Correlation between the Compressive, Tensile Strength of...

Transcript of Correlation between the Compressive, Tensile Strength of...

Research ArticleCorrelation between the Compressive TensileStrength of Old Concrete under Marine Environment andPrediction of Long-Term Strength

Weilai Yao1 Shiyong Jiang2 Wei Fei1 and Tao Cai1

1Civil Engineering Department Logistical Engineering University Chongqing 401311 China2Training Department Logistical Engineering University Chongqing 401311 China

Correspondence should be addressed to Shiyong Jiang jiangshiy163com

Received 22 March 2017 Accepted 3 May 2017 Published 25 May 2017

Academic Editor Andrey E Miroshnichenko

Copyright copy 2017 Weilai Yao et al This is an open access article distributed under the Creative Commons Attribution Licensewhich permits unrestricted use distribution and reproduction in any medium provided the original work is properly cited

Compressive strength and tensile strength are important mechanical properties of concrete The long-term strength of concreteunder real service environment is an important parameter when evaluating existing buildings which should also be properlyconsidered in structural design In this study the relationship between compressive and splitting tensile strength of old concreteexisting for long period under marine environment was investigated At a deserted harbour concrete cores samples were drilledby pairs in site For each pair of samples the two cores were drilled from the adjacent location and conducted to compressivesplitting tensile test respectively 48 compressive and splitting tensile strengths were finally obtained From the test results tensilestrength presents general uptrend with compressive strength and the two parameters are well positively correlated Exponentialmodel generally recommended by building codes or literatures is still capable of describing the relationship between compressiveand tensile strength of old deteriorated concrete when function parameters are properly determined Based on statistical theory andthe experimental result of this study a method for predicting long-term tensile strength of concrete is developed and an exampleis given which may provide a potential way to estimate long-term concrete strength under real marine environment

1 Introduction

The value of tensile strength of concrete affects the perfor-mance of structures such as the shear force resistance and theload-bearing capacity of anchors with concrete cone failureas decisive failure mode Hence as concrete compressivestrength tensile strength is another critical mechanical prop-erty which should be appropriately considered in structuredesign The real value of the in situ tensile and compressivestrengths of concrete deteriorated under authentic serviceenvironments for long time provide a necessary basis forthe evaluation of structures especially for those which haveexisted for long period already Considering the complexitycost and time-consuming nature of performing tensile testsmany researchers and building guidelines are interested topredict the tensile strength from compressive strength andtheir relationship in a simplified method with satisfactory

accuracy [1ndash5]Most correlations proposed by building codesor literatures are based on normal curing conditions andtesting age of 28 days In reality there are many differenttime- load- and environment-dependent impacts on con-crete existing in real service conditions for long term There-fore the compressive-tensile strength relationship in buildingcodes cannot be assumed without further observations andinvestigations [5 6]

On the other hand so far the concrete strength isconsidered as time invariant when conducting structuraldesign and calculation In this way constructions should becompletely reliable and the service life should be infinite aslong as119877 gt 119878 (119877 and 119878 represent resistance and stress in broadsense) is satisfied in designing stage But in fact resistanceof material such as concrete strength may degrade withtime in outdoor environments which leads to degradation ofreliability and overall structure performance In this respect

HindawiAdvances in Materials Science and EngineeringVolume 2017 Article ID 8251842 12 pageshttpsdoiorg10115520178251842

2 Advances in Materials Science and Engineering

it is worthwhile to underline that the time-varying char-acteristics of concrete exposed to outdoor environment arenecessary to be further researchedMoreover in constructiondurability assessment or structure life prediction the long-term concrete strength along with its time-varying featuresis essential information However it is not simple to carry outstudies to research the changing law of concrete strength inlong term since it may takes several years or decades to runthe tests

Accelerated aging tests and simulative environmentaltests are mainly adopted to study the environmental impactson concrete strength Li et al [7] researched acidification cor-rosion depth and compressive strength of concrete subjectedto sulphuric acid environments by accelerated tests Theresults show that the remaining compressive strength valuesfor the concrete exposed to pH = 2 and 3 sulphuric acid waterenvironments and wet-dry cyclic sulphuric acid environmentwith pH = 2 are 74 72 and 80 of initial strengthrespectively An accelerated corrosion by a sulphate solutionin a dry-wet cycle was introduced to simulate the externalsulphate corrosion environment by Zhou et al [8] Theaccelerated corrosion test results indicate that the strengthdegradation of concrete by sulphate attack had a significantrelation with the corrosion depth Cai et al [9] assessed theconcrete strength and deformation property under artificialsea water erosion environment Concrete stress and straincurve was researched with the number of wet and dry cyclesof 0 times 10 times 20 times 30 times 40 times 50 times and60 times A biaxial concrete strength criterionwas establishedtaking into account the stress ratio and the number of dry-wetcycles Ramli et al [10] studied the environmental resistanceof concrete incorporating coconut fibresThree types of simu-lated aggressive environments were adopted air environmentin a tropical climate alternate air and seawater environmentsin a 14-day cycle and continuous immersion in seawaterShang et al [11] investigated mechanical properties of plainconcrete and air-entrained concrete subjected to freeze-thawcycles (F-T-C) The influences of F-T cycles on ultrasonicvelocity and mechanical properties of air-entrained concreteand plain concrete were analysed Also accelerated aging testor simulative environmental test is adopted in [12ndash18] whichshows that it is convenient and time saving to adopt suchexperimental method to study the environmental effects onconcrete properties However there are apparent differencesbetween real service condition and artificial environmentsince the latter can merely reproduce several environmentalfactors such as sulphate chloride ion acid high temperatureand humidity In fact the real environment is far moreintricate and cannot be simply represented by simulativeenvironmental test In addition in the previous literaturesabove the longest aging time was 365 days [17] which cannotbe regarded as a long enough period when comparing tothe working life in practical engineering Moreover tensilestrength of concrete was scarcely discussed in those previousstudies

There are only a few existing studies that investigatedlong-term environmental effects on concrete strength underreal service conditions However only compressive strengthwas researched Ismail et al [19] investigated compressive

Table 1 The atmosphere chloride content of Zhoushan city

Distance to sea(m) 2 100 140 200 260 340 500

Meanprecipitationvalue ofchloride perday (120583gcm2d)

11130 10856 3998 3638 2941 2427 2951

strength loss of concrete exposed to outdoor environmentby 6 yearrsquos monitoring Studies by Mehta [20] Shekarchiet al [21] and Washa and Wendt [22] discussed the long-term concrete compressive strength under actual marineenvironment None of them addressed tensile strength andthe correlation between compressive and tensile strength ofconcrete

The major thrust of this study is to obtain both com-pressive and tensile strengths of concrete under real marineenvironment for long period (up to 61 years) and identify thecorrelation between the twomechanical properties Concretecores were drilled out by pairs at a deserted harbour inZhoushan city Zhejiang province China Every two coresof each pair were conducted in compressive and tensilesplitting test respectively then the relationship betweenlong-term compressive and tensile strength was concludedThe applicability of compressive-tensile strength relationshiprecommended by literatures or building codes for con-crete without deterioration (fresh concrete) was examinedA better fitted relationship function was presented Afterthat based on statistical theory and a compressive strengthpredictingmodel from literature a tensile strength predictingmethod was established and a calculating example wasprovided for interpreting which may offer a potential wayto estimate long-term tensile strength of concrete under realmarine environment

2 Experimental Program

21 Concrete Cores Drilling Zhoushan is a coastal city inChina Constructions and buildings there are deterioratedby typical marine environment like seawater marine atmo-sphere tidal waves and so onThe yearly average temperatureis 15 to 20 degrees Celsius The content of chloride ion inatmosphere of Zhoushan city is given in Table 1

Concrete cores samples were drilled from 4 differentsites at a deserted harbour of Zhoushan city Site A is theconcrete slab of a deserted dock built in 1955 When tiderises the distance between the dock slab and sea level is 4mapproximately Site B is a large piece of plain concrete onseabeach which was left as construction waste when nearbynew harbour was established in 2011 Site C is a concretepedestal of streetlight casted in 2000 Site D is the reinforcedconcrete roof of a deserted building constructed in 2005Theabove four sites (A B C and D) which had existed for 615 16 and 11 years till our test began are in adjacent areasAll of them are not immersed by sea water due to their highenough places and in atmosphere all time Concrete cores

Advances in Materials Science and Engineering 3

Figure 1 The cores drilling site

drilled fromeach siteweremarked as groupA groupB groupC and group D respectively

In this study the operations of drilling and testing referto the technical specification for testing concrete strengthwith drilled core [23] Location of steel bars was detectedby magnetic spectroscopy steel detector and proper drillingplaces (away from bars) were selected in order to avoiddamage to reinforcement Cores with diameter as 75mmwere mostly drilled which are smaller than standards coresamples in the formerly mentioned technical specification[23] Another 4 standard cores with diameter as 100mmwere drilled since the 75mm-diameter drilling barrel wasseverely worn outThe concrete cores were obtained by pairsFor each pair of samples the two cores were conducted tocompressive and tensile test respectively aiming to investigatethe relationship between compressive and tensile strengthsThe 2 cores of each pairwere drilled fromclose enoughplaceswhich ensures that they consist of same batch of concretewithidentical deterioration The place (site A) for drilling cores isshown in Figure 1

22 Cores Processing The drilled cores were carefully pro-cessed including incising and end faces dealing beforemechanical tests

221 Cores Incising Based on the mentioned test specifi-cation [23] after processing the height-diameter ratio ofcore samples should be 1 theoretically which can value from095sim105 in actual operation Incision machine with doubleparallel blades was used and the distance between two bladeswill determine the height of each core Before incising thedistance of double blades was carefully adjusted and thenfixed in order to ensure that the height-diameter ratio ofeach core is in the allowed range as 095sim105 The incisingprocession is shown in Figure 2(a)

After incision cores were paired up Two cores of eachpair were confirmed to be obtained from close enoughlocations The matched cores were placed in pairs shown inFigure 2(b)

222 Cores Selecting and Loading Test Preparing Accordingto the test specification [23] there should be no more than 1steel bar in qualified core and the diameter of steel bar should

be less than 10mm The possibly existing steel bar should bevertical to the shaft of core Samples with obvious cracks orflaws were excluded According to the above prerequisites 96eligible cores (48 pairs) were finally selected The end facesof all cores were levelled Belt grinder machine or polymercement mortar was adopted to make end faces smooth andlevel as shown in Figure 3(a)

The scales of each qualified core sample were measuredVernier caliper was applied to measure the diameters Diam-eter was measured twice for each core at two vertical placesand the average value was adopted as the final diameterwhich would be applied in the further strength calculation(Figure 3(b)) Steel tap was applied tomeasure the core height(Figure 3(c)) Lines were drawn on those samples that wouldbe tensile split to indicate the failure areas as shown inFigure 3(d)

23 Loading Test All of the 96 core samples were numberedbefore loading test Every two cores of each pairwere the samebatch of concrete and deteriorated by environment equallyone sample was conducted to compressive test while theother was conducted to tensile splitting test Two universaltesting machines with measuring range as 500KN and100KN are applied to compressive and tensile splitting testrespectively Finally 48 compressive strengths were obtainedas well as 48 tensile splitting strengths Compressive andtensile splitting tests are shown in Figures 4(a) and 4(b)

Test information as serial number sample scale andthe maximum applied force of each core sample is givenin Table 2 Data number consists of a three-part code and thealeph (A B C andD) represents the group of samples whichalso indicates the places where concrete cores were drilledThe second figure in data number presents the sequence ofsample pair in each group The third figure in data numberindicates the type of mechanical experiment 1 representstensile splitting test and 2 represents compressing test 119889and ℎ represent the diameter and height of core samplerespectively 119889ℎ is the height-diameter ratio which are all inthe allowable range as 095sim105 119865 is the maximum appliedforce of each sample in loading test

24 Strength Calculation According to the technical speci-fication for testing concrete strength with drilled core [23]compressive strength of core samplewas calculated as follows

119891cucor = 119865c119860 (1)

where 119891cucor is compressive strength 119865c is the measuredmaximum compressive force in the test 119860 is the area ofcompressive section

The tensile split strength was calculated as [23]

119891cts = 0637 sdot 119865splcor119860 ts (2)

where 119891cts is tensile splitting strength 119865splcor is the measuredmaximumsplitting force of each sample119860 ts is the area of splitsection 0637 is a coefficient derived from elastic theory

4 Advances in Materials Science and Engineering

(a)

95sim99mm

95sim99

mm

70sim75mm

70sim75

mm

(b)

Figure 2 Incision progress and the incised cores

(a) (b)

(c) (d)

Figure 3 End face levelling measuring scale and preparing for loading tests

(a) (b)

Figure 4 Loading test

Advances in Materials Science and Engineering 5

Table 2 The primary data of experiment

Data number Test type dmm hmm hd FKN Data number Test type dmm hmm hd FKNA-1-1 Tensile splitting 995 98 098 4416 A-1-2 Compressive 990 98 099 24212A-2-1 Tensile splitting 730 73 100 4108 A-2-2 Compressive 730 73 100 18345A-3-1 Tensile splitting 730 73 100 4948 A-3-2 Compressive 730 74 101 21726A-4-1 Tensile splitting 735 73 099 2806 A-4-2 Compressive 735 74 101 7346A-5-1 Tensile splitting 725 73 101 2536 A-5-2 Compressive 730 73 100 12043A-6-1 Tensile splitting 730 73 100 4026 A-6-2 Compressive 730 74 101 19554A-7-1 Tensile splitting 735 73 099 2633 A-7-2 Compressive 735 73 099 14440A-8-1 Tensile splitting 730 72 099 4162 A-8-2 Compressive 735 74 101 16185A-9-1 Tensile splitting 735 75 102 3480 A-9-2 Compressive 725 73 101 16114A-10-1 Tensile splitting 725 73 101 2277 A-10-2 Compressive 730 73 100 12592A-11-1 Tensile splitting 735 73 099 2044 A-11-2 Compressive 735 73 099 12044A-12-1 Tensile splitting 730 73 100 2369 A-12-2 Compressive 725 73 099 11141B-1-1 Tensile splitting 730 73 100 3626 B-1-2 Compressive 735 72 098 16048B-2-1 Tensile splitting 735 73 099 3426 B-2-2 Compressive 730 73 100 13001B-3-1 Tensile splitting 735 70 095 3072 B-3-2 Compressive 735 70 095 13143B-4-1 Tensile splitting 735 70 095 2920 B-4-2 Compressive 735 70 095 19610B-5-1 Tensile splitting 730 73 100 1735 B-5-2 Compressive 735 72 098 18628B-6-1 Tensile splitting 735 74 101 3818 B-6-2 Compressive 735 73 099 13279B-7-1 Tensile splitting 730 74 101 3764 B-7-2 Compressive 730 73 100 12980B-8-1 Tensile splitting 735 73 099 3442 B-8-2 Compressive 735 73 099 11168B-9-1 Tensile splitting 735 73 099 4264 B-9-2 Compressive 735 73 099 15336B-10-1 Tensile splitting 735 73 099 4048 B-10-2 Compressive 730 72 099 12965B-11-1 Tensile splitting 735 73 099 4848 B-11-2 Compressive 735 72 098 13582B-12-1 Tensile splitting 735 72 098 4262 B-12-2 Compressive 735 73 099 27546B-13-1 Tensile splitting 735 73 099 4734 B-13-2 Compressive 735 74 101 19214B-14-1 Tensile splitting 735 72 098 3976 B-14-2 Compressive 735 74 101 13607B-15-1 Tensile splitting 735 70 095 2053 B-15-2 Compressive 735 70 095 12086B-16-1 Tensile splitting 730 73 100 2032 B-16-2 Compressive 735 72 098 10814C-1-1 Tensile splitting 735 73 099 3378 C-1-2 Compressive 730 73 100 10045C-2-1 Tensile splitting 730 73 100 3370 C-2-2 Compressive 730 73 100 8958C-3-1 Tensile splitting 735 73 099 3794 C-3-2 Compressive 735 72 098 7664C-4-1 Tensile splitting 735 72 098 3464 C-4-2 Compressive 735 73 099 8027C-5-1 Tensile splitting 735 73 099 4094 C-5-2 Compressive 735 73 099 11000C-6-1 Tensile splitting 735 73 099 2633 C-6-2 Compressive 735 74 101 13809C-7-1 Tensile splitting 735 73 099 3610 C-7-2 Compressive 735 73 099 6836C-8-1 Tensile splitting 730 73 100 3438 C-8-2 Compressive 730 72 099 9091C-9-1 Tensile splitting 735 73 099 2838 C-9-2 Compressive 735 73 099 10707C-10-1 Tensile splitting 735 73 099 3080 C-10-2 Compressive 730 72 099 6120C-11-1 Tensile splitting 730 73 100 3208 C-11-2 Compressive 735 73 099 8687C-12-1 Tensile splitting 735 73 099 3454 C-12-2 Compressive 730 73 100 8790D-1-1 Tensile splitting 730 70 096 3270 D-1-2 Compressive 735 70 095 8207D-2-1 Tensile splitting 735 71 097 2561 D-2-2 Compressive 740 73 099 13860D-3-1 Tensile splitting 735 72 098 2928 D-3-2 Compressive 730 73 100 6838D-4-1 Tensile splitting 730 72 099 2320 D-4-2 Compressive 730 72 099 6578D-5-1 Tensile splitting 735 73 099 2518 D-5-2 Compressive 735 74 101 11032D-6-1 Tensile splitting 735 73 099 3102 D-6-2 Compressive 730 72 099 6535D-7-1 Tensile splitting 730 72 099 2162 D-7-2 Compressive 735 73 099 4414D-8-1 Tensile splitting 995 98 098 3706 D-8-2 Compressive 995 95 095 13954

6 Advances in Materials Science and Engineering

25 Size Effect In the above technical specification [23]diameter of standard concrete core is 100mmHowever thereare usually large amount of steel bars in the field testingstructures as a result drilling standard cores may causedamage to the reinforcement Therefore nonstandard coreswith smaller scale are widely adopted in actual engineeringas well as in this study Besides different guidelines or codesmay also adopt specimens with different shapes or sizes Inorder to make the test results of this study more generallyapplicable the size effect of nonstandard core samples wasdiscussed and then strength of core was converted to that of150 times 150 times 150mm concrete cube specimen which is definedas standard specimen in common construction standardssuch as Europe codes [24] and China standards [25]

251 Size Effect of Compressive Strength Great deal of exper-imental studies conducted by China Academy of BuildingResearch demonstrated that when the height-diameter ratioof core equals 1 compressive strength of core samples withdiameters ranging from 70 to 75mm is identical to thatof standard core samples as well as 150 times 150 times 150mmconcrete cube specimens which manifests that the size effecton compressive strength may not be considered [23] Aitcinet al [26] also showed that when the height equals diameterno significant difference is observed between compressivestrength of cores and cube specimens Hence this paper doesnot take account of the size effect on compressive strengthFurthermore the compressive strengths of core samples inthis study were regarded as the strengths of 150 times 150 times150mm concrete cube specimens [23]

252 Size Effect of Tensile Split Strength Through experi-mental research and theoretical analysis Bazant et al [27]Duan et al [28] and Rocco et al [29 30] show that the tensilesplitting strength of concrete is strongly determined by thesize of test specimen Wide range of experimental studieswere carried out on cubes cylinder and prisms to investigatethe size effect of tensile splitting strength by Kadlecek et al[31] It was demonstrated that the size effect highly dependson the areas of splitting fracture section rather than the shapeof test specimens which creates a unifying measurement forsize effect A generalized size effect formula was presentedwhich can be applied to cores or cubes obtained from existingstructures According to Kadlecek et al [31] the tensilesplitting strength of concrete cores was converted to thestrength of standard test specimen (150 times 150 times 150mm)Thesize effect formula is given as [31]

119896119901 = 119891tscor119891ts = 2 sdot 119860minus0128 (3)

where 119896119901 is coefficient of size effect 119891tscor is the tensilesplitting strength of drilled core samples 119891ts is the tensilesplitting strength of standard test specimen (150 times 150 times150mm)119860 is the area of splitting fracture section of concretecore (cm2)

60

45

30

15

000 15 30 45 60 75

fNM

(Mpa

)

f=O (Mpa)

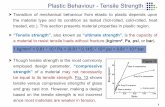

Group A (1955s)Group B (2011s)Group C (2000s)

Sub-group15sim35Mpa

fNM = 019 middot f=O34

fNM = 0439 middot f=O055

fNM = 134 middot (f=O10)23

fNM = 028 middot f=O23

fNM = 049 middot f=O05

Group D (2005s)fNM = 1033 middot f=O

035

(best fitting curve)

Figure 5 Compressive and splitting tensile strength

3 Results and Discussion

31 The Relationship between Long-Term Compressive andTensile Strength According to Section 25 strengths of coresamples were converted to strengths of standard test speci-mens in order to improve practicability of the test result inthis research All of the 48 data points are presented in acoordinate system (Figure 5) with compressive strength as119909-axis and tensile splitting strength as 119910-axis

The experimental result signifies that compressive andtensile strength of concrete deteriorated by the marineenvironment of Zhoushan city for long term still present acertain regularity The data points in Figure 5 distribute tothe right oblique upward forming a zonal shape Althoughdata points present discreteness it is clear that as the raisingof compressive strength the tensile strength of the sameconcrete tends to increase as well The correlation coefficientbetween compressive and splitting tensile strength is 072demonstrating that the two types of strength are still wellpositively correlated under environmental effects for longperiod of time

Generally exponential law is recommended by literaturesor building guidelines to express the relationship betweencompressive and tensile strength of concrete cured undernormal conditions and without environmental deterioration(fresh concrete) [25 32ndash34] (Table 3 left column) In Table 3119891cu and 119891c are the compressive strength of 150 times 150 times150mm standard concrete cube and 150300mm cylinderrespectively 119891ts is the splitting tensile strength of 150 times 150 times150mm standard concrete cube119891t represents the axial tensilestrength of concrete 119891c and 119891t are converted into 119891cu and119891ts based on the conversion formula borrowed from otherpieces of literature 119891cu = 125119891c and 119891t = 09119891ts [32] Thenfor fresh concrete the relationships between compressiveand tensile strength in left column Table 3 are rewrittenas the right column where the strengths are 119891cu and 119891tscorresponding to the mechanical indexes of the test results

Advances in Materials Science and Engineering 7

Table 3 Compressive-tensile relationship

119891t = 026 sdot 119891cu23 [32]119891ts = 055 sdot radic119891c [34]

119891t = 14 sdot ( 119891c10)23 [33]

119891t = 0395 sdot 119891cu055 [25]

997904rArr

119891ts = 028 sdot 119891cu23119891ts = 049 sdot radic119891cu119891ts = 134 sdot (119891cu10 )

23

119891ts = 0439 sdot 119891cu055mdash 119891ts = 019 sdot 119891cu34 [32]

Table 4 The SSE of recommended functions

Proposed functions SSE119891ts = 019119891cu34 580081119891ts = 0439119891cu055 254530119891ts = 134(119891cu10)23 311486119891ts = 028119891cu23 361975119891ts = 049119891cu05 347893

in this study Whether these existing compressive-tensilestrength relationships (Table 3) for fresh concrete are stillsuitable for the deteriorated concrete in this paper or not wasfurther explored

As observed from Figure 5 all the correlations betweencompressive and tensile strength for fresh concrete recom-mended by building codes or literatures are increasing func-tions that basically present the tendency of the experimentalresults in this research However from the deviation distancebetween test results and these proposed function curves inFigure 5 none of them expresses the compressive-tensilestrength relationship of the deteriorated concrete accuratelyenough The SSE (sum of squares due to error calculated as(4)) which is one of important indexes presenting goodnessof curve fitting is shown in Table 4

SSE = 119899sum119894=1

(119910119894 minus 119910119894)2 (4)

where 119910119894 and 119910119894 represent the experimental and predicted(through the proposed functions) tensile strength of concreteand 119899 is the number of data analysed

The SSE statistic is the least-squares error of the fitwith a value closer to zero indicating a better fit Nev-ertheless the SSE of all proposed functions listed in thispaper are large together with quite small 119877-square statisticsindicating poor fitting effects to the experimental resultsIn addition the index as (theoretical value minus experimen-tal value)experimental value is used to reflect the errorsbetween experimental values and model predicted values(Figures 6(a)sim6(e)) It is clear that all the relations for freshconcrete 119891ts = 019119891cu34 119891ts = 0439119891cu055 119891ts =134(119891cu10)23 119891ts = 028119891cu23 and 119891ts = 049119891cu05 are in-clined to underestimate the tensile strength One possiblereason may be that after environmental deterioration forlong time compressive strength exhibits more degradationthan tensile strength which increases the ratio of tensilestrength to compressive strength

From the above discussion it is shown that all thecompressive-tensile strength relationships for fresh concretelisted in this study are not applicable to the environmen-tally deteriorated concrete with satisfactory accuracy whichmay imply that appropriate revisions are needed Henceadjustment for parameters in exponential function wasmade aiming to promote the goodness of curve fittingThe compressive-tensile strength relationship in exponentialform can be written as

119891ts = 119886 sdot 119891cu119887 (5)

where 119886 and 119887 are fitting parametersAccording to the test results the function which best

presents the relationship between compressive strength andtensile strength in this study was obtained through nonlinearcurve fitting (Figure 5)

119891ts = 102 sdot 119891cu036 (6)

The SSE and 119877-square of such fitting are 81256 and05344 Also the predicting error shown in Figure 6(f)is reasonably moderate which confirms that even for theconcrete deteriorated bymarine environment for long periodof time the compressive-tensile strength relationship canalso be rationally described by exponential function withacceptable accuracy if the parameters of function wereproperly determined This best fitting function (see (6))can be regarded as a modified version of the compressive-tensile strength relationship recommended by guidelines orliteratures for fresh concrete

Furthermore although concrete cores from groups AB C and D are deteriorated by marine environment fordifferent periods (61 5 16 and 11 years) and present variousranges of strengths they commonly share the same sub-group (compressive strength ranging from 15Mpa to 35MpaFigure 7) which may imply that the compressive-tensilestrength correlation119891ts = 102119891cu036 is adequately suitable forconcrete with compressive strength from 15Mpa to 35Mparegardless of the exact deteriorated period within severaldecades

In concrete technology the aggregate strength is usuallynot a factor considered in normal strength concrete becausewith the exception of lightweight aggregates the aggregatepartial is several times stronger than the matrix and theinterfacial transition zone in concrete In other words withmost natural aggregates the strength of the aggregates ishardly utilized because the failure is determined by theother two phases (matrix and interfacial transition zone)However aggregate characteristics other than strength suchas the size shape surface texture grading and miner-alogy are known to affect concrete strength in varyingdegrees It may be anticipated that independent of thewater-cement ratio the size shape and surface texture ofaggregate particles would influence the characteristics ofthe interfacial transition zone and therefore affect concretestrength Furthermore since the interfacial transition zonecharacteristics have more effect on the tensile strength ofconcrete compared to the compressive strength it is to beexpected that with a given concrete mixture any changes

8 Advances in Materials Science and Engineering

0 5 10 15 20 25 30 35 40 45 50

Data number

minus08

minus06

minus04

minus02

00

02

04

06

08

(Theo

minus E

xpe)

Exp

efNM = 019 middot f=O

34Fitting error of

(a)

0 5 10 15 20 25 30 35 40 45 50

Data number

minus08

minus06

minus04

minus02

00

02

04

06

08

(Theo

minus E

xpe)

Exp

e

fNM = 0439 middot f=O055Fitting error of

(b)

0 5 10 15 20 25 30 35 40 45 50

Data number

minus08

minus06

minus04

minus02

00

02

04

06

08

(Theo

minus E

xpe)

Exp

e

fNM = 134 middot (f=O10)23Fitting error of

(c)

0 5 10 15 20 25 30 35 40 45 50

Data number

minus08

minus06

minus04

minus02

00

02

04

06

08

(Theo

minus E

xpe)

Exp

e

fNM = 028 middot f=O23Fitting error of

(d)

0 5 10 15 20 25 30 35 40 45 50

Data number

minus08

minus06

minus04

minus02

00

02

04

06

08

(Theo

minus E

xpe)

Exp

e

fNM = 049 middot f=O05Fitting error of

(e)

fNM = 102 middot f=O036Fitting error of

0 5 10 15 20 25 30 35 40 45 50

Data number

minus08

minus06

minus04

minus02

00

02

04

06

08

(Theo

minus E

xpe)

Exp

e

(f)

Figure 6 Prediction errors

in the coarse aggregates properties would influence thetensile-compressive strength relationship of the materialWang et al [35] investigated the effects of the maximumaggregate size 119889max on concrete tensile strength and fracturetoughness Considering that concrete is highly heterogonousinclusion of 119889max in a final relation of concrete fracture

modelling is necessary A simple methodology for analysingquasibrittle fracture of small notched three-point-bend con-crete specimen was presented to determine tensile strengthand fracture toughness Fictitious crack growth before themaximum load is considered by the maximum aggregatesize 119889max Also the tensile strength controlled (119891t-controlled)

Advances in Materials Science and Engineering 9

Group A Group B Group C Group D

sim35MpaSubgroup 15

0

10

20

30

40

50

60

70

Com

pres

sive s

treng

th (M

pa)

Group DGroup CGroup BGroup A

Total number of data points 12 16 12

7 11 11 7

8

The number of data points in subgroup(15sim35Mpa)

Figure 7 The subgroup shared by groups A B C and D

failure and fracture toughness controlled (119870IC-controlled)failure link 119889max to the fictitious crack growth at the peakload [36]However in the experimental research of this studysince the places for drilling core samples had existed foryears the authors of this paper were not capable of obtainingenough original engineering data in detail such as mix pro-portion size of aggregate and aggregate grading Althoughaggregates near surface are roughly shown in the photographsof core sample (eg Figure 3) the information of aggregatesuch as the maximum size shape and distribution cannotbe accurately obtained since each sample has been incisedand processed Hence the characteristics of aggregate are notparticularly considered in Section 24 In future researchtaking aggregate into analysis may be the further targetwhich might add more profound explanations to the testresult of this study

32 Prediction of Long-Term Strengthunder Marine Environment

321 Prediction of Long-Term Compressive Strength Basedon sufficient investigations on existing costal buildings inChina and Japan Niu [37] empirically concluded a pos-sible model for estimating long-term compressive strengthof concrete under marine environment A nonstationarystochastic process is applied to describe the changing lawof concrete compressive strength with time At a certaintime 119905 the compressive strength is regarded as a randomvariable obeying normal distributionThe probability densityfunction at any time is given as follows

119901119891 (119909 119905) = 1radic2120587120590119891 (119905) exp[[

minus(119909 minus 120583119891 (119905))221205901198912 (119905) ]

] (7)

where 120583119891(119905) 120590119891(119905) is mean value and standard derivation ofconcrete compressive strength after time 119905 (year) which canbe calculated as

Compressive strength (characteristic value)Tensile strength (characteristic value)

70 21 2814

t (year)

00

15

30

10

15

20

25

30

35

Stre

ngth

(Mpa

)

Figure 8 The predicted compressive and tensile strength

120583119891 (119905) = 120585 (119905) 1205830 (8)

120590119891 (119905) = 120578 (119905) 1205900 (9)

where 1205830 1205900 are mean value and standard derivation ofconcrete compressive strength at 28 days (119905 = 0) 120585(119905) and120578(119905) are two functions of time which are given as

120585 (119905) = 12488119890minus00347(ln 119905minus03468)2 120578 (119905) = 00143119905 + 16024 (10)

Therefore when 1205830 1205900 are given the probability densityfunction (PDF) of concrete compressive strength at anytime is determined by (7)sim(10) Then compressive strengthwith specific probability assurance rate at given time can bedetermined through the PDF For example as stipulated inthe Europe code [24] andChina standard [25] the probabilityassurance of the concrete characteristic compressive strengthis 95 Based on the PDF characteristic compressive strengthcan be obtained by numerical calculation or simply by thefollowing formula (see (11)) since the probability is normallydistributed

119891cu119896 (119905) = 120583119891 (119905) minus 1645 sdot 120590119891 (119905) (11)

For instance the mean value and standard derivation ofconcrete compressive strength at 28 days are 3115Mpa and3738Mpa respectively According to the above Niursquos model[37] the characteristic compressive strength (119891cu119896) at anytime is worked out as shown in Figure 8 Strength with otherprobability assurance rates can be calculated similarly Niursquosmodel provides a possible method that is able to predict long-term concrete compressive strength undermarine conditionsincluding marine atmosphere tidal areas and immersedregions by seawater [37 38] According to the predictedresults by Niursquos model the compressive strength of concreteunder marine environment shows increment in first 1 or2 years after casting This could be due to the continuing

10 Advances in Materials Science and Engineering

internal chemical reactions within concrete which gives riseto strength growth For instance formation of salt crystalscontributes towards enhancing cohesion among aggregateswhich induces strength increase Under long-term environ-mental effects corrosive substance attacks and the expansionsor shrinkages caused by environments would induce crackswithin concrete especially for those with inadequate mixdesign Once the cracks are initiated it allows the furtherpenetration ofmore harmful and corrosive substances whichultimately reduces the durability and strength of concretein a substantial manner For that reason concrete strengthtends to degrade with time in later period Such possiblecharacteristic of strength change was concluded by Niu [37]through numerous investigations on coastal constructions inChina and Japan

322 Prediction of Long-TermTensile Strength In Section 31for concrete with compressive strength ranging from 15Mpato 35Mpa the recommended exponential function by thisstudy 119891ts = 102119891cu036 is applied to describe the compressive-tensile strength correlationwithin acceptable error regardlessof the specific deteriorated period among several decades

Similar to Niursquos model both compressive and tensilestrength are regarded as stochastic processes in this studywhich are two random variables at certain time The exper-imental research in this paper essentially presents the rela-tionship (see (6)) between those two random variablesThenat given time 119905 the PDF of tensile strength can be derivedthrough the theory of probability An example is providedherein to elucidate themethod for calculating the statistic dis-tribution of tensile strength and then the long-term tensilestrength is predicted

For tensile strength the Cumulate Distribution Function(CDF) is derived as

119865119891ts(119905) (119909) = 119875 119891ts (119905) lt 119909 = 119875 102 sdot 119891cu (119905)036 lt 119909= 119875119891cu (119905) lt 1

102 sdot 1199091036= 119865119891cu(119905) ( 1

102 sdot 1199091036) (12)

where 119891ts(119905) and 119891cu(119905) are the tensile strength and compres-sive strength at given time 119905 which are both randomvariables119865119891ts(119905)(119909) and 119865119891cu(119905)(119909) are the Cumulate Distribution Func-tion (CDF) of random variable 119891ts(119905) 119891cu(119905)

Then the probability density function of tensile strengthcan be obtained through differential operation as

119901119891ts(119905) = 119889119865119891ts(119905) (119909)119889119909 = 119889119865119891cu(119905) ((1102) sdot 1199091036)119889119909= 1102 sdot 1

036 sdot 119909(1036minus1)119901119891cu(119905) ( 1102 sdot 1199091036)

(13)

According to Niursquos research [35 36] at given time 119905concrete compressive strength obeys normal distribution as(8) hence

119901119891cu(119905) ( 11021199091036)

= 1radic2120587120590119891 (119905)exp[[

minus((1102) 1199091036 minus 120583119891 (119905))2

21205901198912 (119905) ]]

(14)

Bringing (14) into (13) the PDF of tensile strength atcertain time 119905 is obtained119901119891ts(119905)

= 272 sdot 119909178radic2120587120590119891 (119905) exp[[

minus((1102) 1199091036 minus 120583119891 (119905))2

21205901198912 (119905) ]] (15)

Based on the statistic distribution of 119891ts(119905) shown as(15) tensile strength with specific probability assurancerate such as 95 (characteristic value) can be calculatedthrough numerical calculation as well as tensile strengthwithsome other probability assurance rates The predicted tensilestrength is shown in Figure 8 Resembling to the long-termcompressive strength the long-term tensile strength presentsslight increase in the initial period and then decreases withtime however it appears as a relatively moderate tendencyThis section provides a possible method for estimating long-term tensile strength of concrete under marine environmentUsing the method proposed herein the concrete tensilestrength is predicted in several years or decades rather thanseveral days or weeks only

4 Conclusions and Prospects

An experimental research was carried out in this study toinvestigate the relationship between the long-term compres-sive and tensile strength of concrete under realistic marineenvironment Exponential function obtained through non-liner fitting is recommended to quantitatively describe suchcorrelation Based on the tests results a possible method forpredicting long-term tensile strength is developed Accordingto the finds in this study the following conclusions can bedrawn

(1) For concrete exposing to marine environments ofZhoushan city for long period as several years ordecades compressive and tensile strength presentcertain regularity as compressive strength increas-ing the tensile strength tends to increase as wellThe correlation coefficient between the two types ofstrength is 072 indicating that they arewell positivelycorrelated after environmental deterioration

(2) The exponential functions for fresh concrete (119891ts =019119891cu34 119891ts = 0439119891cu055 119891ts = 134(119891cu10)23119891ts = 028119891cu23 and 119891ts = 049119891cu05) proposedby building guidelines or literatures only roughlydescribe the overall tendency of compressive-tensile

Advances in Materials Science and Engineering 11

strength relationship for deteriorated concrete LargeSSE along with quite small119877-square statistics indicatetheir poor fitting effects By adjusting the parametersof exponential function a best fitting curve (119891ts =102119891cu036) is recommended by this paper whichdemonstrates that the exponential model can beextensively used to describe the compressive-tensilestrength relationships for both fresh and deterioratedconcrete Moreover the best fitting function (119891ts =102119891cu036) may be suitable for concrete with com-pressive strength ranging from 15Mpa to 35Mparegardless of the specific deteriorating period withinseveral decades

(3) A potential tensile strength predicting method isestablished within the frame-work of probabilityanalysis The compressive and tensile strengths ofconcrete are regarded as two stochastic processesThetest in this study essentially investigated the relation-ship of them Based on formerly known probabilitydistributions of compressive strength from literaturethe probability distributions of tensile strength atgiven time 119905 is determined through statistical anal-ysis Then tensile strength with specific probabilityassurance rate (such as 95) can be worked out andprediction of long-term tensile strength is accom-plished which may provide meaningful informationin life-through estimations durability assessment orstructural health monitoring

In future studies aiming to experimentally character-ize a more representative relationship between long-termcompressive and tensile strength of concrete under marineenvironment the authors of this paper will obtain addedconcrete samples from various coastal areas not limited toZhoushan city The characteristics of aggregate may be takeninto analysis Also the effectiveness of the method in thispaper for predicting long-term tensile strengthwill be furtherverified

Conflicts of Interest

The authors declare that they have no conflicts of interest

Acknowledgments

The study was financially supported by the project namedService Life Prediction of Strengthened RC Beam (KJ-2015030) and provided by Chongqing Administration ofLand Resources and Housing The test conducted in thispaper was under the help of Yong Cheng ConstructionDetection Research Co Ltd Ningbo

References

[1] C Gaedicke A Torres K C T Huynh and A Marines ldquoAmethod to correlate splitting tensile strength and compressivestrength of pervious concrete cylinders and coresrdquoConstructionand Building Materials vol 125 pp 271ndash278 2016

[2] K Yan H Xu G Shen and P Liu ldquoPrediction of splittingtensile strength from cylinder compressive strength of concrete

by support vector machinerdquo Advances in Materials Science andEngineering vol 2013 Article ID 597257 2013

[3] M H Severcan ldquoPrediction of splitting tensile strength fromthe compressive strength of concrete using GEPrdquo Neural Com-puting and Applications vol 21 no 8 pp 1937ndash1945 2012

[4] M Saridemir ldquoEmpirical modeling of splitting tensile strengthfrom cylinder compressive strength of concrete by geneticprogrammingrdquo Expert Systems with Applications vol 38 no 11pp 14257ndash14268 2011

[5] F A Oluokun ldquoPrediction of concrete tensile strength fromits compressive strength Evaluation of existing relations fornormal weight concreterdquo ACI Materials Journal vol 88 no 3pp 302ndash309 1991

[6] M Weber and C Thiele ldquoCorrelation between the compres-sive and tensile strength of old concretes applicability ofthe relationship described by DIN EN 1992-1-1rdquo Beton- UndStahlbetonbau vol 111 no 10 pp 635ndash644 2016

[7] B Li L Cai K Wang and Y Zhang ldquoPrediction of theresidual strength for durability failure of concrete structure inacidic environmentsrdquo Journal Wuhan University of TechnologyMaterials Science Edition vol 31 no 2 pp 340ndash344 2016

[8] Y Zhou H Tian L Sui F Xing and N Han ldquoStrength dete-rioration of concrete in sulfate environment an experimentalstudy and theoretical modelingrdquo Advances in Materials Scienceand Engineering vol 2015 Article ID 951209 13 pages 2015

[9] J Cai F Zhang W Cui S Chen and P Liu ldquoConcretestrength and deformation property under sea water erosionenvironmentrdquo Advanced Materials Research vol 446-449 pp2554ndash2559 2012

[10] M Ramli W H Kwan and N F Abas ldquoStrength and durabilityof coconut-fiber-reinforced concrete in aggressive environ-mentsrdquo Construction and Building Materials vol 38 pp 554ndash566 2013

[11] H-S Shang T-H Yi and X-X Guo ldquoStudy on strengthand ultrasonic velocity of air-entrained concrete and plainconcrete in cold environmentrdquo Advances in Materials Scienceand Engineering vol 2014 Article ID 706986 7 pages 2014

[12] B S Thomas R C Gupta P Mehra and S Kumar ldquoPer-formance of high strength rubberized concrete in aggressiveenvironmentrdquo Construction and Building Materials vol 83article no 6441 pp 320ndash326 2015

[13] J O Okeniyi I O Oladele O M Omoniyi C A Loto and AP Popoola ldquoInhibition and compressive-strength performanceof Na2Cr2O7 and C10H14N2Na2O8sdot2H2O in steel-reinforcedconcrete in corrosive environmentsrdquo Canadian Journal of CivilEngineering vol 42 no 6 pp 408ndash416 2015

[14] W H Kwan M Ramli and C B Cheah ldquoFlexural strength andimpact resistance study of fibre reinforced concrete in simulatedaggressive environmentrdquo Construction and Building Materialsvol 63 pp 62ndash71 2014

[15] M Ramli W H Kwan and N F Abas ldquoApplication of non-corrosive barchip fibres for high strength concrete enhance-ments in aggressive environmentsrdquo Composites Part B Engi-neering vol 53 pp 134ndash144 2013

[16] X Yuan B Li G Cui S Zhao and M Zhou ldquoEffect of fly ashand early strength agent on durability of concrete exposed tothe cyclic sulfate environmentrdquo Journal Wuhan University ofTechnology Materials Science Edition vol 25 no 6 pp 1065ndash1069 2010

[17] E Guneyisi M Gesoglu and K Mermerdas ldquoStrength deteri-oration of plain and metakaolin concretes in aggressive sulfate

12 Advances in Materials Science and Engineering

environmentsrdquo Journal of Materials in Civil Engineering vol 22no 4 pp 403ndash407 2010

[18] J P Gorninski D C Dal Molin and C S KazmierczakldquoStrength degradation of polymer concrete in acidic environ-mentsrdquoCement and Concrete Composites vol 29 no 8 pp 637ndash645 2007

[19] M Ismail B Muhammad and M E Ismail ldquoCompressivestrength loss and reinforcement degradations of reinforcedconcrete structure due to long-term exposurerdquo Constructionand Building Materials vol 24 no 6 pp 898ndash902 2010

[20] P KMehta ldquoDurability of concrete exposed tomarine environ-ment - A fresh lookrdquo ACI Structure Journal vol 109 pp 1ndash301988

[21] M Shekarchi A Rafiee and H Layssi ldquoLong-term chloridediffusion in silica fume concrete in harsh marine climatesrdquoCement and Concrete Composites vol 31 no 10 pp 769ndash7752009

[22] GWWasha andK FWendt ldquoFifty year properties of concreterdquoAmerican Concrete Institute vol 72 no 1 pp 20ndash28 1975

[23] China Engineering Construction Standardization AssociationCECS 03 2007 Technical Specification for Testing ConcreteStrength with Drilled Core China Building Industry PressBeijing China 2007

[24] European Committee for Standardization Concrete-Part 1Specification Performance Production and Conformity Euro-pean Committee 2006

[25] Ministry of Housing and Urban-Rural Development of thePeoplersquos Republic of China GB 50010-2010 Code for Designof Concrete Structures China Building Industry Press BeijingChina 2010

[26] P C Aitcin S L Sarkar and P Laplante ldquoLong-term character-istics of a very high strength concreterdquo Concrete Internationalvol 12 no 1 pp 40ndash44 1990

[27] Z P Bazant M T Kazemi T Hasegawa and J MazarsldquoSize effect in Brazilian split-cylinder tests Measurements andfracture analysisrdquo ACI Materials Journal vol 88 no 3 pp 325ndash332 1991

[28] K Duan X Hu and F H Wittmann ldquoScaling of quasi-brittlefracture Boundary and size effectrdquoMechanics of Materials vol38 no 1-2 pp 128ndash141 2006

[29] C Rocco G V Guinea J Planas and M Elices ldquoSize effectand boundary conditions in the Brazilian test experimentalverificationrdquo Materials and Structures vol 32 no 217 pp 210ndash217 1999

[30] C Rocco G V Guinea J Planas andM Elices ldquoSize effect andboundary conditions in the brazilian test theoretical analysisrdquoMaterials Structures vol 32 pp 437ndash444 1999

[31] V Kadlecek S Modry and V Kadlecek ldquoSize effect of testspecimens on tensile splitting strength of concrete generalrelationrdquoMaterials and Structures vol 35 no 1 pp 28ndash34 2002

[32] Z Guo Theory of Reinforced Concrete Tsinghua UniversityPress Beijing China 2013

[33] International Federation for Structural Concrete (FIB) FIB056-Model Code 2010 Concrete Structures DCCDocument Compe-tence Center Siegmar Kastl eK Germany Lausanne Switzer-land 2010

[34] ACI committee 318-14 Building Code Requirements for Struc-tural Concrete American Concrete Institute Farmington HillsMich USA 2014

[35] YWang X Hu L Liang andW Zhu ldquoDetermination of tensilestrength and fracture toughness of concrete using notched 3-p-b specimensrdquo Engineering Fracture Mechanics vol 160 pp 67ndash77 2016

[36] J Guan X Hu and Q Li ldquoIn-depth analysis of notched 3-p-bconcrete fracturerdquo Engineering Fracture Mechanics vol 165 pp57ndash71 2016

[37] D Niu ldquoChanging models of concrete strength along withtime in marine environmentrdquo Journal of Xirsquoan University ofArchitecture and Technology vol 27 no 03 pp 49ndash52 1995

[38] Q Zhao Y Yong and G Sen ldquoReliability estimation of in-service tunnel shield capacityrdquo in Proceedings of the Interna-tional Conference on Pipelines and Trenchless Technology 2009ICPTT 2009 Advances and Experiences with Pipelines andTrenchless Technology for Water Sewer Gas and Oil Applica-tions pp 1783ndash1792 Shanghai China 2009

Submit your manuscripts athttpswwwhindawicom

ScientificaHindawi Publishing Corporationhttpwwwhindawicom Volume 2014

CorrosionInternational Journal of

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Polymer ScienceInternational Journal of

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

CeramicsJournal of

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

CompositesJournal of

NanoparticlesJournal of

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

International Journal of

Biomaterials

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

NanoscienceJournal of

TextilesHindawi Publishing Corporation httpwwwhindawicom Volume 2014

Journal of

NanotechnologyHindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Journal of

CrystallographyJournal of

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

The Scientific World JournalHindawi Publishing Corporation httpwwwhindawicom Volume 2014

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

CoatingsJournal of

Advances in

Materials Science and EngineeringHindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Smart Materials Research

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

MetallurgyJournal of

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

BioMed Research International

MaterialsJournal of

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

2 Advances in Materials Science and Engineering

it is worthwhile to underline that the time-varying char-acteristics of concrete exposed to outdoor environment arenecessary to be further researchedMoreover in constructiondurability assessment or structure life prediction the long-term concrete strength along with its time-varying featuresis essential information However it is not simple to carry outstudies to research the changing law of concrete strength inlong term since it may takes several years or decades to runthe tests

Accelerated aging tests and simulative environmentaltests are mainly adopted to study the environmental impactson concrete strength Li et al [7] researched acidification cor-rosion depth and compressive strength of concrete subjectedto sulphuric acid environments by accelerated tests Theresults show that the remaining compressive strength valuesfor the concrete exposed to pH = 2 and 3 sulphuric acid waterenvironments and wet-dry cyclic sulphuric acid environmentwith pH = 2 are 74 72 and 80 of initial strengthrespectively An accelerated corrosion by a sulphate solutionin a dry-wet cycle was introduced to simulate the externalsulphate corrosion environment by Zhou et al [8] Theaccelerated corrosion test results indicate that the strengthdegradation of concrete by sulphate attack had a significantrelation with the corrosion depth Cai et al [9] assessed theconcrete strength and deformation property under artificialsea water erosion environment Concrete stress and straincurve was researched with the number of wet and dry cyclesof 0 times 10 times 20 times 30 times 40 times 50 times and60 times A biaxial concrete strength criterionwas establishedtaking into account the stress ratio and the number of dry-wetcycles Ramli et al [10] studied the environmental resistanceof concrete incorporating coconut fibresThree types of simu-lated aggressive environments were adopted air environmentin a tropical climate alternate air and seawater environmentsin a 14-day cycle and continuous immersion in seawaterShang et al [11] investigated mechanical properties of plainconcrete and air-entrained concrete subjected to freeze-thawcycles (F-T-C) The influences of F-T cycles on ultrasonicvelocity and mechanical properties of air-entrained concreteand plain concrete were analysed Also accelerated aging testor simulative environmental test is adopted in [12ndash18] whichshows that it is convenient and time saving to adopt suchexperimental method to study the environmental effects onconcrete properties However there are apparent differencesbetween real service condition and artificial environmentsince the latter can merely reproduce several environmentalfactors such as sulphate chloride ion acid high temperatureand humidity In fact the real environment is far moreintricate and cannot be simply represented by simulativeenvironmental test In addition in the previous literaturesabove the longest aging time was 365 days [17] which cannotbe regarded as a long enough period when comparing tothe working life in practical engineering Moreover tensilestrength of concrete was scarcely discussed in those previousstudies

There are only a few existing studies that investigatedlong-term environmental effects on concrete strength underreal service conditions However only compressive strengthwas researched Ismail et al [19] investigated compressive

Table 1 The atmosphere chloride content of Zhoushan city

Distance to sea(m) 2 100 140 200 260 340 500

Meanprecipitationvalue ofchloride perday (120583gcm2d)

11130 10856 3998 3638 2941 2427 2951

strength loss of concrete exposed to outdoor environmentby 6 yearrsquos monitoring Studies by Mehta [20] Shekarchiet al [21] and Washa and Wendt [22] discussed the long-term concrete compressive strength under actual marineenvironment None of them addressed tensile strength andthe correlation between compressive and tensile strength ofconcrete

The major thrust of this study is to obtain both com-pressive and tensile strengths of concrete under real marineenvironment for long period (up to 61 years) and identify thecorrelation between the twomechanical properties Concretecores were drilled out by pairs at a deserted harbour inZhoushan city Zhejiang province China Every two coresof each pair were conducted in compressive and tensilesplitting test respectively then the relationship betweenlong-term compressive and tensile strength was concludedThe applicability of compressive-tensile strength relationshiprecommended by literatures or building codes for con-crete without deterioration (fresh concrete) was examinedA better fitted relationship function was presented Afterthat based on statistical theory and a compressive strengthpredictingmodel from literature a tensile strength predictingmethod was established and a calculating example wasprovided for interpreting which may offer a potential wayto estimate long-term tensile strength of concrete under realmarine environment

2 Experimental Program

21 Concrete Cores Drilling Zhoushan is a coastal city inChina Constructions and buildings there are deterioratedby typical marine environment like seawater marine atmo-sphere tidal waves and so onThe yearly average temperatureis 15 to 20 degrees Celsius The content of chloride ion inatmosphere of Zhoushan city is given in Table 1

Concrete cores samples were drilled from 4 differentsites at a deserted harbour of Zhoushan city Site A is theconcrete slab of a deserted dock built in 1955 When tiderises the distance between the dock slab and sea level is 4mapproximately Site B is a large piece of plain concrete onseabeach which was left as construction waste when nearbynew harbour was established in 2011 Site C is a concretepedestal of streetlight casted in 2000 Site D is the reinforcedconcrete roof of a deserted building constructed in 2005Theabove four sites (A B C and D) which had existed for 615 16 and 11 years till our test began are in adjacent areasAll of them are not immersed by sea water due to their highenough places and in atmosphere all time Concrete cores

Advances in Materials Science and Engineering 3

Figure 1 The cores drilling site

drilled fromeach siteweremarked as groupA groupB groupC and group D respectively

In this study the operations of drilling and testing referto the technical specification for testing concrete strengthwith drilled core [23] Location of steel bars was detectedby magnetic spectroscopy steel detector and proper drillingplaces (away from bars) were selected in order to avoiddamage to reinforcement Cores with diameter as 75mmwere mostly drilled which are smaller than standards coresamples in the formerly mentioned technical specification[23] Another 4 standard cores with diameter as 100mmwere drilled since the 75mm-diameter drilling barrel wasseverely worn outThe concrete cores were obtained by pairsFor each pair of samples the two cores were conducted tocompressive and tensile test respectively aiming to investigatethe relationship between compressive and tensile strengthsThe 2 cores of each pairwere drilled fromclose enoughplaceswhich ensures that they consist of same batch of concretewithidentical deterioration The place (site A) for drilling cores isshown in Figure 1

22 Cores Processing The drilled cores were carefully pro-cessed including incising and end faces dealing beforemechanical tests

221 Cores Incising Based on the mentioned test specifi-cation [23] after processing the height-diameter ratio ofcore samples should be 1 theoretically which can value from095sim105 in actual operation Incision machine with doubleparallel blades was used and the distance between two bladeswill determine the height of each core Before incising thedistance of double blades was carefully adjusted and thenfixed in order to ensure that the height-diameter ratio ofeach core is in the allowed range as 095sim105 The incisingprocession is shown in Figure 2(a)

After incision cores were paired up Two cores of eachpair were confirmed to be obtained from close enoughlocations The matched cores were placed in pairs shown inFigure 2(b)

222 Cores Selecting and Loading Test Preparing Accordingto the test specification [23] there should be no more than 1steel bar in qualified core and the diameter of steel bar should

be less than 10mm The possibly existing steel bar should bevertical to the shaft of core Samples with obvious cracks orflaws were excluded According to the above prerequisites 96eligible cores (48 pairs) were finally selected The end facesof all cores were levelled Belt grinder machine or polymercement mortar was adopted to make end faces smooth andlevel as shown in Figure 3(a)

The scales of each qualified core sample were measuredVernier caliper was applied to measure the diameters Diam-eter was measured twice for each core at two vertical placesand the average value was adopted as the final diameterwhich would be applied in the further strength calculation(Figure 3(b)) Steel tap was applied tomeasure the core height(Figure 3(c)) Lines were drawn on those samples that wouldbe tensile split to indicate the failure areas as shown inFigure 3(d)

23 Loading Test All of the 96 core samples were numberedbefore loading test Every two cores of each pairwere the samebatch of concrete and deteriorated by environment equallyone sample was conducted to compressive test while theother was conducted to tensile splitting test Two universaltesting machines with measuring range as 500KN and100KN are applied to compressive and tensile splitting testrespectively Finally 48 compressive strengths were obtainedas well as 48 tensile splitting strengths Compressive andtensile splitting tests are shown in Figures 4(a) and 4(b)

Test information as serial number sample scale andthe maximum applied force of each core sample is givenin Table 2 Data number consists of a three-part code and thealeph (A B C andD) represents the group of samples whichalso indicates the places where concrete cores were drilledThe second figure in data number presents the sequence ofsample pair in each group The third figure in data numberindicates the type of mechanical experiment 1 representstensile splitting test and 2 represents compressing test 119889and ℎ represent the diameter and height of core samplerespectively 119889ℎ is the height-diameter ratio which are all inthe allowable range as 095sim105 119865 is the maximum appliedforce of each sample in loading test

24 Strength Calculation According to the technical speci-fication for testing concrete strength with drilled core [23]compressive strength of core samplewas calculated as follows

119891cucor = 119865c119860 (1)

where 119891cucor is compressive strength 119865c is the measuredmaximum compressive force in the test 119860 is the area ofcompressive section

The tensile split strength was calculated as [23]

119891cts = 0637 sdot 119865splcor119860 ts (2)

where 119891cts is tensile splitting strength 119865splcor is the measuredmaximumsplitting force of each sample119860 ts is the area of splitsection 0637 is a coefficient derived from elastic theory

4 Advances in Materials Science and Engineering

(a)

95sim99mm

95sim99

mm

70sim75mm

70sim75

mm

(b)

Figure 2 Incision progress and the incised cores

(a) (b)

(c) (d)

Figure 3 End face levelling measuring scale and preparing for loading tests

(a) (b)

Figure 4 Loading test

Advances in Materials Science and Engineering 5

Table 2 The primary data of experiment

Data number Test type dmm hmm hd FKN Data number Test type dmm hmm hd FKNA-1-1 Tensile splitting 995 98 098 4416 A-1-2 Compressive 990 98 099 24212A-2-1 Tensile splitting 730 73 100 4108 A-2-2 Compressive 730 73 100 18345A-3-1 Tensile splitting 730 73 100 4948 A-3-2 Compressive 730 74 101 21726A-4-1 Tensile splitting 735 73 099 2806 A-4-2 Compressive 735 74 101 7346A-5-1 Tensile splitting 725 73 101 2536 A-5-2 Compressive 730 73 100 12043A-6-1 Tensile splitting 730 73 100 4026 A-6-2 Compressive 730 74 101 19554A-7-1 Tensile splitting 735 73 099 2633 A-7-2 Compressive 735 73 099 14440A-8-1 Tensile splitting 730 72 099 4162 A-8-2 Compressive 735 74 101 16185A-9-1 Tensile splitting 735 75 102 3480 A-9-2 Compressive 725 73 101 16114A-10-1 Tensile splitting 725 73 101 2277 A-10-2 Compressive 730 73 100 12592A-11-1 Tensile splitting 735 73 099 2044 A-11-2 Compressive 735 73 099 12044A-12-1 Tensile splitting 730 73 100 2369 A-12-2 Compressive 725 73 099 11141B-1-1 Tensile splitting 730 73 100 3626 B-1-2 Compressive 735 72 098 16048B-2-1 Tensile splitting 735 73 099 3426 B-2-2 Compressive 730 73 100 13001B-3-1 Tensile splitting 735 70 095 3072 B-3-2 Compressive 735 70 095 13143B-4-1 Tensile splitting 735 70 095 2920 B-4-2 Compressive 735 70 095 19610B-5-1 Tensile splitting 730 73 100 1735 B-5-2 Compressive 735 72 098 18628B-6-1 Tensile splitting 735 74 101 3818 B-6-2 Compressive 735 73 099 13279B-7-1 Tensile splitting 730 74 101 3764 B-7-2 Compressive 730 73 100 12980B-8-1 Tensile splitting 735 73 099 3442 B-8-2 Compressive 735 73 099 11168B-9-1 Tensile splitting 735 73 099 4264 B-9-2 Compressive 735 73 099 15336B-10-1 Tensile splitting 735 73 099 4048 B-10-2 Compressive 730 72 099 12965B-11-1 Tensile splitting 735 73 099 4848 B-11-2 Compressive 735 72 098 13582B-12-1 Tensile splitting 735 72 098 4262 B-12-2 Compressive 735 73 099 27546B-13-1 Tensile splitting 735 73 099 4734 B-13-2 Compressive 735 74 101 19214B-14-1 Tensile splitting 735 72 098 3976 B-14-2 Compressive 735 74 101 13607B-15-1 Tensile splitting 735 70 095 2053 B-15-2 Compressive 735 70 095 12086B-16-1 Tensile splitting 730 73 100 2032 B-16-2 Compressive 735 72 098 10814C-1-1 Tensile splitting 735 73 099 3378 C-1-2 Compressive 730 73 100 10045C-2-1 Tensile splitting 730 73 100 3370 C-2-2 Compressive 730 73 100 8958C-3-1 Tensile splitting 735 73 099 3794 C-3-2 Compressive 735 72 098 7664C-4-1 Tensile splitting 735 72 098 3464 C-4-2 Compressive 735 73 099 8027C-5-1 Tensile splitting 735 73 099 4094 C-5-2 Compressive 735 73 099 11000C-6-1 Tensile splitting 735 73 099 2633 C-6-2 Compressive 735 74 101 13809C-7-1 Tensile splitting 735 73 099 3610 C-7-2 Compressive 735 73 099 6836C-8-1 Tensile splitting 730 73 100 3438 C-8-2 Compressive 730 72 099 9091C-9-1 Tensile splitting 735 73 099 2838 C-9-2 Compressive 735 73 099 10707C-10-1 Tensile splitting 735 73 099 3080 C-10-2 Compressive 730 72 099 6120C-11-1 Tensile splitting 730 73 100 3208 C-11-2 Compressive 735 73 099 8687C-12-1 Tensile splitting 735 73 099 3454 C-12-2 Compressive 730 73 100 8790D-1-1 Tensile splitting 730 70 096 3270 D-1-2 Compressive 735 70 095 8207D-2-1 Tensile splitting 735 71 097 2561 D-2-2 Compressive 740 73 099 13860D-3-1 Tensile splitting 735 72 098 2928 D-3-2 Compressive 730 73 100 6838D-4-1 Tensile splitting 730 72 099 2320 D-4-2 Compressive 730 72 099 6578D-5-1 Tensile splitting 735 73 099 2518 D-5-2 Compressive 735 74 101 11032D-6-1 Tensile splitting 735 73 099 3102 D-6-2 Compressive 730 72 099 6535D-7-1 Tensile splitting 730 72 099 2162 D-7-2 Compressive 735 73 099 4414D-8-1 Tensile splitting 995 98 098 3706 D-8-2 Compressive 995 95 095 13954

6 Advances in Materials Science and Engineering

25 Size Effect In the above technical specification [23]diameter of standard concrete core is 100mmHowever thereare usually large amount of steel bars in the field testingstructures as a result drilling standard cores may causedamage to the reinforcement Therefore nonstandard coreswith smaller scale are widely adopted in actual engineeringas well as in this study Besides different guidelines or codesmay also adopt specimens with different shapes or sizes Inorder to make the test results of this study more generallyapplicable the size effect of nonstandard core samples wasdiscussed and then strength of core was converted to that of150 times 150 times 150mm concrete cube specimen which is definedas standard specimen in common construction standardssuch as Europe codes [24] and China standards [25]

251 Size Effect of Compressive Strength Great deal of exper-imental studies conducted by China Academy of BuildingResearch demonstrated that when the height-diameter ratioof core equals 1 compressive strength of core samples withdiameters ranging from 70 to 75mm is identical to thatof standard core samples as well as 150 times 150 times 150mmconcrete cube specimens which manifests that the size effecton compressive strength may not be considered [23] Aitcinet al [26] also showed that when the height equals diameterno significant difference is observed between compressivestrength of cores and cube specimens Hence this paper doesnot take account of the size effect on compressive strengthFurthermore the compressive strengths of core samples inthis study were regarded as the strengths of 150 times 150 times150mm concrete cube specimens [23]

252 Size Effect of Tensile Split Strength Through experi-mental research and theoretical analysis Bazant et al [27]Duan et al [28] and Rocco et al [29 30] show that the tensilesplitting strength of concrete is strongly determined by thesize of test specimen Wide range of experimental studieswere carried out on cubes cylinder and prisms to investigatethe size effect of tensile splitting strength by Kadlecek et al[31] It was demonstrated that the size effect highly dependson the areas of splitting fracture section rather than the shapeof test specimens which creates a unifying measurement forsize effect A generalized size effect formula was presentedwhich can be applied to cores or cubes obtained from existingstructures According to Kadlecek et al [31] the tensilesplitting strength of concrete cores was converted to thestrength of standard test specimen (150 times 150 times 150mm)Thesize effect formula is given as [31]

119896119901 = 119891tscor119891ts = 2 sdot 119860minus0128 (3)

where 119896119901 is coefficient of size effect 119891tscor is the tensilesplitting strength of drilled core samples 119891ts is the tensilesplitting strength of standard test specimen (150 times 150 times150mm)119860 is the area of splitting fracture section of concretecore (cm2)

60

45

30

15

000 15 30 45 60 75

fNM

(Mpa

)

f=O (Mpa)

Group A (1955s)Group B (2011s)Group C (2000s)

Sub-group15sim35Mpa

fNM = 019 middot f=O34

fNM = 0439 middot f=O055

fNM = 134 middot (f=O10)23

fNM = 028 middot f=O23

fNM = 049 middot f=O05

Group D (2005s)fNM = 1033 middot f=O

035

(best fitting curve)

Figure 5 Compressive and splitting tensile strength

3 Results and Discussion

31 The Relationship between Long-Term Compressive andTensile Strength According to Section 25 strengths of coresamples were converted to strengths of standard test speci-mens in order to improve practicability of the test result inthis research All of the 48 data points are presented in acoordinate system (Figure 5) with compressive strength as119909-axis and tensile splitting strength as 119910-axis

The experimental result signifies that compressive andtensile strength of concrete deteriorated by the marineenvironment of Zhoushan city for long term still present acertain regularity The data points in Figure 5 distribute tothe right oblique upward forming a zonal shape Althoughdata points present discreteness it is clear that as the raisingof compressive strength the tensile strength of the sameconcrete tends to increase as well The correlation coefficientbetween compressive and splitting tensile strength is 072demonstrating that the two types of strength are still wellpositively correlated under environmental effects for longperiod of time

Generally exponential law is recommended by literaturesor building guidelines to express the relationship betweencompressive and tensile strength of concrete cured undernormal conditions and without environmental deterioration(fresh concrete) [25 32ndash34] (Table 3 left column) In Table 3119891cu and 119891c are the compressive strength of 150 times 150 times150mm standard concrete cube and 150300mm cylinderrespectively 119891ts is the splitting tensile strength of 150 times 150 times150mm standard concrete cube119891t represents the axial tensilestrength of concrete 119891c and 119891t are converted into 119891cu and119891ts based on the conversion formula borrowed from otherpieces of literature 119891cu = 125119891c and 119891t = 09119891ts [32] Thenfor fresh concrete the relationships between compressiveand tensile strength in left column Table 3 are rewrittenas the right column where the strengths are 119891cu and 119891tscorresponding to the mechanical indexes of the test results

Advances in Materials Science and Engineering 7

Table 3 Compressive-tensile relationship

119891t = 026 sdot 119891cu23 [32]119891ts = 055 sdot radic119891c [34]

119891t = 14 sdot ( 119891c10)23 [33]

119891t = 0395 sdot 119891cu055 [25]

997904rArr

119891ts = 028 sdot 119891cu23119891ts = 049 sdot radic119891cu119891ts = 134 sdot (119891cu10 )

23

119891ts = 0439 sdot 119891cu055mdash 119891ts = 019 sdot 119891cu34 [32]

Table 4 The SSE of recommended functions

Proposed functions SSE119891ts = 019119891cu34 580081119891ts = 0439119891cu055 254530119891ts = 134(119891cu10)23 311486119891ts = 028119891cu23 361975119891ts = 049119891cu05 347893

in this study Whether these existing compressive-tensilestrength relationships (Table 3) for fresh concrete are stillsuitable for the deteriorated concrete in this paper or not wasfurther explored

As observed from Figure 5 all the correlations betweencompressive and tensile strength for fresh concrete recom-mended by building codes or literatures are increasing func-tions that basically present the tendency of the experimentalresults in this research However from the deviation distancebetween test results and these proposed function curves inFigure 5 none of them expresses the compressive-tensilestrength relationship of the deteriorated concrete accuratelyenough The SSE (sum of squares due to error calculated as(4)) which is one of important indexes presenting goodnessof curve fitting is shown in Table 4

SSE = 119899sum119894=1

(119910119894 minus 119910119894)2 (4)

where 119910119894 and 119910119894 represent the experimental and predicted(through the proposed functions) tensile strength of concreteand 119899 is the number of data analysed

The SSE statistic is the least-squares error of the fitwith a value closer to zero indicating a better fit Nev-ertheless the SSE of all proposed functions listed in thispaper are large together with quite small 119877-square statisticsindicating poor fitting effects to the experimental resultsIn addition the index as (theoretical value minus experimen-tal value)experimental value is used to reflect the errorsbetween experimental values and model predicted values(Figures 6(a)sim6(e)) It is clear that all the relations for freshconcrete 119891ts = 019119891cu34 119891ts = 0439119891cu055 119891ts =134(119891cu10)23 119891ts = 028119891cu23 and 119891ts = 049119891cu05 are in-clined to underestimate the tensile strength One possiblereason may be that after environmental deterioration forlong time compressive strength exhibits more degradationthan tensile strength which increases the ratio of tensilestrength to compressive strength

From the above discussion it is shown that all thecompressive-tensile strength relationships for fresh concretelisted in this study are not applicable to the environmen-tally deteriorated concrete with satisfactory accuracy whichmay imply that appropriate revisions are needed Henceadjustment for parameters in exponential function wasmade aiming to promote the goodness of curve fittingThe compressive-tensile strength relationship in exponentialform can be written as

119891ts = 119886 sdot 119891cu119887 (5)

where 119886 and 119887 are fitting parametersAccording to the test results the function which best

presents the relationship between compressive strength andtensile strength in this study was obtained through nonlinearcurve fitting (Figure 5)

119891ts = 102 sdot 119891cu036 (6)