Cranes

Transcript of Cranes

CRANES

April 8, 2023 1Er. Satya Narayan Shah

CRANESAny of a diverse group of machines that lift and move heavy objects. Cranes differ from hoists, elevators, and other devices intended for vertical lifting, and from conveyors, which continuously lift or carry bulk materials such as grain or coal. Cranes have been widely used only since the introduction of steam engines, internal-combustion engines, and electric motors in the 19th century. They range in type and function from the largest derrick cranes to small, mobile truck cranes. Most derrick cranes can lift 5 – 250 tons. Floating cranes, built on barges for constructing bridges or salvaging sunken objects, may be able to lift 3,000 tons (2,700 metric-tons). Small truck cranes are mounted on heavy, modified trucks; they make up in mobility and ease of transport what they lack in hoisting capacity.

April 8, 2023 2Er. Satya Narayan Shah

Typical Cranes

April 8, 2023 3Er. Satya Narayan Shah

PULLEYS

April 8, 2023 4Er. Satya Narayan Shah

PULLEYA pulley, is a mechanism composed of a wheel on an axle or shaft that may have a groove between two flanges around its circumference. A rope, cable, belt, or chain usually runs over the wheel and inside the groove, if present. Pulleys are used to change the direction of an applied force, transmit rotational motion, or realize a mechanical advantage in either a linear or rotational system of motion. Two or more pulleys together are called a block and tackle.April 8, 2023 5Er. Satya Narayan Shah

PULLEY

• Fixed A fixed or class 1 pulley has a fixed axle. That is, the axle is "fixed" or anchored in place. A fixed pulley is used to change the direction of the force on a rope (called a belt). A fixed pulley has a mechanical advantage of 1. A mechanical advantage of one means that the force is equal on both sides of the pulley and there is no multiplication of force.

April 8, 2023 6Er. Satya Narayan Shah

PULLEY

Movable A movable or class 2 pulley has a free axle. That is, the axle is "free" to move in space. A movable pulley is used to multiply forces. A movable pulley has a mechanical advantage of 2. That is, if one end of the rope is anchored, pulling on the other end of the rope will apply a doubled force to the object attached to the pulley.

April 8, 2023 7Er. Satya Narayan Shah

PULLEY

• Compound A compound pulley is a combination of a fixed and a movable pulley system.

• Block and tackle - A block and tackle is a compound pulley where several pulleys are mounted on each axle, further increasing the mechanical advantage. Block and tackles usually lift objects with a mechanical advantage greater than 2.

April 8, 2023 8Er. Satya Narayan Shah

PULLEYS

April 8, 2023 9Er. Satya Narayan Shah

WINCH

A winch is a mechanical device that is used to pull in (wind up) or let out (wind out) or otherwise adjust the "tension" of a rope or wire rope (also called "cable" or "wire cable"). In its simplest form it consists of a spool and attached hand crank. In larger forms, winches stand at the heart of machines as diverse as tow trucks, steam shovels and elevators. The spool can also be called the winch drum. More elaborate designs have gear assemblies and can be powered by electric, hydraulic, pneumatic or internal combustion drives. Some may include a solenoid brake and/or a mechanical brake or ratchet and pawl device that prevents it from unwinding unless the pawl is retracted.April 8, 2023 10Er. Satya Narayan Shah

Hydraulic SystemY

April 8, 2023 11Er. Satya Narayan Shah

Hydraulic Pump & Motor

April 8, 2023 Er. Satya Narayan Shah 12

April 8, 2023 Er. Satya Narayan Shah 13

Hydraulic System

April 8, 2023 14Er. Satya Narayan Shah

Typical Hydraulic Circuit

April 8, 2023 Er. Satya Narayan Shah 15

CRANES

• The word crane is taken from the fact that these machines have a shape similar to that of the tall, long-necked bird of the same name.

• A crane is a machine that is capable of raising and lowering heavy objects and moving them horizontally.

• Cranes are distinguished from hoists, which can lift objects but that cannot move them sideways.

• Cranes are also distinguished from conveyors, that lift and move bulk materials, such as grain and coal, in a continuous process.

April 8, 2023 16Er. Satya Narayan Shah

CRANESHuman beings have used a wide variety of devices to lift heavy objects since ancient times. One of the earliest versions of the crane to be developed was the shaduf, first used to move water in Egypt about four thousand years ago. The shaduf consists of a long, pivoting beam balanced on a vertical support. A heavy weight is attached to one end of the beam and a bucket to the other. The user pulls the bucket down to the water supply, fills it, then allows the weight to pull the bucket up. The beam is then rotated to the desired position and the bucket is emptied. The shaduf is still used in rural areas of Egypt and India.

April 8, 2023 17Er. Satya Narayan Shah

CRANES

• As early as the first century, cranes were powered by human beings or animals operating a treadmill or large wheel.

• Consisted of a long wooden beam, known as a boom, connected to a rotating base. The wheel or treadmill powered a drum, around which a rope was wound. The rope was connected to a pulley at the top of the boom and to a hook that lifted the weight.

April 8, 2023 18Er. Satya Narayan Shah

Mechanical principlesGeneral

There are two major considerations in the design of cranes.1.The crane must be able to lift a load of a specified weight.2.The crane must remain stable and not topple over when the load is lifted and moved to another location

April 8, 2023 19Er. Satya Narayan Shah

Mechanical principlesStability

• the sum of all moments about any point such as the base of the crane must equate to zero.

• the magnitude of load that is permitted to be lifted ("rated load”) is some value less than the load that will cause the crane to tip (providing a safety margin).

• stability-limited rated load for a crawler crane is 75% of the tipping load; limited rated load for a mobile crane supported on outriggers is 85% of the tipping load. -established by the American Society of Mechanical Engineers ,ASME B30.5-2007 Mobile and Locomotive Cranes.

April 8, 2023 20Er. Satya Narayan Shah

Mechanical principlesStability

• Standards for cranes mounted on ships or offshore platforms are somewhat more strict because of the dynamic load on the crane due to vessel motion. Additionally, the stability of the vessel or platform must be considered.

• For stationary pedestal or kingpost mounted cranes, the moment created by the boom, jib, and load is resisted by the pedestal base or kingpost. Stress within the base must be less than the yield stress of the material or the crane will fail.

April 8, 2023 Er. Satya Narayan Shah 21

Mechanical principlesLifting capacity

• Lever- a horizontal beam (the lever) pivoted about a point called the fulcrum to achieve optimum mechanical advantage.

• Pulley- A jib crane contains fixed pulley block. another block attached to the load.

• hydraulic cylinder- used directly to lift the load or indirectly to move the jib or beam that carries another lifting device.

April 8, 2023 22Er. Satya Narayan Shah

TYPES OF CRANESMobile

• Truck-mounted crane• Side lift crane• Rough terrain crane• All terrain crane• Crawler crane• Railroad crane• Floating crane• Aerial crane

April 8, 2023 23Er. Satya Narayan Shah

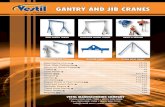

TYPES OF CRANESFixed

Tower crane Self-erecting crane

Telescopic crane Hammerhead crane

Level luffing crane Gantry crane

Overhead crane Deck crane

Jib crane Bulk-handling crane

Loader crane

April 8, 2023 24Er. Satya Narayan Shah

Truck-mounted crane

• truck carrier provides the mobility for this type of crane.

• able to travel on highways• When working on the jobsite, outriggers are extended

horizontally from the chassis to provide more stability.

• Most cranes of this type also have moving counterweights for stabilization beyond that provided by the outriggers

• Truck cranes range in lifting capacity from about 10 tons to about 1300 tons.April 8, 2023 25Er. Satya Narayan Shah

Sidelift crane

• A sidelifter crane is a road-going truck or semi-trailer, able to hoist and transport ISO standard containers. Container lift is done with parallel crane-like hoists, which can lift a container from the ground or from a railway vehicle.

April 8, 2023 26Er. Satya Narayan Shah

Rough terrain crane

These telescopic cranes are single-engine machines, with the same engine powering the undercarriage and the crane, similar to a crawler crane. In a rough terrain crane, the engine is usually mounted in the undercarriage rather than in the upper, as with crawler crane.April 8, 2023 27Er. Satya Narayan Shah

All terrain crane

A mobile crane with the necessary equipment to travel at speed on public roads, and on rough terrain at the job site using all-wheel and crab steering. Combine the roadability of Truck-mounted Cranes and the maneuverability of Rough Terrain Cranes.

April 8, 2023 28Er. Satya Narayan Shah

Crawler crane

• crane mounted on an undercarriage with a set of tracks (also called crawlers) that provide stability and mobility

• lifting capacity from about 40 tons to 3500 tons• stable on its tracks with no outriggers• capable of traveling with a load• main disadvantage is that they are very heavy,

and cannot easily be moved from one job site to another without significant expense

April 8, 2023 29Er. Satya Narayan Shah

Railroad crane

• crane mounted on a railroad car• used for maintenance work, recovery

operations and freight loading in goods yards

April 8, 2023 30Er. Satya Narayan Shah

Floating crane

• mounted on a pontoon or barges• used mainly in bridge building and port

construction• loading and unloading of especially heavy or

awkward loads on and off ships• lifting capacity exceeding 10,000 tons

April 8, 2023 31Er. Satya Narayan Shah

Aerial crane

• 'Sky cranes' usually are helicopters designed to lift large loads

• Helicopters are able to travel to and lift in areas that are difficult to reach by conventional cranes

• most commonly used to lift units/loads onto shopping centers and high-rises

• Can be used to lift cars, boats, swimming pools, etc• disaster relief after natural disasters for clean-up, and

during wild-fires they are able to carry huge buckets of water to extinguish fires.

April 8, 2023 32Er. Satya Narayan Shah

Tower crane• Tower crane is a modern form of balance crane. Fixed to the ground

(and sometimes attached to the sides of structures as well), tower cranes often give the best combination of height and lifting capacity and are used in the construction of tall buildings.

• The jib (boom) and counter-jib are mounted to the turntable, where the slewing bearing and slewing machinery are located. The counter-jib carries a counterweight, usually of concrete blocks, while the jib suspends the load from the trolley. The Hoist motor and transmissions are located on the mechanical deck on the counter-jib, while the trolley motor is located on the jib. The crane operator either sits in a cabin at the top of the tower or controls the crane by radio remote control from the ground. The lifting hook is operated by using electric motors to manipulate wire rope cables through a system of sheaves.

April 8, 2023 33Er. Satya Narayan Shah

Tower crane• In order to hook and unhook the loads, the operator

usually works in conjunction with a signaller (known as a 'rigger' or 'swamper'). They are most often in radio contact, and always use hand signals. The rigger directs the schedule of lifts for the crane, and is responsible for the safety of the rigging and loads.

• A tower crane is usually assembled by a telescopic jib (mobile) crane of greater reach and in the case of tower cranes that have risen while constructing very tall skyscrapers, a smaller crane (or derrick) will often be lifted to the roof of the completed tower to dismantle the tower crane afterwards.

April 8, 2023 34Er. Satya Narayan Shah

Tower crane

Generally two arrangements of Tower cranes •Top-slewing (fixed tower) tower cranes have fixed towers and a swing circle mounted at the top, allowing only the jib, tower top, and operator cabin to rotate.•Bottom slewing (slewing tower) tower cranes have the swing circle located at the base, and both the tower and jib assembly rotate relative to the base.April 8, 2023 Er. Satya Narayan Shah 35

Selection of Tower Crane• bottom-slewing cranes are suitable mainly for

shorter-term service of low-rise buildings. Fast erection.

• top-slewing cranes serve high-rise building on jobs requiring a crane for a long duration. Slow erection.

• They are selected when – Site conditions are restrictive.– Lift height and reach are great.– There is no need for mobility

April 8, 2023 Er. Satya Narayan Shah 36

Self-erecting crane

Generally a type of tower crane, these cranes, also called self-assembling or "Kangaroo" cranes, lift themselves off the ground using jacks, allowing the next section of the tower to be inserted at ground level or lifted into place by the partially erected crane itself. They can thus be assembled without outside help, or can grow together with the building or structure they are erecting.

April 8, 2023 37Er. Satya Narayan Shah

Telescopic crane

A telescopic crane has a boom that consists of a number of tubes fitted one inside the other. A hydraulic or other powered mechanism extends or retracts the tubes to increase or decrease the total length of the boom. These types of booms are often used for short term construction projects, rescue jobs, lifting boats in and out of the water, etc. The relative compactness of telescopic booms make them adaptable for many mobile applications.

April 8, 2023 38Er. Satya Narayan Shah

Hammerhead crane

The "hammerhead", or giant cantilever, crane is a fixed-jib crane consisting of a steel-braced tower on which revolves a large, horizontal, double cantilever; the forward part of this cantilever or jib carries the lifting trolley, the jib is extended backwards in order to form a support for the machinery and counter-balancing weight. In addition to the motions of lifting and revolving, there is provided a so-called "racking" motion, by which the lifting trolley, with the load suspended, can be moved in and out along the jib without altering the level of the load. These cranes are generally constructed in large sizes, up to 350 tons.

April 8, 2023 39Er. Satya Narayan Shah

Level luffing crane

• Normally a crane with a hinged jib will tend to have its hook also move up and down as the jib moves (or luffs). A level luffing crane is a crane of this common design, but with an extra mechanism to keep the hook level when luffing.

April 8, 2023 40Er. Satya Narayan Shah

Gantry crane

A gantry crane has a hoist in a fixed machinery house or on a trolley that runs horizontally along rails, usually fitted on a single beam (mono-girder) or two beams (twin-girder). The crane frame is supported on a gantry system with equalized beams and wheels that run on the gantry rail, usually perpendicular to the trolley travel direction. These cranes come in all sizes, and some can move very heavy loads, particularly the extremely large examples used in shipyards or industrial installations. A special version is the container crane (or "Portainer" crane, named by the first manufacturer), designed for loading and unloading ship-borne containers at a port.

April 8, 2023 41Er. Satya Narayan Shah

Overhead crane

• Also known as a 'suspended crane', this type of crane work very similar to a gantry crane but instead of the whole crane moving, only the hoist / trolley assembly moves in one direction along one or two fixed beams, often mounted along the side walls or on elevated columns in the assembly area of factory. Some of these cranes can lift very heavy loads.

April 8, 2023 42Er. Satya Narayan Shah

Deck crane

Located on the ships and boats, these are used for cargo operations or boat unloading and retrieval where no shore unloading facilities are available. Most are diesel-hydraulic or electric-hydraulic.

April 8, 2023 43Er. Satya Narayan Shah

Jib crane

A jib crane is a type of crane where a horizontal member (jib or boom), supporting a moveable hoist, is fixed to a wall or to a floor-mounted pillar. Jib cranes are used in industrial premises and on military vehicles. The jib may swing through an arc, to give additional lateral movement, or be fixed. Similar cranes, often known simply as hoists, were fitted on the top floor of warehouse buildings to enable goods to be lifted to all floors.

April 8, 2023 44Er. Satya Narayan Shah

Bulk-handling crane

Bulk-handling cranes are designed from the outset to carry a shell grab or bucket, rather than using a hook and a sling. They are used for bulk cargoes, such as coal, minerals, scrap metal etc.

April 8, 2023 45Er. Satya Narayan Shah

Loader crane

A loader crane (also called a knuckle-boom crane or articulating crane ) is a hydraulically-powered articulated arm fitted to a truck or trailer, and is used for loading/unloading the vehicle. The numerous jointed sections can be folded into a small space when the crane is not in use. One or more of the sections may be telescopic.

April 8, 2023 46Er. Satya Narayan Shah

Major Components of Crane• Winch -a winder (also called a wire rope drum)• wire ropes or chains, that can be used both to lift

and lower materials and to move them horizontally.

• simple machines Pulleys to create mechanical advantage and thus move loads beyond the normal capability of a human.

• Carrier- truck, crawler, barge, rail mounted carrier etc.

April 8, 2023 47Er. Satya Narayan Shah

Major Components of Crane• Boom - The large arm mainly responsible for lifting • Counterweights - Multi-ton weights placed on the back of the cab

to prevent the crane from tipping during lifts • Two-gear pump - Hydraulic pump system that uses two rotating

gears to pressurize oil • Jib - Lattice structure that extends out of the boom • Outriggers - Supports that keep the crane balanced • Rotex gear - Large gear under the cab that allows the boom to be

rotated • Load Moment Indicator - Array of lights located in the cab just

above the operator's eye level; flashes if crane's lifting limits are reached

April 8, 2023 48Er. Satya Narayan Shah

Outriggers

April 8, 2023 49Er. Satya Narayan Shah

Rotex gear

April 8, 2023 Er. Satya Narayan Shah 50

Load Moment Indicator

April 8, 2023 51Er. Satya Narayan Shah

Boom & JIB

April 8, 2023 52Er. Satya Narayan Shah

Cabin & Weight

Cockpit

Weight to keep the rope taut

April 8, 2023 53Er. Satya Narayan Shah

Major Components of Crane

April 8, 2023 Er. Satya Narayan Shah 54

RIGGINGA crane is designed to pick (or lift) a load through the use of a hoisting mechanism using ropes. The load must be properly attached to the crane by a rigging system. To properly attach the load, it is necessary to determine the forces that will affect the job, and then to select and arrange the equipment that will move the load safely.

April 8, 2023 Er. Satya Narayan Shah 55

ILLUSTRATIONS ATTACHED WITH HANDOUTS

Important Parameters For Lifting• Weight: correctly determine the load. • Center of Gravity : The center of gravity of an object is that location where the

object will balance when lifted. A load that is slung above and through the center of gravity will be in equilibrium. It will not tend to slide out of the hitch or become unstable.

• Stresses: it must be remembered that all forces must be in equilibrium. The angle sling leg makes with the load is important factor which determine the stress in the sling. The angle should not be less (10°), it should be around 45°.

• Factor of safety: This factor is defined as the usual breaking strength of the material divided by the allowable load weight. This factor is normally taken between 5 and 10.

• SLINGS: The safety and efficiency of a lift depend on the working attachments that secure the load to the crane hook. may be wire rope, chain, or nylon-web straps. When using a slingGenerally called slings, these working attachments to lift, remember that the capacity of the sling depends on its material and size, the configuration in which it’s used, its type of end terminals, and the angle that the legs make with the load.

April 8, 2023 Er. Satya Narayan Shah 56

QUESTION PLEASE

April 8, 2023 Er. Satya Narayan Shah 57

THANK YOU ALL

Satya Narayan ShahB.Sc. In Mechanical Engineering (India)MS in Manufacturing Engineering & Management (UK)

April 8, 2023 58Er. Satya Narayan Shah

Contact: [email protected]