Corrugator Steam Joints - Kadant · SX® Rotary Joint LJX ™ Rotary Joint CorrPro ® Rotary Joint...

Transcript of Corrugator Steam Joints - Kadant · SX® Rotary Joint LJX ™ Rotary Joint CorrPro ® Rotary Joint...

Engineered reliability and performance.

Corrugator Steam JointsAdvanced rotary joint technology

Steam joint solutionsfor demandingapplications.

Innovation

2

Rotary steam joints have been a part of the corrugating manufacturing process since the 1930’s, when Kadant Johnson inventedthe rotary pressure joint. Since then, Kadant Johnson has incorporated advances in sealing technology, rotary joint and syphondesign, and materials to extend the application range of the conventional rotary joint.

Kadant Johnson has performed extensive research to study the behavior of condensate in steam-heated rolls to evaluate:u Critical performance parameters for drilled corrugator rolls and plain-shell rollsu Amount of blow-through steam requiredu Effects of corrugator speed on heat transfer rates and temperature profile uniformityu Effects of syphon design and syphon clearance

Seal technology for demanding applicationsUntil recently, the most popular sealing technology used in corrugating applications was the pressure-type joint, with resin-impregnated carbon graphite seal rings. Silver Streak™ seal rings have since replaced the resin seals to allow higher speeds and steam pressures and longer seal ring life.

Balanced seal technology combined with advanced seal geometry offers maximum seal life, reduced maintenance downtime, and improved reliability at any speed.

Rigid syphon assemblyRigid syphons eliminate the deficiencies of conventional syphons. There are no threadedtubes or bent pipes to “dance” inside the roll. The one-piece, mechanical (horizontal)tube has an integral tapered-wedge to lock the horizontal tube in place. After thelocking elbow is engaged, the syphon clearance is fixed at the proper syphon clearance.Bouncing syphons, dancing bent pipes, and syphon failures are virtually eliminated.

SX® Rotary Joint LJX™ Rotary Joint CorrPro® Rotary Joint

Self-Supported Rod-Supported Bracket-Supported

Steam system optimization

3

Maximize Heat Transfer

Kadant Johnson’s extensive research into condensate behavior and heat transfer in rotating rolls and corrugator hot plates hasbeen combined with an intimate knowledge of steam joints, syphons, and the integration of these components with the steamsystem to provide a holistic steam distribution and handling system; one that delivers more heat, more consistently, moreefficiently. Kadant Johnson offers three unique steam system options for corrugating plants: ThermoTrap™, ThermoPlus™, and ThermoMax® systems. The type of system is dependent on the specific needs of the plant.

How each system measures up:ThermoTrap™Steam System

ThermoPlus™Steam System

ThermoMax®

Steam System

Optimal speed range (fpm) 150–900 150–1,200 150–2,500

Number of hot plate zones Three Three Four

Proven design � � �

High-energy efficiency � � �

Rapid condensate return at start-up � � �

High-speed capability with Turbulator® bars � �

Consistent roll temperatures at higher speeds � �

Uniform cross direction roll temperature � �

PLC control with graphic user interface � �

Improved visibility of system operation � �

Increased feedwater pump life � �

Supervisory control of blow-through steam � �

Reduction of roll bowing following stop � �

Fast response to grade changes �

Ability to handle wide range of load variation �

Optimum condensate drainage from plain-shell rolls �

Rapid hotplate temperature response �

Reduced feedwater pump horsepower �

Reduced troubleshooting time �

Rapid air removal at start-up �

Remote performance diagnostics �

One-piecebody

Split wedgesyphon support

Convex sealring

Corrosion resistant nippleavailable threaded or withquick release “Q” flange

Two carbon guides

Stainless steel spring

4

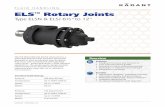

SX® Rotary Joint

M

O

GJ

B F

C

A

E

P

Z

S

D

H

K

Features

u Two internal support guides

u Optimized seal diameter

u Convex seal ring in compression

u Maximum carbon guide separation

u Adjustable syphon clearance option

Benefits

u Increased life and reliability

u Extended seal life, reduced maintenance

u Self-aligning seal, longer life

u Improved rotary joint and syphon support

u Optimized syphon clearance

Ratings

Maximum Pressure: 300 psig (20 bar)

Maximum Temperature: 550°F (288°C)

Maximum Speed: 350 RPM

Size (K) M P S A B C D E F G H J O Z Units

11⁄2" 11⁄4" 3⁄4" 1⁄2", 3⁄4" 1.50 1.75 6.56 1.44 1.75 2.19 7.81 9.50 11.75 0.72 5.81 inches

38 45 167 36 45 55 198 240 298 18 148 mm

* 11⁄2" * 11⁄4" * 3⁄4" * 1⁄2", 3⁄4" 1.50 1.75 6.56 1.44 1.75 2.19 8.00 9.69 11.94 0.72 5.81 inches

38 45 167 36 45 55 203 246 303 18 148 mm

Z

A

K

H

C

GJ

B F

P

M

E

D

S

O

Adjustable syphon option*

5

Size M P B D E G J Units

11⁄2" 11⁄4" 3⁄4" 2.75 4.90 1.88 5.53 11.62 inches70 124 48 140 295 mm

LJX™ Rotary Joint

Ratings*

Maximum Pressure: 300 psig (20 bar)

Maximum Temperature: 500°F (260°C)

Maximum Speed: 350 RPM

* Running at maximum ratings for speed andpressure simultaneously is not recommended.

Features

u SecureLock™ syphon retention plate

u Ultra-rigid syphon assembly with self-locking elbow

u Heavy-duty mounting rods with integral sleeves

u Visual seal ring wear indicator

u Simple upgrade with no piping modifications

Benefits

u Improved bonding, especially at higher speeds

u Maximum heat across all board combinations

u Increased equipment reliability and operating life

u Cost-effective upgrade and quick ROI

u Safer operating environment

B

E

G

J

P

M

D

Head

SecureLock™retention plate

Corrosion-resistantnipple

Body with integrallug sleeve

Lockingnut

Rigid support rod

Stainless steelspring

Conical wedge tosecure horizontal pipe

6

LJ-PT™ Rotary Joint

C

M

B

P

J

SE

AH

DG

Features

u Balanced seal design with Silver Streak technology

u External rod-supported, locked in place

u Seal wear indicator

u Retrofit type LJ™ rotary joints

Benefits

u Minimized seal loading and seal wear

u Increased reliability at higher speeds

u On-machine measurement of seal wear

u Optimized syphon clearance

Ratings

Maximum Pressure: 225 psig (15 bar)

Maximum Temperature: 450°F (232°C)

Maximum Speed: 400 RPM

Size M P S A B C D E G H J Units

11⁄2" 11⁄4" 3⁄4" 3⁄4"1.88 2.75 6.12 5.38 1.25 4.56 9.56 11.06 inches48 70 155 137 32 116 243 280 mm

Balanced sealloading

Split wedgesyphon support

Seal platecompensates for

angularmisalignmentFull flow

area

Convex seal ring

Stainless steelsprings

Corrosion-resistantend cap

Rigid support rod

E

BS

M

J

D

P

G

C

A

CorrPro® Rotary Joint

7

Features

u Balanced seal design with Silver Streak technology

u Circular bracket mounting

u Adjustable syphon clearance option

u Accommodates thermal expansion up to 25 mm

Benefits

u Minimized seal loading and seal wear

u Rigid support for safety and reliability

u Optimal heat transfer and temperature uniformity

u Designed for “wide roll” installations

M

E

J

B

D

P

G

C

A

S

SizeSyphonType

M P S A B C D E G J Units

11⁄2" Stationary 11⁄4", 11⁄2" 3⁄4", 1" 3⁄4"1.88 3.00 9.45 5.38 3.00 2.12 8.37 inches48 76 240 137 76 54 213 mm

11⁄2" Rotating 11⁄4", 11⁄2" 3⁄4", 1" 3⁄4", 1"1.88 3.00 9.45 4.30 3.00 2.12 8.37 inches48 76 240 109 76 54 213 mm

SizeSyphonType

M P S A B C D E G J Units

2" Rotating 2" 11⁄2" 11⁄4"2.80 3.25 9.50 8.26 3.00 3.09 12.76 inches71 83 241 210 76 78 324 mm

Convex seal ring

Locking nut

360° ring bracketmounted to rollbearing housing

Seal platecompensates for

angular misalignment

Stainless steel springs

Conical wedgeto secure

horizontal pipe

Full flowarea

Back Page Title

Kadant is a global supplier of high-value, critical components andengineered systems used in processindustries worldwide.

www.kadant.com

Contact us:

KADANT JOHNSON LLC805 Wood StreetThree Rivers, MI 49093 USA

Tel: +1-269-278-1715Email: [email protected]

Corrugator Steam Joints-3007 (US) 03/2017

Replaces: Corrugator Steam Joints-3006 (US)

© 2017 Kadant Inc.

Flexible hoseFlexible hose is engineered specifically for use as inlet and outlet connections to KadantJohnson rotary joints. It is used to prevent pipe strains from creating stress on the rotatingjoint and enhances the rotating joint’s built-in flexibility. Available in sizes from 1⁄4” to 8”with threaded or flanged couplings.

Pivot Body™ syphon elbowThe Pivot Body syphon elbow allows a syphon pipe to be inserted into a roll through thejournal and then pivot into place. Unlike conventional syphon elbows, the Pivot Bodysyphon elbow does not rely on a hinge pin to hold vertical and horizontal pipes together. Itspatented pinless design provides improved performance and increased reliability comparedto conventional syphon elbows. U.S. Patent No. 7,618,068.

Liqui-Mover® pumpsLiqui-Mover condensate pumps replace conventional centrifugal pumps and motors inreturning condensate at high pressures. Both float and float-free condensate pump designsare available as complete skid-mounted assemblies or as stand-alone pressure-poweredpumps. Liqui-Mover pumps are rated up to 250 psig (17 bar).

Steam trapsKadant's proprietary steam traps are designed forthe varying steam loads in the corrugatingprocess and the unique requirements of rotatingsteam-heated rolls.

Variable Moisture Steam™ shower supply systemA Variable Moisture Steam shower supply system aidswith proper flute formation on single facers, especiallyfor those running at high speeds.