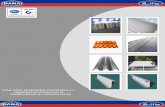

Corus Panels Profiles Systems

-

Upload

miruna-breniuc -

Category

Documents

-

view

276 -

download

6

Transcript of Corus Panels Profiles Systems

System Selector

Corus Panels and Profiles

April 2006

Cl/Sfb

UniclassL5221:P4

EPICE111:X4

(4-) Rh

Corus Colorcoat® Products and Services

CP&PR&W09:5000:UK:4/2006

www.coruspanelsandprofiles.co.uk

Care has been taken to ensure that thisinformation is accurate, but Corus Group Plc,including its subsidiaries, does not acceptresponsibility or liability for errors orinformation which is found to be misleading.

Suggestions for, or descriptions of, the enduse or application of products or methods ofworking are for information only and CorusUK Limited and its subsidiaries accept noliability thereof. Before using productssupplied or manufactured by Corus UK Ltdand its subsidiaries the customer shouldsatisfy themselves of their suitability.

Armacor, Celestia, Colorcoat, ColorcoatConnection, Confidex, Guardian, HPS200,Prisma, Repertoire, Trimapanel and Trisometare registered trademarks of Corus.

Copyright 2006Corus

Designed by Plum Design & Advertising

Corus Panels and ProfilesSevern DriveTewkesbury Business ParkTewkesburyGL20 8TXTel: +44 (0) 1684 856600Fax: +44 (0) 1684 856601E-mail: [email protected]: technical@coruspanelsandprofiles.co.ukwww.coruspanelsandprofiles.co.uk

18 E4 - Hybrid acoustic system

20 W1 - Built up wallwith trapezoidal profiles

22 W2 - Trimapanel compositewall panel system

4 R1 - Built up roofwith trapezoidal profiles

6 R2 - Built up roofwith secret fix profiles

8 R3 - Superdeck membranefaced composite panel system

10 R4 - Trisomet roof tile system

12 E1 - Trisomet composite panel system

14 E2 - Trinsul system

16 E3 - Built up acoustic system

24 W3 - Guardian rockfibrecomposite panel system

26 W4 - Façade system

28 S1 - Structural metal roofdecking

30 S2 - Structural liner tray system

32 Refurbishment solutions

34 Flashings

40 Platinum Partnership System Warranty

42 Corus in construction overview

43 Overview of technical services

Contentspage page

System Selector 3

Platinum Services Contents

Corus Panels and Profiles have a wealth of experience gained over 40 years manufacturing cladding materials for the construction industry.

We are uniquely placed to provide the construction market with anextensive range of products which, combined with newly introducedproduct placement software, offer a wide choice of Platinum warranteed cladding systems.

Platinum Services

One product does not fit all. Corus Panels

and Profiles live and breathe cladding, and have

used their considerable expertise to offer a wide

range of tried and tested roof and wall cladding

system packages. These mix and match systems

enable the architect to create a more visually

inspiring structure while they take care of the

technical details.

The Corus Panels and Profiles offer is therefore

quite simple, with an extensive range of products

and a choice of systems, you benefit from pre-

designed systems suitable for most applications

which can be covered by a free Platinum warranty.

Choice in design, choice in aesthetics,

choice in performance.

For an easier approach to your envelope

solution just call 01684 856600

2 System Selector

36 Corus Colorcoat®

products and services

38 Profile selector

Systems for roof application

Systems for wall application

Systems for wall application cont.

Structural systems

Systems for roof or wall applicationGeneral Information

System Selector 54 System Selector

Built up roof with trapezoidal profiles Built up roof with trapezoidal profiles

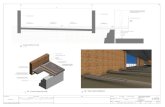

System R1-Built up roof with trapezoidal profiles A non-combustible built up roofing system, which offers designflexibility and a wide choice of profile options.

5.5mm steel fastenerswith 19mm washers

External skin

Instalocspacer system

Purlin

Liner profile

Mineral fibreinsulation

Low to high pitch lightweight insulated roofs. Especially suited to large commercialand industrial buildings.

Trapezoidal liner panel, with Instaloc bracket and bar spacer system, mineral fibre insulation, and trapezoidal outer sheet.

Non-combustible insulation to BS476 Part 6.

Provides typical sound reduction of 41 dB, higher values achievable depending on build up specification.

0.25 W/m2K will be achieved by a typical system depth of 170 mmOther U values can be achieved to a level of 0.18 W/m2K.

Extensive outer profile range, see profile selector (P36) Liner profile to suit.Outer profiles available in Corus Colorcoat HPS200®, Colorcoat Prisma®, Colorcoat Armacor® or aluminium.Liner profiles in bright white lining enamel.

Up to 4 metres depending on profile selection and load conditions.

System width: 700mm to 1067mm (depending on profile).Maximum system length: 22m (depending on profile and transport).

Stainless steel self drilling screws with sealing washers. Coated carbon steel screws can be used where a lower life expectancy is acceptable.

Site assembled Polycarbonate or GRP.

4º minimum.

Please see “Roof and Wall - Site assembled systems” brochure.

Purpose

System description

Fire performance

Acoustic performance

U Value

System options

Span capability

Dimensions

Fastening system

Rooflights

Roof pitch

Further information

Benefits

• With a built up roof, low and varied U values can be accommodated; U values can be engineered tocomply with 2006 Part L2.

• Increasing insulation thickness does not imposesignificant weight increase.

• Low material cost.

• All components are readily recycled.

• Standard built up systems provide good soundreduction characteristics.

• Flexibility of specification. There is a wide choice of outer profiles, liners, insulation, coating types and metal types.

• The roof can be rapidly lined out to provide a dryworking area underneath.

• The system allows flexibility of design.

• Simple replacements.

• Mineral fibre has good fire properties and isinexpensive and light.

• Most profiles are nestable, light and easy to handle.

• Extra vapour control layers and breather membranescan be incorporated into built up systems.

• Instaloc spacer systems are designed to reduce coldbridging.

• Factory curving available.

Project: Del Monte Unit, Team Valley, Tyneside. System: Built up roof.

Built up roof with secret fix profiles Built up roof with secret fix profiles

System Selector 76 System Selector

System R2-Built up roof with secret fix profiles A low pitch, secret fix, built up roofing system which is non-combustibleand offers long spans when used over our structural decks.

5.5mm steel fastenerswith 19mm washers

External skin

Instaloc

spacer system

Purlin Mineral fibreinsulation

Benefits

• Secret fix profiles have no fixings penetrating theweathering sheet.

• Very low pitches (minimum 11/2º) are possible.

• With a built up roof, low and varied U values can be accommodated; U values can be engineered tocomply with 2006 Part L2.

• Increasing insulation thickness does not impose asignificant weight increase.

• The roof can be rapidly lined out to provide a dryworking area underneath.

• Mineral fibre has good fire properties and isinexpensive and light.

• Standard built up systems provide good soundreduction characteristics.

• The system allows flexibility of design.

• Most profiles are nestable, light and easy to handle.

• Extra vapour control layers and breather membranescan be incorporated into built up systems.

• Instaloc spacer systems are designed to reduce cold bridging.

• Low material cost.

• All components are readily recycled.

• Secret fix roofing has the benefit of aesthetic appealas it resembles traditional standing seam roofing.

• Built up systems can be specified with perforatedliners to provide acoustic absorbency for noise-generating environments.

• Factory curving available.

Project: Space Decks, Chard. System: ALU-SEAM®.

Purpose Especially suited to very low pitch roofs where the attractive traditional aesthetic appeal of metal standing seam is required.

System description Trapezoidal liner panel or structural roof deck, with Instaloc bracket and bar spacer system, mineral fibre insulation roll, and secret fix outer sheet.

Fire performance Non-combustible insulation to BS476 Part 6.

Acoustic performance Provides typical sound reduction of 43 dB, higher value achievable depending on build up specification. When used with perforated liner the system provides sound absorption in the order of 0.25-0.35 at 500Hz, depending on build up specification.

U value 0.25 W/m2K will be achieved by a typical system depth of 170 mmOther U values can be achieved to a level of 0.18 W/m2K.

System options Outer profile: Seam-loc® or ALU-SEAM®

Seam-loc® in Corus Colorcoat HPS200®, Colorcoat Prisma®, Colorcoat Armacor®.ALU-SEAM

® in coated, plain or stucco embossed aluminium.Liner or deck profiles in bright white lining enamel.

Span capability With liner panel up to 2 metres depending on profile and load conditions. With structural deck up to 8 metres depending on deck specification and load conditions.

Dimensions System width: 410mm (outer profile).Maximum length: 30m.

Fastening systems Outer sheet is retained by galvanised steel clips (Seam-loc® only) or extruded aluminium clips.Stainless steel self-drilling screws with sealing washers. Coated carbon steel screws can be used where a lower life expectancy is acceptable. (Not suitable with aluminium)

Rooflights Factory made insulated rooflights.

Roof pitch 11/2º minimum.

Further information Please see “Roof and Wall - Site assembled systems” brochure.

Liner profile

Benefits

• Standard deck fixing and Rubberfuse single layermembrane fixing techniques.

• Standing seam appearance is available as a separate application.

• HCFC and CFC free foam.

• Closed cell foam and bonded construction makes thepanel ideal for high humidity situations.

• The panels are made in a factory controlledenvironment making the system less dependent onsite conditions during installation.

• Cold bridging is eliminated.

• Must be installed by an approved contractor.

• Composite panel convenience with the benefit of fullywelded waterproof junctions and interfaces.

• LPCB approved.

• Air Permeability ratings greatly exceed requirementsof current building regulations.

Superdeck Superdeck

System Selector 98 System Selector

System R3-Superdeckmembrane faced composite panel systemAn LPCB approved PIR foam composite panel providing onecomponent solution for flat roofing applications.

Purlin Rubberfusemembrane

PIR(HCFC free)

insulant

1000/32mm profile Joint - heat welded

Project: Alexandera Works. System: Superdeck.

Purpose Flat, lightweight insulated roofs providing speed and simplicity of construction.

System description Trapezoidal profiled metal structural lining skin, PIR insulation core and Rubberfuse TPO singleply membrane external skin. (Laps to be site welded)

Fire performance LPCB approved.

Acoustic performance Provides typical sound reduction of 29 dB.

U value 0.25 W/m2K will be achieved by a typical system depth of 80mm.

System options External membrane: High performance synthetic polyolefin TPO 1.2mm thick.Internal profile: Trapezoidal (32/1000)Internal profile available in Corus Colorcoat HPS200®, Colorcoat Prisma®, Colorcoat Armacor®, Bright white lining enamel.

Span capability Up to 2.75 metres depending on load conditions.

Dimensions System width: 1000mm.System lengths: 3000mm up to 12000mm.System thickness: 80mm (plus profile).

Fastening systems Stainless steel self-drilling screws with sealing washers. Coated carbon steel screws can be used where a lower life expectancy is acceptable.

Rooflights Factory made insulated rooflights.

Roof pitch 1.8º.

Further information Please contact us for specific details.

Benefits

• The Trisomet roof tile system is very quick to install.

• The building can be quickly weatherproofed to allowinternal fitting out to proceed well before slating ortiling is complete.

• The composite panels comprise an insulated airtightconstruction, suitable for all types of modern building.

• From the outside the roof has the appearance oftraditional tiles.

• From the inside the composite panels present a cleanwhite finish without the need for roof trusses.

• All the air space under the roof lining is warm and thespace is usable.

• When finished, the system provides a two layerdefence against rain penetration.

• The panel's new steel interlocking robust joint gives 1 hour fire resistance.

• The interlocking angled joint compresses tightly togive excellent resistance to air permeability.

• HCFC and CFC free.

• Panels are made in a factory controlled environmentmaking the system less dependent on site conditionsduring installation.

• Closed cell foam and bonded construction makes thepanel ideal for high humidity situations.

• Cold bridging is virtually eliminated.

• The system’s interlocking liner joint gives flushinternal finish with no shadow line or ‘sag’.

Trisomet roof tile system Trisomet roof tile system

System Selector 1110 System Selector

System R4-Trisomet roof tile system

A fast track composite roof system providing an insulatedconstruction with the appearance of traditional tiles.

Trisomet compositepanel

Top hat section

Protile roofing system.(Alternatively tiles orslates can be used)

PIR (HCFC free)insulant

Purlin

Purpose Provides fast track weatherproofing to a building and a traditional tiled appearance.

System description Steel top hats supporting protile fixed to Trisomet composite panel, comprising trapezoidal profiledmetal outer skin, autohesively bonded insulated PIR core, micro-plank profiled metal lining skin.

Acoustic performance Provides typical sound reduction of 36 dB.

U value 0.25 W/m2K will be achieved by typical system depth of 80 mm.

System options Outer profile: Protile or traditional tiles or slatesInternal profile: Smooth bright white polyester, internal face planked.

Span capability Up to 4 metres depending on load conditions.

Dimensions System width: 1000mm.System length: 6000mm maximum.System thickness: 40mm, 60mm, 80mm.

Fastening systems Stainless steel self-drilling screws with sealing washers. Coated carbon steel screws can be used where a lower life expectancy is acceptable.

Rooflights Factory made insulated rooflights.

Roof pitch 4˚ minimum.

Further information Please see “Roof and wall composite panels” brochure.

Benefits

• The Trisomet panel's steel interlocking robust jointgives 1 hour fire resistance.

• The panel carries approval by the LPCB and FM forboth roof and wall applications.

• The interlocking angled joint compresses tightly togive excellent resistance to air permeability.

• Cold bridging is virtually eliminated.

• Trisomet is HCFC and CFC free, complying with Kyoto protocol.

• Closed cell foam and bonded construction makes thepanel ideal for high humidity situations.

• Trisomet is fast to fix with the complete claddingsystem installed in one go. No additional supportsteelwork is needed for ridge flashings.

• Panels are made in a factory controlled environment,making the system less dependent on site conditionsduring installation.

• Installation cost is low due to the simplicity and speed of installation.

• No side lap sealant is required for Trisomet, whichreduces cost, time and labour.

• The system’s interlocking liner joint gives flushinternal finish with no shadow line or ‘sag’.

Trisomet Trisomet

System Selector 1312 System Selector

System E1-Trisomet composite panel system

A PIR foam composite roof and wall system providing fasttrack insulated construction, with LPCB and FM approval.

Fixings

External skin

Inner lining sheet

Purlin

PIR (HCFC free)insulant

Project: Blessed George Napier School. System: Trisomet®. Product: Colorcoat HPS200® in Hamlet.

Purpose Lightweight insulated panel for roof and wall applications.

System description Trapezoidal profiled metal outer skin, autohesively bonded PIR insulated core, micro-plank profiled metal lining skin.

Fire performance FM and LPCB approval. 1 Hour fire resistence tested to BS476 Part 22 & BSEN13.

Acoustic performance Provides typical sound reduction of 29 dB.

U value 0.25 W/m2K will be achieved by a typical system depth of 80 mm.

System options Outer profile: Corus Colorcoat Armacor®, Colorcoat HPS200®, Colorcoat Prisma®, external face profiled 1000/32.Internal Profile: Smooth bright white polyester, internal face planked.

Span capability Up to 4 metres depending on load conditions.

Dimensions System width: 1000mm.System length: 6000mm maximum.System thickness: 40mm, 60mm, 80mm, 100mm.

Fastening systems Stainless steel self-drilling screws with sealing washers. Coated carbon steel screws can be used where a lower life expectancy is acceptable.

Rooflights Factory assembled triple or double skin Polycarbonate or GRP.

Roof pitch 4˚ minimum.

Further information Please see “Roof and wall composite panels” brochure.

Benefits

• Rockfibre Trinsul offers superb fire properties.

• Design freedom with a choice of outer profiles, metal and coating types.

• Cold bridging is virtually eliminated.

• Trinsul provides good sound reductioncharacteristics.

• Seam-loc secret fix roofing and WP40 flat plank wall cladding can be specified as an alternative to trapezoidal cladding.

• Simple replacements.

• Trinsul can be specified with perforated liners toprovide acoustic absorbency for noise generatingenvironments.

• Most profiles are nestable, light and easy to handle.

• All components are readily recycled.

Trinsul Trinsul

System E2 -Trinsul system

System Selector 1514 System Selector

Site assembled composite roof and wall cladding, providing a fire ratedconstruction with the benefits of both built up systems and compositepanels.

External skinPurlinLiner profile Rock fibreinsulation

Purpose Insulated roof and wall cladding, suitable for all commercial and industrial buildings, especially where stringent fire safety standards are a requirement.

System description Trapezoidal liner panel, with rock fibre insulation profiled to match the inner and outer sheet. Outer sheet is offered in options of WP40 plank, secret fix or trapezoidal profiles.

Fire performance FM and LPCB approval. 1 Hour fire resistence tested to BS476 Part 22 & BSEN13.

Acoustic performance Provides typical sound reduction up to 36 dB, higher values achievable depending on build up specification. When used with perforated liner this system provides sound absorption in the order of 0.25-0.35 at 500Hz, depending on build up specification.

U value 0.25 W/m2K will be achieved by typical system depth of 145 mm.Other U values can be achieved to a level of 0.18 W/m2K.

System options Extensive outer profile range, see profile selector (P36)Liner profile to suit.Outer profiles available in Corus Colorcoat HPS200®, Colorcoat Prisma®, Colorcoat Armacor®

or aluminium. Liner profiles in bright white lining enamel.

Span capability Up to 3 metres depending on profile selection and load conditions.

Dimensions System width: 300mm to 1067mm.Maximum system length: 30m (depending on profile and transport).

Fastening systems Stainless steel self-drilling screws with sealing washers. Coated carbon steel screws can be used where a lower life expectancy is acceptable.

Rooflights Site assembled Polycarbonate or GRP.

Roof pitch 11/2º minimum for secret fix or 4º for trapezoidal roof profiles.

Further information Please contact us for specific details.

Project: The Enigma Building, Milton Keynes System: Built up wall with CH47

Built up Acoustic system Built up Acoustic system

System E3-Built up acoustic system

Built up acoustic roof and wall system with rock fibre non-combustibleinsulation, providing acoustic sound reduction and noise absorption.

System Selector 1716 System Selector

Benefits

• Low and varied U values can be accommodated; U values can be engineered to comply with 2006 Part L2.

• Increasing insulation thickness does not imposesignificant weight increase.

• Low material cost.

• The acoustic roof and wall systems provide excellentacoustic properties both for sound reduction andnoise absorption.

• The system provides architectural design freedom,offering vertical or horizontal profiles, feature bands,fascia panels and a great range of colours andfinishes.

• All components are readily recycled.

• Simple replacements.

• Rockfibre has good fire properties and is inexpensive and light.

• The system allows flexibility of design.

• Most profiles are nestable, light and easy to handle.

• Instaloc spacer systems are designed to reduce cold bridging.

External skinMineral fibre

insulation 25mm slab

Instaloc spacer system

Perforated liner profile

Top hat spacer100mm strip

Vapourcontrol layer

Mineral fibre quilt

Purpose Thermally and acoustically insulated roof and wall system for providing acoustic damping within the building.

System description Trapezoidal perforated liner panel, top hat spacer, rockfibre insulation slab, vapour control layer with Instaloc bracket and bar spacer system, rock fibre quilt and trapezoidal outer sheet.

Fire performance Non-combustible insulation to BS476 Part 6.

Acoustic performance Provides typical sound reduction of 30 dB for roof and 27dB for wall, depending on build up specification. When used with a perforated liner this system provides sound absorption in the order of 0.25-0.35 at 500Hz, depending on build up specification.

U value Wall: 0.35 W/m2K will be achieved by typical system depth of 185 mmRoof: 0.25 W/m2K will be typically achieved by typical system depth of 235 mmOther U values can be achieved to a level of 0.18 W/m2K.

System options Extensive outer profile range, see profile selector (P36) Liner profile to suit, LP1000, RL32/1000Outer profiles available in Corus Colorcoat HPS200®, Colorcoat Prisma®, Colorcoat Armacor®

or aluminium. Liner profiles in bright white lining enamel.

Span capability Up to 4.0 metres depending on profile selection and load conditions.

Dimensions System width: 300mm to 1067mm (depending on profile).Maximum system length: 22m (depending on profile and transport).

Fastening systems Stainless steel self-drilling screws with sealing washers. Coated carbon steel screws can be used where a lower life expectancy is acceptable.

Further information Please see “Roof and Wall - Site assembled systems” brochure.

Hybrid acoustic system Hybrid acoustic system

System E4-Hybrid acoustic system

System Selector 1918 System Selector

A combination of a built up system and a PIR Trisomet compositepanel to provide a simple roof and wall system for sound reductionand absorption.

5.5mm steel fastenerswith 19mm washers

Trisomet outer panel

Benefits

• The hybrid acoustic system offers good soundabsorption, whilst using the Trisomet composite panelto give a simple system without the need for a vapourcontrol layer.

• With a built up roof, low and varied U values can be accommodated; U values can be engineered tocomply with 2006 Part L2.

• The Trisomet panel's steel interlocking robust jointgives 1 hour fire resistance.

• The panel carries approval by the LPCB and FM forboth roof and wall applications.

• The interlocking angled joint compresses tightly togive excellent resistance to air permeability.

• Closed cell foam and bonded construction makes thepanel ideal for high humidity situations.

• Trisomet is fast to fix with the complete claddingsystem installed in one go. No additional supportsteelwork is needed for ridge flashings.

• Panels are made in a quality controlled factory,making the system less dependent on site conditionsduring installation.

• Trisomet is HCFC and CFC free, complying with theKyoto protocol.

• Installation cost is low due to the simplicity and speed of installation.

• No side lap sealant is required for Trisomet, whichreduces cost, time and labour.

• Cold bridging is virtually eliminated.

Perforated

liner profile

PurlinInstaloc

spacer system

Mineral fibre

insulation

Project: Project Zenith. System: Built up wall with WP40, Trisomet roof.

Purpose Thermally and acoustically insulated roof and wall system providing simple construction solutions for acoustic damping within the building

System description Perforated metal lining panel, Instaloc bracket and bar spacer system with insulation and Trisomet composite panel outer.

Fire performance Firewall construction to BS 476 Part 22, providing up to 4 hours integrity and 30 minutes insulation.

Acoustic performance Provides typical sound reduction of 31 dB for roof and 30dB for wall, higher value achievable depending on build up specification. This system provides sound absorption in the order of 0.8 at 500Hz.

U value Wall: 0.35 W/m2K will be achieved by a typical system depth of 100 mm

Roof: 0.25 W/m2K will be achieved by a typical system depth of 120 mm

Other U values can be achieved to a level of 0.18 W/m2K.

System options Outer profile: Corus Colorcoat Armacor®, Colorcoat HPS200®, Colorcoat Prisma®, external face profiled 1000/32.Liner profile to suit, liner profiles in bright white lining enamel, perforated or plain.Mineral wool quilt and Instaloc spacer system to specification.

Span capability Up to 4 metres depending on profile selection and load conditions.

Dimensions System width: 1000mm.

System length: 6000mm maximum.

System thickness: 40mm, 60mm, 80mm, 100mm.

Fastening systems Stainless steel self-drilling screws with sealing washers.

Coated carbon steel screws can be used where a lower life expectancy is acceptable.

Roof pitch 4º minimum.

Further information Please contact us for specific details.

Built up wall with trapezoidal profiles Built up wall with trapezoidal profiles

System W1-Built up wall with trapezoidal profiles A non-combustible built up wall cladding system, which offers designflexibility and a wide choice of profile options.

External skinInstaloc

spacer system

Purlin

Liner profile Mineral fibre

Purpose Lightweight insulated walls, especially suited to commercial and industrial buildings. Profiles may run vertically or horizontally for different architectural effects.

System description Trapezoidal liner panel, with Instaloc bracket and bar spacer system, mineral fibre insulation,and trapezoidal outer sheet.

Fire performance Non-combustible insulation to BS476 Part 6.Firewall construction to BS 476 Part 22, providing up to 4 hours integrity and 30 minutes insulation – depending on specification.

Acoustic performance Provides typical sound reduction of 37 dB, higher values achievable depending on build up specification.

U value 0.35 W/m2K will be achieved by typical system depth of 120 mmOther U values can be achieved to a level of 0.18 W/m2K.

System options Extensive outer profile range, see profile selector (P36).Liner profile to suit.Outer profiles available in Corus Colorcoat HPS200®, Colorcoat Prisma®, Colorcoat Armacor® or aluminium. Liner profiles in bright white lining enamel.

Span capability Up to 4 metres depending on profile selection and load conditions.

Dimensions System width: 300mm to 1067mm (depending on profile).

Maximum system length: 22m (depending on profile and transport).

Fastening systems Stainless steel self-drilling screws with sealing washers. Coated carbon steel screws can be used where a lower life expectancy is acceptable.

Further information Please see “Roof and Wall - Site assembled systems” brochure.

System Selector 2120 System Selector

Benefits

• Low and varied U values can be accommodated; U values can be engineered to comply with 2006 Part L2.

• All components are readily recycled.

• The system allows flexibility of design.

• Standard built up systems provide good soundreduction characteristics.

• Built up wall systems provide architectural designfreedom, offering vertical or horizontal profiles,feature bands, and fascia panels.

• Flexibility of specification. There is a wide choice ofouter profiles, liners, insulation, coating types andmetal types.

• All our fire walls are extensively tested at WarringtonFire Research Centre, giving guaranteed performance,quality and compliance.

• Low material cost.

• Mineral fibre has good fire properties and isinexpensive and light.

• Simple replacements.

• Most profiles are nestable, light and easy to handle.

• Increasing insulation thickness does not imposesignificant weight increase

• Instaloc spacer systems are designed to reduce cold bridging.

Project: Beaver Distribution Ltd., Dublin. System: Built up wall with CH47.

Benefits

• Architecturally aesthetic.

• The interlocking joint compresses tightly to giveexcellent resistance to air permeability.

• Cold bridging is virtually eliminated.

• The panel carries approval by the LPCB and FM.

• HCFC and CFC free, complying with Kyoto protocol.

• Mechanically fixed top hat inserts to accommodatethermal cycles.

• The panels are made in a factory controlledenvironment making the system less dependent onsite conditions during installation.

• Installation cost is low due to the simplicity andspeed of installation.

• The system’s interlocking liner joint gives a flushinternal finish with no shadow line.

• Closed cell foam and bonded construction makes thepanel ideal for high humidity situations.

• Choice is given to the designer to use secret fix orthrough fix panels.

Trimapanel composite wall panel system Trimapanel composite wall panel system

System Selector 2322 System Selector

System W2-Trimapanel composite wall panel system

A PIR composite wall system providing reliable insulated wallconstruction, with flat appearance and LPCB and FM approval.

Project: Eco-Factory, Baglan Bay. System: Trimapanel®. Product: Colorcoat Celestia® in Aquarius.

Continuous highperformance sealant

strip 9 x 3mm

Self adhesiveperimeter

gasket

Insulationinfill

Primary fastener

Top hat closure

PIR (HCFC Free)

insulant

Externalskin

Purpose To provide fast track insulated construction with a flat appearance.

System description Microrib external skin, autohesively bonded PIR insulated core, micro-plank profiled metal lining skin.

Fire performance LPCB and FM approved.

Acoustic performance Provides typical sound reduction of 30dB.

U value 0.35 W/m2K will be achieved by typical system depth of 70 mm

Other U values can be achieved to a level of 0.25 W/m2K.

System options Outer profile: Corus Colorcoat Armacor®, Colorcoat HPS200®, Colorcoat Prisma®, external face micro-rib.Internal profile: Smooth bright white polyester, internal face planked.

Span capability Up to 4 metres depending on load conditions.

Dimensions System standard width 1000mm (non standard 600mm or 900mm).System length up to 10000mm.System thickness: 70mm, 90mm.

Fastening systems Stainless steel self-drilling screws with sealing washers. Coated carbon steel screws can be used where a lower life expectancy is acceptable. Fixings are concealed in the Trimapanel.

Further information Please see “Roof and Wall - Site assembled systems” brochure.

Guardian rockfibre composite panel system Guardian rockfibre composite panel system

System W3-Guardian rockfibre composite panel system

An LPCB approved, non-combustible rockfibre cored composite wallsystem providing an insulated construction with a flat appearance.

Continuous highperformance sealant

strip 9 x 3mm

Self adhesiveperimeter gasket

Primaryfastener

Top hat closure

Rockfibreinsulation core

Externalskin

System Selector 2524 System Selector

Benefits

• The non-combustible Guardian panels can be used ascompartment walls and tight to boundaries.

• Architecturally aesthetic.

• The panel is approved to LPCB Grade A and iscertified to a high level of fire resistance.

• HCFC and CFC free.

• Core material properties are inherent to good fireperformance.

• Panels are made in a factory controlled environment,making the system less dependent on site conditionsduring installation.

• Cold bridging is virtually eliminated.

• Choice is given to the designer to use secret fix orthrough fix panels.

Project: Studwelders HQ, Chepstow. System: Guardian®*. Product: Colorcoat Celestia® in Sirius.

Purpose To provide fast track non-combustible construction with a flat appearance.

System description Microrib external skin, rock fibre insulating core, micro-plank profiled metal lining skin.

Fire performance Non-combustible insulation to BS476 Part 6. Firewall construction to BS 476 Part 22, providing up to 90 minutes integrity and up to 90 minutes insulation.Grade A LPCB approval LPS 1181.

U value 0.35 W/m2K will be achieved by typical system depth of 120 mmOther U values can be achieved to a level of 0.3 W/m2K.

System options Outer profile: Corus Colorcoat Armacor®, Colorcoat HPS200®, Colorcoat Prisma®, external face micro-rib or planked.Internal profile: Smooth bright white polyester, internal face planked.

Span capability Up to 6 metres depending on load conditions.

Dimensions Guardian Secret Fix (SF) panel standard width 1000mm (non standard 600 or 900mm).Guardian Through Fix (TF) panel standard width 1150mm (non standard 1000mm).Panel length up to 9000mm. Panel thickness: to suit U value as above.

Fastening systems Stainless steel self-drilling screws with sealing washers. Coated carbon steel screws can be used where a lower life expectancy is acceptable. Fixings are concealed in the Guardian SF panel.

Further information Please see “Roof and wall composite panels” brochure.

Façade system Façade system

System W4-Façade system

System Selector 2726 System Selector

A flat composite façade panel system with recessed edges offering a choice of bespoke wall solutions.

Inner metal flatpre-finished liner

15mm flush foamedEPDM - black,horizontal and

vertical

Hidden stainlesssteel self-drilling

screws withsealing washers.

Fully bondedcore

External face withrecessed edges

Project: The City Inn, Glasgow. System: Façade system. Product: Colorcoat Celestia® in Orion.

Benefits

• The system is designed with flush gasketed jointsboth horizontally and vertically.

• The designer has freedom over panel size and corematerial, providing a bespoke solution.

• Flexibility to incorporate louvres and windows.

• Rainscreen option with honeycomb aluminium coreavailable.

• The panels are offered in a wide range of pre and post-finished options and a choice of metal types.

• Façade panels are manufactured with flat, smoothexternal faces.

• Product properties can be varied according to thecore selected, for instance non-combustible andacoustic solutions.

Purpose Flat panel architectural façades for high specification buildings.

System description Pre-finished metal outer flat panel with recessed edges, fully bonded insulation core, inner metal flat pre-finished liner.

Fire performance When used with mineral wool insulation: Non-combustible insulation to BS476 Part 6.

U value Variety of U values available. Depends on specification - bespoke product.

System options Wide range of external pre finished steel options including: Colorcoat HPS200®, Colorcoat Celestia®, Colorcoat Prisma®, Corus Colorcoat Armacor®. External face material options: steel, aluminium, stainless steel.Wide range of internal finishes including: Smooth bright white polyester, and all of the above.15mm flush gasket foamed EPDM - black, horizontal and vertical.

Dimensions System length up to 4000mm. System width up to 1100mm. System thickness: to suit U value.

Fastening systems Hidden stainless steel self-drilling screws with sealing washers.

Further information Please see “Façade systems” brochure.

Claddingrail

Structural metal roof decking Structural metal roof decking

System S1-Structural metal roof decking

System Selector 2928 System Selector

A structural metal deck system capable of large spans to support slabinsulation and external membrane providing a flat insulated roof.

Optional vapourcontrol layer

Metal decking Rigid insulationboard

External weatherproofmembrane

Benefits

• Contemporary roofs using structural metal deckingand membranes, installed by approved contractors,providing a “flat” roof solution.

• Profiled decks provide long spanning capability toreduce secondary supports.

• Light-weight construction, reducing the load on thebuilding structure.

• Roof decking may be used to restrain the top flangeof support beams.

• Diaphragm design is provided free of charge by CorusPanels and Profiles. This can eliminate in plane roofbracing for a more visually pleasing and less costly design.

• Structural roof decks can be specified with perforatedwebs, to provide acoustic absorbency for noisegenerating environments.

• Waterproof joints can be made for laps and upstands.Complex roofs and roof openings, therefore, do notpresent a problem.

• The roof can be rapidly decked out to provide a dry working area underneath.

• Low and varied U values can be accommodated; U values can be engineered to comply with 2006 Part L2.

• Being the largest UK manufacturer of roof decksoffers greater flexibility to the customer.

Project: The Trafford Centre, Manchester. System: Structural roof decking.

Purpose Long spanning, flat, lightweight, insulated roofs. Suited to roofs with any complexity of shape.

System description Profiled metal decking panel, rigid insulation board and membrane weatherproof outer.

Acoustic performance Provides typical sound reduction of 45 dB, higher value achievable depending on build up specification.

U value 0.25 W/m2K will be achieved by typical system depth of 80 mm.

Other U values can be achieved to a level of 0.1 W/m2K.

System options Extensive structural deck range, see profile selector (P36).Deck profiles are available in bright white lining enamel, plain galvanised steel, Corus Colorcoat HPS200®, or aluminium. Membrane and insulation specification is to choice.

Span capability Up to 9.5 metres depending on profile selection and load conditions.

Dimensions Panel width: 1000mm.Panel length: 3000mm up to 12000mm.Panel thickness: to suit U value.

Fastening systems Stainless steel self-drilling screws with sealing washers. Coated carbon steel screws can be used where a lower life expectancy is acceptable.

Rooflights Factory made insulated rooflights.

Roof pitch 0º.

Further information Please see “Roof decking profile selector” brochure.

Structural liner tray system Structural liner tray system

System S2-Structural liner tray system

System Selector 3130 System Selector

A complete self-supporting roof and wall system, that spansbetween the main frames of a building, providing a flatinternal finish.

Mineral woolinsulation roll

Trisomet composite panel

Structural liner tray

Benefits

• Structural liner tray removes the requirement forpurlins or rails.

• The tray is clean and flat internally, giving a neat and hygienic finish.

• Increasing insulation thickness does not impose a significant weight increase.

• All components are readily recycled.

• The roof can be rapidly lined out to provide a dry working area underneath.

• Low and varied U values can be accommodated; U values can be engineered to comply with 2006 Part L2.

• Liner tray systems provide good sound reductioncharacteristics.

• System can be specified with perforated liners toprovide acoustic absorbency for noise generatingenvironments.

• A number of fire and acoustic options are offered.

• Diaphragm design is provided free of charge by Corus Panels & Profiles. This can eliminate in planeroof bracing for a more visually pleasing and lesscostly design.

Project: Neath Port Tabot Hospital, Baglan, Port Talbot. System: Structural Liner Tray with Trisomet.

Purpose Self-supporting insulated roof and wall system with flat internal surface. Especially suited to commercial and industrial buildings with a hygienic internal requirement.

System description Structural liner tray, with Instaloc bracket and bar spacer system, mineral fibre insulation, and Trisomet composite panel.

Fire performance Non combustible insulation to BS476 Part 6. LPCB approved and complies with FM.

Acoustic performance Provides sound reduction up to 46 dB, depending on build up specification.

U value 0.25 W/m2K will be achieved by typical system depth of 190 mm

Other U values can be achieved to a level of 0.18 W/m2K.

System options Outer profile: Trisomet composite panel available in Corus Colorcoat HPS200®, Colorcoat Prisma®, Colorcoat Armacor®.Structural liner tray in bright white organic coating.

Span capability Up to 6 metres depending on tray thickness and load conditions.

Dimensions System width: 600mm.Maximum system length: 30m.System thickness: 170mm to 230mm.

Fastening systems Stainless steel self-drilling screws with sealing washers. Coated carbon steel screws can be used where a lower life expectancy is acceptable.

Roof pitch 4º.

Further information Please contact us for specific details.

Systems Selector 33

Refurbishment Solution Systems

32 Systems Selector

Refurbishment Solution Systems

Standardised systems are not always appropriate, especially when itcomes to refurbishment projects. Each one is different and requiresthe specific attention that Corus Refurbishment Solutions can bring.We offer a number of bespoke refurbishment solution systems for anytype of refurbishment project.

Refurbishment Solution Systems

• Corus Refurbishment Solutions will offer the optimumsolution for clients. No particular type of product,contractor or system is preferred.

• An experienced team with both on-site and technicalexpertise will provide a well engineered refurbishmentdesign.

• The time consuming processes necessary for any projectare taken away from the client, without taking awaycontrol.

• We can develop solutions that will eliminate or minimisedisruption to business operations.

• Platinum Warranty is offered on all Corus RefurbishmentSolutions projects.

• Overcladding and flat to pitch roof systems are just twoof the refurbishment systems we offer. Contact us for fulldetails of all our solutions.

Overcladding for roof & wall systemOver cladding is the most effective and the simplest way to

transform the aesthetic image of any building.

Suitable for over roofing failing pitched roofs of any material.

The old roofing is retained for use as a liner. A new vapour

protection layer may be added if the old roof cannot be

adequately sealed.

Alternatively the existing roof covering may be removed and

replaced with a metal lining panel in combination with

improved insulation and a new metal top sheet.

The new cladding will usually be installed onto a spacer

system, fixed back to the existing structure and insulation can

be installed as well to upgrade thermal performance.

This combination of refurbishment causes minimal disruption

inside the building.

Flat to pitch roof systemA completely new lightweight galvanised steel frame

superstructure is fitted over the existing flat roof.

The framework provides support for a new pitched metal roof,

which quickly clears rainwater from the area.

A standing seam system might be chosen for the new roof,

especially if the pitch is low, for greater slope a simple through

fix trapezoidal profile can be employed.

Low density mineral wool roll insulation may be installed on

top of the old roof to improve U values and reduce heat loss

from the building.

Left before: Sterling House, Potters Bar. Right after: Sterling House, Potters Bar. Colorcoat®

Product: Celestia®

in Sirius.

Flashings Flashings

Flashings

System Selector 3534 System Selector

To complement the wide range of profiled sheets, Corus Panels and Profiles manufacture trims asstandard in 3m lengths and a variety of girths to suitindividual customers requirements. Longer 4m and 6mlengths are available on request in girths between250mm and 600mm.

For high quality finishes a strippable film can be appliedto the external surface for additional protection fromscratches and scuff marks during subsequent handlingand fixing.

Ridge Flashing

Barge board

Window head drip flashing

Window side flashing

Valley Flashing Gutter System and Eaves

Apron

Curve barge board flashing

Parapet and inboard gutter

Window sill flashingDrip flashing - type 1Roof to brick wall abutment Wall to brick wall abutment Internal corner External corner

System Selector 3736 System Selector

Corus Colorcoat® Products and Services Corus Colorcoat® Products and ServicesCorus Colorcoat® Products and ServicesCorus Colorcoat® Products and Services

To ensure the long-term performance and appearance of the building,it is important that the pre-finished steel product is specifiedalongside the cladding system.

Corus Colorcoat® Products and Services

The Colorcoat® brand provides the recognised mark of

quality and metal envelope expertise exclusively from

Corus. Over the course of 40 years, Corus has developed

a range of technically leading Colorcoat® pre-finished steel

products which have been comprehensively tested and are

manufactured to the highest quality standards. These are

supported by a range of services such as comprehensive

guarantees, colour consultancy and technical support and

guidance.

Repertoire® colour consultancy

The Repertoire® colour consultancy can advise on colours

and colour strategies using a range of standard shades, as

well as discussing individual bespoke colour requirements.

Corus can match almost any shade from physical

swatches to commonly used references such as RAL,

NCS and British Standard and more unusual standards.

Confidex® Guarantee

Evolved from 40 years’ experience Corus has in

pre-finished steel development and manufacture.

Available with Colorcoat HPS200®, Colorcoat Celestia®

and Colorcoat Prisma®, the Confidex® Guarantee is clear

and simple to register, can easily be transferred if building

ownership changes and provides peace of mind and

reduced risk for the supply chain.

TopcoatPrimerPre-treatmentMetallic coatingSubstrateMetallic coatingPre-treatmentPrimerBacking coat

Colorcoat HPS200®

Exclusive coating technology, superior performance and

the unique Confidex® Guarantee make Colorcoat HPS200®

the most specified pre-finished steel product in Europe for

roof and wall cladding. Now maintenance free for up to

30 years.

Colorcoat Prisma®

The ideal choice to deliver eye-catching buildings that

will stand the test of time. Technically and aesthetically

superior to PVDF (PVF2), Colorcoat Prisma® is readily

available in the most popular solid and metallic colours.

All backed up with the unique Confidex® Guarantee

providing cover for up to 25 years on walls.

Colorcoat Celestia®

Offers the creative scope of a metallic effect combined

with superior durability and performance all

backed up with the Confidex® Guarantee.

Colorcoat Armacor®

Colorcoat Armacor® is a high-build pre-finished steel

product with a tough and attractive textured top-coat.

As a medium term building envelope solution, Colorcoat

Armacor® offers a price competitive durable alternative

to leathergrain plastisols.

Project: Eco-Factory, Baglan Bay. System: Trimapanel®. Product: Colorcoat Celestia® in Aquarius.

For more information about Corus Colorcoat® products and services visit

www.colorcoat-online.com or

call the Colorcoat Connection® helpline on 01244 892434.

R19 • • •

R32/1000 • • •

R35A • • •

R38A • • • •

R40 • • • •

R46 • • •

R60 • • •

R100 • • •

Trisomet • • • •

C19 • • •

C32/1000 • •

C32S • •

C35A • •

C38A • • •

C46 • •

C60 • •

R13.5/3 • • •

C13.5/3 • •

Superdeck •

Trimapanel •

Guardian •

Arcline 40 • •

CH47 • •

R1

Bui

lt up

roof

with

trap

ezoi

dal p

rofil

es

R2

Bui

lt up

roof

with

secr

et fi

x pr

ofile

s

R3

Sup

erde

ck c

ompo

site

pane

l sys

tem

R4

Tris

omet

roof

til

e sy

stem

E1

Tr

isom

et c

ompo

site

pane

l sys

tem

E2Tr

insu

l sys

tem

E3B

uilt

up a

cous

tic s

yste

m

E4H

ybrid

aco

ustic

sys

tem

W1

Bui

lt up

wal

l with

trap

ezoi

dal p

rofil

es

W2

Trim

apan

el c

ompo

site

wal

l pan

el s

yste

m

W3

Gua

rdia

n ro

ckfib

re

com

posi

te p

anel

sys

tem

W4

Faça

de s

yste

m

S1

Str

uctu

ral m

etal

roof

dec

king

S2

Str

uctu

ral l

iner

tray

sys

tem

WP40 • • •

1000/19 Protile •

Facades •

Seam-loc • • • •

Alu-seam • • • •

HL130/600 •

D19 •

D32S •

D35 •

D46 •

D60 •

D100 •

D159 •

D210 •

D135 •

D153 •

D158 •

D200 •

CL6/914 • • • •

LP1000 • • • •

1000/19 • • • • •

C19 • • • • • •

RL32/1000 • • • • •

Profiles Profiles

Profile selector

System Selector 3938 System Selector

R1

Bui

lt up

roof

with

trap

ezoi

dal p

rofil

es

R2

Bui

lt up

roof

with

secr

et fi

x pr

ofile

s

R3

Sup

erde

ck c

ompo

site

pane

l sys

tem

R4

Tris

omet

roof

til

e sy

stem

E1

Tr

isom

et c

ompo

site

pane

l sys

tem

E2Tr

insu

l sys

tem

E3B

uilt

up a

cous

tic s

yste

m

E4H

ybrid

aco

ustic

sys

tem

W1

Bui

lt up

wal

l with

trap

ezoi

dal p

rofil

es

W2

Trim

apan

el c

ompo

site

wal

l pan

el s

yste

m

W3

Gua

rdia

n ro

ckfib

re

com

posi

te p

anel

sys

tem

W4

Faça

de s

yste

m

S1

Str

uctu

ral m

etal

roof

dec

king

S2

Str

uctu

ral l

iner

tray

sys

tem

System Selector 41

Corus in Construction

Platinum Partnership System Warranty

We are delighted to offer our Platinum Warranty against a specification

that involves any of our systems.

Integrated Supply Chains, Partnering, RethinkingConstruction, all laudable propositions in theory, but whatabout in practice?

Corus Panels and Profiles not only recognised thebenefits of Integrated Supply Chains etc, but also havedone something about it with the introduction of thePlatinum Warranty.

With over 40 years of experience in serving the needs ofthe construction industry, who better placed to offer asystem warranty that is both meaningful and manageableand which addresses the needs of the ever changingconstruction world? Through the use of our accreditedinstallers and suppliers, Corus Panels and Profiles areable to offer a warranty on the building envelope for up to 30 years.

Such is Corus Panels and Profiles belief that theintegrated supply chain route is without doubt the wayforward, they are commissioning the building of adedicated technical training school where methods ofinstallation are trained and tested, to comply with thestrict criteria required to maintain membership of theapproved Platinum contractor network.

The Platinum Warranty is completely free of charge andextends to cover installation and structural integrity for 12 years, providing that all work had been carried out byour dedicated nationwide team of Platinum approvedcontractors.

Corus Panels and Profiles, having the largest and mostcomprehensive product range in the constructionmarket place are able to offer their Platinum Warrantyon a wide choice of products including:

• Built up systems• Composite panel systems• Façade systems• Structural roof decking systems• Tray and tile systems• Fire and acoustic systems• Secret fix systems

The Warranty is linked to the Corus Confidex®

Guarantee and is administered by Corus Panels andProfiles for complete peace of mind, with just one pointof contact in the unlikely event of a problem.

With the Platinum Warranty you can be confident ofreceiving a meaningful warranty, supported by one ofthe largest construction product manufacturers in theworld.

Whether your product is new-build or refurbishment,complete envelope or small project it is perfectly suitedto the Corus Panels and Profiles Platinum PartnershipSystem Warranty.

Construction represents some 30 per cent of Corus' £10billion annual turnover and is the largest single part of thebusiness.

Our proposition to the construction industry bringstogether quality products, systems, services and peoplewho are committed to just one thing – our customers’success.

A diverse product range encompassing 16 integratedbusiness units, enables Corus to deliver steel forstructural and roofing applications through to specialised,cladding systems, pre finished steels and high-techbuilding components.

Backed by an unrivalled reputation in steel andaluminium, our teams develop both systems andsolutions that make construction projects safer, faster,more flexible and cost effective.

At every stage of the project we work in closecollaboration with our customers, providing the kind oftechnical advice and consultancy that helps deliversuccessful results.

With an annual research and development spend of£27m, Corus has developed an extensive selection ofinnovative products and systems, ensuring we are in aunique position to provide added value whenever steeland aluminum is used in the construction industry.

www.corusconstruction.com

40 System Selector

Platinum Partnership System Warranty

Corus in Construction

System Selector 4342 System Selector

Overview of technical services Further Information

Overview of technical services Further Information

Diaphragm Design - reducessteelwork requirements and thereforereduces costs as well as improvingaesthetics. Using software approved byProfessor Mike Davies our technicaldepartment can produce a diaphragmdesign for your building.

Structural calculations - can becarried out to the relevant BritishStandards, to ensure suitability of theselected profile.

Thermal Modelling - 2D and 3Dthermal modelling can be produced andused to calculate your 'f', 'psi' and 'U'values, analysing all cold bridges foraccurate results.

Acoustic Calculations - we canpredict acoustic values using softwaredeveloped by Solford University. Thisallows the building construction to beamended to suit your acousticrequirements without a costly and timeconsuming multiple testing programme.

Robust Details - our technicaldepartment has produced a range ofstandard 'robust details' in auto-cad.These can be imported directly into youproject drawings, detailing the f and psivalues, however if our standard rangedoes not cover your needs we are ableto produce job specific robust details `for you.

Construction Advice - we offer adviceon installation, design and any otheraspect of the use of Corus Panels andProfiles products, including site visitswhere required.

NBS Specs - we also offer aspecification writing service, using NBS,detailing not only the Corus Panels &Profiles products but also the fasteners,and sealants etc. for all types ofconstruction and conditions.

All free of charge to our customers!

Corus Panels and Profiles Technical Department providesa wide range of services, including the following:

Further information on all the systems featured is available, please contactus to request specific details or any of the following brochures:

Corus Panels and ProfilesSevern DriveTewkesbury Business ParkTewkesburyGL20 8TXTel: +44 (0) 1684 856600Fax: +44 (0) 1684 856601E-mail: [email protected]: technical@coruspanelsandprofiles.co.ukwww.coruspanelsandprofiles.co.uk