CRAWLER DOZER...ENGINE Model Case Family IV 667TA/E66, Tier III certified Cylinders 6 Bore/Stroke...

Transcript of CRAWLER DOZER...ENGINE Model Case Family IV 667TA/E66, Tier III certified Cylinders 6 Bore/Stroke...

ENGINE

Model

Case Family IV 667TA/E66, Tier III certified

Cylinders 6

Bore/Stroke 4.1 in x 5.2 in(104 x 132 mm)

Displacement 414 in3 (6.7 L)

Fuel injection Direct

Fuel #2 Diesel

Fuel filter Spin-on within-line strainer

Air intake Cross-flow

Cooling Liquid

Engine speeds (rpm)

High idle - no load 2220+50

Rated - full load 2000

Low idle 800-1050

Horsepower per SAE J1349

Net 96 (72 kW) @ 2000 rpm

Gross 99 (74 kW) @ 2000 rpm

Peak torque @ 1400 rpm

Net 321 lb·ft (435 N·m)

Gross 325 lb·ft (441 N·m)

Engine lubrication –

Pump Deep sump plate cooler with pressurized

under-piston nozzles

Pump operating angle ratings

Side-to-side 45°

Fore and aft 45°

Oil filtration Replaceable, spin-onfull-flow cartridge

ENGINE COOLING

Radiator –

Core size area 583 in2 (0.38 m2)

Rows of tubes 4

Fan –

Diameter 21.6 in (550 mm)

Ratio 1.1:1

ELECTRICAL SYSTEM

Alternator 90 amp

Battery 12-volt low-maintenance700 cold-cranking amps

@ 0° F (-18 C)

POWERTRAIN

Dual path hydrostatic

Pump – variable axial piston

Motor – variable bent axis piston

Maximum drawbar pull* 40,000 lb (178 kN)

Transmission Single lever control –electronic straight tracking

Oil filter 4 micron, spin-onreplaceable

Travel speeds* –

Forward 0-6 mph (0-9.7 km/h)

Reverse 0-6 mph (0-9.7 km/h)

*Measured using standard track chain. Increase travel speeds by 4% and reduce drawbar pull by 4% with the optional CELT track chain.

Parking brakes Heavy-duty, spring-applied,

hydraulic pressure release

Steering brakes Hydrostatic

Final drive 2 helical gearreduction to planetary output

Ratio 62:1

TRANSMISSION COOLING

Type Oil to water

Core size 431 in2 (0.28 m2)

HYDRAULIC SYSTEMStandard equipment pump

Pump flow @ 2000 rpm@ 3000 psi (209 kPA) 20.3 gpm

(76.8 L/min)

Max. system pressure 3025+75 psi(20 855+515 kPA)

CYLINDERS

Lift cylinder (2)

Bore diameter 3.50 in (89 mm)

Rod diameter 1.75 in (44.5 mm)

Stroke 15.5 in (394 mm)

Angle cylinder (2)

Bore diameter 3.50 in (89 mm)

Rod diameter 1.75 in (44.5 mm)

Stroke 15.5 in (394 mm)

Tilt cylinder (1)

Bore diameter 3.50 in (89 mm)

Rod diameter 1.75 in (44.5 mm)

Stroke 5.80 in (144 mm)

UNDERCARRIAGE

Track adjustment Hydraulic

Frame Rigid suspension

Length of track on ground 93 in (2352 mm)

Track link pitch 6.73 in (171 mm)

Track shoe height 2.06 in (52 mm)

Pin diameter 1.32 in (33 mm)

Bushing diameter –

CLT track 2.24 in (57 mm)

CELT track 3.0 in (76 mm)

Bolt diameter 0.625 in (16 mm)

Track shoes per side 40

Track rollers per side 7

Carrier rollers per side 1

Track roller rail dia. 7.48 in (190 mm)

TRACK ON GROUND

Shoe Area – in2 (cm2)

18 in (457 mm) 3334 (21 510)

20 in (508 mm) 3704 (23 897)

24 in (610 mm) 4449 (28 703)

28 in (711 mm) 5186 (33 458)

TRACK

Extra Long Track

18 in (457 mm) closed grousers and CLT

18 in (457 mm) open grousers and CELT

20 in (645 mm) closed grousers and CLT

20 in (645 mm) open grousers and CELT

Wide Track

18 in (457 mm) closed grousers and CLT

18 in (457 mm) open grousers and CELT

20 in (645 mm) closed grousers and CLT

20 in (645 mm) open grousers and CELT

24 in (610 mm) closed grousers and CLT

24 in (610 mm) open grousers and CELT

LGP

28 in (711 mm) closed grousers and CLT

28 in (711 mm) open grousers and CELT

XLT/WT/LGPCRAWLER DOZERTIER III CERTIFIED850L

Page 1 of 4

OPERATOR ENVIRONMENT

ROPS canopy

Single lever control for speed, steeringand direction

Forward/reverse speed ratio selector

Adjustable armrests

Foot rests

Retractable seat belt, 2 in (51 mm)

Vinyl suspension seat w/back adjustment

Tool storage

Headliner

Floormat

Mirror

INSTRUMENTATION

Warning lights:

Air filter

Alternator

Diagnostic fault indicator

Engine coolant temperature

Engine oil pressure

Hydraulic filter

Low fuel level

Park brake engaged

Service soon indicator

Transmission filter

Transmission pressure

Transmission temperature

Gauges:

Battery voltage

Fuel level

Digital hourmeter/tachometer/diagnostic/service reminder

Transmission oil temperature

Transmission speed indicator

Water temperature

Audible warnings:

Engine coolant temperature

Engine oil pressure

Low fuel level

Transmission pressure

Temperature/hydraulic temperature

BLADE

Variable blade pitch 52° forward60° rearward

Lift speed (per second) 18 in (457 mm)

Cutting edge Reversible andreplaceable

Width 8.0 in (203 mm)

Thickness 0.75 in (19 mm)

RIPPER

Max. penetration 14 in (356 mm)

Width 72.4 in (1839 mm)

Cut width 70.1 in (1780 mm)

Max. ground clearance 17.3 in(439 mm)

Points Replaceable

Max. number of shanks 5

Tooth spacing –

with 5 teeth 17.8 in (452 mm)

with 3 teeth 34 in (864 mm)

Hydraulic cylinder (double-acting)

Diameter 3.25 in (82.6 mm)

Stroke 8.4 in (213 mm)

Rod 1.75 in (44.5 mm)

SERVICE CAPACITIES

Fuel tank 50 gal (189.3 L)

Engine oil w/filter 16.7 qt (15.8 L)

Engine oil w/o filter 15.8 qt (15 L)

Engine cooling system 28 qt (26.5 L)

Hydraulic reservoir 20 gal (75.7 L)

Final drive (per side) 15 qt (14.2 L)

Track rollers (ea.) 0.26 qt (0.25 L)

Front idlers (ea.) 0.52 qt (0.49 L)

Carrier rollers (ea.) 0.25 qt (0.24 L)

OPERATING WEIGHTS

Unit equipped with ROPS, full fuel tank, 170 lb(77 kg) operator, drawbar, side shield, trackguides, backup alarm, horn and lights.

Long Track 19,600 lb (8900 kg)

Wide Track 20,200 lb (9181 kg)

LGP 20,700 lb (9402 kg)

Add-on weights –

Drawbar 85 lb (38 kg)

Ripper (3 shank) 1,400 lb (646 kg)

Winch 1,200 lb (545 kg)

Front counterweight 880 lb (399 kg)

Cab 930 lb (422 kg)

ROPS heater 71 lb (32 kg)

CELT chain 115 lb (52 kg)

Center rockguard 234 lb (106 kg)

Sweeps 104 lb (47 kg)

Dual batteries 64 lb (29 kg)

850L Page 2 of 4

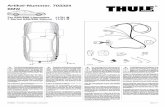

DIMENSIONS

Long Track (XLT) Wide Track (WT) Low Ground Pressure (LGP)

BLADES

Blade width 104 in (2642 mm) 110 in (2794 mm) 110 in (2794 mm) 120 in (3048 mm) 124 in (3150 mm) 130 in (3302 mm)

SAE blade capacity 2.16 yd3 (1.65 m3) 2.32 yd3 (1.77 m3) 2.32 yd3 (1.77 m3) 2.52 yd3 (1.93 m3) 2.60 yd3 (1.99 m3) 2.73 yd3 (2.09 m3)

A. Blade lift above ground 34.4 in (874 mm) 34.4 in (874 mm) 34.4 in (874 mm) 34.4 in (874 mm) 34.4 in (874 mm) 34.4 in (874 mm)

B. Blade depth below ground 19 in (483 mm) 19 in (483 mm) 19 in (483 mm) 19 in (483 mm) 19 in (483 mm) 19 in (483 mm)

Blade angle both directions 25° 25° 25° 25° 25° 25°

Blade tilt, each end (up to 8.3°) 15 in (381 mm) 15.9 in (404 mm) 15.9 in (404 mm) 17.3 in (439 mm) 17.9 in (455 mm) 18.8 in (478 mm)

C. Blade height 36 in (914 mm) 36 in (914 mm) 36 in (914 mm) 36 in (914 mm) 36 in (914 mm) 36 in (914 mm)

D. Cast reach 13.7 in (348 mm) 16.4 in (417 mm) 9.4 in (239 mm) 13.9 in (353 mm) 13.8 in (351 mm) 16.4 in (417 mm)

E. Cut reach 0.7 in (18 mm) 3.5 in (86 mm) -3.6 in (-91 mm) 0.9 in (23 mm) 0.8 in (20 mm) 3.4 in (86 mm)

TRACKS

Track gauge 62 in (1.57 m) 62 in (1.57 m) 70 in (1.78 m) 70 in (1.78 m) 70 in (1.78 m) 70 in (1.78 m)

Shoe width 20 in (508 mm) 20 in (508 mm) 24 in (610 mm) 24 in (610 mm) 28 in (711 mm) 28 in (711 mm)

F. Track on ground 93 in (2.35 m) 93 in (2.35 m) 93 in (2.35 m) 93 in (2.35 m) 93 in (2.35 m) 93 in (2.35 m)

Area of track on ground 3704 in2 (2.38 m2) 3704 in2 (2.38 m2) 4449 in2 (2.87 m2) 4449 in2 (2.87 m2) 5186 in2 (3.34 m2) 5186 in2 (3.34 m2)

Ground pressure 5.3 psi (40.1 kPa) 5.3 psi (40.1 kPa) 4.5 psi (31.3 kPa) 4.5 psi (31.3 kPa) 4.0 psi (27.6 kPa) 4.0 psi (27.6 kPa)

DIMENSIONS

G. Height to top of ROPS 109.2 in (2773 mm) 109.2 in (2773 mm) 109.2 in (2773 mm) 109.2 in (2773 mm) 109.2 in (2773 mm) 109.2 in (2773 mm)

Height to top of cab 109.2 in (2773 mm) 109.2 in (2773 mm) 109.2 in (2773 mm) 109.2 in (2773 mm) 109.2 in (2773 mm) 109.2 in (2773 mm)

with air conditioning 109.8 in (2788 mm) 109.8 in (2788 mm) 109.8 in (2788 mm) 109.8 in (2788 mm) 109.8 in (2788 mm) 109.8 in (2788 mm)

H. Ground clearance w/drawbar 14.9 in (379 mm) 14.9 in (379 mm) 14.9 in (379 mm) 14.9 in (379 mm) 14.9 in (379 mm) 14.9 in (379 mm)

I. Length –

Blade straight with drawbar 174 in (4408 mm) 174 in (4408 mm) 174 in (4408 mm) 174 in (4408 mm) 174 in (4408 mm) 174 in (4408 mm)

Blade straight with ripper 206 in (5233 mm) 206 in (5233 mm) 206 in (5233 mm) 206 in (5233 mm) 206 in (5233 mm) 206 in (5233 mm)

J. Width –

Blade straight 104 in (2642 mm) 110 in (2794 mm) 110 in (2794 mm) 120 in (3048 mm) 124 in (3150 mm) 130 in (3301 mm)

Blade angled 96 in (2446 mm) 102 in (2585 mm) 102 in (2585 mm) 111 in (2815 mm) 114 in (2907 mm) 120 in (3043 mm)

K. Over track 80 in (2032 mm) 80 in (2032 mm) 94 in (2388 mm) 94 in (2388 mm) 98 in (2489 mm) 98 in (2489 mm)

AC

D E

KJ

BF

H

G

I

850L Page 3 of 4

STANDARD EQUIPMENT

OPERATOR’S COMPARTMENT

Isolation mounted ROPS/FOPS canopy withheadliner and floormat

Vinyl suspension seat w/back adjustment &adjustable armrests

Retractable seat belt, 2 in (51 mm)

Foot rests

ENGINE

Case 667TA/E66

Automatic fan belt tensioner

Integral engine oil cooling

Fuel filter

Dual element radial seal air cleaner

90 amp alternator

700 CCA 12-volt battery

Anti-sandblast radiator

Engine side panels

Anti-freeze to -34°F

Pusher fan

POWERTRAIN

Dual path infinitely variable, single-lever con-trolled hydrostatic drive with electronic straighttracking, power turns & counter-rotatation,4-position forward/reverse ratio control

Final drive – Triple reduction – helical gear/planetary. decelerator with hydrostatic driveretardation

Automatic spring applied hydraulic releaseparking brake

BLADE

52° - 60° variable pitch with integraladjustment tool

Single lever control for blade lift, angle and tilt

UNDERCARRIAGE

Easy clean track covers

Hydraulic track adjusters

Case Lubricated Track Chain

Permanently lubricated track and carrier rollers

Track adjuster guard

Track guides (front and rear)

Shock resistance idler mounting

OTHER

Backup alarm

Horn

Anti-vandalism package

Mirror

Pre-cleaner

Operator’s manual enclosure

Master disconnect switch

Front pull hook

Hand throttle

Decelerator

Final drive seal guard

O-ring face seal hydraulic fittings

Vertical spin-on hydraulic & fuel filters

Hinged grill with tether

Tool storage area

OPTIONAL EQUIPMENT

OPERATOR’S COMPARTMENT

Cab (w/heater, 25,598 BTU (7.5 kW)/hr air con-ditioner, defroster, front windshield washer and2F-1R lights)

3 in (76 mm) seat belt

Deluxe air suspension seat

HYDRAULICS

4 spool hydraulic valve for field-installed ripper

REAR MOUNTED EQUIPMENT

Ripper, parallelogram 5 slot with 3 shanks

BLADES

104 in (2.6 m) or 110 in (2.8 m) XLT w/18 in(457 mm) shoes

110 in (2.6 m) or 120 in (3.0 m) WT w/24 in(610 mm) shoe

124 in (3.2 m) or 130 in (3.3 m) LGP w/28 in(711 mm) shoes

GUARDS

Sweeps

Center rockguard

SCREENS

Rear ROPS and cab

Side ROPS

Radiator brush

OTHER

Lights – halogen, 4 front, 2 rear for cab or ROPS

Counterweight, front

Retrieval hitch

Drawbar

Special paint

Case Extended Life Track

Cold start aid and dual batteries

Turbo precleaner

Winch drive

Form No. CCE1190521R Printed in U.S.A. © 2008 CNH America LLC Replaces form no. CCE1190521 All Rights Reserved

NOTE: All specifications are stated in accordance with SAE Standards or Recommended Practices, where applicable.NOTE: All engines meet current EPA emissions requirements.IMPORTANT: Case Construction Inc. reserves the right to change these specifications without noticeand without incurring any obligation relating to such change. Case Construction Inc. does not warrantthe safety or reliability of attachments from other manufacturers.Case is a registered trademark of CNH America LLC. Any trademarks referred to herein, in association with goodsand/or services of companies other than CNH America LLC, are the property of those respective companies.

www.casece.com

L SERIES CRAWLER DOZERS750L I 850L

L SERIES CRAWLER DOZERS750L I 850L

Climb in and feel the power. For site prep or fi nish grading, road-and-bridge, residential or commercial work, Case 750L and 850L crawler dozers have the power to get the job done. Whether you need stability to work on steep slopes or extra power to carry your load through a turn, Case dozers deliver. And they do it with exceptional control and maneuverability.

Like all Case equipment, these dozers are industry leaders when it comes to serviceability. They’re also top of the line in terms of operator comfort. What that means for your business is more time—productive time—running the machine and less time maintaining it. And that delivers more money to the bottom line.

More powerTier 3-certifi ed engines on the 750L and 850L produce 84 and 96 net horsepower, respectively. That’s enough muscle to move any material around the job site. The Case PowerStat hydrostatic drivetrain delivers greater drawbar pull at all travel speeds for more push power and productivity.

The combination of 10 speed settings with infi nitely variable steering provides maximum maneuverability with counter rotation. A variable-displacement dual-path hydrostatic drive delivers plenty of pulling power.

Easy operationSingle-lever speed control provides adjustable steering for easy, precise operation. By tilting the control right or left, operators can slow the track on either side to turn the machine. This maintains power to both tracks, letting you push a full load through a turn without braking or raising the blade.

Operators can also adjust the sensitivity of the steering and the forward/reverse modulation to suit personal preference or conditions. These easy-to-operate controls boost productivity in any application, making the 750L and 850L ideal for residential, commercial or road-and-bridge work.

750L LGP750L LT 750L WT

3

850L XLT 850L WT 850L LGP

L SERIES CRAWLER DOZERS750L I 850L

4

Tier 3-certifi ed engineThe Case 750L and 850L crawler dozers are powered by turbocharged Tier 3-certifi ed, fuel-effi cient Case Family IV engines. The 4.5-liter and 6.7-liter engines deliver 84 and 96 net horsepower respectively and provide clean-burning power and plenty of torque to move more material per hour.

Exclusive hydrostatic drive Operation is easy with single-lever control of speed and direction. Combine that with the Case-exclusive PowerStat hydrostatic drive, and you have the power and control you need to push the fullest blades of material, even through curves and turns.

Undercarriage durability Based on the conditions you’re most likely to encounter, you can choose from Case Lubricated Track (CLT) or Case Extended Life Track (CELT) for optimum undercarriage performance. Regardless of which you select, you’ll fi nd that the triple-reduction, high-capacity fi nal drive with helical-cut gears makes the 750L and 850L among the quietest dozers in their size class.

Track optionsThe 750L and 850L are available in long track (LT), wide track (WT) and low ground pressure (LGP) versions to match operating conditions. The 850L also comes in extra long track (XLT). Both dozers feature a 49-degree sloping track frame cover and ample space between track and machine to keep the undercarriage free of dirt and debris.

Adjustable blade pitchThe built-in pitch-adjustment tool makes it easy to set the blade pitch to match soil conditions, with a range from 52 degrees forward to 60 degrees rearward.

L SERIES CRAWLER DOZERS750L I 850L

5

Easy-access tilt cabThe hydraulic, easy-tilt operator platform gives you access to the drivetrain in less than 10 minutes.

Attachment optionsSeveral attachment options are available, including specialty blades, rippers, drawbars, winches and more.

Low operating heightThe height of the ROPS is only 109 inches on both the 750L and 850L, making these machines ideal for residential construction projects. The low overall operating height also makes them easier to transport

More uptimeEasy maintenance keeps your machine in top shape. Quick-access diagnostic test ports are standard on these crawler dozers. Swing-out service panels and spin-on fi lters reduce maintenance time, too.

Quieter, comfortable cabCase dozers feature one of the quietest cabs in the industry. Conveniently placed, easy-to-operate controls and an optional air-ride seat help keep the operator comfortable throughout the day. Heat and air conditioning are standard cab features.

L SERIES CRAWLER DOZERS750L I 850L

L SERIES CRAWLER DOZERS750L I 850L

Wide-open visibility and unbeatable comfortThe fi rst thing you’ll notice on the Case 750L and 850L is how easy it is to get into the cab with the wide doors. Once you’re sitting in the optional air suspension seat, you can adjust the seat and controls to your liking.

Your visibility is clear to the blade and the entire job site. The high-capacity heater and air-conditioning will handle the toughest temperatures. This environment helps operators be more productive.

Easy maintenance means more uptime Case designed these crawler dozers, like all Case machines, to be easy to maintain. We know that the easier it is to service and maintain equipment, the more likely it gets done. And that translates into uptime.

Ease of maintenance starts with eye-level fl uid sight gauges and ground-line access to key service checkpoints. These include coolant and hydraulic system gauges and quick-access diagnostic ports. An auto belt tensioner, swing-out service panels and spin-on fi lters also speed up routine maintenance.

Service access on Case dozers is second to none. With the hydraulic, easy-tilt operator platform, access to the drivetrain takes less than 10 minutes.

The bottom line is that these machines are engineered for easy daily maintenance and routine service. That increases uptime and lowers ownership costs.

X7

You can count on CaseYou can count on Case and your Case dealer for full-service solutions—productive equipment, expert advice, fl exible fi nancing, genuine Case parts andfast service. We’re here to provide you with the ultimate ownership experience. Case prideYou can take pride in the Case name on your machine. It’s backed by morethan a century of productivity and performance. Case and your Case dealerare here for you, not only when you buy the machine, but also after you put1,000 or 10,000 hours on it. A rich, proud historyCase Construction Equipment’s heritage spans more than 165 years. Growingfrom J.I. Case’s innovations with steam-powered machinery in the late 1800s,Case developed road-building equipment that helped create early 20th centurystreets and highways across the world. By 1912, Case was well on its way toestablishing itself as a full-line equipment manufacturer. The company continued to expand its construction equipment business over the years. Celebrating a tradition of innovation In 1957, Case produced the world’s fi rst integrated loader/backhoe made andwarranted by one manufacturer. Over the decades and into the 21st century,Case has continued to develop a long line of industry fi rsts and has taken aleadership role in pioneering new products and solutions. Today, Case produces15 lines of equipment and more than 90 models to meet your toughestconstruction challenges. Supported by manufacturing and sales in more than150 countries, Case serves the needs of our customers worldwide. Coast-to-coast customer supportIn North America, Case equipment is sold and serviced by more than 375 dealerlocations. No matter where you work, we’re here to support and protectyour investment and exceed your expectations. To locate a Case dealer or learn more about Case equipment or customerservice, go to www.casece.com or call 1-866-54CASE6. It all adds up. You can count on Case.

L SERIES CRAWLER DOZERS

850L XLT WT LGPEngine 96 net hp (72 kW) 96 net hp (72 kW) 96 net hp (72 kW)

Operating weight 19,600 lb (8900 kg) 20,200 lb (9181 kg) 20,700 lb (9402 kg)

Blade capacity 104 in (2.6 m) blade 2.2 cu yd (1.7 cu m)

110 in (2.8 m) blade 2.3 cu yd (1.8 cu m)

124 in (3.1 m) blade 2.6 cu yd (2.0 cu m)

Track on ground 93 in (2.4 m) 93 in (2.4 m) 93 in (2.4 m)

Biodiesel B5 or B20* B5 or B20* B5 or B20*

750L LT WT LGPEngine 84 net hp (63 kW) 84 net hp (63 kW) 84 net hp (63 kW)

Operating weight 18,900 lb (8569 kg) 19,700 lb (8955 kg) 20,200 lb (9163 kg)

Blade capacity 104 in (2.6 m) blade2.2 cu yd (1.7 cu m)

110 in (2.8 m) blade2.3 cu yd (1.8 cu m)

124 in (3.1 m) blade2.6 cu yd (2.0 cu m)

Track on ground 89 in (2.3 m) 89 in (2.3 m) 89 in (2.3 m)

Biodiesel B5 or B20* B5 or B20* B5 or B20*

750L

850L

Looking for product specs, customer testimonials, competitive comparisons, fi nance offers and more? Visit us at www.casece.com or call 866-54CASE6

NOTE: All engines meet current EPA emission regulations.

NOTE: All specifi cations are stated in accordance with SAE standards or recommended practices, where applicable.

IMPORTANT: Case Construction Equipment Inc. reserves the right to change these specifi cations without notice and without incurring any obligation relating to such change. Availability of some models and equipment builds vary according to the country in which the equipment is used. The illustrations and text may include optional equipment and accessories and may not include all standard equipment. Your Case dealer/distributor will be able to give you details of the products and their specifi cations available in your area.

©2009 CNH America LLC. All rights reserved. Case is a registered trademark of CNH America LLC. Any trademarks referred to herein, in association with goods and/or services of companies other than CNH America LLC, are the property of those respective companies. Printed in U.S.A.

Always read the operator’s manual before operating any equipment. Inspect equipment before using it, and be sure it is operating properly. Follow the product safety signs and use any safety features provided.

Form No. CCE200911750L Replaces: CCE12030701

Contains 10% post-consumer fi ber

Case construction equipment is biodiesel friendly.

* B20 approved following Case guidelines for biodiesel blends above fi ve percent. See your Case dealer for details.

![General Catalogue · A-4 PLP TECHNICAL DATA NOMINAL SIZE SIZE 05 Geometric displacement according to UNI-ISO 3662 (cm3/r) [in3/r] í ò ì U õ ó ò Actual displacement (cm3/r) [in3/r]](https://static.fdocuments.in/doc/165x107/60622d1114327a1025116053/general-catalogue-a-4-plp-technical-data-nominal-size-size-05-geometric-displacement.jpg)

![Eatonpub/@eaton/@hyd/... · Eaton® Medium Duty Piston Pump Parts Information August, 1995 Model 70142 / 70144, 20.3 cm3/r [1.24 in3/r] Displacement and 70145, 23.6 cm3/r [1.44 in3/r]](https://static.fdocuments.in/doc/165x107/60f6ae474c5e651b9c1b22b4/eaton-pubeatonhyd-eaton-medium-duty-piston-pump-parts-information-august.jpg)