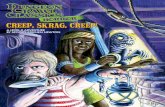

CREEP

-

Upload

attittude-blogger -

Category

Science

-

view

219 -

download

5

Transcript of CREEP

CREEP

SUHAIL K S

2ND M.Sc BPS

CBPST, KOCHI

It can be defined as the slow & progressive (increasingly continuing) deformation of a material with time under a constant stress.

It is both a time & temperature dependent phenemenon.

Creep is probably the most widely studied long-term

property.

It results from the viscoelastic flow of the polymer with

time.

Creep

Creep

The method of carrying out creep tests is to subject the specimen to a constant stress while maintaining the temperature constant and measuring the extent of deformation.

The resulting data are presented as deformation (strain)-time curve.

Creep curve

Details

Instantaneous elastic strain

Deformation (strain)

Time

A

V0

E

D

C

B

Primary

Creep

Secondary Steady-State

Creep

Tertiary

Creep

Details

When a load is applied at the beginning of a creep test, the instantaneous elastic deformation (AB) is followed by transient or primary creep (BC) then the secondary or steady-state creep (CD) and finally by tertiary or accelerated creep (DE).

Instantaneous deformations Elastic

The primary creep rate has a decreasing rate because of work hardening. It is similar to delayed elasticity (retarded elasticity) and the deformations are recoverable.

Secondary creep is essentially viscous in character. The minimum creep rate (V0) is determined by the slope Δε/Δt.

RTE

n eAt

TYPES OF CREEP

2.Flexural creep1.Tensile creep

3. Compressive creep

Effect of nano particles in polymers

Many studies shows that the addition of nanoparticles to

neat polymers can significantly improve the creep

resistance of the polymers at various stress and

temperature levels.

During creep deformation, the molecularchains are

stretched and re-oriented.

Creep behaviour is affected by molecularweight,degree of

crystallinity, and the chemical resistance of the polymer.

The entangled high aspect ratioCNTs have strong interaction

with the polymer chains and potentially act as physical

barriers for chain re-orientation.

This pseudo physical barrier effectively reduces creep

deformation when the material is stressed.

At low stress level interfacialbonding holds and the CNT forms

a network of crosslinking elements that interconnect the

epoxy chains,this action increases the effective crosslinking

density of the network which reduces mobility and

reorientation of the amorphous epoxy chains.

At higher stress level polymer/CNTinterface are prone to

failure and as a the ability of the nanotubes to limit polymer

chain movement is negligible.

Creep behaviour on epoxy/CNT nanocomposites

Creep behaviour on epoxy/CNT nanocomposites

Creep tests

Creep performance is commonly

represented by creep compliance J(t) and

where ε(t) is creep strain and σ is applied

stress.

For dry atmosphere and NC with different

filler content the creep compliance curves

are given in Fig. 5.

As seen from the figure the inclusion of clay

nanoparticles into epoxyresin led to a

sufficient reduction of creep compliance of

NC specimens dried in atmosphere of 24%

RH. Nevertheless for humid atmospheres

absorbed moisture

significantly affected creep behaviour,

leading to high deformability.

Creep of PU/CLAY nanocomposites

Figure 11 shows the creep and recoverycurves of PU/clay C20A nanocomposites. The addition of clay leads to a lower creep recovery.

THANK YOU