ DQ

ADTDt

where, DQ is the heat input or heat lost (J), h theheat transfer coefficient (W/m2K), A the heattransfer surface area (m2), DT the differencein temperature between the solid surface andsurrounding fluid area (K), Dt the time period(s).46 If the heat of fusion of water is 333.55 J/gand heat transfer coefficient is 10,000 W/m28C,the total heat is ca. 17,000 J and DT¼ 518C.46

Therefore from the beginning of freeze dryingprocess, the temperature in a freezer should belower than ca. 508C than that of a sample.

We wish to add two comments to protect readersfrom any misleading generalizations. First, ourresults and subsequent conclusions are limited bythe experimental window we used. For example,the freezing rate cannot be infinitely large orsmall since it is limited by the intrinsic thermalconductivities of suspensions. Second, when wefreeze-dried our materials, we did not useannealing and secondary drying steps. All ofthe conditions after the freezing step were keptconstant in our experiment. We only analyzedonly the effect of freezing rate without changingany other conditions. Of course, these subsequentsteps can also influence the drying process ofnano-suspensions and thus their redispersibility.

CONCLUSIONS

Freezing drying is a common process to retain theredispersibility of drug nanoparticles after drying.

DOI 10.1002/jps JOURNA

The effect of the freezing rate and the concentra-tion of cryoprotectants was systematically inves-tigated using a naproxen nano-suspension. Theredispersibility of nanoparticles did not correlatestraightforwardly with either the freezing rate orcryoprotectant concentration. Within the wholerange of freezing rate and cryoprotectant con-centrations, a faster freezing rate and a higherconcentration were generally better. However, anadverse effect of cryoprotectant addition wasfound in many cases. In a redispersibility mapof freezing rate and concentration, a region ofpoor redispersibility was found. At a relativelyslow freezing rate region, a slower freezing rateresulted in a lower aggregation of nanoparticles.Slow freezing could lead cryoprotectants to fullymigrate into a cryo-concentrated liquid phase,resulting in a high local concentration of cryopro-tectant. The high concentration could effectivelyprevent the aggregation of nanoparticles.

ACKNOWLEDGMENTS

This Research was supported by the Chung-AngUniversity Research Grants in 2008.

REFERENCES

1. Lee J. 2003. Drug nano- and microparticles pro-cessed into solid dosage forms: Physical properties.J Pharm Sci 92:2057–2068.

2. Grau MJ, Kayser O, Muller RH. 2000. Nanosuspen-sions of poorly soluble drugs—Reproducibility ofsmall scale production. Int J Pharm 196:155–157.

3. Liversidge GG, Conzentino P. 1995. Drug particlesize reduction for decreasing gastric irritancy andenhancing absorption of naproxen in rats. Int JPharm 125:309–313.

4. Liversidge GG, Cundy K. 1995. Particle size reduc-tion for improvement of oral bioavailability ofhydrophobic drugs: I. Absolute oral bioavailabilityof nanocrystalline danazol in beagle dogs. Int JPharm 125:91–97.

5. Liu R, editor. 2000. Particle size reduction, inwater-insoluble drug formation. Buffalo Grove:Interpharm Press. pp. 455–492.

6. Merisko-Liversidge E, Sarpotdar P, Bruno J, Hajj S,Wei L, Peltier N, Rake J, Shaw JM, Pugh S, PollinL, Jones J, Corbett T, Cooper E, Liversidge GG.1996. Formulation and antitumor activity evalua-tion of nanocrystalline suspensions of poorly solubleanticancer drugs. Pharm Res 13:272–278.

7. Serajuddin ATM. 1999. Solid dispersion of poorlywater-soluble drugs: Early promises, subsequent

L OF PHARMACEUTICAL SCIENCES, VOL. 98, NO. 12, DECEMBER 2009

4816 LEE ET AL.

problems, and recent breakthroughs. J Pharm Sci88:1058–1066.

8. Yamada T, Saito N, Imai T. 1999. Effect of grindingwith hydroxypropyl cellulose on the dissolution andparticle size of a poorly water-soluble drug. ChemPharm Bull 47:1311–1313.

9. Merisko-Liversidge E, McGurk SL, Liversidge GG.2004. Insulin nanoparticles: A novel formulationapproach for poorly water soluble Zn-insulin.Pharm Res 21:1545–1553.

10. Bosch HW, Ostrander KD, Hovey DC. 2003.Nanoparticulate compositions comprising amor-phous cyclosporine and methods of making andusing such compositions. US Patent number6,656,504.

11. Pace GW, Mishra AK. 2004. Water-insoluble drugparticle process. US Patent number 6,682,761.

12. Ryde NP, Ruddy SB. 2002. Solid dose nanoparticu-late compositions comprising a synergistic com-bination of a polymeric surface stabilizer anddioctyl sodium sulfosuccinate. US Patent number6,375,986.

13. Ryde NP, Ruddy SB. 2002. Nanoparticulate disper-sions comprising a synergistic combination of apolymeric surface stabilizer and dioctyl sodiumsulfosuccinate. US Patent number 6,592,903.

14. Chambers E, Mitragotri S. 2004. Prolonged circula-tion of large polymeric nanoparticles by non-cova-lent adsorption on erythrocytes. J Control Release100:111–119.

15. Rosell-Lompart J, Fernandez de la Mora J. 1994.Generation of monodisperse droplets 0.3 to 4 mmin diameter from electrified cone-jets of highly con-ducting and viscous liquid. J Aerosol Sci 25:1093–1119.

16. Gomez A, Bingham D, de Juan L, Tang K. 1998.Production of protein nanoparticles by electrospraydrying. J Aerosol Sci 29:561–574.

17. Amidon GL, Lennernas H, Shah VP, Crison J. 1995.A theoretical basis for a biopharmaceutic drugclassification: The correlation of in vitro drug pro-duct dissolution and in vivo bioavailability. PharmRes 12:413–420.

18. Torchilin VP. 2000. Drug targeting. Eur J PharmSci 11:S81–S91.

19. Zheng JY, Bosch HW. 1997. Sterile filtration ofnanocrystal drug formulation. Drug Dev Ind Pharm23:1087–1093.

20. Schmidt C, Bodmeier R. 1999. Incorporation ofpolymeric nanoparticles into solid dosage forms.J Control Release 57:115–125.

21. Hill TL. 2001. A different approach to nanothermo-dynamics. Nano Lett 1:273–275.

22. Lee J. 2004. Intrinsic adhesion force of lubricants tosteel surface. J Pharm Sci 93:2310–2318.

23. Ploehn HJ, Russel WB. 1990. Interactions betweencolloidal particles and soluble polymers. Adv ChemEng 15:137–228.

JOURNAL OF PHARMACEUTICAL SCIENCES, VOL. 98, NO. 12, DECEMBER 200

24. Philip J, Gnanaprakash G, Jayakumar T, Kalyana-sundaram P, Raj B. 2003. Three distinct scenariosunder polymer, surfactant, and colloidal inter-action. Macromolecules 36:9230–9236.

25. Berglund KD, Przybycien TM, Tilton RD. 2003.Coadsorption of sodium dodecyl sulfate with hydro-phobically modified nonionic cellulose polymers. 1.Role of polymer hydrophobic modification. Lang-muir 19:2705–2713.

26. Berglund KD, Przybycien TM, Tilton RD. 2003.Coadsorption of sodium dodecyl sulfate with hydro-phobically modified nonionic cellulose polymers. 2.Role of surface selectivity in adsorption hysteresis.Langmuir 19:2714–2721.

27. Chaubal MV, Popescu C. 2008. Conversion of nano-suspensions into dry powders by spray drying: Acase study. Pharm Res 25:2302–2308.

28. Abdelwahed W, Degobert G, Stainmesse S, Fessi H.2006. Freeze-drying of nanoparticles: Formulation,process and storage considerations. Adv Drug DelivRev 58:1688–1713.

29. Konan YN, Gurny R, Allemann E. 2002. Prepara-tion and characterization of sterile and freeze-driedsub-200 nm nanoparticles. Int J Pharm 233:239–252.

30. Lee J, Cheng Y. 2006. Critical freezing rate in freezedrying nanocrystal dispersions. J Control Release111:185–192.

31. Aumelas A, Serrero A, Durand A, Dellacherie E,Leonard M. 2007. Nanoparticles of hydrophobicallymodified dextrans as potential drug carrier sys-tems. Colloids Surf B Biointerfaces 59:74–80.

32. Berejnov V, Husseini NS, Alsaied OA, Thorne RE.2006. Effects of cryoprotectant concentration andcooling rate on vitrification of aqueous solutions.J Appl Cryst 39:244–251.

33. Hirsjarvi S, Peltonen L, Kainu L, Hirvonen J. 2006.Freeze-drying of low molecular weight poly(L-lacticacid) nanoparticles: Effect of cryo- and lyoprotec-tants. J Nanosci Nanotechnol 6:3110–3117.

34. Layre AM, Couvreur P, Richard J, Requier D,Eddine Ghermani N, Gref R. 2006. Freeze-dryingof composite core-shell nanoparticles. Drug DevelopInd Pharm 32:839–846.

35. Kesisoglou F, Panmai S, Wu Y. 2007. Nanosizing—Oral formulation development and biopharmaceu-tical evaluation. Adv Drug Deliv Rev 59:631–644.

36. Abdelwahed W, Degobert G, Fessi H. 2006.Investigation of nanocapsules stabilization byamorphous excipients during freeze-drying andstorage. Eur J Pharm Biopharm 63:87–94.

37. Goldblith SA, Rey L, Rothmayr WW. 1975. Freezedrying and advanced food technology. London:Academic Press.

38. Bakaltcheva I, Ganong JP, Holtz BL, Peat RA, ReidT. 2000. Effects of high-molecular-weight cryopro-tectants on platelets and the coagulation system.Cryobiology 40:283–290.

9 DOI 10.1002/jps

FREEZING RATE EFFECT 4817

39. Zambaux MF, Bonneaux F, Gref R, Dellacherie E,Vigneron C. 1999. MPEO-PLA nanoparticles: Effectof MPEO content on some of their surface proper-ties. J Biomed Mater Res 44:109–115.

40. Sonner C, Maa YF, Lee G. 2002. Spray-freeze-drying for protein powder preparation: Particlecharacterization and a case study with trypsinogenstability. J Pharm Sci 91:2122–2139.

41. Sameti M, Bohr G, Ravi Kumar MNV, Kneuer C,Bakowsky U, Nacken M, Schmidt H, Lehr CM.2003. Stabilization by freeze-drying of cationicallymodified silica nanoparticles for gene delivery. Int JPharm 266:51–60.

42. Searles JA, Carpenter JF, Randolph TW. 2001. Theice nucleation temperature determines the primarydrying rate of lyophilization for samples frozen on atemperature-controlled shelf. J Pharm Sci 90:860–871.

DOI 10.1002/jps JOURNA

43. Saez A, Guzman M, Molpeceres J, Aberturas MR.2000. Freezedrying of polycaprolactone and poly-(D,L-lactic-glycolic) nanoparticles induce minorparticle size changes affecting the oral pharmaco-kinetics of loaded drugs. Eur J Pharm Biopharm50:379–387.

44. Quintanar-Guerrero D, Ganem-Quintanar A, Alle-mann E, Fessi H, Doelker E. 1998. Influence of thestabilizer coating layer on the purification andfreeze-drying of poly(D,L-lactic acid) nanoparticlesprepared by an emulsion diffusion technique.J Microencapsul 15:107–120.

45. Miller SC, Drabik BR. 1984. Rheological propertiesof poloxamer vehicules. Int J Pharm 18:269–276.

46. McCabe WL, Smith JC, Harriott P. 2005. Unitoperations of chemical engineering. Columbus,OH: McGraw- Hill. pp. 299–324.

L OF PHARMACEUTICAL SCIENCES, VOL. 98, NO. 12, DECEMBER 2009